Study on Dispersion of Impulse Discharge in SF6 and Eco-Friendly Insulating Gas C4F7N/CO2

Abstract

1. Introduction

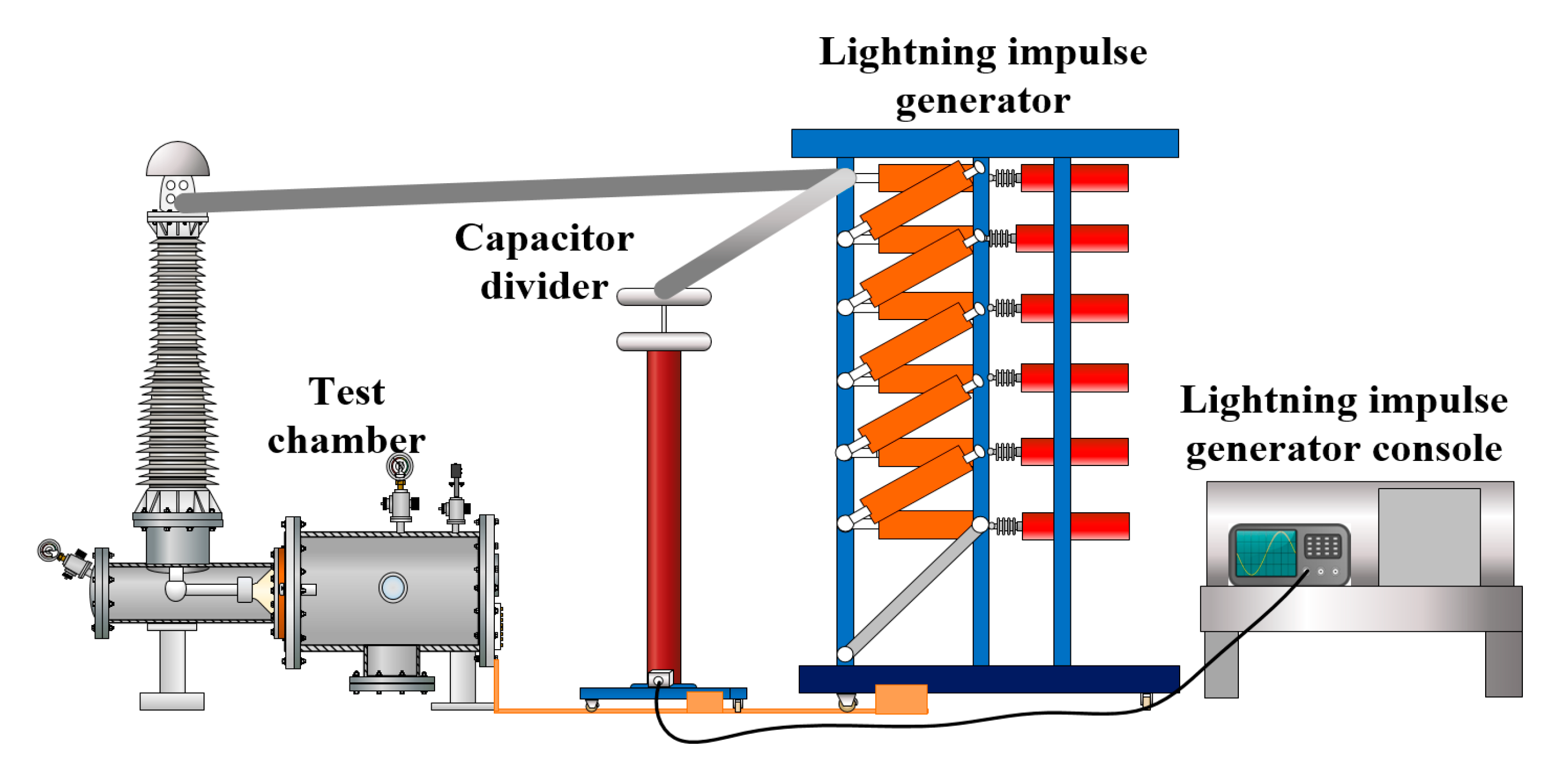

2. Experimental Setup and Methodology

2.1. Experimental Setup

2.2. Methodology

3. Results and Analysis

3.1. Effect of Pressure on Dispersion

3.2. Effect of Electric Field NonUniformity

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| GIL | Gas-insulated line |

| DISP | Dispersion |

References

- Cressault, Y.; Connord, V.; Hingana, H.; Teulet, P.; Gleizes, A. Transport properties of CF3I thermal plasmas mixed with CO2 gas or N2 as an alternative to SF6 plasmas in high-voltage circuit breakers. J. Phys. D-Appl. Phys. 2011, 44, 495202. [Google Scholar] [CrossRef]

- Zhao, H.; Li, X.; Zhu, K.; Wang, Q. Study of the arc interruption performance of SF6/CO2 mixtures as a substitute for SF6. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2657–2667. [Google Scholar] [CrossRef]

- Li, P.; Yan, X.; Wang, H.; Zhang, Q.; Jin, G.; Gao, Y.; Mu, S. Research and application of UHVAC gas-insulated transmission line. Power Syst. Technol. 2017, 41, 3161–3167. [Google Scholar]

- Kieffel, Y.; Irwin, T.; Ponchon, P.; Owens, J. Green Gas to Replace SF6 in Electrical Grids. IEEE Power Energy Mag. 2016, 14, 32–39. [Google Scholar] [CrossRef]

- Liu, T.; Sun, H.; Li, G.; Zhang, Y.; Wang, J.; Xiao, J. Decay characteristic of gas arc in C4F7N/N2 and C₄F₇N/CO₂ gas mixture by thomson scattering. J. Phys. D Appl. Phys. 2025, 58, 045203. [Google Scholar] [CrossRef]

- Zhao, H.; Li, X.; Tang, N.; Jiang, X.; Lin, H. Dielectric Properties of fluoronitriles/ CO2 and SF6/N2 mixtures as a possible SF6-substitute gas. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1332–1339. [Google Scholar] [CrossRef]

- Tu, Y.; Cheng, Y.; Wang, C.; Ai, X.; Zhou, F.; Chen, G. Insulation Characteristics of fluoronitriles/CO2 gas mixture under DC electric field. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1324–1331. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, W.; Yu, J.; Yu, Z. Insulation properties of C4F7N/CO2 mixtures under lightning impulse. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 159–166. [Google Scholar] [CrossRef]

- Zhang, T.; Chang, L.; Zhou, W. Study on Impulse Discharge Voltage Calculation of Environmentally Friendly Insulation Gas in Slightly Non-Uniform Electric Field. Electronics 2025, 14, 2116. [Google Scholar] [CrossRef]

- Hu, S.; Qiu, R.; Zhou, W. Dielectric properties and synergistic effect evaluation method of C4F7N mixtures. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 793–800. [Google Scholar] [CrossRef]

- Li, X.L.; Liu, L.; Wang, W.; Geng, Z.X. Analysis of breaking characteristics of C4F7N/CO2 mixture gas in circuit breaker. Energies 2024, 17, 2638. [Google Scholar] [CrossRef]

- Nechmi, H.E.; Beroual, A.; Girodet, A.; Vinson, P. Fluoronitriles/CO2 gas mixture as promising substitute to SF6 for insulation in high voltage applications. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2587–2593. [Google Scholar] [CrossRef]

- Zhao, S.; Xiao, D.; Zhang, H.; Deng, Y. Investigation on discharge polarity effect of CF3I/N2 Gas mixtures under lightning impulse. Proc. CSEE 2017, 37, 3636–3642. [Google Scholar]

- Wen, T.; Zhang, Q.; Guo, C.; Zhang, L.; Ma, Y.; Tan, X. Reversal phenomenon of discharge polarity effect in SF6 needle-plate gap under impulse voltage. High Volt. Eng. 2015, 41, 275–281. [Google Scholar]

- IEC 60060; High-Voltage Test Techniques-Part 1: General Definitions and Test Requirements. IEC: Geneva, Switzerland, 2010.

- Zhang, X.; Xiao, S.; Han, Y.; Cressault, Y. Experimental studies on power frequency breakdown voltage of CF3I/N2 mixed gas under different electric fields. Appl. Phys. Lett. 2016, 108, 092901. [Google Scholar] [CrossRef]

- Wei, H.; Sun, F.; Liu, P.; Jiang, X.; Wang, Z. ±100 kV three-electrode field-distortion gas spark switch. High Power Laser Part. Beams 2012, 24, 881–884. [Google Scholar] [CrossRef]

| Electrode Types | Radius/mm | d/mm | Electric Field Nonuniformity f |

|---|---|---|---|

| Plate-plate electrodes | / | 2.5 | 1.01 |

| Sphere-plate electrodes | 3 | 5 | 2.4 |

| 3 | 20 | 6.9 | |

| Needle-plate electrodes | 0.5 | 10 | 13.8 |

| 0.5 | 15 | 18.9 | |

| 0.5 | 20 | 23.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; He, F.; Chang, L.; Zhou, W. Study on Dispersion of Impulse Discharge in SF6 and Eco-Friendly Insulating Gas C4F7N/CO2. Energies 2025, 18, 3228. https://doi.org/10.3390/en18133228

Zhang T, He F, Chang L, Zhou W. Study on Dispersion of Impulse Discharge in SF6 and Eco-Friendly Insulating Gas C4F7N/CO2. Energies. 2025; 18(13):3228. https://doi.org/10.3390/en18133228

Chicago/Turabian StyleZhang, Tianran, Fang He, Lubin Chang, and Wenjun Zhou. 2025. "Study on Dispersion of Impulse Discharge in SF6 and Eco-Friendly Insulating Gas C4F7N/CO2" Energies 18, no. 13: 3228. https://doi.org/10.3390/en18133228

APA StyleZhang, T., He, F., Chang, L., & Zhou, W. (2025). Study on Dispersion of Impulse Discharge in SF6 and Eco-Friendly Insulating Gas C4F7N/CO2. Energies, 18(13), 3228. https://doi.org/10.3390/en18133228