Decoupling Analysis of Parameter Inconsistencies in Lithium-Ion Battery Packs Guiding Balancing System Design

Abstract

1. Introduction

- Parameter coupling: The influence of cell parameter inconsistencies on overall pack performance exhibits strong interdependencies [25].

- Measurement constraints: Key parameters of cells such as capacity, SOC, and CE cannot be directly measured during aging tests without disassembling the pack.

- Irreversibility and non-reproducibility: Irreversible parameter changes and non-repeatable experimental conditions prevent result verification.

- A controlled single-variable approach is innovatively introduced to inconsistency evolution analysis. Based on the developed battery pack simulation model, this study quantitatively decouples how each factor (e.g., initial capacity, internal resistance, CE) independently drives pack capacity degradation. This solves the problem of unclear fade mechanisms of pack capacity under multi-parameter coupling in traditional experimental science and offers crucial evidence for identifying the main factors of pack capacity fade.

- Previous studies select active/passive balancing systems based solely on cost and balancing time. The correlation between inconsistency types (SOC/capacity/resistance) and optimal balancing system is systematically proposed for the first time based on decoupling analysis. These findings provide new guidance and a novel dimension for selecting balancing systems.

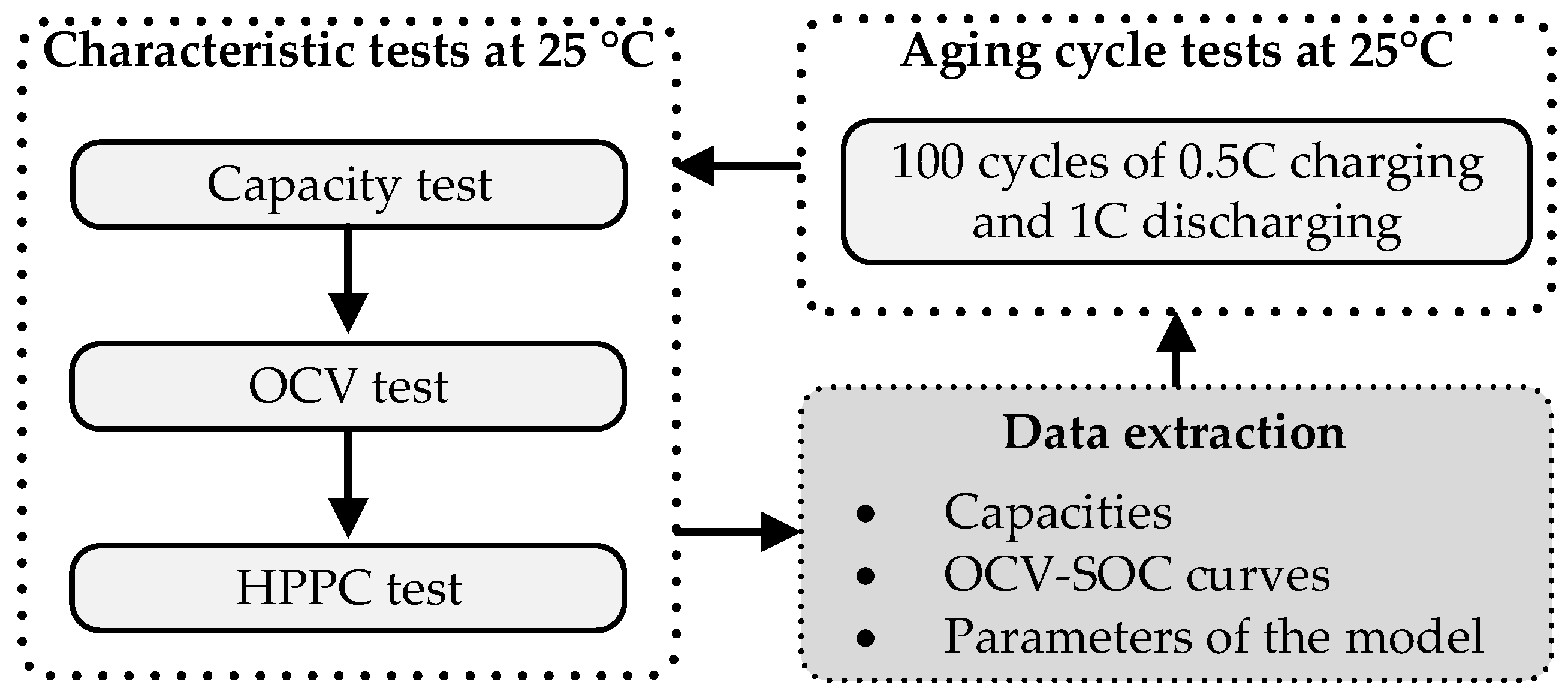

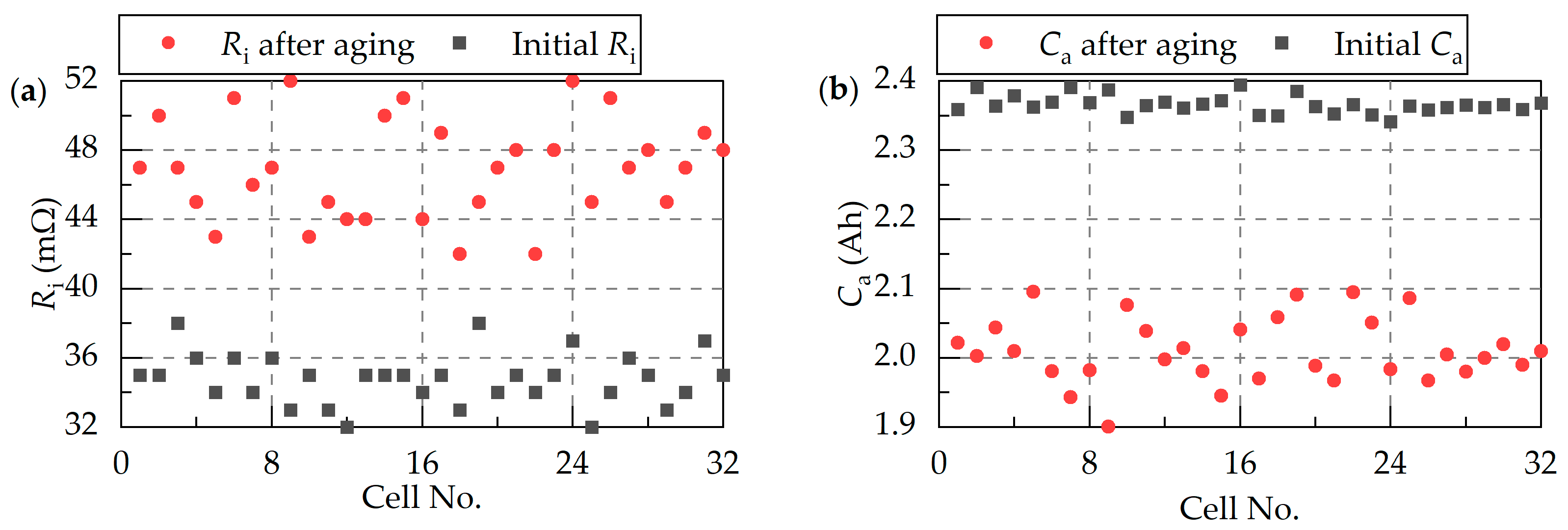

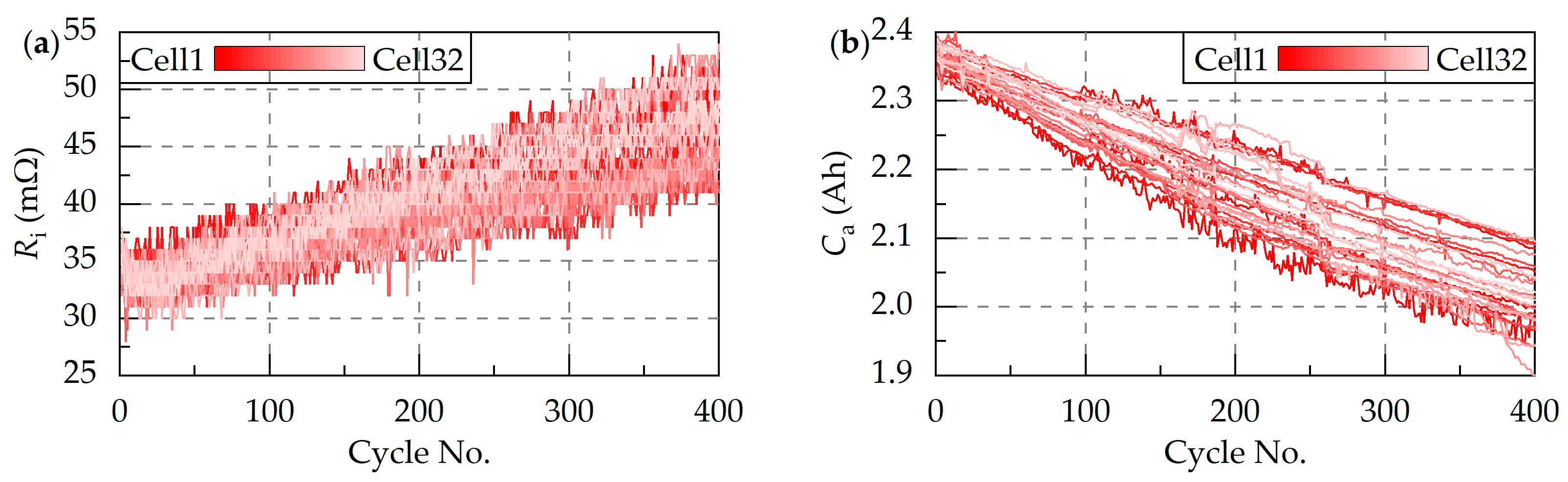

2. Battery Experiment

3. Construction of Simulation Model

3.1. Battery Cell Model

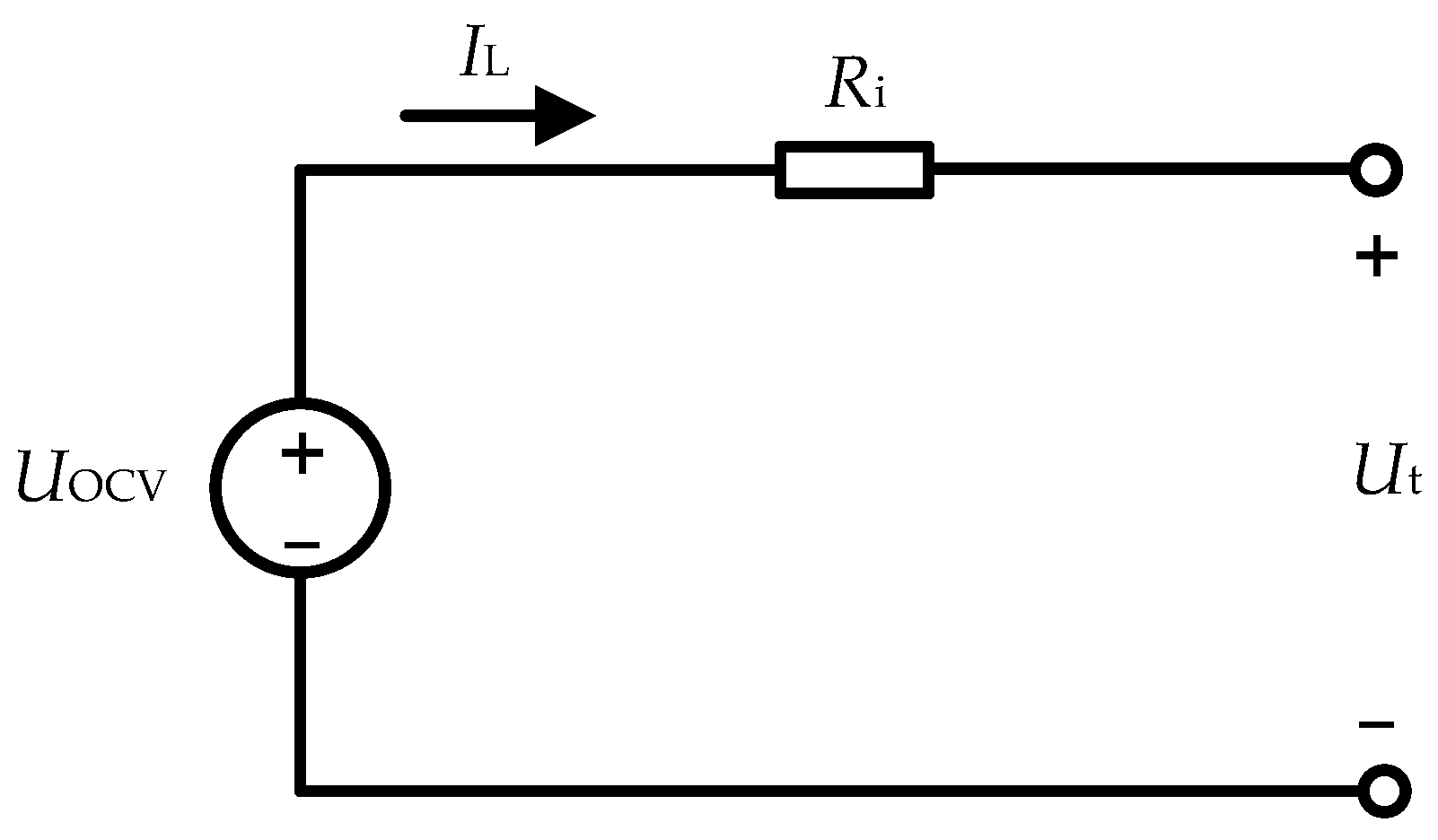

3.1.1. Equivalent Circuit Model

3.1.2. Thermal Model

3.1.3. Aging Model

3.2. Battery Pack Model

3.2.1. Basic Model

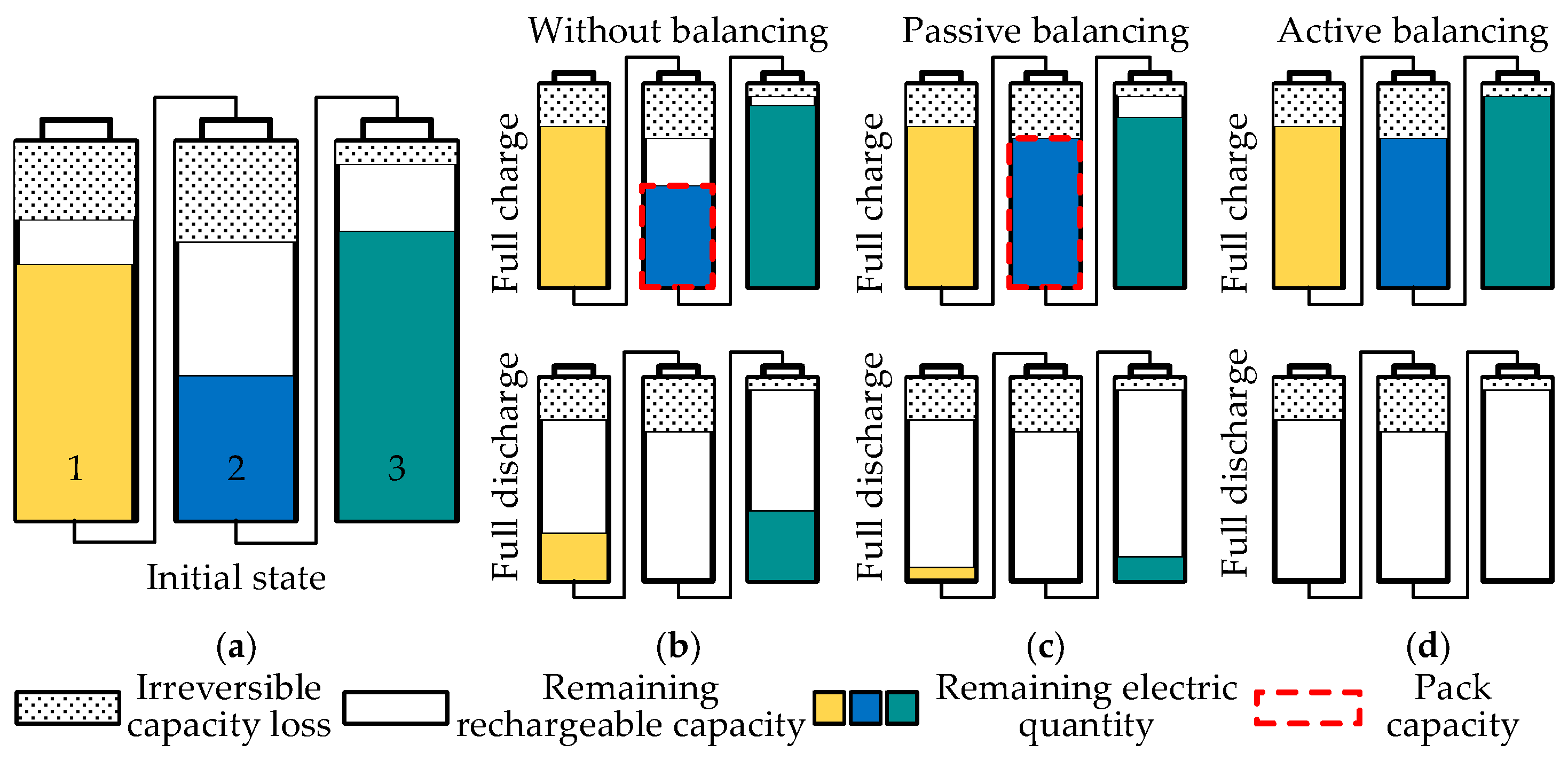

- Battery packs without balancing systems. Cell 1 exhibits the minimum remaining rechargeable capacity in the initial state, while Cell 2 demonstrates the minimum remaining electric quantity and the smallest total capacity. During charging, Cell 1 gets fully charged first, whereas Cell 2 gets fully discharged first during discharging. This demonstrates that the total pack capacity is constrained by the two cells, and the battery pack state is defined accordingly as follows [30]:where and denote the capacity and SOC of the battery pack without the balancing system, and Ca and z indicate the capacity and SOC of cells.

- Battery packs with passive balancing systems. Dissipative resistors continuously discharge Cells 1 and 3 during charging to ensure Cell 2 achieves full charge. Passive balancing is disabled during discharging, allowing Cell 2 (with the minimum remaining electric quantity) to get fully discharged first. Consequently, the theoretical maximum capacity of the battery pack with the passive balancing system equals the capacity of the weakest cell. The battery pack state is defined as follows:where and denote the capacity and SOC of the battery pack with the passive balancing system.

- Battery packs with active balancing systems. Since energy can be transferred among cells, it can theoretically ensure that all cells reach full charge or full discharge simultaneously. The state is defined as follows for the battery pack:where and denote the capacity and SOC of the battery pack with the active balancing system.

3.2.2. Difference Model

4. Decoupling Analysis of Inconsistencies

4.1. Simulation of Battery Pack Connected in Parallel

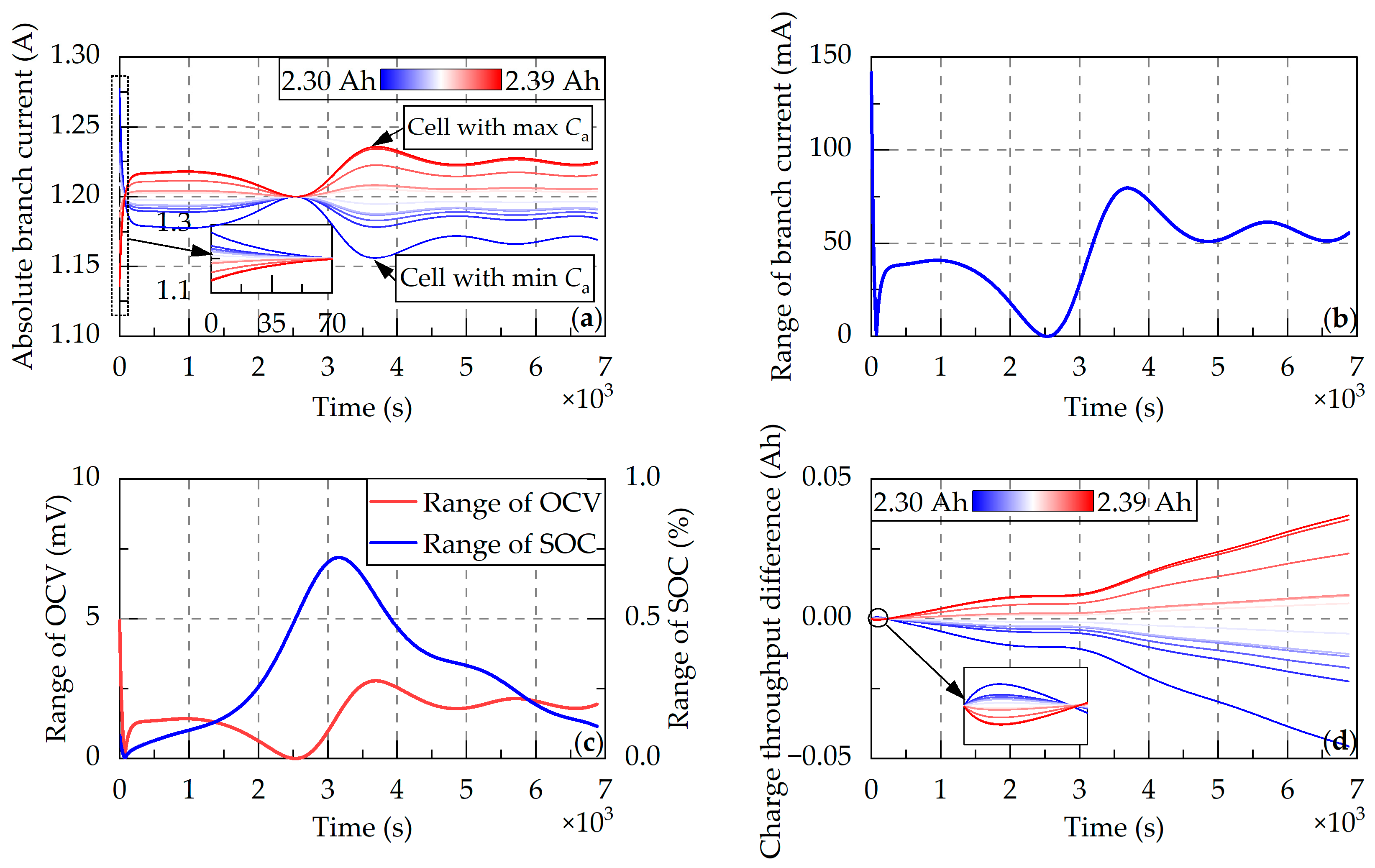

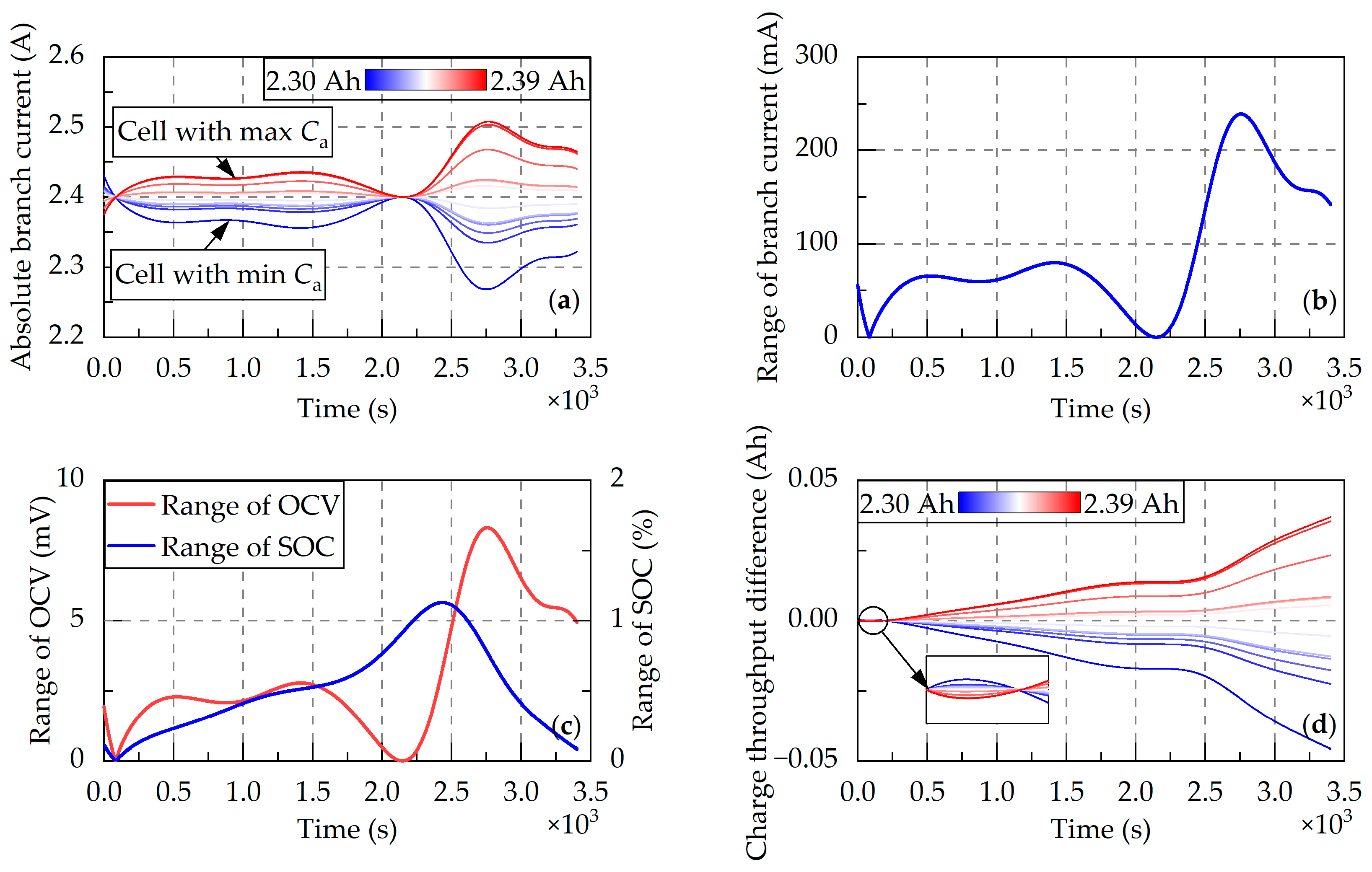

4.1.1. Inconsistent Initial Capacity

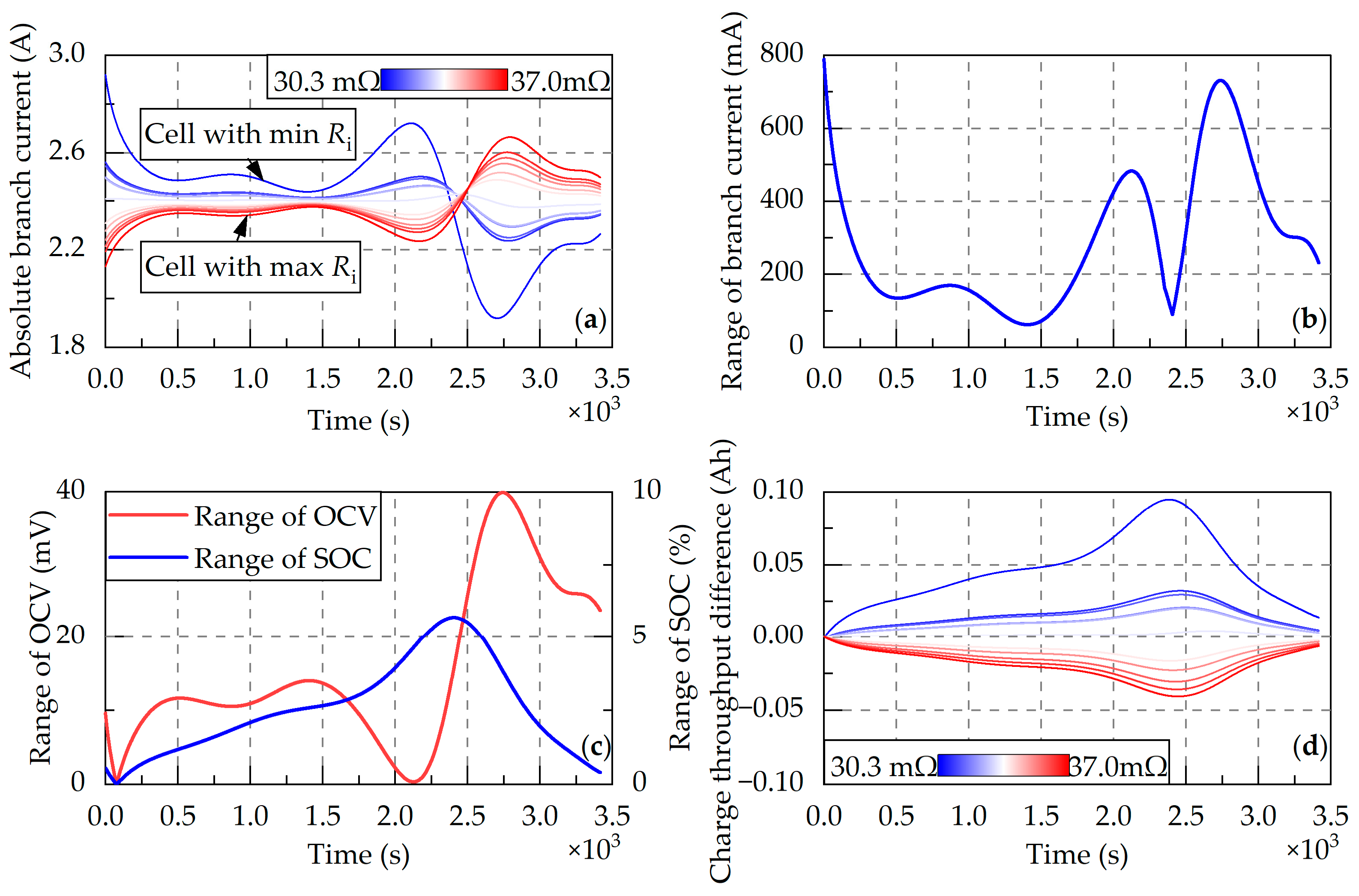

4.1.2. Inconsistent Initial Internal Resistance

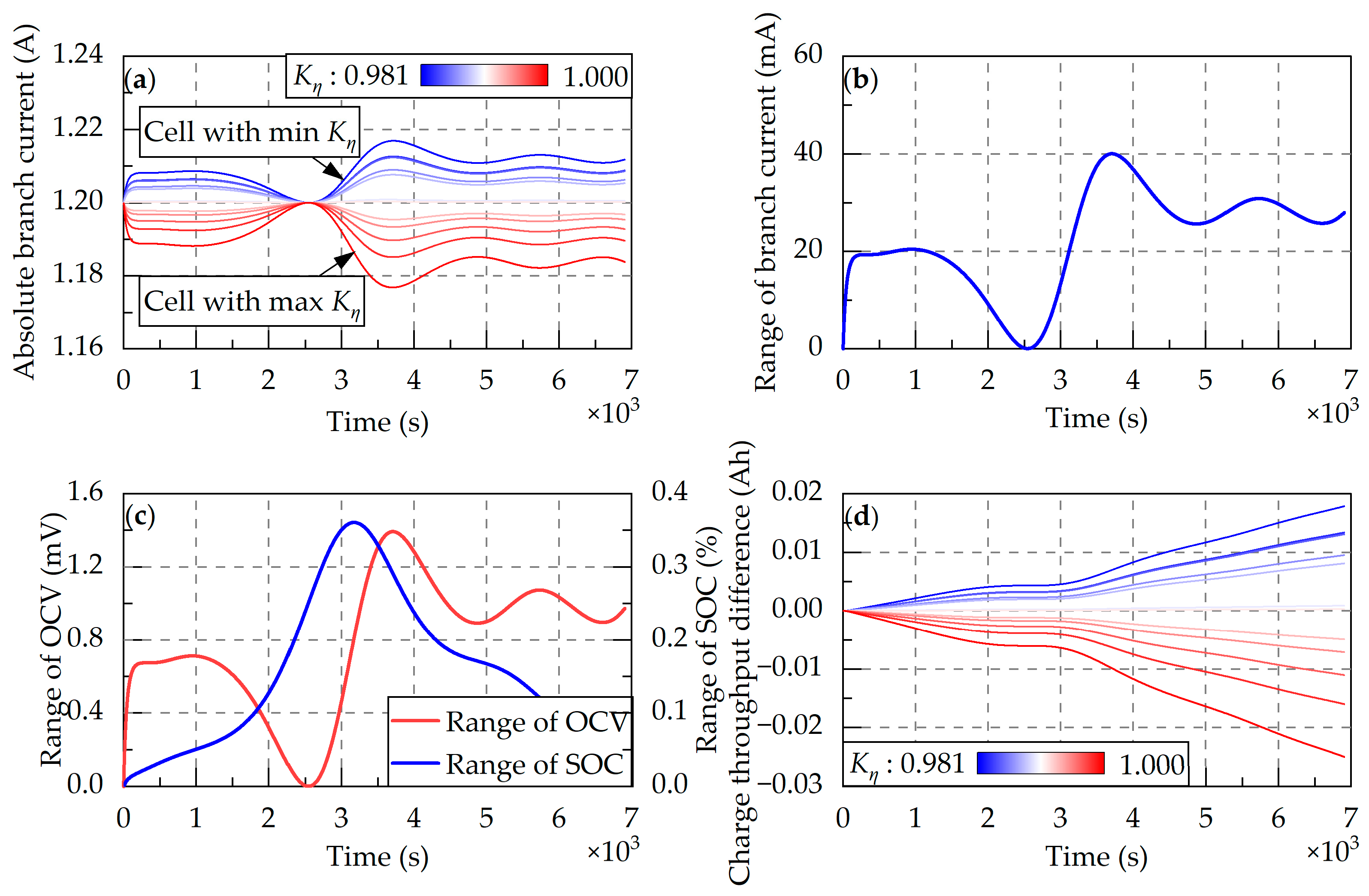

4.1.3. Inconsistent Coulombic Efficiency

4.1.4. Inconsistent Capacity Fade Rate or Resistance Growth Rate

4.2. Simulation of Battery Pack Connected in Series

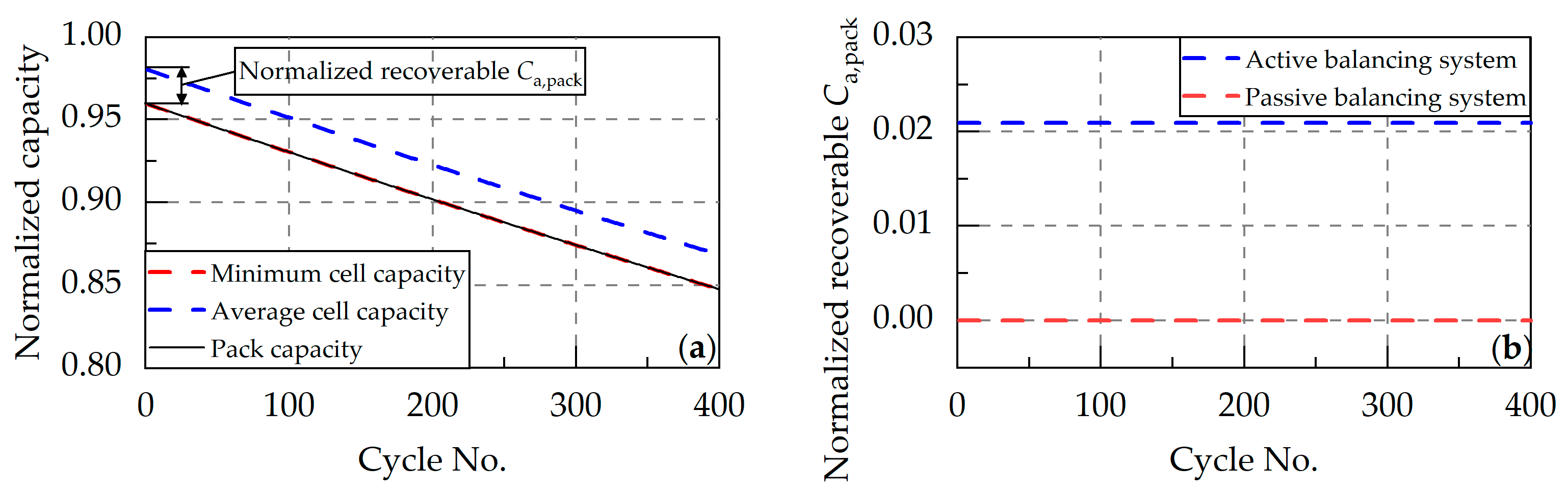

4.2.1. Inconsistent Initial Capacity

4.2.2. Inconsistent Initial Internal Resistance

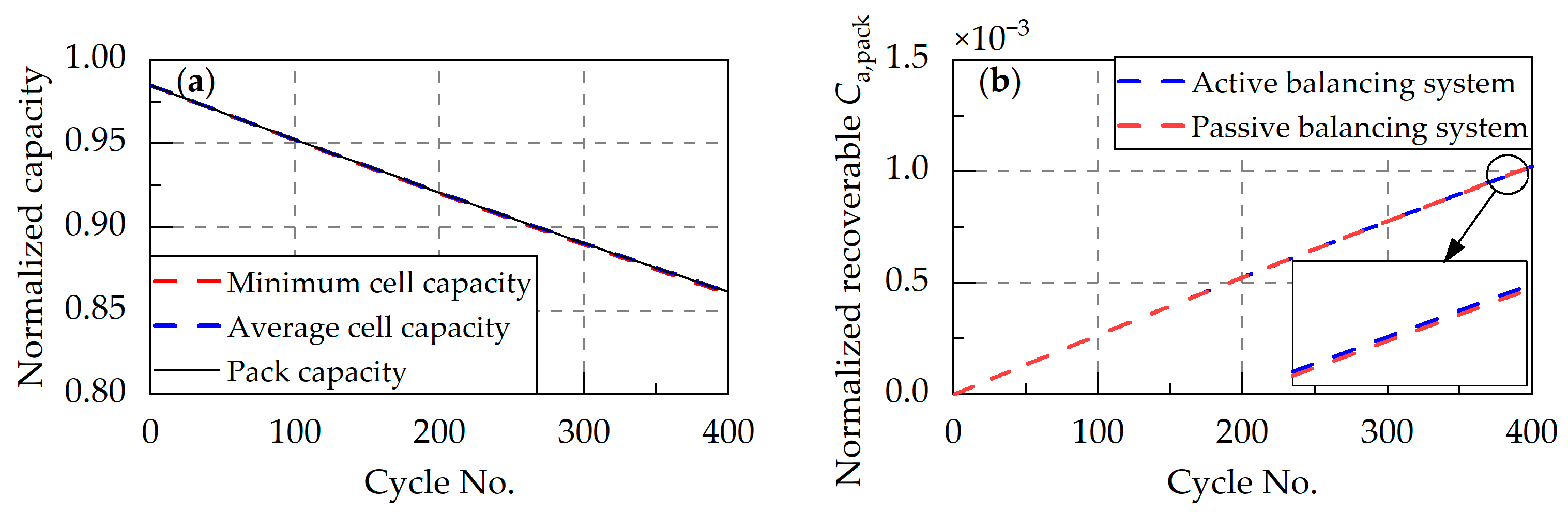

4.2.3. Inconsistent Initial SOC

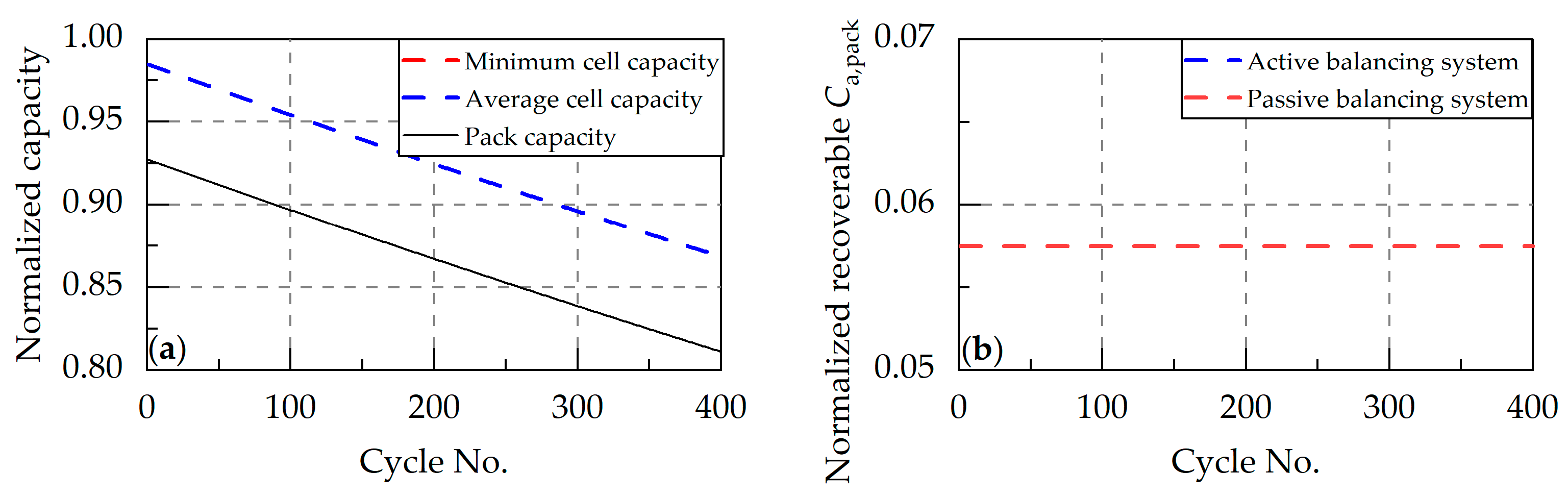

4.2.4. Inconsistent Coulombic Efficiency

4.2.5. Inconsistent Capacity Fade Rate

4.2.6. Inconsistent Resistance Growth Rate

5. Discussion

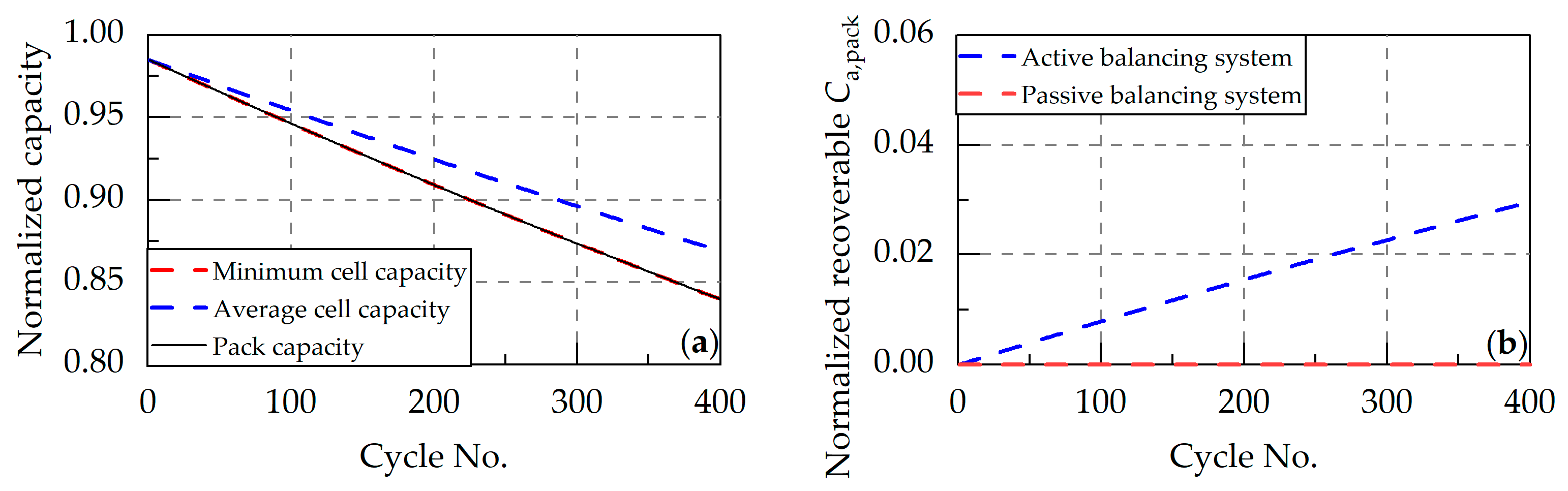

- Capacity inconsistency. Capacity inconsistencies primarily arise from steady-state differences from initial capacity and dynamic differences caused by varying capacity fade rates. Although CE inconsistencies indirectly contribute to capacity inconsistencies, their impact remains negligible compared to the former factors. As mentioned earlier, passive balancing systems cannot address capacity inconsistencies. Only active balancing systems ensuring full charge and discharge of all cells can achieve theoretical maximum pack capacity, while persistent capacity inconsistencies impose heavy loads on active balancing circuits. For well-managed packs with pre-screened capacities, the costly and complex active balancing systems can be avoided.

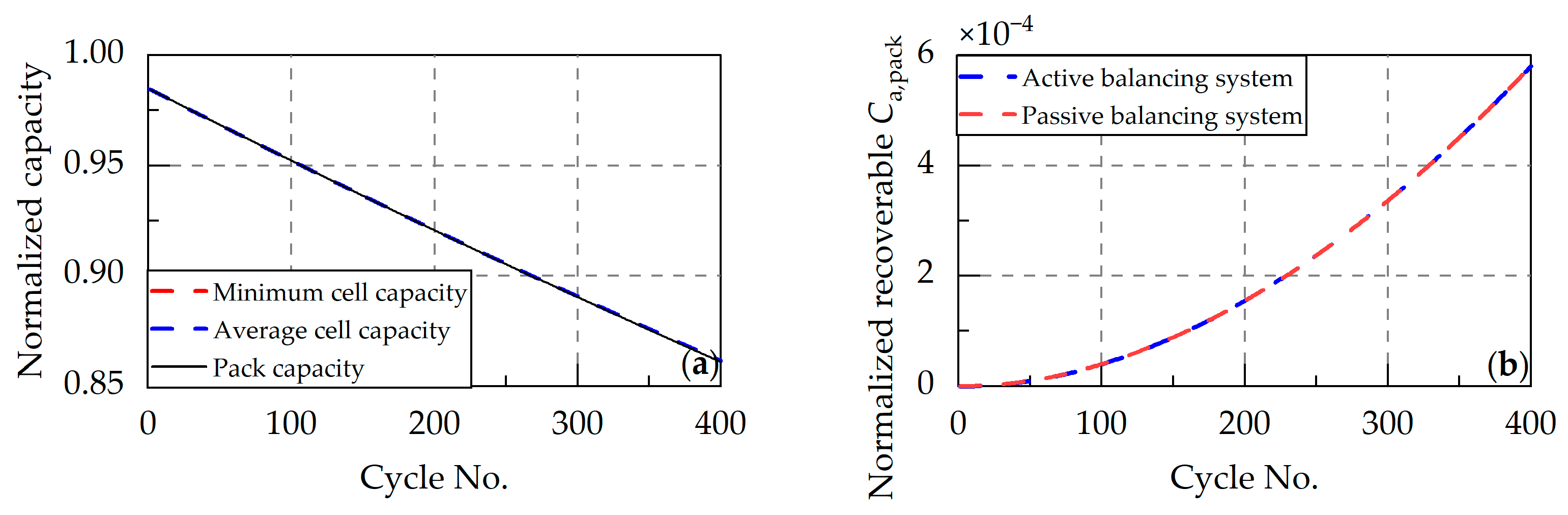

- Resistance inconsistency. Resistance inconsistencies originate from inconsistent initial resistances and resistance growth rates. Large resistance differences can induce thermal differences, indirectly affecting CE and capacity fade rates. However, in packs with optimized thermal management systems, such effects remain negligible. Simulations confirm that resistance inconsistencies do not greatly affect the capacity of series-connected battery packs. However, like parallel-connected packs, they can limit the available power and overall performance. Notably, series-connected packs demand stricter consistency in capacity and charge during pre-assembly screening, with resistance uniformity being comparatively less critical.

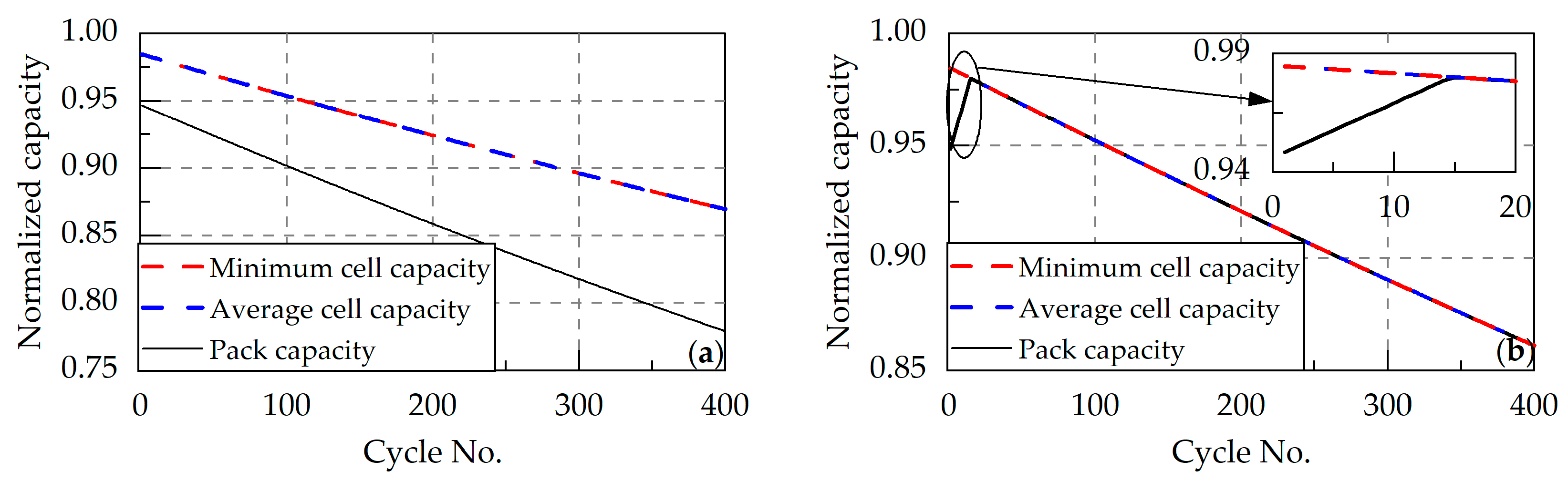

- Charge inconsistency. Initial SOC and CE variations jointly determine charge inconsistency. Initial SOC-induced charge inconsistencies remain constant during cycling, while CE-induced charge differences accumulate with aging. Initial SOC variations can be eliminated early in the pack’s life through balancing systems, so their impact is transient. In contrast, CE-induced charge differences are persistent, requiring continuous balancing throughout the pack’s life. Simulation experiments show that charge inconsistencies are the main cause of pack capacity fading, while in the case of only inconsistent charge, there is almost no difference in the pack capacity loss that can be restored through passive or active balancing systems. To reduce balancing loads, pre-assembly screening should minimize initial SOC variations, coupled with manufacturing process improvements to reduce CE inconsistencies. Notably, the above simulation is for battery packs with uniform heat dissipation. Long-term aging may amplify thermal inconsistencies, which can further indirectly cause charge differences due to temperature-dependent CE. While balancing systems can address resultant pack capacity losses, an effective thermal management system remains essential throughout the battery’s lifecycle, significantly reducing the operational burden on balancing circuits.

6. Conclusions

- Parallel-connected packs can avoid the need for external balancing systems due to self-balancing mechanisms. However, excessive internal resistance inconsistencies may cause individual cells to experience current rates that exceed the pack averages, which accelerates aging and poses safety risks.

- In series-connected packs, inconsistencies in capacity and charge accelerate degradation, with charge inconsistency caused by different CE and initial SOC being the primary factor. Capacity inconsistency can only be addressed through active balancing systems, while both active and passive balancing systems are effective for packs with charge inconsistencies. Although internal resistance inconsistencies have a relatively minor impact on the capacity of series-connected packs, they do constrain power performance.

- For packs with well-controlled capacity and thermal uniformity, a passive balancing current of 0.001 C can eliminate up to 3.8% capacity loss within 15 cycles. Therefore, pre-assembly capacity screening and thermal management during operation are critical. Under these conditions, passive balancing systems can significantly reduce complexity and costs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ashok, B.; Kannan, C.; Mason, B.; Ashok, S.D.; Indragandhi, V.; Patel, D.; Wagh, A.S.; Jain, A.; Kavitha, C. Towards Safer and Smarter Design for Lithium-Ion-Battery-Powered Electric Vehicles: A Comprehensive Review on Control Strategy Architecture of Battery Management System. Energies 2022, 15, 4227. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Zhou, S.; Yan, Q.; Zhan, H.; Cheng, Y.; Yin, W. Impact of Individual Cell Parameter Difference on the Performance of Series–Parallel Battery Packs. ACS Omega 2023, 8, 10512–10524. [Google Scholar] [CrossRef] [PubMed]

- Tian, J.; Fan, Y.; Pan, T.; Zhang, X.; Yin, J.; Zhang, Q. A Critical Review on Inconsistency Mechanism, Evaluation Methods and Improvement Measures for Lithium-Ion Battery Energy Storage Systems. Renew. Sustain. Energy Rev. 2024, 189, 113978. [Google Scholar] [CrossRef]

- Dhanaselvam, J.; Rukkumani, V.; Saravanakumar, K.; Rajesh, R. A Critical Review on Key Issues of Performance Degradation Factors for Lithium-Ion Batteries. IOP Conf. Ser. Earth Environ. Sci. 2024, 1375, 012021. [Google Scholar] [CrossRef]

- Kumar, N.; Ramakrishnan, S.M.; Panchapakesan, K.; Subramaniam, D.; Masters, I.; Dowson, M.; Das, A. In-Depth Evaluation of Micro-Resistance Spot Welding for Connecting Tab to 18,650 Li-Ion Cells for Electric Vehicle Battery Application. Int. J. Adv. Manuf. Technol. 2022, 121, 6581–6597. [Google Scholar] [CrossRef]

- Ghaeminezhad, N.; Wang, Z.; Ouyang, Q. A Review on Lithium-Ion Battery Thermal Management System Techniques: A Control-Oriented Analysis. Appl. Therm. Eng. 2023, 219, 119497. [Google Scholar] [CrossRef]

- Yu, H.; Wang, L.; Zhang, Z.; Li, Y.; Yang, S.; He, X. Insight Understanding of External Pressure on Lithium Plating in Commercial Lithium-Ion Batteries. Adv. Funct. Mater. 2024, 34, 2406966. [Google Scholar] [CrossRef]

- Roy, P.K.; Shahjalal, M.; Shams, T.; Fly, A.; Stoyanov, S.; Ahsan, M.; Haider, J. A Critical Review on Battery Aging and State Estimation Technologies of Lithium-Ion Batteries: Prospects and Issues. Electronics 2023, 12, 4105. [Google Scholar] [CrossRef]

- Schomburg, F.; Heidrich, B.; Wennemar, S.; Drees, R.; Roth, T.; Kurrat, M.; Heimes, H.; Jossen, A.; Winter, M.; Cheong, J.Y.; et al. Lithium-Ion Battery Cell Formation: Status and Future Directions towards a Knowledge-Based Process Design. Energy Environ. Sci. 2024, 17, 2686–2733. [Google Scholar] [CrossRef]

- Uzair, M.; Abbas, G.; Hosain, S. Characteristics of Battery Management Systems of Electric Vehicles with Consideration of the Active and Passive Cell Balancing Process. World Electr. Veh. J. 2021, 12, 120. [Google Scholar] [CrossRef]

- Mohammadi, F. Lithium-Ion Battery State-of-Charge Estimation Based on an Improved Coulomb-Counting Algorithm and Uncertainty Evaluation. J. Energy Storage 2022, 48, 104061. [Google Scholar] [CrossRef]

- Simolka, M.; Heger, J.-F.; Traub, N.; Kaess, H.; Friedrich, K.A. Influence of Cycling Profile, Depth of Discharge and Temperature on Commercial LFP/C Cell Ageing: Cell Level Analysis with ICA, DVA and OCV Measurements. J. Electrochem. Soc. 2020, 167, 110502. [Google Scholar] [CrossRef]

- Spitthoff, L.; Shearing, P.R.; Burheim, O.S. Temperature, Ageing and Thermal Management of Lithium-Ion Batteries. Energies 2021, 14, 1248. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Hannan, M.A.; Karim, T.F.; Hussain, A.; Hussain, A.; Saad, M.H.M.; Ayob, A.; Miah, M.S.; Miah, M.S.; Miah, M.S.; et al. Intelligent Algorithms and Control Strategies for Battery Management System in Electric Vehicles: Progress, Challenges and Future Outlook. J. Clean. Prod. 2021, 292, 126044. [Google Scholar] [CrossRef]

- Tan, C.M.; Yang, Y.; Kumar, K.J.M.; Mishra, D.D.; Liu, T.-Y. Addressing Practical Challenges of LiB Cells in Their Pack Applications. Sci. Rep. 2024, 14, 10126. [Google Scholar] [CrossRef]

- Xia, B.; Yang, Y.; Zhou, J.; Chen, G.; Liu, Y.; Wang, H.; Wang, M.; Lai, Y. Using Self Organizing Maps to Achieve Lithium-Ion Battery Cells Multi-Parameter Sorting Based on Principle Components Analysis. Energies 2019, 12, 2980. [Google Scholar] [CrossRef]

- Feng, X.-H.; Li, Z.-Z.; Gu, F.-S.; Zhang, M.-L. Structural Design and Optimization of Air-Cooled Thermal Management System for Lithium-Ion Batteries Based on Discrete and Continuous Variables. J. Energy Storage 2024, 86, 111202. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Huang, L.; Song, J.; Huang, Z. Study on the Influence of Connection Structure between Batteries on Battery Pack Performance. Electronics 2024, 13, 817. [Google Scholar] [CrossRef]

- Ashraf, A.; Ali, B.; Alsunjury, M.S.A.; Goren, H.; Kilicoglu, H.; Hardan, F.; Tricoli, P. Review of Cell-Balancing Schemes for Electric Vehicle Battery Management Systems. Energies 2024, 17, 1271. [Google Scholar] [CrossRef]

- Xie, J.; Lin, H.; Qu, J.; Shi, L.; Chen, Z.; Chen, S.; Zheng, Y. Hierarchical Structure-Based Wireless Active Balancing System for Power Batteries. Energies 2024, 17, 4602. [Google Scholar] [CrossRef]

- Sun, W.; Li, Y.; Liu, L.; Mai, R. A Switched-capacitor Battery Equalization Method for Improving Balancing Speed. IET Electr. Power Appl. 2021, 15, 555–569. [Google Scholar] [CrossRef]

- Abareshi, M.; Hamzeh, M.; Farhangi, S.; Alavi, S.M.M. Robust Control of a Forward-converter Active Battery Cell Balancing. IET Power Electron. 2023, 16, 1271–1280. [Google Scholar] [CrossRef]

- Duraisamy, T.; Kaliyaperumal, D. Adaptive Passive Balancing in Battery Management System for E-mobility. Int. J. Energy Res. 2021, 45, 10752–10764. [Google Scholar] [CrossRef]

- Hemavathi, S. Overview of Cell Balancing Methods for Li-ion Battery Technology. Energy Storage 2021, 3, e203. [Google Scholar] [CrossRef]

- Xia, Q.; Yang, D.; Wang, Z.; Ren, Y.; Sun, B.; Feng, Q.; Qian, C. Multiphysical Modeling for Life Analysis of Lithium-Ion Battery Pack in Electric Vehicles. Renew. Sustain. Energy Rev. 2020, 131, 109993. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z.; Chen, Z.; Chen, Z.; Chen, Z. A Comprehensive Review of Battery Modeling and State Estimation Approaches for Advanced Battery Management Systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Zhou, W.; Zheng, Y.; Pan, Z.; Lu, Q. Review on the Battery Model and SOC Estimation Method. Processes 2021, 9, 1685. [Google Scholar] [CrossRef]

- Lai, X.; Zhou, L.; Zhu, Z.; Zheng, Y.; Sun, T.; Shen, K. Experimental Investigation on the Characteristics of Coulombic Efficiency of Lithium-Ion Batteries Considering Different Influencing Factors. Energy 2023, 274, 127408. [Google Scholar] [CrossRef]

- Zhang, Z.; Cheng, X.; Lu, Z.-Y.; Gu, D.-J. SOC Estimation of Lithium-Ion Battery Pack Considering Balancing Current. IEEE Trans. Power Electron. 2018, 33, 2216–2226. [Google Scholar] [CrossRef]

- Hu, L.; Hu, X.S.; Che, Y.H.; Feng, F.; Lin, X.K.; Zhang, Z.Y. Reliable State of Charge Estimation of Battery Packs Using Fuzzy Adaptive Federated Filtering. Appl. Energy 2020, 262, 15. [Google Scholar] [CrossRef]

- Song, Z.; Yang, X.-G.; Yang, N.; Delgado, F.P.; Hofmann, H.; Sun, J. A Study of Cell-to-Cell Variation of Capacity in Parallel-Connected Lithium-Ion Battery Cells. eTransportation 2021, 7, 100091. [Google Scholar] [CrossRef]

- Gong, X.; Xiong, R.; Mi, C.C. Study of the Characteristics of Battery Packs in Electric Vehicles With Parallel-Connected Lithium-Ion Battery Cells. IEEE Trans. Ind. Appl. 2015, 51, 1872–1879. [Google Scholar] [CrossRef]

- Lv, J.; Song, W.; Feng, Z.; Li, Y.; Ding, Y. Performance and Comparison of Equalization Methods for Lithium Ion Batteries in Series. Int. J. Energy Res. 2021, 45, 4669–4680. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Size | Ø18 × 65 mm |

| Normal capacity | 2.4 Ah |

| Cut-off voltages | 3.0–4.2 V |

| Max discharge rate | 4 C (0~40 °C) |

| Normal charge rate | 0.5 C at 25 °C |

| Operating temperature | −20–60 °C for discharge and 10–45 °C for charge |

| Mass | 48 g |

| Parameters | z0 | Ca,0 | Ri,0 | Kη | Ca,400 | Ri,400 |

| Expectation | 0.5 | 2.363 Ah | 34.78 mΩ | 0.9884 | 2.026 Ah | 47.04 mΩ |

| Standard deviation | 0.01 | 0.03 Ah | 1.53 mΩ | 5 × 10−5 | 0.06 Ah | 3.13 mΩ |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Ca,0 (Ah) | 2.34 | 2.33 | 2.33 | 2.35 | 2.30 | 2.39 | 2.38 | 2.36 | 2.36 | 2.34 | 2.39 | 2.36 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Ri,0 (mΩ) | 35.5 | 36.4 | 35.9 | 34.3 | 35.2 | 33.6 | 36.1 | 33.0 | 33.1 | 33.5 | 30.3 | 37.0 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Kη (10−1) | 9.83 | 9.89 | 9.91 | 9.94 | 9.96 | 9.89 | 9.81 | 9.85 | 9.83 | 10.00 | 9.85 | 9.92 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| SOC0 (%) | 50.5 | 51.8 | 47.7 | 50.9 | 50.3 | 48.7 | 49.6 | 50.3 | 53.6 | 52.8 | 48.7 | 53.0 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Kη (10−1) | 9.8834 | 9.8844 | 9.8841 | 9.8839 | 9.8840 | 9.8831 | 9.8839 | 9.8847 | 9.8839 | 9.8839 | 9.8835 | 9.8839 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| kC (−10−4 Ah) | 8.47 | 8.53 | 8.07 | 7.02 | 6.20 | 8.02 | 8.40 | 7.85 | 8.35 | 10.0 | 6.87 | 7.87 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| kR (10−2 mΩ) | 2.86 | 2.65 | 4.16 | 3.23 | 2.29 | 4.38 | 4.23 | 2.24 | 2.22 | 2.90 | 3.21 | 3.73 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| SOC0 (%) | 47.9 | 48.0 | 48.9 | 49.2 | 49.8 | 50.1 | 50.5 | 50.7 | 51.0 | 51.4 | 51.4 | 51.7 |

| Kη (10−1) | 9.8831 | 9.8834 | 9.8835 | 9.8839 | 9.8839 | 9.8839 | 9.8839 | 9.8839 | 9.8840 | 9.8841 | 9.8844 | 9.8847 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Y.; Ye, W.; Zhang, Q.; Wang, J.; Lu, J. Decoupling Analysis of Parameter Inconsistencies in Lithium-Ion Battery Packs Guiding Balancing System Design. Energies 2025, 18, 3439. https://doi.org/10.3390/en18133439

Duan Y, Ye W, Zhang Q, Wang J, Lu J. Decoupling Analysis of Parameter Inconsistencies in Lithium-Ion Battery Packs Guiding Balancing System Design. Energies. 2025; 18(13):3439. https://doi.org/10.3390/en18133439

Chicago/Turabian StyleDuan, Yanzhou, Wenbin Ye, Qiang Zhang, Jixu Wang, and Jiahuan Lu. 2025. "Decoupling Analysis of Parameter Inconsistencies in Lithium-Ion Battery Packs Guiding Balancing System Design" Energies 18, no. 13: 3439. https://doi.org/10.3390/en18133439

APA StyleDuan, Y., Ye, W., Zhang, Q., Wang, J., & Lu, J. (2025). Decoupling Analysis of Parameter Inconsistencies in Lithium-Ion Battery Packs Guiding Balancing System Design. Energies, 18(13), 3439. https://doi.org/10.3390/en18133439