The Influence of Absorber Properties on Operating Parameters and Electricity Generation in the Solar Chimney with a Vertical Collector

Abstract

1. Introduction

2. Materials and Methods

2.1. Solar Chimney and Its Location

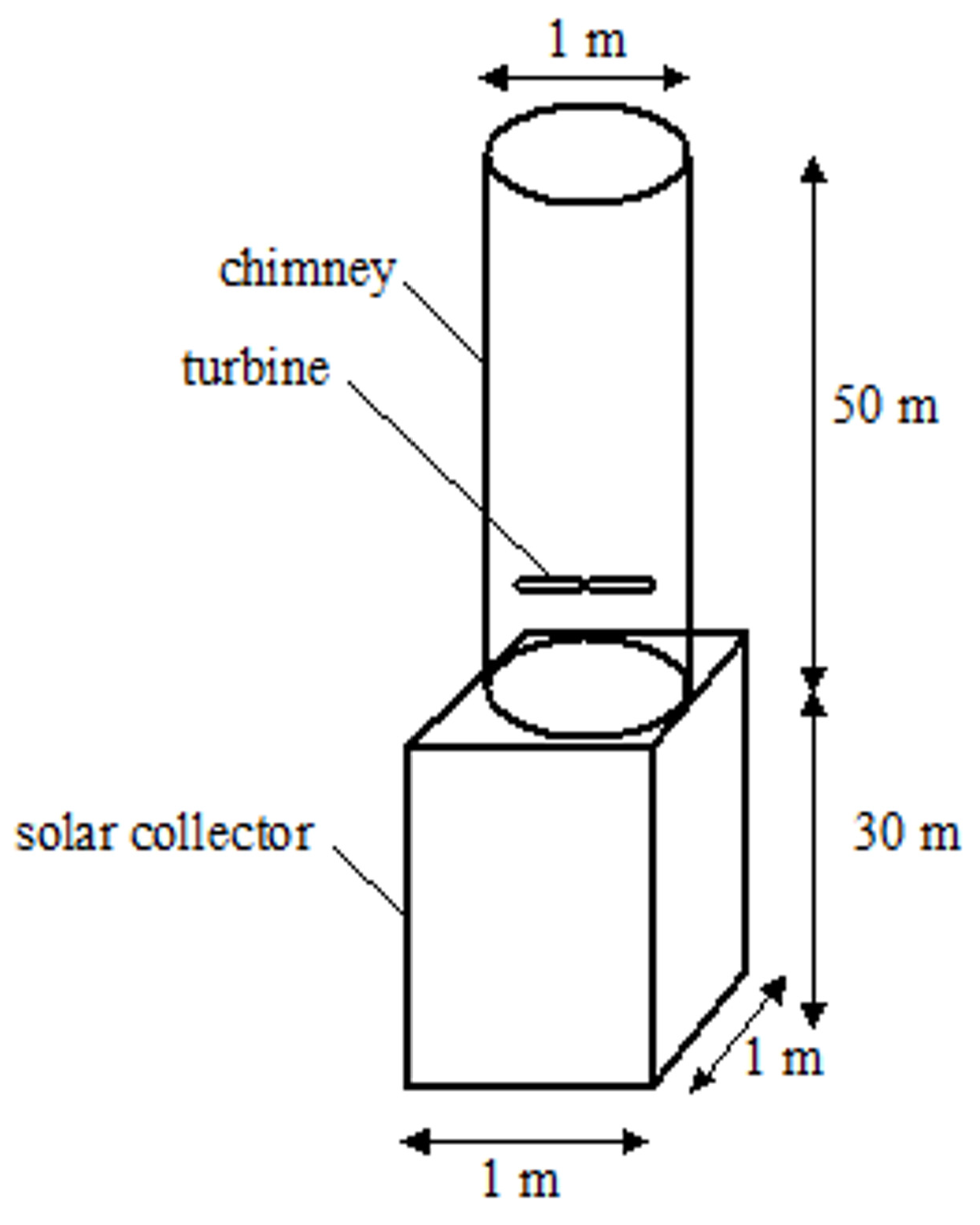

2.2. Solar Chimney

2.3. Mathematical Model

Calculations of Solar Chimney

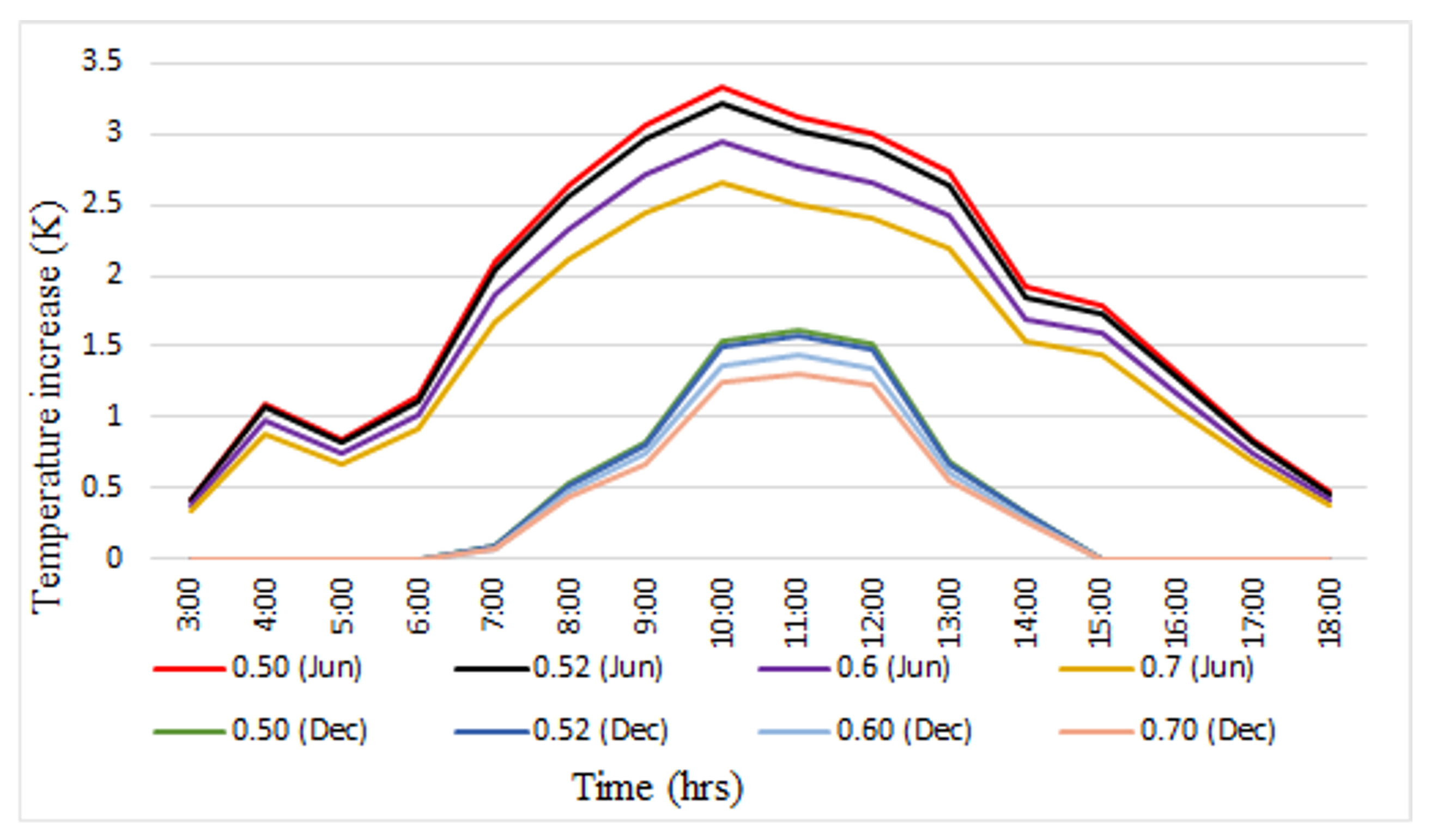

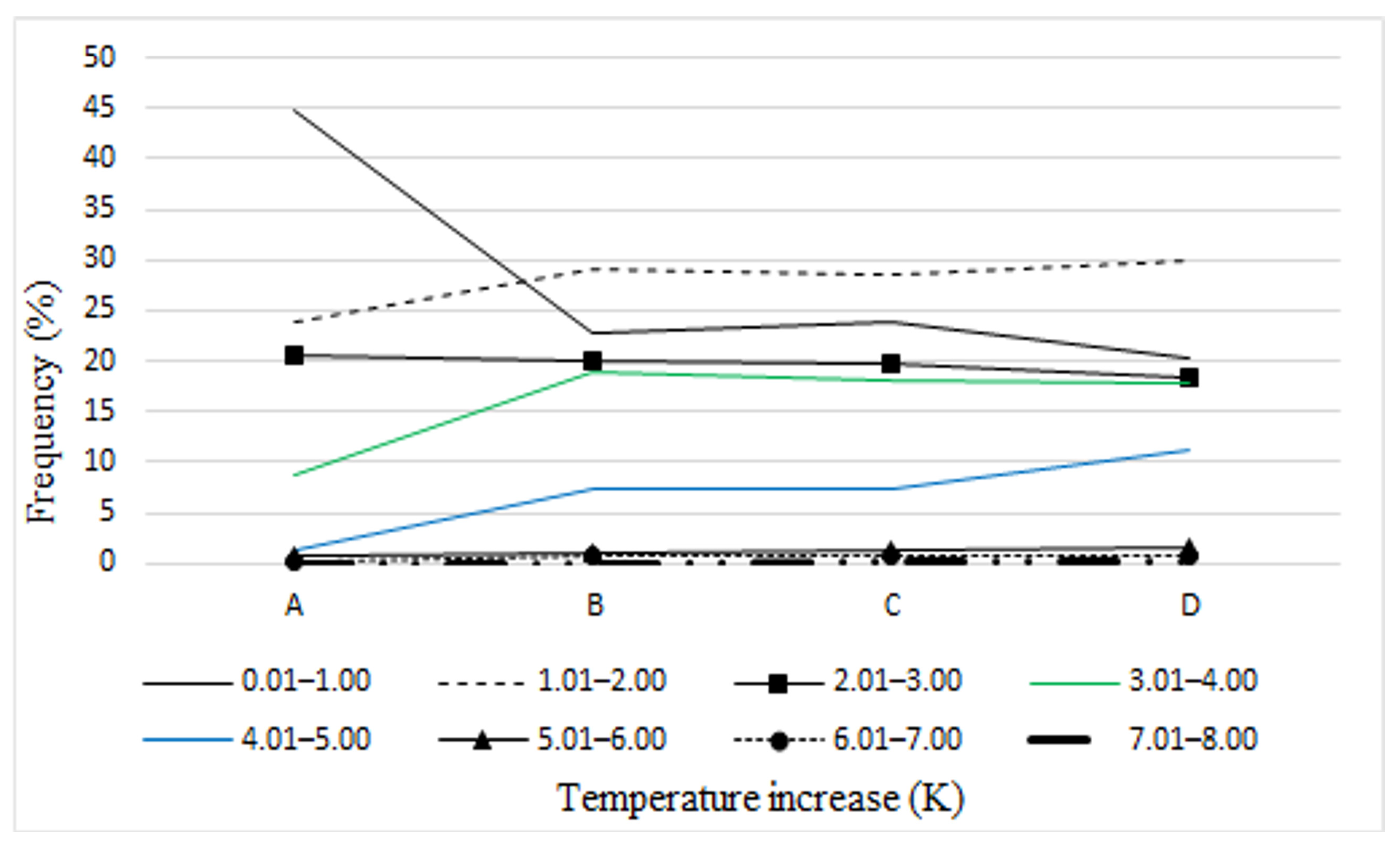

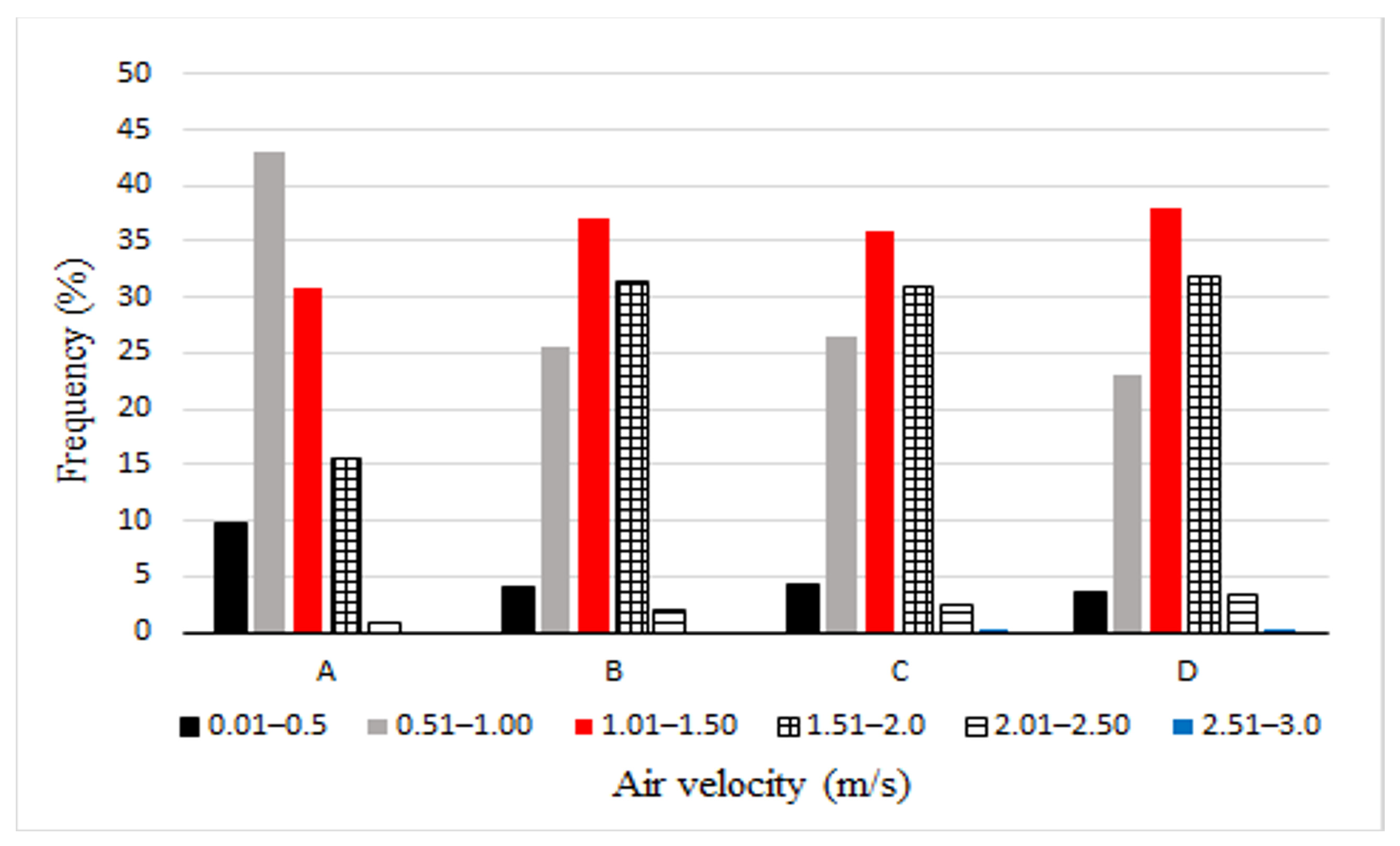

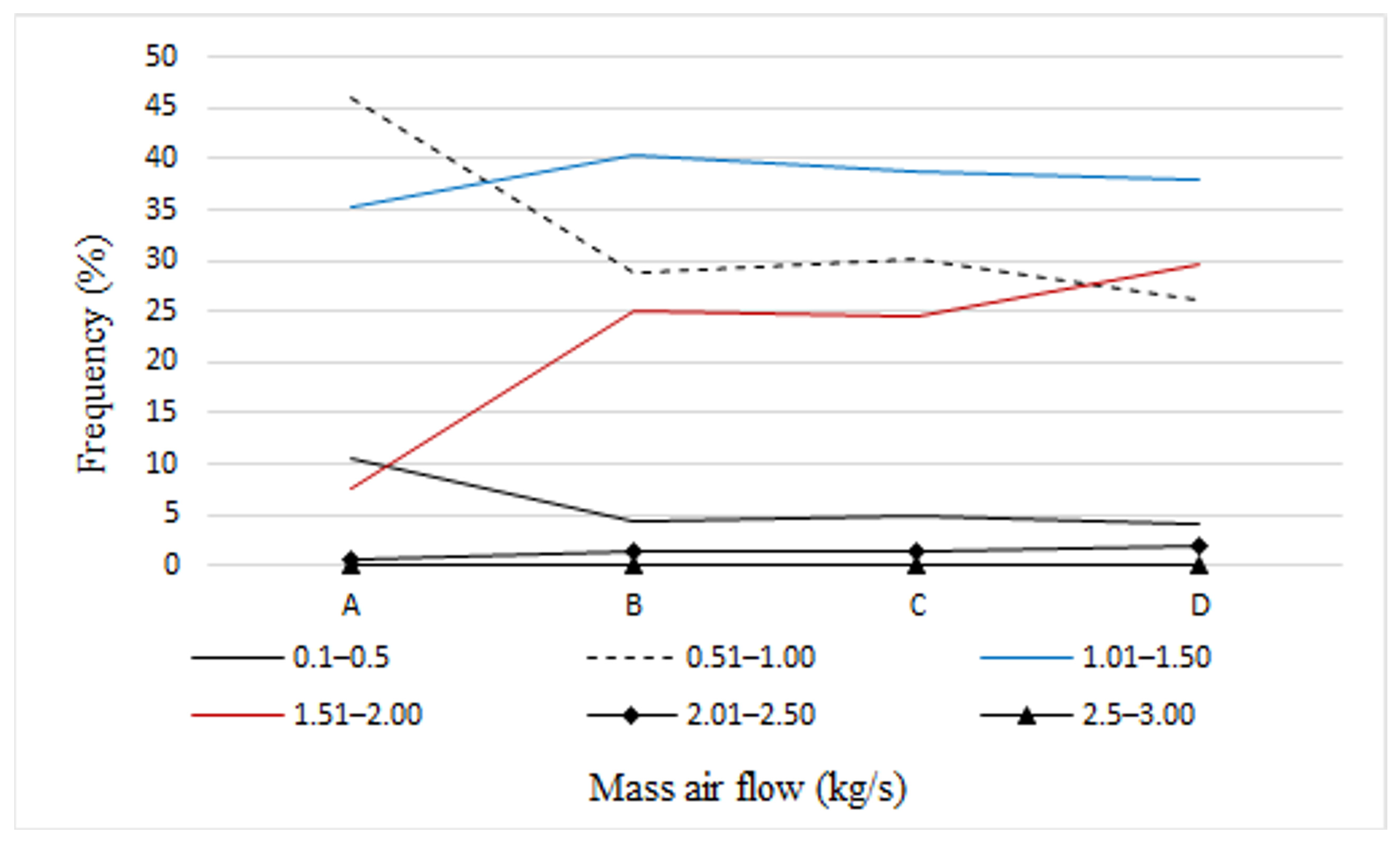

3. Results

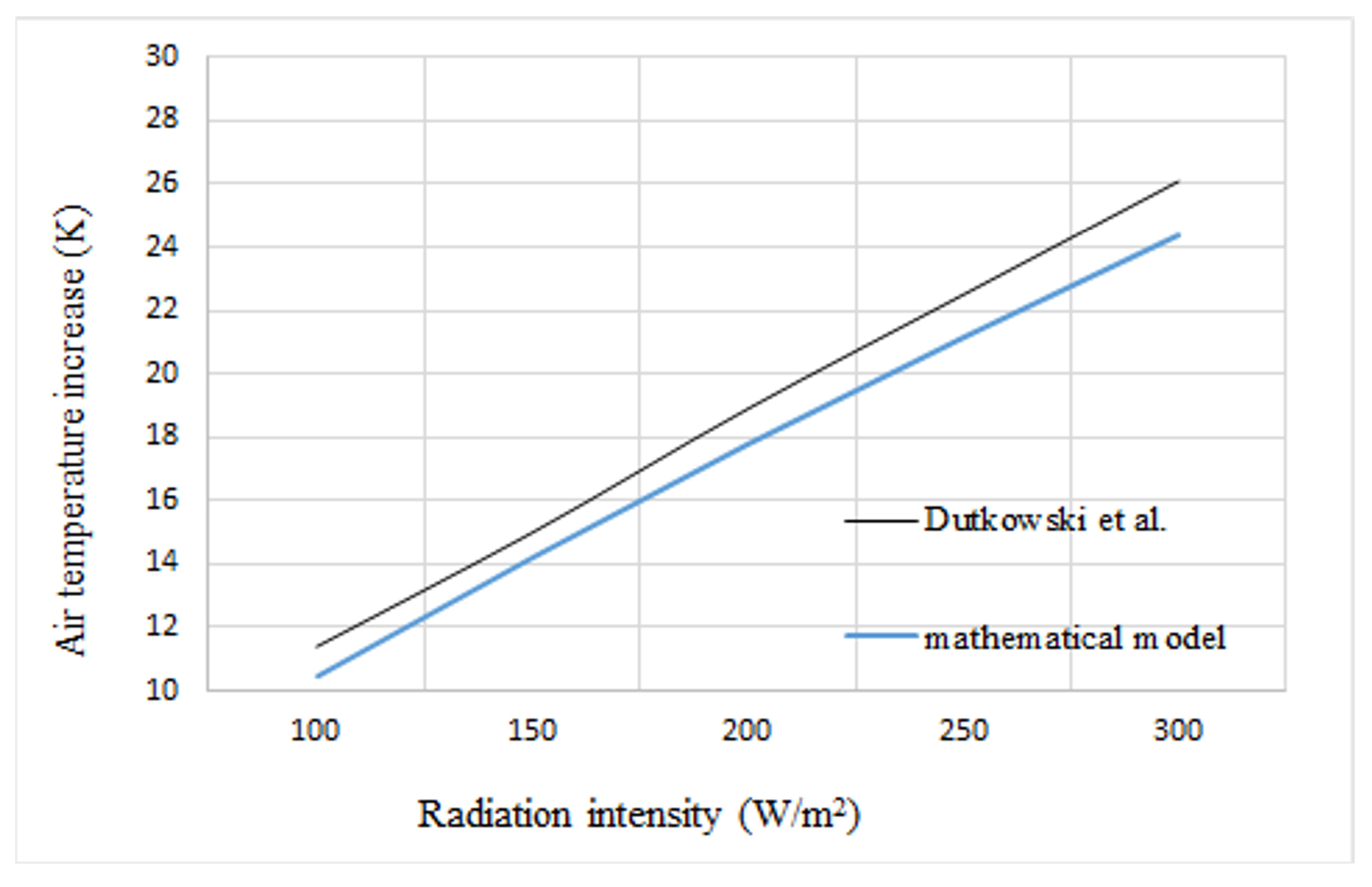

3.1. Model Validation

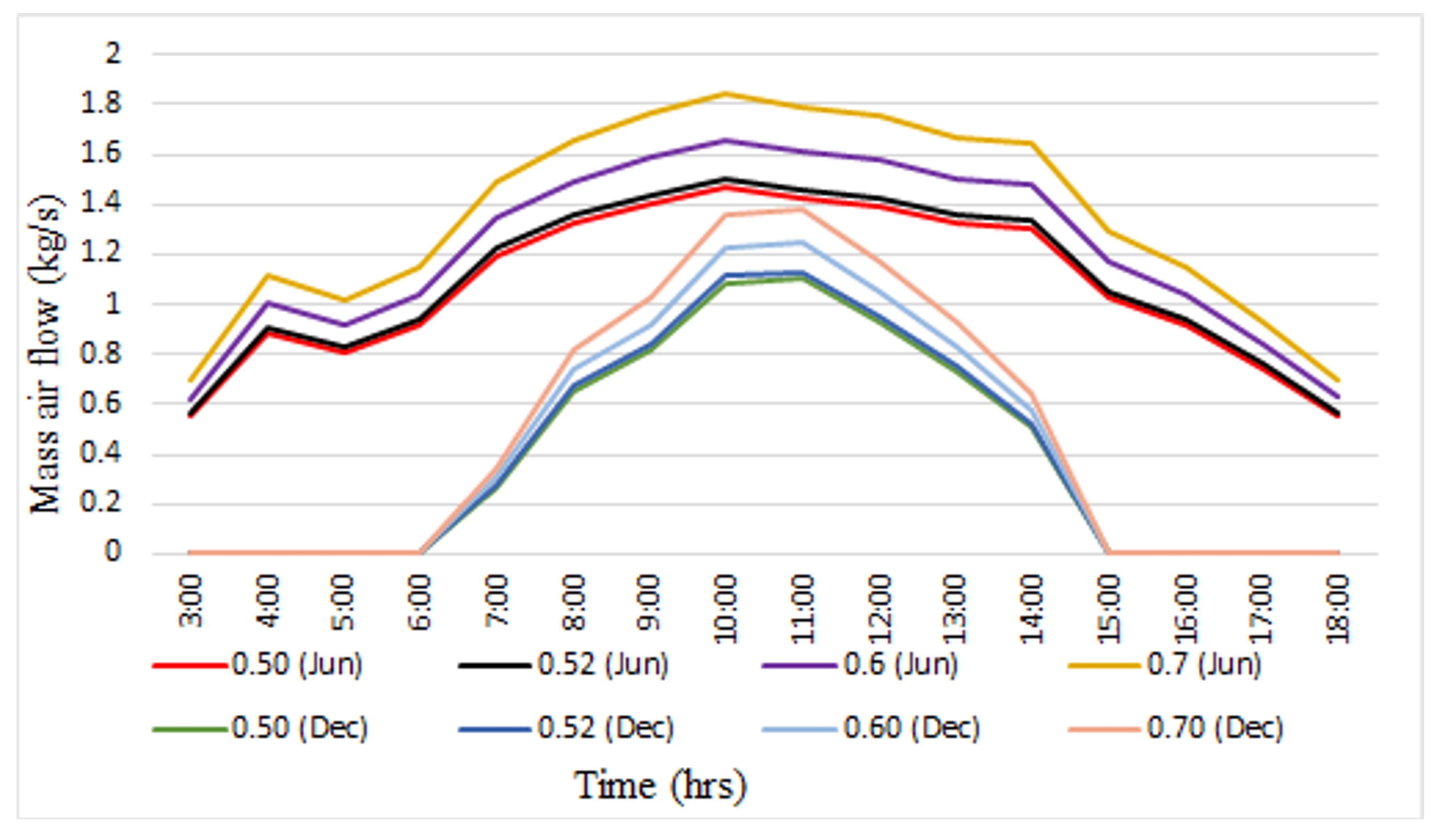

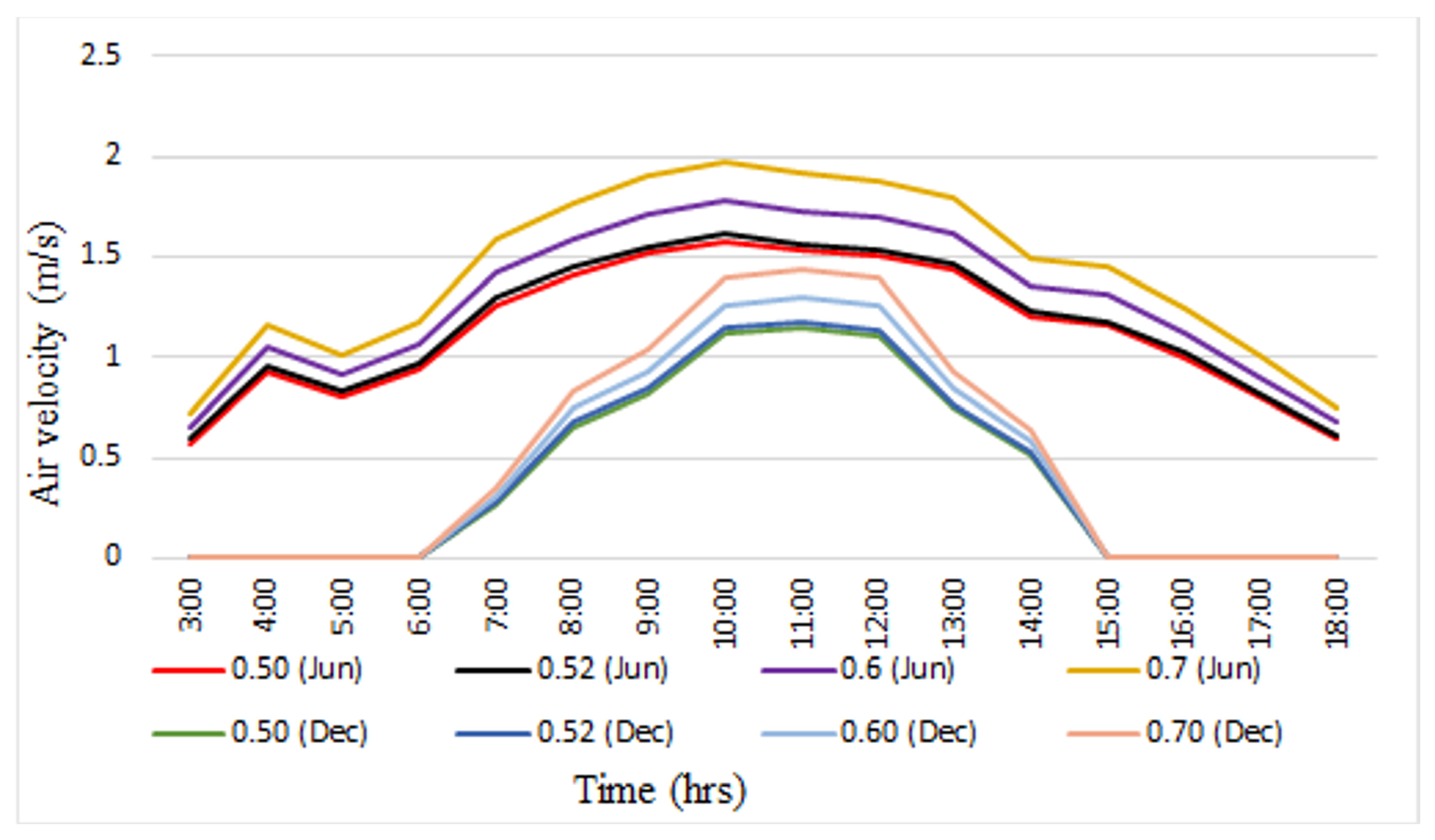

3.2. Sensitivity Analysis for Discharge Coefficient Cd

- (1)

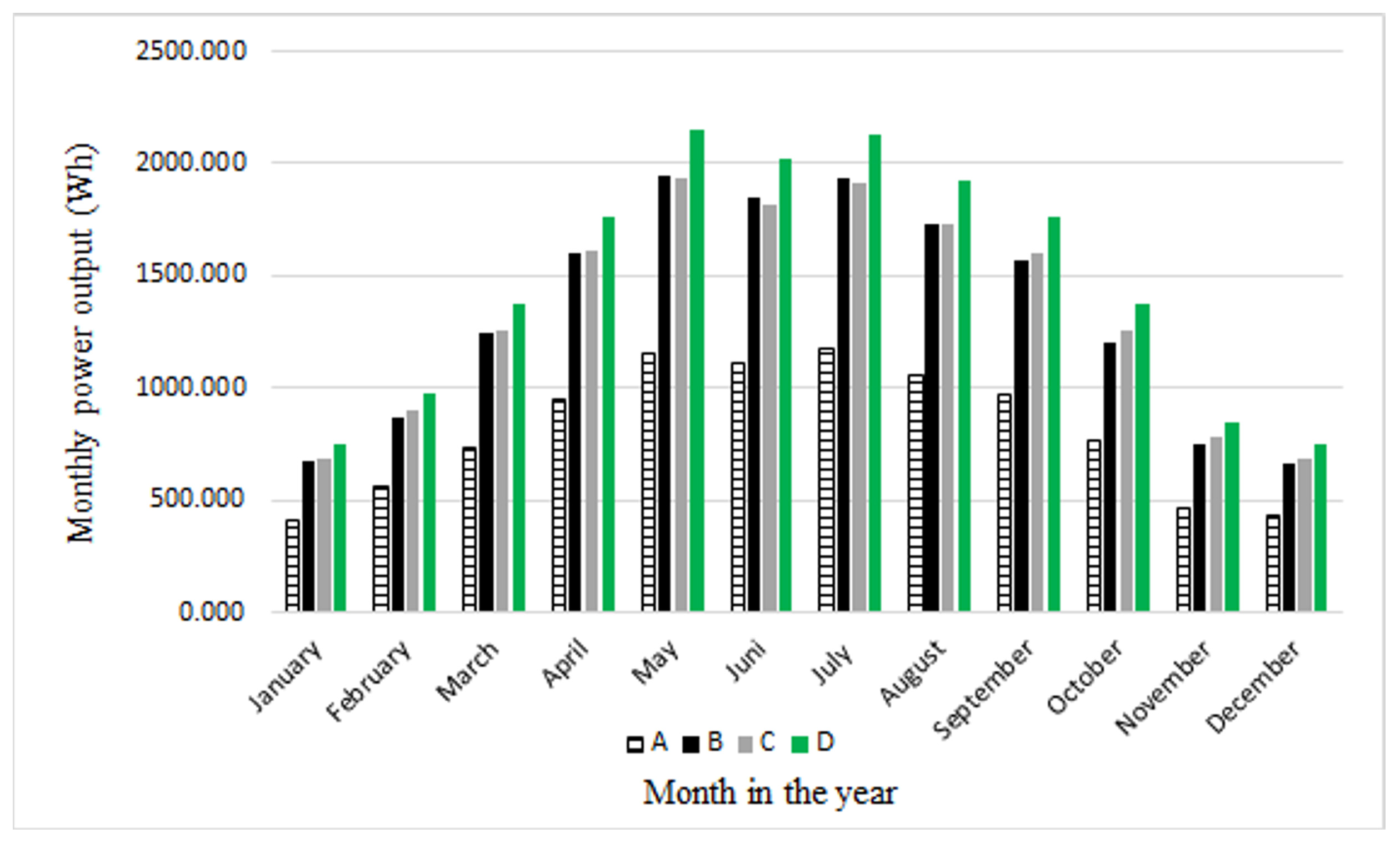

- Variant A is an installation with an absorber covered with black paint with an absorption coefficient of 0.95 and an emission coefficient of 0.95.

- (2)

- Variant B is a system with an absorber covered with CuO with an absorption coefficient of 0.85 and an emission coefficient of 0.11.

- (3)

- Variant C is a system with an absorber covered with black chrome with an absorption coefficient of 0.98 and an emission coefficient of 0.14.

- (4)

- Variant D is a system with an absorber covered with TiNOX with an absorption coefficient of 0.95 and an emission coefficient of 0.05.

4. Discussion

5. Conclusions

- (1)

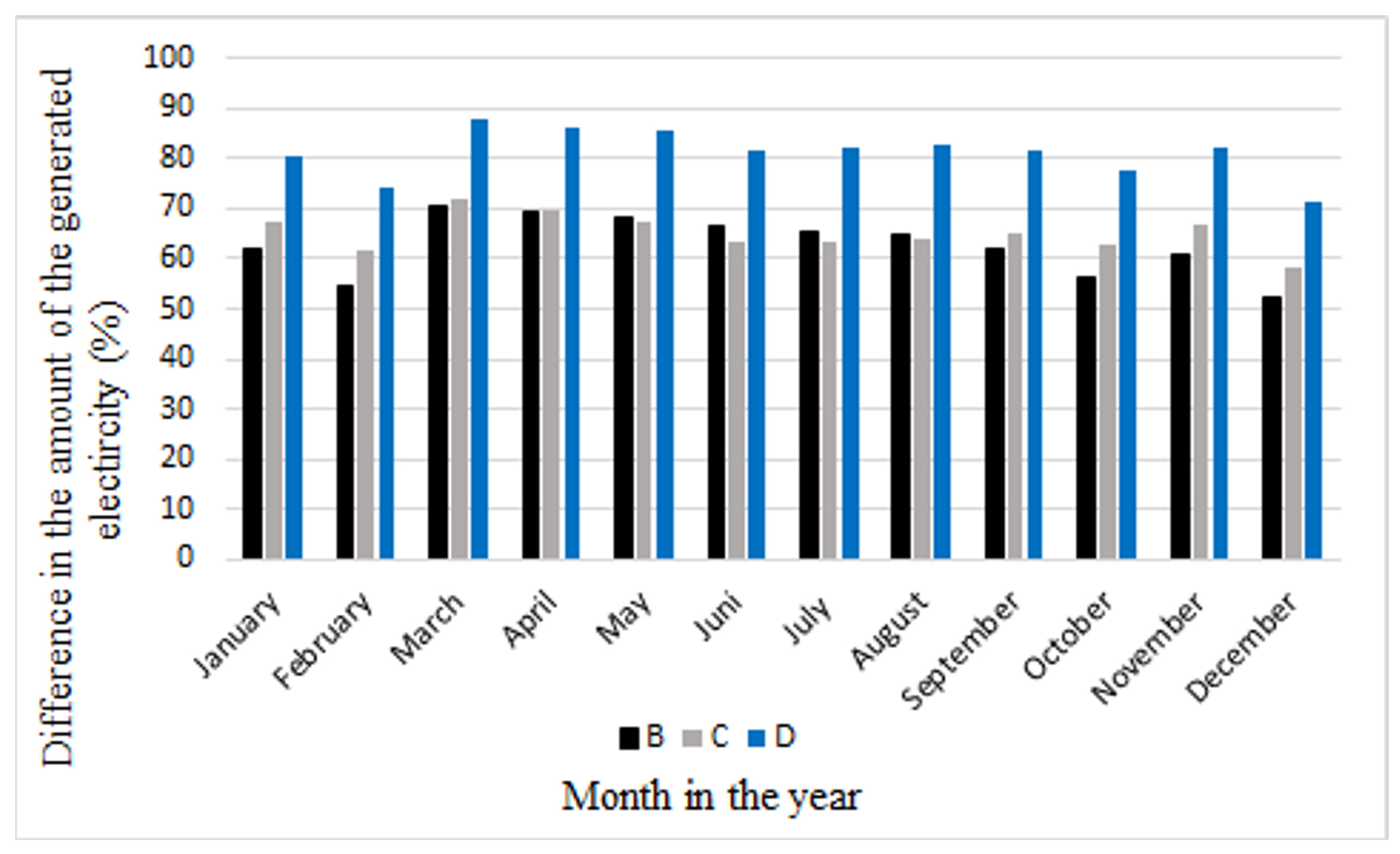

- The largest increases in temperature, air velocity and mass air flow can be achieved in systems with an absorber characterized by the highest absorption coefficient and the lowest emission coefficient.

- (2)

- The installation of a solar chimney with an absorber covered with a selective coating having an absorption coefficient of 0.95 and an emission coefficient of 0.05 allowed the generation of the largest amount of electricity during the year.

- (3)

- The year-long analysis of the solar chimney operation showed that the use of selective absorber coatings allows for the generation of an average of 62.8% (variant B) to 81.4% (variant D) more electricity compared to an absorber with a non-selective coating.

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AA | absorber surface, m2 |

| Ac | collector cross-section, m2 |

| Ach | cross-section of the chimney, m2 |

| Ai | cross-sectional area of the inlet, m2 |

| Ao | cross-sectional area of the outlet, m2 |

| a | length of the collector side, m |

| b | length of the collector side, m |

| Cd | coefficient of discharge |

| cp | specific heat, J/kgK |

| d | distance between glass and absorber, m |

| di | insulation thickness of the collector bottom, m |

| F′ | efficiency of the absorber |

| FR | heat transfer coefficient |

| total radiation on an inclined surface, W/m2 | |

| g | gravitational acceleration, m/s2 |

| H | height of the chimney, m |

| Hcoll | height of the collector, m |

| hc1 | convective heat transfer coefficient, W/m2K |

| hr1 | heat transfer coefficient from the radiation between the absorber and the glass, W/m2K |

| hr2 | equivalent coefficient of heat transfer by radiation between the glass and the sky, W/m2K |

| hc2 | convective heat transfer coefficient from the glass surface to the environment caused by the wind, W/m2K |

| L | characteristic value |

| air mass flow, kg/s | |

| Nu | Nusselt number |

| Pel | electric power, W |

| Pr | Prandtl number |

| Q | effective capacity of the collector, W |

| Ra | Rayleigh number |

| Re | Reynolds number |

| Ta | ambient temperature, K |

| TA | absorber temperature, K |

| Tc | glass temperature, K |

| Tf | average air temperature in the collector, K |

| Tsky | temperature of the sky, K |

| tA | absorber temperature, °C |

| ta | ambient temperature, °C |

| tc | glass temperature, °C |

| tf | average air temperature in the collector, °C |

| ti | temperature of the air that leaves the collector channel, °C |

| ti,2 | temperature at the inlet of the chimney, °C |

| u | air speed in the chimney channel, m/s |

| u1 | air speed assumed in first approximation, m/s |

| Ud | heat loss coefficient of the collector bottom, W/m2K |

| UL | loss factor, W/m2K |

| Ug | equivalent coefficient of heat loss through the front surface of the collector, W/m2K |

| volumetric air flow rate through the chimney, m3/s | |

| vw | wind speed, m/s |

| Greek symbols | |

| β′ | air volume expansion coefficient, 1/K |

| γ | constant, equal 0.75 |

| εA | absorber emissivity |

| εc | glass emissivity |

| ηt | efficiency of the turbine |

| θ | angle between vertical plane and collector, ° |

| λ | thermal conductivity coefficient, W/mK |

| λi | thermal conductivity coefficient of the collector’s thermal insulation, W/mK |

| ν | kinematic viscosity coefficient, m2/s |

| ρi | air density at the inlet to the chimney, kg/m3 |

| ρ0 | air density at the inlet to the collector, kg/m3 |

| σ | Stefan–Boltzmann constant, W/m2K4 |

| τα | mean transmission–absorption coefficient |

| pressure difference generated in the solar chimney, Pa | |

| ΔT | temperature difference between absorber and glass, K |

References

- Xaman, J.; Vargas-Lopez, R.; Gijon-Rivera, M.; Zavala-Guillen, I.; Jimenez, M.J.; Arce, J. Transient thermal analysis of a solar chimney for buildings with three different types of absorbing materials: Copper plate/PCM/concrete wall. Renew. Energy 2019, 136, 139–158. [Google Scholar] [CrossRef]

- Hirunlabh, J.; Kongduang, W.; Namprakai, P.; Khedari, J. Study of natural ventilation of houses by a metallic solar wall under tropical climate. Renew. Energy 1999, 18, 109–119. [Google Scholar] [CrossRef]

- Naraghi, M.H.; Blanchard, S. Twenty-four hour simulation of solar chimneys. Energy Build. 2015, 94, 219–226. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Al-Snani, H. Effect of selective coating on the thermal performance of flat plate solar air heaters. Energy 2010, 35, 1820–1828. [Google Scholar] [CrossRef]

- Smolec, W.; Jaroszyński, M.; Janus, B. Wpływ właściwości absorbera i szyb na sprawność płaskich kolektorów słonecznych do podgrzewania powietrza. Pr. Nauk. IICh PAN 2010, 14, 21–39. [Google Scholar]

- Huh, J.; Ahn, C.S.; Rahaman, M.; Bang, B.H.; Yarin, A.L.; Aldalbahi, A.; Yoon, S.S. Enhancing the buoyancy of air flows inside vertical solar chimneys using a G/CNT/AgNW-coated heat collector. Int. Commun. Heat Mass Transf. 2024, 156, 107675. [Google Scholar] [CrossRef]

- Al-Rjoub, A.; Rebouta, L.; Costa, P.; Vieira, L. Multi-layer solar selective absorber coatings based on W/WSiAlNx/WSiAlOyNx/SiAlOx for high temperature applications. Sol. Energy Mater. Sol. Cells 2018, 186, 300–308. [Google Scholar] [CrossRef]

- Dan, A.; Biswas, A.; Sarkar, P.; Kashyap, S.; Chattopadhyay, K.; Barshilia, H.C.; Basu, B. Enhancing spectrally selective response of W/WAlN/WAlON/Al2O3–based nanostructured multilayer absorber coating through graded optical constants. Sol. Energy Mater. Sol. Cells 2018, 176, 157–166. [Google Scholar] [CrossRef]

- Salarpour, N.; Azadani, L.N. Optimization and evaluation of thermo-hydraulic performance of solar air heaters equipped with different roughness geometries. Case Stud. Therm. Eng. 2024, 61, 105037. [Google Scholar] [CrossRef]

- Atia, A.; Bouabdallah, S.; Ghernaout, B.; Teggar, M.; Benchatti, T. Applied, Investigation of various absorber surface shapes for performance improvement of solar chimney power plant. Therm. Eng. 2023, 235, 121395. [Google Scholar] [CrossRef]

- Sheelam, S.; Chandramohan, V.P. Influence of pitch and height of pentagonal ribbed absorber plate of solar air heater for performance enhancement with environmental analysis. Therm. Sci. Eng. Prog. 2024, 56, 103035. [Google Scholar] [CrossRef]

- Abulkhair, H.; Alsaiari, A.O.; Ahmed, I.; Almatrafi, E.; Madhukeshwara, N.; Sreenivasa, B. Heat transfer and air flow friction in solar air heaters: A comprehensive computational and experimental investigation with wire-roughened absorber plate. Case Stud. Therm. Eng. 2023, 48, 103148. [Google Scholar] [CrossRef]

- Kamali, R.; Binesh, A.R. The importance of rib shape effects on the local heat transfer and flow friction characteristics of square ducts with ribbed internal surfaces. Int. Commun. Heat Mass Transf. 2008, 35, 1032–1040. [Google Scholar] [CrossRef]

- Karmveer, T.A.; Gupta, N.K.; Singh, H. An experimental study of thermohydraulic performance of solar air heater having multiple open trapezoidal rib roughnesses. Exp. Heat Transf. 2024, 37, 313–333. [Google Scholar] [CrossRef]

- Chaudhari, M.; Sharma, S.L.; Debbarma, A. Exergetic performance analysis of solar air heater with inverted L-shape ribs as roughness element. Arch. Thermodyn. 2023, 44, 241–267. [Google Scholar] [CrossRef]

- Ghritlahre, H.K. An experimental study of solar air heater using arc shaped wire rib roughness based on energy and exergy analysis. Arch. Thermodyn. 2021, 42, 115–139. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, Y.; Wang, F.; Wang, X. Enhancement of natural ventilation of a novel roof solar chimney with perforated absorber plate for building energy conservation. Appl. Therm. Eng. 2016, 107, 653–661. [Google Scholar] [CrossRef]

- Itaya, Y.; Adachi, K.; Mizuno, M.; Hasatani, M. Heat transfer and heat storage characteristics of optically semitransparent-material packed-bed solar air heater. J. Chem. Eng. Jpn. 1989, 22, 11–17. [Google Scholar] [CrossRef]

- Chen, W.; Qu, M. Analysis of the heat transfer and airflow in solar chimney drying system with porous absorber. Renew. Energy 2014, 63, 511–518. [Google Scholar] [CrossRef]

- Din, S.I.U.; Ibrahim, A.; Ajeel, R.K.; Fazlizan, A.; Ishak, A.A.; Al-Aasam, A.B. Thermal performance analysis of a double-pass solar air heater with lava rock as porous and sensible heat storage material. J. Energy Storage 2024, 95, 112564. [Google Scholar] [CrossRef]

- Shbailat, S.J.; Nima, M.A. Possible energy saving of evaporative passive cooling using a solar chimney of metal foam porous absorber. Energy Convers. Manag. 2021, 12, 100118. [Google Scholar] [CrossRef]

- Pretorius, J.P.; Kroger, D.G. Critical evaluation of solar chimney power plant performance. Sol. Energy 2006, 80, 535–544. [Google Scholar] [CrossRef]

- Pluta, Z. Podstawy Teoretyczne Fototermicznej Konwersji Energii Słonecznej; Politechniki Warszawskiej: Warszawa, Poland, 2006. [Google Scholar]

- Pudlik, W. Wymiana i Wymienniki Ciepła; Politechnika Gdańska: Gdańsk, Poland, 2012. [Google Scholar]

- Incopera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; John Wiley: Hoboken, NJ, USA, 1996. [Google Scholar]

- Bejan, A. Convection Heat Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Berdowska, S. Analysis of the all-year operation of the solar chimney in Polish climatic conditions. Energies 2022, 15, 4738. [Google Scholar] [CrossRef]

- Ong, K.S. A mathematical model of a solar chimney. Renew. Energy 2003, 28, 1047–1060. [Google Scholar] [CrossRef]

- Schlaich, J. The Solar Chimney-Electricity from the Sun; Edition Axel Menges: Stuttgart, Germany, 1995. [Google Scholar]

- Cao, F.; Zhao, L.; Li, H.; Guo, L. Performance analysis of conventional and sloped solar chimney power plants in China. Appl. Therm. Eng. 2013, 50, 582–592. [Google Scholar] [CrossRef]

- Dutkowski, K.; Piątkowski, P. Badania eksperymentalne prototypowego, pasywnego powietrznego kolektora słonecznego z pokryciem poliwęglanem komorowym. Instal 2015, 3, 17–23. [Google Scholar]

- Arce, J.; Jiménez, M.J.; Guzmán, J.D.; Heras, M.R.; Alvarez, G.; Xamán, J. Experimental study for natural ventilation on a solar chimney. Renew. Energy 2009, 34, 2928–2934. [Google Scholar] [CrossRef]

- Bassiouny, R.; Koura, N.S.A. An analytical and numerical study of solar chimney use for room natural ventilation. Energy Build. 2008, 40, 865–873. [Google Scholar] [CrossRef]

- Flourentzou, F.; Van der Maas, J.; Roulet, C.A. Natural ventilation for passive cooling: Measurement of discharge coefficients. Energy Build. 1998, 27, 283–292. [Google Scholar] [CrossRef]

- Wiśniewski, G.; Gołębiowski, S.; Gryciuk, M.; Kurowski, K.; Więcka, A. Kolektory Słoneczne, Energia Słoneczna w Mieszkalnictwie, Hotelarstwie i Drobnym Przemyśle; Dom wydawniczy MEDIUM: Warszawa, Poland, 2008. [Google Scholar]

- Ministerstwo Inwestycji i Rozwoju Rzeczypospolitej Polskiej. Data for Energy Calculations of Buildings. Available online: https://www.gov.pl/web/archiwum-inwestycje-rozwoj/dane-do-obliczen-energetycznych-budynkow (accessed on 8 January 2022).

- B&Q, United Kingdom. Sandtex 10 Year Black Satin Multi-Surface Paint 2.5 l. Available online: https://www.diy.com/departments/sandtex-10-year-black-satin-multi-surface-paint-2-5l/5010131585135_BQ.prd (accessed on 8 July 2025).

- IndiaMART. Black Anodizing Services. Available online: https://www.indiamart.com/proddetail/black-anodizing-services-2851205644930.html (accessed on 8 July 2025).

- Kwon, Y.S.; Li, Y.; Huang, B. Scalable, Low-Cost Fabrication of Selective Solar Absorber by Ultrasonic Spray Coating. ES Mater. Manuf. 2023, 20, 812. [Google Scholar] [CrossRef]

- Made-in-China B2B Sales Platform. Absorber Tinox Blue Selective coating for Flat Plate Collector. Available online: https://smmtmaterial.en.made-in-china.com/product/vaoRWiDVYGcr/China-Absorber-Tinox-Blue-Selective-Coating-for-Flat-Plate-Solar-Collector.html (accessed on 8 July 2025).

- Ren, X.H.; Wang, P.L.; Zhang, C.X.; Song, Y.J.; Shang, J.; Wang, L.; Zhao, F.Y. Heat removal and ventilation limitations of the solar chimney attached with a built enclosure: Correlations of thermal Rayleigh numbers, port arrangements and discrete heating elements. Renew. Energy 2024, 221, 119782. [Google Scholar] [CrossRef]

- Zhang, H.; Tao, Y.; Nguyen, K.; Han, F.; Li, J.; Shi, L. A wall solar chimney to ventilate multi-zone buildings. Sustain. Energy Technol. Assess 2021, 47, 101381. [Google Scholar] [CrossRef]

- Wang, H.; Lei, C. A numerical investigation of combined solar chimney and water wall for building ventilation and thermal comfort. Build. Environ. 2020, 171, 106616. [Google Scholar] [CrossRef]

- Asadi, S.; Fakhari, M.; Fayaz, R.; Mahdaviparsa, A. The effect of solar chimney layout on ventilation rate in buildings. Energy Build. 2016, 123, 71–78. [Google Scholar] [CrossRef]

- Saifi, N.; Baadi, A.; Ghedamsi, R.; Guerrout, A.; Settou, N. An experimental study and numerical simulation of natural ventilation in a semi-arid climate building using a wind catcher with evaporative cooling system and solar chimney. J. Build. Eng. 2024, 85, 108475. [Google Scholar] [CrossRef]

| Collector Cover | Absorption Coefficient, α | Emission Coefficient, ε |

|---|---|---|

| Black paint | 0.95 | 0.95 |

| Aluminum-coated CuO | 0.85 | 0.11 |

| Black chrome | 0.98 | 0.14 |

| TiNOX | 0.95 | 0.05 |

| Parameter | Value |

|---|---|

| Gravitational acceleration | 9.81 m/s2 |

| Stefan–Boltzmann constant | 5.67∙10−8 |

| Ground reflectivity | 0.2 |

| Coefficient of reflection of radiation from the interface | 0.142 |

| Extinction coefficient | 20 m−1 |

| Collector glass thickness | 0.004 m |

| Glass emissivity | 0.95 |

| Absorber area | 30 m2 |

| Chimney height | 50 m |

| Diameter of the chimney | 1 m |

| Turbine efficiency | 0.8 |

| Installation | Amount of Electricity |

|---|---|

| A | 9773.7 Wh |

| B | 16,031.2 Wh |

| C | 16,155.0 Wh |

| D | 17,806.6 Wh |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berdowska, S. The Influence of Absorber Properties on Operating Parameters and Electricity Generation in the Solar Chimney with a Vertical Collector. Energies 2025, 18, 3740. https://doi.org/10.3390/en18143740

Berdowska S. The Influence of Absorber Properties on Operating Parameters and Electricity Generation in the Solar Chimney with a Vertical Collector. Energies. 2025; 18(14):3740. https://doi.org/10.3390/en18143740

Chicago/Turabian StyleBerdowska, Sylwia. 2025. "The Influence of Absorber Properties on Operating Parameters and Electricity Generation in the Solar Chimney with a Vertical Collector" Energies 18, no. 14: 3740. https://doi.org/10.3390/en18143740

APA StyleBerdowska, S. (2025). The Influence of Absorber Properties on Operating Parameters and Electricity Generation in the Solar Chimney with a Vertical Collector. Energies, 18(14), 3740. https://doi.org/10.3390/en18143740