Improving Efficiency of Rolling Mill Stand Electric Drives Through Load Alignment

Abstract

1. Introduction

2. Review of Publications

2.1. Efficiency of Frequency-Controlled Drives Under Variable Loads

2.2. Efficiency Calculation Methods

- Efficiency calculation accuracy is very sensitive to changes in equivalent circuit parameters. These parameters depend on load but the dependency is non-linear.

- The load torque of the stand electric drive is measured discretely (pass by pass) or continuously during each pass. In this case, the optimization of the equivalent circuit is very complicated.

2.3. Existing Rolling Mill Electric Drive Speed and Load Alignment Systems

- -

- they are difficult to implement on an operating rolling mill at variable loads;

- -

- there are no experimental research and industrial trials.

3. Problem Statement

3.1. Control Object Description

3.2. Analysis of Oscillograms with Draft Settings of the Ski Formation System and the LDC

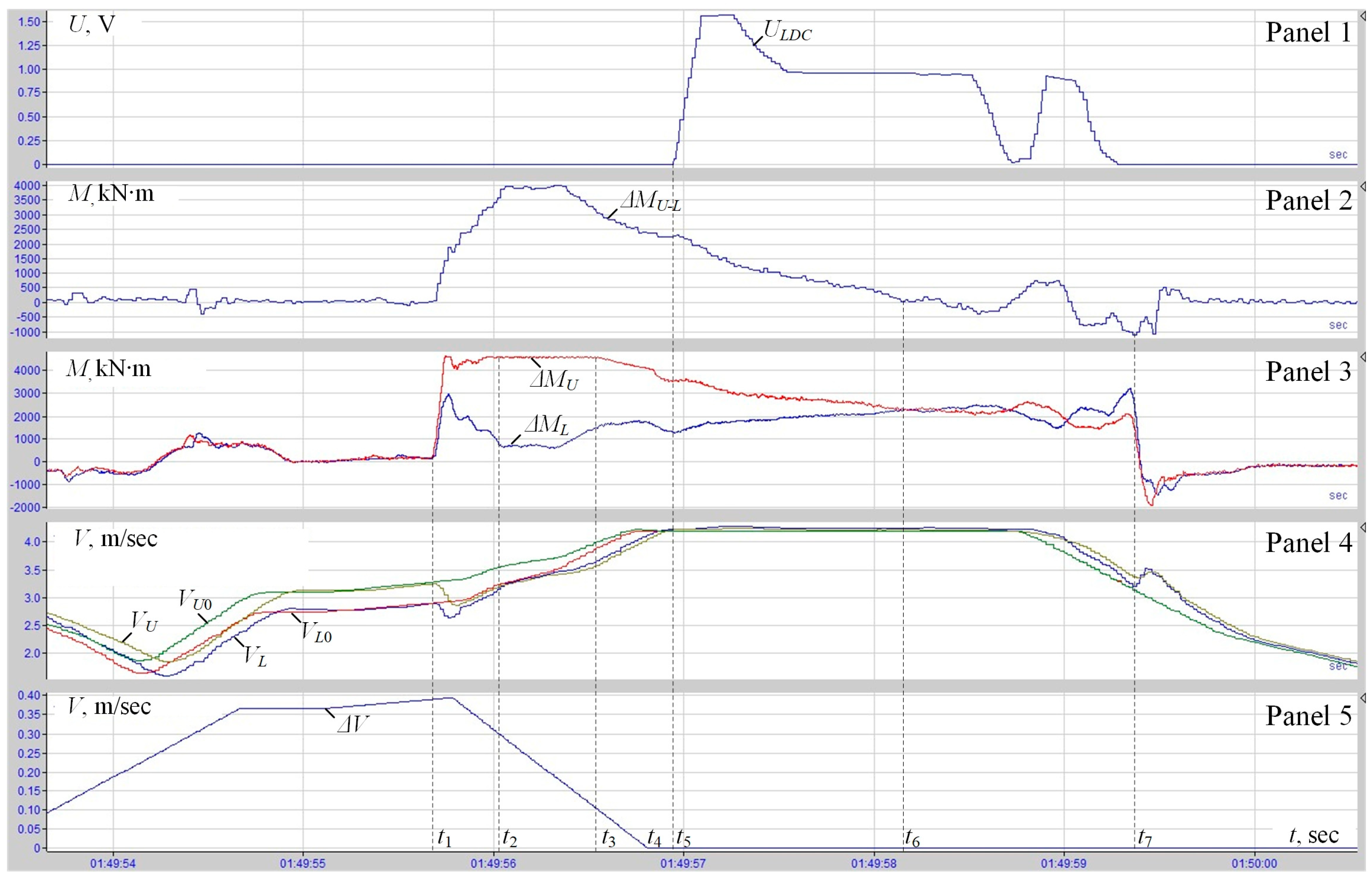

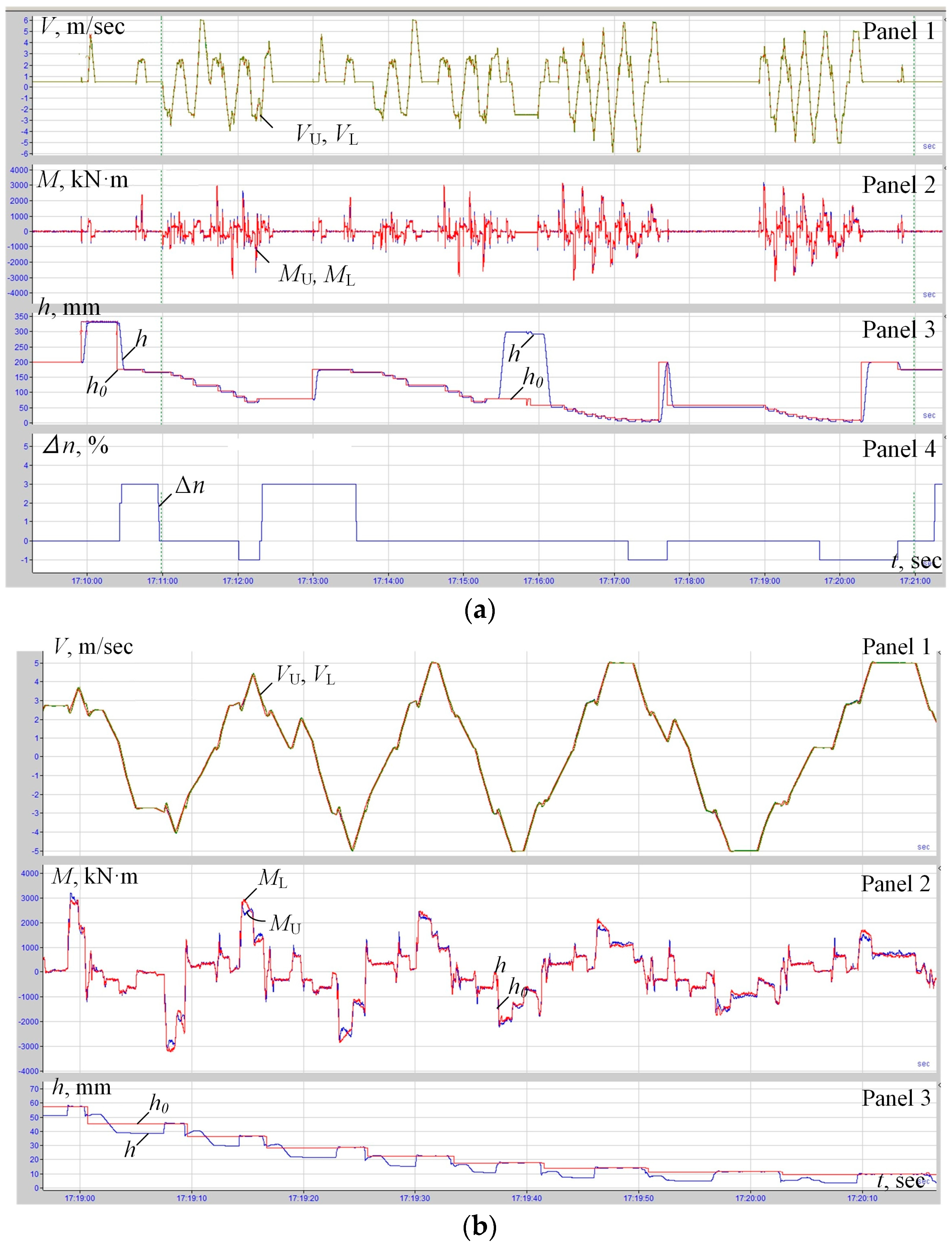

- During the ski-formation system operation, the LDC operation is blocked. The speed adjustment signal at the LDC output (panel 1) occurs only after the Speed Difference for the Ski signal is removed (panel 5). Moreover, it is generated with a delay (t4–t5) and almost immediately reaches the limit.

- During the operation of the ski-formation system, the LMD torque (panel 3) reaches the limit, while the UMD load is approximately twice below the rated value.

- After the signal occurrence on the LDC output (panel 1), loads are slowly aligned (panel 3).

3.3. Research Objectives

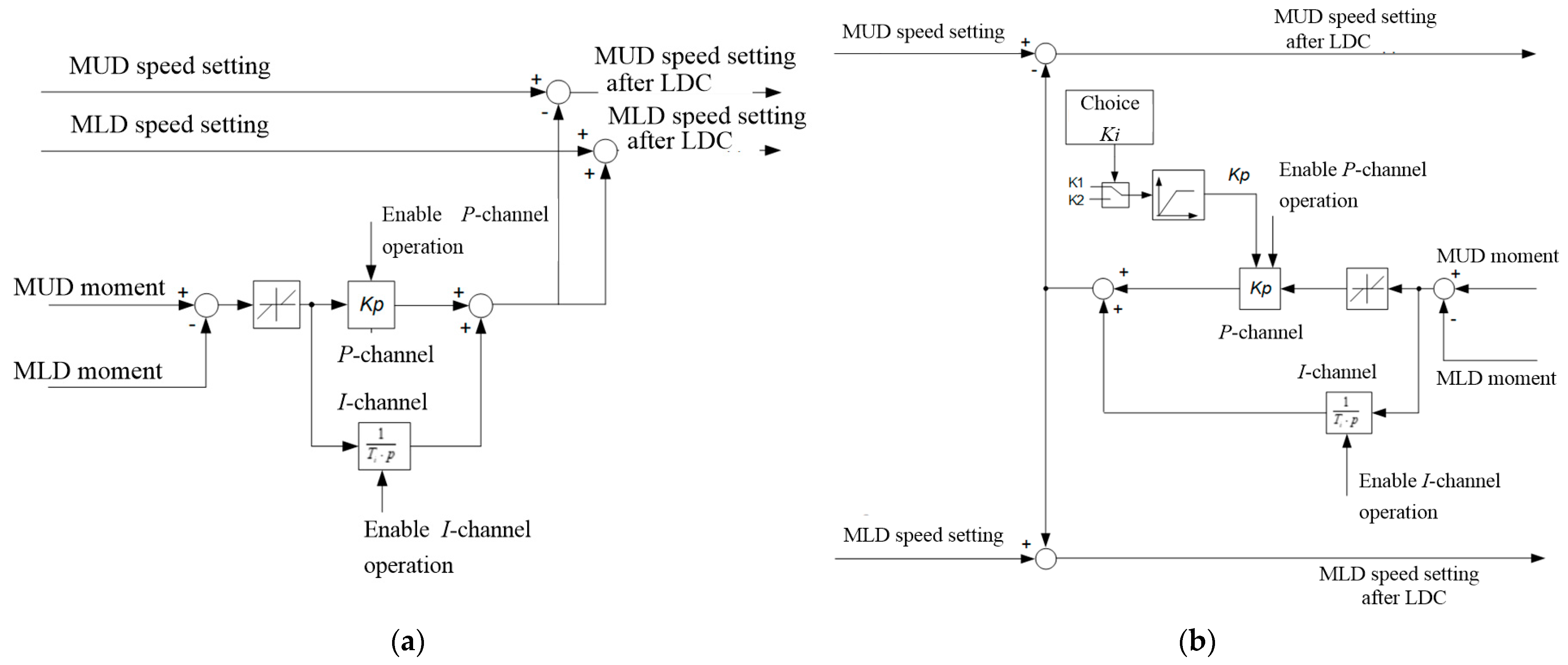

- Analyzing the electricity losses with the draft UMD and LMD control algorithm. Justifying the torque alignment method based on motor speed alignment. Developing the LDC with a switching structure to facilitate the method implementation.

- Developing an observer for electricity losses recovered using electric drive parameters. Using the observer to assess the losses in the draft and developed electric drive control algorithms.

- Conducing an experimental analysis of loss reduction following the deployment of the algorithm accelerating speed alignment.

4. Materials and Methods

4.1. Speed Alignment Experiment with Existing Control Algorithms

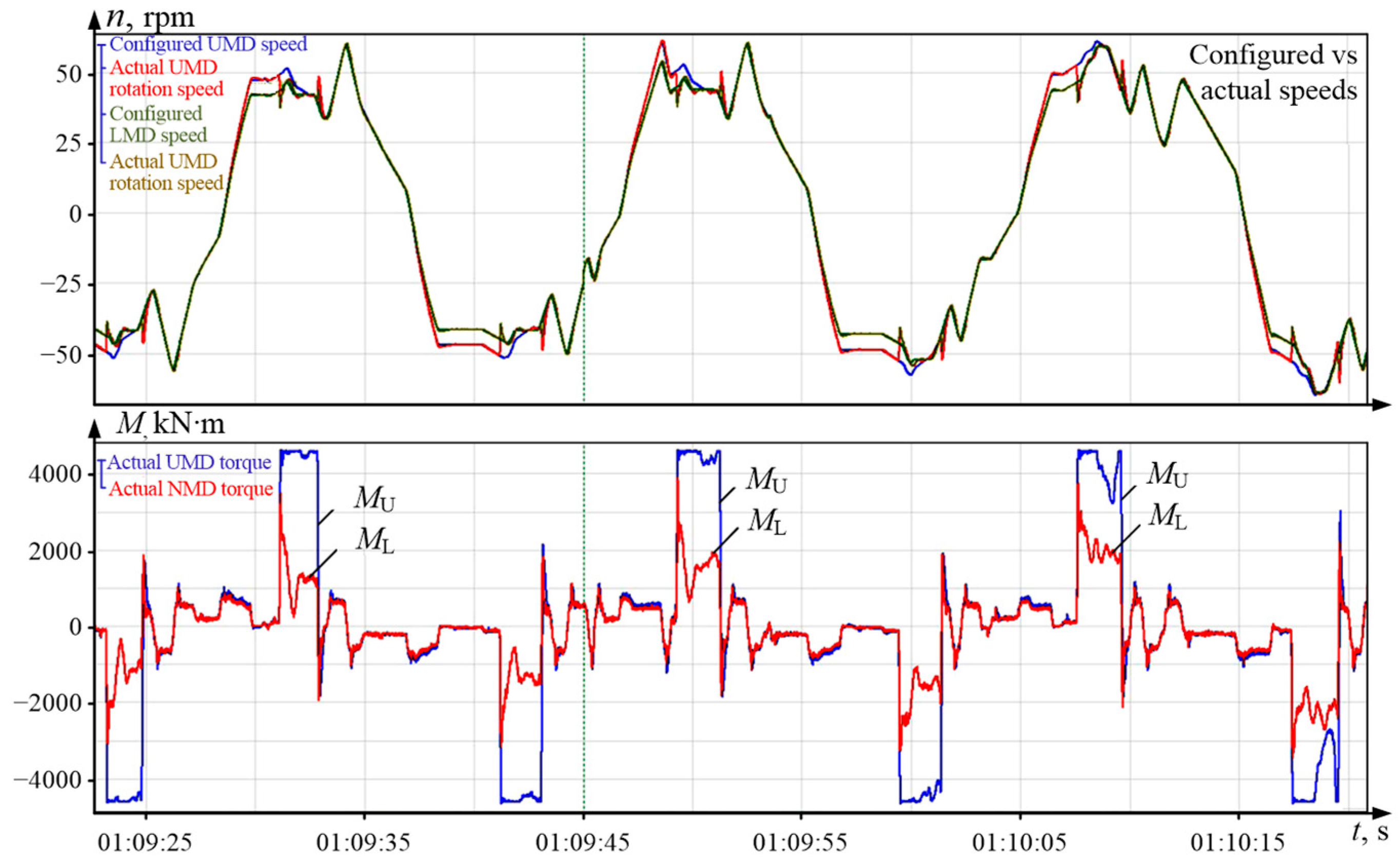

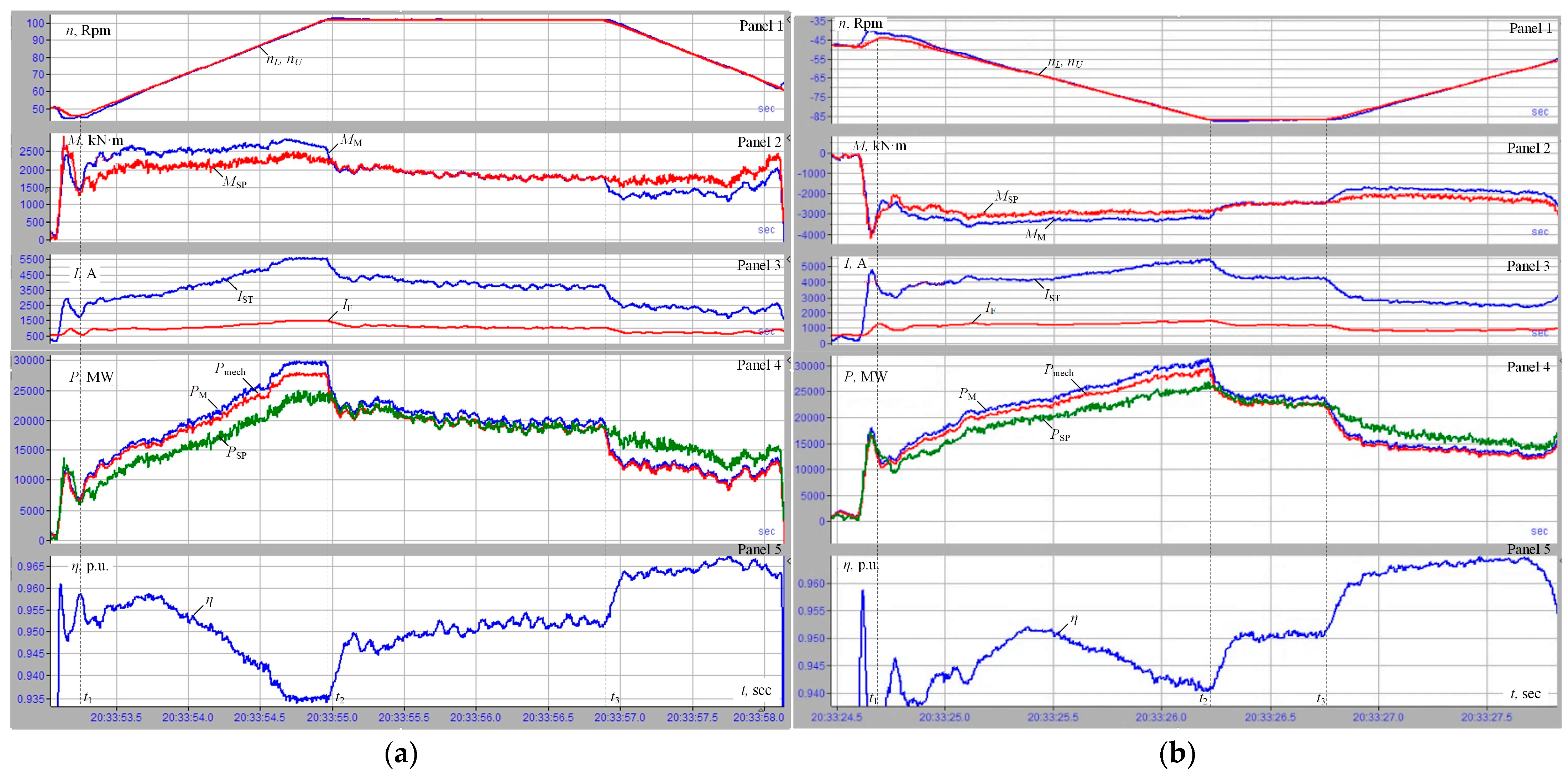

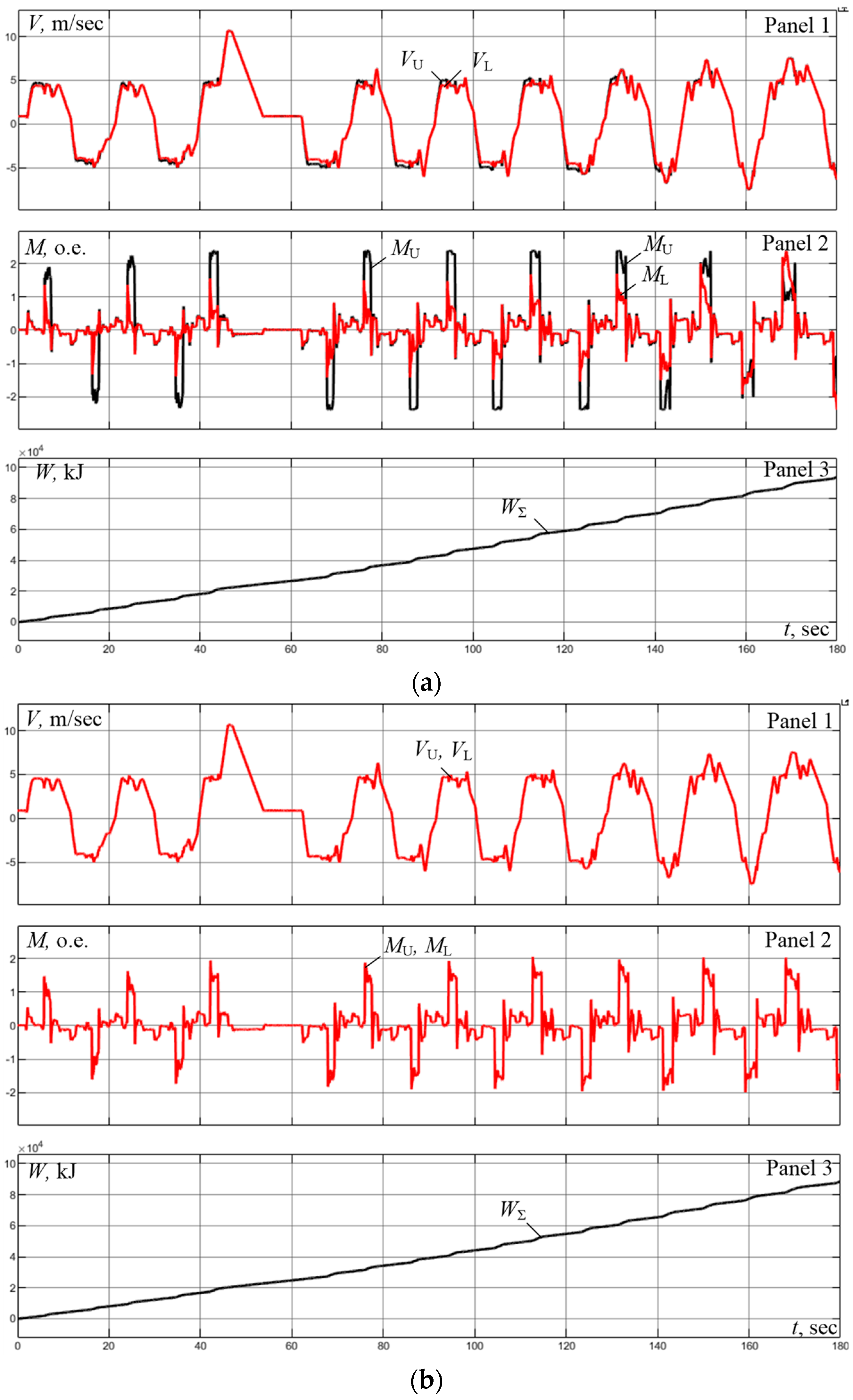

- A speed misalignment of ±5% results in a 2× difference in torques while their ratios are opposite.

- The no-ski state (zero-speed misalignment) provides almost complete alignment of torques.

- During the first passes, the LDC is not activated, therefore torques are not aligned in Figure 7a.

- The misalignment of speeds shown in Figure 7a does not result in the desired bend of the workpiece front end (or it is not visible at least). However, this causes LMD motor overloading and UMD motor underloading resulting in multiple adverse effects.

4.2. Dependency of Motor Efficiency and Load

4.3. The Experimental Assessment of Electricity Losses

- -

- no ski effect: 0.633 MW;

- -

- with a 7% ski effect: 0.752 MW.

5. Implementation

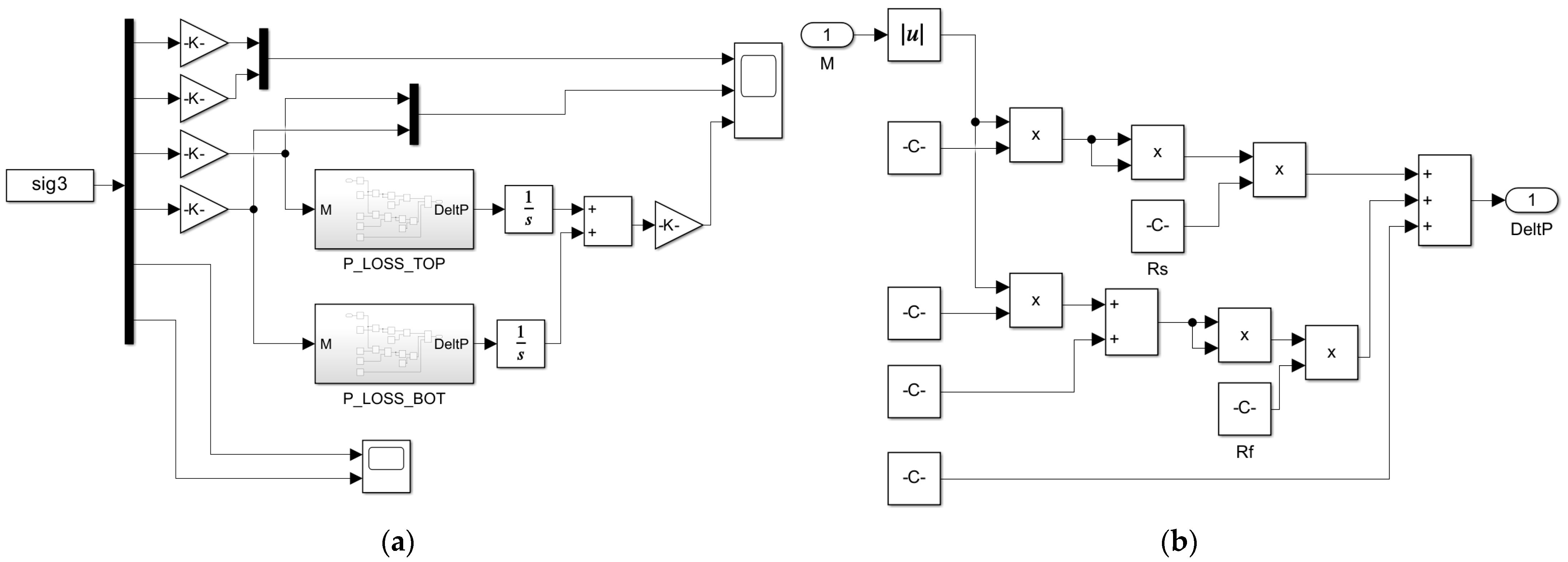

5.1. The Development of the Power Loss Observer

5.2. The Development of an Adaptable LDC

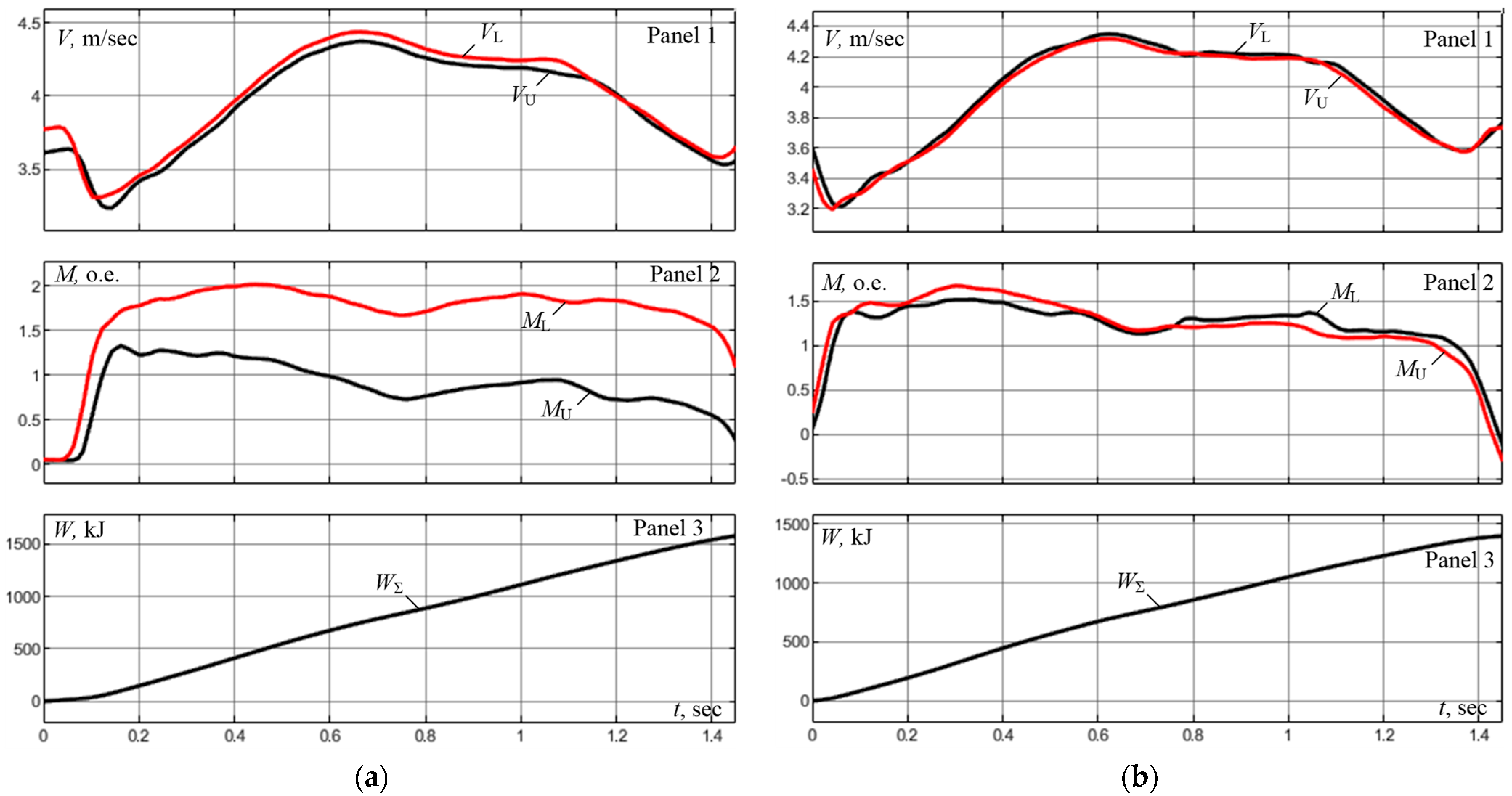

5.3. Modeling Study

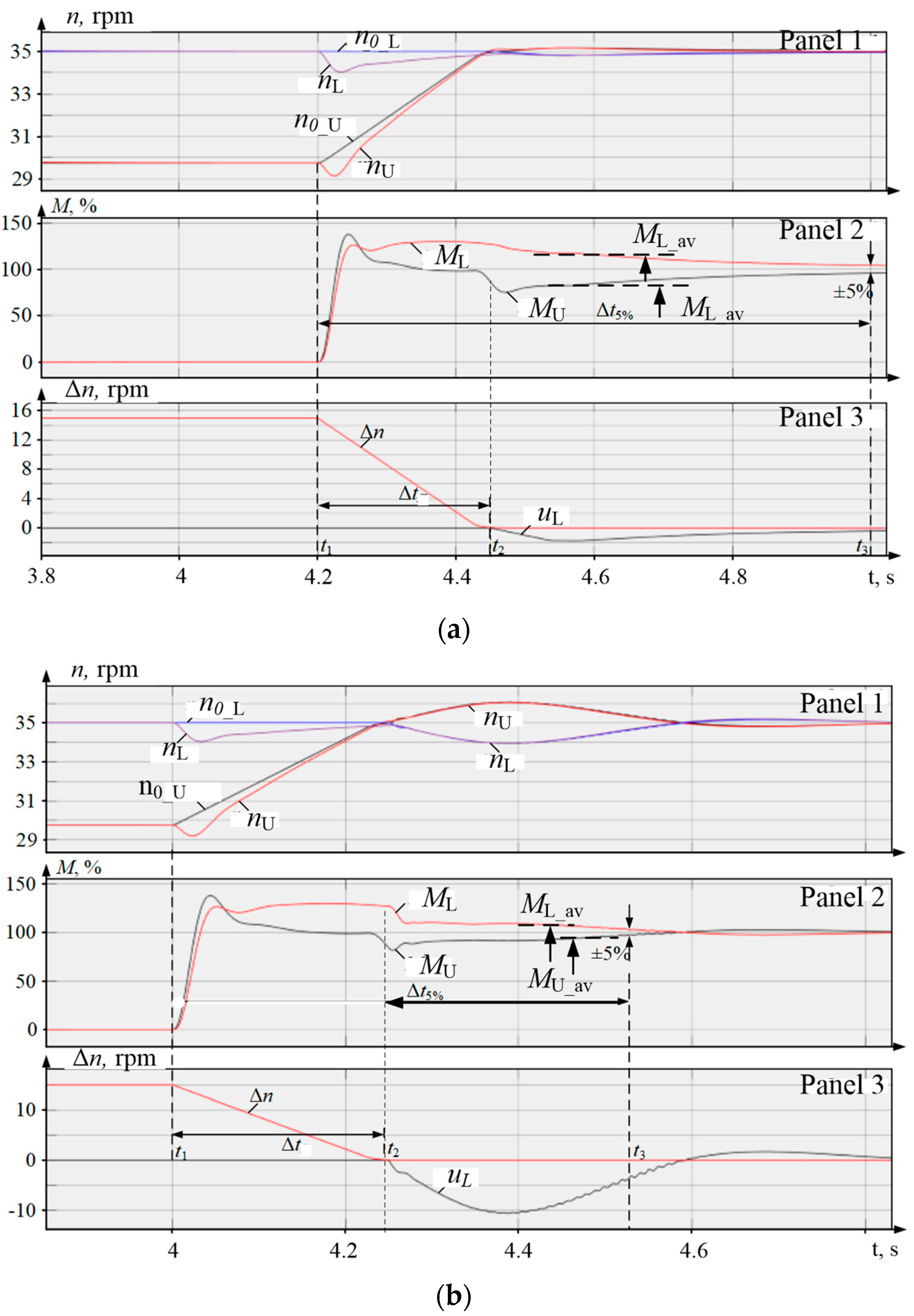

- The steady misalignments of torques under the ski-formation mode over the interval t1–t2 are identical and equal 30% (the LMD torque is 130% while the UMD torque is 100%). This can be attributed to the fact that the LDC does not operate in this interval.

- The arrival time for the 5% deviation zone of the steady torque of 100% is reduced by 2.1 times from Δt5% = 0.62 s to Δt5% = 0.3 s.

6. Results

6.1. The Analysis of Loads in Finishing Passes

6.2. Power Costs Assessment for a Finishing Rolling Cycle

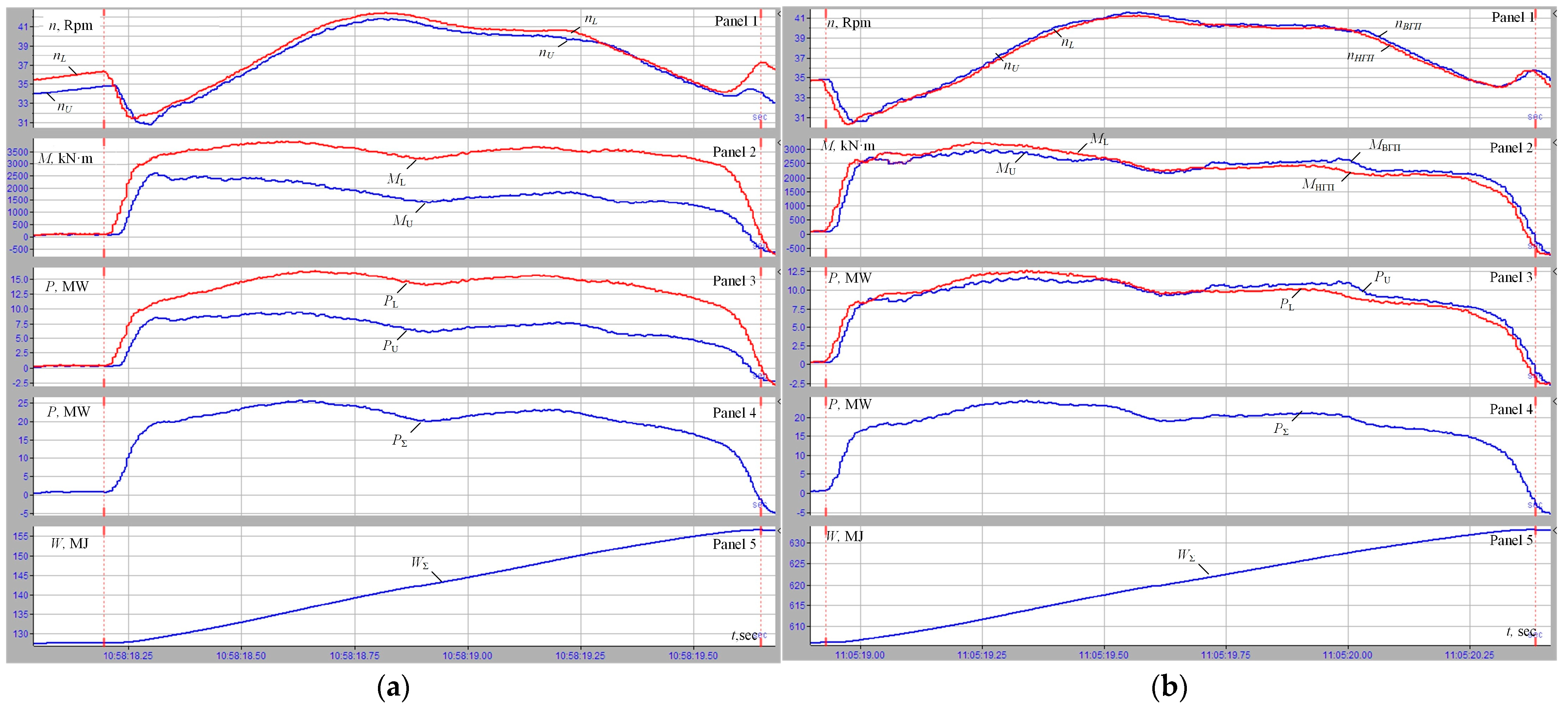

- -

- -

- the difference in power costs for the 180 s rolling cycle in question is 5330 kJ (1.48 kWh) or 5.7%.

7. Summarizing Research Results and Prospects

7.1. Summary of the Deployment Results

7.2. Further Research Prospects

- Optimizing speed mode for each pass by setting the optimal acceleration and deceleration rates, which is relevant for both plate mills and continuous rolling mills [59]. According to the oscillograms in Figure 12, efficiency is higher in steady rolling modes than during acceleration under load (Panel 5). In this case, the power graphs shown in Panel 4 are identical, and power losses are therefore at the minimum. Thus, the possibility of efficiency analysis helps optimize the ratio of dynamic and steady-state intervals to help reduce power and electricity losses. This can also be achieved by selecting the optimal acceleration and deceleration rates.

- The knowledge of efficiency may be useful when optimizing rolling programs for the existing product types or when developing programs for new types of rolled products. The procedures and examples of such solutions are studied in [60,61]. This can be effective when launching the production of sheets made of difficult-to-form grades of steel used for the production of large-diameter pipes. Since the share of such products is constantly increasing, any power loss reduction can have a significant effect on the factory and the sector.

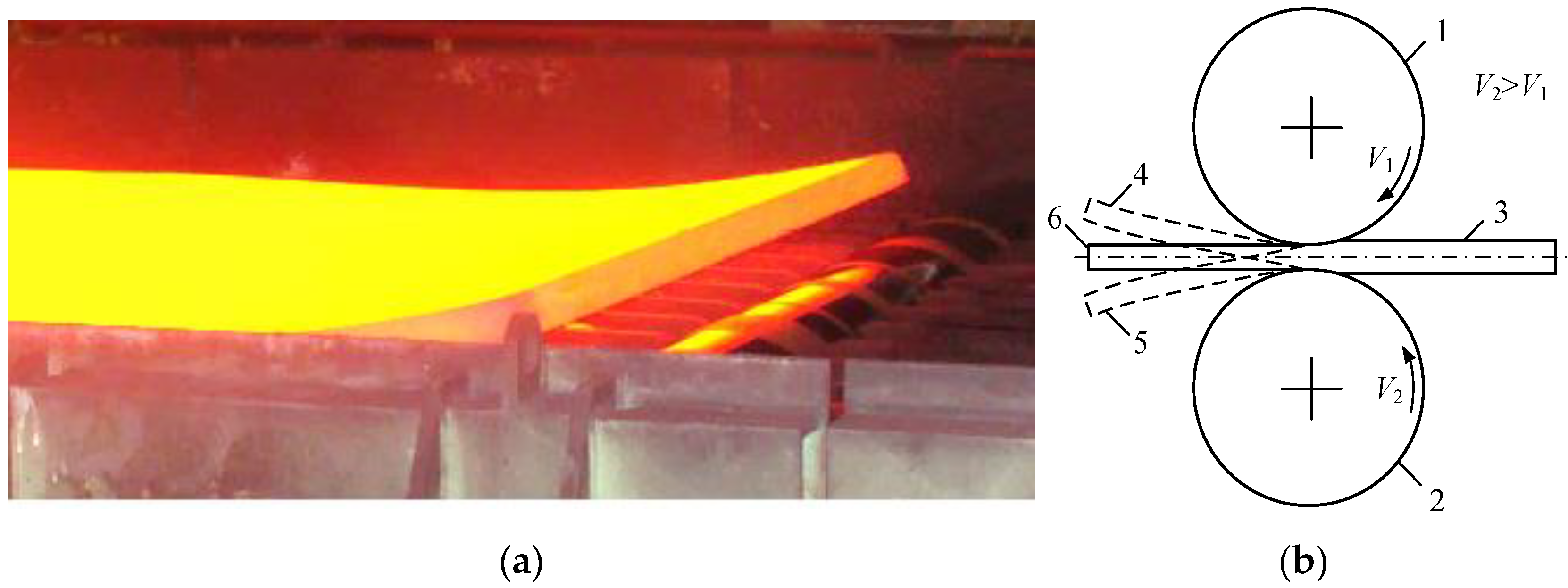

- The impact of rolling stand motor speed misalignment on their electromagnetic torques in the quasi-steady rolling mode was studied for the first time. The experiments showed that a 5% difference in speeds results in a three times difference in UMD and LMD motor torques. One of the reasons for this is the bending of the front end of the workpiece (the ski effect)

- The authors were the first to study the impacts of rolling stand motor load misalignment on the efficiency and the losses of electric power. The total power losses at a 7% speed misalignment equal to about 19% of the power losses during rolling, which is unacceptable.

- We developed a motor electricity loss and efficiency monitor. We analyzed the efficiency oscillograms (Figure 12) produced through the monitor recovery in the online mode. We confirmed the overwhelming impact of electricity losses on the efficiency of the electric drive and the linear dependency of the stator current and the motor torque.

- We developed and studied a load alignment method for the UMD and LMD motors of a plate rolling mill stand. A load division controller with a switching structure that facilitates the implementation of the method in question was deployed in industrial settings. The technological and financial effects of power loss reduction due to its operation are confirmed.

8. Conclusions

- We stressed the importance of energy saving in the most energy-intensive industrial sector, ferrous metallurgy. Significant electricity savings can be achieved by increasing the efficiency of high-power electric drives of rolling mills. When analyzing the experimental oscillograms of the 5000 plate mill electric drives, we showed the multi-factor difference between the upper and lower roller motors, which results in reduced efficiency.

- The review of publications confirmed the impact of load on the efficiency of frequency-controlled electric drives. We considered the known efficiency calculation methods with partial speed and changing loads and identified their drawbacks. We justified the development of an efficiency and electric loss observer that calculates these parameters in the online mode. We gave the rationale for the experimental analysis of power parameters that help process the signals recorded in data arrays. Following the analysis of publications, we confirmed the feasibility of developing an electric drive control method to facilitate load alignment between the upper and lower roller motors of a rolling stand with a high response rate.

- We described the horizontal stand electric drives of the 5000 mill. It is fitted with 12 W synchronous motors with frequency speed control. We showed that the difference in UMD and LMD motor torques is caused by the speed misalignment required for ski formation. A load division controller designed for torque alignment cannot facilitate the required response rate and is not activated during the first passes. Experiments confirm that when the speed difference is ±5% in the steady state, the difference between UMD and LMD motor torques is triple. This results in increased power losses due to the reduction of efficiency.

- The efficiency of the stand electric drive was analyzed, and its reduction was confirmed when loads were above the rated value. The total power losses at a 7% speed misalignment equal 0.633 MW or 18.9% of the power losses during rolling with zero-misalignment. We developed an electric drive electricity loss and efficiency observer. It is a program in Matlab Simulink that facilitates the calculation of these parameters in the online mode or using data arrays recorded during rolling.

- We developed a load alignment method that involves forced upper and lower roller electric drive speed alignment by isolating the integral LDC part and increasing the gain factor of the proportional part. We presented a load division controller with a switching structure that facilitates the implementation of the method in question. Research carried out with modeling confirmed the 2× reduction of torque alignment time.

- The algorithm implementing the suggested speed alignment method in the steady state was deployed in the APCS of a 5000 mill. We performed a comparative analysis of oscillograms obtained during an 11 min rolling cycle with the existing and deployed ski-formation and load-division algorithms. The confirmed electricity loss reduction was 3.5%.

- The analysis of losses over a long operating period confirmed the technical effectiveness of deploying the developments. Further research prospects include the optimization of speed modes for each pass (by setting the optimal acceleration and deceleration rates) and developing rolling programs for new product types. In these cases, the deployment of the efficiency observer can improve the precision of power loss assessment. The development of an LDC based on the fuzzy logic methods is also a relevant goal.

- The developed load alignment method and load-division controller with a switching structure used for the implementation of the method should be used in the electric drives of the operating rolling mills. Their use involves individual electric drives for the upper and lower stand rollers and the ski formation mode. The specific modules to be fitted with the developed solutions include roughing stands of hot-rolled plate mills and bar and shape mills, as well as stands of some pipe-rolling mills. The general nature of the approach is facilitated due to the similarity of the rolling technology and loading modes of the electric drives. A more accurate assessment of efficiency metrics will require additional research in each specific case.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Brusa, E.; Delprete, C.; Giorio, L. Smart Manufacturing in Rolling Process Based on Thermal Safety Monitoring by Fiber Optics Sensors Equipping Mill Bearings. Appl. Sci. 2022, 12, 4186. [Google Scholar] [CrossRef]

- Orcajo, G.A.; Rodríguez, D.J.; Cano, J.M.; Norniella, J.G.; Ardura, G.P.; Llera, T.R.; Cifrián, R.D. Dynamic estimation of electrical demand in hot rolling mills. In Proceedings of the 2015 IEEE Industry Applications Society Annual Meeting, Addison, TX, USA, 18–22 October 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Du, R.; Liu, Z.; Ge, L.; Cui, J.; He, L. A New Electrohydraulic Hybrid Energy-Saving System Used on the Reversible Rolling Mills. Adv. Mater. Sci. Eng. 2023, 2023, 1–17. [Google Scholar] [CrossRef]

- Szemmelveisz, T.; Kun, E. Energy efficiency enhancement in the Hot Rolling Mill. Mater. Sci. Eng. 2014, 3, 43–50. Available online: https://matarka.hu/koz/ISSN_2063-6792/vol_39-2_2014_eng/ISSN_2063-6792_vol_39_2_2014_eng_043-050.pdf (accessed on 22 February 2025).

- Kuznetsov, K.B.; Gorozhankin, A.N.; Funk, T.A.; Khusainov, S.N.; Kruglov, G.A.; Korzhov, A.V. Ways to decrease losses in electric drives and improvement of electrical safety during their service. Russ. Electr. Eng. 2017, 88, 209–211. [Google Scholar] [CrossRef]

- Karandaev, A.S.; Khramshin, V.R.; Khramshin, R.R.; Barankova, I.I. Conceptual Area of Development of Power Saving Thyristor Electric Drives of Rolling Mills. Procedia Eng. 2016, 150, 3–10. [Google Scholar] [CrossRef]

- Usynin, Y.S.; Shishkov, A.N.; Sychev, D.A.; Savosteenko, N.V.; Khayatov, E.S. Improving the energy efficiency of electric drives of reciprocating rolling mills. Russ. Electr. Eng. 2015, 86, 709–711. [Google Scholar] [CrossRef]

- Holtz, J.; da Cunha, G.; Petry, N.; Torri, P.J. Control of Large Salient-Pole Synchronous Machines Using Synchronous Optimal Pulsewidth Modulation. IEEE Trans. Ind. Electron. 2015, 62, 3372–3379. [Google Scholar] [CrossRef]

- Gasiyarov, V.R.; Maklakov, A.S.; Lisovski, R.A. Grid power control by medium voltage AC drives based on back-to-back converters. In Proceedings of the 2018 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), Moscow and St. Petersburg, Russia, 29 January–1 February 2018; pp. 629–631. [Google Scholar] [CrossRef]

- Variable Frequency Drives. Energy Efficiency Reference Guide. Available online: https://natural-resources.canada.ca/energy-efficiency/energy-star/variable-frequency-drives (accessed on 22 February 2025).

- Power Parameters of the Electric Drive Based on a Frequency Controller. Available online: https://www.artesk.ru/invertor_ikonom.html (accessed on 22 February 2025).

- Yu, J.; Zhang, T.; Qian, J. Testing methods for electric motors. Electr. Mot. Prod. 2011, 6, 95–172. [Google Scholar] [CrossRef]

- Voronin, S.S.; Radionov, A.A.; Karandaev, A.S.; Erdakov, I.N.; Loginov, B.M.; Khramshin, V.R. Justifying and Implementing Concept of Object-Oriented Observers of Thermal State of Rolling Mill Motors. Energies 2024, 17, 3878. [Google Scholar] [CrossRef]

- Metelkov, V.P. Estimation of a resource of induction motors stator winding insulation in cyclic operation. Bulletin of the South Ural State University. Ser. Power Eng. 2013, 13, 96–100. Available online: https://www.powervestniksusu.ru/index.php/PVS/article/view/424 (accessed on 22 February 2025).

- Zyuzev, A.M.; Metelkov, V.P. Toward the Evaluation of the Thermal State of an Induction Motor in the Recursive Short-Term Mode. Russ. Electr. Eng. 2014, 85, 554–558. [Google Scholar] [CrossRef]

- Braslavsky, I.Y.; Ishmatov, Z.S.; Polyakov, V.N. Energy-Saving Asynchronous Electric Drive; Akademia: Moscow, Russia, 2004; p. 202. [Google Scholar]

- Lee, S.; Son, Y. Motor Load Balancing with Roll Force Prediction for a Cold-Rolling Setup with Neural Networks. Mathematics 2021, 9, 1367. [Google Scholar] [CrossRef]

- Jin, X.; Li, C.; Wang, Y.; Li, X.; Xiang, Y.; Gu, T. Investigation and Optimization of Load Distribution for Tandem Cold Steel Strip Rolling Process. Metals 2020, 10, 677. [Google Scholar] [CrossRef]

- Zhao, H.; Chen, W.; Qu, F.; Chen, H. Research on power balance of multi-motor drive for mining belt transportation. In Proceedings of the 7th International Conference on Electronic Technology and Information Science (ICETIS), Harbin, China, 21–23 January 2022; pp. 1–5. Available online: https://ieeexplore.ieee.org/document/9788591 (accessed on 22 February 2025).

- Hu, Z.; Yang, J.; Zhao, Z.; Sun, H.; Che, H. Multi-objective optimization of rolling schedules on aluminum hot tandem rolling. Int. J. Adv. Manuf. Technol. 2016, 85, 85–97. [Google Scholar] [CrossRef]

- Wang, D. Load Balance Control of Top/Bottom WRs for Single Stand Reversing Cold Mill. CFHI Technol. 2009, 131, 32–35. (In Chinese) [Google Scholar]

- Yang, J.; Su, B.; Chen, L.; Zhang, J. Load Balance Control of Mill Driving System. Metall. Equip. 2013, 202, 5–10. (In Chinese) [Google Scholar]

- Weizheng, L.; Ming, Z.; Ruicheng, Z.; Ying, S. The Research on Load Balance Controller of Roller Single Roller Drive System Based on Fuzzy PID. In Proceedings of the 2020 Chinese Control And Decision Conference (CCDC), Hefei, China, 22–24 August 2020; pp. 5255–5260. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, D.; Zhang, X.; Huang, W.; Zheng, G.; Liu, M. Optimization of Rolling Schedule for Single-Stand Reversible Cold Rolling Mill Based on Multiobjective Artificial Fish Swarm Algorithm. Wirel. Commun. Mob. Comput. 2022, 2022, 1–15. [Google Scholar] [CrossRef]

- Wang, G. Preliminary Investigations of the Impact of Variable-Frequency Drive (VFD) Output Voltage on Motor Efficiency. ASHRAE Trans. 2019, 125, 696–702. [Google Scholar]

- Li, Y.; Liu, M.; Lau, J.; Zhang, B. A novel method to determine the motor efficiency under variable speed operations and partial load conditions. Appl. Energy 2015, 144, 234–240. [Google Scholar] [CrossRef]

- César da Silva, J.; Leite de Vasconcelos Lima, T.; de Lucena Júnior, J.A.; Jordão Lyra, G.; Vidal Souto, F.; de Souza Pimentel, H.; Antônio Belo, F.; Cavalcante Lima Filho, A. Non-Invasive Method for In-Service Induction Motor Efficiency Estimation Based on Sound Acquisition. Appl. Sci. 2020, 10, 3757. [Google Scholar] [CrossRef]

- Gasiyarov, V.R.; Radionov, A.A.; Loginov, B.M.; Karandaev, A.S.; Gasiyarova, O.A.; Khramshin, V.R. Development and Practical Implementation of Digital Observer for Elastic Torque of Rolling Mill Electromechanical System. J. Manuf. Mater. Process. 2023, 7, 41. [Google Scholar] [CrossRef]

- Sujeeth, A.; Di Cataldo, A.; Tornello, L.D.; Pulvirenti, M.; Salvo, L.; Sciacca, A.G.; Scelba, G.; Cacciato, M. Power Loss Modelling and Performance Comparison of Three-Level GaN-Based Inverters Used for Electric Traction. Energies 2024, 17, 595. [Google Scholar] [CrossRef]

- Chilikin, M.G.; Sandler, A.S. A Guideline to Electric Drives; Energoizdat: Moscow, Russia, 1981; p. 576. [Google Scholar]

- Chayakulkheeree, K.; Hengsritawat, V.; Nantivatana, P. Particle Swarm Optimization Based Equivalent Circuit Estimation for On-Service Three-Phase Induction Motor Efficiency Assessment. Eng. J. 2017, 21, 101–110. [Google Scholar] [CrossRef]

- Bonaldi, E.L.; Lambert-Torres, G.; Salomon, C.P.; Cortez, A.D.; da Silva, J.G.B.; da Silva, L.E.B.; Oliveira, L.E.D.L.D.; Santana, W.C. Differential Evolution based Air-Gap Torque method approach for induction motor efficiency estimation. In Proceedings of the 2015 18th International Conference on Intelligent System Application to Power Systems (ISAP), Porto, Portugal, 11–16 September 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Jangjit, S.; Laohachai, P. Parameter Estimation of Three-Phase Induction Motor by Using Genetic Algorithm. J. Electr. Eng. Technol. 2009, 4, 360–364. [Google Scholar] [CrossRef]

- ibaPDA Scalable Basic Software for Measured Data Collection. Available online: https://www.iba-ag.com/en/ibapda (accessed on 22 February 2025).

- Niu, F.; Sun, K.; Huang, S.; Hu, Y.; Liang, D.; Fang, Y. A Review on Multimotor Synchronous Control Methods. IEEE Trans. Transp. Electrif. 2023, 9, 22–33. [Google Scholar] [CrossRef]

- Jerkovic Stil, V.; Varga, T.; Bensic, T.; Barukcic, M. A Survey of Fuzzy Algorithms Used in Multi-Motor Systems Control. Electronics 2020, 9, 1788. [Google Scholar] [CrossRef]

- Ristic, L.; Bebic, M.; Jetvic, D.; Jeftenic, B.; Statkic, S.; Nikolic, A. Controlled multi motor drives of high power belt conveyors: Practical experiences during the exploitation of the system on open pit mine. In Proceedings of the 13th WSEAS International Conference on Electric Power Systems, High Voltages, Electric Machines (POWER 13), Chania, Greece, 27–29 August 2013; pp. 65–70. [Google Scholar]

- Jerkovic Stil, V.; Varga, T.; Bensic, T.; Barukcic, M. Fuzzy Algorithms in Multi-Motor Systems. Encyclopedia. Available online: https://encyclopedia.pub/entry/3013 (accessed on 15 February 2025).

- Ikeda, H.; Hanamoto, T. Fuzzy controller of multi-inertia resonance system designed by Differential Evolution. In Proceedings of the International Conference on Electrical Machines and Systems (ICEMS), Busan, Republic of Korea, 26–29 October 2013; pp. 2291–2295. [Google Scholar] [CrossRef]

- Fan, L.P.; Liu, Y. A Control Method for Load Balance between Upper and Lower Roll of Four-High Hot Rolling Mill. Appl. Mech. Mater. 2014, 687–691, 167–170. [Google Scholar] [CrossRef]

- Yang, J.M.; Su, B.; Lv, J.; Che, H.J. The improved load balance adjustor of multi-motor driving system. In Proceedings of the 32nd Chinese Control Conference, Xi’an, China, 26–28 July 2013; pp. 5305–5310. Available online: https://ieeexplore.ieee.org/document/6640363 (accessed on 15 February 2025).

- Zhu, C.; Tu, Q.; Jiang, C.; Pan, M.; Huang, H. A Cross Coupling Control Strategy for Dual-Motor Speed Synchronous System Based on Second Order Global Fast Terminal Sliding Mode Control. IEEE Access 2020, 8, 217967–217976. [Google Scholar] [CrossRef]

- Chen, W.; Yifei, W.; Du, R.; Chen, Q.; Wu, X. Speed Tracking and Synchronization of a Dual-Motor System via Second Order Sliding Mode Control. Math. Probl. Eng. 2013, 2013, 919837. [Google Scholar] [CrossRef]

- Kucsera, P.; Beres, Z. Hot Rolling Mill Hydraulic Gap Control (HGC) thickness control improvement. Acta Polytech. Hung. 2015, 12, 93–106. Available online: https://acta.uni-obuda.hu/Kucsera_Beres_62.pdf (accessed on 15 February 2025).

- Zhang, F.; Zhang, Y.; Hou, J.; Wang, B. Thickness control strategies of plate rolling mill. Int. J. Innov. Comput. Inf. Control. 2015, 11, 1227–1237. [Google Scholar]

- Zhang, F.; Zhang, Y.; Chen, H. Automatic Gauge Control of Plate Rolling Mill. Int. J. Control. Autom. 2016, 9, 143–156. [Google Scholar] [CrossRef]

- Radionov, A.A.; Gasiyarov, V.R.; Karandaev, A.S.; Loginov, B.M.; Khramshin, V.R. Advancement of Roll-Gap Control to Curb the Camber in Heavy-Plate Rolling Mills. Appl. Sci. 2021, 11, 8865. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, D.; Tan, R.; Xie, Q. Controlled Cooling Temperature Prediction of Hot-Rolled Steel Plate Based on Multi-Scale Convolutional Neural Network. Metals 2022, 12, 1455. [Google Scholar] [CrossRef]

- de Oliveira Abreu, L.G.; de Faria, G.L.; de Faria, R.J.; Matsubara, D.B.; Porcaro, R.R. Optimizing Rolling Strategies for API 5L X80 Steel Heavy Plates Produced by Thermomechanical Processing in a Reversible Single-Stand Mill. Metals 2024, 14, 746. [Google Scholar] [CrossRef]

- Radionov, A.A.; Gasiyarov, V.R.; Karandaev, A.S.; Loginov, B.M.; Khramshin, V.R. Controlling the Electric Drives of the Reversing Rolling Stand Rolls of a Rolling Mill to Form a Curvature at the Workpiece Front End. In Proceedings of the IEEE 13th International Conference on Power Electronics and Drive Systems (PEDS), Toulouse, France, 9–12 July 2019; 7p. [Google Scholar] [CrossRef]

- Kiefer, T.; Kugi, A. An analytical approach for modelling asymmetrical hot rolling of heavy plate. Math. Comp. Model. Dyn. 2008, 14, 249–267. [Google Scholar] [CrossRef]

- Fajfar, P.; Salej Lah, A.; Kraner, J.; Kugler, G. Asymmetric rolling process. Mater. Geoenviron. 2017, 64, 151–160. [Google Scholar] [CrossRef]

- Philipp, M.; Schwenzfeier, W.; Fischer, F.D.; W’odlinger, R.; Fischer, C. Front end bending in plate rolling influenced by circumferential speed mismatch and geometry. J. Mater. Process. Technol. 2007, 184, 224–232. [Google Scholar] [CrossRef]

- Anders, D.A.; Münker, T.; Artel, J.; Weinberg, K. Dimensional analysis of front-end bending in plate rolling applications. J. Mater. Process. Technol. 2012, 212, 1387–1398. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, L.; Cui, X.; Zhu, X. Research on numerical simulation and process parameters of three-roll bending based on thickness characteristics of extra-thick plate. Adv. Mech. Eng. 2019, 11. [Google Scholar] [CrossRef]

- Gasiyarov, V.R.; Loginov, B.M.; Zinchenko, M.A.; Semitko, A.Y. Improving the Load Balancing System of the Rolling Mill Stand Drives. In Proceedings of the International Russian Automation Conference (RusAutoCon), Sochi, Russia, 5–11 September 2021; pp. 1067–1073. [Google Scholar] [CrossRef]

- Kalachev, Y.N. Vector Control (Practical Notes); EFO: Moscow, Russia, 2013; p. 63. Available online: https://www.studmed.ru/kalachev-yu-n-vektornoe-regulirovanie-zametki-praktika-_8deff3fceef.html (accessed on 15 February 2025).

- Gasiyarov, V.R.; Radionov, A.A.; Loginov, B.M.; Zinchenko, M.A.; Gasiyarova, O.A.; Karandaev, A.S.; Khramshin, V.R. Method for Defining Parameters of Electromechanical System Model as Part of Digital Twin of Rolling Mill. J. Manuf. Mater. Process. 2023, 7, 183. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, L.; Zhang, D.; Jiao, Q. A new speed optimization algorithm with application in pickling and rolling line. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Qi, X.; Wang, T.; Xiao, H. Optimization of Pass Schedule in Hot Strip Rolling. J. Iron Steel Res. Int. 2012, 19, 25–28. [Google Scholar] [CrossRef]

- Hu, X.; Zhao, Z.; Wang, J.; Wang, Z.; Liu, X.; Wang, G. Optimization of Holding Temperature and Holding Thickness for Controlled Rolling on Plate Mill. J. Iron Steel Res. Int. 2006, 13, 21–25. [Google Scholar] [CrossRef]

- Moon, C.H.; Lee, Y. The effects of rolling method changes on productivity in thick plate rolling process. J. Mater. Process. Technol. 2010, 210, 1844–1851. [Google Scholar] [CrossRef]

- Karandaev, A.S.; Yachikov Diagnosis, I.M.; Radionov, A.A.; Liubimov, I.V.; Druzhinin, N.N.; Khramshina, E.A. Fuzzy Algorithms for of Furnace Transformer Insulation Condition. Energies 2022, 15, 3519. [Google Scholar] [CrossRef]

| Type | Individual |

|---|---|

| Power | 2 × 12 MW |

| Motor shaft speed | (0–60)/115 rpm |

| Rated electromagnetic torque MN | 2 × 1.91 MN m |

| Maximum torque during rolling | 2 × 3.82 MN m (200% MN) |

| Maximum overload torque | 2 × 4.23 MN m (225% MN) |

| Torque during shutdown | 2 × 5.25 MN m (275% MN) |

| Type | UINPUT.N, V | IN, A | PN, MW | UINPUT.N, V | Cooling | Comment |

|---|---|---|---|---|---|---|

| Converteam MV 7308 SA AFE | 3300 | 800 | 8.4 | 3300 | Water | Converter type parallel-connected |

| Figure Number | Notation | Value, kN·m | Factor *, p.u. | Difference, kN·m | % MN |

|---|---|---|---|---|---|

| Figure 7a | MU_av | 3600 | 1.9 | 1800 | 94 |

| (5% ski) | ML_av | 1800 | 0.94 | ||

| Figure 7b | MU_av | 2700 | 1.4 | 200 | 10.4 |

| (no ski) | ML_av | 2500 | 1.3 |

| Motor Torque | Efficiency | Factor *, p.u. |

|---|---|---|

| 0.4MN | 0.94 | 0.97 |

| MN | 0.968 | 1 |

| 2.4MN | 0.956 | 0.987 |

| Parameter | Dimensionality | No-Ski Rolling | 7% Ski Rolling | ||

|---|---|---|---|---|---|

| Upper | Lower | Upper | Lower | ||

| Absolute torque value | kN·m | 2401 | 2444 | 1318 | 3510 |

| Average torque factor | – | 1.25 | 1.27 | 0.68 | 1.82 |

| Average power on the shaft | MW | 9.52 | 9.63 | 7.08 | 14.0 |

| Average efficiency | – | 0.968 | 0.968 | 0.967 | 0.963 |

| Power losses | MW | 0.3147 | 0.3183 | 0.21416 | 0.5379 |

| Total power losses | MW | 0.633 | 0.752 | ||

| Power losses difference | MW | 0.119 | |||

| % | 18.9 | ||||

| Total power per pass | MJ | 27 | 28 | ||

| Power cost reduction per pass | MJ | 1 | 0 | ||

| % | 3.7 | 0 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voronin, S.S.; Radionov, A.A.; Karandaev, A.S.; Lisovsky, R.A.; Loginov, B.M.; Zinchenko, M.A.; Khramshin, V.R.; Erdakov, I.N. Improving Efficiency of Rolling Mill Stand Electric Drives Through Load Alignment. Energies 2025, 18, 3175. https://doi.org/10.3390/en18123175

Voronin SS, Radionov AA, Karandaev AS, Lisovsky RA, Loginov BM, Zinchenko MA, Khramshin VR, Erdakov IN. Improving Efficiency of Rolling Mill Stand Electric Drives Through Load Alignment. Energies. 2025; 18(12):3175. https://doi.org/10.3390/en18123175

Chicago/Turabian StyleVoronin, Stanislav S., Andrey A. Radionov, Alexander S. Karandaev, Roman A. Lisovsky, Boris M. Loginov, Mark A. Zinchenko, Vadim R. Khramshin, and Ivan N. Erdakov. 2025. "Improving Efficiency of Rolling Mill Stand Electric Drives Through Load Alignment" Energies 18, no. 12: 3175. https://doi.org/10.3390/en18123175

APA StyleVoronin, S. S., Radionov, A. A., Karandaev, A. S., Lisovsky, R. A., Loginov, B. M., Zinchenko, M. A., Khramshin, V. R., & Erdakov, I. N. (2025). Improving Efficiency of Rolling Mill Stand Electric Drives Through Load Alignment. Energies, 18(12), 3175. https://doi.org/10.3390/en18123175