1. Introduction

Under the dual pressure of intensifying global climate change and the depletion of traditional energy sources, energy transition has become an urgent task for global sustainable development [

1,

2,

3,

4]. As the process of energy conservation and emission reduction accelerates around the world, China proposed in September 2020 to achieve a “CO

2 emissions peak by 2030 and work towards carbon neutrality by 2060”. However, rural areas in severely cold regions of China suffer from harsh climatic conditions, high energy consumption for heating, and severe environmental pollution. This not only hinders the development of the region’s economy and the comfort level of people’s homes but also creates significant constraints on the sustainable development of energy and the environment [

5,

6]. Therefore, developing new heating systems suitable for rural buildings in severely cold regions and improving the utilization rate of renewable energy are of great significance for promoting the coordinated development of energy and the environment.

Solar energy is widely used for its large reserves and inexhaustible, clean, and environmentally friendly properties [

7,

8,

9,

10,

11,

12]. Most of the residential buildings in rural areas are single-story or multi-story monolithic buildings, and the roof space is convenient for the placement of solar collectors. However, solar energy resources are greatly affected by daily variations and weather conditions, resulting in a mismatch between heat demand and heat supply [

13,

14]. To address the intermittency and instability of single-source solar energy systems, many researchers have combined solar energy with other renewable energy sources and have conducted studies in different regions comparing different building types.

The joint application of solar energy and air source heat pumps (ASHPs) is the most common form of coupled heating system. Li et al. [

15] applied a coupled solar energy and air source heat pump (SASHP) system in rural areas in northwest China and found that the SASHP system reduced CO

2 emissions by as much as 10,960.7 kg annually compared with the use of ASHPs alone throughout the entire heating season. Long et al. [

16] evaluated the performance of an SASHP system under Tibetan climate conditions and optimized its key design parameters. The results showed that the solar collector area and the water tank volume are the priority factors for the design of SASHP systems in Tibet. Yue et al. [

17] applied an SASHP system to the Beijing–Tianjin–Hebei region in China. They found that although solar thermal heating has the lowest environmental impacts and carbon emissions among the various heating methods, it is not the best solution for clean heating in rural areas. Gao et al. [

18] combined an SASHP system with phase-change energy storage to design and develop a heating system for extremely cold regions. Chen et al. [

19] investigated a phase-change energy storage SASHP system that improved heat pump performance under extreme weather conditions, with a COP of up to 1.79. The above studies show that the SASHP system is applicable in rural areas; however, significant climatic differences exist among regions in China, which pose a great challenge to the utilization of complementary solar and air source systems.

Coupled systems of solar energy and ground source heat pumps (SGSHPs) are also frequently used for single-building heating. Compared with ASHPs, GSHPs use shallow soil at a relatively constant temperature as the heat source, and the ambient temperature has less influence on the system. Hong-Seok Mun et al. [

20] employed an SGSHP system for the heating of a rural pigsty, which effectively guaranteed a suitable temperature. Yang et al. [

21] applied an SGSHP composite heating system to agricultural greenhouses in cold areas. The COP of the composite system was 3.32. Compared with electric heating and pure soil source heat pump heating, the composite system heating method reduced electricity consumption by 70.74% and 12.17%, respectively, which indicates better environmental benefits. Farzin M. Rad et al. [

22] evaluated the overall feasibility of an SGSHP system in cold climates by comparing and analyzing several cities. They found that Vancouver, which was the city with the mildest climate, was the best city for its application. However, SGSHP systems require high-soil conditions and are complicated to construct and maintain. The effectiveness and costs of their application in rural residences need to be further demonstrated.

Similarly to heat pump systems, heating systems that utilize electricity as an auxiliary energy source for solar energy include resistive, electrode vacuum/micro-pressure, graphene electric heating, resistive vacuum hot-water, and electromagnetic systems. Among them, electromagnetic heating is highly efficient and fast, allows water and electricity to be kept separate, which is safe and environmentally friendly, saves space, and can be started and stopped at any time in the low-temperature environment of cold regions. The coupling of electromagnetic energy as auxiliary heating energy with solar energy is a new heating system construction idea applied to single rural residences in cold regions. Currently, there are few studies on applying electromagnetic heating devices to building heating systems, and most of them focus on improving the performance of the electromagnetic heater itself [

23,

24,

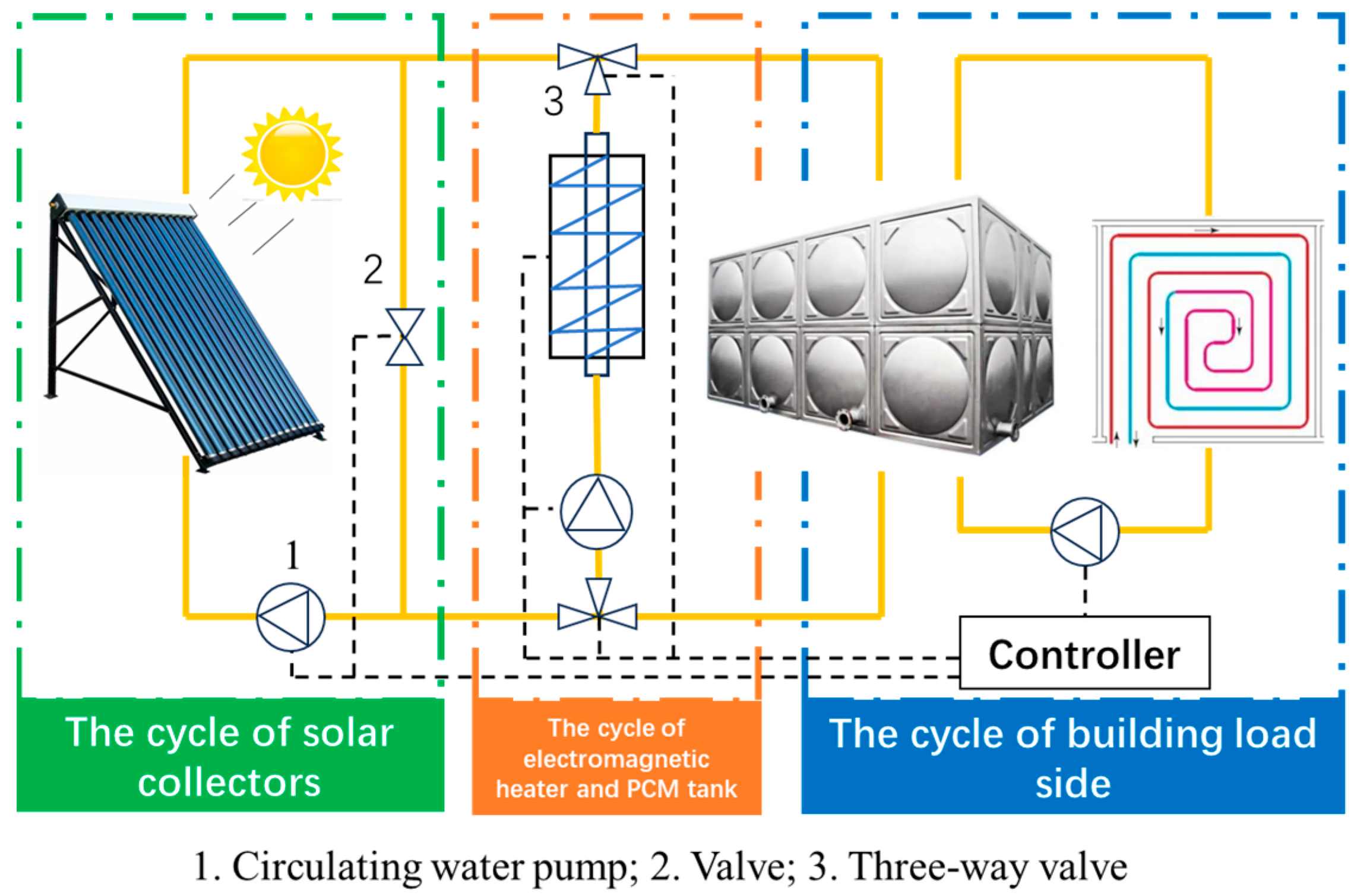

25]. In this study, we applied solar energy coupled with electromagnetic energy to the heating system of a rural residence.

Previous studies have demonstrated the feasibility of coupling solar energy with other renewable energy sources for single-building heating and hot-water technologies. However, the application of various types of renewable energy needs to take into account many factors, such as climatic and geological conditions, building load characteristics, system performance, economic costs, etc., and the configuration of renewable energy system integration under different climatic conditions varies. There are still fewer choices of heating system forms suitable for single residential buildings in rural areas in severe-cold Chinese regions. The improvement of performance and optimization of integrated renewable energy heating systems should be a focus of academic research [

26,

27,

28].

The optimization of multi-energy integrated energy supply systems is the key to improving the overall performance and sustainability of the system. Single-objective optimization methods cannot achieve the performance trade-off among multiple objectives and are not suitable for optimizing the integrated performance of building energy systems. Multi-objective optimization methods can more comprehensively evaluate system performance. Common multi-objective optimization methods include the Pareto front method, weighted sum method, ε-constraint method, and multi-criteria decision-making method, etc. [

29,

30,

31]. FAHP, AHP, TOPSIS, ELECTRE, PROMETHEE, and ANP are several commonly used multi-criteria decision-making methods. Among them, AHP combines qualitative and quantitative methods to determine the weights of multi-objective optimization, which is simple and easy to implement, but is highly subjective and requires rich design experience from the decision-makers. The TOPSIS method is good at ranking solutions based on distance, but usually assumes that the weights are pre-determined or obtained through other methods (such as entropy weight method), and has weak modeling ability for potential dependencies between criteria. The ELECTRE/PROMETHEE methods are based on outranking and are good at handling incomparability and imprecision, but the model construction is usually more complex, and the interpretability is not as intuitive as weight-based methods like FAHP. ANP can handle complex dependencies and feedback relationships between criteria, but the model construction and calculation are extremely complex [

32,

33,

34,

35,

36,

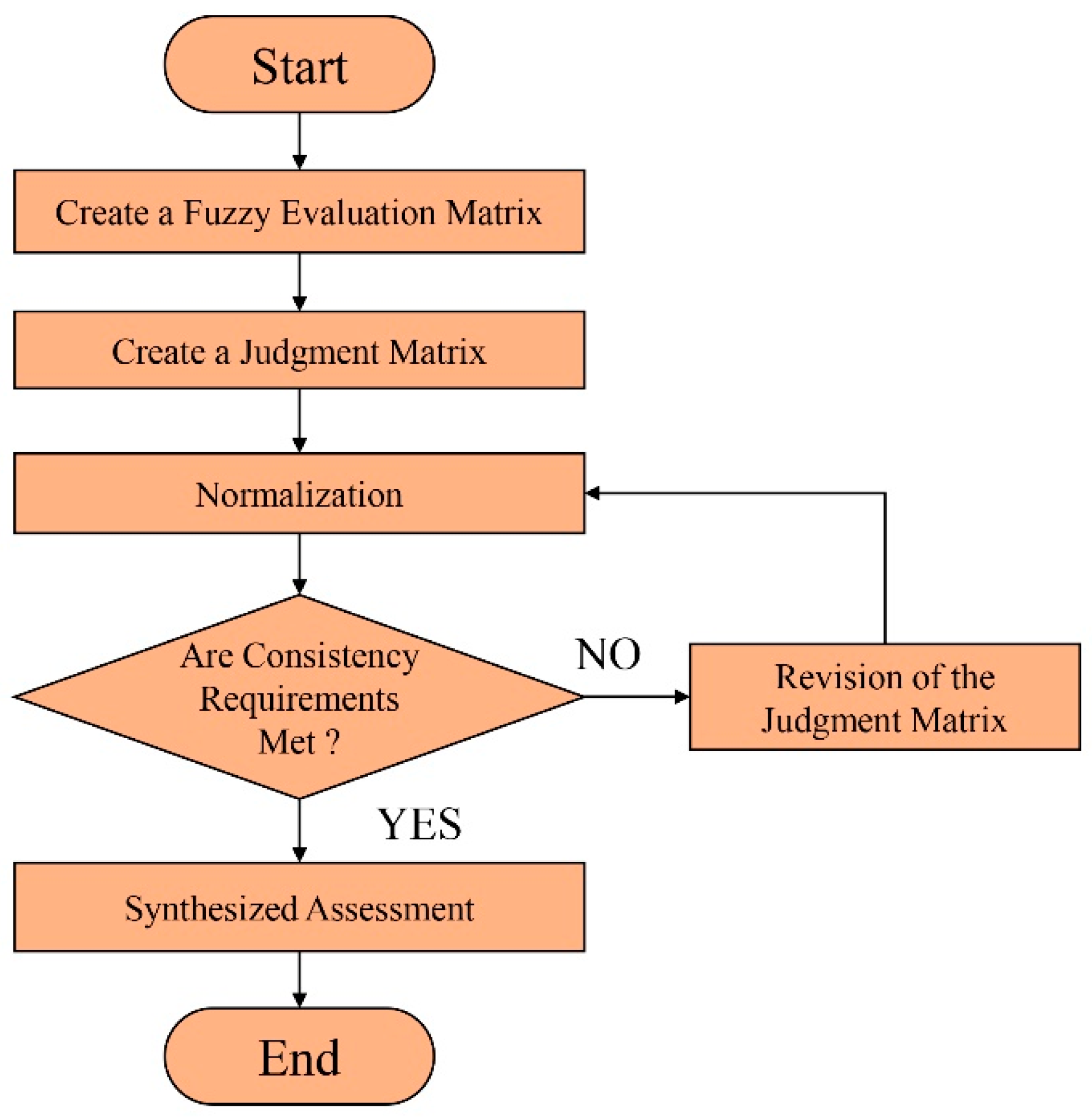

37]. In contrast, the FAHP method introduces fuzzy mathematics theory on the basis of AHP, which can effectively handle subjective judgments and uncertainties, and can systematically decompose complex problems, clearly define the relative importance relationships among various levels of elements, making weight determination more precise, the operation more concise, the adaptability stronger, and reducing the influence of subjective judgments on the results [

38,

39,

40]. Consequently, the FAHP method is widely used in multi-objective decision-making problems with more evaluation indicators and more complex decision-making processes [

41,

42,

43,

44].

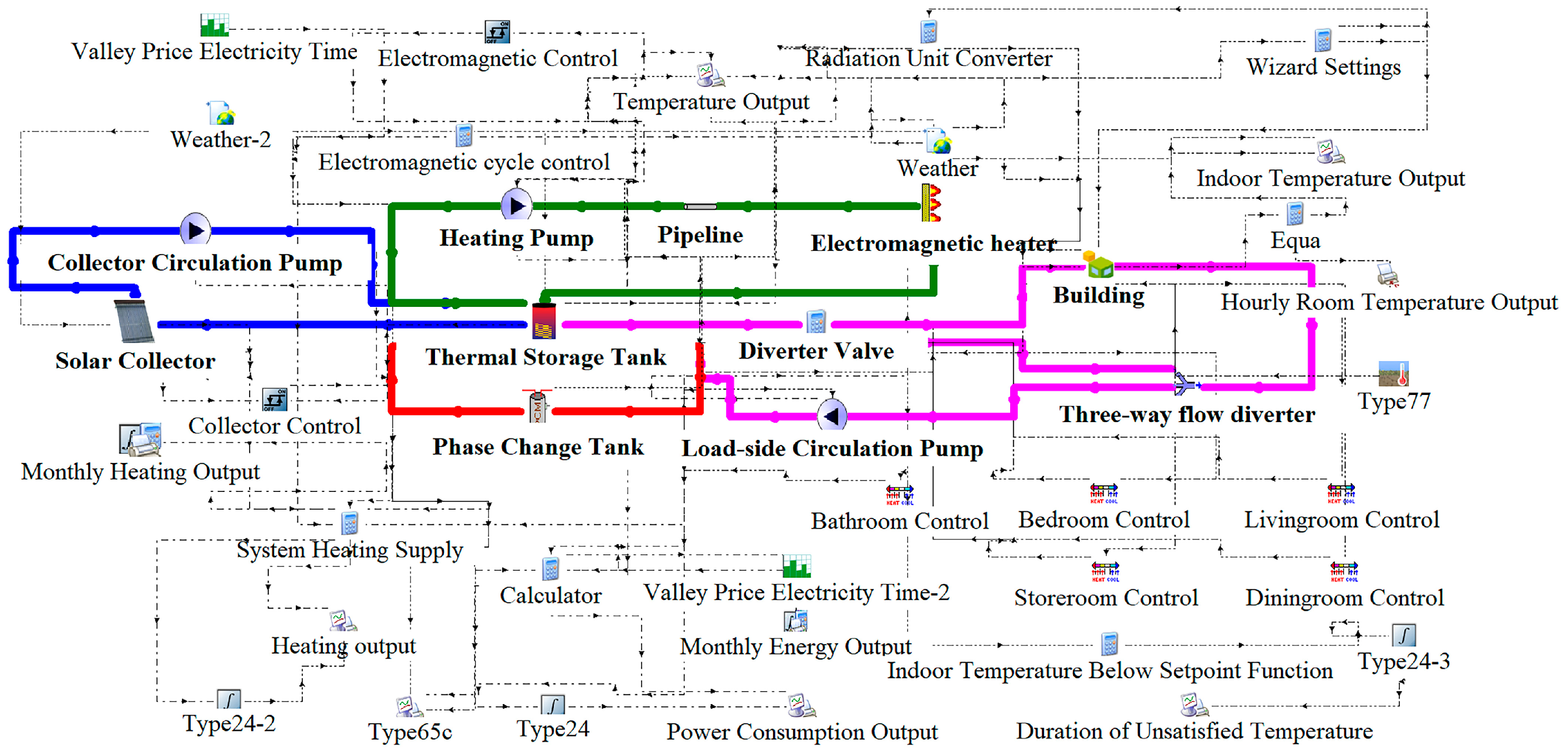

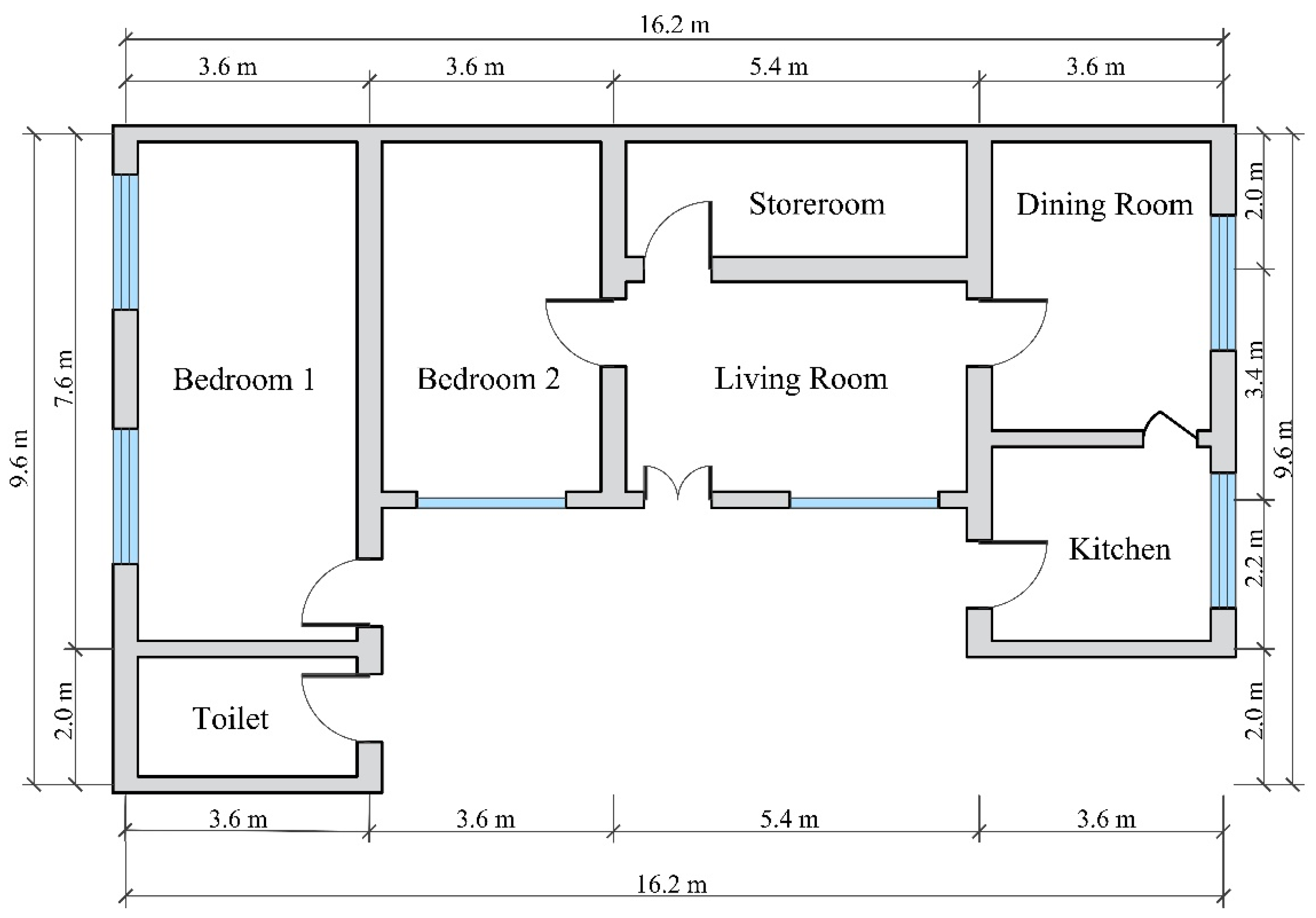

In conclusion, in order to promote the application of multi-energy coupled heating systems represented by SEHS in individual rural houses, this paper adopts FAHP to provide a multi-objective optimization method that can be implemented rapidly and weakens subjective influence, providing a decision-making basis for the optimal design of this system in rural residential buildings in severe cold regions. In this study, we employ the phase-change material (PCM) water tank technology [

45,

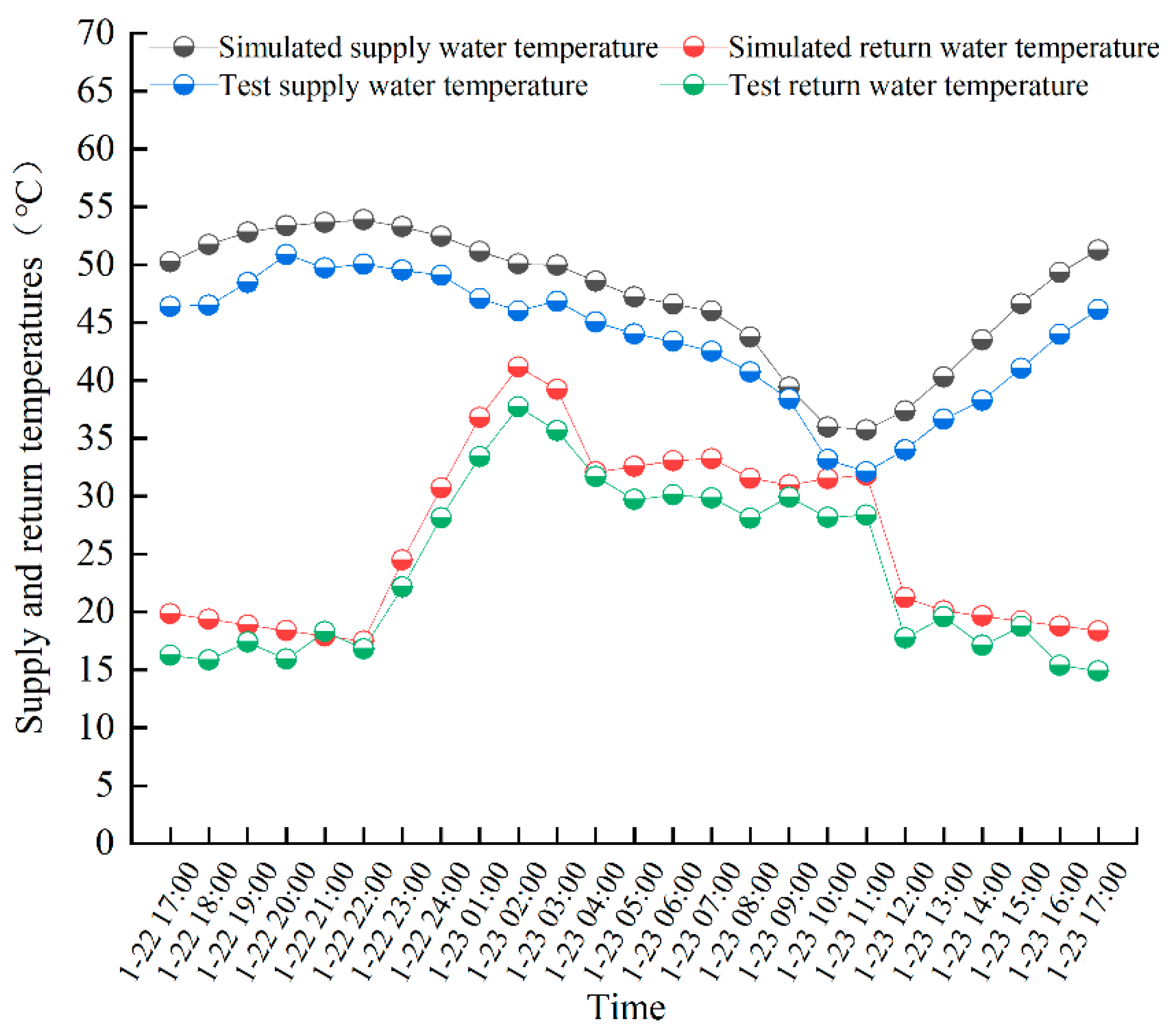

46] to design an SEHS, taking single residential buildings in rural areas in severe-cold regions as the research object; establish a system simulation model using TRNSYS 18 software; and verify the accuracy of the model by building an experimental platform. A comprehensive evaluation index system of the system is established, and the AHP is used to determine the weight of each factor and define the comprehensive objective function to establish a multi-objective optimization model based on the FAHP. Taking the collector area, the collector inclination angle, the volume of water in the tank, the PCM volume, the rated power of the electromagnetic heater, the collector’s circulating water pump flow rate, the electromagnetic heater’s circulating water pump flow rate, and the user side’s circulating water pump flow rate as the optimization variables, a multi-objective optimization study is carried out using the orthogonal test to provide references for the application configuration and operation setup of SEHSs with a combined PCM tank in cold regions.

The main contributions of this study can be summarized as follows:

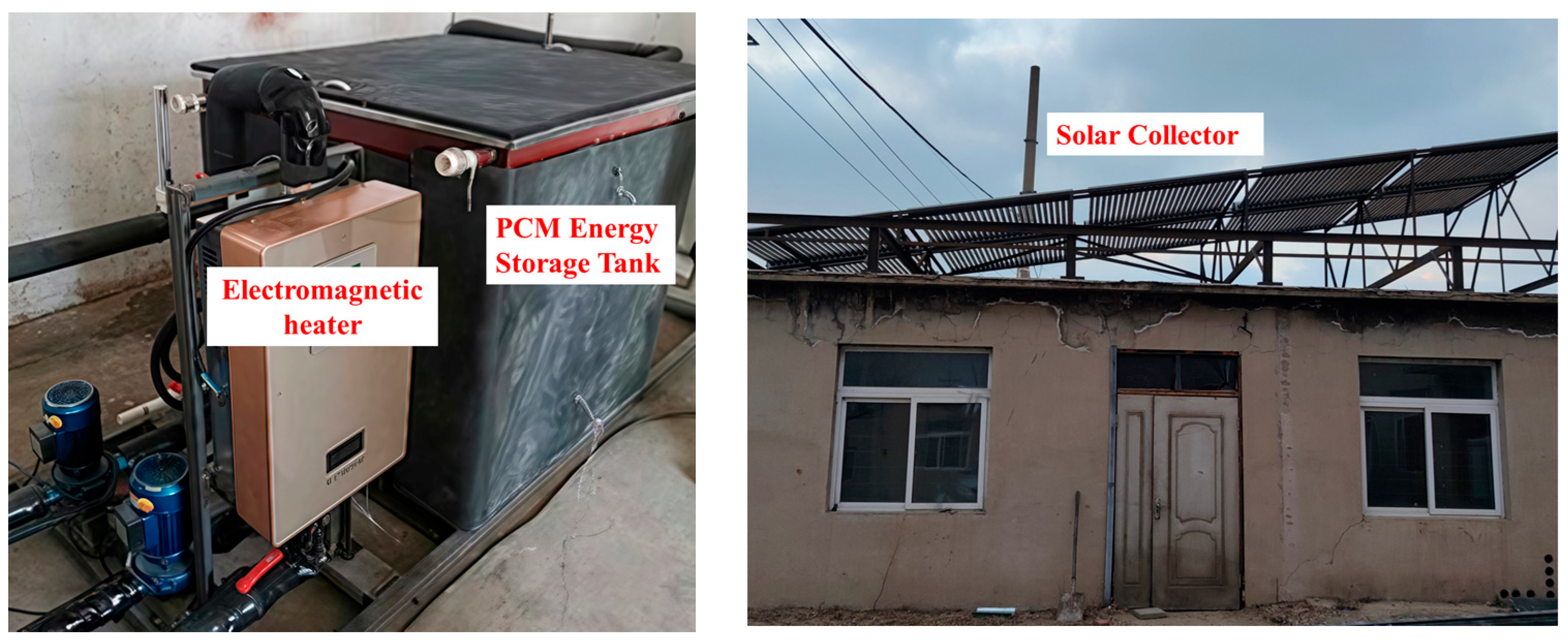

(1) We propose an SEHS for PCM water tank integration applicable to isolated rural houses in a severe-cold region and build a platform for the actual testing of the system;

(2) The FAHP method is proposed for application in the multi-objective optimization of a multi-energy integrated heating system, and a multi-objective optimization model of SEHS performance is constructed;

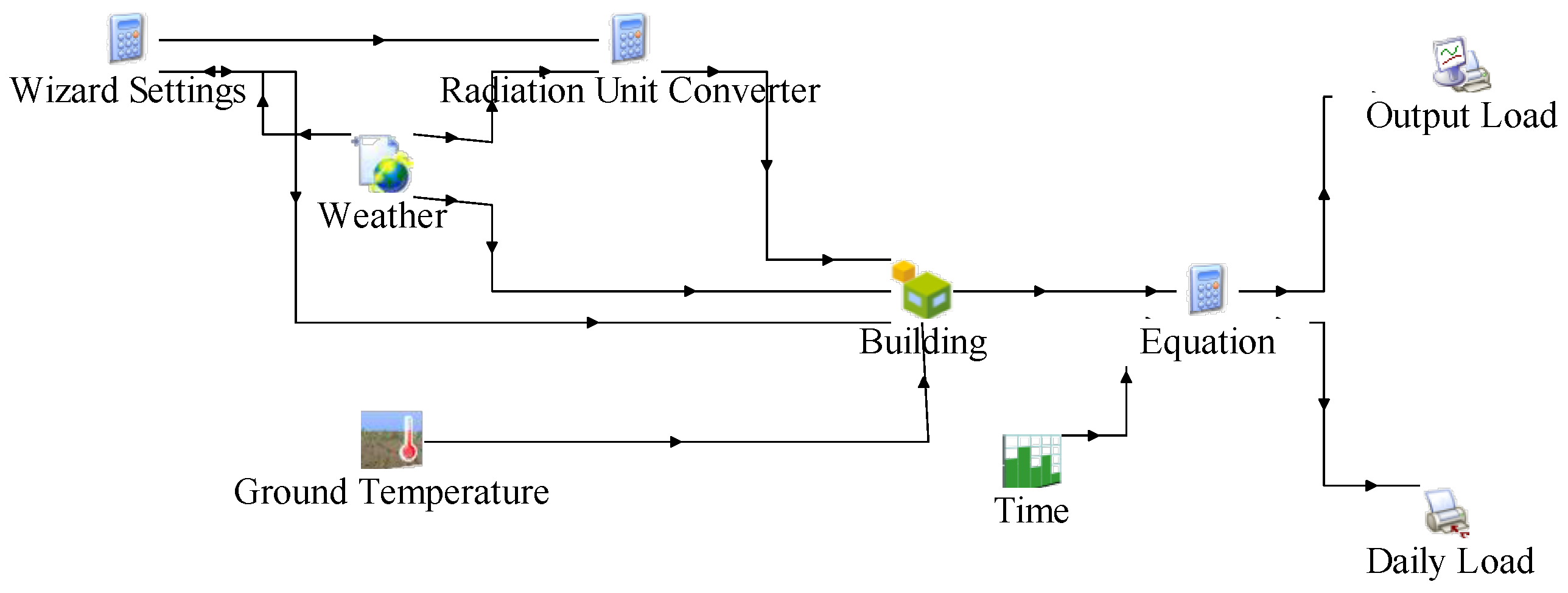

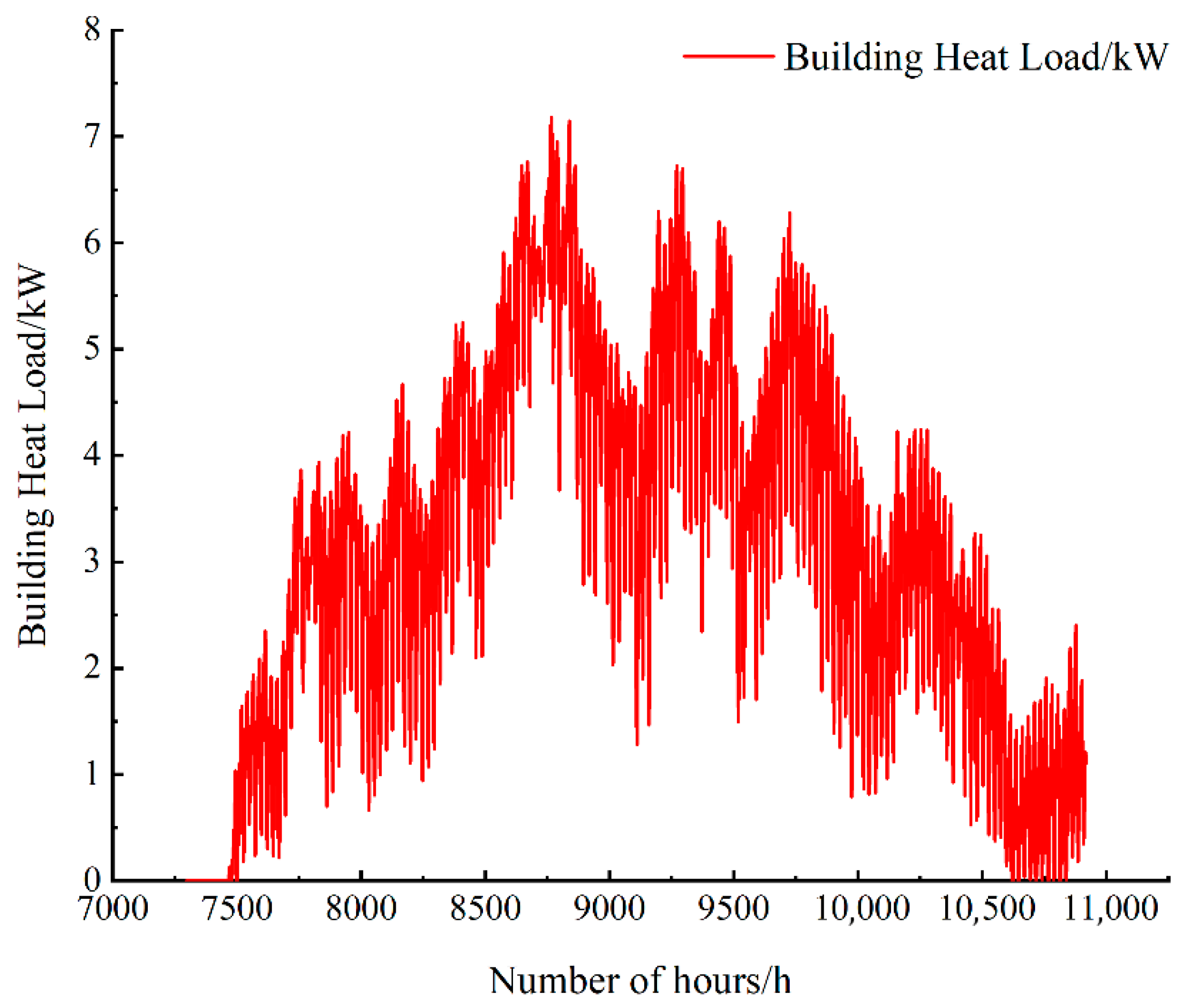

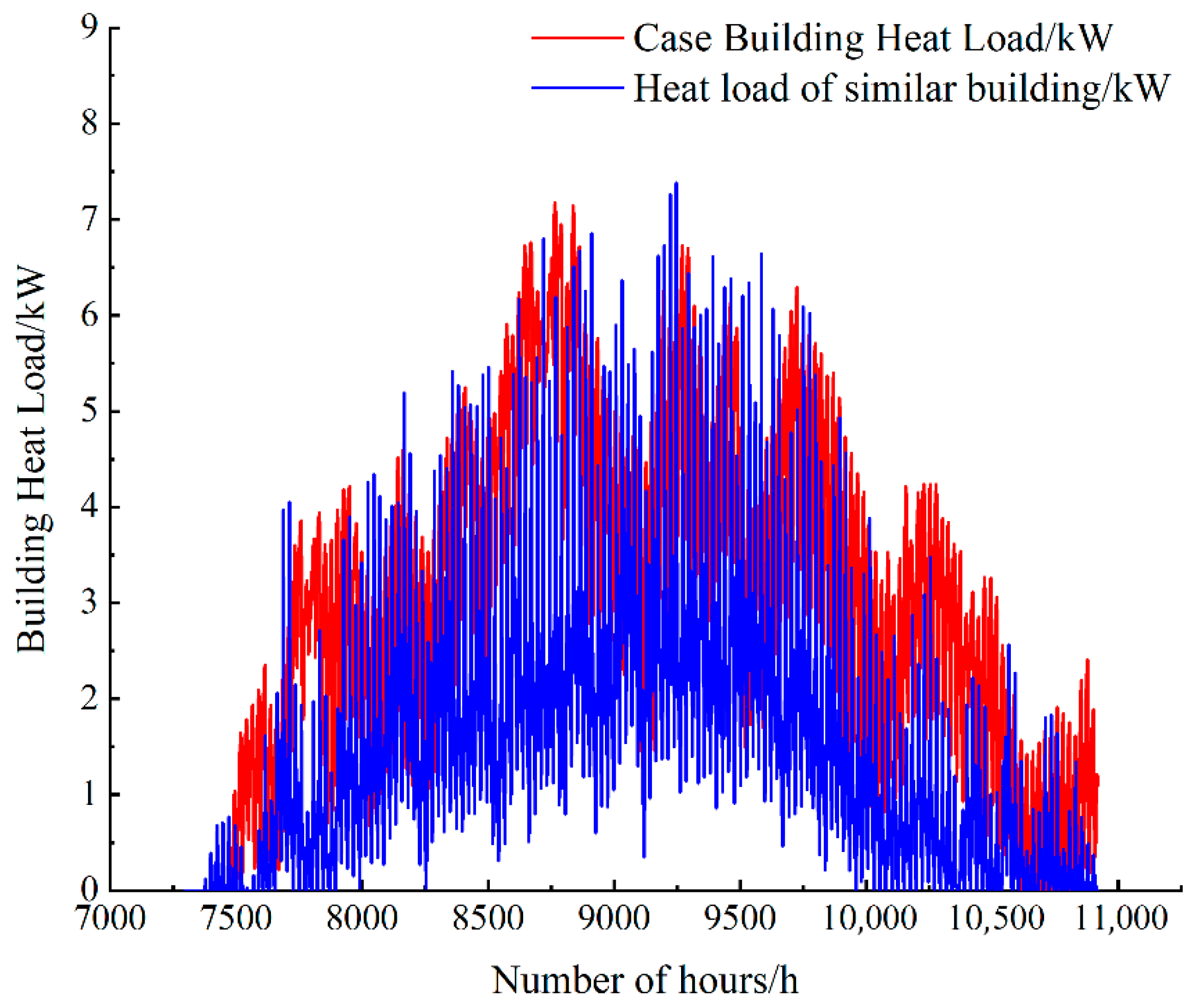

(3) We carry out case studies for typical farmhouses in rural areas in severe-cold regions, use TRNSYS 18 to build a simulation model of the SEHS for PCM water tank integration, and use orthogonal test methods to obtain the simulation system operation data and establish a dataset for multi-objective optimization decision-making.

7. Comprehensive Evaluation Indicators

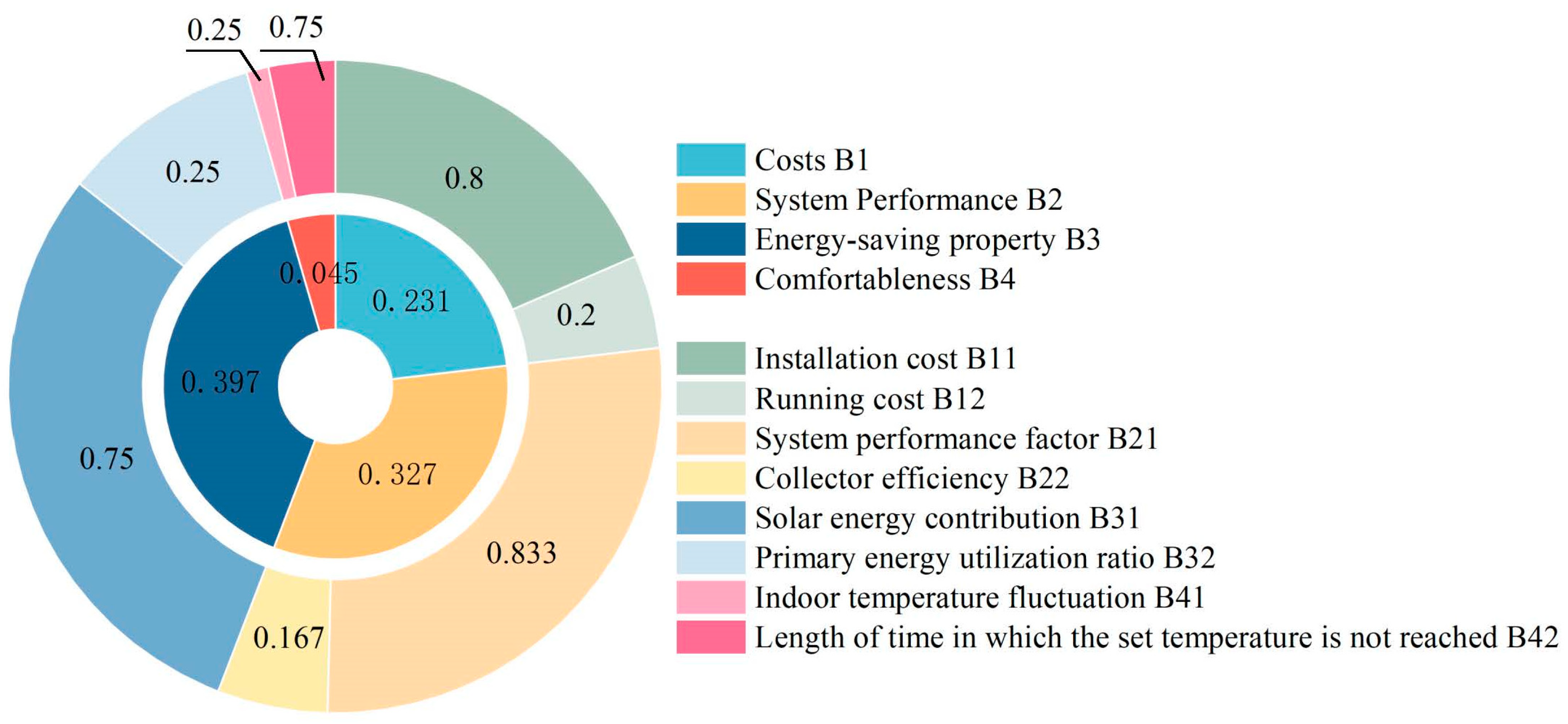

According to the method described in the previous section, the second-level fuzzy evaluation results are represented by

B21,

B22,

B23,

B24, and

, and the second-level fuzzy evaluation matrix is obtained:

The first-level fuzzy evaluation matrix is then calculated:

In summary, the weights of the constructed comprehensive evaluation system are shown in

Figure 11.

Before constructing the optimization objective function, the input data need to be pre-processed appropriately. Firstly, the original input data are dimensionless; therefore, they are all mapped to the range of [0, 1] to ensure that the impact of the data of different indicators on the objective function is balanced and avoid disproportionate impact on the objective function because of the size of the value of a single variable. Secondly, the direction of the objective function is unified; in this study, the smaller the value, the more the evaluation index is positive, while the larger the value, the more the evaluation index is negative. According to the calculated weights of the first-level indicators and those of the second-level indicators, the multi-objective optimization function of the solar–electromagnetic energy coupled heating system,

, is constructed as follows:

where

is the formula for the installation and operating costs;

is the solar collector efficiency;

is the system heating performance coefficient;

is the solar contribution rate, %;

is the primary energy utilization rate, %;

is the variance of room temperature fluctuation; and

is the penalty function for the length of time in which the heating temperature demand is not met.

Based on engineering experience, the installation and operating costs can be calculated with the following formula:

where

is the area of the solar collector, m

2;

is the volume of the heat storage tank, m

3;

is the volume of the phase-change material, m

3;

is the density of the PCM, kg/m

3;

is the rated power of the electromagnetic heater, kW;

is the unit price of the water pump, RMB;

is the installation cost of the equipment, i.e., 10% of the total equipment cost;

is the system power consumption during the day, RMB/ kW·h;

is the system power consumption at night, RMB/ kW·h;

is the daytime power consumption of the system, kW·h; and

is the nighttime power consumption of the system, kW·h.

where

is the daytime power consumption of the collector’s circulating pump, kW·h;

is the daytime power consumption of the electromagnetic heater’s circulating pump, kW·h;

is the daytime power consumption of the user side’s circulating pump, kW·h;

is the daytime power consumption of the electromagnetic heater, kW·h;

is the nighttime power consumption of the collector, kW·h;

is the electromagnetic heater’s daytime power consumption, kW·h;

is the user side’s circulating pump’s nighttime power consumption, kW·h; and

is the electromagnetic heater’s nighttime power consumption, kW·h.

The solar collector efficiency is calculated as

where

is the heat absorbed by the collector, kW, and

is the product of radiation intensity per unit area, kW/m

2.

The system

COP is calculated as

In the formula, is the total heat supply of the system, kW·h, and is the total power consumption of the system, which is equal to the sum of and , kW·h.

Solar Energy Utilization

is calculated as

where

QJ is the total heat collected by the collector, kW·h.

The primary energy utilization rate is calculated as

In the above formula, is the power plant power supply efficiency, here taken as 42%; is the grid transmission efficiency, here taken as 92%; and is the compressor motor efficiency, here taken as 90%.

The expression for the variance of room temperature fluctuations is

where

is the average of the data and

n is the number of data.

Orthogonal Experimental Design

As mentioned earlier, for the multi-objective optimization of the SEHS, we considered eight factors, which are the collector area, the collector inclination, the volume of water in the tank, the volume of PCM, the rated power of the electromagnetic heater, the circulating pump flow rate of the collector, the circulating pump flow rate of the electromagnetic heater, and the circulating pump flow rate of the user side. Five different levels were designed for each factor, as shown in

Table 11. If each level of each factor is analyzed in one simulation, a total of 5

8 tests are to be conducted, which is not feasible. It is necessary to ensure the accuracy of the tests while ensuring the reasonableness of the number of simulation tests; therefore, the orthogonal test method was used in this study. An eight-factor, five-level orthogonal table was generated by using the allpairs tool, and a total of 46 simulation tests were required. The parameters of each group are shown in

Table 12.

8. Results and Discussion

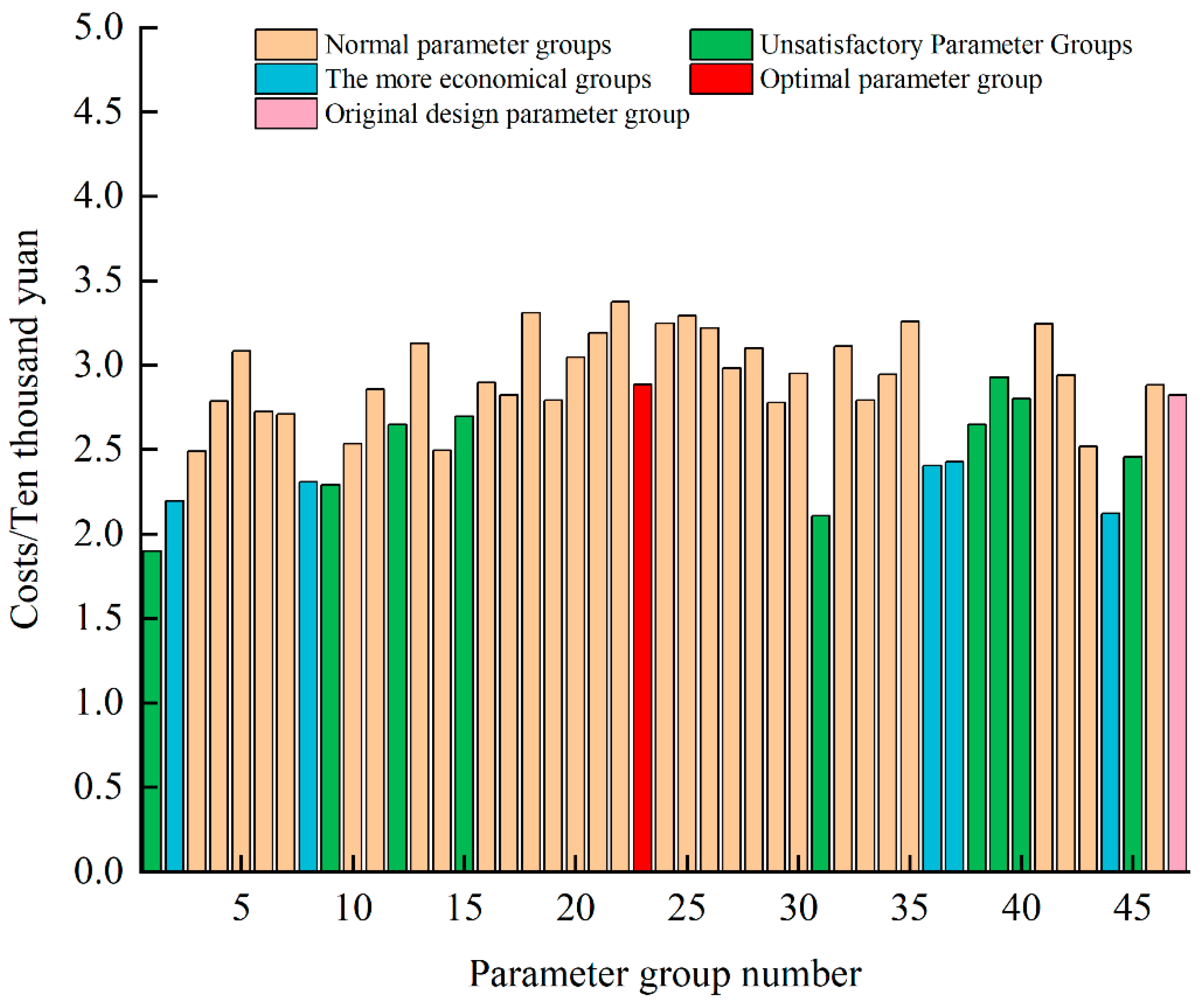

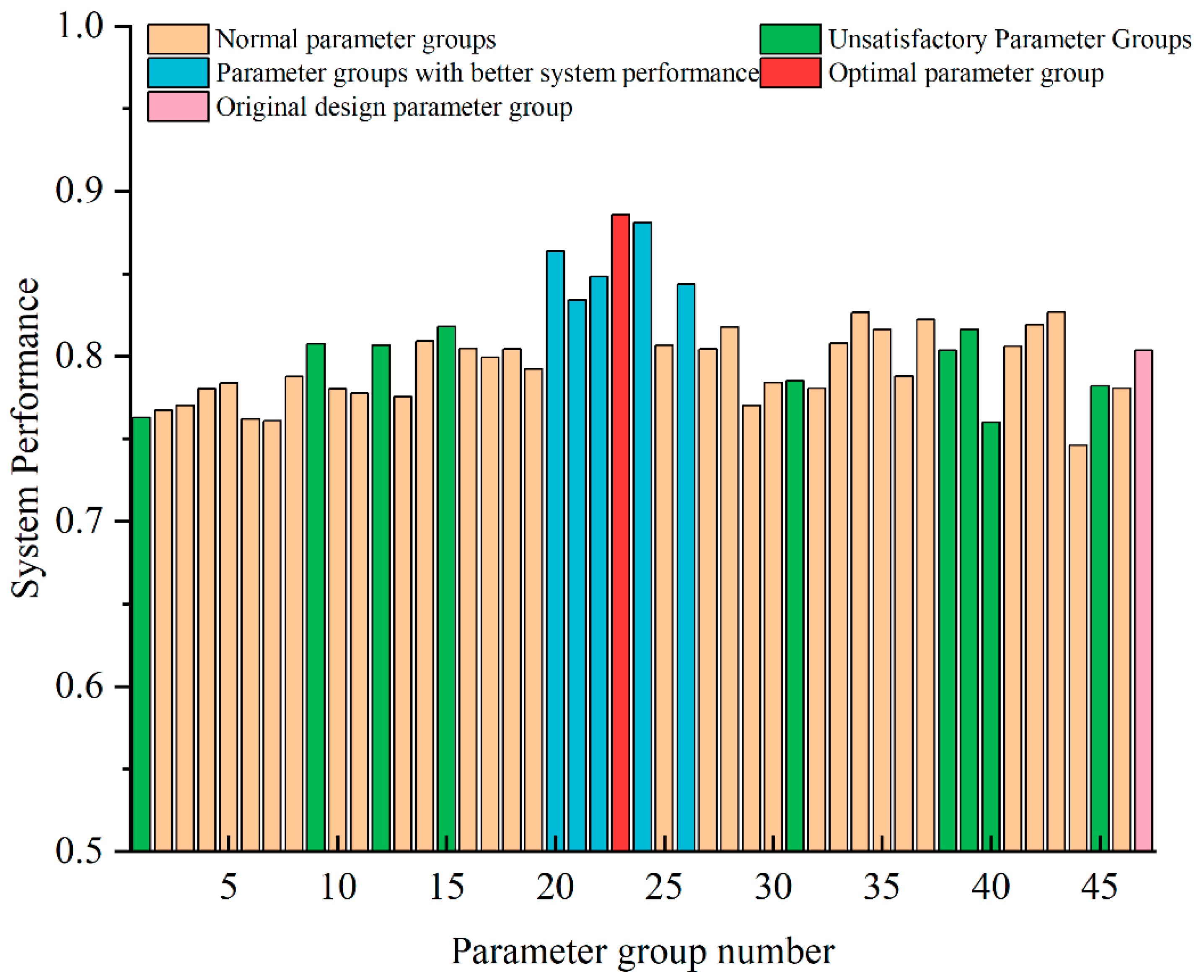

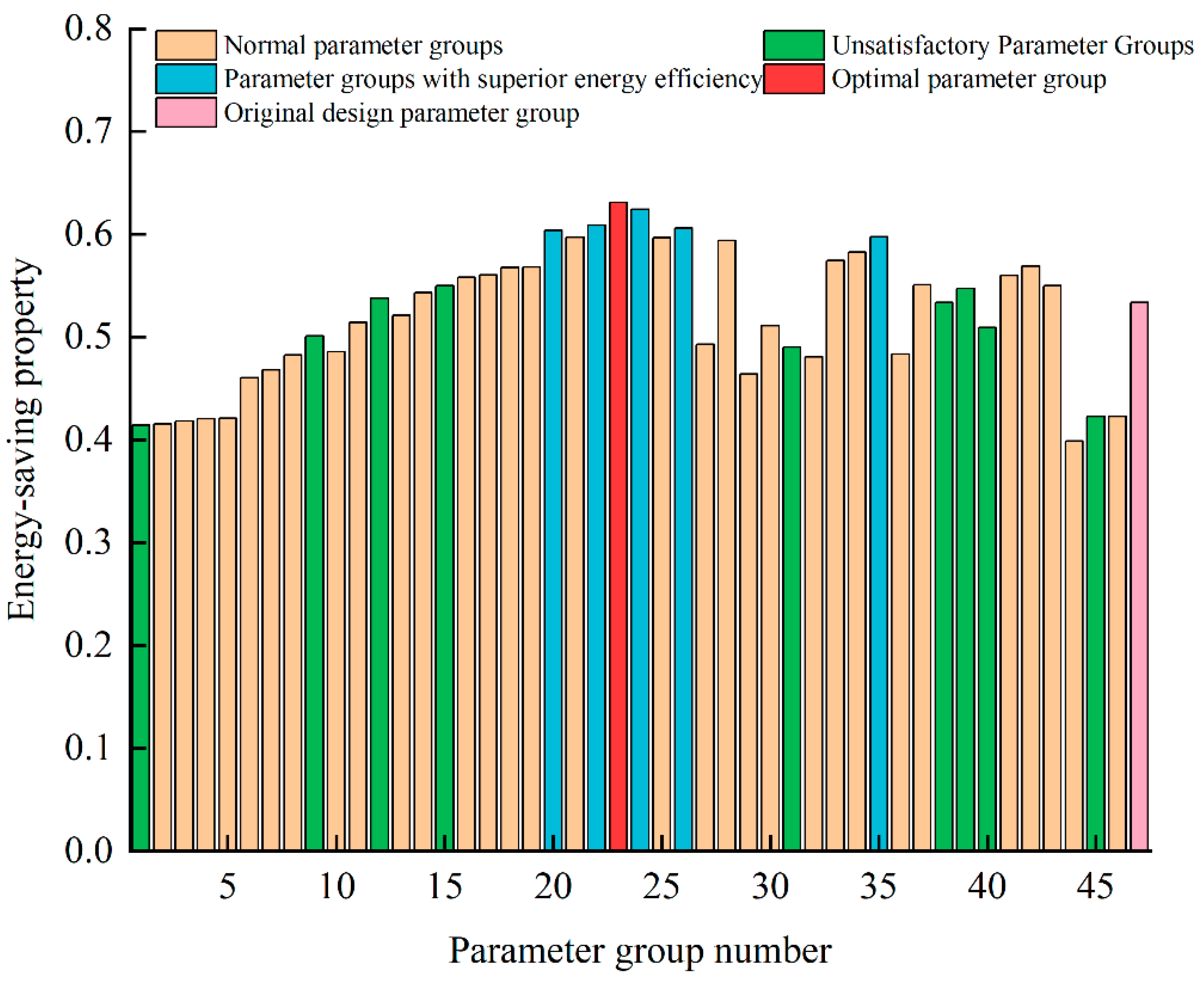

The 46 sets of parameters in the orthogonal test table are input into the TRNSYS simulation model, and the running data are derived from the system simulation to calculate the objective function value of the SEHS, as shown in

Figure 12. The smaller the objective function value, the more significant the optimization effect. From

Figure 12, it can be seen that the objective function values are all negative, indicating that the overall optimization effect obtained by using the FAHP method is good. Among them, the objective function value of parameter group 23 is the smallest, indicating that this group of parameters is the optimal combination for multi-objective optimization. Compared with the initial design parameters, the comprehensive system performance of this group of parameters increases by 38%, the room temperature fluctuation increases by 17.0%, the economic costs increase by 2.2%, system performance increases by 10.24%, and energy efficiency increases by 18.23%. The volatility of the indoor comfort indicators for the farmhouse is high; it is considered that the indoor temperature fluctuation must be within 20% and that the total number of hours in which the design temperature is not met must be less than 120 h (5 days) to meet the design requirements. Among the parameter groups, groups 1, 9, 12, 15, 31, 38, 39, 40, and 45 do not meet the above indoor temperature design requirements and are considered unsatisfactory.

Figure 13 shows the optimization results of the room temperature fluctuation for each optimized parameter group, as well as the original parameter group. It can be clearly seen that the optimization results of groups 2, 3, 6, 29, and 46 are much higher than those of the other parameter groups and better than the original design parameter group. Compared with the latter, the room temperature fluctuations for these groups are reduced by 13%, 15%, 13%, 14%, and 15%, respectively.

Figure 14 shows the costs optimization results for each optimized parameter group, as well as the original parameter group. It can be clearly seen that the optimization results of groups 2, 8, 36, 37, and 44 are much higher than the optimization results of the other parameter groups and are better than the original design parameter group. Compared with the latter, the costs for these groups are improved by 22%, 18%, 15%, 14%, and 25%, respectively.

Figure 15 shows the optimization results of system performance for each optimized parameter group, as well as the original parameter group. It can be clearly seen that the optimization results of groups 20, 21, 22, 24, and 26 are much higher than the optimization results of the other parameter groups and better than the original design parameter group. Compared with the latter, the system performance for these groups is improved by 7%, 4%, 6%, 10%, and 5%, respectively.

Figure 16 shows the optimization results of energy efficiency for each optimized parameter group, as well as the original parameter group. It can be clearly seen that the optimization results of groups 20, 22, 24, 26, and 35 are much higher than those of the other parameter groups and better than the original design parameter group. Compared with the latter, the energy efficiency for these groups is improved by 13%, 14%, 17%, 14%, and 12%, respectively.

It can be seen from the above analysis that the multi-objective optimization analysis of multi-energy complementary heating system performance using FAHP has obvious advantages. Through the rational design of the index system and arithmetic process, the scientificity and operability of decision-making, the ability to quantify fuzzy information, the flexibility of multi-factor integration and the adaptability of complex systems can all be improved, and the results are intuitive and interpretable.

9. Conclusions

A multi-objective optimization study of an SEHS with an integrated PCM tank is carried out by using TRNSYS 18 for different parameter sets separately; the optimized results are analyzed, and the following conclusions are obtained.

(1) The simulation results of 46 groups are input into the FAHP multi-objective optimization comprehensive objective function, which results in the minimum value of the objective function for parameter group 23. The values of the parameters of the optimal objective function are as follows: a collector area of 32 m2, a collector inclination angle of 51.48°, a water volume in the tank of 3.5 m3, a volume of PCM of 0.15 m3, a rated power of the electromagnetic heater of 15 kW, a circulating pump flow rate of the collector of 1550 m3/h, a circulating water pump flow rate of the electromagnetic heater of 3860 m3/h, and a circulating water pump flow rate of the user side of 1130 m3/h. This parameter set can better meet the building heating demand.

(2) In addition to the minimum objective function as the basis for optimization, in this study, we also consider the comfort factor. The parameter groups with indoor temperature fluctuations greater than 20% compared with the initial design value and a number of hours in which the set temperature is not met greater than 120 h are regarded as not satisfying the design requirements. Even if there is a parameter group with a lower objective function value, if it does not meet the comfort requirements, it cannot be used as an optimized design solution.

(3) Compared with the initial design values, the optimal combination of system values improves the overall performance by 38%, the room temperature fluctuation by 17%, the economic costs by 2.2%, system performance by 10.24%, and energy efficiency by 18.23%.

This study demonstrates that the FAHP method can be used to conduct multi-objective decision-making for coupled heating systems in a simple and efficient manner, thereby achieving their optimal design. It holds significant engineering significance and provides guidance for optimizing the design parameters of coupled heating systems. Although this method effectively realizes the system optimization function, its dynamic adaptability is limited. In the future, it is necessary to consider introducing time-varying weights or combining it with machine learning (such as fuzzy neural networks) to enhance the real-time optimization capability. Additionally, future work should also focus on ensuring the effective deployment and execution of the optimization strategy. This requires focusing on the collaboration between the optimization layer and the underlying execution system, and conducting in-depth research on the communication architecture and control strategies for real-time optimization decisions. Such research must address the challenges of instantaneity, reliability, and precise control in complex coupled systems, thereby significantly improving their intelligent operation level.