The Impact of Diesel Injection Strategy and In-Cylinder Temperature on the Combustion and Emissions of Ammonia/Diesel Dual-Fuel Marine Engine

Abstract

1. Introduction

2. Experimental and Numerical Research Methods

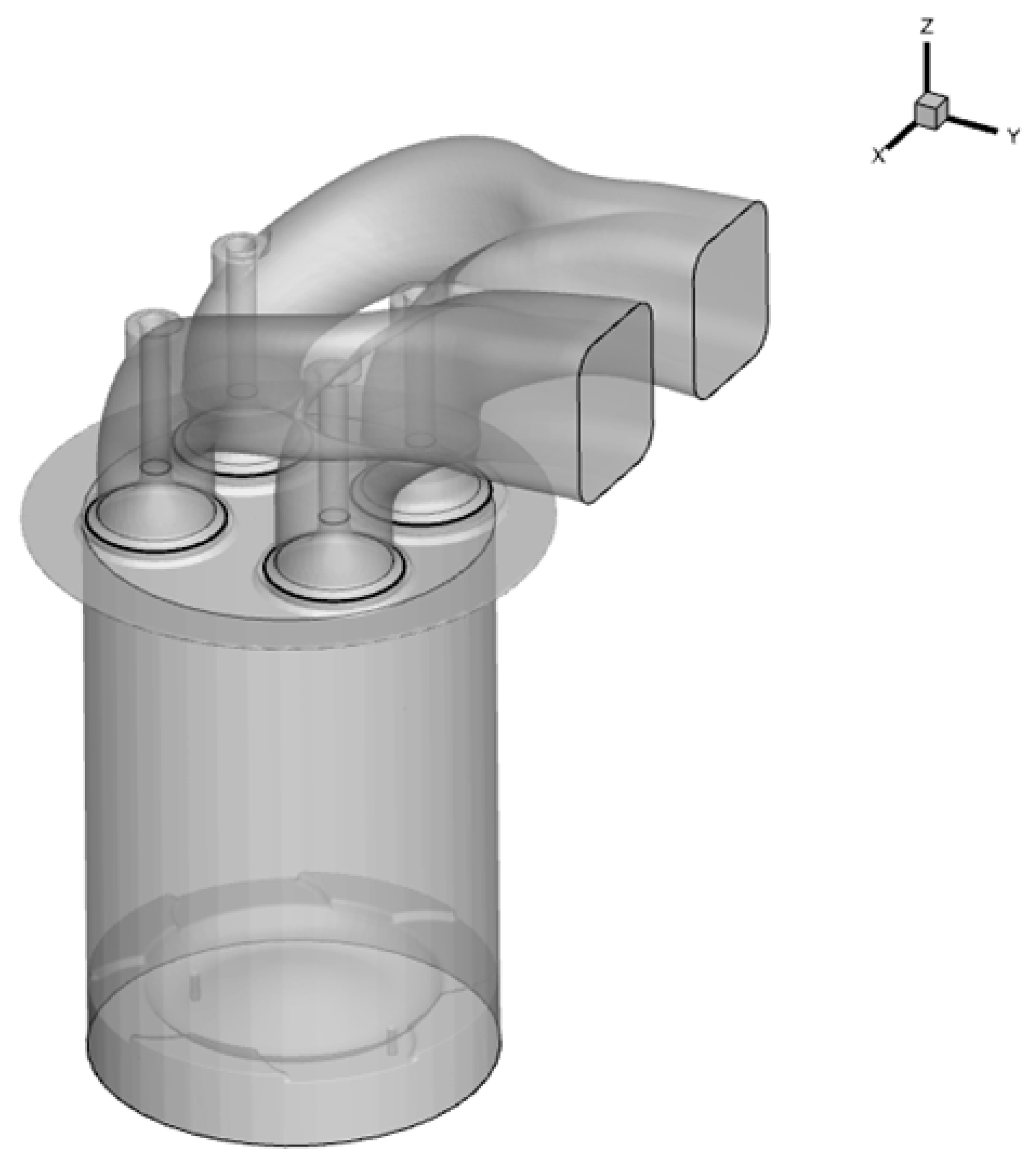

2.1. Experimental Setup

2.2. Simulation Models

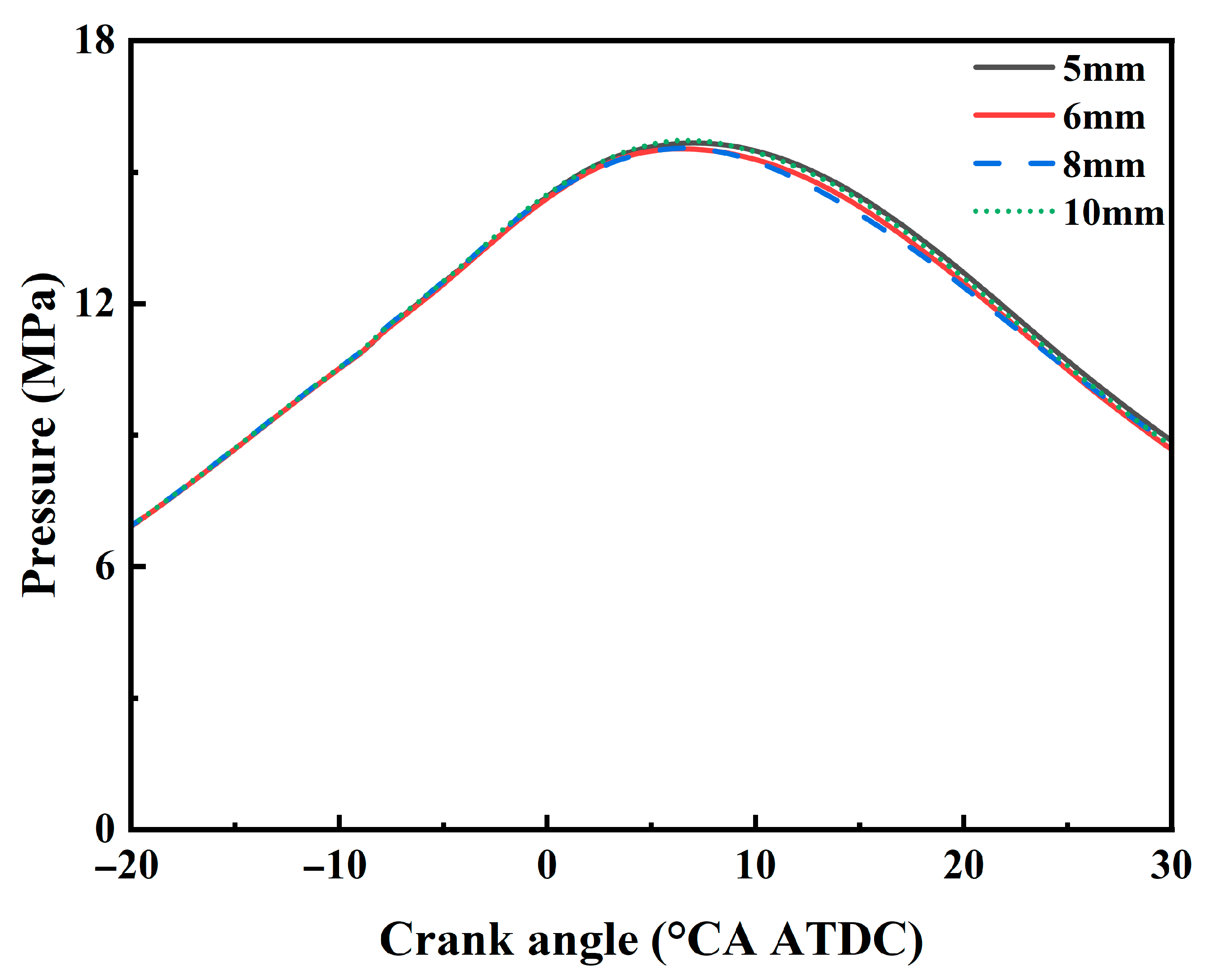

2.3. Model Validation

2.4. Data Processing

2.5. Content of Simulation Calculations

3. Results and Analysis

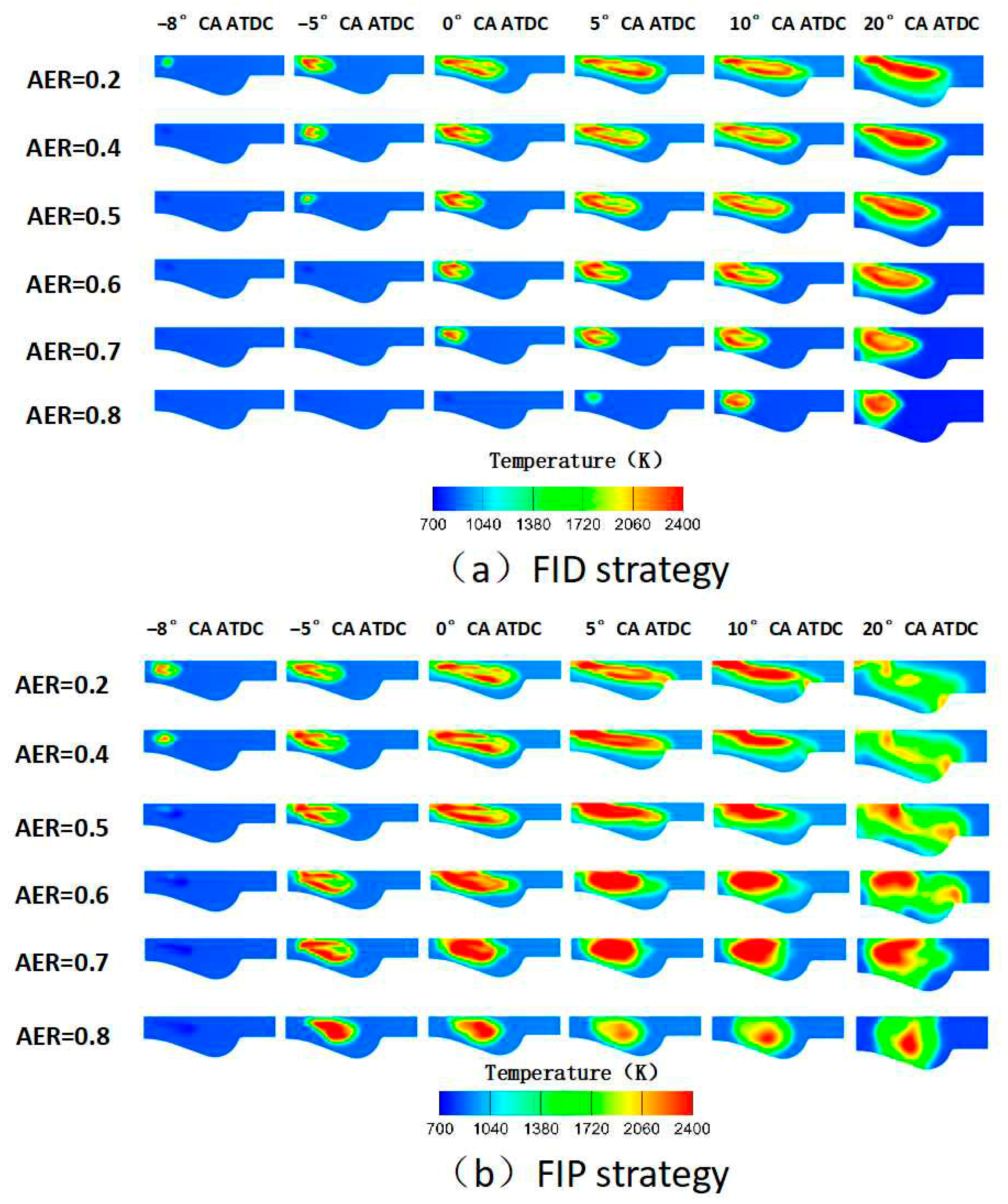

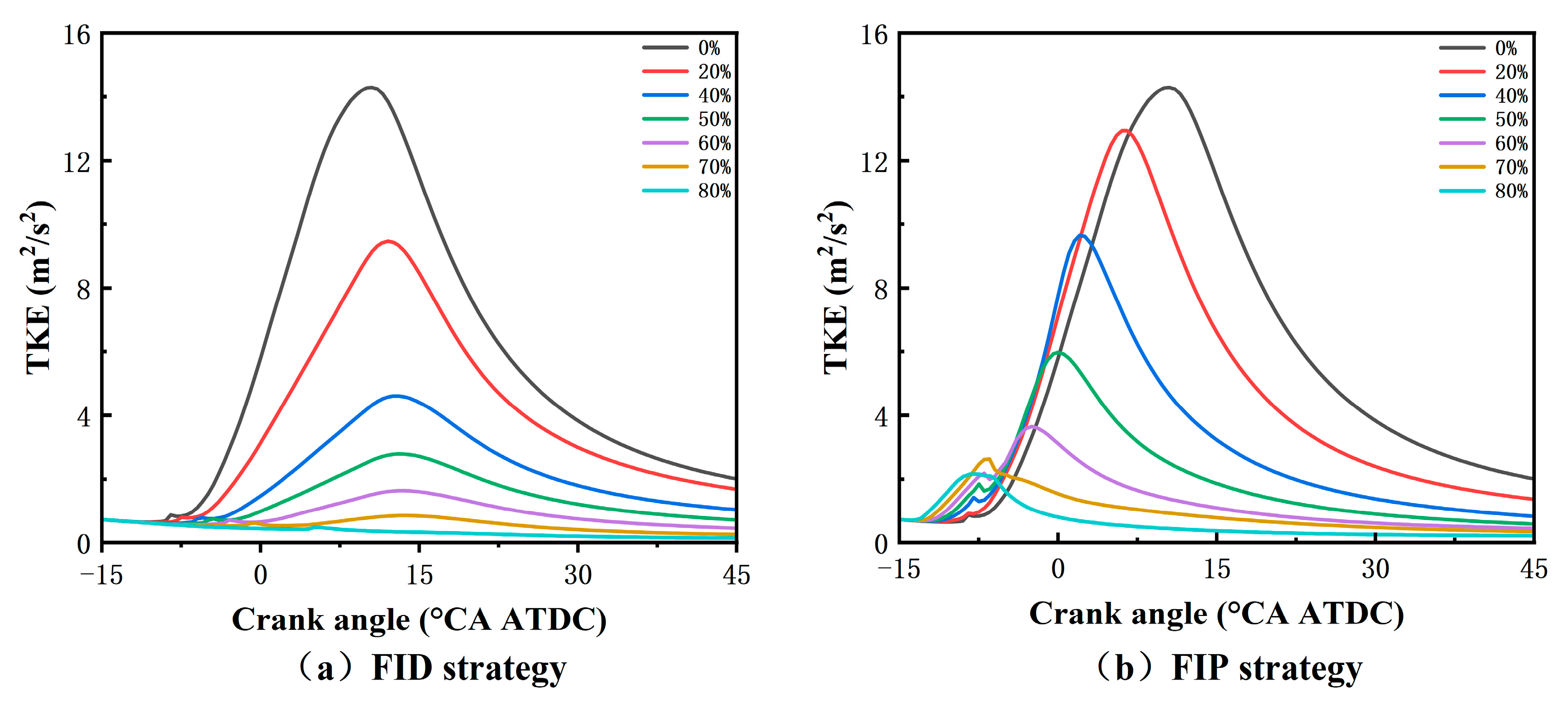

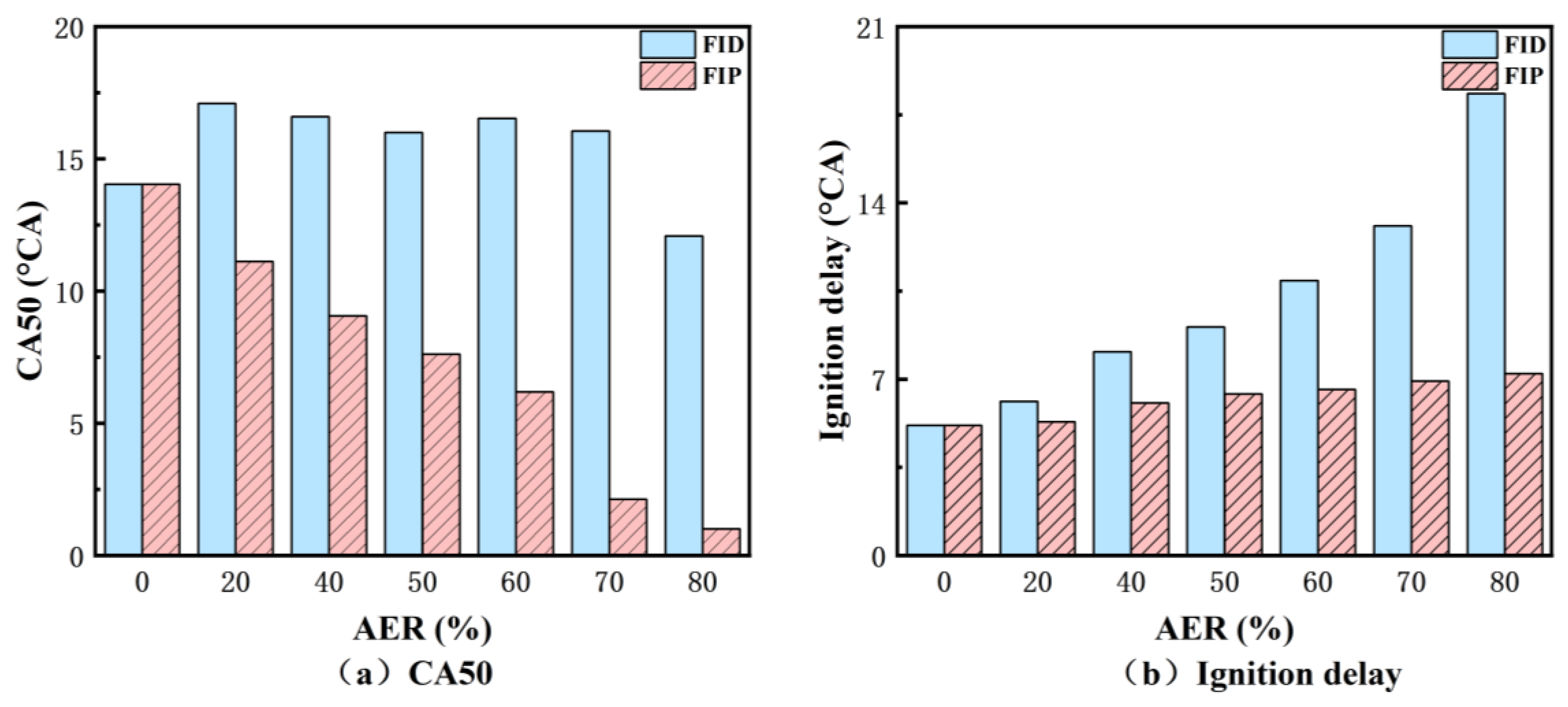

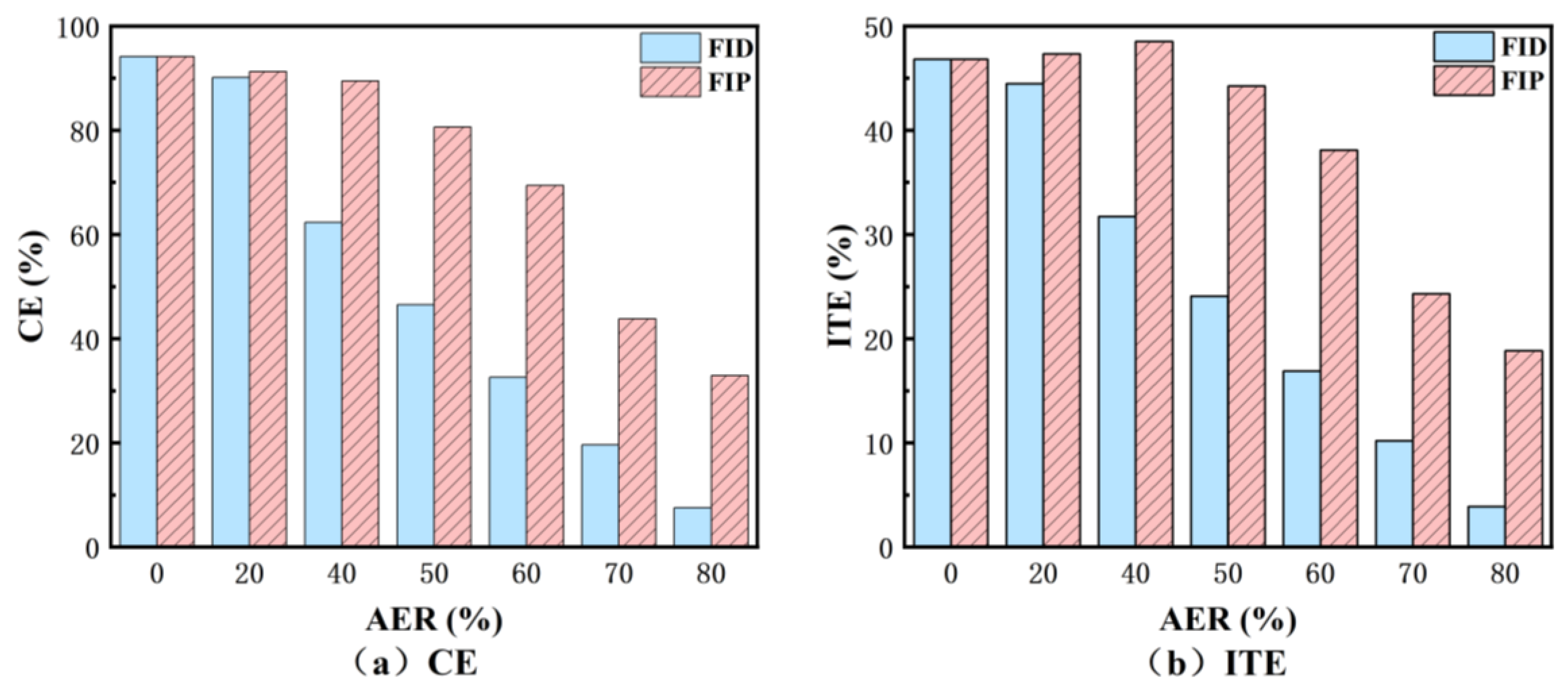

3.1. Comparative Analysis of FID and FIP Strategies

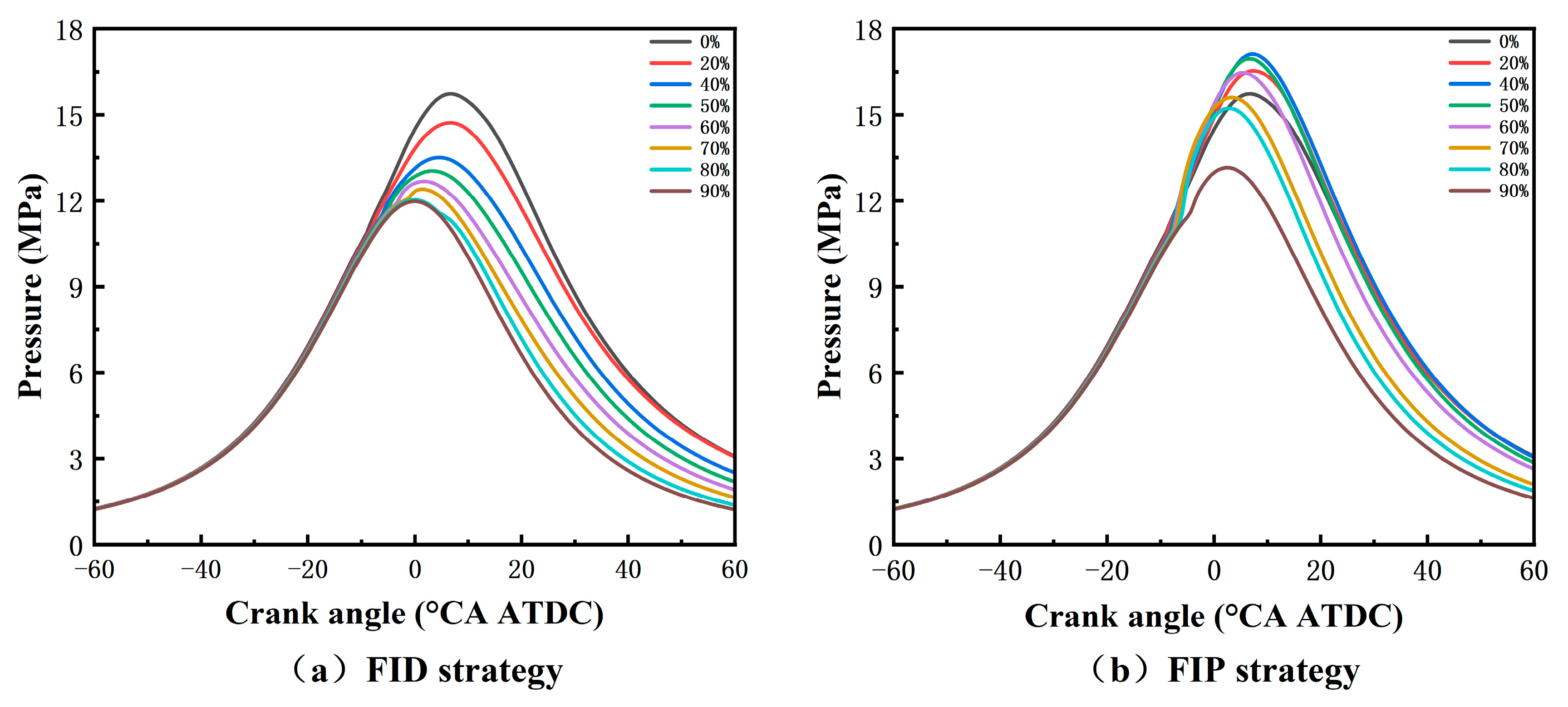

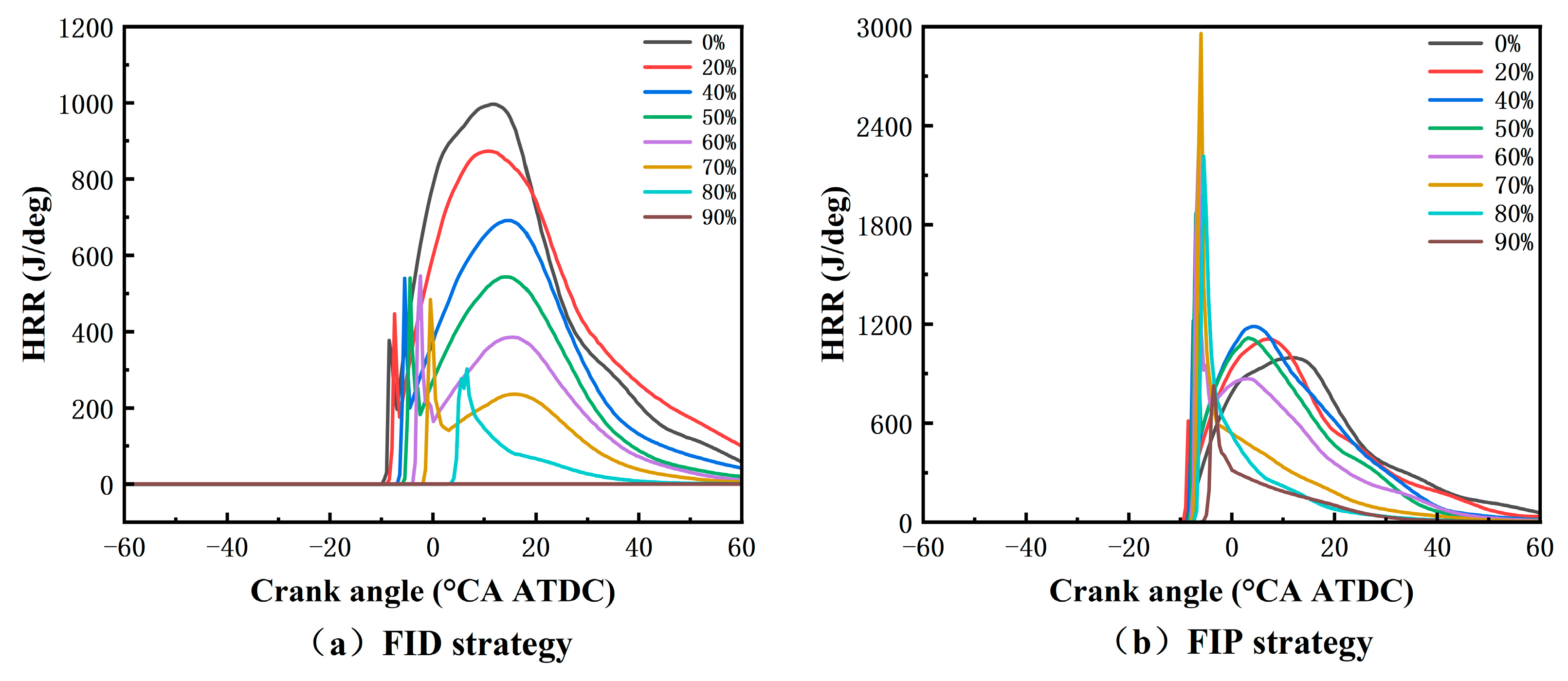

3.1.1. Combustion Characteristics

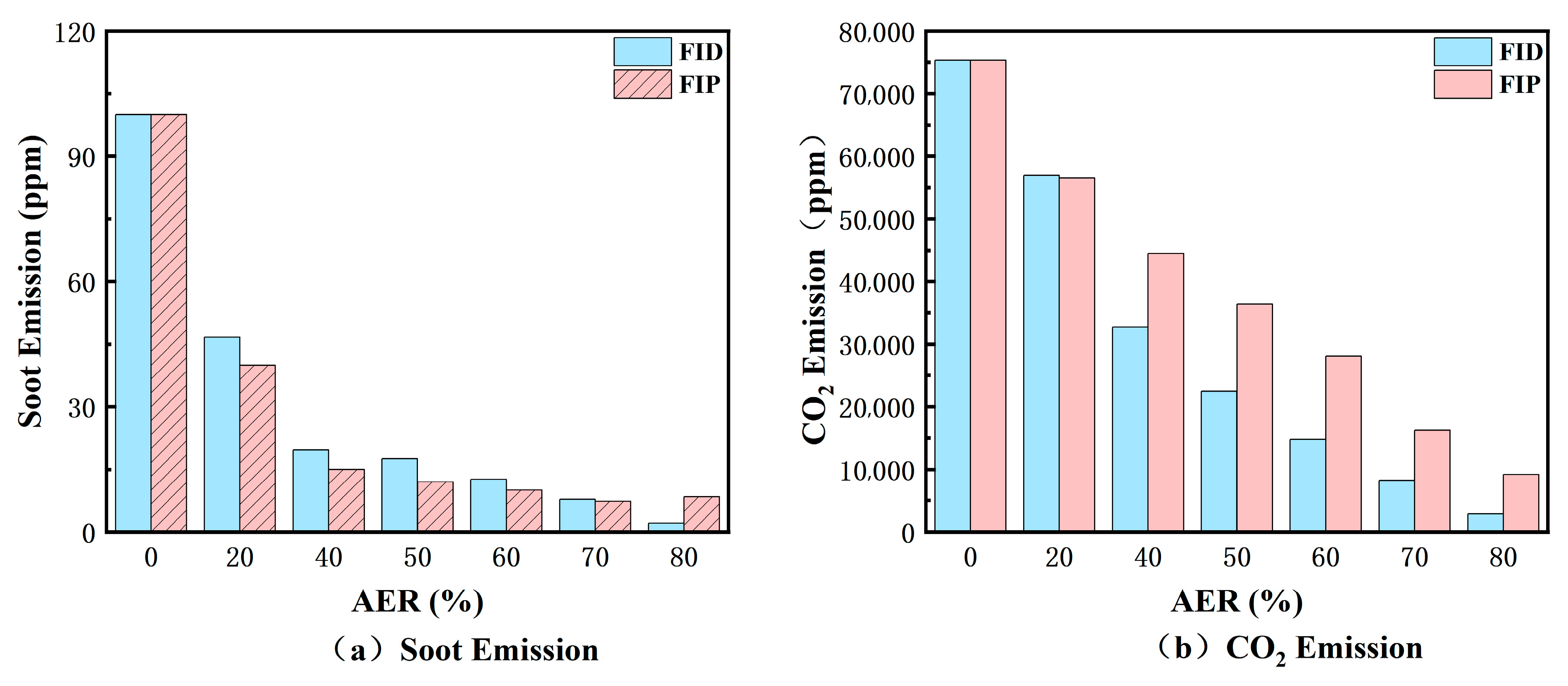

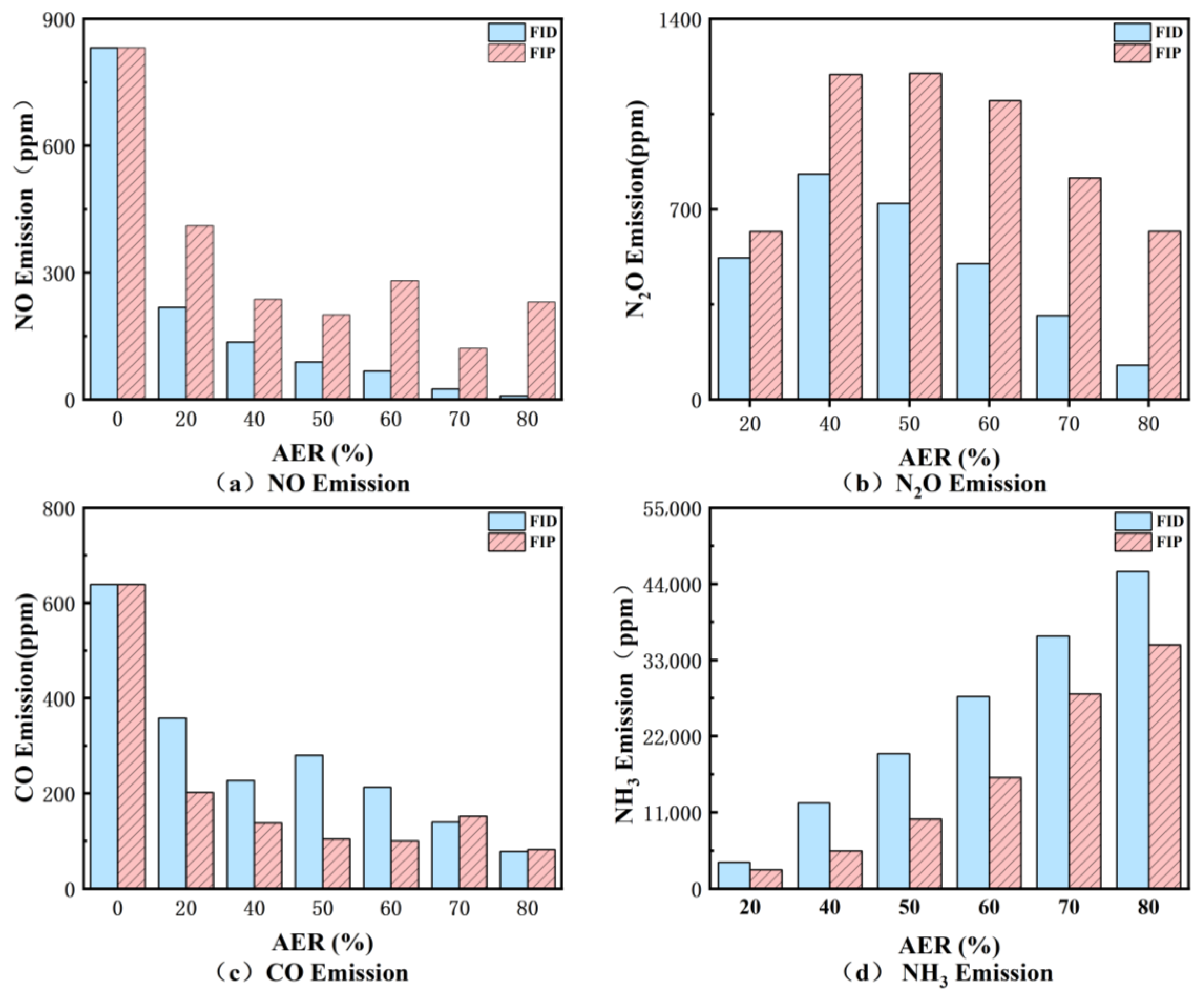

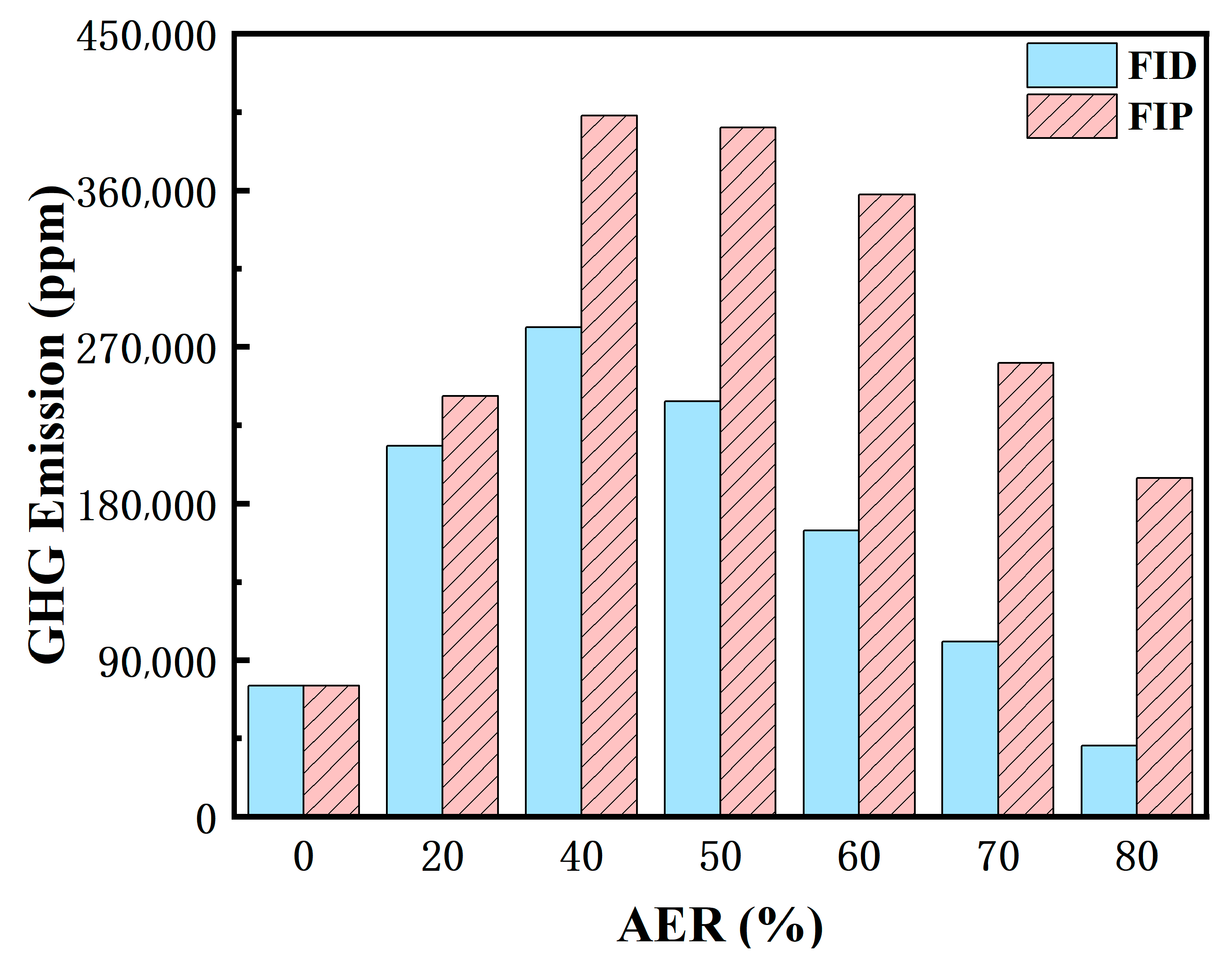

3.1.2. Emission Characteristics

3.2. Optimized Combustion Strategy

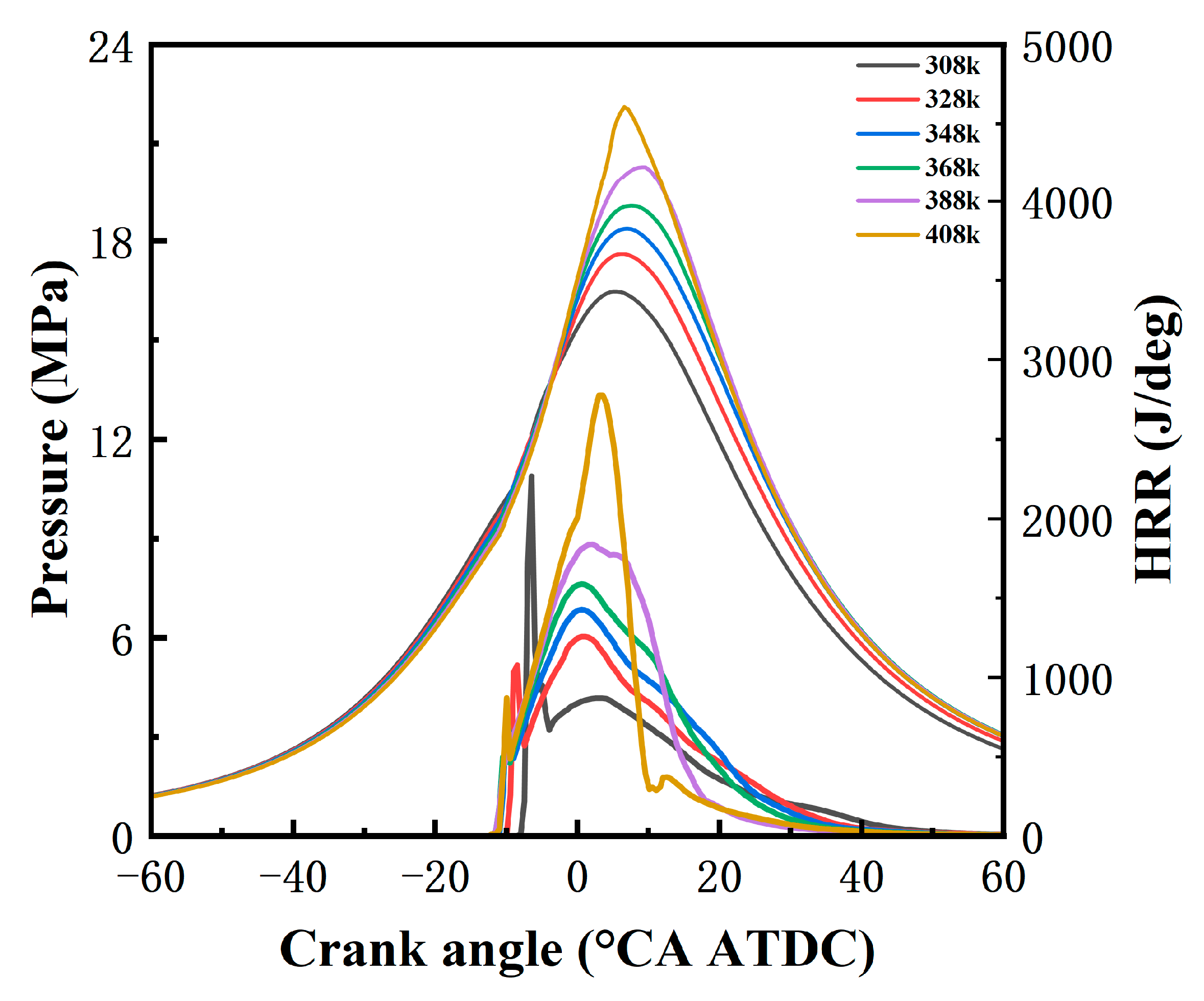

3.2.1. Combustion Characteristics of Optimized Strategies

3.2.2. Emission Characterization of Optimized Strategies

3.2.3. Optimized Results

4. Conclusions

- (1)

- The Fixed Injection Duration (FID) strategy keeps the injection duration constant, which results in a decrease in injection pressure, reducing the diesel’s kinetic energy and leading to poorer atomization. In contrast, the Fixed Injection Pressure (FIP) strategy maintains the injection pressure, allowing for better atomization of the diesel and improved combustion, which results in higher engine performance under this strategy.

- (2)

- An increase in AER will cause a decrease in the combustion effect of the ADDF engine. For the large-bore marine engine in this study, when the AER is 40%, the FIP strategy can still overcome the adverse effects of ammonia, allowing the engine to achieve higher in-cylinder pressure, heat release rate, and indicated thermal efficiency.

- (3)

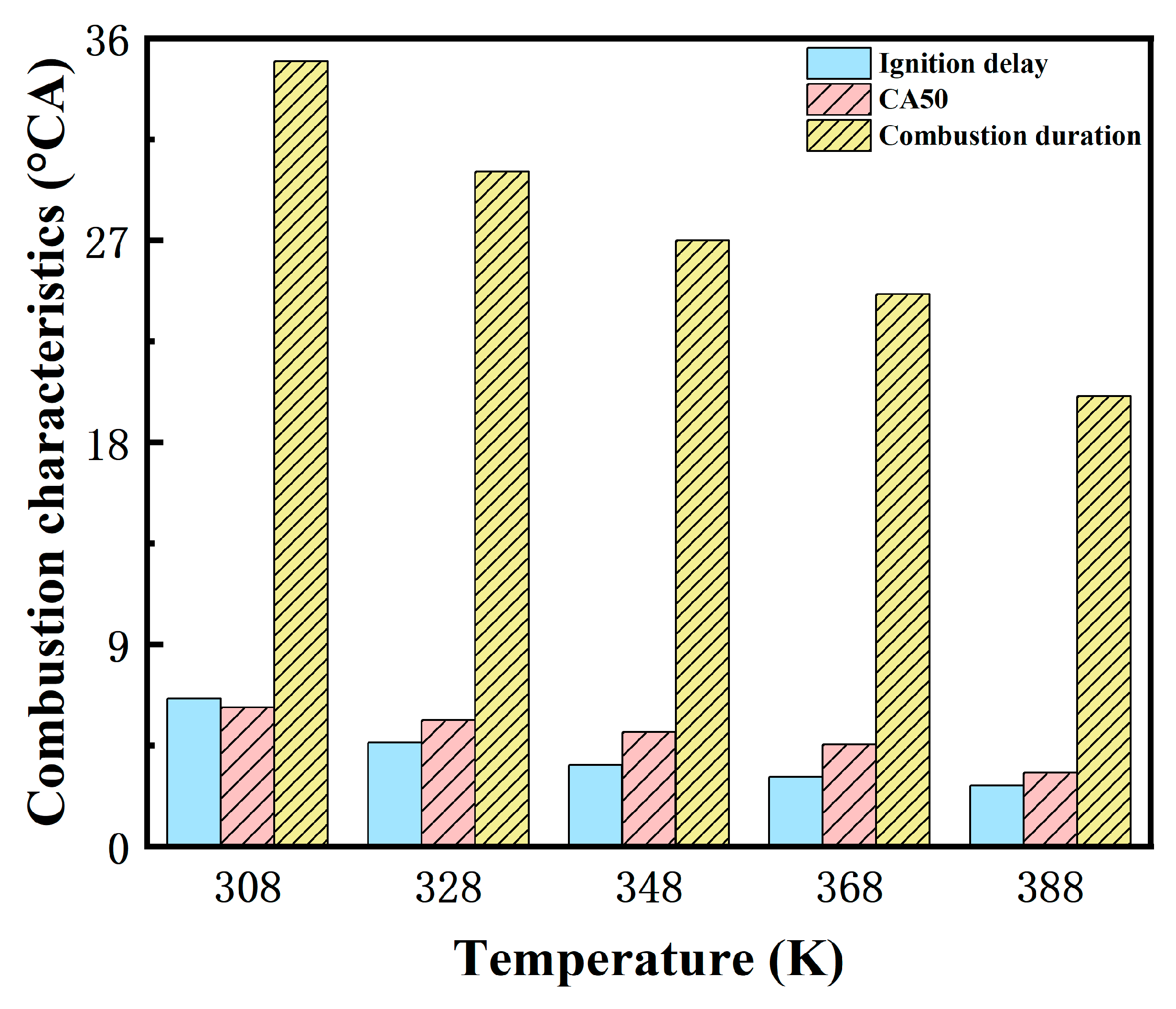

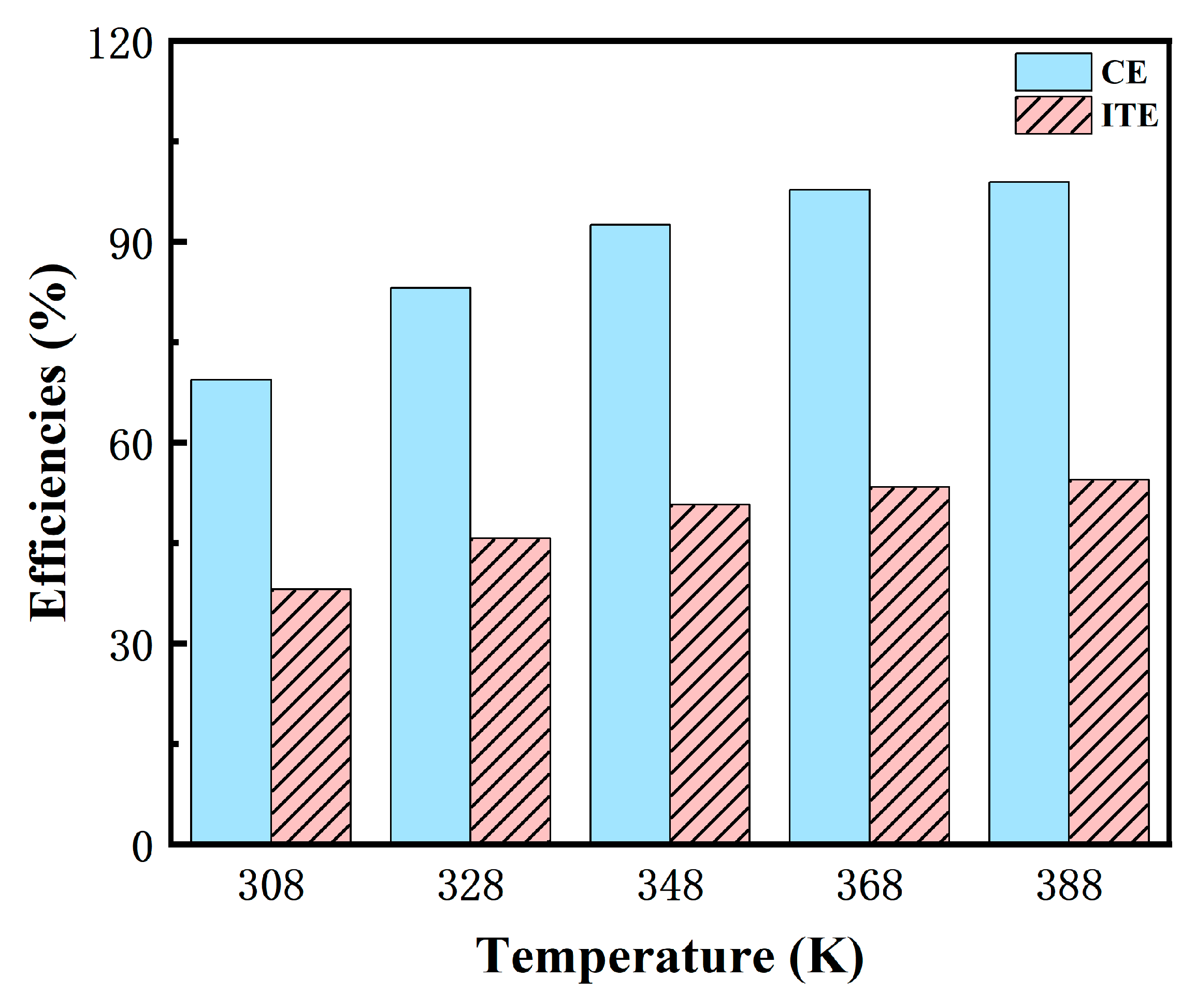

- As the initial temperature in the cylinder increases, the combustion environment improves significantly. Ignition delay is shortened, flame propagation speed increases, and the combustion phase CA50 is advanced. The advancement of ignition delay weakens the rapid combustion characteristics in the initial phase, and the effect of premixed combustion becomes less significant. Instead, diesel diffusion combustion dominates, showing significant diffusion combustion effects.

- (4)

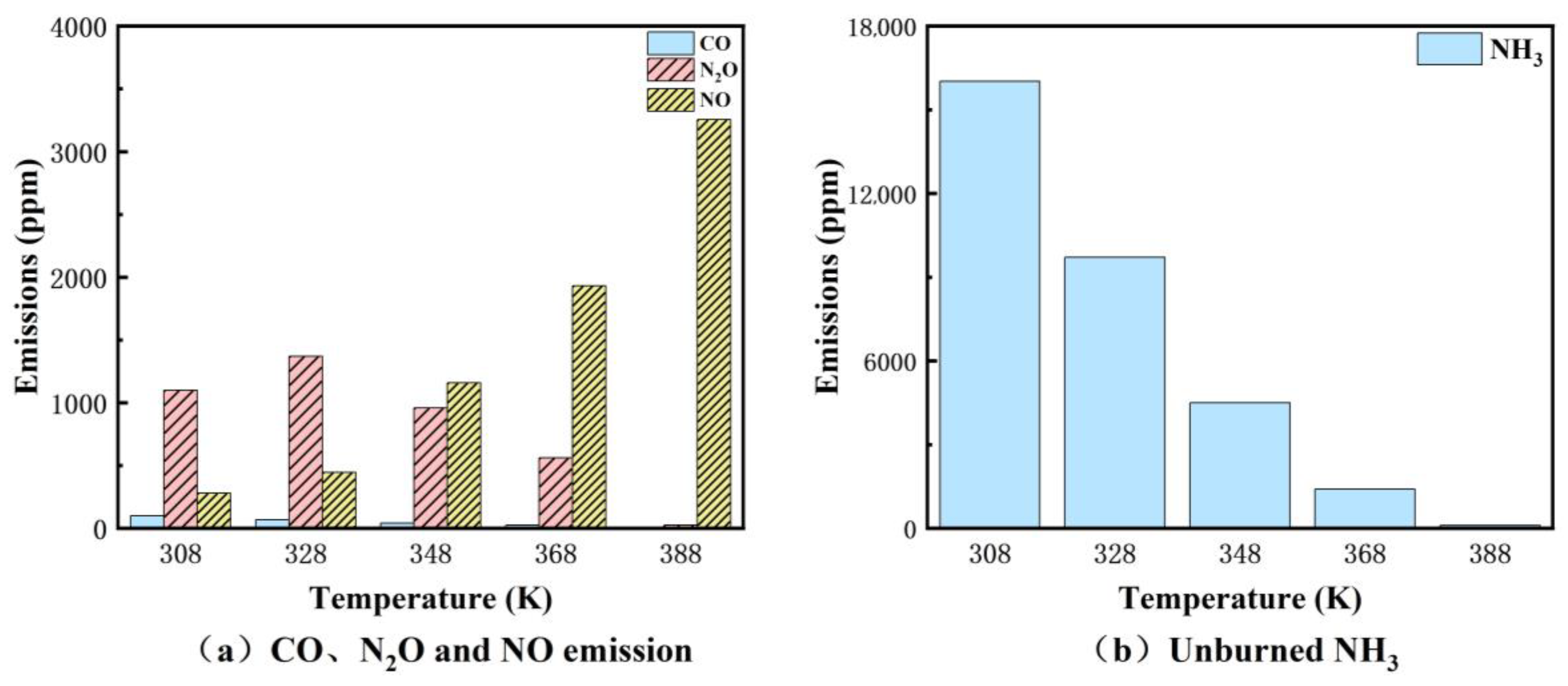

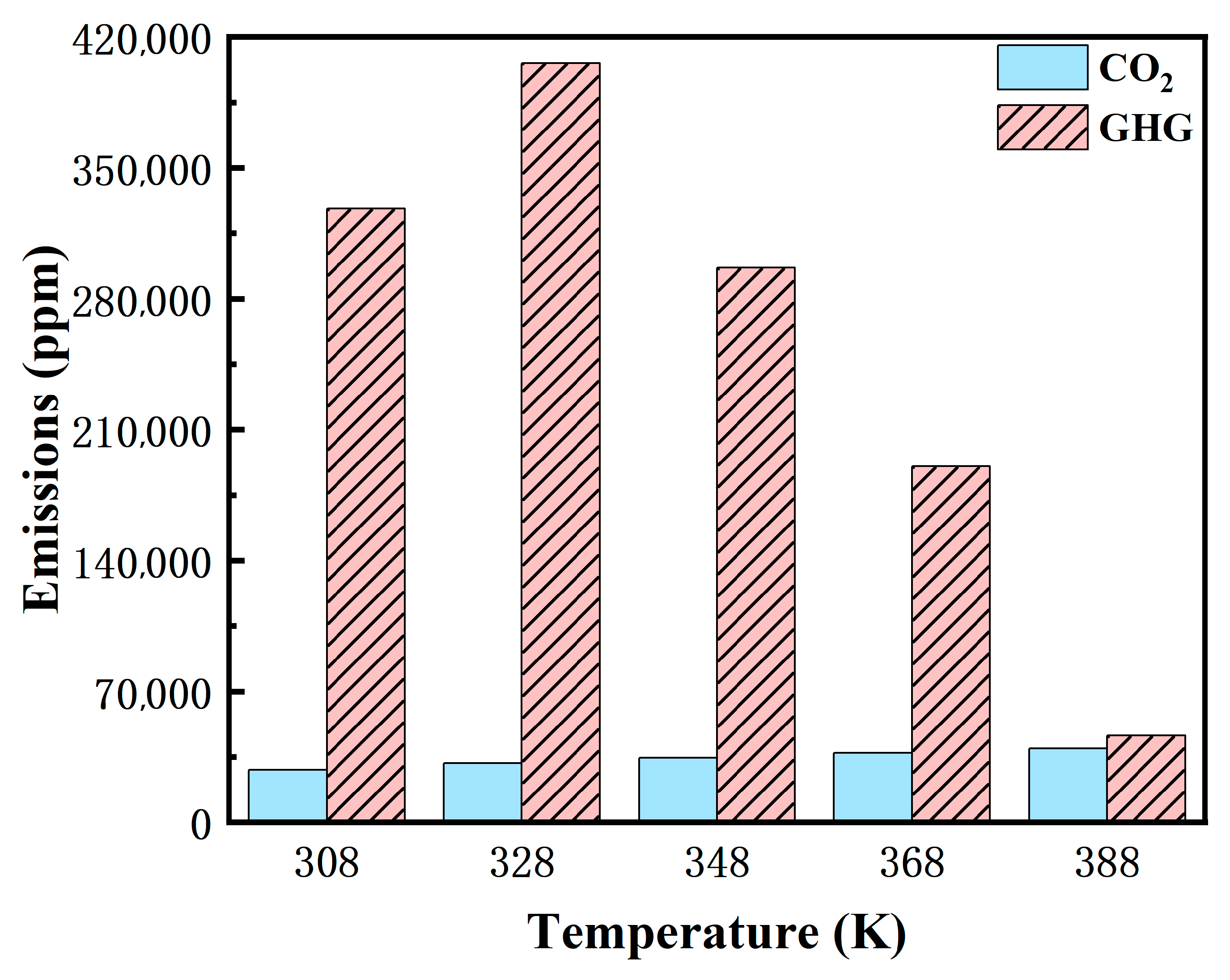

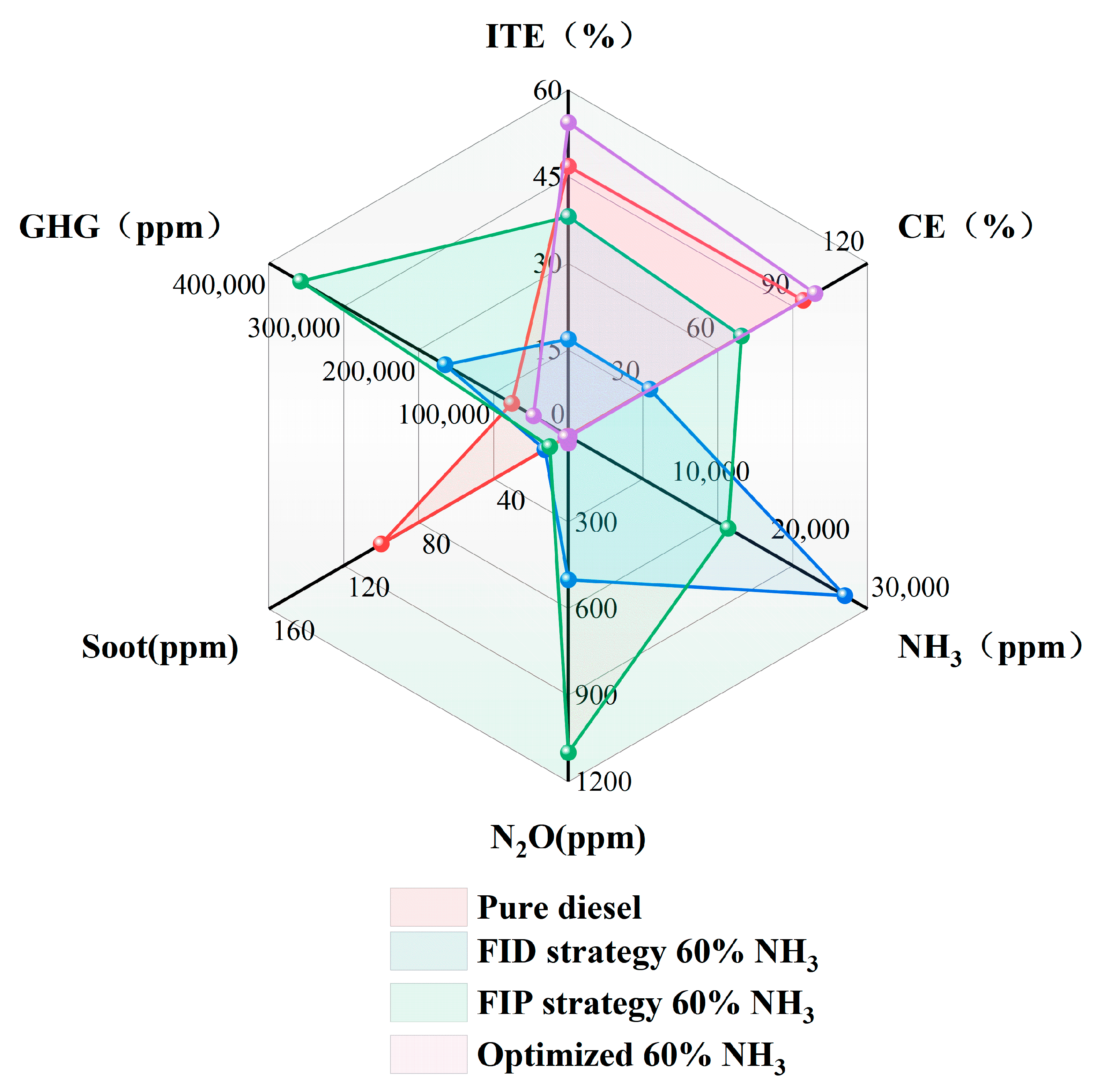

- The optimum strategy, utilizing the FIP strategy with an AER of 60% and initial cylinder temperature of 388 K, significantly increases the indicated thermal efficiency to 54.47%, which is 16.36% higher than that of the FIP-only strategy without increasing initial cylinder temperature, and 7.64% higher than that of the pure diesel mode. Additionally, N2O emissions are reduced from 1099 ppm to 25 ppm, and unburned ammonia emissions are reduced from 16,016 ppm to 100 ppm. Compared to the pure diesel mode, greenhouse gas emissions have decreased by 40%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cline, W.R. Scientific basis for the greenhouse effect. Econ. J. 1991, 101, 904–919. [Google Scholar] [CrossRef]

- Ledley, T.S.; Sundquist, E.T.; Schwartz, S.E.; Hall, D.K.; Fellows, J.D.; Killeen, T.L. Climate change and greenhouse gases. Eos Trans. Am. Geophys. Union 1999, 80, 453–458. [Google Scholar] [CrossRef]

- Johnson, B.T. Diesel engine emissions and their control. Platin. Met. Rev. 2008, 52, 23–37. [Google Scholar] [CrossRef]

- Corbett, J.J.; Fischbeck, P. Emissions from ships. Science 1997, 278, 823–824. [Google Scholar] [CrossRef]

- Bayramoğlu, K.; Bayraktar, M.; Seyhan, A.; Yuksel, O. Evaluation of techniques to reduce carbon emissions from ships within the scope of revised greenhouse gas emission targets for 2030, 2040, and 2050. Ocean. Eng. 2025, 334, 121605. [Google Scholar] [CrossRef]

- Milojević, S.; Glišović, J.; Savić, S.; Bošković, G.; Bukvić, M.; Stojanović, B. Particulate matter emission and air pollution reduction by applying variable systems in tribologically optimized diesel engines for vehicles in road traffic. Atmosphere 2024, 15, 184. [Google Scholar] [CrossRef]

- Shurpali, N.; Agarwal, A.K.; Srivastava, V. Greenhouse Gas Emissions; Energy, Environment, and Sustainability; Springer: Singapore, 2019. [Google Scholar] [CrossRef]

- Castresana, J.; Gabina, G.; Martin, L.; Uriondo, Z. Comparative performance and emissions assessments of a single-cylinder diesel engine using artificial neural network and thermodynamic simulation. Appl. Therm. Eng. 2021, 185, 116343. [Google Scholar] [CrossRef]

- Marinković, D.; Dezső, G.; Milojević, S. Application of machine learning during maintenance and exploitation of electric vehicles. Adv. Eng. Lett. 2024, 3, 132–140. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Jovanović, I.; Koričan, M. Application of fuel cells with zero-carbon fuels in short-sea shipping. Appl. Energy 2022, 309, 118463. [Google Scholar] [CrossRef]

- Wagner, N. Towards sustainable maritime transport: Focus on the early phase of technology development related to alternative fuels. Energy Sustain. Dev. 2025, 85, 101686. [Google Scholar] [CrossRef]

- Qi, H.; Huang, X.; Sheeraz, M. Green financing for renewable energy development: Driving the attainment of zero-emission targets. Renew. Energy 2023, 213, 30–37. [Google Scholar] [CrossRef]

- Sagin, S.V.; Sagin, S.S.; Fomin, O.; Gaichenia, O.; Zablotskyi, Y.; Píštěk, V.; Kučera, P. Use of biofuels in marine diesel engines for sustainable and safe maritime transport. Renew. Energy 2024, 224, 120221. [Google Scholar] [CrossRef]

- Ogden, J.M. Hydrogen: The fuel of the future? Phys. Today 2002, 55, 69–75. [Google Scholar] [CrossRef]

- Zamfirescu, C.; Dincer, I. Using ammonia as a sustainable fuel. J. Power Sources 2008, 185, 459–465. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Murtaza, S.Z.M.; Al-Othman, A.; Alami, A.H.; Singh, K.; Olabi, A.G. Ammonia: A versatile candidate for the use in energy storage systems. Renew. Energy 2022, 194, 955–977. [Google Scholar] [CrossRef]

- Erdemir, D.; Dincer, I. A perspective on the use of ammonia as a clean fuel: Challenges and solutions. Int. J. Energy Res. 2021, 45, 4827–4834. [Google Scholar] [CrossRef]

- Dolan, R.H.; Anderson, J.E.; Wallington, T.J. Outlook for ammonia as a sustainable transportation fuel. Sustain. Energy Fuels 2021, 5, 4830–4841. [Google Scholar] [CrossRef]

- Rocha, R.C.; Zhong, S.; Xu, L.; Bai, X.; Costa, M.; Cai, X.; Kim, H.; Brackmann, C.; Li, Z.; Aldén, M. Structure and laminar flame speed of an ammonia/methane/air premixed flame under varying pressure and equivalence ratio. Energy Fuels 2021, 35, 7179–7192. [Google Scholar] [CrossRef]

- Nie, X.; Bi, Y.; Shen, L.; Lei, J.; Wan, M.; Wang, Z.; Liu, S.; Huang, F. Combustion and emission characteristics of ammonia-diesel dual fuel engine at different altitudes. Fuel 2024, 371, 132072. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Zhang, Z.; Zhang, B.; Hu, J.; Zhong, W.; Ye, Y. Effect of ammonia energy ratio and load on combustion and emissions of an ammonia/diesel dual-fuel engine. Energy 2024, 302, 131860. [Google Scholar] [CrossRef]

- Xu, L.; Xu, S.; Bai, X.S.; Repo, J.A.; Hautala, S.; Hyvönen, J. Performance and emission characteristics of an ammonia/diesel dual-fuel marine engine. Renew. Sustain. Energy Rev. 2023, 185, 113631. [Google Scholar] [CrossRef]

- Wu, B.; Zi, Z.; Jin, S.; Pei, Y.; Wang, D. Effect of diesel injection strategy and ammonia energy fraction on ammonia-diesel premixed-charge compression ignition combustion and emissions. Fuel 2024, 357, 129785. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Dev, S.; Liko, B.; Lafrance, S. Effects of ammonia energy fraction and diesel injection timing on combustion and emissions of an ammonia/diesel dual-fuel engine. Fuel 2022, 314, 122723. [Google Scholar] [CrossRef]

- Hu, Z.; Dong, D.; Wei, W.; Zhang, H.; Wei, F.; Zhou, M.; Li, G. Numerical investigation on energy ratios and injection strategies of an ammonia-diesel dual-fuel marine engine. Int. J. Hydrogen Energy 2024, 70, 522–536. [Google Scholar] [CrossRef]

- Abd Alla, G.H.; Soliman, H.A.; Badr, O.A.; Abd Rabba, M.F. Effect of injection timing on the performance of a dual fuel engine. Energy Convers. Manag. 2002, 43, 269–277. [Google Scholar] [CrossRef]

- Richards, K.J.; Senecal, P.K.; Pomraning, E. CONVERGE, version 3.0; Convergent Science: Madison, WI, USA, 2019.

- Schmidt, D.P.; Rutland, C.J. A new droplet collision algorithm. J. Comput. Phys. 2000, 164, 62–80. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, M.; Liu, H.; Xie, M.; Wang, T.; Zhou, L. Development of a new spray/wall interaction model for diesel spray under PCCI-engine relevant conditions. At. Sprays 2014, 24, 41–80. [Google Scholar] [CrossRef]

- Amsden, A.A.; O’Rourke, P.J.; Butler, T.D. A Computer Program for Chemically Reactive Flows with Sprays; Technical Report LA-11560-MS; Los Alamos Laboratory: Los Alamos, NM, USA, 1989.

- Beale, J.C.; Reitz, R.D. Modeling spray atomization with the Kelvin-Helmholtz/Rayleigh-Taylor hybrid model. At. Sprays 1999, 9, 623–650. [Google Scholar] [CrossRef]

- Dec, J.E. Advanced compression-ignition engines—Understanding the in-cylinder processes. Proc. Combust. Inst. 2009, 32, 2727–2742. [Google Scholar] [CrossRef]

- Kong, S.C.; Marriott, C.D.; Reitz, R.D.; Christensen, M. Modeling and experiments of HCCI engine combustion using detailed chemical kinetics with multidimensional CFD. SAE Trans. 2001, 110, 1007–1018. [Google Scholar]

- Xu, L.; Chang, Y.; Treacy, M.; Zhou, Y.; Jia, M.; Bai, X. A skeletal chemical kinetic mechanism for ammonia/n-heptane combustion. Fuel 2023, 331, 125830. [Google Scholar] [CrossRef]

- Tan, D.; Meng, Y.; Tian, J.; Zhang, C.; Zhang, Z.; Yang, G.; Cui, S.; Hu, J.; Zhao, Z. Utilization of renewable and sustainable diesel/methanol/n-butanol (DMB) blends for reducing the engine emissions in a diesel engine with different pre-injection strategies. Energy 2023, 269, 126785. [Google Scholar] [CrossRef]

- Chen, H.; He, J.; Hua, H. Investigation on combustion and emission performance of a common rail diesel engine fueled with diesel/biodiesel/polyoxymethylene dimethyl ethers blends. Energy Fuels 2017, 31, 11710–11722. [Google Scholar] [CrossRef]

- Lee, G.W.; Shon, B.H.; Yoo, J.G.; Jung, J.-H.; Oh, K.-J. The influence of mixing between NH3 and NO for a De-NOx reaction in the SNCR process. J. Ind. Eng. Chem. 2008, 14, 457–467. [Google Scholar] [CrossRef]

- Selleri, T.; Melas, A.D.; Joshi, A.; Manara, D.; Perujo, A.; Suarez-Bertoa, R. An overview of lean exhaust denox aftertreatment technologies and nox emission regulations in the european union. Catalysts 2021, 11, 404. [Google Scholar] [CrossRef]

- Lu, P.; Ye, L.; Yan, X.; Chen, X.; Fang, P.; Chen, D.; Che, D.; Cen, C. N2O inhibition by toluene over Mn-Fe spinel SCR catalyst. J. Hazard. Mater. 2021, 414, 125468. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Quality Assurance Guidance Document-Model Quality Assurance Project Plan for the PM Ambient Air; United States Environmental Protection Agency: Washington, DC, USA, 2001.

- Mathieu, O.; Petersen, E.L. Experimental and modeling study on the high-temperature oxidation of Ammonia and related NOx chemistry. Combust. Flame 2015, 162, 554–570. [Google Scholar] [CrossRef]

- Song, Y.; Hashemi, H.; Christensen, J.M.; Zou, C.; Marshall, P.; Glarborg, P. Ammonia oxidation at high pressure and intermediate temperatures. Fuel 2016, 181, 358–365. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Engine type | mm | Six-cylinder, turbocharged, water-cooled |

| Bore × Stroke | mm | 210 × 300 |

| Connecting rod | mm | 625 |

| Number of Cylinders | - | 6 |

| Engine speed | rpm | 908.6 |

| Rated power output | kW | 990 |

| Diesel injection holes | - | 12 |

| Compression ratio | - | 15.5 |

| Equipment Name | Companies | Model Specifications | Accuracy |

|---|---|---|---|

| Dynamometer | HORIBA, Kyoto, Japan | AMP 280–4 C | ±2 rpm |

| Air flowmeter | ABB, Zurich, Switzerland | FMT700-P | ±0.8% |

| NOx sensor | NGK, Nagoya, Japan | SNS3500B | ±30 ppm |

| Cylinder pressure sensor | Kistler, Winterthur, Switzerland | 6125 C | ±0.4% |

| Temperature sensor | SIEMENS, Munich, Germany | Thermal coupling K Type | ±2.5 K |

| Data acquisition system | AVL, Graz, Austria | PUMA | - |

| Parameter | Unit | Value |

|---|---|---|

| Engine speed | rpm | 908.6 |

| Diesel injection timing | °CA ATDC | −15 |

| Diesel injection duration | °CA | 35 |

| Diesel injection pressure | bar | 625 |

| Diesel injection volume | mg | 870 |

| Initial cylinder temperature | K | 308 |

| AER (%) | MD (mg) | MN (mg) | Injection Pressure (bar) | Injection Duration (°CA) | ||

|---|---|---|---|---|---|---|

| FID | FIP | FID | FIP | |||

| 0 | 870 | 0 | 625 | 625 | 35 | 35 |

| 20 | 696 | 394.3 | 400 | 28 | ||

| 40 | 522 | 788.6 | 225 | 21 | ||

| 50 | 435 | 985.7 | 156 | 17.5 | ||

| 60 | 348 | 1182.8 | 100 | 14 | ||

| 70 | 261 | 1380 | 56 | 10.5 | ||

| 80 | 174 | 1577.1 | 25 | 7 | ||

| 90 | 87 | 1774.2 | 6 | 3.5 | ||

| Parameter | Unit | Value |

|---|---|---|

| Strategy | - | FIP |

| AER | % | 60 |

| Initial cylinder temperature | K | 308, 328, 348, 368, 388, 408 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, W.; Luo, S.; Wu, J.; Lou, H.; Wang, L.; Wu, F.; Li, L.; Huang, F.; He, H. The Impact of Diesel Injection Strategy and In-Cylinder Temperature on the Combustion and Emissions of Ammonia/Diesel Dual-Fuel Marine Engine. Energies 2025, 18, 3631. https://doi.org/10.3390/en18143631

Guan W, Luo S, Wu J, Lou H, Wang L, Wu F, Li L, Huang F, He H. The Impact of Diesel Injection Strategy and In-Cylinder Temperature on the Combustion and Emissions of Ammonia/Diesel Dual-Fuel Marine Engine. Energies. 2025; 18(14):3631. https://doi.org/10.3390/en18143631

Chicago/Turabian StyleGuan, Wei, Songchun Luo, Jie Wu, Hua Lou, Lei Wang, Feng Wu, Li Li, Fuchuan Huang, and Haibin He. 2025. "The Impact of Diesel Injection Strategy and In-Cylinder Temperature on the Combustion and Emissions of Ammonia/Diesel Dual-Fuel Marine Engine" Energies 18, no. 14: 3631. https://doi.org/10.3390/en18143631

APA StyleGuan, W., Luo, S., Wu, J., Lou, H., Wang, L., Wu, F., Li, L., Huang, F., & He, H. (2025). The Impact of Diesel Injection Strategy and In-Cylinder Temperature on the Combustion and Emissions of Ammonia/Diesel Dual-Fuel Marine Engine. Energies, 18(14), 3631. https://doi.org/10.3390/en18143631