1. Introduction

While sustainability has been a prominent topic of discussion for decades, it has received particular emphasis in the last decade, driven by global climate commitments and stricter policies promoting carbon neutrality, resource efficiency, and holistic life cycle assessments (LCA). Yet, sustainability often remains a broad and sometimes ambiguous concept. In the context of the building industry, it encompasses reducing carbon emissions, enhancing energy efficiency, using sustainable materials, and ensuring resilience to climate change, all while enhancing occupant well-being, maintaining economic viability, and addressing societal needs. The building sector is considered key in the efforts towards decarbonization and the accomplishment of the Sustainable Development Goals, due to the vast emissions it currently produces and its apparent inefficiency in terms of energy performance. In the European Union (EU), 42% of the total energy consumption and 35% of the GHG emissions are attributed to buildings [

1], while around 75% of the building stock is considered energy inefficient [

2]. These facts necessitate sustainable building renovation and effective energy efficiency measures in order to reach the EU climate neutrality target for 2050, as well as the expected 55% emission reduction by 2030, as indicated by the European Green Deal [

3]. Initiatives such as the Renovation Wave [

4] aim to significantly boost renovation rates and optimize the relevant processes while accelerating deep energy renovations in buildings, in this way promoting the adoption of nearly-zero and positive energy buildings. In addition, the revised EU Emissions Trading System (ETS2) [

5], introduced in 2023, targets CO

2 emissions from fuel combustion in the building sector. Although it focuses specifically on operational performance, ETS2 reinforces the importance of reducing emissions in the use phase, one of the key dimensions evaluated through LCA in building renovation projects. EU emission trends indicate an optimistic reduction in the GHG emissions related to the building sector since 1990 levels, while projections suggest a 53% reduction by 2040 if member states fully implement existing policies, or up to 62% if additional measures are taken [

6]. To assess the success of these measures, the utilization of standardized frameworks, targeted indicators, and relevant evaluation tools is necessary.

Evaluating the sustainability of a building renovation requires a comprehensive approach that integrates multiple assessment methodologies. A key framework for such evaluations is LCA, which enables a thorough analysis of environmental impacts across a building’s lifespan, from material extraction and construction to operation and end-of-life. LCA provides insights into resource use, energy consumption, carbon footprint, and waste generation, ensuring that sustainability considerations extend beyond immediate operational efficiency to the entire life cycle of the building. Following a similar rationale, life cycle costing (LCC) assesses the economic viability of different building solutions by quantifying initial investments, operational costs, maintenance expenses, and end-of-life costs over the building’s service life. Several LCA and LCC tools are available to facilitate these assessments, ranging from commercial software solutions to research-driven, non-commercial platforms. Among the various tools available, VERIFY introduces several unique contributions to the field of sustainability assessment in building renovation. It combines dynamic LCA and LCC analysis with real-time or simulated operational data, supports scenario-based comparisons at the component level, and integrates regulatory frameworks such as Level(s) and EN 15978 [

7]. Its capacity to model both embodied and operational impacts with user-defined time steps, along with harmonized KPI reporting, enables more accurate and context-sensitive evaluations of renovation strategies. These features distinguish VERIFY from conventional static tools and enhance its applicability in diverse building types and policy environments. Widely used LCA tools include SimaPro [

8], GaBi, OneClick LCA [

9], and the ATHENA™ Impact Estimator [

10], each offering varying capabilities in impact quantification, material flow analysis, and scenario modeling. Additionally, integrated LCA-LCC software, such as LCAiT, BeCost, BEES, EQUER, and TEAM™, provide enhanced LCC functionality along with environmental impact assessment [

11]. Several research-driven tools also focus on national datasets, specific building typologies, and integration with building information modeling (BIM), expanding the applicability of traditional LCA methodologies and bridging the gap between scientific analysis and practical implementation.

However, despite the advantages of life cycle-based tools for this purpose, their application in building renovation remains challenging. Barriers include limited data availability, inconsistent methodological frameworks, and the difficulty of accounting for changing operational conditions over time. While LCA and LCC methodologies have advanced, key limitations persist, particularly the lack of dynamic life cycle approaches that can reflect evolving factors such as climate conditions, decarbonizing energy mixes, and building use patterns. Addressing these gaps remains essential for improving the accuracy and relevance of renovation assessments [

12].

Recent work in dynamic LCA, particularly within the building sector, demonstrates significant methodological advances and supports the novelty and relevance of VERIFY. Salati et al. [

13] presented a comprehensive review of dynamic LCA frameworks, highlighting emerging modeling approaches and key sources of temporal and spatial uncertainty in building assessments. Another study, focusing on building stock, emphasizes the inconsistent application of dynamic parameters and the need for more robust frameworks that balance temporal/spatial resolution with versatility across building types [

14]. Additionally, an open-source Python package released in June 2025 (lcpy) exemplifies the growing demand for tools that support parametric dynamic LCA and LCC, integrating uncertainty and optimization workflows [

15]. These advances affirm the importance of dynamic modeling in LCA and strengthen the case for VERIFY as a holistic, flexible tool that integrates dynamic LCA/LCC with policy-aligned KPI reporting, regulatory compliance, and scenario-based analysis.

Many of the LCA tools discussed above (e.g., SimaPro [

8], GaBi, OneClick LCA [

9], ATHENA™ [

10], and others) rely on static data, limiting their ability to incorporate real-time variations such as changes in energy supply mix, user occupancy, and building usage patterns. These tools typically use fixed annual average values, rather than real-time or context-specific inputs, when estimating operational impacts across the life cycle, leading to potentially unrealistic sustainability assessments [

16]. This is coupled with the lack of life cycle inventories and information on technological innovations related to building energy performance, such as bio-based insulation materials, building-integrated photovoltaic solutions, and their overall effect on a building’s energy performance, especially when coupled with other conventional or innovative interventions. In addition, existing standards lack consistency in defining complex renovations versus individual materials, making their application challenging. LCC indicators, which include both quantitative and qualitative aspects, require better integration of temporal variability, particularly to account for long-term uncertainties such as energy price volatility and inflation. These factors significantly influence life cycle cost outcomes and the assumptions behind discount rate selection, which can substantially affect the interpretation of economic sustainability. To facilitate the transition to a circular economy, LCA and LCC tools must evolve to become more operational, user-friendly, and capable of real-time performance monitoring [

17].

While LCA offers a comprehensive view of the environmental impacts of building renovation, it is often complemented by other sustainability frameworks. Energy performance certificates (EPCs), widely used in Europe, assess operational energy efficiency, while green certifications such as LEED and BREEAM apply broader, multi-criteria assessments. Additionally, economic aspects of sustainability are addressed through LCC, which, together with LCA, underpins more holistic evaluations. The European Standard EN 15978 and the Level(s) framework provide the methodological foundation for integrating these assessments in practice. In this work, we adopt LCA and LCC methodologies supported by the VERIFY platform to assess renovation impacts across environmental and economic dimensions. However, assessing a building’s sustainability extends beyond LCA and LCC alone. While LCA captures the full environmental footprint of renovation, other widely used assessment frameworks focus on different sustainability dimensions. For example, energy performance certificates (EPCs), which serve as a regulatory mechanism in many countries, provide a standardized means of classifying buildings based on their operational energy efficiency [

18]. These certificates guide policymakers and stakeholders in implementing targeted renovations to enhance energy performance, often supported by complementary advances in building monitoring and management technologies through frameworks such as the Smart Readiness Indicator (SRI) [

19]. At the same time, green building certification schemes such as the LEED (Leadership in Energy and Environmental Design) [

20] and the BREEAM (Building Research Establishment Environmental Assessment Method) [

21] offer multi-criteria sustainability assessments that account for energy efficiency, water usage, indoor environmental quality, and material selection. These frameworks build upon LCA principles while also integrating broader socioeconomic and ecological considerations, ensuring a more holistic evaluation of sustainability [

22]. In addition to environmental and economic considerations, occupant well-being has become an essential aspect of sustainability. The WELL building standard focuses on enhancing human health and well-being within the built environment, addressing factors such as air quality, lighting, and mental health to create spaces that promote occupant wellness. This certification does not replace LCA or EPCs but rather complements them, reinforcing the idea that sustainability must also consider human-centric design principles [

23]. At the European level, sustainability in buildings is further guided by the European Standard EN 15978, which establishes a calculation method for implementing LCA in buildings and defines life cycle phases such as production, construction, operation, and end of life [

24]. Additionally, the Level(s) framework, introduced by the European Commission, provides a structured, unified approach to life cycle evaluation and reporting, aligning with EU sustainability goals and ensuring consistency across assessments [

25].

Building upon these frameworks, holistic sustainability assessment is crucial in guiding decision-making for renovation projects, ensuring that environmental, economic, and social impacts are all accounted for throughout a building’s life cycle [

26]. Fragmented approaches, i.e., those that consider operational energy use and efficiency alone, fail to capture key sustainability factors such as embodied energy, material sourcing, and end-of-life disposal options. These life cycle stages significantly influence a building’s comprehensive environmental impact, particularly in the context of renovation, where changes to a building’s behavior, systems, and material composition are complex. Research suggests that embodied carbon emissions (those associated with the production, transportation, and installation of building materials) are projected to rival or soon surpass operational emissions [

27] in the near future, making it imperative for sustainability assessments to adopt a life cycle perspective rather than focusing solely on energy efficiency metrics [

28].

To bridge this gap, decision makers require advanced tools that integrate multiple sustainability dimensions rather than relying solely on traditional energy or environmental assessments. These tools should facilitate data-driven decision-making by leveraging LCA and LCC methodologies, helping stakeholders balance cost, performance, and long-term benefits while ensuring compliance with sustainability regulations. Such an integrated approach would also allow policymakers, designers, and industry professionals to make more informed choices, which would not only minimize environmental impacts but also enhance economic viability and occupant well-being.

In this context, the present study examines the application of VERIFY, a tool designed to assess the environmental and economic performance of buildings using a component-level scenario-based prospective life cycle approach. The platform supports dynamic assessments by integrating time-series operational data, including temperature, occupancy patterns, and on-site energy production and consumption. VERIFY generates comprehensive sustainability reports with flexible, user-defined time steps and incorporates key performance indicators (KPIs) aligned with recognized international and EU-wide standards. Specifically, the tool follows ISO 14040 and ISO 14044 for LCA, ISO 15686-5 for LCC, and EN 15978 for building sustainability assessment [

7,

29,

30,

31], while also incorporating the EU Level(s) framework for energy performance and global warming potential (GWP) indicator reporting. Key information regarding the tool’s background, architecture, and implementation is briefly presented in the following sections. Further details on VERIFY can be found in previous studies [

11,

32]. The primary goal of this study is to present the experiences and results obtained from applying VERIFY in three real-world building renovation projects and to provide insights into the challenges and key considerations when employing life cycle-based assessment tools for sustainability-oriented decision-making.

This study is structured as follows:

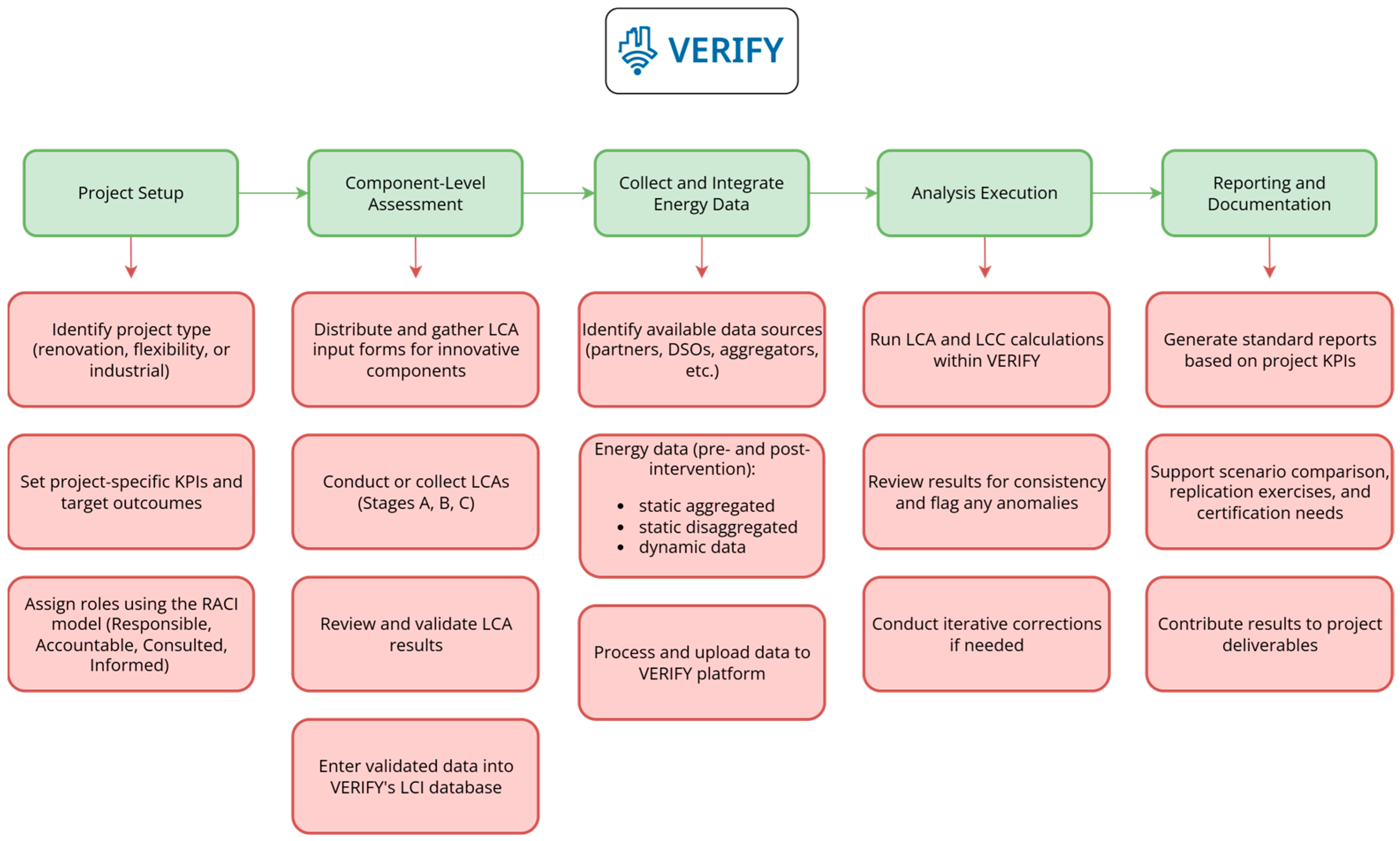

Section 2 presents the methodology, detailing the VERIFY tool’s background, framework, and analytical capabilities.

Section 3 describes the three real-world case studies where VERIFY was applied, highlighting their characteristics and renovation strategies.

Section 4 presents the results of the life cycle assessments, showcasing the environmental and economic performance before and after renovation.

Section 5 discusses the methodological, technical, and practical challenges encountered during the application of VERIFY, addressing issues such as data availability, regulatory alignment, and integration with other sustainability assessment frameworks.

Section 6 concludes with key findings and recommendations for future applications of life cycle-based tools in the building sector.

3. Use Cases

VERIFY was applied and tested in three distinct renovation projects, serving as use cases (UCs) in Italy (UC#1), Spain (UC#2), and the Netherlands (UC#3). These UCs are demonstrated as part of the Horizon Europe (HEU) project InCUBE (Grant Agreement no. 101069610). InCUBE brings together 23 partners from seven European countries, envisioning to unlock the EU renovation wave through cutting-edge standardized and integrated processes based on four key pillars of innovation: digitalization, industrialization, new technologies and materials and new markets entrants, all while accounting for social inclusion, gender mainstreaming and upskilling of current and potential future workforce. The selection of the renovation projects aimed to reflect a variety of building typologies (i.e., cultural/administrative, multi-owner residential, and student housing) representative of the European building stock, ensuring the most adequate coverage of climatic (alpine in Trento, Italy; semi-arid Mediterranean in Zaragoza, Spain; temperate oceanic in Groningen, the Netherlands), as well as regulatory and socioeconomic conditions, based on the requirements of the relevant HEU topic. This variety enables a more comprehensive validation of the VERIFY tool’s applicability and robustness across differing energy needs, renovation constraints, and user profiles, supporting the generalizability of the findings.

The key characteristics of these UCs, including gross floor area, construction year, occupant profiles, and energy performance, are summarized in

Table 4. Detailed simulation parameters, encompassing data on building elements, operational conditions, and heating, cooling, and domestic hot water (DHW) systems before (pre-renovation) and after (post-renovation) interventions, are provided in

Supplementary S2. Further details are outlined in the following paragraphs, providing the rationale for the selection of the specific three UCs and a concise overview of the renovation actions planned for each.

The Centro Santa Chiara (UC#1) is a cultural heritage building owned by the Municipality of Trento and located in the Santa Chiara District, southeast of the historic city center. It is one of Trento’s most significant venues for cultural and recreational activities. The district, which has faced social and structural decline since the 1990s, is now part of a broader urban regeneration effort focusing on deep renovation of publicly owned buildings for mixed tertiary and residential use. UC#1 was selected to demonstrate how sustainability goals can be integrated into the renovation of culturally significant structures, an increasingly relevant challenge in Europe, where over 25% of older buildings are classified as heritage [

43]. A detailed study has previously assessed the building’s energy performance and the potential impact of proposed interventions [

36]. The renovation transformed the building into a multi-functional space hosting municipal archive, administrative offices, startup hubs, exhibition spaces, and enhanced access to the Cuminetti experimental theater. Innovative upgrades include mineral wool insulation, 20.1 kW BIPV shingles, and a geothermal heat pump system (249 kW heating/295 kW cooling), replacing existing gas boilers. These are combined with conventional measures such as wall insulation, double-glazed windows, standard PV panels, LED lighting, and connection to a low-temperature DHC system using geothermal and waste heat. A full breakdown of the building components, technologies, and cost/performance data is provided in

Supplementary S2.

UC#2 is a five-story privately owned residential building with 40 dwellings in the Balsas de Ebro Viejo District, Zaragoza. Built in 1971, it is part of a working-class neighborhood now prioritized for refurbishment due to energy inefficiencies and aging infrastructure. The building is one of 18 blocks receiving municipal support, and its typology is representative of 126 similar structures in the area, offering strong potential for replication of scalable renovation solutions. Renovation actions addressed structural and energy inefficiencies with a mix of industrialized and conventional measures. These include 2000 m

2 of modular façades, new vertical circulation zones with elevators, and a rooftop PV system (~100 MWh/year). Heating will shift from individual gas boilers to heat pumps and electric boilers to enable full electrification. Conventional improvements include high-performance glazing and expanded polystyrene insulation. A key challenge for UC#2 is executing the renovation activities while residents remain in their homes, necessitating careful planning and coordination to minimize disruptions. Detailed specifications, including system types, technical characteristics, and associated costs, are included in

Supplementary S2.

The Heemskerckflat building (UC#3) is a privately owned student housing facility located in the Zeeheldenbuurt District in Groningen South, Netherlands. It exemplifies the wider European challenge of upgrading aging post-war apartment blocks built in the 1960s and 1970s, which are now technologically outdated and nearing the end of their economic lifespan. Demolition is often not a viable option, making deep renovation a strategic and sustainable alternative. With 15% of Dutch households living in similar buildings, UC#3 offers strong replicability potential across the Netherlands and beyond. The renovation transformed the building into a modern, energy-efficient residence tailored to student needs. Redesign plans eliminate surplus shared spaces, creating larger private rooms with en-suite bathrooms, organized into groups of seven sharing a kitchen. Communal amenities such as a lounge, library, and laundry room will be relocated to the ground floor. The building will also be vertically and horizontally expanded to enhance functionality. Key interventions include prefabricated façades with 88.4 kW of integrated BIPV panels, full thermal insulation, and high-performance glazing. These upgrades will significantly reduce reliance on the existing 475 kW gas boiler. Advanced construction methods, including BIM-based design, robotic demolition, and scaffold-less cranes, will improve efficiency and minimize environmental impact. A full inventory of building components, technologies, and performance-cost data is available in

Supplementary S2.

The inclusion of a cultural heritage building (UC#1) was a deliberate decision aimed at capturing the complexities associated with renovating historically significant structures, which represent a substantial portion of the European building stock. Although such buildings pose unique architectural and regulatory constraints that could introduce bias, their integration offers valuable insights into the adaptability of life cycle assessment tools in challenging renovation contexts. Further barriers in the assessment of this kind of building lie in the scarcity of necessary input data (e.g., materials used or interventions performed during previous renovations). To mitigate this potential bias and ensure broader applicability, the remaining use cases (UC#2 and UC#3) reflect standard residential typologies with diverse occupancy profiles, ownership models, and renovation approaches. This balanced selection enables a more comprehensive validation of the VERIFY tool and supports the transferability of the findings across different building types and contexts.

4. Results

The application of VERIFY across the three InCUBE UCs has provided a comprehensive overview of the energy, environmental, and economic benefits associated with deep renovation interventions. The assessment was conducted over a 50-year study period, as defined by the EU Level(s) framework for life cycle evaluation in buildings. The analysis covers the operational stage of the building and its components, as well as the construction and end-of-life (EoL) stages of the relevant systems. This section presents the key findings, structured around the comparative analysis between baseline and post-renovation scenarios.

A cross-pilot comparison (

Table 5) reveals significant variability in performance improvements across the three UCs, reflecting differences in initial building conditions, renovation strategies, and contextual constraints. Note that the table refers only to energy behavior-related components and the renovation activities, not the existing buildings themselves. Among the pilots, the Spanish case demonstrated the highest relative reductions across all three sustainability indicators, underlining the comprehensive nature of the interventions and the relatively high energy inefficiency of the pre-renovation building. The Italian pilot, despite facing significant challenges due to the building’s cultural heritage status, achieved notable reductions in both energy consumption and GHG emissions. In the Netherlands, while energy demand reductions were more modest, the renovation yielded substantial environmental benefits, demonstrating that even in constrained architectural settings, significant improvements in environmental performance are achievable. It is important to note that the total floor area of UC#3 has been significantly increased; thus, only the KPIs presented per unit of floor area are comparable between the pre- and post-renovation status.

The renovation actions undertaken at the Santa Chiara building in Trento (UC#1), Italy, primarily targeted a reduction in thermal needs and an enhancement of occupant comfort, while respecting the constraints of the heritage structure. The adopted renovation scenario incorporated two PV systems—standard PV modules and Tegosolar solutions combined with the installation of a ground source heat pump (GSHP) system, aimed at boosting both the energy efficiency and the sustainability profile of the building. The implementation of these measures resulted in a 23% reduction in lifetime primary energy demand, a 32% decrease in the life cycle GWP, and a 16% decrease in the average annual life cycle costs. The estimated payback period for the overall renovation investment is approximately 12 years. These improvements substantiate the potential for significant sustainability gains even in culturally protected buildings.

The renovation of the Spanish pilot (UC#2), a multi-family residential building in Zaragoza, incorporated a combination of modular façade solutions and conventional energy efficiency upgrades, such as enhanced insulation, high-efficiency windows, and replacement of outdated heating and DHW systems. These interventions were further supported by the installation of PV systems to facilitate on-site electricity generation for self-consumption. The integration of these advanced renovation measures resulted in a 51% reduction in lifetime primary energy demand, a remarkable 66% decrease in life cycle GWP, and a 51% reduction in total life cycle costs. The payback period for the renovation investment was calculated at approximately 5 years, highlighting the economic attractiveness of the intervention.

In the Dutch pilot (UC#3), a student housing building in Groningen, the renovation strategy focused on the integration of cutting-edge technologies such as the “Expanding Space” prefabricated façade system and BIPV systems. These upgrades aimed at simultaneously reducing the building’s energy demands and generating electricity on-site, although certain limitations regarding grid saturation prevented full utilization of PV generation at the time of assessment. Following renovation, the building achieved a 36% reduction in lifetime primary energy demand, a 51.2% reduction in life cycle GWP, and a 38% decrease in life cycle costs on a per square meter basis. It is important to note that the life cycle cost figures refer exclusively to renovation actions and do not include the original construction costs of the building. Additionally, due to the significant expansion in total floor area and increased occupancy (from 229 to 265 residents), no meaningful overall payback period could be derived within the VERIFY framework. The financial assessment of the renovation thus focuses strictly on energy-related parameters, excluding potential increases in rental income or other economic considerations not captured by VERIFY.

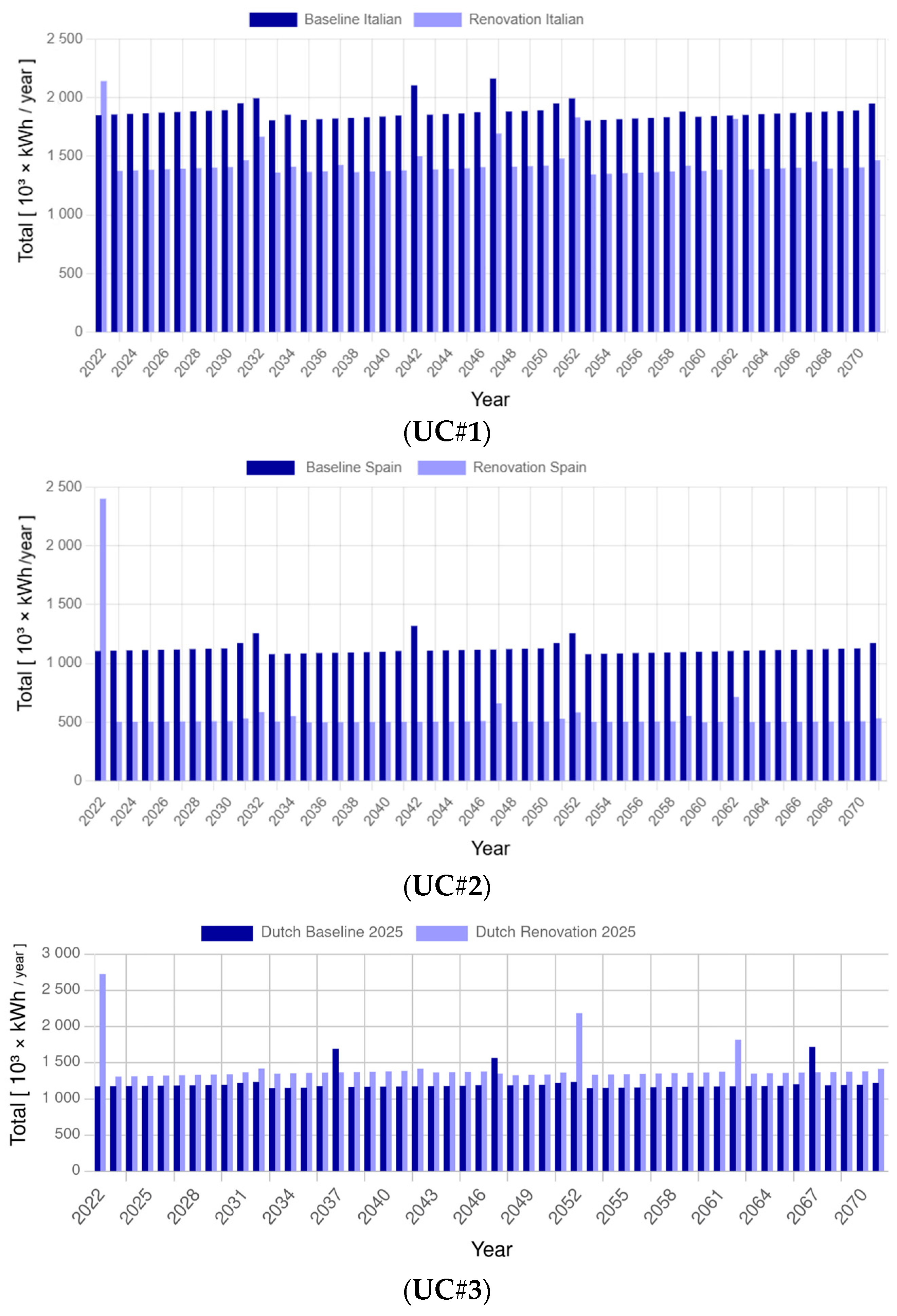

The temporal results are presented by performance category: annual primary energy demand, annual greenhouse gas (GHG) emissions, and annual life cycle costs (LCC), with each category encompassing comparative figures across all three UCs. This structure allows for a coherent analysis of trends over the 50-year assessment period, facilitating direct comparison between baseline and renovation scenarios. The figures also capture key life cycle events such as component replacements and system degradation, which are reflected as periodic fluctuations in the performance indicators.

Figure 4 illustrates the annual primary energy demand across the three UCs. In the UC#1, the renovated scenario shows an average annual demand of approximately 1.44 GWh, with notable peaks of 1.83 GWh and 1.82 GWh occurring in years 30 and 40, respectively. These peaks correspond to scheduled component replacements: the PV system, which reaches end of life after 30 years, and the glazing systems installed during renovation, which are replaced in year 40. Despite these peaks, the demand remains consistently lower than that of the baseline scenario throughout the assessment period. In UC#2, the average primary energy demand after renovation is significantly reduced to 552 MWh/year, with a peak of 710 MWh in year 40, again reflecting scheduled replacements. This peak results from the replacement of glazing systems, while a previous replacement of the PV system with a 25-year lifetime occurs in year 25 and contributes to a smaller peak. Overall, the renovation leads to a substantial reduction in demand when compared to the baseline. The UC#3 presents an average demand of 1.40 GWh/year in the renovated scenario, with a peak of 2.18 GWh in year 30. This peak results from the combined replacement of the PV system and part of the glazing systems; additional glazing replacements occur in year 40. Although UC#3 has a higher absolute demand due to increased floor area and occupancy after renovation, it still outperforms the baseline on a per m

2 basis throughout most of the assessment period. These observed peaks align with planned component renewal cycles and are not due to modeling assumptions, reaffirming the value of long-term life cycle analysis in accurately capturing renovation dynamics.

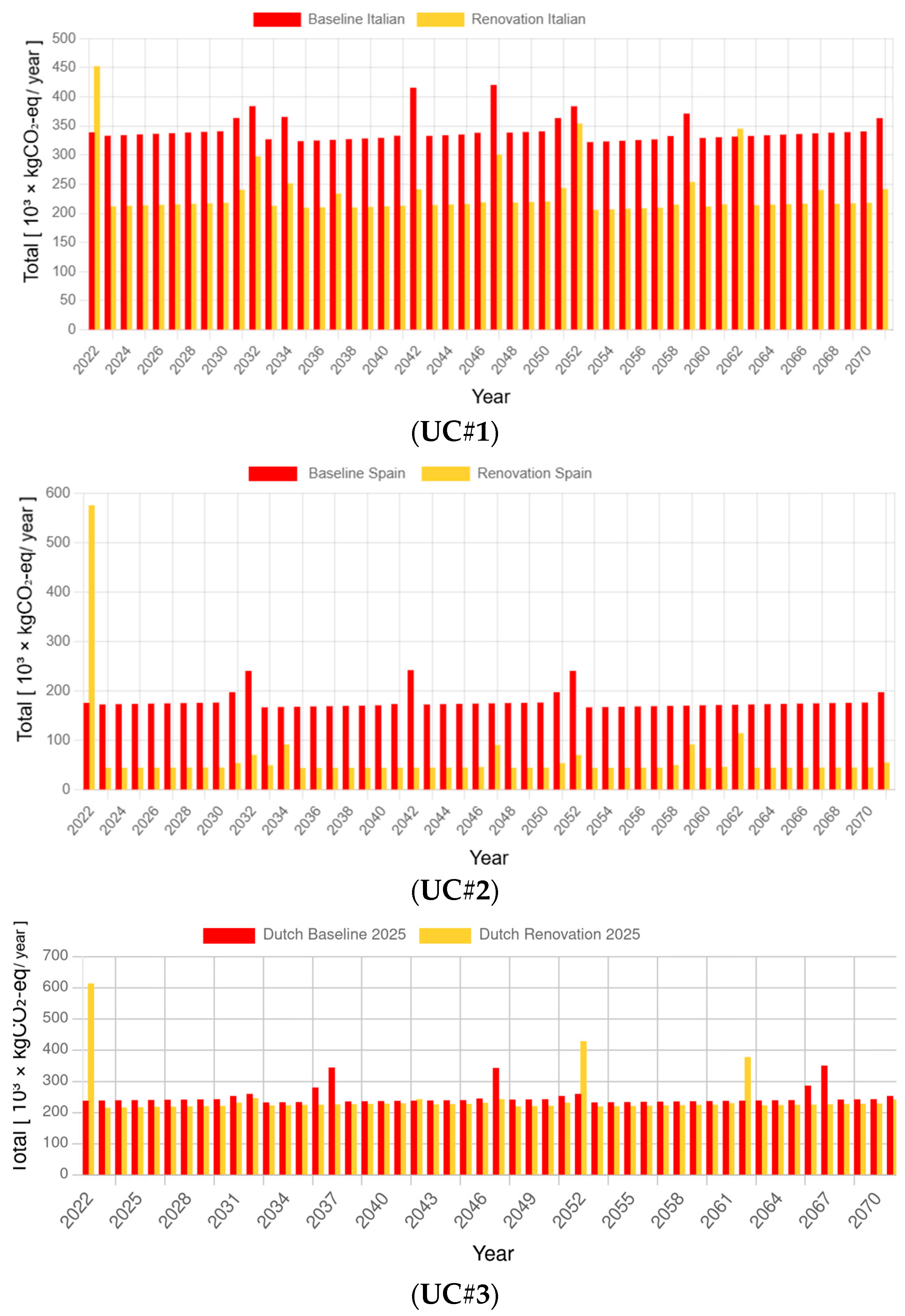

Annual GHG emissions trends are shown in

Figure 5 for UC#1, UC#2, and UC#3 over the 50-year analysis period. In UC#1, emissions under the renovation scenario average 231.7 t CO

2-eq/year, with a peak of 353.6 t in year 30, primarily due to the embodied emissions associated with the replacement of the PV system. A second, smaller increase appears in year 40, reflecting the replacement of glazing systems. Despite these peaks, emissions remain well below the baseline throughout the evaluation period. In UC#2, average emissions fall to 60 t CO

2eq/year, with a temporary rise to 114 t in year 40, attributed to the replacement of glazing components. An earlier increase also occurs in year 25, when the PV system reaches the end of its service life and is replaced. In UC#3, average emissions reach 239 t CO

2eq/year, with a peak of 427 t in year 30 due to the simultaneous replacement of the PV system and part of the glazing systems; additional glazing elements are renewed in year 40. Although UC#3 has higher absolute emissions due to expanded building size and occupancy, the renovated scenario still performs better than the baseline on a per m

2 basis, reinforcing the value of integrated energy-efficient technologies and on-site renewables. As with primary energy demand, the observed peaks are consistent with scheduled replacement events and not modeling artifacts, underlining the importance of a life cycle perspective in emissions evaluation.

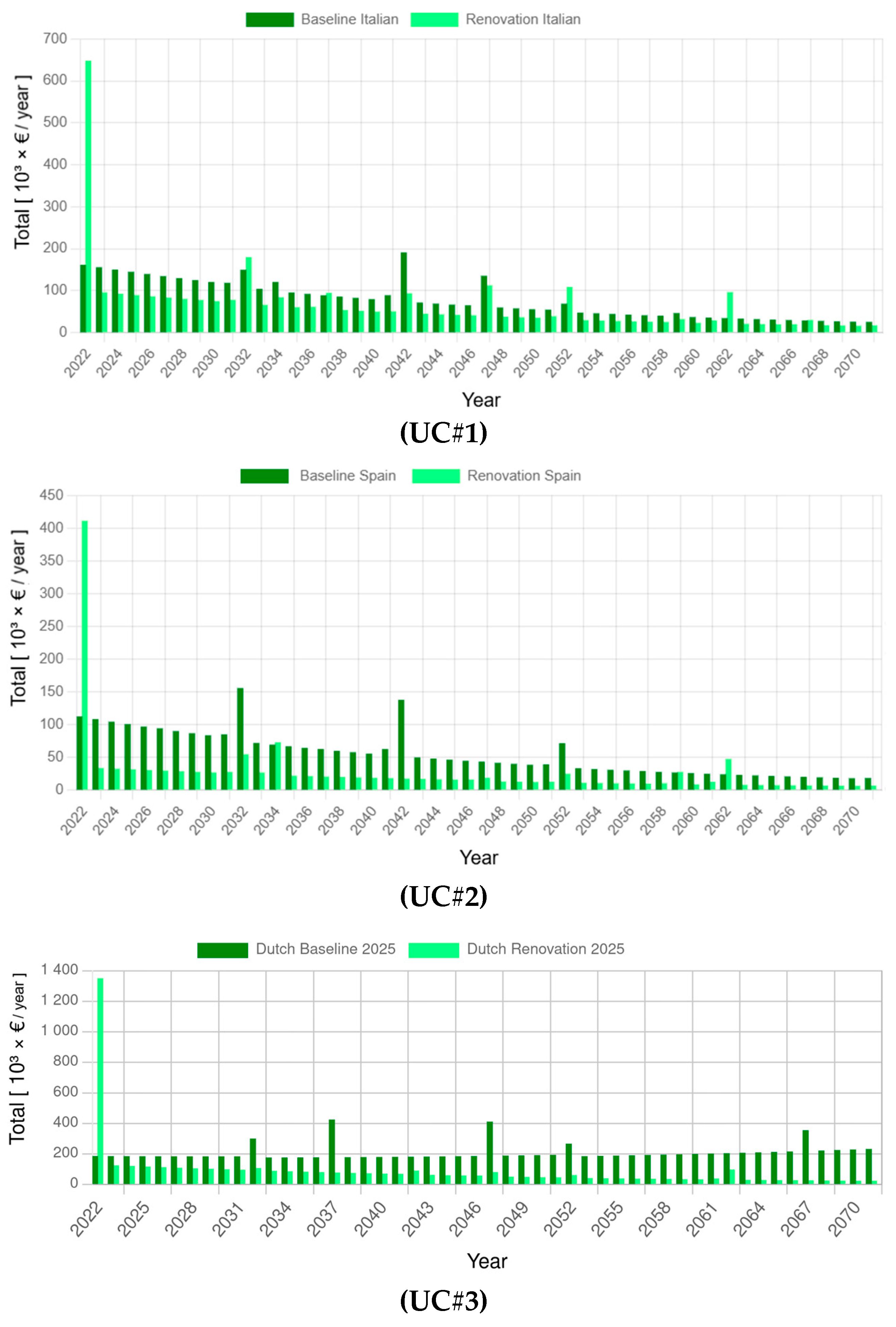

Figure 6 presents the life cycle cost evolution for UC#1, UC#2, and UC#3, respectively. In all three cases, the renovation scenarios result in significantly lower total costs compared to the respective baselines. However, distinct cost peaks are observed in years 30 and 40, which correspond to the scheduled replacement of key building systems in accordance with their expected service lives. These include heating and cooling systems (e.g., ground source and water-to-water heat pumps), photovoltaic installations (standard and building-integrated), and envelope elements such as modular façades and high-performance windows. Specifically, in UC#1 and UC#3, the PV systems are replaced in year 30, with glazing replacements occurring in year 40. In UC#2, the PV system is replaced in year 25, while glazing systems are renewed in year 40. While these midlife interventions temporarily increase annual costs, they are an anticipated part of the life cycle strategy and do not offset the overall financial benefits of the renovation. The long-term savings achieved through improved energy efficiency and reduced operational expenditures remain dominant throughout the assessment period. It is also important to note that the LCC figures presented refer exclusively to renovation-related actions covering construction, operation, maintenance, replacement, and end-of-life stages, and exclude costs related to the initial construction of the buildings.

Overall, these findings confirm that, while retrofit and replacement interventions lead to transient increases in energy consumption, emissions, and costs, the holistic renovation strategy yields substantial long-term environmental and economic benefits. While the results presented demonstrate clear benefits of renovation interventions across all use cases, it is important to acknowledge the presence of inherent uncertainties in life cycle assessments. Factors such as variability in component lifespan, future energy prices, grid emission factors, and maintenance requirements can influence the outcomes. Although a formal sensitivity analysis was not performed in this study, these uncertainties are expected to affect absolute values rather than the comparative trends between pre- and post-renovation scenarios.

5. Discussion

The application of life cycle-based tools, such as VERIFY, for assessing building renovation scenarios entails several methodological, technical, and practical challenges that must be addressed to ensure robust and meaningful outcomes. While LCA/LCC provides a comprehensive approach to assessing the environmental and economic impacts of renovation strategies over a building’s entire lifespan, its effective utilization requires overcoming issues related to data availability, methodological inconsistencies, regulatory alignment, and practical usability. In this section, an attempt is made to explore these challenges in more depth and discuss their implications for sustainability assessments in the built environment.

One of the most fundamental challenges in using LCA tools is ensuring the availability and quality of input data. Conducting an LCA requires extensive and detailed inventories on materials, energy consumption, emissions, and waste generation at each stage of a building’s life cycle—from raw material extraction and manufacturing to operation and eventual demolition. However, in many cases, such data are incomplete, inconsistent, or difficult to obtain. For instance, while well-established materials such as concrete or steel have comprehensive life cycle inventories available from databases such as Ecoinvent [

44] or the European Platform on Life Cycle Assessment (EPLCA), innovative or emerging building technologies may lack reliable environmental data. This is particularly problematic for assessing novel insulation materials, new PV technologies, bio-based construction products, or new energy storage solutions, which may not yet be fully integrated into LCA databases. In such cases, users must rely on manufacturer data or estimated values, introducing uncertainties into the assessment that might be higher than those introduced by utilizing LCI data from LCA databases. Additionally, country-specific variations in electricity grids, construction practices, and material supply chains further complicate data collection. For example, the embodied carbon of cement varies significantly depending on the regional energy mix used in its production, meaning that an assessment conducted using generic global or European values may not accurately reflect a building’s real environmental footprint. The fact that the manufacturers of a solution are not necessarily the ones responsible for its installation or end-of-life treatment adds an extra layer of complexity to the extraction of life cycle data.

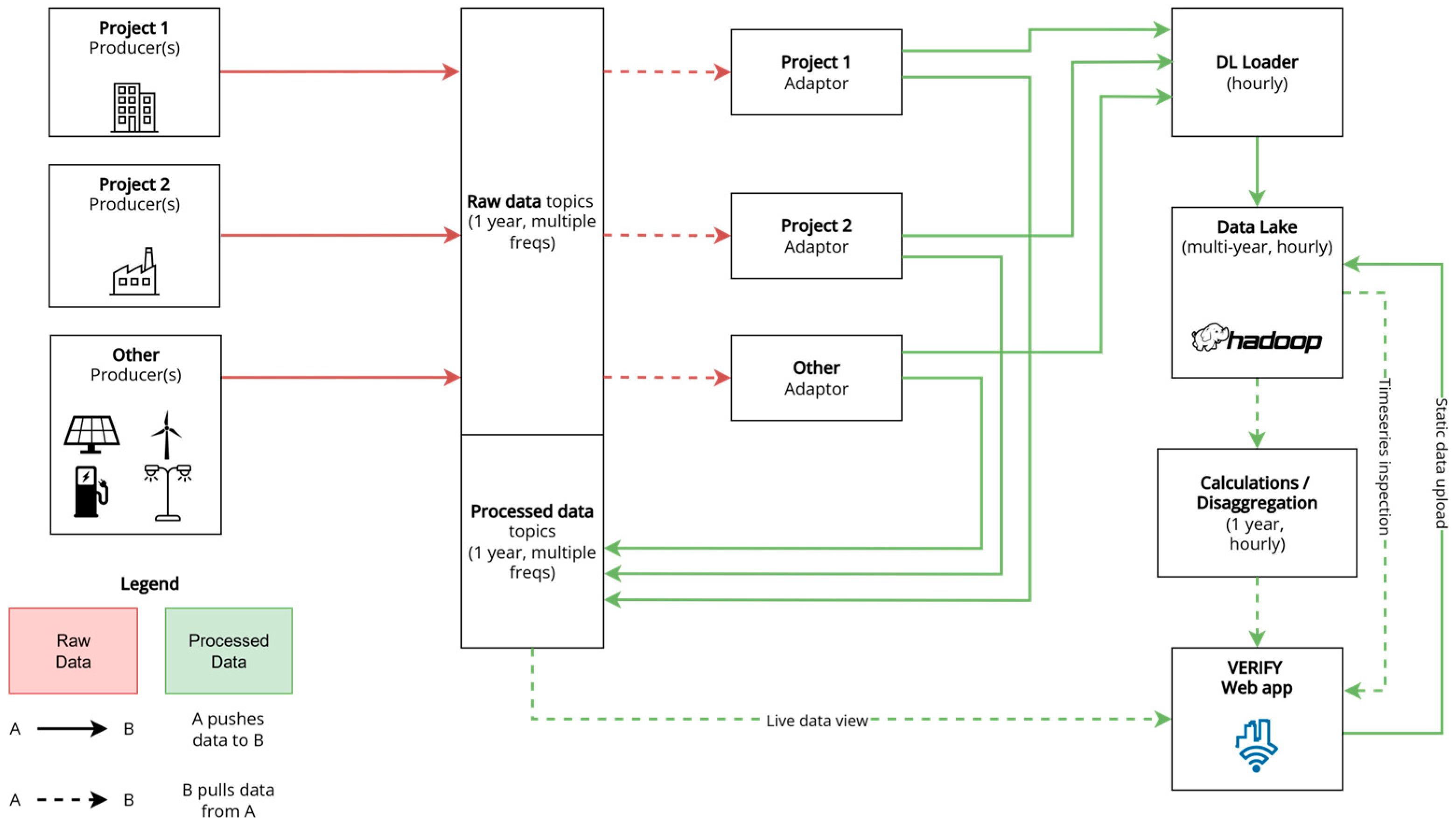

VERIFY attempts to tackle the data availability issue by employing synthetic data models and predictive algorithms that are tailored to location-specific characteristics. The platform leverages APIs to access external databases for estimating RES production, taking seasonal variability into account. When external data is unavailable or insufficient, VERIFY generates simulated datasets internally to ensure accuracy and continuity. Its internal LCA database comprises information on energy performance technologies (e.g., RES carriers, insulation, glazing, thermal comfort, and ventilation) derived from leading LCA software and environmental product declarations. To tackle the challenge of grid emission factor volatility and its effect on GWP calculations, VERIFY uses a logistic regression model to estimate the emissions of future periods using historical data available in its database, aiming to provide a more realistic estimate of a renovation’s future performance. Through the above techniques, VERIFY can effectively combine real and simulated data to estimate the environmental and economic impacts of energy upgrades, reducing the need for costly custom analyses even in data-scarce situations.

Another key challenge lies in the divergence between life cycle-based sustainability assessments and more conventional evaluation approaches, such as energy performance certificates (EPCs). EPCs are commonly used across Europe to assess and communicate a building’s operational energy performance, based on standardized usage profiles, internal temperature setpoints, and average monthly climatic data. However, this approach is limited to operational energy use and does not account for embodied carbon or life cycle costs associated with renovation activities. As a result, renovation measures that improve operational efficiency, such as upgrading to high-performance HVAC systems, may lead to favorable EPC ratings, even when the embodied impacts of the materials and systems introduced are substantial. In contrast, frameworks such as the EU Level(s) emphasize a whole-life perspective, incorporating both embodied and operational environmental impacts over a building’s lifespan. The results observed in the use cases underscore this divergence: while EPCs and energy models reflected substantial operational improvements, VERIFY’s life cycle-based assessment presented more tempered gains due to the inclusion of embodied energy and carbon from construction materials and technologies. These differences highlight the need for integrating LCA and LCC into building sustainability assessments, particularly for renovation projects where the embodied impacts of new interventions can significantly influence the overall environmental and economic performance.

While energy audits and simulation tools often focus on operational performance, VERIFY incorporates emissions from material production, system replacements, and midlife interventions. Consequently, projected emission savings tend to be more conservative but reflect a more comprehensive picture. Additional factors may also contribute to deviations between simulated and actual performance. These include modeling assumptions, occupant behavior, the actual performance of installed systems compared to specifications, and weather variability. For instance, unusually high temperatures in Spain during 2024 [

45] likely increased cooling demand beyond predicted levels, while heating needs may have decreased. Such discrepancies emphasize the need for integrated and adaptive assessment frameworks. Life cycle-based tools, such as VERIFY, complement energy models by capturing hidden environmental burdens and supporting more robust sustainability evaluations, especially in renovation contexts where embodied impacts are non-negligible.

Compiling accurate life cycle inventories (LCIs) remains a critical and often resource-intensive aspect of applying LCA tools in building renovation projects. This process involves detailed specification of materials, energy inputs, transport logistics, installation procedures, and end-of-life scenarios for each component. While VERIFY streamlines these tasks by offering predefined templates and a curated database of material properties, accurate user input and contextual expertise remain essential to ensure data reliability. Material misclassification and incomplete maintenance accounting can significantly affect LCA outcomes, with the assumed service life of key technologies being a particularly influential parameter. For example, underestimating or overestimating the lifespan of heat pumps can misrepresent replacement frequencies and associated environmental impacts. Furthermore, many renovation-related innovations involve complex, multi-material components—such as prefabricated façade panels with integrated insulation and glazing—which require careful decomposition into their individual material flows for precise modeling.

Although accounting for future technological advancements in LCA is inherently uncertain, scenario analysis or sensitivity testing can provide useful insights into long-term sustainability. For example, projecting improvements in material efficiency or the decarbonization of energy systems enables the construction of alternative development pathways. While VERIFY currently relies on static assumptions for most component parameters, integrating forward-looking scenarios could enhance its capacity to support long-term planning. In practice, access to detailed environmental data is often limited. Many project stakeholders act as system integrators rather than manufacturers, and, therefore, may not possess full information on the embedded impacts of the components used. This underscores the need for transparency and consistency in defining system boundaries, especially when comparing across renovation scenarios, to ensure that results are both reliable and comparable.

The dynamic nature of LCA results introduces additional complexity in renovation decision-making. Unlike static assessments that provide a snapshot of a building’s performance at a given point in time, LCA outcomes can evolve substantially due to factors such as grid decarbonization, material production efficiencies, and regulatory shifts. This means that an intervention that appears sustainable today may not retain the same advantage in the future. For example, a building renovation scenario that relies on natural gas for heating may currently have a lower operational carbon footprint than an electric heat pump system in regions with high-carbon electricity grids. However, as grid electricity becomes increasingly sourced from renewables, the relative environmental performance of these options will shift, potentially altering the ranking of renovation strategies over a 50-year assessment period. VERIFY attempts to address this challenge by incorporating real-time data streams and flexible modeling approaches, but long-term projections remain subject to external uncertainties. Decision-makers must therefore carefully consider scenario planning and sensitivity analyses when interpreting LCA results for renovation projects.

Regulatory alignment is a critical consideration when using LCA-based tools in the context of sustainable building renovations. The European Union’s Level(s) framework provides structured sustainability indicators that emphasize whole-life carbon assessment, resource-efficient material use, and life cycle cost analysis. VERIFY has been explicitly developed to align with Level(s), incorporating its methodology and metrics into the tool’s core calculation processes. This ensures both regulatory compliance and enhances the credibility of assessment outcomes. Levels(s) require the integration of life cycle carbon emissions—including both embodied and operational impacts—which VERIFY fully supports, bridging the gap between traditional energy performance assessments and LCA-driven sustainability evaluations. Additionally, as compliance with Level(s) becomes a common requirement in EU-funded renovation initiatives, such as those under the Horizon Europe framework, VERIFY, as an LCA/LCC tool, remains adaptable to evolving policy frameworks, offering users a future-proof solution for sustainability reporting.

Finally, the practical usability and accessibility of LCA tools present challenges for broader adoption in real-world renovation projects. Despite the advanced analytical capabilities of platforms such as VERIFY, they require a certain level of technical expertise, making them less accessible to non-specialist users such as building owners, municipal planners, or small-scale developers. The complexity of LCA terminology, coupled with the need for precise data inputs, can create barriers to effective implementation. For instance, a facility manager may struggle to interpret the implications of different GWP impact categories or to determine the most appropriate LCC discount rate to apply. To mitigate this issue, VERIFY incorporates interactive visualizations and intuitive user interfaces, but additional efforts—such as targeted training programs, simplified workflows, and decision-support guidance—are needed to bridge the knowledge gap. A key trade-off in the use of LCA tools lies between model precision and practical usability. While highly detailed models provide more accurate results, they require extensive data collection and input processing, which may discourage widespread use among stakeholders with limited resources. Currently, VERIFY offers a strong foundation aligned with general needs for building performance evaluation, cost-benefit analysis, and sustainability reporting. Nevertheless, its present configuration may not yet fully accommodate the diverse technical capacities and decision-making needs of all user groups. To address this, the platform is being developed with an adaptive strategy that prioritizes modularity and customization, ensuring it can evolve in response to user feedback and sector-specific requirements.

6. Conclusions

In this paper, the challenges and barriers to adopting LCA/LCC-based methodological approaches for the evaluation of building renovation efficacy are discussed and analyzed. Key issues discussed include data availability and quality, methodological discrepancies between LCA and other assessment frameworks, complexity in life cycle inventory creation, and the dynamic nature of LCA results over long assessment periods. Additionally, alignment with regulatory frameworks such as Level(s) and the usability of LCA tools for non-expert users are highlighted as critical factors to their broader adoption and impact.

To demonstrate the merits of a comprehensive approach, the application of VERIFY, a web-based tool integrating life cycle inventory as well as operational energy presumption and economic data, is presented as an alternative approach to existing methods. VERIFY is used to evaluate renovation interventions across three use cases in Italy, Spain, and the Netherlands and highlights the potential of deep renovation interventions to achieve substantial long-term benefits, even under diverse climatic, regulatory, and architectural conditions. The findings indicate that while early renovation stages may incur short-term increases in overall energy use, emissions, or cost, a comprehensive life cycle analysis reveals clear long-term benefits across all cases. The findings also show that these benefits would have been overestimated if operational energy consumption alone was considered to evaluate the viability of the renovation activities.

Despite these promising outcomes, the deployment of LCA tools in real-world renovation projects remains constrained by several methodological, technical, and practical challenges. Data availability and reliability pose a persistent issue, particularly in obtaining life cycle inventory data for novel technologies or region-specific components. While LCA-based tools such as VERIFY offer powerful capabilities for assessing the sustainability of building renovation scenarios, their effective application requires addressing these challenges through improved data integration, standardization of methodologies, and enhanced user support. Regulatory alignment will also be essential to ensure consistency and comparability of results across projects and regions. To overcome such barriers in the adoption of life cycle-based renovation assessments, the following policy actions are recommended. First, the establishment of EU-wide harmonized LCA and LCC data standards—supported by open-access databases and aligned with frameworks such as Level(s)—would address issues of data fragmentation and improve result comparability. Second, mandating the inclusion of embodied carbon metrics in national renovation strategies and energy performance certificate schemes would incentivize a whole-life approach to building sustainability. Finally, dedicated funding and technical support should be made available to ensure that public authorities and small stakeholders can access and apply advanced LCA tools in practice. This study demonstrates the value of life cycle-based assessment tools, such as VERIFY, in evaluating the sustainability performance of building renovation strategies. By integrating environmental and economic metrics over a building’s entire lifespan, VERIFY supports decision-making and enables a more holistic understanding of renovation outcomes. Future research will focus on extending VERIFY’s application to real-time operational and renovation datasets from pilot buildings, facilitating further tool validation and adaptation to the diverse requirements of renovation projects across Europe.

Looking ahead, a promising direction for future development involves the integration of artificial intelligence (AI) techniques to enable predictive LCA capabilities. By leveraging historical data and real-time inputs from building systems, AI-driven models could support forecasting of environmental and economic impacts under various renovation scenarios. While such functionality is not currently within the scope of the VERIFY project, the platform’s modular and data-centric architecture provides a solid foundation for incorporating predictive analytics in future iterations. This advancement could further enhance decision-making by enabling scenario optimization and early-stage impact estimation, especially in data-scarce or fast-changing renovation contexts.