1. Introduction

Stepper motors (SMs) are widely used in aerospace motion mechanisms because of their brushless feature, excellent response to start-up, stopping and reverse, high running precision, reliable structure, and simple control [

1,

2,

3]. Seeing that bipolar motors can produce more torque than unipolar motors with the same size, they are quite suitable for space motion mechanisms, with smaller space size, being more lightweight, and having more required torque. However, their disadvantage is that the control circuit is more complex compared to unipolar motors [

4]. Hence, the research of advanced control technology to improve SM drive performance plays an important role in space applications. In view of the reliability of space motion systems and the requirement of easy integration with other systems, one of the main difficulties of SMs is the lack of the drive scheme that matches the mission.

The drive schemes of SMs have been discussed in previous work. Aranjo et al. [

5] presented a versatile drive control system of SMs. Kim et al. [

6] studied a new position control method of SMs by the microstepping technique. Nevertheless, the drive performance of these schemes is not well tested in practice. Le et al. [

7] introduced an effective closed-loop control method for SM drives. However, its implementation requires parameter identification. In addition, the proposed algorithm is executed on an industrial test bench from an outside manufacturer. To improve the current tracking performance of the current subdivision, several feedback control approaches were discussed in [

8,

9,

10,

11,

12,

13]. The position feedback was implemented using encoders to improve current subdivision [

14]. However, these approaches require complex calculations. Several schemes using the current subdivision or the combining of the current subdivision with a closed loop were discussed in [

15,

16,

17]. These methods have improved the drive performance of SMs. Nevertheless, they are effective at either low speeds [

15] or medium and high speeds [

17], but not over all speeds. In view of self-adaption and learning ability, the neural networks (NNs) play a strong role in power electronics and motor drive control [

18]. In [

19], a recurrent NN-based algorithm is introduced to compute the robust adaptive model predictive speed control law by solving an optimization problem in real-time. In [

20], two vector source inverters based on an artificial NN are presented as a new intelligent direct torque control applied to a doubly fed induction motor. Liu et al. [

21] proposed a gradient descent algorithm-based B-spline wavelet NN learning adaptive controller for linear motor systems under system uncertainties and actuator saturation constraints. Li [

22] proposed a robust control method with NNs to improve three-dimensional tracking performance of the spherical SM system. Tran et al. [

23] introduced an adaptive feed-forward proportional-resonant current control strategy with the NN to improve the motion accuracy of the SM. These application cases show that NN algorithms are a powerful tool in motor drive control systems with uncertainties.

In consideration of the ability in processing speed and logical capacity, and the advantages of high performance and high density, FPGA has a significant impact on industrial control systems. The design methodology of control systems based on FPGA is summarized in [

24]. Idkhajine et al. [

25] introduced an integrated control scheme of synchronous motors based on Actel Fusion FPGA. Muresan et al. [

26] designed a fractional order PI controller executed on the FPGA for the direct current (DC) motor speed control. It can be inferred that hardware controllers realized by FPGA with digital structure and easy verification are widely designed in industry.

As seen from previous research, most of the schemes discussed are applicable to lightweight load drives in a good environment. However, the proposed system is located in a harsh aerospace environment containing the wide temperature variation range and complex radiation from gamma rays, high-energy protons, and cosmic rays, which can lead to the failure of low-quality electronic components and single event upset (SEU) of the digital signal processor (DSP) [

27], the programmable logic controller (PLC) [

28], or the microcontroller unit (MCU) [

29], which may result in measurement data loss and function interruption of the drive system. Therefore, in some heavy load drive aerospace systems, these previous schemes can not meet the requirements. It is absolutely necessary for us to propose a new control method and design a drive circuit with high-quality and anti-irradiation electronic components for the SM heavy load drive over the full speed range. As shown in

Figure 1, the SM in this paper is used to drive the heavy filter wheel embedded with four optical filters that are used for making the centers of four optical filters be collinear with the center of the light through the hole to enable the infrared detector to measure infrared radiation of the corresponding spectrum from the measured object. In summary, in view of the reliability of the aerospace motion control system, the requirement of easy integration with other electronic systems, and the complex radiation of the aerospace environment, this paper focuses on the design of an FPGA-based SM driver in aerospace applications. The main contributions of this paper are summarized as follows.

A current subdivision method incorporating BPNN is proposed to ensure stable current regulation of the SM.

The general measurement methods are presented to accurately detect the rotor position and phase current.

An FPGA-based SM drive circuit is designed to be suitable for the aerospace environment.

The rest of this paper is organized as follows.

Section 2 explains the current stabilization technique employed for the motor.

Section 3 describes the hardware implementation on a single FPGA.

Section 4 presents the experimental results to confirm the effectiveness of the designed driver. Finally, the conclusion is summarized in

Section 5.

2. SM Constant Current Control

Figure 2 shows the structure of the SM system. In

Figure 2,

is the electromagnetic torque

,

is the angular velocity

,

is the no-load torque

,

is the external disturbance torque

,

is the load torque

, and

is the Hall sensor torque

.

The dynamic model of the system is expressed as

where

J is the moment of inertia

, and

is the viscous friction coefficient

.

The angular velocity of the motor can be calculated as

where

is the rotor position angle

.

The sum of

,

,

, and

is denoted as

that is a nonlinear function, which is written as

Based on Equations (

1)–(

3), the system dynamic model is rewritten as

If the reference position signal

is given, then the position signal error is defined by

, and the tracking error is expressed as [

30]

where

is a design parameter that is a positive constant. This parameter plays a decisive role in controlling the position and speed of the motor.

By using

, Equations (

4) and (

5), the system dynamic model is transformed to be

where

is a nonlinear function with respect to

J,

,

,

, and

where the term

contains all the signals with respect to time and can be defined as

BPNN is used to estimate

. BPNN’s output is denoted as

. From Equation (

8),

,

,

,

, and

are selected as BPNN’s inputs. Hence, BPNN’s input is given by

The tracking controller is chosen to be

where

is a positive design parameter.

Substituting Equation (

10) into Equation (

6) gives the tracking error system

From Equation (

11), the Lyapunov function is defined as

Because

J is positive, and

if and only if

. Thus,

is globally positive definite. The first derivative of Equation (

12) with respect to time can be expressed as

Using Equation (

11) and the assumption

yields

Because both

and

are positive, the first term of the right-hand side of Equation (

14) satisfies

Therefore, when

, the first derivative of Equation (

12) with respect to time can satisfy

Seeing that

is negative semidefinite, and both

and

are positive, hence, if

, one has

, namely,

The general solution of Equation (

17) can be expressed as

where

is a constant that is determined by the initial conditions of the function,

is an arbitrary constant.

Differentiating Equation (

18) yields

If the parameters

and

are chosen appropriately, Equations (

18) and (

19) can satisfy

Based on the LaSalle theorem [

31], it is concluded that

is the equilibrium point of globally asymptotic stability of the tracking error system (Equation (

11)) by using control law (Equation (

10)) when

. As a consequence, if the tracking error system (Equation (

11)) starts from any initial condition

, one has

Considering the right-hand side of Equation (

14), when the second term is positive and its absolute value is greater than the absolute value of the first term, namely,

the first derivative of Equation (

12) will become positive. To improve the system stability, the first term should be more negative. In fact, the value

is quite small. The first derivative of Equation (

12) is more likely to be negative when

is large. However, the first term of the right-hand side of Equation (

10) will dominate the tracking controller when large

is employed, which will reduce the system sensitivity to

. Therefore, the appropriate

is selected to balance the stability and sensitivity of the system.

Due to uncertainties in

caused by deviations and modeling errors, the approximation error of

is calculated indirectly. Rearranging Equation (

11) yields

is compared to

to obtain

, which is used for calculating

r by Equation (

5).

r is used for calculating the approximation error (Equation (

26)) and

(Equation (

10)). The approximation error is used for training BPNN by the back-propagation algorithm [

32]. BPNN’s weights and biases are adjusted to obtain

to minimize the approximation error. BPNN’s input is vector

with five elements

,

,

,

, and

(Equation (

9)). Because there is no effective strategy to determine the number of layers and neurons in BPNN [

32], BPNN’s structure is chosen with one hidden layer that includes six neurons. Log-Sigmoid functions are selected as the activation functions of neurons in the hidden layer. Linear function is selected as the activation function of the neuron in the output layer. The states and activation values of the neurons in each layer are computed by some formulas described in [

32]. BPNN’s weights and biases are updated using the approximate steepest descent rule [

32].

For two-phase bipolar SMs, each phase current

is calculated as

where

is the phasor sum of the two-phase currents

,

is the electrical angle (°), which relates to

by

, and

is the number of pole-pairs on the rotor.

Each phase torque

can be expressed as

where

is the magnetic flux linkage

that is constant.

If the torque ripple is zero, based on Equations (

27) and (

28), the total torque measured on the motor shaft

is expressed as

Based on Equation (

29), to generate the desired torque

, the reference current

is selected as

By using Equation (

27), each phase ideal current

is calculated as

Theoretically, if each phase current is set according to the sinusoidal law, then the amplitude of the phasor sum of the two-phase currents will be a constant value. The phase current is subdivided to better approximate the sine and cosine curves. Therefore, each full step is subdivided into

M micro steps [

33]. The step division coefficient corresponding to the desired

M for each phase is computed as

The current subdivision is employed to significantly improve the operational stability and control accuracy of the SM.

Moreover,

M can affect the rotor speed. The step angle is denoted as

. The rotor rotation frequency is denoted as

. The time interval between subdivision points is denoted as

.

is given by

The crystal oscillator frequency is denoted as

f. The subdivision interval is denoted as

Q, which is computed as

Based on Equations (

33) and (

34), one obtains

From Equation (

35), one gets

From the above analysis, it can be inferred that the rotor position and phase current are two crucial detection parameters for achieving constant current control of the SM. The ideal phase current can be obtained through the rotor position parameter, while the current phase current value can be obtained through the phase current parameter. By combining the ideal phase current with the current phase current, a matching pulse width modulation (PWM) control signal can be generated to drive the SM. Next, the implementation of the proposed scheme on an FPGA-based circuit board will be introduced.

4. Experimental Results

The motor needs to operate in two modes, uniform rotation and fixed point motion, for infrared radiation measurement requirements at continuous high speeds and specific locations. In two modes, the design parameter

, the design parameter

, and the proposed scheme will be compared to the adaptive control scheme including the variable structure controller and control circuit described in [

34,

35]. The experimental data are obtained by the oscilloscope, the stabilized voltage supply, serial debugging assistant, and Identify logic analyzer from Synopsys, Inc. (Sunnyvale, CA, USA), integrated into Libero software.

In the first experiment, two control schemes are employed to achieve the uniform rotation of the motor, respectively. From

Figure 9, when running at 0.5

, both methods are valid. Nevertheless, the current ripple when operating in the adaptive control scheme is slightly higher. When running at 1

, 1.5

, and 2

, respectively, the high current ripple prevents the motor from running stably for long periods of time. For the adaptive control scheme, when the motor speed is greater than 2

, the bus current is eventually converted to the blocking current that causes the motor to stop running. For the proposed scheme, when the motor speed is less than or equal to 7.5

, the low current ripple keeps the bus current constant to maintain the smooth operation of the motor. In fact, when the motor speed is greater than 7.5

, the motor is locked-rotor because the reduction in the output torque caused by the high speed makes it unable to overcome the load torque. In other words, the proposed scheme can achieve a maximum steady speed of 7.5

for the motor under the current load. From

Figure 10, for the adaptive control scheme, when operating at 2

, the phase current waveform is distorted compared to the sine or cosine wave. However, when operating at 2

, the phase current waveform is very close to the sine or cosine wave for the proposed scheme. When operating at 7.5

, the phase current is converted to the constant locked-rotor current for the adaptive control scheme. However, when operating at 7.5

, the phase current waveform is still very close to the sine or cosine wave for the proposed scheme. The synthesis of the two-phase current whose waveform is very close to the sine or cosine wave is inevitably a bus current with an almost constant amplitude. This is the meaning of the constant current. By Equation (

27), the phase current ripple will inevitably cause the distortion and pulsation of the bus current. This will cause the vibration, unstable operation, out-of-step phenomenon, locked-rotor, and burnout of the motor. Therefore, the proposed scheme can make the current ripple very low, realize the constant bus current, and ensure the smooth functioning of the motor. Moreover, it can also adjust the output current to adapt to varying speeds and loads.

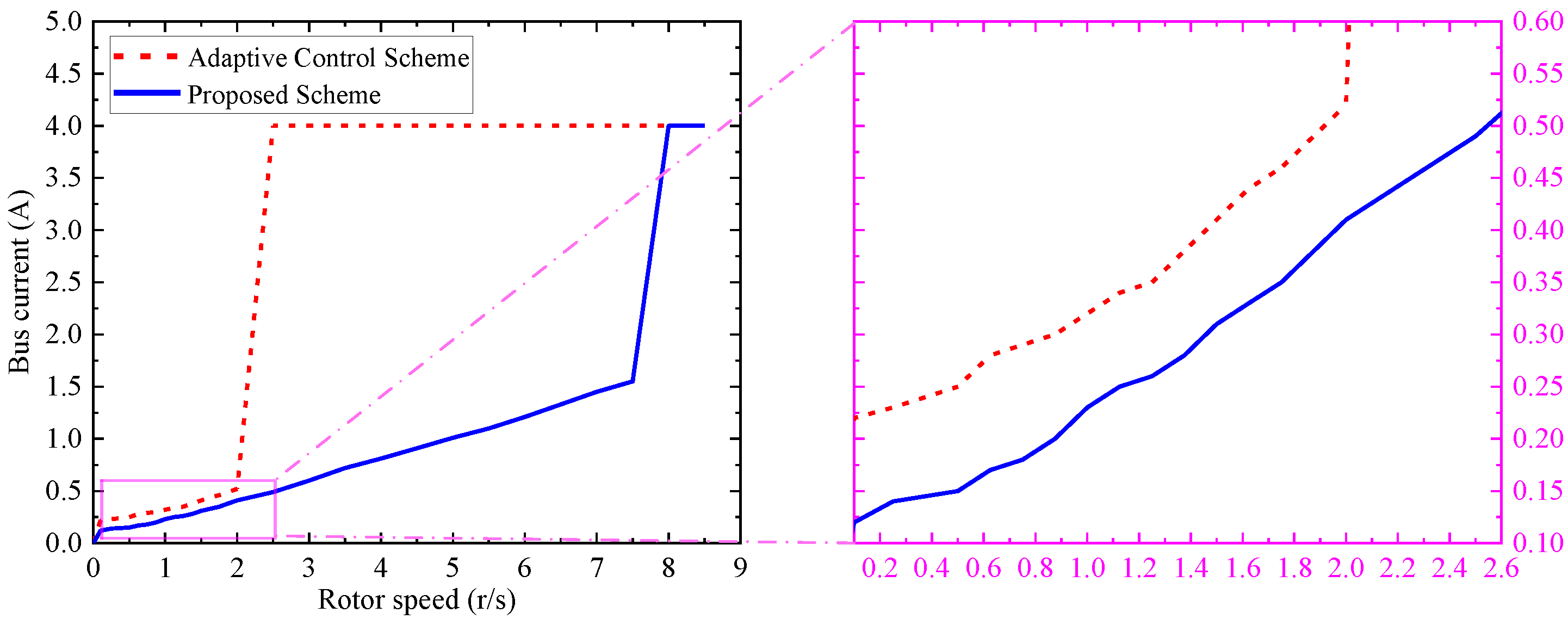

From

Figure 9 and

Figure 10, we conclude that the proposed scheme saves more on power consumption than the adaptive control scheme. To quantitatively study the power consumption of the motor under the stable operation, the steady current in the 28

bus that supplies power to the two H-bridge circuits when accelerating from 0 to 8.5

in 18

is shown in

Figure 11. The desired operating speed is 2

. At 2

, the steady current

is about 0.52

for the adaptive control scheme, and the steady current

is about 0.41

for the proposed scheme. The bus voltage is denoted as

.

The power consumption

of the adaptive control scheme is approximately calculated as

The power consumption

of the proposed scheme can be approximately calculated as

Hence, the power consumption saving of the proposed scheme

is approximately computed as

This energy-saving scheme, in addition to reducing the size of the power supply, can also

- (1)

Extend in-orbit lifespan: Reduce battery consumption, prolong satellite operation time, and increase profit or scientific value.

- (2)

Lower replacement costs: With extended battery life, fewer replacements are needed, reducing maintenance expenses.

- (3)

Improve mission flexibility: Remaining power can be used for additional tasks or emergency situations, increasing the success rate of missions.

- (4)

Simplify thermal management: Decreased heat generation simplifies cooling design, reducing complexity and cost.

- (5)

Increase system redundancy: Less reliance on individual components enhances overall system reliability.

In summary, the long-term benefits include longer operational time, lower maintenance costs, higher mission success rates, and greater system reliability.

In the second experiment, two control schemes are used to implement the fixed point motion of the motor, respectively. If the motor runs at 0.1

, the reference position

(°) with respect to

t is expressed as

When the four centers of the optical filters 1∼4 are collinear with the center of the light through the hole, respectively, the position of the filter wheel is

,

,

, and

, respectively.

in Equation (

50) is a trajectory used for sequential infrared radiation measurement of the four spectral segments. In

Figure 12 and

Figure 13, there are larger position errors when the filter wheel reaches the above four target positions for the adaptive control scheme. Moreover, the arrival index of

in Equation (

50) and that of the desired time for the filter wheel are poor. The filter wheel stays at the four target positions for 5

for infrared radiation measurement, respectively. In fact, the infrared radiation measurement effect will begin to be affected when the position error is greater than or equal to

. For the adaptive control scheme, it is clear that the fixed point motion of the motor is not suitable for infrared radiation measurement. In

Figure 12 and

Figure 13, there are smaller position errors in the above four target positions for the proposed scheme. Moreover, the arrival index of

in Equation (

50) and that of the desired time for the filter wheel are good. It is clear that the fixed-point motion of the motor by the proposed scheme is suitable for infrared radiation measurement.

To test the position tracking performance of the proposed controller at higher speeds, the motor performs the fixed point motion at 0.2

, 1

, 2

, 4

, and 7.5

, respectively. Their reference positions are all similar to

in Equation (

50). Their experimental results are shown in

Figure 12 and

Figure 13. When operating at 0.2

, the performance of the adaptive control scheme is too poor to be used for infrared radiation measurement. The large current ripple prevents the motor from implementing the fixed point motion at 1

, 2

, 4

, and 7.5

for the adaptive control scheme, respectively. Nevertheless, like 0.1

, when operating at 0.2

, 1

, 2

, 4

, and 7.5

, respectively, the position tracking performance of the proposed scheme is good enough to satisfy the infrared radiation measurement requirements.

In view of the characteristics of the space environment and the existence of severe vibration during the launch of the satellite, the temperature cycle experiment and vibration experiment are carried out successively. During the execution of the temperature cycle experiment, and after performing the vibration experiment, the previously described experiments need to be implemented once, respectively. It is shown that the experimental results are very close to those of the routine experiment. Therefore, the feasibility of the proposed scheme is further verified.

Finally,

Table 5 summarizes the main features of the proposed scheme in comparison with the adaptive control scheme [

34,

35], constant voltage drive [

36], and the fuzzy logic method [

37]. From

Table 5, it can be observed that compared with existing solutions, the proposed scheme has advantages such as a fully integrated design, low power consumption, small current ripple, high load capability, the ability to achieve higher steady-state speed, and low tracking error. In conclusion, the designed driver has been proven to be effective and capable of adjusting the output current to achieve the desired speed when the load changes.

5. Conclusions

A SM driver designed for aerospace applications is presented. This driver utilizes a BPNN for reference current estimation and employs current subdivision for PWM signal generation. The driver’s hardware circuit design is detailed. The system dynamically adjusts drive current based on workload variations and maintains a stable bus current in the H-bridge circuit during periods of stable workload. This approach offers improved power efficiency compared to previous solutions. The entire control scheme, including rotor position angle measurement, two-phase current measurement, and BPNN-based current subdivision control, is implemented on a single FPGA. Experimental results demonstrate the effectiveness of the proposed driver.

Although the proposed method possesses a degree of universality, its practical application necessitates the consideration of motor parameter discrepancies, load inertia variations, and hardware resource constraints. Future research will focus on implementing parameter self-adaptive control, robust control techniques, and hardware optimization strategies to enhance the scheme’s generalization capabilities and extend its application range.

In view of the significance of numerical precision for practical applications, future work will focus on this issue, with specific research areas including the following:

- (1)

Assessing the impact of different fixed-point bit-widths and quantization strategies on control accuracy.

- (2)

Developing numerical error models and designing error compensation algorithms.

- (3)

Proposing FPGA-implementable quantitative precision optimization schemes tailored to the specific characteristics of the control system.

Performance under varying loads or speed fluctuations is a worthwhile area for further investigation. Future work considers the following:

- (1)

Varying the mass of the filter wheel, or using an adjustable inertia load, to simulate different load conditions.

- (2)

Introducing external disturbances, such as simulating speed fluctuations, to test the robustness of the proposed control strategy.

Furthermore, future work will systematically evaluate the driver’s performance under various potential fault modes, explore fault-tolerance and degradation mechanisms, and propose corresponding optimization measures to enhance the system’s robustness and reliability.

It should be pointed out that the impact of total harmonic distortion (THD) on motor performance has been carefully considered. During the design process, an optimized PWM control strategy and output filtering circuits were adopted to reduce harmonics. Nevertheless, because the application prioritizes motor accuracy over efficiency, a fast current response was prioritized, and thus, requirements for THD were appropriately relaxed. Furthermore, due to the specific nature of aerospace applications, volume and weight constraints are considered key factors, and adding additional filter circuits would significantly increase the system’s volume and weight. Therefore, a compromise solution was chosen. In the future, reducing THD further while meeting volume and weight constraints will be researched through more advanced control algorithms or novel filtering technologies.