Digital Twin for Energy-Intelligent Bakery Operations: Concepts and Applications

Abstract

1. Introduction

- RQ1: How can digital twins optimize energy-intensive bakery operations?

- RQ2: What technological and organizational barriers limit DT adoption in bakeries?

2. Energy Consumption and Hurdles in the Bakery Industry

2.1. Energy Demand and Consumption in the Bakery Industry

2.2. Inefficiencies and Challenges

3. Digital Twin for Energy Management in Bakery Industries

3.1. Industrial Applications of DT Technology

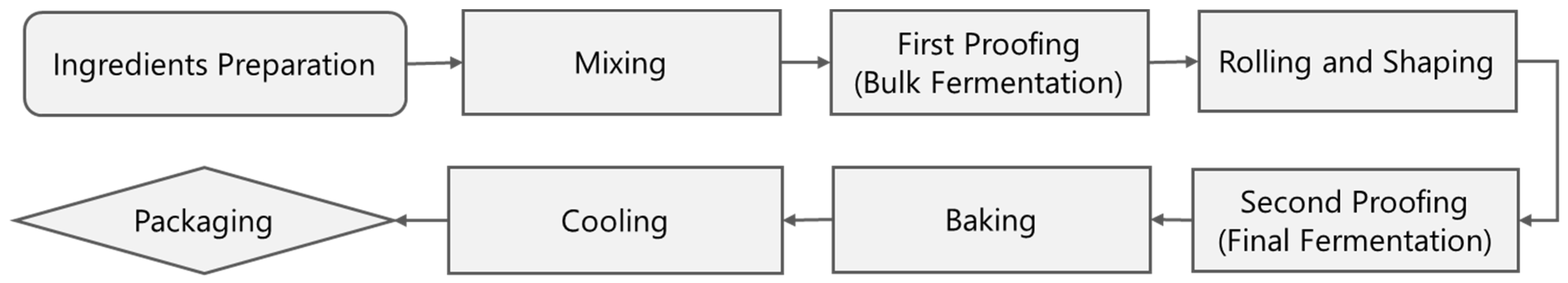

3.2. Adaptation of Digital Twin in Bakery Operations

3.3. Real-Time Monitoring and Predictive Maintenance

3.4. Renewable Integration and Energy Optimization

3.5. Power Converters and Their Role in Digital Twin-Based Energy Management Systems

3.6. Cross-Sector Insights

4. Intelligent Energy Control in Bakeries with Digital Twins

4.1. Bakery Energy System Modeling

4.2. Baking Process Optimization

4.3. Predictive Fault Detection and Maintenance

4.4. Waste Heat Recovery Management

4.5. Sustainable Smart Bakeries

5. Improvements, Challenges, and Future Perspectives

5.1. Digital Twin-Driven Improvements

5.2. Adoption Constraints

5.2.1. Technical Barriers

5.2.2. Organizational and Operational Challenges

5.3. Future Research Directions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Marechal, F.; Muller, D. Energy Management Methods for the Food Industry. In Handbook of Water and Energy Management in Food Processing; Elsevier Inc.: Amsterdam, The Netherlands, 2008; pp. 221–255. ISBN 978-184569467-8. [Google Scholar]

- Muller, D.C.A.; Marechal, F.M.A.; Wolewinski, T.; Roux, P.J. An Energy Management Method for the Food Industry. Appl. Therm. Eng. 2007, 27, 2677–2686. [Google Scholar] [CrossRef]

- Briatore, F.; Russo, M.L. Literature Review on AI for Energy Forecasting. In Proceedings of the 2024 4th International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Male, Maldives, 4–6 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Melesse, T.Y.; Orrù, P.F. The Digital Revolution in the Bakery Sector: Innovations, Challenges, and Opportunities from Industry 4.0. Foods 2025, 14, 526. [Google Scholar] [CrossRef] [PubMed]

- Melesse, T.Y.; Di Pasquale, V.; Riemma, S. Digital Twin Models in Industrial Operations: State-of-the-Art and Future Research Directions. IET Collab. Intell. Manuf. 2021, 3, 37–47. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Franciosi, C.; Di Pasquale, V.; Riemma, S. Analyzing the Implementation of Digital Twins in the Agri-Food Supply Chain. Logistics 2023, 7, 33. [Google Scholar] [CrossRef]

- Javaid, M. Digital Twin Applications toward Industry 4.0: A Review. Cogn. Robot. 2023, 3, 71–92. [Google Scholar] [CrossRef]

- Ismail, F.B.; Al-Faiz, H.; Hasini, H.; Al-Bazi, A.; Kazem, H.A. A Comprehensive Review of the Dynamic Applications of the Digital Twin Technology across Diverse Energy Sectors. Energy Strategy Rev. 2024, 52, 101334. [Google Scholar] [CrossRef]

- Olu-Ajayi, R.; Alaka, H.; Owolabi, H.; Akanbi, L.; Ganiyu, S. Data-Driven Tools for Building Energy Consumption Prediction: A Review. Energies 2023, 16, 2574. [Google Scholar] [CrossRef]

- You, M. Digital Twins Based Day-Ahead Integrated Energy System Scheduling under Load and Renewable Energy Uncertainties. Appl. Energy 2022, 305, 117899. [Google Scholar] [CrossRef]

- Hashmi, R.; Liu, H.; Yavari, A. Digital Twins for Enhancing Efficiency and Assuring Safety in Renewable Energy Systems: A Systematic Literature Review. Energies 2024, 17, 2456. [Google Scholar] [CrossRef]

- Ma, S. Digital Twin and Big Data-Driven Sustainable Smart Manufacturing Based on Information Management Systems for Energy-Intensive Industries. Appl. Energy 2022, 326, 119986. [Google Scholar] [CrossRef]

- Li, H. Data-Driven Hybrid Petri-Net Based Energy Consumption Behaviour Modelling for Digital Twin of Energy-Efficient Manufacturing System. Energy 2022, 239, 122178. [Google Scholar] [CrossRef]

- Awouda, A.; Traini, E.; Bruno, G.; Chiabert, P. IoT-Based Framework for Digital Twins in the Industry 5.0 Era. Sensors 2024, 24, 594. [Google Scholar] [CrossRef]

- Barata, J. How Will the Digital Twin Shape the Future of Industry 5.0? Technovation 2024, 134, 103025. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Pasquale, V.D.; Riemma, S. Digital Twin Models in Industrial Operations: A Systematic Literature Review. Procedia Manuf. 2020, 42, 267–272. [Google Scholar] [CrossRef]

- Qiao, J.; Zhang, M.; Qiu, L.; Mujumdar, A.S.; Ma, Y. Visual Early Warning and Prediction of Fresh Food Quality Deterioration: Research Progress and Application in Supply Chain. Food Biosci. 2024, 58, 103671. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Bollo, M.; Di Pasquale, V.; Riemma, S. Digital Twin for Inventory Planning of Fresh Produce. IFAC-Pap. 2022, 55, 2743–2748. [Google Scholar] [CrossRef]

- Wang, Y.; Li, K.; Gan, S.; Cameron, C. Analysis of Energy Saving Potentials in Intelligent Manufacturing: A Case Study of Bakery Plants. Energy 2019, 172, 477–486. [Google Scholar] [CrossRef]

- Therkelsen, P.; Masanet, E.; Worrell, E. Energy Efficiency Opportunities in the U.S. Commercial Baking Industry. J. Food Eng. 2014, 130, 14–22. [Google Scholar] [CrossRef]

- Darehshouri, S.; Michelsen, N.; Schüth, C.; Schulz, S. A Low-cost Environmental Chamber to Simulate Warm Climatic Conditions. Vadose Zone J. 2020, 19, e20023. [Google Scholar] [CrossRef]

- Ben Othman, F.; Maurel, A.; Delattaignant, S.; Roque, M.; Louis Alexandre, A.; Roque, C. Study of a New Humidifier Configuration Designed for Climatic Chambers. Build. Environ. 2023, 242, 110463. [Google Scholar] [CrossRef]

- Zhuang, L.; Chen, X.; Guan, X. A Decentralized Method for Energy Conservation of an HVAC System. Build. Simul. 2020, 13, 155–170. [Google Scholar] [CrossRef]

- Ureta, M.M.; Goñi, S.M.; Salvadori, V.O.; Olivera, D.F. Energy Requirements during Sponge Cake Baking: Experimental and Simulated Approach. Appl. Therm. Eng. 2017, 115, 637–643. [Google Scholar] [CrossRef]

- Le-bail, A.; Dessev, T.; Jury, V.; Zuniga, R.; Park, T.; Pitroff, M. Energy Demand for Selected Bread Making Processes: Conventional versus Part Baked Frozen Technologies. J. Food Eng. 2010, 96, 510–519. [Google Scholar] [CrossRef]

- Davidson, I. Oven Efficiency. In Biscuit Baking Technology; Elsevier: Amsterdam, The Netherlands, 2016; pp. 253–267. ISBN 978-0-12-804211-3. [Google Scholar]

- Mukherjee, S.; Asthana, A.; Howarth, M.; Mcneill, R.; Frisby, B. Achieving Operational Excellence for Industrial Baking Ovens. Energy Procedia 2019, 161, 395–402. [Google Scholar] [CrossRef]

- Mumith, J.-A.; Makatsoris, C.; Karayiannis, T.G. Design of a Thermoacoustic Heat Engine for Low Temperature Waste Heat Recovery in Food Manufacturing. Appl. Therm. Eng. 2014, 65, 588–596. [Google Scholar] [CrossRef]

- Ríos-Fernández, J.C. Thermoeconomic Analysis of the IWERS System for Steam Heat Recovery from Bakery Ovens. Energy Sci. Eng. 2024, 12, 2852–2863. [Google Scholar] [CrossRef]

- Mukherjee, S.; Asthana, A.; Howarth, M.; Mcniell, R. Waste Heat Recovery from Industrial Baking Ovens. Energy Procedia 2017, 123, 321–328. [Google Scholar] [CrossRef]

- Papasidero, D.; Corbetta, M.; Pierucci, S.; Pirola, C.; Manenti, F. Studying Oven Technology towards the Energy Consumption Optimisation for the Baking Process. Chem. Eng. Trans. 2015, 45, 481–486. [Google Scholar] [CrossRef]

- Siddique, A.R.M. Phase Change Material-Enhanced Solid-State Thermoelectric Cooling Technology for Food Refrigeration and Storage Applications. J. Energy Storage 2023, 60, 106569. [Google Scholar] [CrossRef]

- Alassafi, H.T.; Al-Gahtani, K.S.; Almohsen, A.S.; Alsugair, A.M. HVAC Maintainability Risks in Healthcare Facilities: A Design Optimization Perspective. Facilities 2024, 42, 30–52. [Google Scholar] [CrossRef]

- Briceño-León, M.; Pazmiño-Quishpe, D.; Clairand, J.-M.; Escrivá-Escrivá, G. Energy Efficiency Measures in Bakeries toward Competitiveness and Sustainability—Case Studies in Quito, Ecuador. Sustainability 2021, 13, 5209. [Google Scholar] [CrossRef]

- Jouhara, H. Waste Heat Recovery Technologies and Applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Gan, S.; Li, K.; Wang, Y.; Cameron, C. IoT Based Energy Consumption Monitoring Platform for Industrial Processes. In Proceedings of the 2018 UKACC 12th International Conference on Control (CONTROL), Sheffield, UK, 5–7 September 2018. [Google Scholar]

- Costa, D.D.D.; Mehl, V.O.; Taborda Aguiar, F.R. Real-Time Assessment of the Overall Effectiveness of Legacy Machine Tools. Prod. Eng. 2024, 18, 983–996. [Google Scholar] [CrossRef]

- Jagadeesh Kannan, R. International Virtual Conference on Industry 4.0: Select Proceedings of IVCI4.0 2020; Lecture Notes in Electrical Engineering Series; Springer Singapore Pte. Limited: Singapore, 2021; ISBN 978-981-16-1244-2. [Google Scholar]

- Feng, Q.; Zhang, Y.; Sun, B.; Guo, X.; Fan, D.; Ren, Y.; Song, Y.; Wang, Z. Multi-Level Predictive Maintenance of Smart Manufacturing Systems Driven by Digital Twin: A Matheuristics Approach. J. Manuf. Syst. 2023, 68, 443–454. [Google Scholar] [CrossRef]

- Melesse, T.Y. Digital Twin-Based Applications in Crop Monitoring. Heliyon 2025, 11, e42137. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Aslam, S.; Wileman, A.; Perinpanayagam, S. Digital Twin in Aerospace Industry: A Gentle Introduction. IEEE Access 2022, 10, 9543–9562. [Google Scholar] [CrossRef]

- Liu, S.; Bao, J.; Lu, Y.; Li, J.; Lu, S.; Sun, X. Digital Twin Modeling Method Based on Biomimicry for Machining Aerospace Components. J. Manuf. Syst. 2021, 58, 180–195. [Google Scholar] [CrossRef]

- Ferrari, A.; Willcox, K. Digital Twins in Mechanical and Aerospace Engineering. Nat. Comput. Sci. 2024, 4, 178–183. [Google Scholar] [CrossRef]

- Deng, S.; Ling, L.; Zhang, C.; Li, C.; Zeng, T.; Zhang, K.; Guo, G. A Systematic Review on the Current Research of Digital Twin in Automotive Application. Internet Things Cyber-Phys. Syst. 2023, 3, 180–191. [Google Scholar] [CrossRef]

- Mendi, A.F. A Digital Twin Case Study on Automotive Production Line. Sensors 2022, 22, 6963. [Google Scholar] [CrossRef]

- Ghenai, C.; Husein, L.A.; Al Nahlawi, M.; Hamid, A.K.; Bettayeb, M. Recent Trends of Digital Twin Technologies in the Energy Sector: A Comprehensive Review. Sustain. Energy Technol. Assess. 2022, 54, 102837. [Google Scholar] [CrossRef]

- Qayyum, F.; Alkanhel, R.; Muthanna, A. Maximizing Efficiency in Energy Trading Operations through IoT-Integrated Digital Twins. Sensors 2023, 23, 9656. [Google Scholar] [CrossRef] [PubMed]

- Bahramnia, P.; Hosseini Rostami, S.M.; Wang, J.; Kim, G. Modeling and Controlling of Temperature and Humidity in Building Heating, Ventilating, and Air Conditioning System Using Model Predictive Control. Energies 2019, 12, 4805. [Google Scholar] [CrossRef]

- Chung, M.H.; Yang, Y.K.; Lee, K.H.; Lee, J.H.; Moon, J.W. Application of Artificial Neural Networks for Determining Energy-Efficient Operating Set-Points of the VRF Cooling System. Build. Environ. 2017, 125, 77–87. [Google Scholar] [CrossRef]

- Arena, S.; Florian, E.; Zennaro, I.; Orrù, P.F.; Sgarbossa, F. A Novel Decision Support System for Managing Predictive Maintenance Strategies Based on Machine Learning Approaches. Saf. Sci. 2022, 146, 105529. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Peer, M.S.; Melesse, T.Y.; Orrù, P.F.; Braggio, M.; Petrollese, M. Next-Generation CSP: The Synergy of Nanofluids and Industry 4.0 for Sustainable Solar Energy Management. Energies 2025, 18, 2083. [Google Scholar] [CrossRef]

- Peer, M.S.; Cascetta, M.; Migliari, L.; Petrollese, M. Nanofluids in Thermal Energy Storage Systems: A Comprehensive Review. Energies 2025, 18, 707. [Google Scholar] [CrossRef]

- Abrazeh, S.; Mohseni, S.-R.; Zeitouni, M.J.; Parvaresh, A.; Fathollahi, A.; Gheisarnejad, M.; Khooban, M.-H. Virtual Hardware-in-the-Loop FMU Co-Simulation Based Digital Twins for Heating, Ventilation, and Air-Conditioning (HVAC) Systems. IEEE Trans. Emerg. Top. Comput. Intell. 2023, 7, 65–75. [Google Scholar] [CrossRef]

- Deshmukh, B.B.; Athavale, V.A.; Vernekar, A.R.; Katkar, Y.R.; Jahagirdar, A.K.; Waghmare, Y.C.; Salunkhe, S.; Gawade, S. Development of a Digital Twin of Heat Energy Storage and Retrieval System for Performance Evaluation through AR-Based Simulation. Cyber-Phys. Syst. 2024, 10, 231–246. [Google Scholar] [CrossRef]

- Ramasamy, S.; Sivasubramaniyam, V.; Gatto, G.; Kumar, A. DC Link Voltage Control Based Energy Management Strategy for Standalone Solar PV Fed Hybrid System. In Proceedings of the 2023 AEIT International Conference on Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Modena, Italy, 17–19 July 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Thangapandi, A.K.; Kumar, A.; Karthigeyan, D.; Ramasamy, S.; Arumugam, V.; Gatto, G. A Novel Artificial Neural Network Based Selection Harmonic Reduction Technique for Single Source Fed High Gain Switched Capacitor Coupled Multilevel Inverter for Renewable Energy Applications. Heliyon 2024, 10, e38550. [Google Scholar] [CrossRef] [PubMed]

- Sivasubramaniyam, V.; Ramasamy, S.; Karthikeyan, V.; Losito, M.; Gatto, G. Review on Environmental and Mobility Applications Based Real-Time Sensors. Discov. Appl. Sci. 2025, 7, 302. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Z.; Karamanakos, P.; Rodriguez, J. Digital Twin Techniques for Power Electronics-Based Energy Conversion Systems: A Survey of Concepts, Application Scenarios, Future Challenges, and Trends. IEEE Ind. Electron. Mag. 2023, 17, 20–36. [Google Scholar] [CrossRef]

- Lei, Z.; Zhou, H.; Dai, X.; Hu, W.; Liu, G.-P. Digital Twin Based Monitoring and Control for DC-DC Converters. Nat. Commun. 2023, 14, 5604. [Google Scholar] [CrossRef]

- Wunderlich, A.; Santi, E. Digital Twin Models of Power Electronic Converters Using Dynamic Neural Networks. In Proceedings of the 2021 IEEE Applied Power Electronics Conference and Exposition (APEC), Phoenix, AZ, USA, 14–17 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 2369–2376. [Google Scholar]

- Diz, S.D.L.; López, R.M.; Sánchez, F.J.R.; Llerena, E.D.; Peña, E.J.B. A Real-Time Digital Twin Approach on Three-Phase Power Converters Applied to Condition Monitoring. Appl. Energy 2023, 334, 120606. [Google Scholar] [CrossRef]

- Henrichs, E.; Noack, T.; Piedrahita, A.M.P.; Salem, M.A.; Stolz, J.; Krupitzer, C. Can a Byte Improve Our Bite? An Analysis of Digital Twins in the Food Industry. Sensors 2022, 22, 115. [Google Scholar] [CrossRef]

- Koulouris, A.; Misailidis, N.; Petrides, D. Applications of Process and Digital Twin Models for Production Simulation and Scheduling in the Manufacturing of Food Ingredients and Products. Food Bioprod. Process. 2021, 126, 317–333. [Google Scholar] [CrossRef]

- Paton, J.; Khatir, Z.; Thompson, H.; Kapur, N.; Toropov, V. Thermal Energy Management in the Bread Baking Industry Using a System Modelling Approach. Appl. Therm. Eng. 2013, 53, 340–347. [Google Scholar] [CrossRef]

- Khan, I.H.; Sablani, S.S.; Nayak, R.; Gu, Y. Machine Learning-based Modeling in Food Processing Applications: State of the Art. Comp. Rev. Food Sci. Food Safe 2022, 21, 1409–1438. [Google Scholar] [CrossRef]

- Isleroglu, H.; Beyhan, S. Prediction of Baking Quality Using Machine Learning Based Intelligent Models. Heat. Mass. Transfer 2020, 56, 2045–2055. [Google Scholar] [CrossRef]

- Yang, R.; Wang, Z.; Chen, J. 3-D Geometric Design of Microwaveable Food Products for Optimal Heating Uniformity Based on Machine Learning-Supervised Multiphysics Models. Food Bioprod. Process. 2024, 147, 393–405. [Google Scholar] [CrossRef]

- Chen, K.; Zhu, X.; Anduv, B.; Jin, X.; Du, Z. Digital Twins Model and Its Updating Method for Heating, Ventilation and Air Conditioning System Using Broad Learning System Algorithm. Energy 2022, 251, 124040. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital Twin-Enabled Anomaly Detection for Built Asset Monitoring in Operation and Maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Gomaa, A. Digital Twins for Improving Proactive Maintenance Management. Eng. Sci. 2024, 9, 60–70. [Google Scholar] [CrossRef]

- Kasper, L.; Schwarzmayr, P.; Birkelbach, F.; Javernik, F.; Schwaiger, M.; Hofmann, R. A Digital Twin-Based Adaptive Optimization Approach Applied to Waste Heat Recovery in Green Steel Production: Development and Experimental Investigation. Appl. Energy 2024, 353, 122192. [Google Scholar] [CrossRef]

- Bassey, K.E.; Opoku-Boateng, J.; Antwi, B.O.; Ntiakoh, A. Economic Impact of Digital Twins on Renewable Energy Investments. Eng. Sci. Technol. J. 2024, 5, 2232–2247. [Google Scholar] [CrossRef]

- Belik, M.; Rubanenko, O. Implementation of Digital Twin for Increasing Efficiency of Renewable Energy Sources. Energies 2023, 16, 4787. [Google Scholar] [CrossRef]

- Arsiwala, A.; Elghaish, F.; Zoher, M. Digital Twin with Machine Learning for Predictive Monitoring of CO2 Equivalent from Existing Buildings. Energy Build. 2023, 284, 112851. [Google Scholar] [CrossRef]

- Elghaish, F.; Matarneh, S.; Hosseini, M.R.; Tezel, A.; Mahamadu, A.-M.; Taghikhah, F. Predictive Digital Twin Technologies for Achieving Net Zero Carbon Emissions: A Critical Review and Future Research Agenda. SASBE 2024. [Google Scholar] [CrossRef]

- Verboven, P.; Defraeye, T.; Datta, A.K.; Nicolai, B. Digital Twins of Food Process Operations: The next Step for Food Process Models? Curr. Opin. Food Sci. 2020, 35, 79–87. [Google Scholar] [CrossRef]

- Brix Skovgaard, A. Digital Twins of Baking Ovens—For Design, Development, Management & Optimisation. Available online: https://forcetechnology.com/en/cases/haas-meincke-digital-twins-baking-ovens (accessed on 5 April 2025).

- Siemens. From Bean to Bar—For the Bakery and Confectionery Industry. Available online: https://www.siemens.com/us/en/industries/food-beverage/bakery-and-confectionery.html (accessed on 12 June 2025).

- Purlis, E. Digital Twin Methodology in Food Processing: Basic Concepts and Applications. Curr. Nutr. Rep. 2024, 13, 914–920. [Google Scholar] [CrossRef] [PubMed]

- Abdurrahman, E.E.M.; Ferrari, G. Digital Twin Applications in the Food Industry: A Review. Front. Sustain. Food Syst. 2025, 9, 1538375. [Google Scholar] [CrossRef]

- Keatley, R. The Use of COMSOL Multiphysics® in the Food Industry. Available online: https://www.comsol.com/blogs/the-use-of-comsol-multiphysics-in-the-food-industry#:~:text=With%20the%20COMSOL%20Multiphysics%C2%AE,in%20one%20intuitive%20software%20environment (accessed on 12 June 2025).

- Melesse, T.Y.; Di Pasquale, V.; Riemma, S. Recent Advances of Digital Twin Application in Agri-Food Supply Chain. In Enterprise Interoperability X; Rodríguez-Rodríguez, R., Ducq, Y., Leon, R., Romero, D., Eds.; Proceedings of the I-ESA Conferences Series; Springer: Cham, Switzerland, 2024; Volume 11, pp. 147–157. [Google Scholar]

- Hassani, H.; Huang, X.; MacFeely, S. Enabling Digital Twins to Support the UN SDGs. BDCC 2022, 6, 115. [Google Scholar] [CrossRef]

- Liu, J.; Cao, X.; Zhou, H.; Li, L.; Liu, X.; Zhao, P.; Dong, J. A Digital Twin-Driven Approach towards Traceability and Dynamic Control for Processing Quality. Adv. Eng. Inform. 2021, 50, 101395. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Elia, V.; Gnoni, M.G. A Classification Proposal of Digital Twin Applications in the Safety Domain. Comput. Ind. Eng. 2021, 154, 107137. [Google Scholar] [CrossRef]

- Yu, W. Energy Digital Twin Technology for Industrial Energy Management: Classification, Challenges and Future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Banyai, K.; Kovacs, L. Identification of Influence of Digital Twin Technologies on Production Systems: A Return on Investment-Based Approach. EEJET 2023, 4, 66–78. [Google Scholar] [CrossRef]

- Lampropoulos, G.; Larrucea, X.; Colomo-Palacios, R. Digital Twins in Critical Infrastructure. Information 2024, 15, 454. [Google Scholar] [CrossRef]

- Iranshahi, K.; Brun, J.; Arnold, T.; Sergi, T.; Müller, U.C. Digital Twins: Recent Advances and Future Directions in Engineering Fields. Intell. Syst. Appl. 2025, 26, 200516. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling Technologies and Tools for Digital Twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Bing, Z.; Enyan, M.; Amu-Darko, J.N.O.; Issaka, E.; Hongyu, L.; Junsen, R.; Xinxing, Z. Digital Twin on Concepts, Enabling Technologies, and Applications. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 420. [Google Scholar] [CrossRef]

- Guikema, S.; Flage, R. Digital Twins as a Security Risk? Risk Anal. 2025, 45, 269–273. [Google Scholar] [CrossRef]

- Jeremiah, S.R.; El Azzaoui, A.; Xiong, N.N.; Park, J.H. A Comprehensive Survey of Digital Twins: Applications, Technologies and Security Challenges. J. Syst. Archit. 2024, 151, 103120. [Google Scholar] [CrossRef]

- Alcaraz, C.; Lopez, J. Digital Twin: A Comprehensive Survey of Security Threats. IEEE Commun. Surv. Tutorials 2022, 24, 1475–1503. [Google Scholar] [CrossRef]

- Hrischev, R.; Shakev, N. Using of Digital Twin Technology on the Stages of Implementation of ERP Systems. In Proceedings of the 2024 IEEE 12th International Conference on Intelligent Systems (IS), Varna, Bulgaria, 29–31 August 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Kober, C.; Medina, F.G.; Benfer, M.; Wulfsberg, J.P.; Martinez, V.; Lanza, G. Digital Twin Stakeholder Communication: Characteristics, Challenges, and Best Practices. Comput. Ind. 2024, 161, 104135. [Google Scholar] [CrossRef]

- Goodwin, T.; Xu, J.; Celik, N.; Chen, C.-H. Real-Time Digital Twin-Based Optimization with Predictive Simulation Learning. J. Simul. 2024, 18, 47–64. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Bollo, M.; Pasquale, V.D.; Centro, F.; Riemma, S. Machine Learning-Based Digital Twin for Monitoring Fruit Quality Evolution. Procedia Comput. Sci. 2022, 200, 13–20. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, X.; Jiang, H.; Liu, X. An Energy-Aware Approach for Industrial Internet of Things in 5G Pervasive Edge Computing Environment. IEEE Trans. Ind. Inf. 2021, 17, 5087–5097. [Google Scholar] [CrossRef]

- Fang, D.; Guan, X.; Lin, L.; Peng, Y.; Sun, D.; Hassan, M.M. Edge Intelligence Based Economic Dispatch for Virtual Power Plant in 5G Internet of Energy. Comput. Commun. 2020, 151, 42–50. [Google Scholar] [CrossRef]

- Shah, K.; Prabhakar, T.V.; Sarweshkumar, C.R.; Abhishek, S.V. Construction of a Digital Twin Framework Using Free and Open-Source Software Programs. IEEE Internet Comput. 2022, 26, 50–59. [Google Scholar] [CrossRef]

| System/Component | Energy Role | Technical Barriers | DT Relevance | Source |

|---|---|---|---|---|

| Baking Ovens | Highest energy consumer; requires constant high temperatures | Heat loss due to poor insulation and frequent door openings | DT can simulate thermal profiles, track energy leaks, and optimize baking cycles | [24] |

| Proofing Chambers | Maintain warm, humid conditions for fermentation | Inefficient temperature/humidity control; operate on fixed schedules | DT can enable predictive control of humidity/temperature based on the fermentation stage | [31] |

| Refrigeration & Cooling | Continuous operation for dough storage, product cooling | Lack of load-responsive control; high base load energy usage | DT enables real-time monitoring of cooling demand and energy loads | [32] |

| HVAC Systems | Air quality and climate regulation in production areas | Overuse due to static settings; poor maintenance (e.g., clogged filters) | DT can model airflow patterns and predict maintenance needs (e.g., dirty filters) | [33] |

| Auxiliary Equipment | Includes mixers, conveyors, packagers, and lighting | Often ignored in energy audits, but cumulatively significant | DT can include auxiliary loads in virtual audit and usage prediction | [34] |

| WHR | Potential energy recovery from the oven and boiler exhaust | Rarely implemented; absence of recovery systems and thermal reuse strategies | DT can simulate recovery potential and optimize reuse strategies | [35] |

| Energy Monitoring Tools | Track and analyze consumption data | Often missing in traditional bakeries, the lack of real-time data impedes efficiency. | The backbone of DT provides essential data for digital modeling and optimization. | [9,36] |

| Legacy Equipment | Used widely in SMEs | Obsolete, energy-inefficient machinery; difficult to retrofit with sensors | Hard to integrate directly into DT, but can be monitored indirectly through external sensors | [37,38] |

| Application Area | Key Objectives | Methodologies Used | Outcomes | Remarks | Sources |

|---|---|---|---|---|---|

| Bakery Industry Digitalization | Review of digital innovations in the bakery sector | Systematic literature review | Bakery Industry Digitalization | Emphasizes the need for more studies in bakery-specific DT applications | [4] |

| Baking Oven Optimization | Design, development, management, and optimization of baking ovens | 3D CAD modeling, sensor integration, high-fidelity simulations | Enhanced control over baking parameters; improved product quality | Focused on industrial-scale ovens; emphasizes the importance of simulation in DT development | [78] |

| Baked Goods Manufacturing | Productivity enhancement through digitalization | Smart sensing technologies, data analytics | Improved manufacturing efficiency; reduced downtime | Highlights the role of smart technologies in bakery production | [79] |

| Food Processing Industry | Review of DT applications across food sectors | Literature review, case study analysis | Identified gaps in DT adoption in the bakery sector; proposed future research directions | Emphasizes the need for more studies in bakery-specific DT applications | [80,81] |

| Thermal Food Processing | Improve quality and safety through DT | COMSOL® Multiphysics modeling, microwave heating simulation | Accurate prediction of temperature and moisture loss; energy-efficient cooking | While not bakery-specific, it offers insights applicable to similar thermal processes in baking | [82] |

| Bakery Industry Digitalization | Review of digital innovations in the bakery sector | Systematic literature review | Bakery Industry Digitalization | Emphasizes the need for more studies in bakery-specific DT applications | [4] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melesse, T.Y.; Peer, M.S.; Ramasamy, S.; Sivasubramaniyam, V.; Braggio, M.; Orrù, P.F. Digital Twin for Energy-Intelligent Bakery Operations: Concepts and Applications. Energies 2025, 18, 3660. https://doi.org/10.3390/en18143660

Melesse TY, Peer MS, Ramasamy S, Sivasubramaniyam V, Braggio M, Orrù PF. Digital Twin for Energy-Intelligent Bakery Operations: Concepts and Applications. Energies. 2025; 18(14):3660. https://doi.org/10.3390/en18143660

Chicago/Turabian StyleMelesse, Tsega Y., Mohamed Shameer Peer, Suganthi Ramasamy, Vigneselvan Sivasubramaniyam, Mattia Braggio, and Pier Francesco Orrù. 2025. "Digital Twin for Energy-Intelligent Bakery Operations: Concepts and Applications" Energies 18, no. 14: 3660. https://doi.org/10.3390/en18143660

APA StyleMelesse, T. Y., Peer, M. S., Ramasamy, S., Sivasubramaniyam, V., Braggio, M., & Orrù, P. F. (2025). Digital Twin for Energy-Intelligent Bakery Operations: Concepts and Applications. Energies, 18(14), 3660. https://doi.org/10.3390/en18143660