Energy Yield Analysis of Bifacial Solar Cells in Northeast Mexico: Comparison Between Vertical and Tilted Configurations

Abstract

1. Introduction

2. Materials and Methods

2.1. Bifacial Solar Cells Studied in This Work

2.2. Measurement Equipment

3. Results

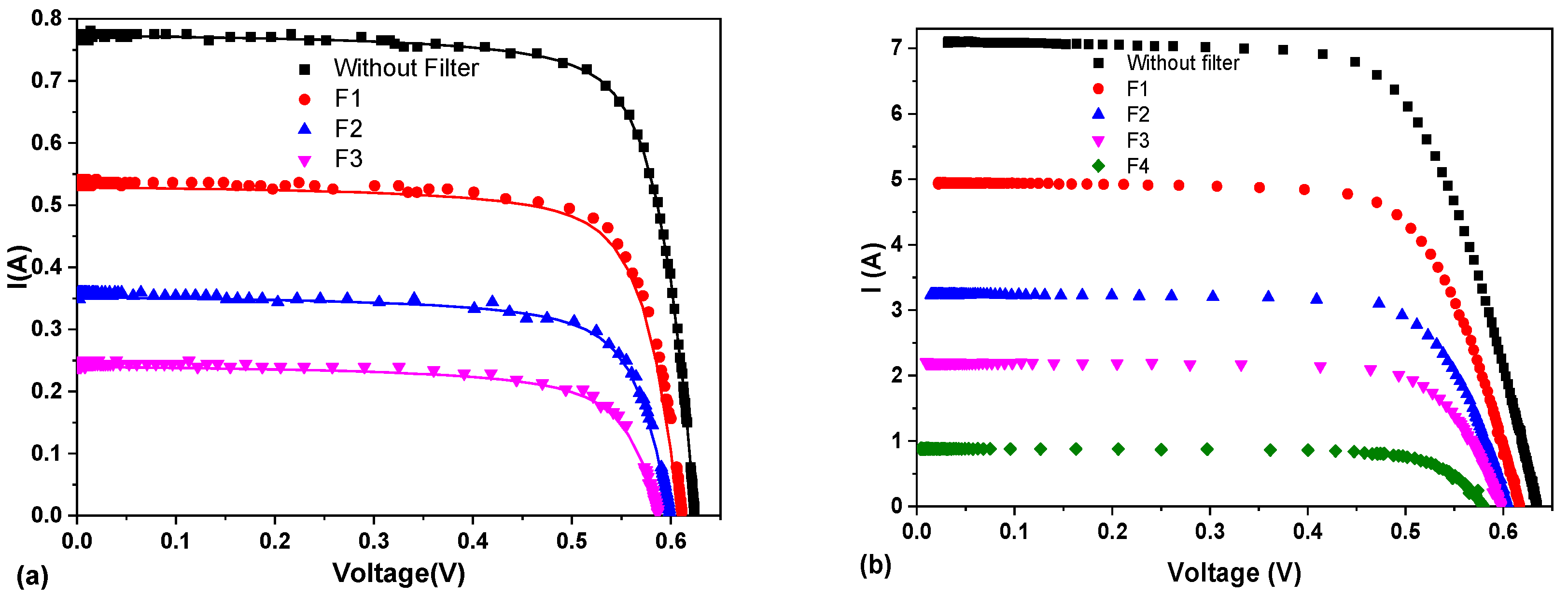

3.1. Validation of the I-V Tracer

3.2. Optimization of Installation Parameters

3.2.1. In Situ Albedo Spectrum

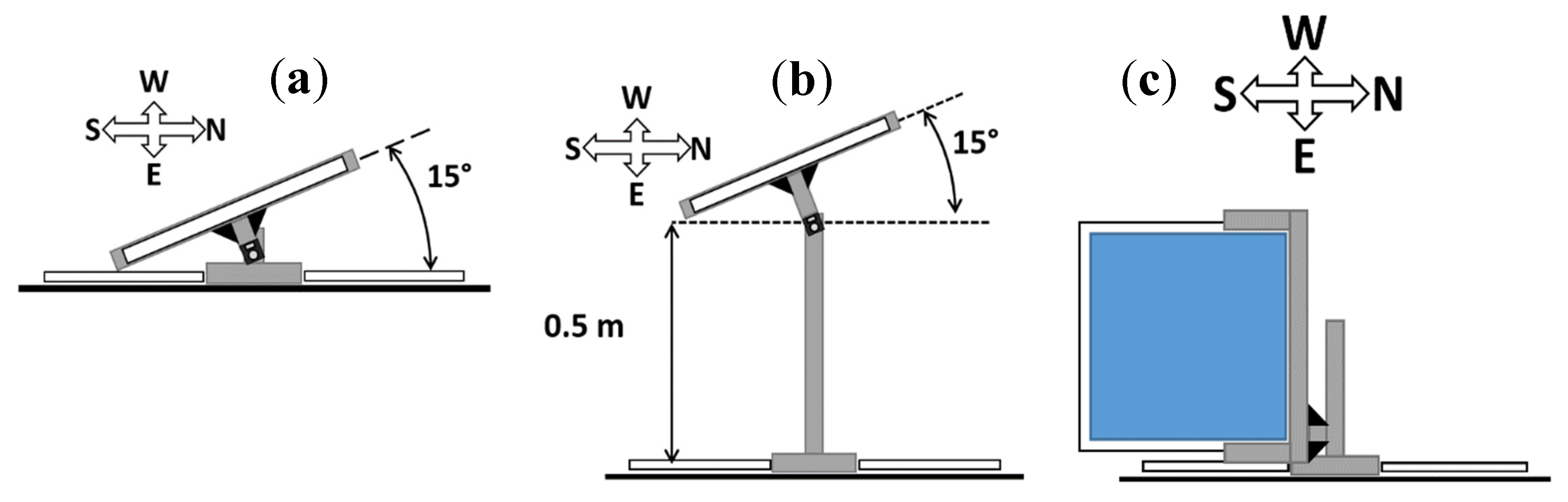

3.2.2. Orientation

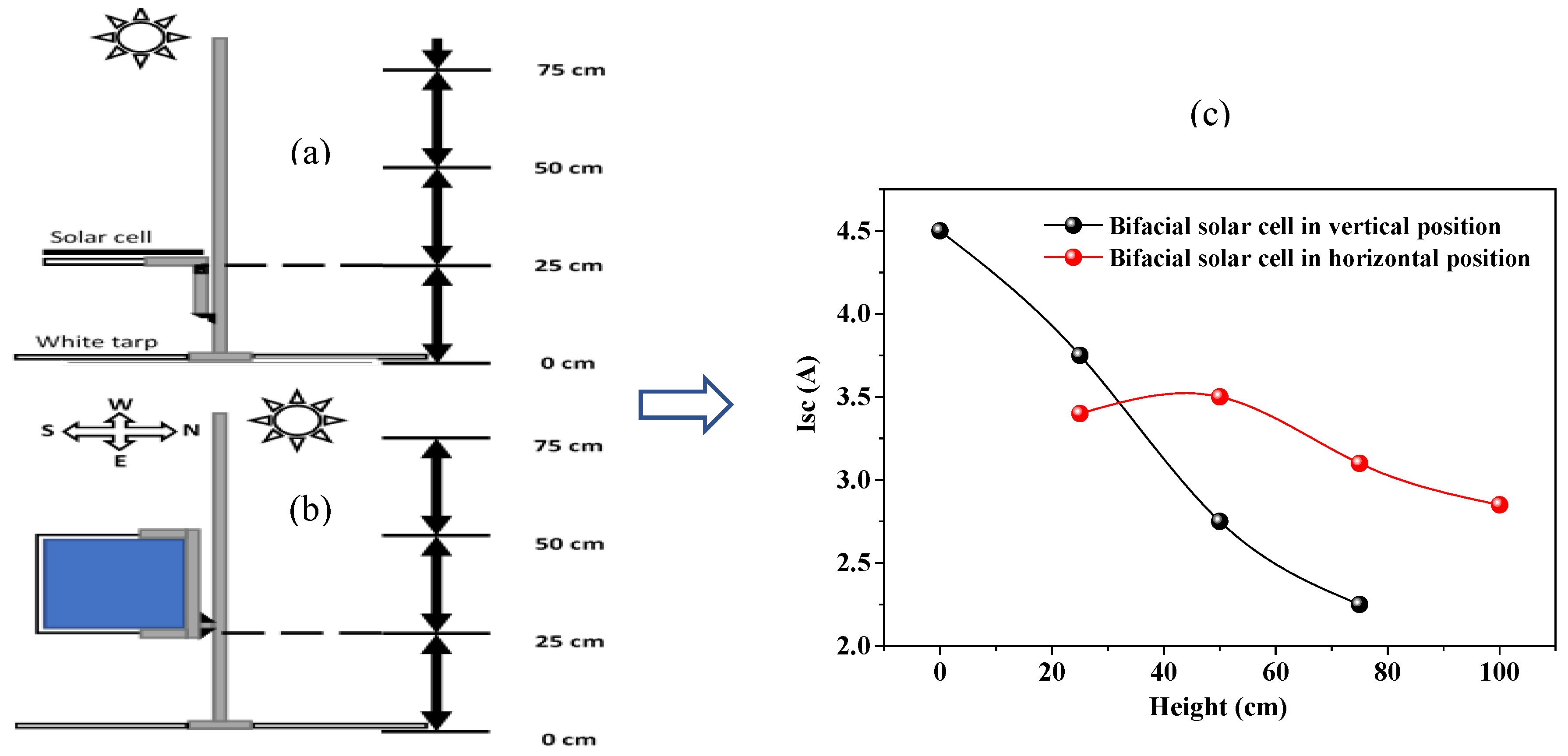

3.2.3. Height Optimization

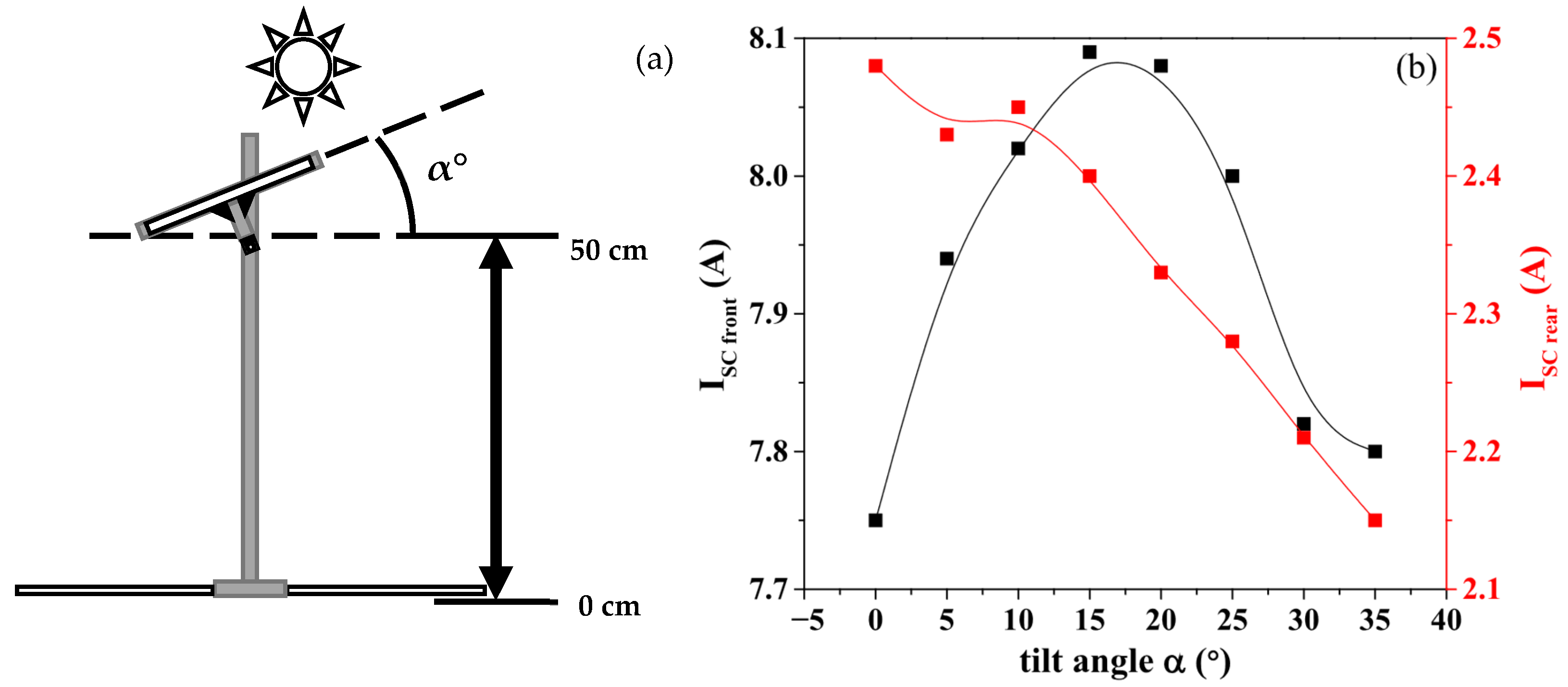

3.2.4. Tilt Angle

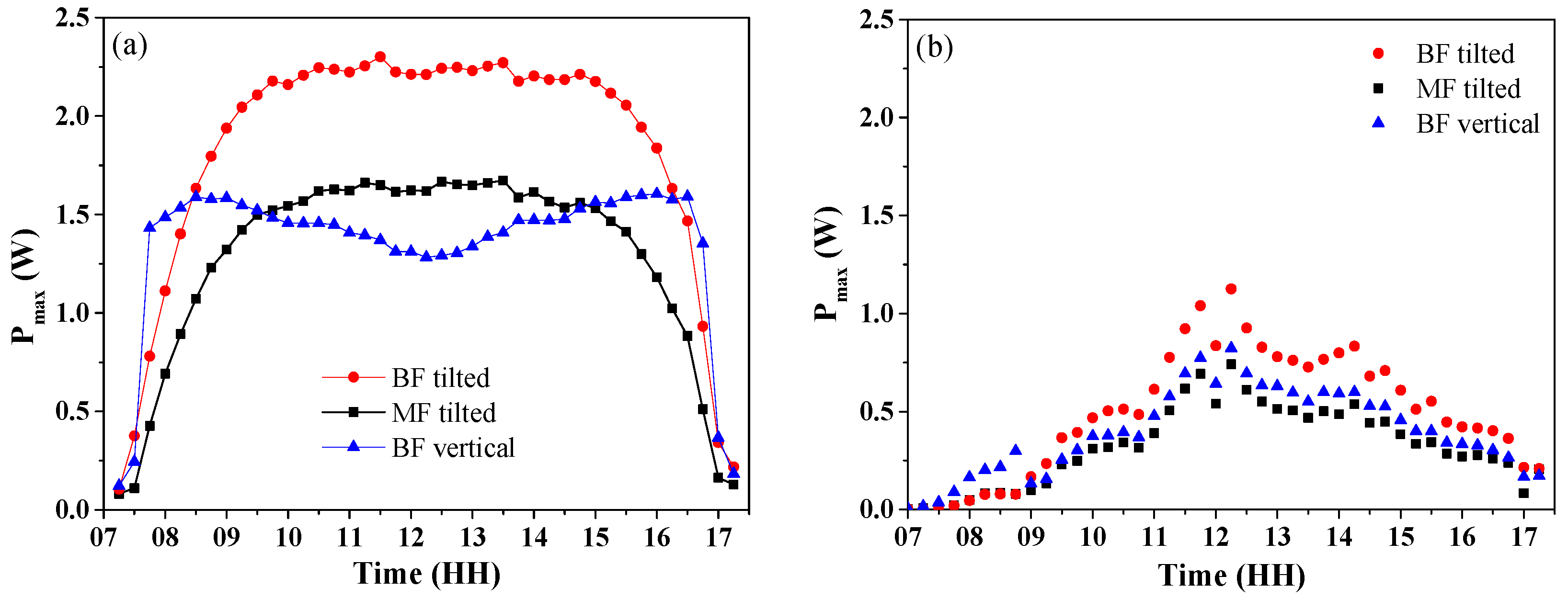

3.3. Daytime Profile of Maximum Power

3.4. Analysis of the Energy Yielded by the Cells

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| I-V | Current–voltage curve tracer |

| Isc | Short-circuit current |

| BIPV | Building-integrated photovoltaics |

| PV | Photovoltaic |

| HIT | Heterojunction with intrinsic thin layer |

| TCO | Transparent conductive oxide |

| SC1 | Solar cell 1 |

| SC2 | Solar cell 2 |

| SC3 | Solar cell 3 |

| ADC | Analog-to-digital converter |

| DAC | Digital-to-analog converter |

| RSENSE | Current sense resistor |

| PR’s | Power relays |

| BFtilted | Bifacial solar cell tilted |

| BFvertical | Bifacial solar cell vertical |

| MFtilted | Monofacial solar cell tilted |

| Pmax | Maximum power |

References

- Maniscalco, M.; Longo, S.; Miccichè, G.; Cellura, M.; Ferraro, M. A Critical Review of the Environmental Performance of Bifacial Photovoltaic Panels. Energies 2023, 17, 226. [Google Scholar] [CrossRef]

- Oberbeck, L.; Alvino, K.; Goraya, B.; Jubault, M. IPVF’s PV Technology Vision for 2030. Prog. Photovolt. 2020, 28, 1207–1214. [Google Scholar] [CrossRef]

- Lee, T.D.; Ebong, A.U. A Review of Thin Film Solar Cell Technologies and Challenges. Renew. Sustain. Energy Rev. 2017, 70, 1286–1297. [Google Scholar] [CrossRef]

- Subedi, K.K.; Phillips, A.B.; Shrestha, N.; Alfadhili, F.K.; Osella, A.; Subedi, I.; Awni, R.A.; Bastola, E.; Song, Z.; Li, D.-B.; et al. Enabling Bifacial Thin Film Devices by Developing a Back Surface Field Using CuxAlOy. Nano Energy 2021, 83, 105827. [Google Scholar] [CrossRef]

- Pearcey, E. Giant Bifacial PV Plants Act as Springboard for Growth. Available online: https://www.solarnews.es/solarnews_internacional/2020/09/02/giant-bifacial-pv-plants-act-as-springboard-for-growth/ (accessed on 28 January 2025).

- Wesoff, E. The Largest US Solar-plus-Storage Plant Will Deploy 690 MW of Bifacial Modules on Trackers. Available online: https://pv-magazine-usa.com/2020/05/15/the-largest-us-solar-plus-storage-plant-will-deploy-690-mw-of-bifacial-modules-on-trackers/ (accessed on 21 February 2025).

- Baumann, T.; Carigiet, F.; Knecht, R.; Klenk, M.; Dreisiebner, A.; Nussbaumer, H.; Baumgartner, F. Performance Analysis of Vertically Mounted Bifacial PV Modules on Green Roof System. In Proceedings of the EU PVSEC 2018, Brussels, Belgium, 28 September 2018; pp. 1–6. [Google Scholar]

- Rojo Martín, J. Enel Hits 1.3GW of Mexican Solar with Launch of First Bifacial-Only Plant. Available online: https://www.pv-tech.org/enel-hits-1-3gw-of-mexican-solar-with-launch-of-first-bifacial-only-plant/ (accessed on 12 February 2025).

- INEGI. Climatology. Available online: http://en.www.inegi.org.mx/temas/climatologia/#Map (accessed on 21 February 2025).

- IEC Technical Specification 60904-1-2. Available online: https://webstore.iec.ch/en/publication/34357 (accessed on 2 February 2025).

- Baloch, A.A.B.; Hammat, S.; Figgis, B.; Alharbi, F.H.; Tabet, N. In-Field Characterization of Key Performance Parameters for Bifacial Photovoltaic Installation in a Desert Climate. Renew. Energy 2020, 159, 50–63. [Google Scholar] [CrossRef]

- Katsaounis, T.; Kotsovos, K.; Gereige, I.; Basaheeh, A.; Abdullah, M.; Khayat, A.; Al-Habshi, E.; Al-Saggaf, A.; Tzavaras, A.E. Performance Assessment of Bifacial C-Si PV Modules through Device Simulations and Outdoor Measurements. Renew. Energy 2019, 143, 1285–1298. [Google Scholar] [CrossRef]

- Castillo-Aguilella, J.E.; Hauser, P.S. Multi-Variable Bifacial Photovoltaic Module Test Results and Best-Fit Annual Bifacial Energy Yield Model. IEEE Access 2016, 4, 498–506. [Google Scholar] [CrossRef]

- Kurz, D.; Dobrzycki, A.; Krawczak, E.; Jajczyk, J.; Mielczarek, J.; Woźniak, W.; Sąsiadek, M.; Orynycz, O.; Tucki, K.; Badzińska, E. An Analysis of the Increase in Energy Efficiency of Photovoltaic Installations by Using Bifacial Modules. Energies 2025, 18, 1296. [Google Scholar] [CrossRef]

- Muehleisen, W.; Loeschnig, J.; Feichtner, M.; Burgers, A.R.; Bende, E.E.; Zamini, S.; Yerasimou, Y.; Kosel, J.; Hirschl, C.; Georghiou, G.E. Energy Yield Measurement of an Elevated PV System on a White Flat Roof and a Performance Comparison of Monofacial and Bifacial Modules. Renew. Energy 2021, 170, 613–619. [Google Scholar] [CrossRef]

- Gu, W.; Li, S.; Liu, X.; Chen, Z.; Zhang, X.; Ma, T. Experimental Investigation of the Bifacial Photovoltaic Module under Real Conditions. Renew. Energy 2021, 173, 1111–1122. [Google Scholar] [CrossRef]

- Baumann, T.; Nussbaumer, H.; Klenk, M.; Dreisiebner, A.; Carigiet, F.; Baumgartner, F. Photovoltaic Systems with Vertically Mounted Bifacial PV Modules in Combination with Green Roofs. Sol. Energy 2019, 190, 139–146. [Google Scholar] [CrossRef]

- Appelbaum, J. Bifacial Photovoltaic Panels Field. Renew. Energy 2016, 85, 338–343. [Google Scholar] [CrossRef]

- Basak, A.; Chakraborty, S.; Behura, A.K. Tilt Angle Optimization for Bifacial PV Module: Balancing Direct and Reflected Irradiance on White Painted Ground Surfaces. Appl. Energy 2025, 377, 124525. [Google Scholar] [CrossRef]

- Yu, B.; Song, D.; Sun, Z.; Liu, K.; Zhang, Y.; Rong, D.; Liu, L. A Study on Electrical Performance of N-Type Bifacial PV Modules. Sol. Energy 2016, 137, 129–133. [Google Scholar] [CrossRef]

- Khan, M.R.; Hanna, A.; Sun, X.; Alam, M.A. Vertical Bifacial Solar Farms: Physics, Design, and Global Optimization. Appl. Energy 2017, 206, 240–248. [Google Scholar] [CrossRef]

- Xu, F.; Yang, X.; Huang, T.; Li, Z.; Ji, Y.; Zhu, R. The Emergence of Top-Incident Perovskite Solar Cells. Nano Energy 2024, 130, 110171. [Google Scholar] [CrossRef]

- Tillmann, P.; Jäger, K.; Becker, C. Minimising the Levelised Cost of Electricity for Bifacial Solar Panel Arrays Using Bayesian Optimisation. Sustain. Energy Fuels 2020, 4, 254–264. [Google Scholar] [CrossRef]

- Geodatos. Geographic Coordinates Searching. Available online: https://www.geodatos.net/coordenadas (accessed on 8 March 2025).

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and Future Köppen-Geiger Climate Classification Maps at 1-Km Resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef]

- Pennington, R.T.; Lehmann, C.E.R.; Rowland, L.M. Tropical Savannas and Dry Forests. Curr. Biol. 2018, 28, R541–R545. [Google Scholar] [CrossRef]

- García, E. Modificaciones al Sistema de Clasificación Climática de Köppen; Universidad Nacional Autónoma de México Instituto de Geografía: Ciudad de México, Mexico, 2004; ISBN 970-32-1010-4. [Google Scholar]

- Amiry, H.; Benhmida, M.; Bendaoud, R.; Hajjaj, C.; Bounouar, S.; Yadir, S.; Raïs, K.; Sidki, M. Design and Implementation of a Photovoltaic I-V Curve Tracer: Solar Modules Characterization under Real Operating Conditions. Energy Convers. Manag. 2018, 169, 206–216. [Google Scholar] [CrossRef]

- Papageorgas, P.; Piromalis, D.; Valavanis, T.; Kambasis, S.; Iliopoulou, T.; Vokas, G. A Low-Cost and Fast PV I-V Curve Tracer Based on an Open Source Platform with M2M Communication Capabilities for Preventive Monitoring. Energy Procedia 2015, 74, 423–438. [Google Scholar] [CrossRef]

- García-Valverde, R.; Chaouki-Almagro, S.; Corazza, M.; Espinosa, N.; Hösel, M.; Søndergaard, R.R.; Jørgensen, M.; Villarejo, J.A.; Krebs, F.C. Portable and Wireless IV-Curve Tracer for >5kV Organic Photovoltaic Modules. Sol. Energy Mater. Sol. Cells 2016, 151, 60–65. [Google Scholar] [CrossRef]

- Zhu, Y.; Xiao, W. A Comprehensive Review of Topologies for Photovoltaic I–V Curve Tracer. Sol. Energy 2020, 196, 346–357. [Google Scholar] [CrossRef]

- Adam, D. Paint It White. Available online: https://www.theguardian.com/environment/2009/jan/16/white-paint-carbon-emissions-climate (accessed on 17 February 2025).

- González-León, C.; Torres, J.; Serrano, J.P.; Rodríguez-Alejandro, A.D.A.; González-Cabrera, N. Estudio tecnico economico de paneles solares interconectados a la red de distribución. Rev. Iberoam. De Cienc. 2018, 5, 94–105. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villarreal-Villela, A.E.; Vigil-Galán, O.; González, E.R.; González Castillo, J.R.; Jiménez-Olarte, D.; López-Oyama, A.B.; Del Angel-López, D. Energy Yield Analysis of Bifacial Solar Cells in Northeast Mexico: Comparison Between Vertical and Tilted Configurations. Energies 2025, 18, 3784. https://doi.org/10.3390/en18143784

Villarreal-Villela AE, Vigil-Galán O, González ER, González Castillo JR, Jiménez-Olarte D, López-Oyama AB, Del Angel-López D. Energy Yield Analysis of Bifacial Solar Cells in Northeast Mexico: Comparison Between Vertical and Tilted Configurations. Energies. 2025; 18(14):3784. https://doi.org/10.3390/en18143784

Chicago/Turabian StyleVillarreal-Villela, Angel Eduardo, Osvaldo Vigil-Galán, Eugenio Rodríguez González, Jesús Roberto González Castillo, Daniel Jiménez-Olarte, Ana Bertha López-Oyama, and Deyanira Del Angel-López. 2025. "Energy Yield Analysis of Bifacial Solar Cells in Northeast Mexico: Comparison Between Vertical and Tilted Configurations" Energies 18, no. 14: 3784. https://doi.org/10.3390/en18143784

APA StyleVillarreal-Villela, A. E., Vigil-Galán, O., González, E. R., González Castillo, J. R., Jiménez-Olarte, D., López-Oyama, A. B., & Del Angel-López, D. (2025). Energy Yield Analysis of Bifacial Solar Cells in Northeast Mexico: Comparison Between Vertical and Tilted Configurations. Energies, 18(14), 3784. https://doi.org/10.3390/en18143784