Sustainable Aviation Fuels: A Comprehensive Review of Production Pathways, Environmental Impacts, Lifecycle Assessment, and Certification Frameworks

Abstract

1. Introduction

2. Sustainable Aviation Fuel Policy

2.1. Current Situation and Global Approach to SAF

2.2. ICAO

2.3. The European Union

2.4. IATA

2.5. Other Entities—Governments, Enterprises, Airlines

3. Types of Sustainable Aviation Fuels

3.1. General Overview

3.2. Fischer–Tropsch (FT)

3.3. Hydroprocessed Esters and Fatty Acids (HEFAs)

3.4. Synthesized Isoparaffins from Hydroprocessed Fermented Sugars (SIPs)

3.5. Alcohol-to-Jet Synthetic Paraffinic Kerosene (ATJ)

3.6. Catalytic Hydrothermolysis Jet Fuel (CHJ)

3.7. E-Fuels (Power-to-Liquid)

3.8. Hydrogen

4. SAF Production Methods

4.1. Certification

4.2. Fischer–Tropsch Hydroprocessed Synthesized Paraffinic Kerosene (FT-SPK)

4.2.1. Synthesized Kerosene with Aromatics Derived by Alkylation of Light Aromatics from Non-Petroleum Sources (FT-SKA)

4.2.2. Co-Hydroprocessing of Fischer–Tropsch Hydrocarbons in a Conventional Petroleum Refinery

4.3. Synthesized Paraffinic Kerosene from Hydroprocessed Esters and Fatty Acids (HEFA-SPK)

- Distillation into fractions;

4.3.1. Co-Hydroprocessing of Esters and Fatty Acids in a Conventional Petroleum Refinery

4.3.2. Co-Processing of HEFA

4.3.3. Synthesized Paraffinic Kerosene from Hydrocarbon—Hydroprocessed Esters and Fatty Acids (HC-HEFA-SPK)

4.4. Synthesized Iso-Paraffins from Hydroprocessed Fermented Sugars (SIP)

4.5. Alcohol-to-Jet Synthetic Paraffinic Kerosene (ATJ-SPK)

- Fermentation of sugar-rich materials (such as sugarcane, corn, and wheat). Alcohol can also be obtained from processing wood (lignocellulose), or even waste, to produce a mash containing ethanol or isobutanol.

- Distillation and blending with Jet-A1 in 10–50% proportions [38].

Synthetic Paraffinic Kerosene with Aromatics (ATJ-SKA)

4.6. Catalytic Hydrothermolysis Jet Fuel (CHJ)

- Cracking (breaking down long-chain hydrocarbons into shorter molecules);

- Hydrolysis (breaking of chemical bonds in a molecule through interaction with water);

- Decarboxylation (removing COOH groups);

- Dehydration (removing water);

- Isomerization;

- Recombination (forming new, more stable hydrocarbon molecules);

- Aromatization [4].

4.7. E-Fuels (Power-to-Liquid)

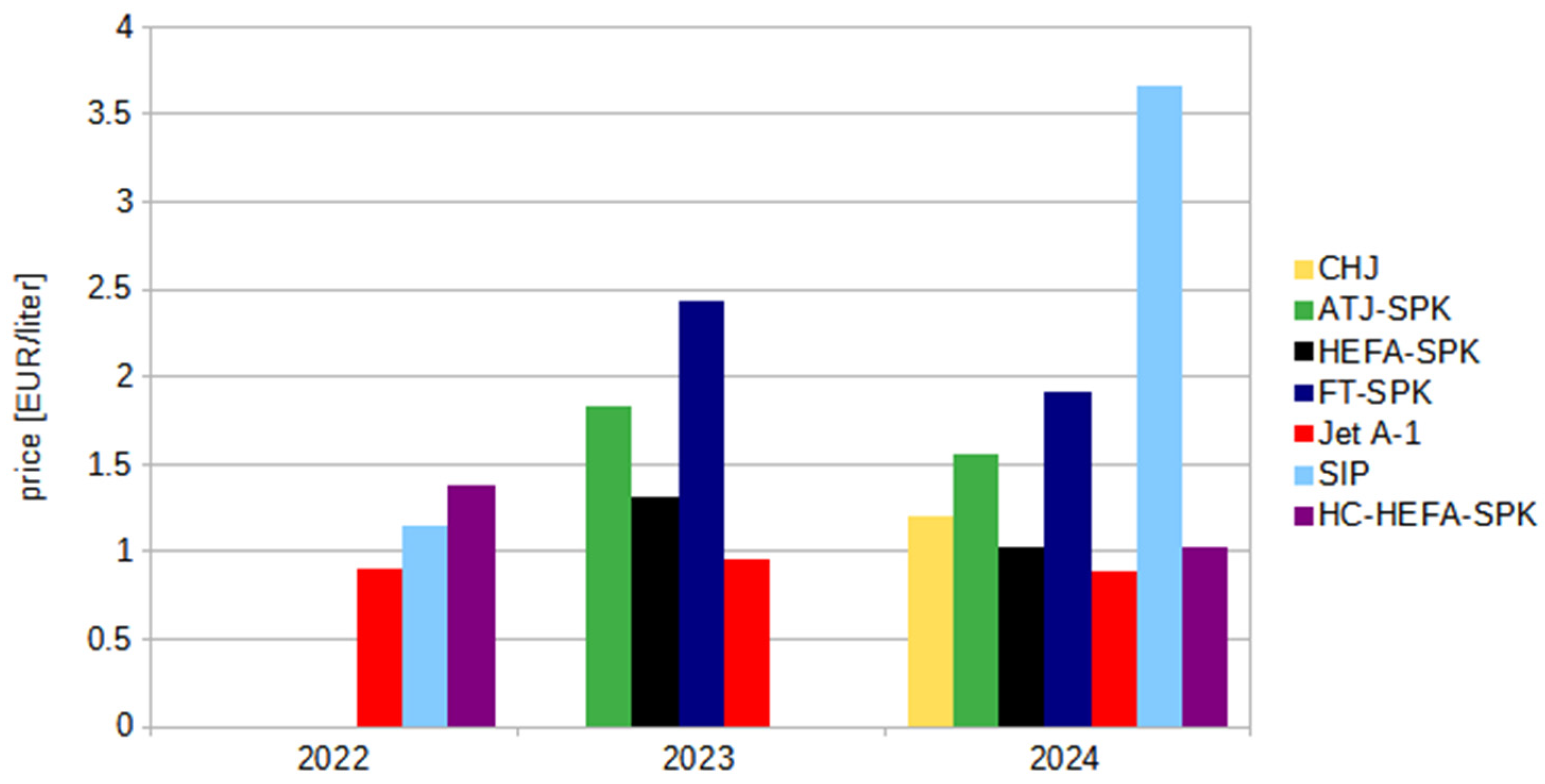

5. Economic Profitability

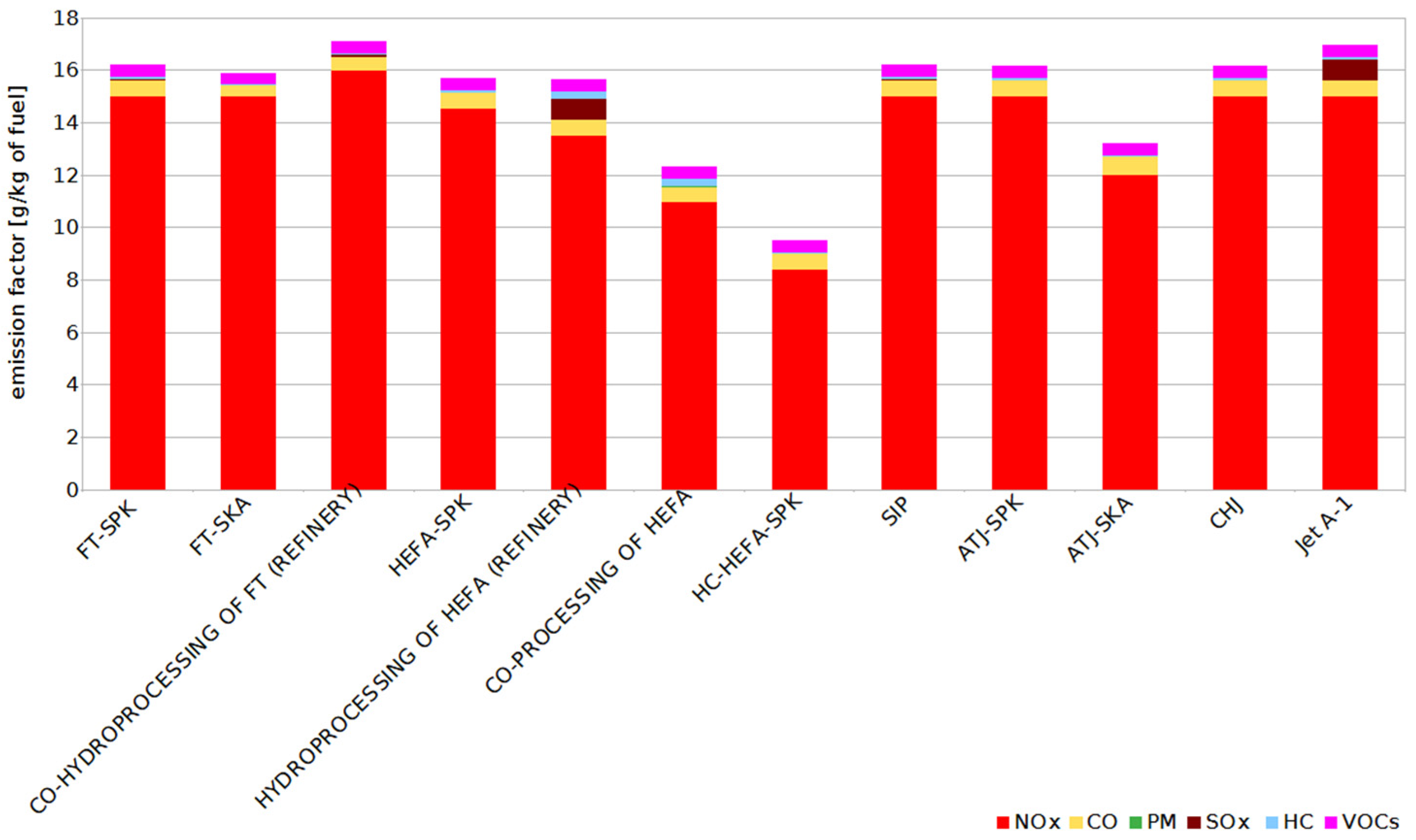

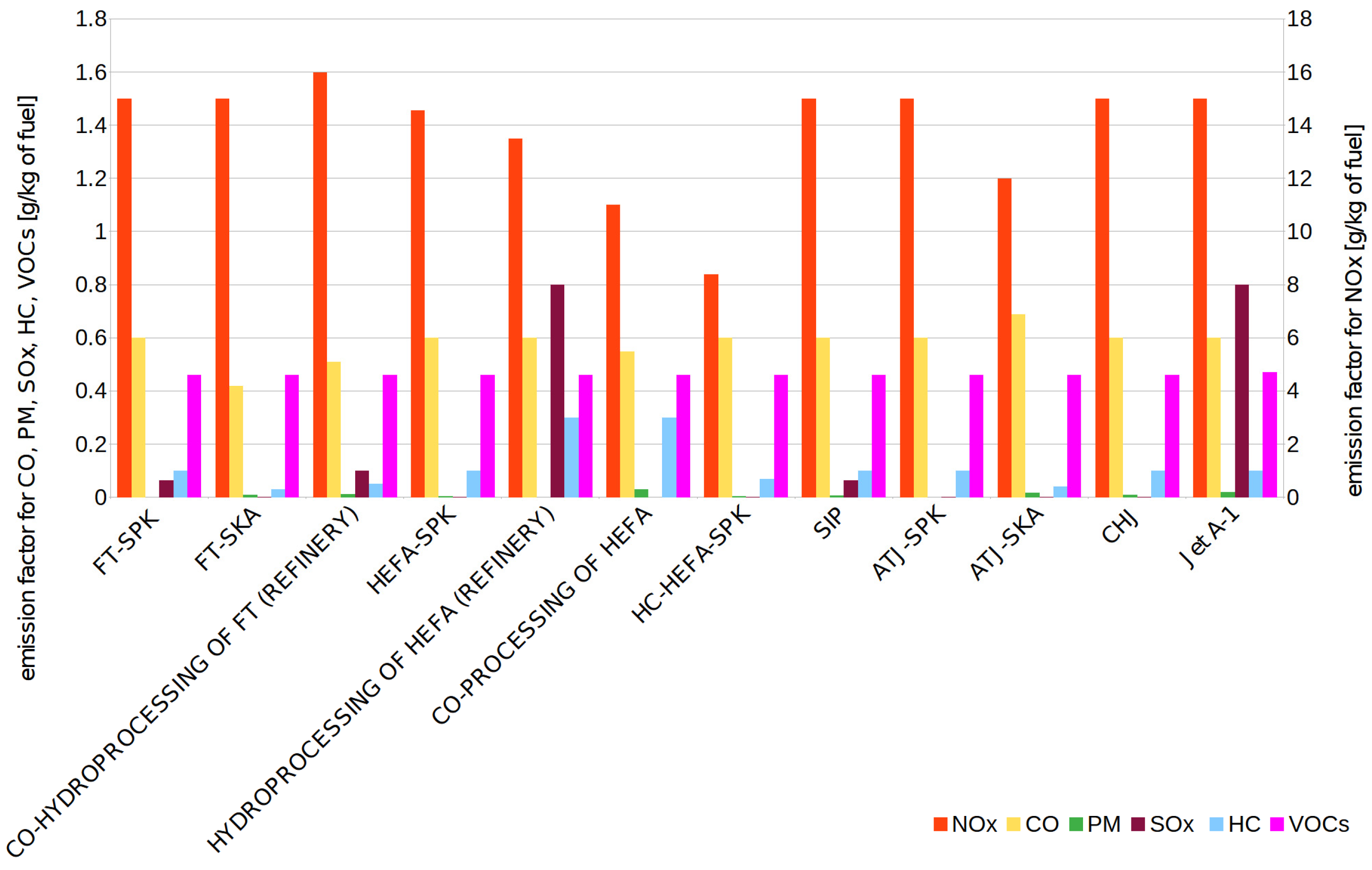

6. Analysis of Emissions from Engines Powered by Sustainable Aviation Fuels

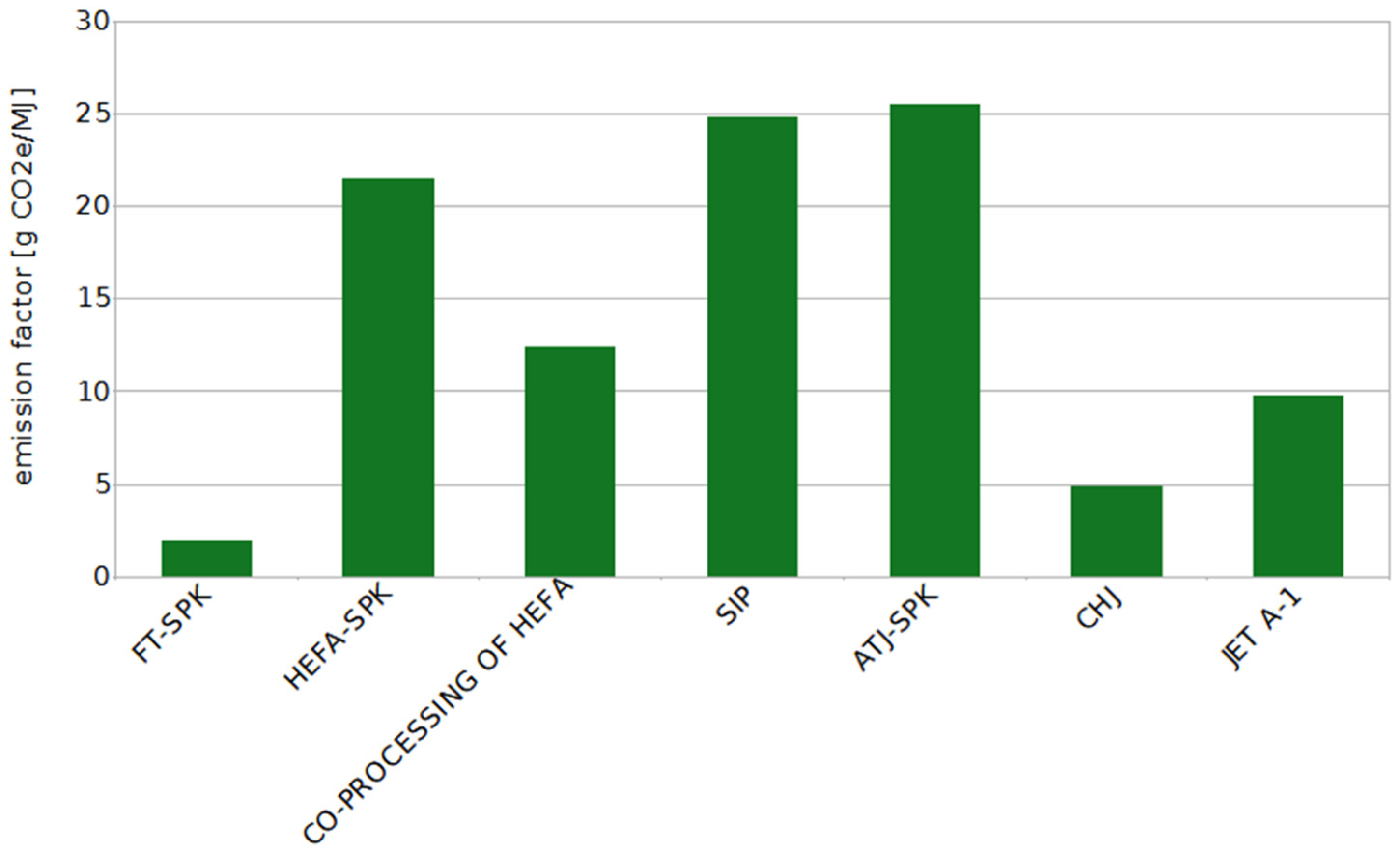

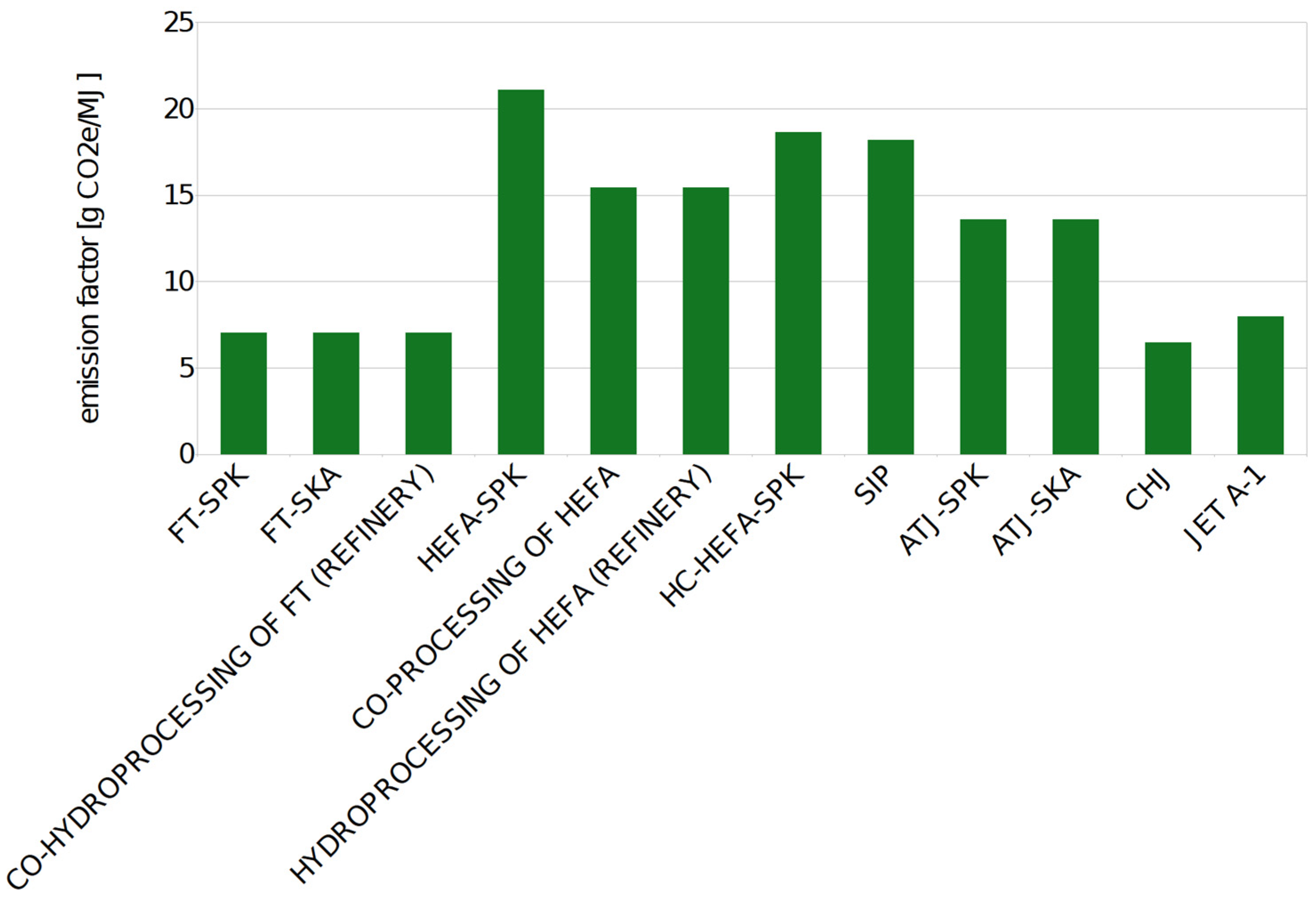

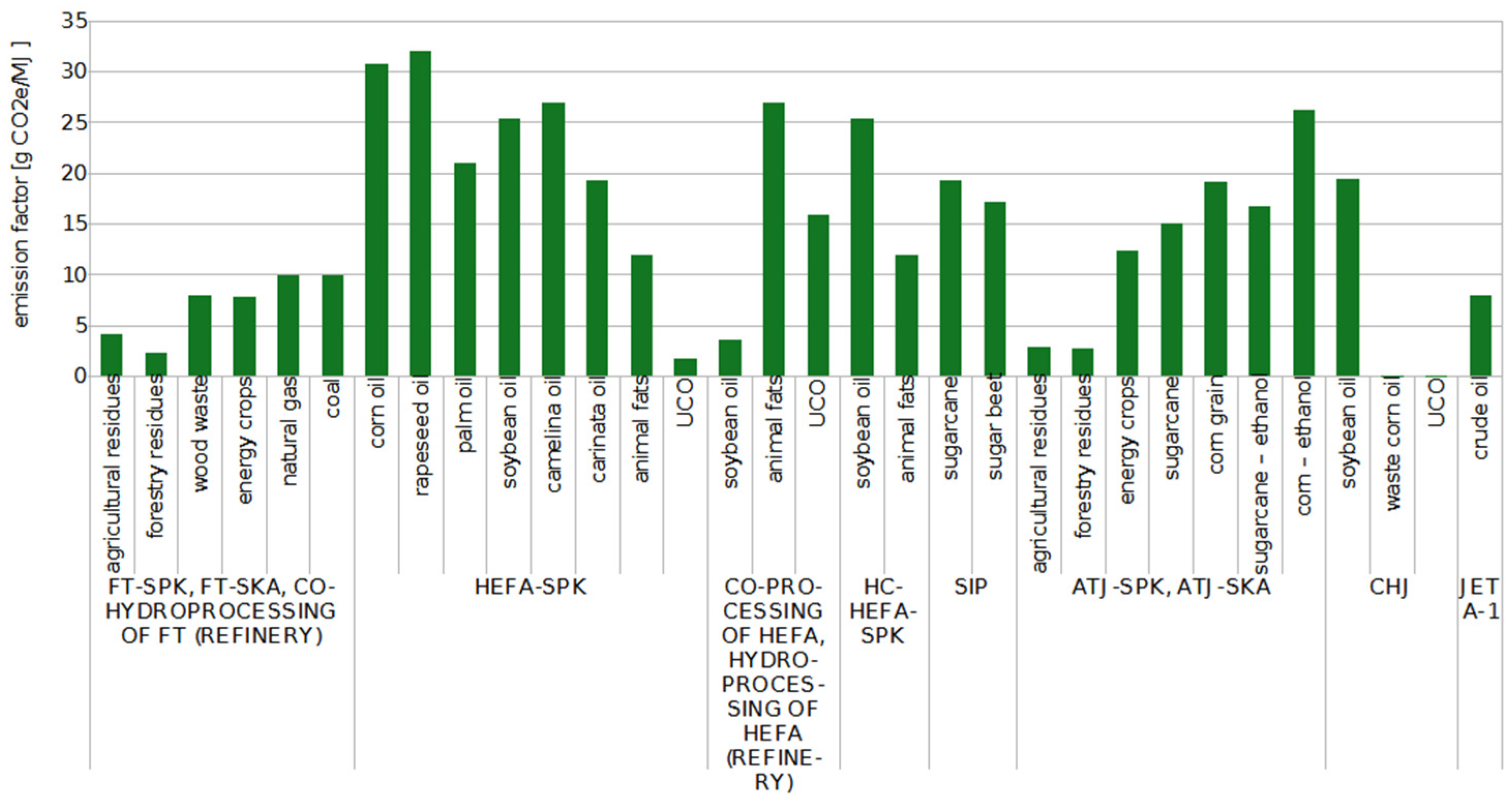

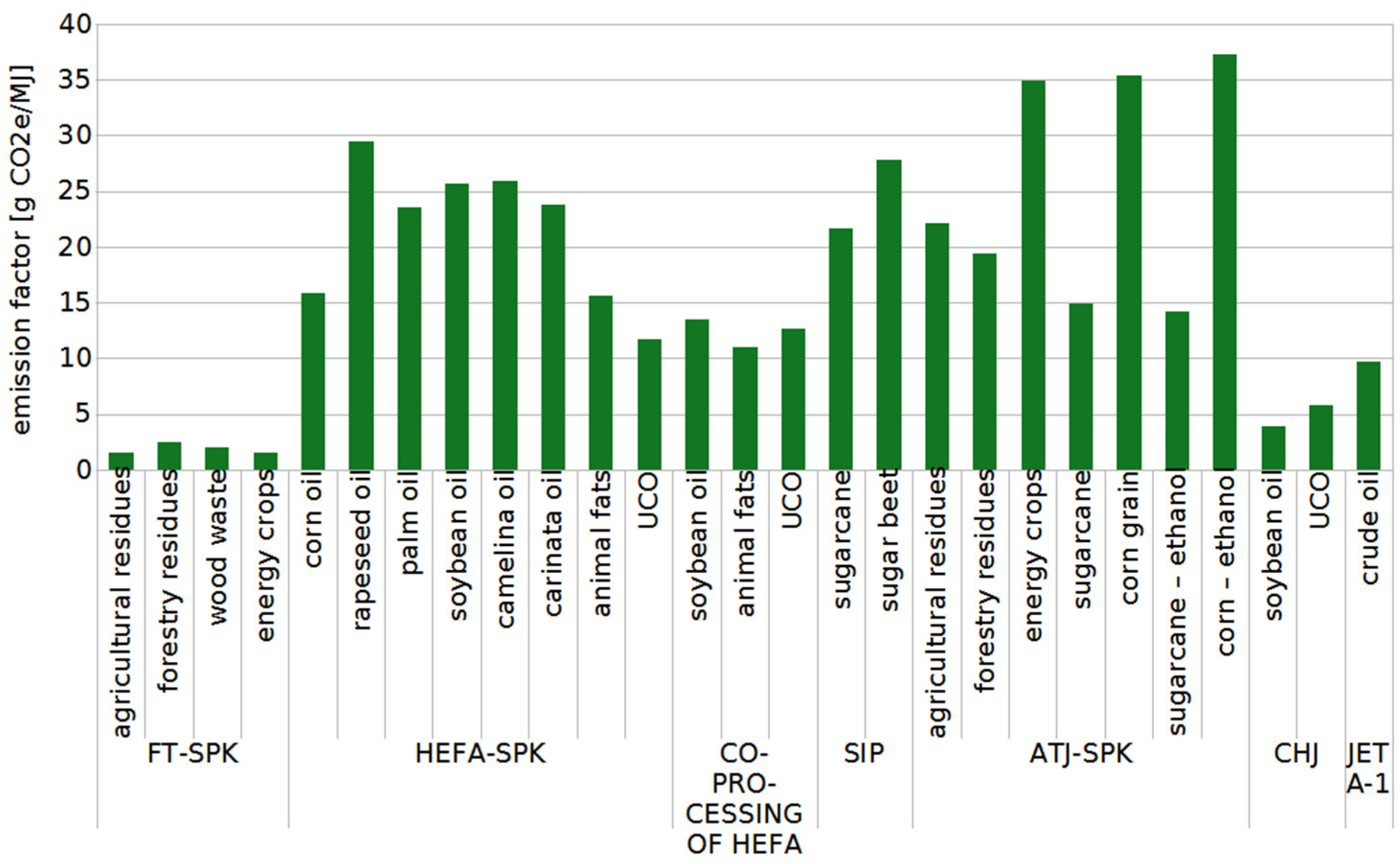

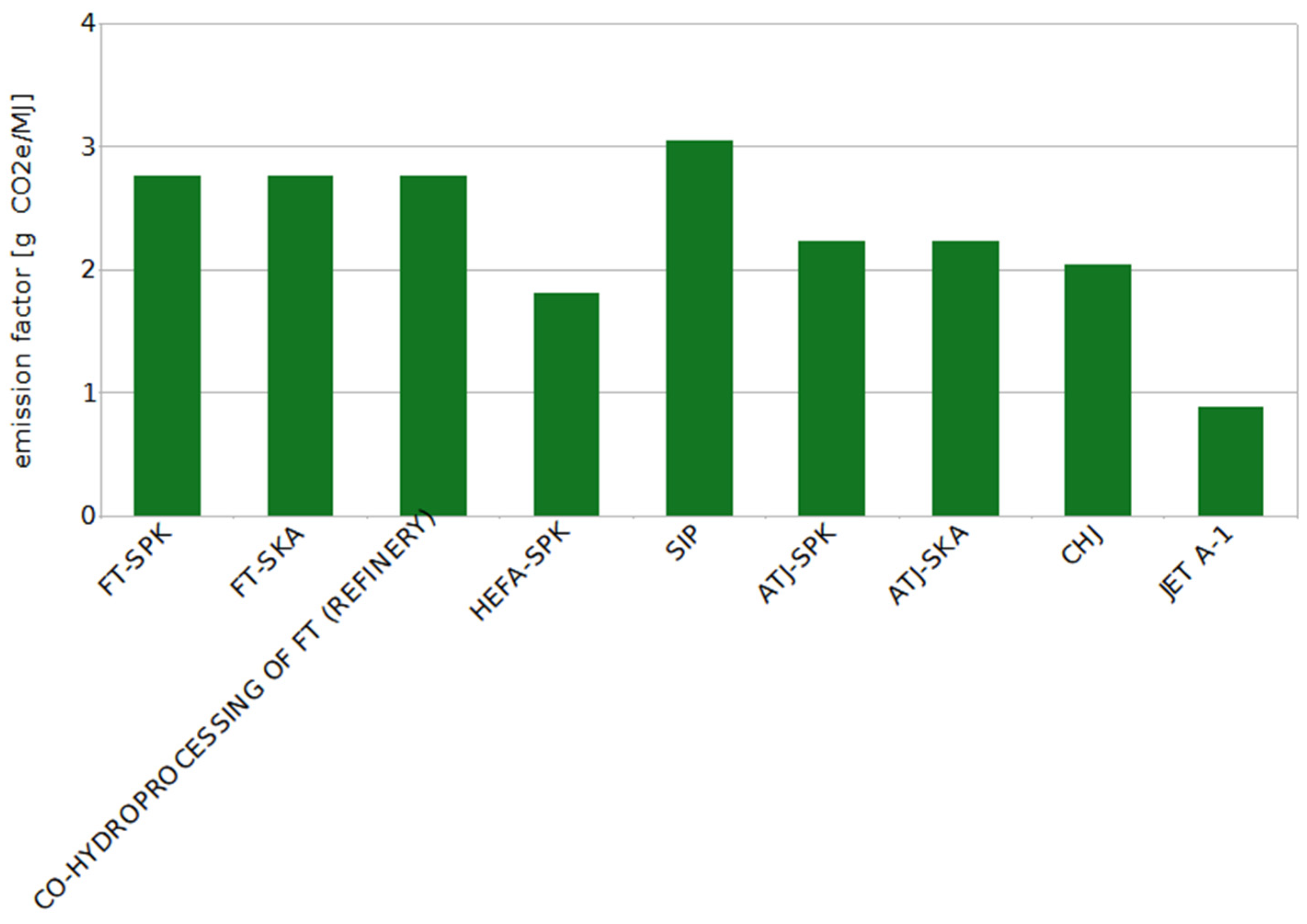

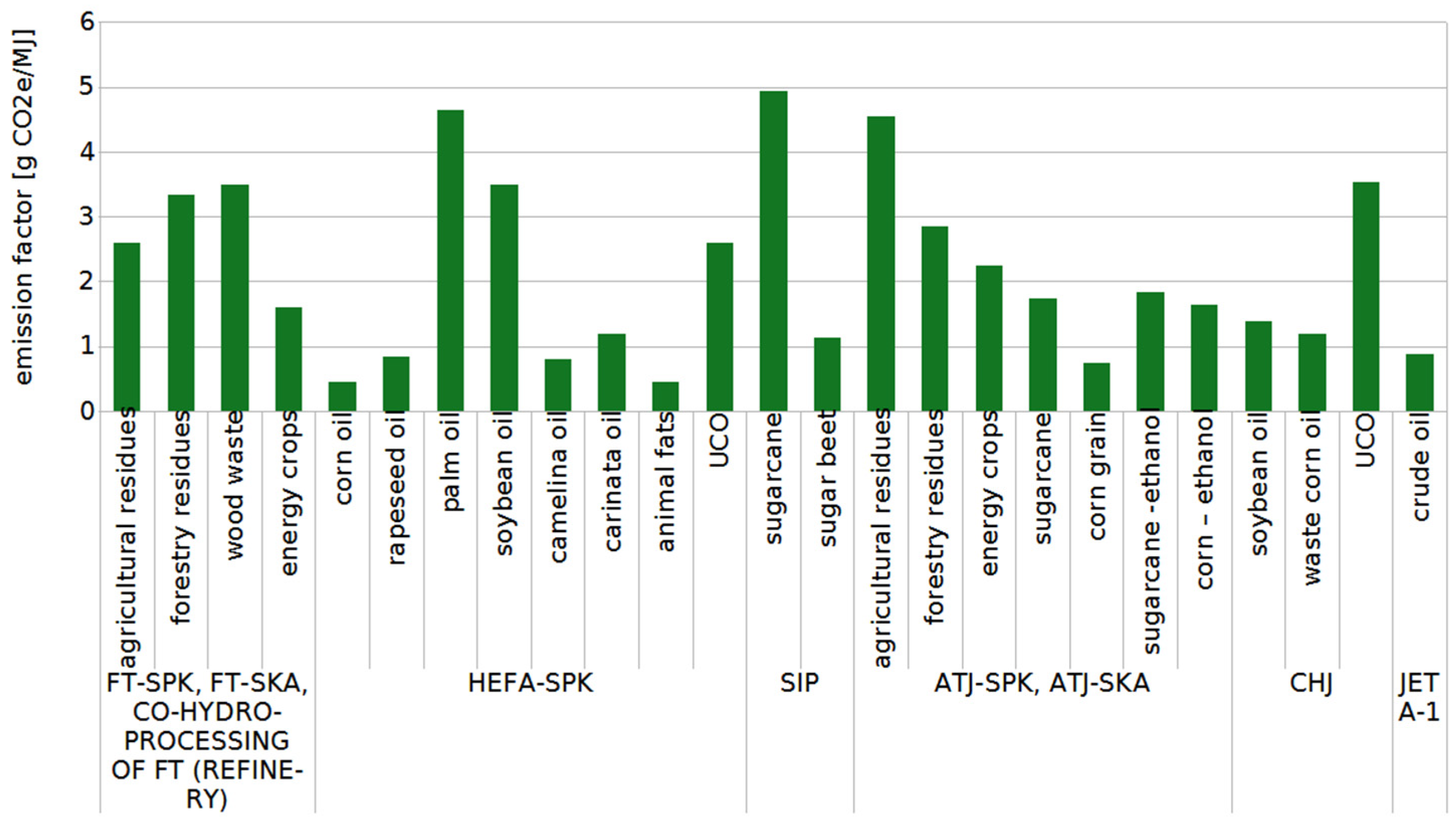

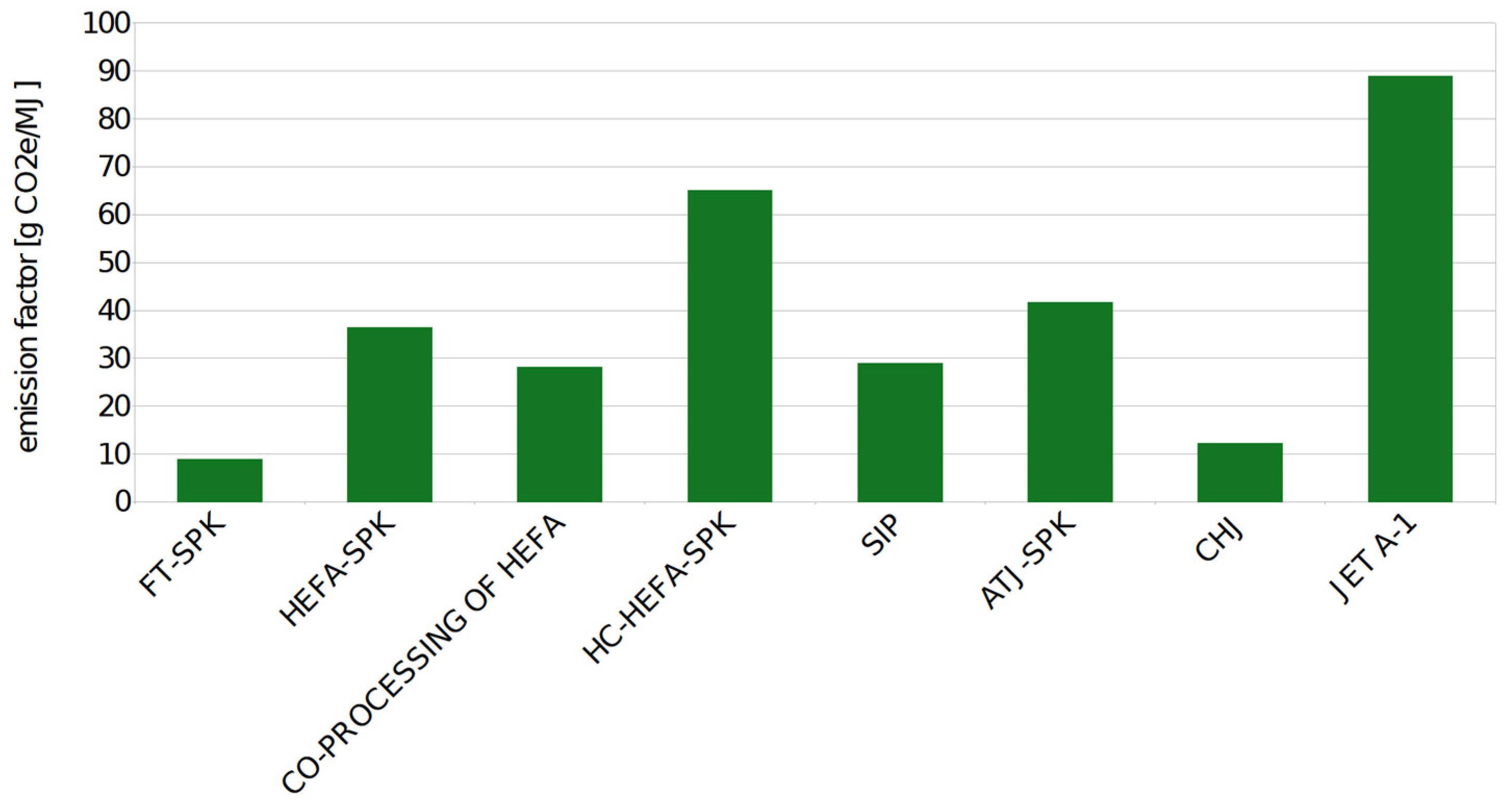

7. Life Cycle Assessment

7.1. Raw Material Acquisition

7.2. Fuel Production

7.3. Transport and Distribution

7.4. Usage

7.5. Waste Disposal and Recycling

7.6. Environmental Impact Across the Entire Life Cycle

- Reduced contribution to global warming and a slowdown in climate change;

- Mitigation of contrail and cirrus cloud formation, which amplify the greenhouse effect;

- Improvement of air quality through the reduction of photochemical smog and atmospheric acidification;

- Decreased degradation of ecosystems, vegetation, soils, and water bodies;

- Reduced human exposure to pollutants associated with respiratory and cardiovascular diseases.

8. Conclusions and Future Outlook

- Introduce long-term, stable incentive frameworks (e.g., tax credits, carbon pricing, production subsidies) to de-risk SAF investments.

- Harmonize certification criteria and LCA methodologies across jurisdictions (e.g., ICAO, EU ETS, CORSIA) to avoid regulatory fragmentation.

- Mandate increasing SAF blending quotas with clear compliance timelines and enforceable targets.

- Prioritize public investment in green hydrogen and CO2 capture infrastructure, enabling scalable PtL deployment.

- Accelerate joint ventures and consortia to develop large-scale SAF production facilities, especially in regions with renewable energy surpluses.

- Integrate SAF supply chains into airport logistics and refueling systems through standardized blending and distribution protocols.

- Diversify feedstock portfolios by investing in non-food biomass, algae, and municipal waste streams to reduce competition with other sectors.

- Advance techno-economic models for SAF scale-up, including PtL systems powered by intermittent renewables.

- Develop standardized LCA frameworks to assess not only CO2 emissions but also non-CO2 effects and land-use impacts.

- Explore catalyst innovation and process intensification to reduce energy input and costs in SAF synthesis pathways.

| Fuel Type | Feedstock | TRL | Production Cost | LCA Emissions | Certification Status | Process Efficiency |

|---|---|---|---|---|---|---|

| HEFA-SPK | bio-oils (palm and corn oil), animal fats, waste materials [21] | 9 [74] | 1028 EUR/tonne [80] | 36.51 g CO2e/MJ | ASTM D7566 Annex A2 (blending rate up to 50%) [20] | 83% [87] |

| FT-SPK | residual or organic waste, biomass [21,30] | 6–8 [74] | 1320 EUR/tonne [80] | 8.97 g CO2e/MJ | ASTM D7566 Annex A1 (blending rate up to 50%) [20] | 20% [38] |

| ATJ-SPK | sugarcane, corn, wheat, lignocellulose [30] | 5–8 [77] | 1011 EUR/tonne [80] | 41.79 g CO2e/MJ | ASTM D7566 Annex A5 (blending rate up to 50%) [20] | 60–75% [87] |

| SIP | algae, fungi, yeast, bacteria [15] | 7–8 [77] | 3990 EUR/1000 L (minimum jet sales price) [46] | 29.03 g CO2e/MJ | ASTM D7566 Annex A3 (blending rate up to 10%) [20] | - |

| CHJ | bio-oils, animal fats, used cooking fats [21] | 5–8 [77] | 1300 EUR/1000 L (minimum jet sales price) [46] | 12.35 g CO2e/MJ | ASTM D7566 Annex A6 (blending rate up to 50%) [20] | - |

| PtL | e.g., electricity from renewable sources, water, CO2 captured from atmosphere [45] | 4–7 [77] | 2670 EUR/tonne (Co-SOEC) [80] | - | - | 24% [87,90] |

| HTL | wet biomass [74] | 5–7 [77] | 1086 EUR/tonne [81] | - | - | 38–64% [88] |

| Pyrolysis | biomass, forestry residues [75] | 4–7 [77] | 481 EUR/1000 L (at a 75 kg/h feed rate) [82] | - | - | 27–28% [87] |

| Hydrogen—SMR | natural gas [76] | 9 [76] | 1380–5520 EUR/tonne [83] | - | - | 65–75% [89] |

| Hydrogen—SMR + CCS | natural gas, CO2 captured from the atmosphere (Carbon Capture and Storage) [76] | 7–8 [76] | 1840–6440 EUR/tonne [83] | - | - | 85–90% [90] |

| Hydrogen—electrolysis | water, electricity from renewable sources [76] | 6–8 (PEM), 5 (SOEC), 9 (AEL) [78] | 4160 EUR/tonne (PEM), 3200–5200 EUR/tonne (AEL) [84] | - | - | 70–90% (PEM), 90–100% (SOEC), 60–80% (AEL) [91] |

| Hydrogen—methane pyrolysis | methane [76] | 3–5 [78] | 2600–3200 EUR/tonne [85] | - | - | 58% [92] |

| Hydrogen—APR (aqueous phase reforming) | glycerol, lignocellulose [76] | 4–5 [79] | 3550 EUR/tonne [86] | - | - | 50–70% [92] |

Author Contributions

Funding

Conflicts of Interest

References

- Watson, M.J.; Machado, P.G.; da Silva, A.V.; Saltar, Y.; Ribeiro, C.O.; Nascimento, C.A.O.; Dowling, A.W. Sustainable aviation fuel technologies, costs, emissions, policies, and markets: A critical review. J. Clean. Prod. 2024, 449, 141472. [Google Scholar] [CrossRef]

- European Union Aviation Safety Agency. Available online: https://www.easa.europa.eu/en (accessed on 16 April 2025).

- IATA. Disappointingly Slow Growth in SAF Production. Available online: https://www.iata.org/en/pressroom/2024-releases/2024-12-10-03/ (accessed on 16 April 2024).

- Lau, J.I.C.; Wang, Y.S.; Ang, T.; Seo, J.C.F.; Khadaroo, S.N.B.A.; Chew, J.J.; Ng Kay Lup, A.; Sunarso, J. Emerging technologies, policies and challenges toward implementing sustainable aviation fuel (SAF). Biomass Bioenergy 2024, 186, 107277. [Google Scholar] [CrossRef]

- Pavlenko, N. An Assessment of the Policy Options for Driving Sustainable Aviation Fuels in the European Union. International Council on Clean Transportation. 2021. Available online: https://theicct.org/publication/an-assessment-of-the-policy-options-for-driving-sustainable-aviation-fuels-in-the-european-union/ (accessed on 16 April 2024).

- Prussi, M.; O’Connell, A.; Lonza, L. Analysis of current aviation biofuel technical production potential in EU28. Biomass Bioenergy 2019, 130, 105371. [Google Scholar] [CrossRef]

- Ng, K.S.; Farooq, D.; Yang, A. Global biorenewable development strategies for sustainable aviation fuel production. Renew. Sustain. Energy Rev. 2021, 150, 111502. [Google Scholar] [CrossRef]

- Gutiérrez-Antonio, C.; Gómez-Castro, F.I.; de Lira-Flores, J.A.; Hernández, S. A review on the production processes of renewable jet fuel. Renew. Sustain. Energy Rev. 2017, 79, 709–729. [Google Scholar] [CrossRef]

- O’Malley, J.; Pavlenko, N.; Hyun Kim, Y. Meeting the SAF Grand Challenge: Current and Future Measures to Increase U.S. Sustainable Aviation Fuel Production Capacity. International Council on Clean Transportation. 2023. Available online: https://theicct.org/publication/us-saf-production-capacity-nov23/ (accessed on 16 April 2024).

- Pavlenko, N.; Searle, S. Assessing the Sustainability Implications of Alternative Aviation Fuels. International Council on Clean Transportation. 2021. Available online: https://theicct.org/publication/assessing-the-sustainability-implications-of-alternative-aviation-fuels/ (accessed on 16 April 2024).

- Borrill, E.; Koh, S.C.L.; Yuan, R. Review of technological developments and LCA applications on biobased SAF conversion processes. Front. Fuels 2024, 2, 1397962. [Google Scholar] [CrossRef]

- Kandaramath Hari, T.; Yaakob, Z.; Binitha, N.N. Aviation biofuel from renewable resources: Routes, opportunities and challenges. Renew. Sustain. Energy Rev. 2015, 42, 1234–1244. [Google Scholar] [CrossRef]

- O’Malley, J.; Pavlenko, N. Leveraging EU Policies and Climate Ambition to Close the Cost Gap Between Conventional and Sustainable Aviation Fuels. International Council on Clean Transportation. 2022. Available online: https://theicct.org/publication/eu-fuels-aviation-cost-gap-safs-apr22/ (accessed on 16 April 2024).

- Rutherford, D.; Sola Zheng, X.; Graver, B.; Pavlenko, N. Potential Tankering Under an EU Sustainable Aviation Fuels Mandate. International Council on Clean Transportation. 2021. Available online: https://theicct.org/publication/potential-tankering-under-an-eu-sustainable-aviation-fuels-mandate/ (accessed on 16 April 2024).

- ICAO. SAF Conversion Processes. Available online: https://www.icao.int/environmental-protection/SAF/Pages/Conversion-processes.aspx (accessed on 16 April 2024).

- O’Connell, A.; Kousoulidou, M.; Lonza, L.; Weindorf, W. Considerations on GHG emissions and energy balances of promising aviation biofuel pathways. Renew. Sustain. Energy Rev. 2019, 101, 504–515. [Google Scholar] [CrossRef]

- IATA. Net Zero 2050: Sustainable Aviation Fuels. Available online: https://www.iata.org/en/iata-repository/pressroom/fact-sheets/fact-sheet-sustainable-aviation-fuels/ (accessed on 16 April 2024).

- Sher, F.; Raore, D.; Klemeš, J.J.; Rafi-ul-Shan, P.M.; Khzouz, M.; Marintseva, K.; Razmkhah, O. Unprecedented Impacts of Aviation Emissions on Global Environmental and Climate Change Scenario. Curr. Pollut. Rep. 2021, 7, 549–564. [Google Scholar] [CrossRef]

- Canovas, A.; Ehrenhaus, A.; Baldo, A.; Wessels, C.; Grassi, C.; Tracastro, M.; Andrade, O.; Cavalett, O.; Gangopadhyay, P.; Boyd, R. About the RSB. Available online: www.rsb.org (accessed on 1 January 2025).

- Deuber, R.d.S.; Bressanin, J.M.; Fernandes, D.S.; Guimarães, H.R.; Chagas, M.F.; Bonomi, A.; Fregolente, L.V.; Watanabe, M.D.B. Production of Sustainable Aviation Fuels from Lignocellulosic Residues in Brazil through Hydrothermal Liquefaction: Techno-Economic and Environmental Assessments. Energies 2023, 16, 2723. [Google Scholar] [CrossRef]

- López Gómez, M.; Posada, J.; Silva, V.; Martínez, L.; Mayorga, A.; Álvarez, O. Diagnosis of Challenges and Uncertainties for Implementation of Sustainable Aviation Fuel (SAF) in Colombia, and Recommendations to Move Forward. Energies 2023, 16, 5667. [Google Scholar] [CrossRef]

- Bauen, A.; Bitossi, N.; German, L.; Harris, A.; Leow, K. Sustainable aviation fuels status, challenges and prospects of drop-in liquid fuels, hydrogen and electrification in aviation. Johns. Matthey Technol. Rev. 2020, 64, 263–278. [Google Scholar] [CrossRef]

- Laurens, L.M.L.; Chen-Glasser, M.; McMillan, J.D. A perspective on renewable bioenergy from photosynthetic algae as feedstock for biofuels and bioproducts. Algal Res. 2017, 24, 261–264. [Google Scholar] [CrossRef]

- CAAFI. Fuel Qualifications. Available online: https://www.caafi.org/fuel-qualifications (accessed on 16 April 2024).

- Eswaran, S.; Subramaniam, S.; Geleynse, S.; Brandt, K.; Wolcott, M.; Zhang, X. Techno-economic analysis of catalytic hydrothermolysis pathway for jet fuel production. Renew. Sustain. Energy Rev. 2021, 151, 111516. [Google Scholar] [CrossRef]

- Peacock, J.; Cooper, R.; Waller, N.; Richardson, G. Decarbonising aviation at scale through synthesis of sustainable e-fuel: A techno-economic assessment. Int. J. Hydrogen Energy 2024, 50, 869–890. [Google Scholar] [CrossRef]

- Gonzalez-Garay, A.; Heuberger-Austin, C.; Fu, X.; Klokkenburg, M.; Zhang, D.; van der Made, A.; Shah, N. Unravelling the potential of sustainable aviation fuels to decarbonise the aviation sector. Energy Environ. Sci. 2022, 15, 3291–3309. [Google Scholar] [CrossRef]

- Graves, C.; Ebbesen, S.D.; Mogensen, M.; Lackner, K.S. Sustainable hydrocarbon fuels by recycling CO2 and H2O with renewable or nuclear energy. In Renewable and Sustainable Energy Reviews; Elsevier Ltd.: Amsterdam, The Netherlands, 2011; Volume 15, pp. 1–23. [Google Scholar] [CrossRef]

- Marques, L.; Vieira, M.; Condeço, J.; Sousa, H.; Henriques, C.; Mateus, M. Review of Power-to-Liquid (PtL) Technology for Renewable Methanol (e-MeOH): Recent Developments, Emerging Trends and Prospects for the Cement Plant Industry. Energies 2024, 17, 5589. [Google Scholar] [CrossRef]

- Braun, M.; Grimme, W.; Oesingmann, K. Pathway to net zero: Reviewing sustainable aviation fuels, environmental impacts and pricing. J. Air Transp. Manag. 2024, 117, 102580. [Google Scholar] [CrossRef]

- Schmidt, P.R.; Habersetzer, A.; Raksha, T. Power-to-Liquids-A Scalable and Sustainable Fuel Supply Perspective for Aviation. Available online: https://www.researchgate.net/publication/360561366 (accessed on 28 June 2025).

- Huber, D.; Birkelbach, F.; Hofmann, R. Unlocking the Potential of Synthetic Fuel Production: Coupled Optimization of Heat Exchanger Network and Operating Parameters of a 1 MW Power-to-Liquid Plant. Chem. Eng. Sci. 2023, 284, 119506. [Google Scholar] [CrossRef]

- Fraunhofer Institute for Solar Energy Systems ISE. Fraunhofer ISE Demonstrates Ultrafine Transport Layers for Electrolyzers. Available online: https://www.ise.fraunhofer.de/en/press-media/press-releases/2025/fraunhofer-ise-demonstrates-ultrafine-transport-layers-for-electrolyzers.html (accessed on 28 June 2025).

- Wang, W.-C.; Tao, L. Corrigendum to “Bio-jet fuel conversion technologies” [Renew Sustain Energy Rev 53 (2016) 801–822]. Renew. Sustain. Energy Rev. 2017, 79, 1556. [Google Scholar] [CrossRef]

- Undavalli, V.; Gbadamosi Olatunde, O.B.; Boylu, R.; Wei, C.; Haeker, J.; Hamilton, J.; Khandelwal, B. Recent advancements in sustainable aviation fuels. Prog. Aerosp. Sci. 2023, 136, 100876. [Google Scholar] [CrossRef]

- Aghamiri, A.R.; Lahijani, P. Catalytic conversion of biomass and plastic waste to alternative aviation fuels: A review. Biomass Bioenergy 2024, 183, 107120. [Google Scholar] [CrossRef]

- Dreszer, K.; Więcław-Solny, L. Produkcja Paliw Silnikowych z Węgla Poprzez Zgazowanie i Syntezę Fischera-Tropscha, Polityka Energetyczna, Tom 10. 2007. Available online: https://se.min-pan.krakow.pl/pelne_teksty21/K21_Dreszer-Wieclaw-Solny.pdf. (accessed on 16 April 2024).

- Goh, B.H.H.; Chong, C.T.; Ong, H.C.; Seljak, T.; Katrašnik, T.; Józsa, V.; Ng, J.-H.; Tian, B.; Karmarkar, S.; Ashokkumar, V. Recent advancements in catalytic conversion pathways for synthetic jet fuel produced from bioresources. Energy Convers. Manag. 2022, 251, 114974. [Google Scholar] [CrossRef]

- Shehab, M.; Moshammer, K.; Franke, M.; Zondervan, E. Analysis of the Potential of Meeting the EU’s Sustainable Aviation Fuel Targets in 2030 and 2050. Sustainability 2023, 15, 9266. [Google Scholar] [CrossRef]

- Ali, M.F.; Abbas, S. A review of methods for the demetallization of residual fuel oils. Fuel Process. Technol. 2006, 87, 573–584. [Google Scholar] [CrossRef]

- van Dyk, S.; Su, J.; Mcmillan, J.D.; Saddler, J. Potential synergies of drop-in biofuel production with further co-processing at oil refineries. Biofuels Bioprod. Biorefining 2019, 13, 760–775. [Google Scholar] [CrossRef]

- van Dyk, S.; Su, J.; Ebadian, M.; Saddler, J. Production of lower carbon-intensity fuels by co-processing biogenic feedstocks: Potential and challenges for refineries. Fuel 2022, 324, 124636. [Google Scholar] [CrossRef]

- Rumizen, M.A. Qualification of Alternative Jet Fuels. Front. Energy Res. 2021, 9, 760713. [Google Scholar] [CrossRef]

- Marszałek, N.; Lis, T. The future of sustainable aviation fuels. Combust. Engines 2022, 191, 29–40. [Google Scholar] [CrossRef]

- Drünert, S.; Neuling, U.; Zitscher, T.; Kaltschmitt, M. Power-to-Liquid fuels for aviation—Processes, resources and supply potential under German conditions. Appl. Energy 2020, 277, 115578. [Google Scholar] [CrossRef]

- Wang, M.; Yu, X. An Overview of the Sustainable Aviation Fuel: LCA, TEA, and the Sustainability Analysis. ICGA 2024 2024, 80, 3. [Google Scholar] [CrossRef]

- Rony, Z.I.; Mofijur, M.; Hasan, M.M.; Ahmed, S.F.; Almomani, F.; Rasul, M.G.; Jahirul, M.I.; Loke Show, P.; Kalam, M.A.; Mahlia, T.M.I. Unanswered issues on decarbonizing the aviation industry through the development of sustainable aviation fuel from microalgae. Fuel 2023, 334, 126553. [Google Scholar] [CrossRef]

- Kurzawska-Pietrowicz, P.; Jasiński, R. A review of alternative aviation fuels. Energies 2024, 17, 3890. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T. Impact of a Jet A-1/HEFA blend on the performance and emission characteristics of a miniature turbojet engine. Int. J. Environ. Sci. Technol. 2018, 15, 1501–1508. [Google Scholar] [CrossRef]

- Civil Aviation Authority of Poland. Report on Exhaust Emissions from Aircraft Engines. Available online: https://ulc.gov.pl/_download/informacje/emisja_spalin_z_silnikw_lotn.pdf (accessed on 12 January 2025).

- Tian, B.; Liu, A.; Chong, C.T.; Fan, L.; Ni, S.; Hull, A.; Rigopoulos, S.; Luo, K.H.; Hochgreb, S. Measurement and simulation of sooting characteristics by an ATJ-SKA biojet fuel and blends with Jet A-1 fuel in laminar non-premixed flames. Combust. Flame 2021, 233, 111582. [Google Scholar] [CrossRef]

- Song, Z.; Li, Z.; Liu, Z. Comparison of emission properties of sustainable aviation fuels and conventional aviation fuels: A review. Appl. Sci. 2024, 14, 5484. [Google Scholar] [CrossRef]

- Schürmann, G.; Schäfer, K.; Jahn, C.; Hoffmann, H.; Bauerfeind, M.; Fleuti, E.; Rappenglück, B. The impact of NOx, CO and VOC emissions on the air quality of Zurich airport. Atmos. Environ. 2007, 41, 103–118. [Google Scholar] [CrossRef]

- Rohkamp, M.; Rabl, A.; Bendla, J.; Neukirchen, C.; Saraji-Bozorgzad, M.R.; Helcig, C.; Hupfer, A.; Adam, T. Gaseous and particulate matter (PM) emissions from a turboshaft engine using different blends of sustainable aviation fuel (SAF). Aerosol Sci. Technol. 2025, 59, 111–126. [Google Scholar] [CrossRef]

- ICAO. Report on the Life Cycle Assessment Methodology of SAF Fuels Under CORSIA. Available online: https://www.icao.int/environmental-protection/CORSIA/Documents/CORSIA_Eligible_Fuels/ICAO%20document%2007%20-%20Methodology%20for%20Actual%20Life%20Cycle%20Emissions%20-%20October%202024.pdf (accessed on 12 January 2025).

- National Centre for Atmospheric Science (NCAS). Scientists Launch UK’s First Sustainable Aviation Fuel Emissions “Chase” Experiment. Available online: https://ncas.ac.uk/scientists-launch-uks-first-sustainable-aviation-fuel-emissions-chase-experiment/ (accessed on 12 January 2025).

- IEA Bioenergy Task 39. The Potential of Sustainable Aviation Fuels: Review of Emissions, Policies and Deployment Challenges. 2024. Available online: https://www.ieabioenergy.com/wp-content/uploads/2024/06/IEA-Bioenergy-Task-39-SAF-report.pdf (accessed on 12 January 2025).

- Harlass, J.; Voigt, C.; Bräuer, A.-S.; Zöger, M.; Dörnbrack, A. Emission Characteristics of SAF in an A350 Engine Test. EGUsphere. 2024. Available online: https://egusphere.copernicus.org/preprints/2024/egusphere-2024-454/ (accessed on 12 January 2025).

- Airbus. World’s First In-Flight Study of Commercial Aircraft Using 100% SAF. 2024. Available online: https://www.airbus.com/en/newsroom/press-releases/2024-06-worlds-first-in-flight-study-of-commercial-aircraft-using-100 (accessed on 12 January 2025).

- Clean Air Task Force (CATF). Contrails: The Climate Impact of Aircraft Particle Emissions and Opportunities for Reduction. 2025. Available online: https://cdn.catf.us/wp-content/uploads/2025/03/18113117/contrails-report.pdf (accessed on 12 January 2025).

- Roundtable on Sustainable Biomaterials (RSB). Non-CO2 Effects of Aviation and SAF’s Role in Mitigation: Final Report. 2024. Available online: https://rsb.org/wp-content/uploads/2024/05/24-5-24-final-report-rsb-non-co2.pdf (accessed on 12 January 2025).

- International Civil Aviation Organization (ICAO). Environmental Report 2025. 2025. Available online: https://www.icao.int/environmental-protection/Documents/EnvironmentalReports/2025/ICAO%20EnvReport%202025.pdf (accessed on 12 January 2025).

- Patyńska, R. Wskaźnik Emisji Metanu z Kopalń Węgla Kamiennego w Polsce, Instytut Gospodarki Surowcami Mineralnymi i Energią Polskiej Akademii Nauk. 2016. Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-1f61c980-b83d-407d-a84c-49e3a22d7452 (accessed on 16 April 2024).

- International Energy Agency. Understanding Methane Emissions. Available online: https://www.iea.org/reports/global-methane-tracker-2024/understanding-methane-emissions#abstract (accessed on 16 April 2024).

- Mannion, L.A.; Redington, C.; Kelly, M.; Bell, A.; Dooley, S. The effect of used cooking oil composition on the specific CO2 e emissions embodied in HEFA-SPK production. Biofuels Bioprod. Biorefining 2024, 18, 837–854. [Google Scholar] [CrossRef]

- Chen, P.H.; Lee, U.; Liu, X.; Cai, H.; Wang, M. Life-cycle analysis of sustainable aviation fuel production through catalytic hydrothermolysis. Biofuels Bioprod. Biorefining 2023, 18, 42–54. [Google Scholar] [CrossRef]

- Antosz, A.; Syrek, H. Emisje gazów cieplarnianych w procesach wydobycia i transportu ropy naftowej. Nafta-Gaz 2012, 68, 233–240. [Google Scholar]

- ICAO. Corsia Eligible Fuels. Available online: https://www.icao.int/environmental-protection/CORSIA/Documents/CORSIA_Eligible_Fuels/ICAO%20document%2006%20-%20Default%20Life%20Cycle%20Emissions%20-%20October%202024.pdf (accessed on 16 April 2024).

- Oehmichen, K.; Majer, S.; Müller-Langer, F.; Thrän, D. Comprehensive LCA of biobased sustainable aviation fuels and JET A-1 multiblend. Altern. Fuels Transp. Recent Adv. Future Chall. 2022, 12, 3372. [Google Scholar] [CrossRef]

- Hasan, M.M.F.; First, E.L.; Boukouvala, F.; Floudas, C.A. A multi-scale framework for CO2 capture, utilization, and sequestration: CCUS and CCU. Comput. Chem. Eng. 2015, 81, 2–21. [Google Scholar] [CrossRef]

- Abrantes, I.; Ferreira, A.F.; Silva, A.; Costa, M. Sustainable aviation fuels and imminent technologies—CO2 emissions evolution towards 2050. J. Clean. Prod. 2021, 313, 127937. [Google Scholar] [CrossRef]

- Díaz-Pérez, M.A.; Serrano-Ruiz, J.C. Catalytic production of jet fuels from biomass. Molecules 2020, 25, 802. [Google Scholar] [CrossRef]

- Wang, B.; Ting, Z.J.; Zhao, M. Sustainable aviation fuels: Key opportunities and challenges in lowering carbon emissions for aviation industry. Carbon Capture Sci. Technol. 2024, 13, 100263. [Google Scholar] [CrossRef]

- Mathanker, A.; Das, S.; Pudasainee, D.; Khan, M.; Kumar, A.; Gupta, R. A review of hydrothermal liquefaction of biomass for biofuels production with a special focus on the effect of process parameters, co-solvents and extraction solvents. Energies 2021, 14, 4916. [Google Scholar] [CrossRef]

- Al-Rumaihi, A.; Shahbaz, M.; Mckay, G.; Mackey, H.; Al-Ansari, T. A review of pyrolysis technologies and feedstock: A blending approach for plastic and biomass towards optimum biochar yield. Renew. Sustain. Energy Rev. 2022, 167, 112715. [Google Scholar] [CrossRef]

- Damiri, A.P.; Stamatakis, E.; Bellas, S.; Zoulias, M.; Mitkidis, G.; Anastasiadis, A.G.; Karellas, S.; Tzamalis, G.; Stubos, A.; Tsoutsos, T. A Review of Alternative Processes for Green Hydrogen Production Focused on Generating Hydrogen from Biomass. Hydrogen 2024, 5, 163–184. [Google Scholar] [CrossRef]

- Renewable Energy Agency. Reaching Zero with Renewables: Biojet Fuels. 2021. Available online: www.irena.org (accessed on 12 January 2025).

- Singh, H.; Li, C.; Cheng, P.; Wang, X.; Liu, Q. A critical review of technologies, costs, and projects for production of carbon-neutral liquid e-fuels from hydrogen and captured CO2. Energy Adv. 2022, 1, 580–605. [Google Scholar] [CrossRef]

- Khalil, Y.F. A Comparative Science-Based Viability Assessment Among Current and Emerging Hydrogen Production Technologies. Appl. Sci. 2025, 15, 497. [Google Scholar] [CrossRef]

- Collis, J.; Duch, K.; Schomäcker, R. Techno-economic assessment of jet fuel production using the Fischer-Tropsch process from steel mill gas. Front. Energy Res. 2022, 10, 1049229. [Google Scholar] [CrossRef]

- Tzanetis, K.F.; Posada, J.A.; Ramirez, A. Analysis of biomass hydrothermal liquefaction and biocrude-oil upgrading for renewable jet fuel production: The impact of reaction conditions on production costs and GHG emissions performance. Renew. Energy 2017, 113, 1388–1398. [Google Scholar] [CrossRef]

- Suntivarakorn, R.; Treedet, W.; Singbua, P.; Teeramaetawat, N. Fast pyrolysis from Napier grass for pyrolysis oil production by using circulating Fluidized Bed Reactor: Improvement of pyrolysis system and production cost. Energy Rep. 2018, 4, 565–575. [Google Scholar] [CrossRef]

- Frieden, F.; Leker, J. Future costs of hydrogen: A quantitative review. Sustain. Energy Fuels 2024, 8, 1806–1822. [Google Scholar] [CrossRef]

- Yue, M.; Lambert, H.; Pahon, E.; Roche, R.; Jemei, S.; Hissel, D. Hydrogen energy systems: A critical review of technologies, applications, trends and challenges. Renew. Sustain. Energy Rev. 2021, 146, 111180. [Google Scholar] [CrossRef]

- Sánchez-Bastardo, N.; Schlögl, R.; Ruland, H. Methane Pyrolysis for Zero-Emission Hydrogen Production: A Potential Bridge Technology from Fossil Fuels to a Renewable and Sustainable Hydrogen Economy. Ind. Eng. Chem. Res. 2021, 60, 11855–11881. [Google Scholar] [CrossRef]

- Li, M.; Ji, W.; Huang, C.; Si, X.; Liu, Q.; Lu, R.; Lu, T. A Review on Green Hydrogen Production by Aqueous Phase Reforming of Lignocellulose and Derivatives. Catalysts 2025, 15, 280. [Google Scholar] [CrossRef]

- van Dyk, S.; Saddler, J. Progress in Commercialization of Biojet/Sustainable Aviation Fuels (SAF): Technologies and policies IEA Bioenergy Task 39 Progress in Commercialization of Biojet/Sustainable Aviation Fuels (SAF): Technologies and policies Published by IEA Bioenergy Published by IEA Bioenergy. 2024. Available online: https://www.iata.org/en/pressroom/2023-releases/2023-06-04-03/ (accessed on 12 January 2025).

- Mathimani, T.; Baldinelli, A.; Rajendran, K.; Prabakar, D.; Matheswaran, M.; Pieter van Leeuwen, R.; Pugazhendhi, A. Review on cultivation and thermochemical conversion of microalgae to fuels and chemicals: Process evaluation and knowledge gaps. J. Clean. Prod. 2019, 208, 1053–1064. [Google Scholar] [CrossRef]

- Hydrogen Fact Sheet—Hydrogen Production—Steam Methane Reforming (SMR). Available online: https://www.amiqweb.es/app/download/9343795/6hydrogenproductionsteammethanereforming.pdf (accessed on 12 January 2025).

- Alizadeh, S.M.; Khalili, Y.; Ahmadi, M. Comprehensive Review of Carbon Capture and Storage Integration in Hydrogen Production: Opportunities, Challenges, and Future Perspectives. Energies 2024, 17, 5330. [Google Scholar] [CrossRef]

- Ahmad Kamaroddin, M.F.; Sabli, N.; Tuan Abdullah, T.A.; Siajam, S.I.; Abdullah, L.C.; Abdul Jalil, A.; Ahmad, A. Membrane-based electrolysis for hydrogen production: A review. Membranes 2021, 11, 810. [Google Scholar] [CrossRef]

- Moghaddam, A.L.; Hejazi, S.; Fattahi, M.; Kibria, M.G.; Thomson, M.J.; AlEisa, R.; Khan, M.A. Methane pyrolysis for hydrogen production: Navigating the path to a net zero future. Energy and Environmental Science. R. Soc. Chem. 2025, 18, 2747–2790. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klimczyk, W.; Jasiński, R.; Niklas, J.; Siedlecki, M.; Ziółkowski, A. Sustainable Aviation Fuels: A Comprehensive Review of Production Pathways, Environmental Impacts, Lifecycle Assessment, and Certification Frameworks. Energies 2025, 18, 3705. https://doi.org/10.3390/en18143705

Klimczyk W, Jasiński R, Niklas J, Siedlecki M, Ziółkowski A. Sustainable Aviation Fuels: A Comprehensive Review of Production Pathways, Environmental Impacts, Lifecycle Assessment, and Certification Frameworks. Energies. 2025; 18(14):3705. https://doi.org/10.3390/en18143705

Chicago/Turabian StyleKlimczyk, Weronika, Remigiusz Jasiński, Jakub Niklas, Maciej Siedlecki, and Andrzej Ziółkowski. 2025. "Sustainable Aviation Fuels: A Comprehensive Review of Production Pathways, Environmental Impacts, Lifecycle Assessment, and Certification Frameworks" Energies 18, no. 14: 3705. https://doi.org/10.3390/en18143705

APA StyleKlimczyk, W., Jasiński, R., Niklas, J., Siedlecki, M., & Ziółkowski, A. (2025). Sustainable Aviation Fuels: A Comprehensive Review of Production Pathways, Environmental Impacts, Lifecycle Assessment, and Certification Frameworks. Energies, 18(14), 3705. https://doi.org/10.3390/en18143705