Evaluation Method of Gas Production in Shale Gas Reservoirs in Jiaoshiban Block, Fuling Gas Field

Abstract

1. Introduction

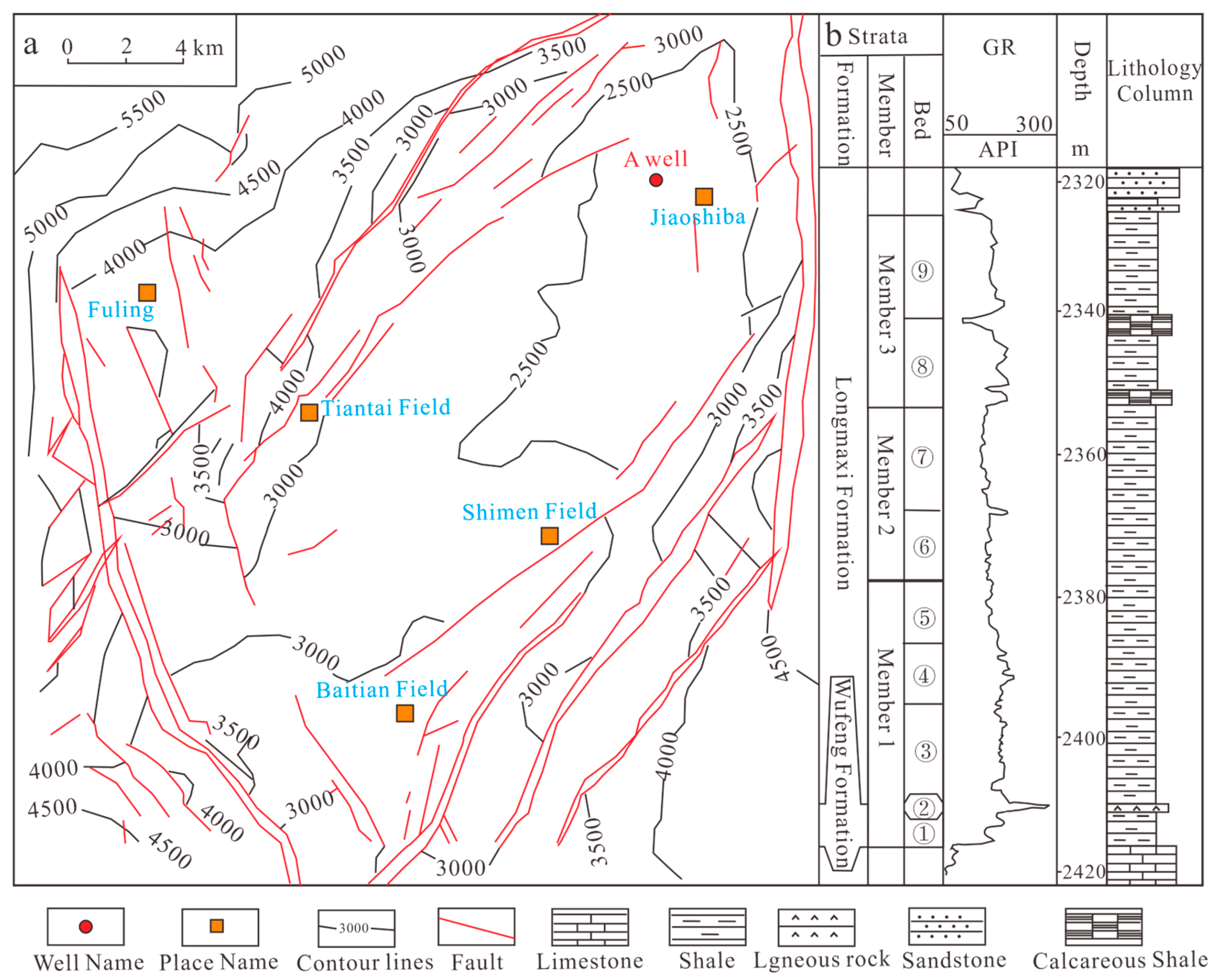

2. Overview of the Research Area

3. Methodology

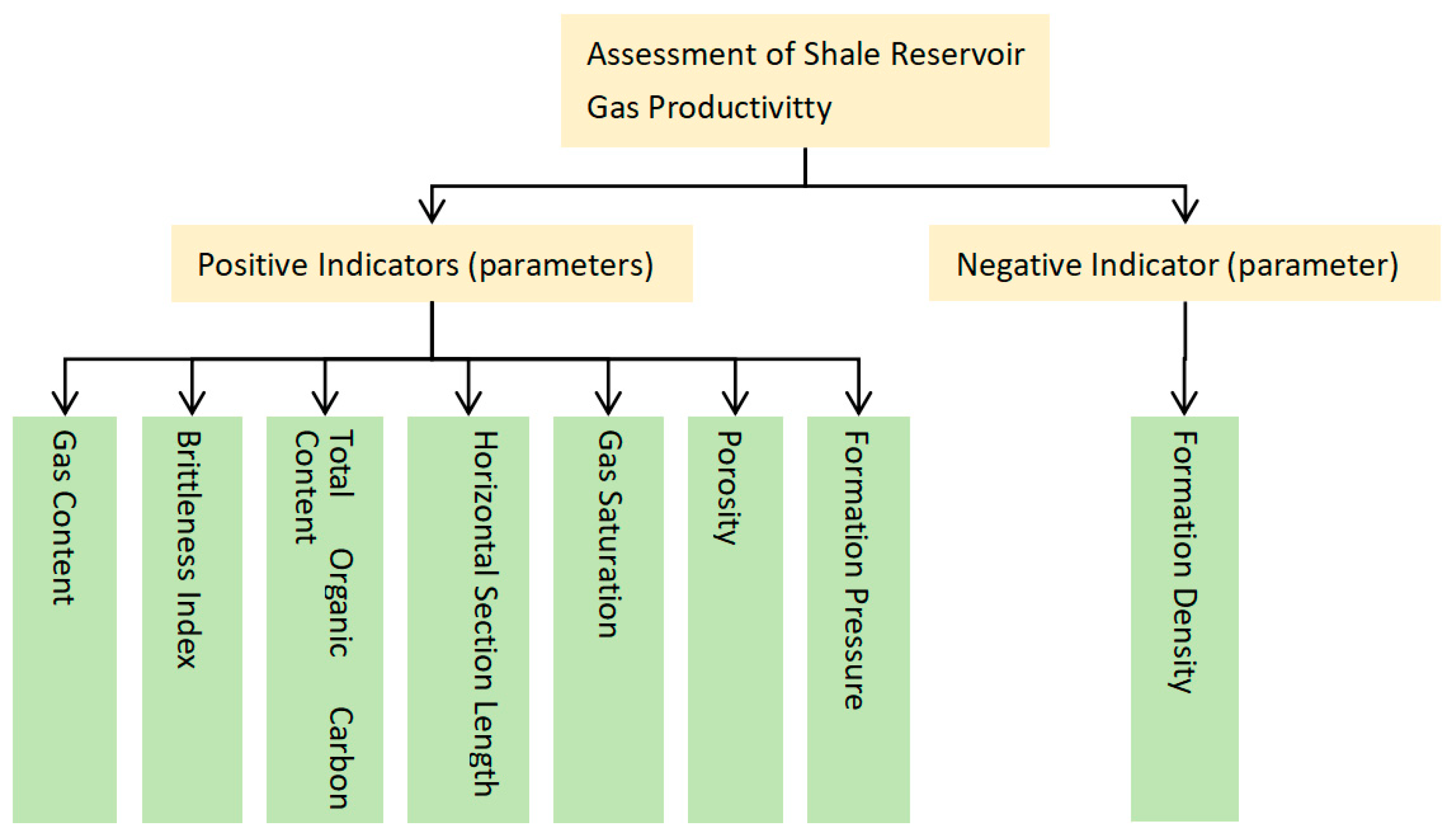

3.1. Selection of Shale Gas-Production Evaluation Parameters

3.2. Establishment of Gas-Production Evaluation Model

3.2.1. The Weight of Gas-Production Evaluation Parameters Is Determined by the Analytic Hierarchy Process

- (1)

- Judgment Matrix is Established

- (2)

- Weight Calculation

- (3)

- Consistency Check

3.2.2. Fuzzy Mathematics Method to Determine the Fuzzy Matrix of Gas-Production Evaluation Parameters

- (1)

- Establishment of Factor Set

- (2)

- Establishment of Evaluation Sets

- (3)

- Data Normalization

3.2.3. Establishment of Comprehensive Gas-Production Evaluation Model

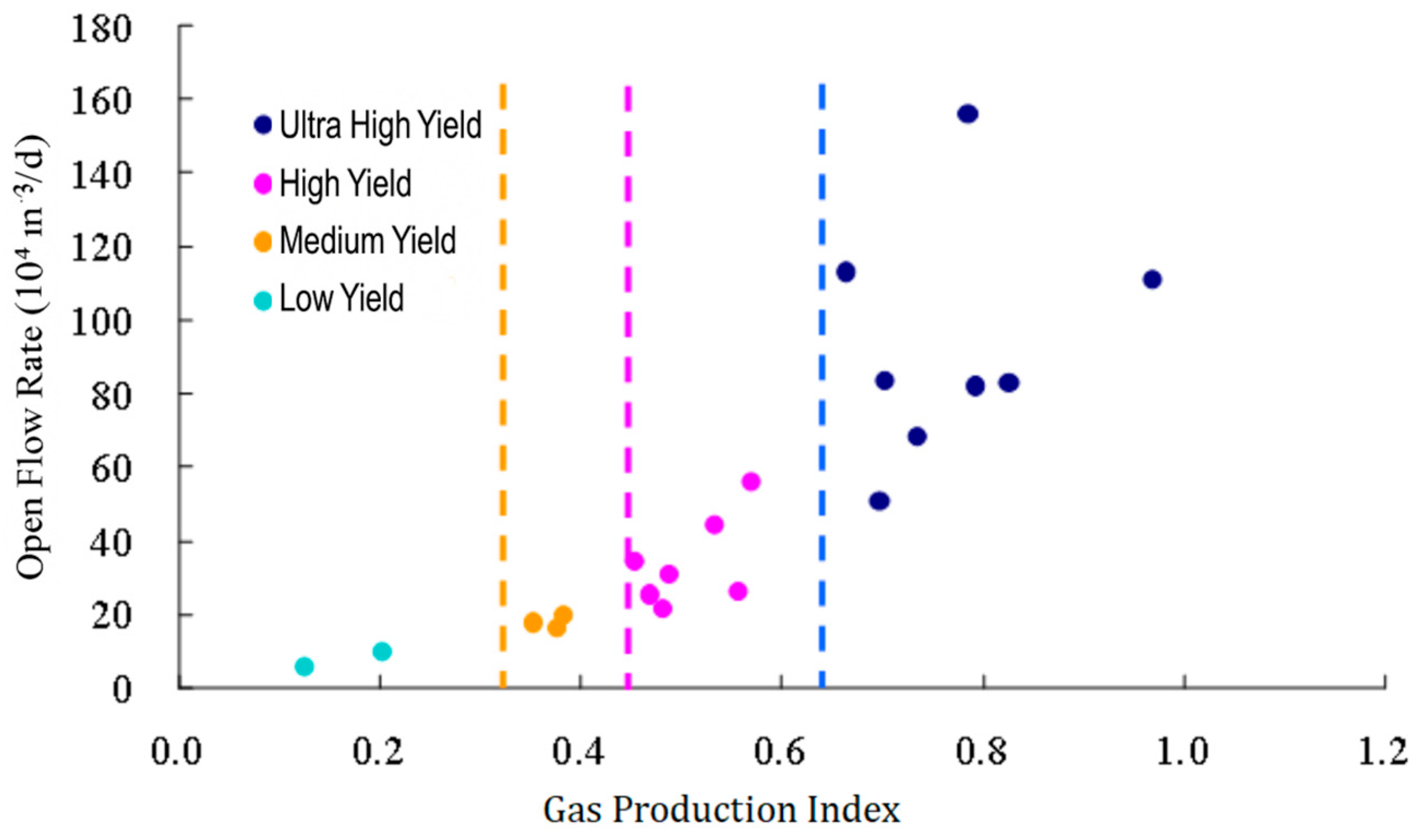

3.3. Classification of Gas-Production Level of Shale in the Study Area

4. Results and Discussion

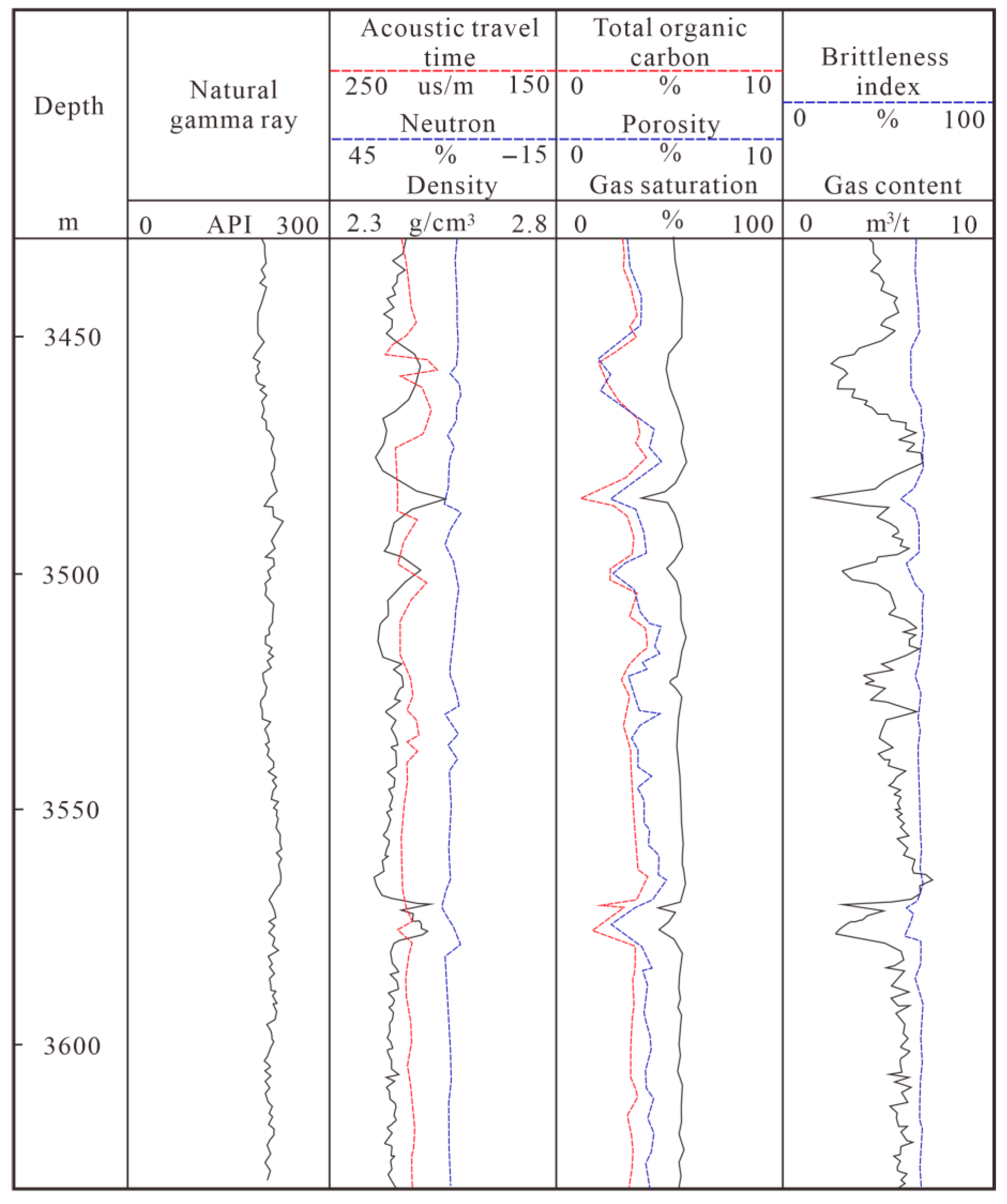

4.1. Case Analysis

4.2. Discussion

5. Conclusions

- (1)

- Gas production, as a comprehensive indicator of reservoir quality and gas-production capability, is primarily evaluated through parameters such as gas content, brittleness index, total organic carbon content, the length of high-quality gas-bearing sections, porosity, gas saturation, formation pressure, and formation density. By employing methods like the Analytic Hierarchy Process (AHP) and fuzzy mathematics, a mathematical model can be established to assess the gas-production potential of shale formations.

- (2)

- Using this model, the gas production of multiple shale gas wells in the Fuling shale gas field in China has been evaluated. In conjunction with actual test results, the gas production of this shale gas field is categorized into three levels: Wells with a gas-production index above 0.65 are classified as ultra-high production; those with an index between 0.45 and 0.65 are classified as high production; those with an index between 0.35 and 0.45 are classified as medium production; and those with an index below 0.35 are classified as low production.

- (3)

- The gas-production index evaluation model established by the Analytic Hierarchy Process can predict and analyze the gas-production potential of a single well in detail, which is of guiding significance for the adjustment of dynamic schemes of shale gas blocks. The application effect on site shows that the evaluation model can predict the gas-production potential well and has good applicability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pang, X.; Shao, X.; Li, M.; Hu, T.; Chen, Z.; Zhang, K.; Jiang, F.; Chen, J.; Chen, D.; Peng, J.; et al. Correlation and difference between conventional and unconventional reservoirs and their unified genetic classification. Gondwana Res. 2021, 97, 73–100. [Google Scholar] [CrossRef]

- Zhu, L.; Ma, Y.; Cai, J.; Zhang, C.; Wu, S.; Zhou, X. Key factors of marine shale conductivity in southern China—Part II: The influence of pore system and the development direction of shale gas saturation models. J. Pet. Sci. Eng. 2022, 209, 109516. [Google Scholar] [CrossRef]

- Qiu, Z.; Zou, C.; Wang, H.; Dong, D.; Wei, L. Discussion on characteristics and controlling factors of differential enrichment of Wufeng-Longmaxi formations shale gas in South China. Nat. Gas Geosci. 2020, 31, 163–175. [Google Scholar] [CrossRef]

- Jin, Z.; Hu, Z.; Gao, B.; Zhao, J. Controlling factors on the enrichment and high productivity of shale gas in the Wufeng-Longmaxi Formations, southeastern Sichuan Basin. Earth Sci. Front. 2016, 23, 1–10. [Google Scholar]

- Liang, X.; Wang, G.; Xu, Z.; Zhang, J.; Chen, Z.; Xian, C.; Lu, L.; Liu, C.; Zhao, C.; Xiong, S. “Sweet spot” comprehensive evaluation technology of complex mountain shale gas reservoir: Taking the Zhaotong National Shale Gas Demonstration Zone as an example. Nat. Gas Ind. 2016, 36, 33–42. [Google Scholar]

- Shi, W.; Zhang, C.; Jiang, S.; Liao, Y.; Shi, Y.; Feng, A.; Young, S. Study on pressure-boosting stimulation technology in shale gas horizontal wells in the Fuling shale gas field. Energy 2022, 254, 124364. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, M.; Tang, H.; Xiao, H.; Zhang, D. Production performance simulation of a horizontal well in a shale gas re-servoir considering the propagation of hydraulic fractures. Geoenergy Sci. Eng. 2023, 221, 111272. [Google Scholar] [CrossRef]

- Chen, S.; Tan, P.; Shi, W.; Zhao, H. A comprehensive Loggingevaluation method for high quality shale gas reservoir in Fuling. Petrol. Drill. Technol. 2020, 48, 131–138. [Google Scholar]

- Tang, X.; Jiang, S.; Jiang, Z.; Li, Z.; He, Z.; Long, S.; Zhu, D. Heterogeneity of Paleozoic Wufeng–Longmaxi formation shale and its effects on the shale gas accumulation in the Upper Yangtze Region, China. Fuel 2019, 239, 387–402. [Google Scholar] [CrossRef]

- Gong, J.; Qiu, Z.; Zou, C.; Wang, H.; Shi, Z. An integrated assessment system for shale gas resources associated with graptolites and its application. Appl. Energy 2020, 262, 114524. [Google Scholar] [CrossRef]

- Liu, L.; Zheng, A.; Bao, H.; Liang, B.; Cai, J.; Zhang, Q.; Liu, S. Optimization of strategies for sustainable and stable gas production in the Jiaoshiba Block of the Fuling Shale Gas Field. Nat. Gas Ind. 2023, 43, 96–104. [Google Scholar]

- Shi, W.; Zhang, Z.; Huang, Z.; Shi, Y.; Liao, Y. Study on calculation method of gas saturation in low-resistivity shale gas reservoir: A case study of Jiaoshiba block in Fuling area. Fault-Block Oil Gas Field 2022, 29, 183–188. [Google Scholar]

- Cai, S.; Xiao, Q.; Zhu, W.; Chen, Q.; Chen, J.; Wang, X. Nanopore structure characteristics and impacting factors of Wufeng-Longmaxi formation shale in southeast Chongqing: A case study of Shizhu Outcrop. Sci. Technol. Eng. 2021, 21, 10603–10612. [Google Scholar]

- Wang, L.; Li, S.; Liu, X.; Hou, Y.; Zhou, C.; Xiang, S.; Wang, M. Water saturation of low resistance shale in the Wufeng-Longmaxi Formation of Sichuan Basin logging evaluation. Sci. Technol. Eng. 2022, 22, 6456–6462. [Google Scholar]

- Yong, R.; Yang, H.; Wu, W.; Yang, X.; Yang, Y.; Huang, H. Controlling factors and exploration potential of shale gas enrichment and high yield in Permian Dalong Formation, northern Sichuan Basin, SW China. Petrol. Explor. Dev. 2025, 52, 285–300. [Google Scholar] [CrossRef]

- Gou, Q.; Xu, S.; Hao, F.; Zhang, B.; Shu, Z.; Yang, F.; Wang, Y.; Li, Q. Quantitative calculated shale gas contents with different lithofacies: A case study of Fuling gas shale, Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2020, 76, 103222. [Google Scholar] [CrossRef]

- Ye, Y.; Tang, S.; Xi, Z.; Jiang, D.; Duan, Y. A new method to predict brittleness index for shale gas reservoirs: Insights from well logging data. J. Petrol. Sci. Eng. 2022, 208, 109431. [Google Scholar] [CrossRef]

- Liao, Y.; Tan, P.; Shi, W.; Feng, A.; He, H. An Evaluation Method for Gas Production Property for Shale Gas Reservoirs in the Fuling Area. Pet. Drill. Tech. 2018, 46, 69–75. [Google Scholar]

- Zang, D.; Wang, S.; Chai, L.; Wang, X.; Chen, J. AHP application to oil shale exploration optimization in Jianchang Basin. J. Xi’an Univ. Sci. Technol. 2014, 34, 180–186. [Google Scholar]

- Han, D.; Zheng, X.; Ding, C.; Gui, D. Empirical study on the application of the analytic hierarchy process in forest fire emergency. J. Wildland Fire Sci. 2024, 42, 78–84. [Google Scholar]

| Scale (aij) | Judgment of the Importance of Two Factors |

|---|---|

| 1 | Factors i and j are equally important |

| 3 | Factor i is slightly more important than factor j |

| 5 | Factor i is significantly more important than factor j |

| 7 | Factor i is much more important than factor j |

| 9 | Factor i is extremely more important than factor j |

| 2, 4, 6, 8 | The scale value of the intermediate state of the comparison between the two factors |

| count backwards | If factor j is compared with factor i, the scale aji = 1/aij |

| Influencing Factor | Air Content | Brittleness Index | Total Organic Carbon Content | Length | Porosity | Gas Saturation | Strata Pressure | Density |

|---|---|---|---|---|---|---|---|---|

| air content | 1 | 2 | 3 | 3 | 5 | 5 | 6 | 7 |

| brittleness index | 0.5 | 1 | 2 | 2 | 3 | 3 | 4 | 5 |

| total organic carbon content | 0.33 | 0.5 | 1 | 1 | 2 | 2 | 3 | 5 |

| length | 0.33 | 0.5 | 1 | 1 | 2 | 2 | 3 | 5 |

| porosity | 0.2 | 0.33 | 0.5 | 0.5 | 1 | 1 | 2 | 3 |

| gas saturation | 0.2 | 0.33 | 0.5 | 0.5 | 1 | 1 | 2 | 3 |

| strata pressure | 0.17 | 0.25 | 0.33 | 0.33 | 0.5 | 0.5 | 1 | 2 |

| density | 0.14 | 0.2 | 0.2 | 0.2 | 0.33 | 0.33 | 0.5 | 1 |

| Matrix Order | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.96 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 | 1.52 |

| Well Number | Air Content | Brittleness Index | Total Organic Carbon Content | Length | Porosity | Gas Saturation | Strata Pressure | Density |

|---|---|---|---|---|---|---|---|---|

| 1 | R11 | R12 | R13 | R14 | R15 | R16 | R17 | R18 |

| 2 | R21 | R22 | R23 | R24 | R25 | R26 | R27 | R28 |

| 3 | R31 | R32 | R33 | R34 | R35 | R36 | R37 | R38 |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ |

| m | Rm1 | Rm2 | Rm3 | Rm4 | Rm5 | Rm6 | Rm7 | Rm8 |

| Number | Well Name | Air Content | Brittleness Index | Total Organic Carbon Content | Length | Porosity | Gas Saturation | Strata Pressure | Density |

|---|---|---|---|---|---|---|---|---|---|

| 1 | F1-2HF | 0.75 | 0.42 | 0.54 | 0.85 | 0.87 | 0.95 | 0.91 | 0.57 |

| 2 | F5-1HF | 0.50 | 0.25 | 0.47 | 0.54 | 0.75 | 0.64 | 0.55 | 0.00 |

| 3 | F6-2HF | 0.76 | 0.67 | 0.84 | 0.90 | 0.85 | 0.76 | 0.98 | 1.00 |

| 4 | F8-1HF | 0.25 | 0.42 | 0.22 | 0.65 | 0.46 | 0.51 | 0.59 | 0.29 |

| 5 | F8-2HF | 0.83 | 0.58 | 0.66 | 0.87 | 1.00 | 0.90 | 1.00 | 0.71 |

| 6 | F9-2HF | 0.20 | 0.00 | 0.00 | 0.00 | 0.69 | 0.00 | 0.00 | 0.29 |

| 7 | F10-1HF | 0.45 | 0.50 | 0.41 | 1.00 | 0.62 | 0.68 | 0.54 | 0.29 |

| 8 | F11-3HF | 0.43 | 1.00 | 0.82 | 0.68 | 0.49 | 0.41 | 0.97 | 0.86 |

| 9 | F12-1HF | 0.87 | 0.58 | 0.80 | 0.90 | 1.00 | 0.88 | 0.98 | 1.00 |

| 10 | F13-2HF | 1.00 | 0.92 | 1.00 | 0.88 | 1.00 | 1.00 | 0.98 | 1.00 |

| 11 | F16-2HF | 0.43 | 0.17 | 0.25 | 0.93 | 0.62 | 0.73 | 0.58 | 0.14 |

| 12 | F17-4HF | 0.21 | 0.75 | 0.58 | 1.00 | 0.21 | 0.35 | 0.16 | 0.43 |

| 13 | F18-3HF | 0.44 | 0.50 | 0.62 | 0.93 | 0.57 | 0.53 | 0.64 | 0.57 |

| 14 | F20-1HF | 0.37 | 0.58 | 0.63 | 0.74 | 0.44 | 0.49 | 0.78 | 0.57 |

| 15 | F21-1HF | 0.22 | 0.50 | 0.43 | 0.36 | 0.29 | 0.41 | 0.49 | 0.29 |

| 16 | F26-3HF | 0.56 | 0.79 | 0.97 | 0.89 | 0.53 | 0.57 | 0.94 | 1.14 |

| 17 | F40-2HF | 0.56 | 0.75 | 0.74 | 0.91 | 0.69 | 0.59 | 0.85 | 1.00 |

| 18 | F44-1HF | 0.30 | 0.58 | 0.55 | 0.80 | 0.33 | 0.49 | 0.60 | 0.43 |

| 19 | F47-2HF | 0.00 | 0.33 | 0.28 | 0.53 | 0.00 | 0.23 | 0.21 | 0.14 |

| 20 | F50-1HF | 0.14 | 0.42 | 0.45 | 0.84 | 0.20 | 0.27 | 0.15 | 0.29 |

| Well Number | Well Name | Obstructed Flow/(104 m3/d) | Gas-Production Index | Gas-Production Level |

|---|---|---|---|---|

| 1 | F1-2HF | 50.70 | 0.70 | Super-productive |

| 2 | F5-1HF | 25.27 | 0.47 | high yield |

| 3 | F6-2HF | 81.92 | 0.79 | Super-productive |

| 4 | F8-1HF | 19.33 | 0.38 | Medium yield |

| 5 | F8-2HF | 155.83 | 0.78 | Super-productive |

| 6 | F9-2HF | 5.70 | 0.12 | low yield |

| 7 | F10-1HF | 26.22 | 0.55 | high yield |

| 8 | F11-3HF | 112.83 | 0.66 | Super-productive |

| 9 | F12-1HF | 82.63 | 0.82 | Super-productive |

| 10 | F13-2HF | 111.02 | 0.97 | Super-productive |

| 11 | F16-2HF | 34.32 | 0.45 | high yield |

| 12 | F17-4HF | 21.59 | 0.48 | high yield |

| 13 | F18-3HF | 55.89 | 0.57 | high yield |

| 14 | F20-1HF | 44.19 | 0.53 | high yield |

| 15 | F21-1HF | 17.39 | 0.35 | Medium yield |

| 16 | F26-3HF | 68.02 | 0.73 | Super-productive |

| 17 | F40-2HF | 83.37 | 0.70 | Super-productive |

| 18 | F44-1HF | 30.85 | 0.49 | high yield |

| 19 | F47-2HF | 9.50 | 0.20 | low yield |

| 20 | F50-1HF | 15.97 | 0.34 | Medium yield |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, H.; Shi, W.; Wang, S. Evaluation Method of Gas Production in Shale Gas Reservoirs in Jiaoshiban Block, Fuling Gas Field. Energies 2025, 18, 3817. https://doi.org/10.3390/en18143817

Rao H, Shi W, Wang S. Evaluation Method of Gas Production in Shale Gas Reservoirs in Jiaoshiban Block, Fuling Gas Field. Energies. 2025; 18(14):3817. https://doi.org/10.3390/en18143817

Chicago/Turabian StyleRao, Haitao, Wenrui Shi, and Shuoliang Wang. 2025. "Evaluation Method of Gas Production in Shale Gas Reservoirs in Jiaoshiban Block, Fuling Gas Field" Energies 18, no. 14: 3817. https://doi.org/10.3390/en18143817

APA StyleRao, H., Shi, W., & Wang, S. (2025). Evaluation Method of Gas Production in Shale Gas Reservoirs in Jiaoshiban Block, Fuling Gas Field. Energies, 18(14), 3817. https://doi.org/10.3390/en18143817