Comminution Flowsheet Energy Requirements of a New Narrow-Vein Mining Method

Abstract

1. Introduction

2. Materials and Methods

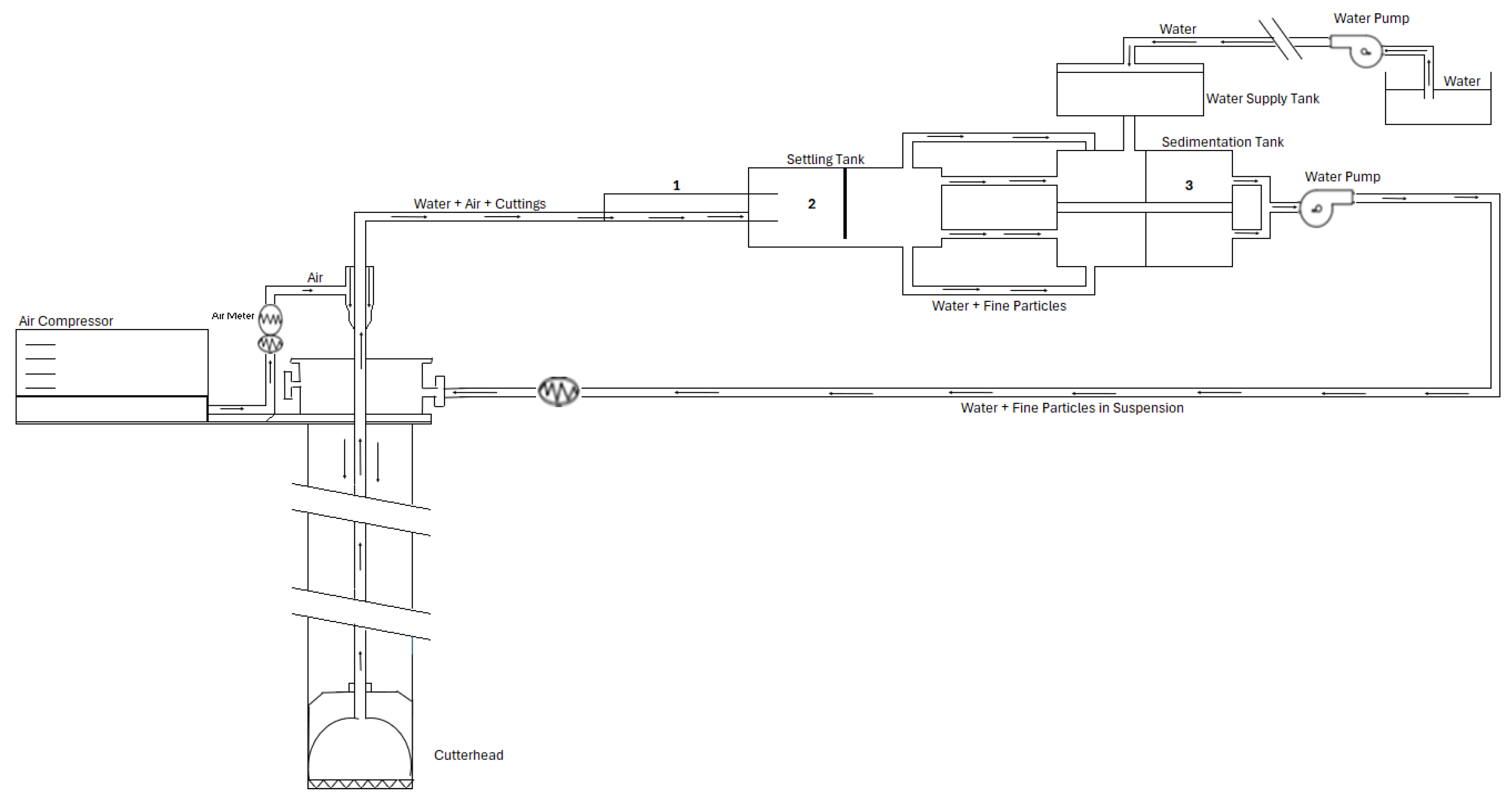

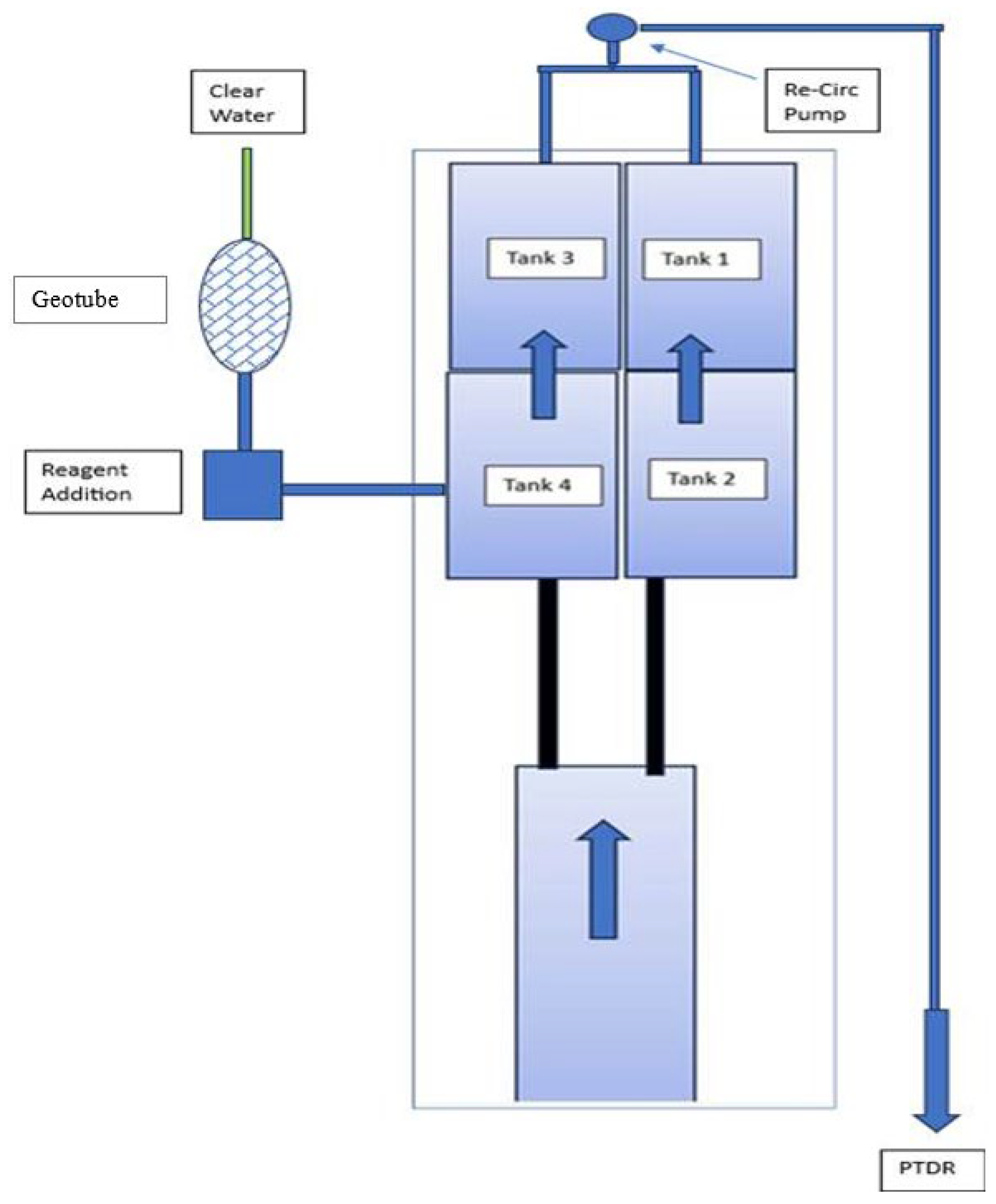

2.1. Cuttings Inventory

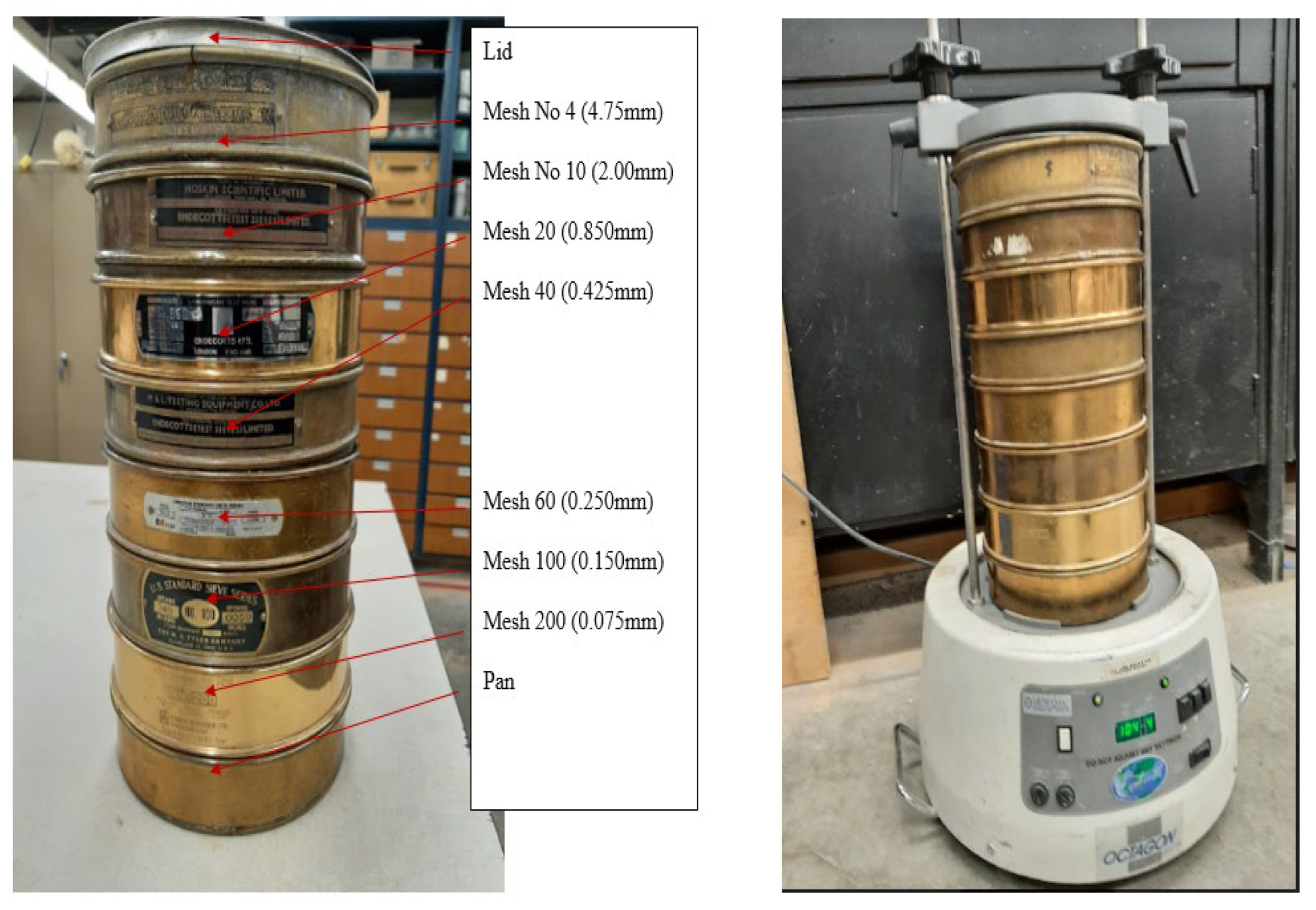

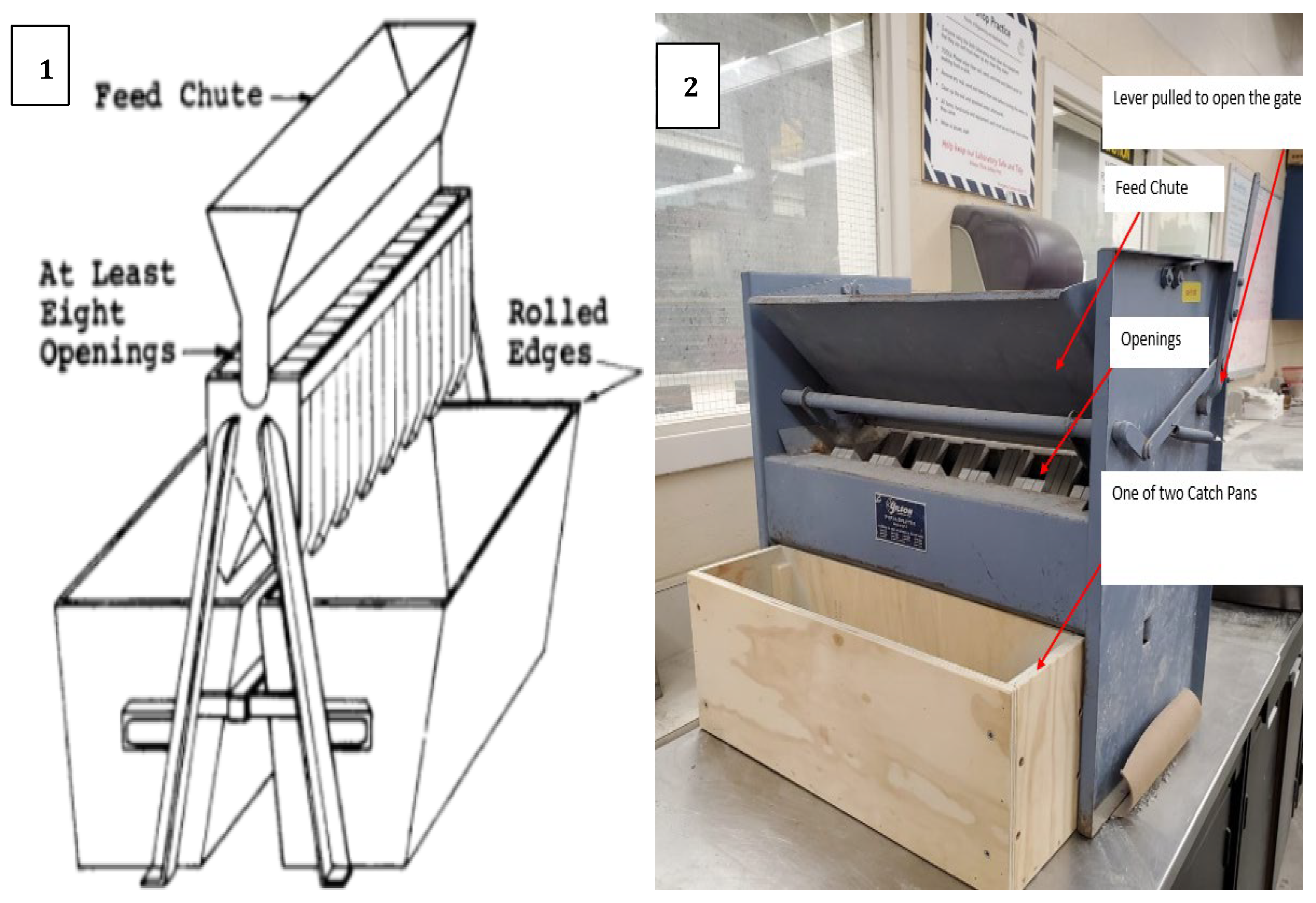

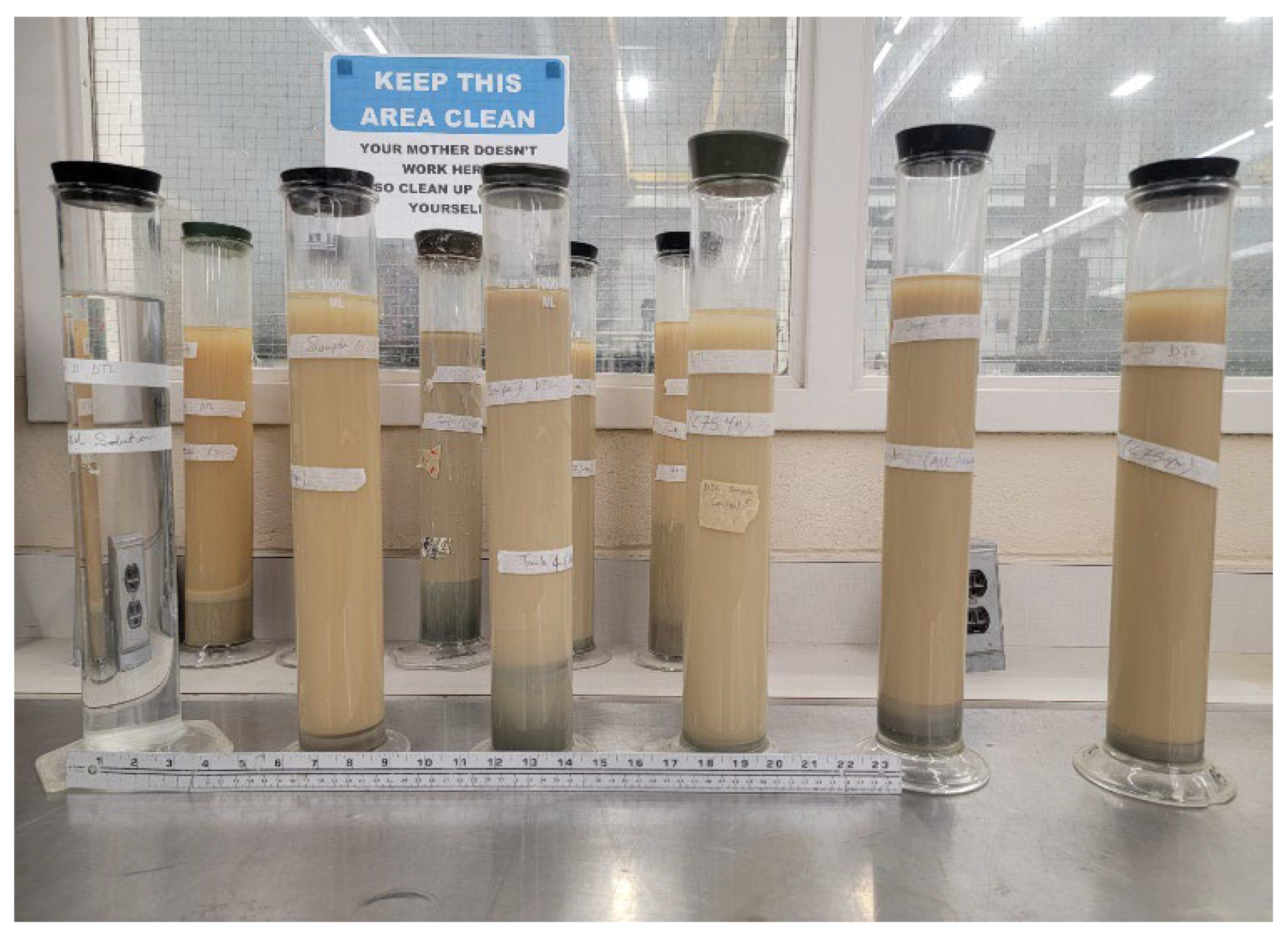

2.2. Methodology for Cuttings Size Analysis

| Sample Source | Circulation Mode | Maximum Particle Size (mm) | Testing Protocol | Type of Particle Size Analysis Method | Sieve Sizes (mm)/ Principle |

|---|---|---|---|---|---|

| Sampling Point 1 | Direct Flush (Shallow Depth) | 4.75 | ASTM D6913 /D6913-17 | Single sieve-set sieving (Dry Method) | Single Sieve Set 4.75, 2.00, 0.85, 0.452, 0.25, 0.15, 0.106 and 0.075 mm |

| Sampling Point 1 | Air Lift Assisted Reverse Circulation | 75.00 | ASTM D6913 /D6913-17 | Composite Sieving (Dry Method) | Designated Separating Sieve 4.75 mm Coarser Sieve Set 75, 50, 37.5, 25, 19, 9.5, 4.75 mm Finer Sieve Set 4.75, 2.00, 0.85, 0.452, 0.25, 0.15, 0.106 and 0.075 mm |

| Sampling Point 2 | N/A | 75.00 | ASTM D6913 /D6913-17 ASTM C702 /C702 M-11 [29] | Composite Sieving (Dry Method) For Unbiased Quartering from large sample bag | Designated Separating Sieve 4.75 mm Coarser Sieve Set 75, 50, 37.5, 25, 19, 9.5, 4.75 mm Finer Sieve Set 4.75, 2.00, 0.85, 0.452, 0.25, 0.15, 0.106 and 0.075 mm |

| Sampling Point 3 | N/A | <75 μm | ASTM D7928-21E1 | Sample was clumpy when dry but disintegrated on rubbing between two the thumb and the index finger | Leveraged terminal velocities based on Stoke’s law [28] |

2.3. (Mineralogical) Composition Evaluation Using X-Ray Diffraction

3. Results

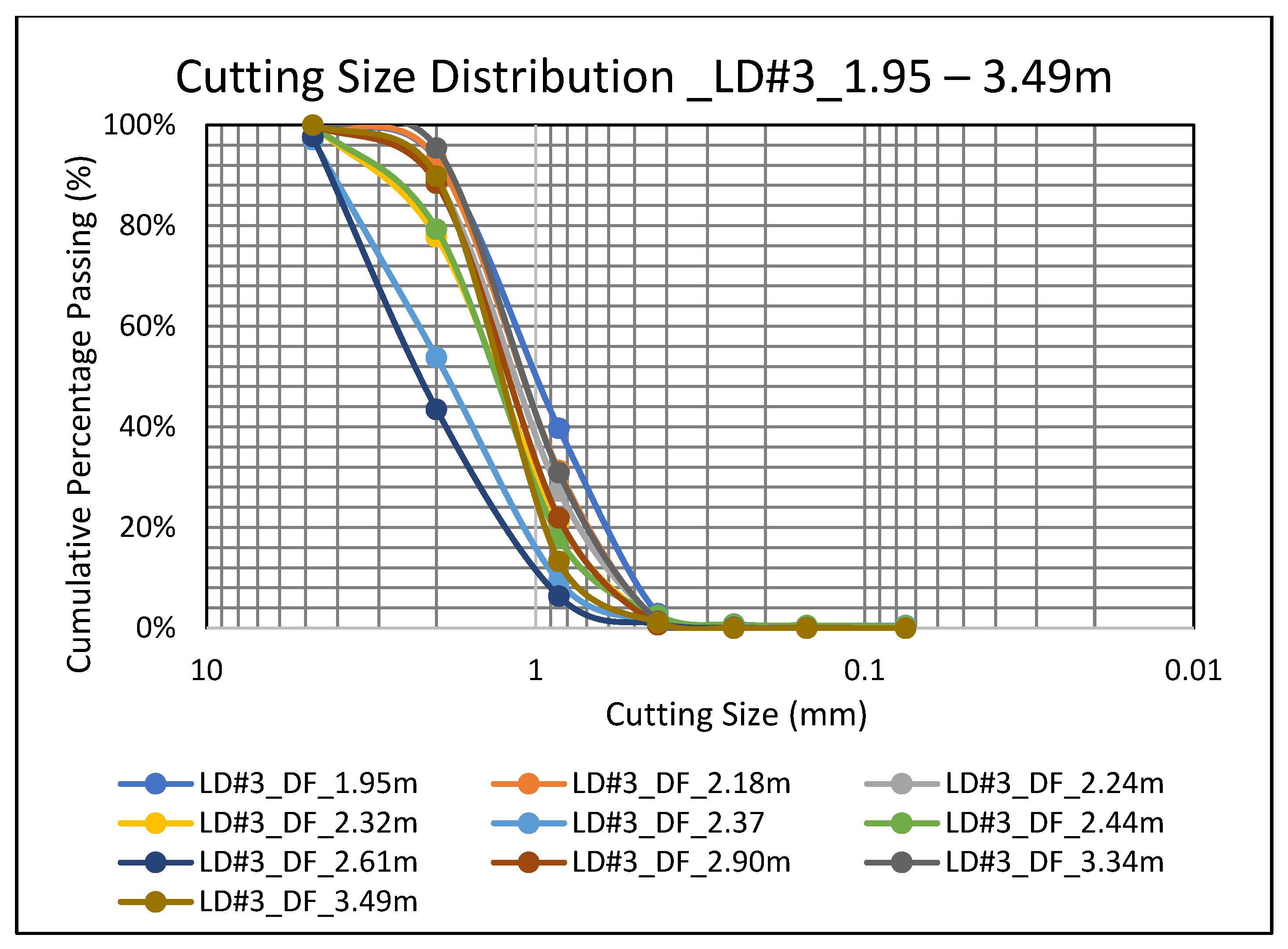

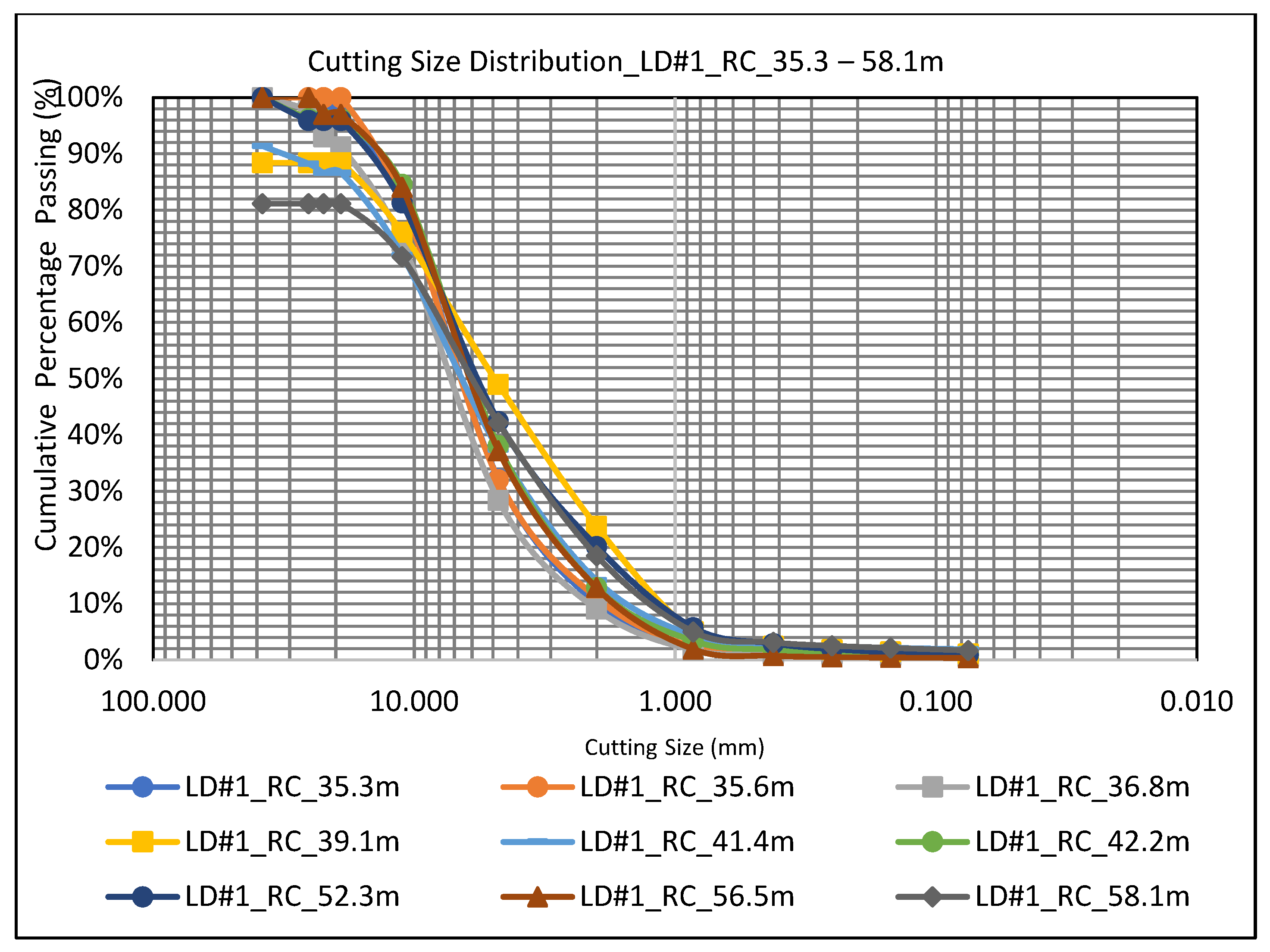

3.1. Results of the Cuttings Size Analyses

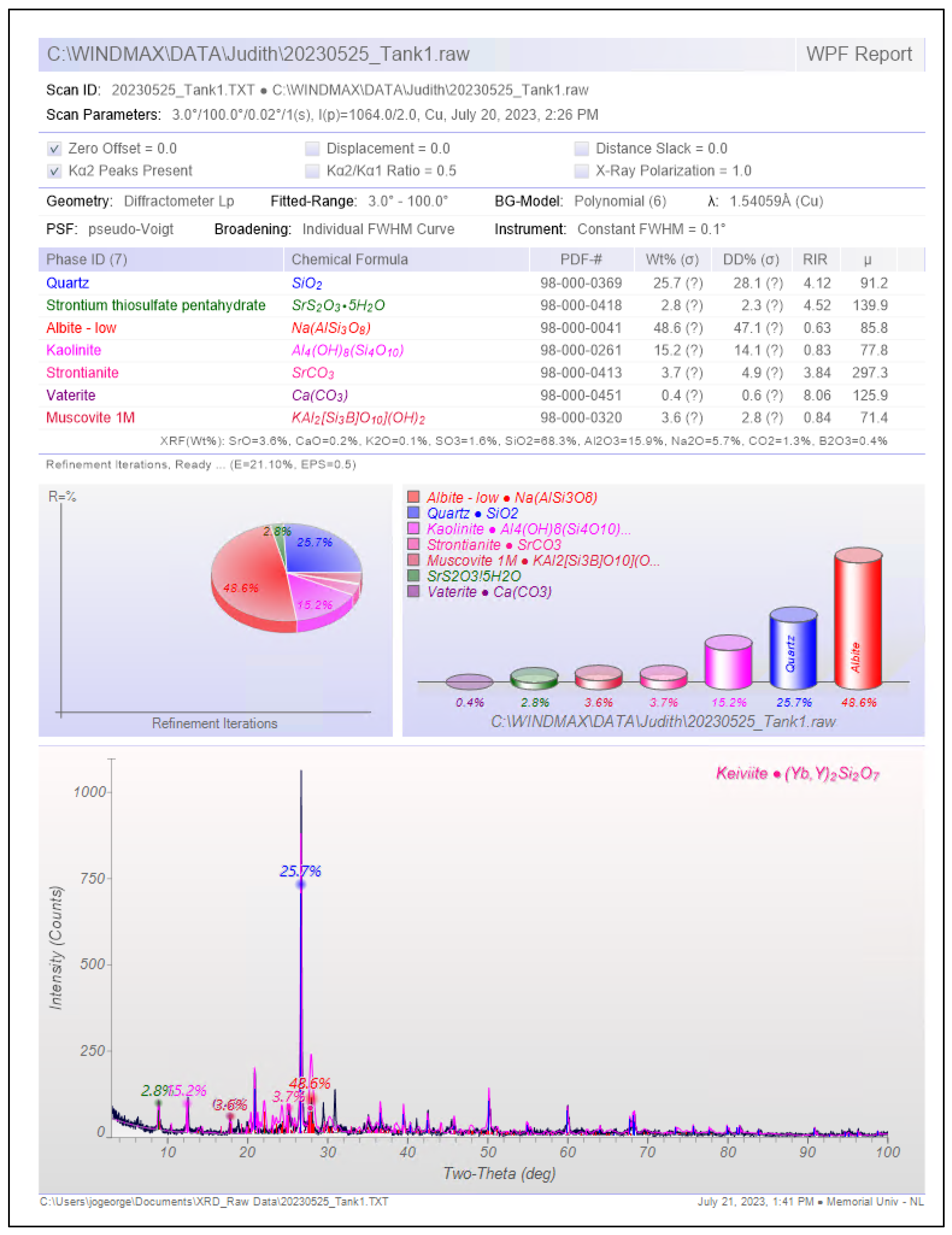

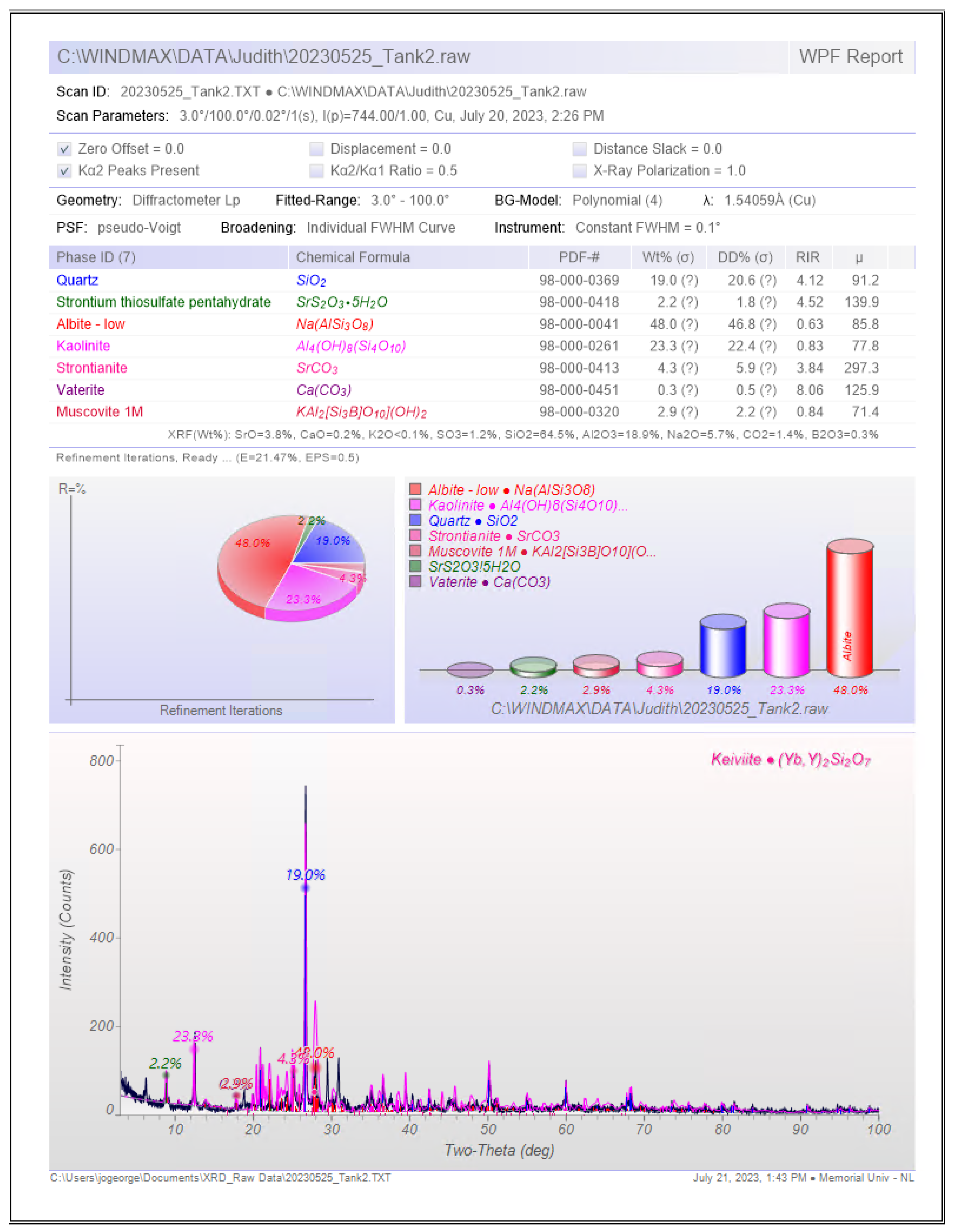

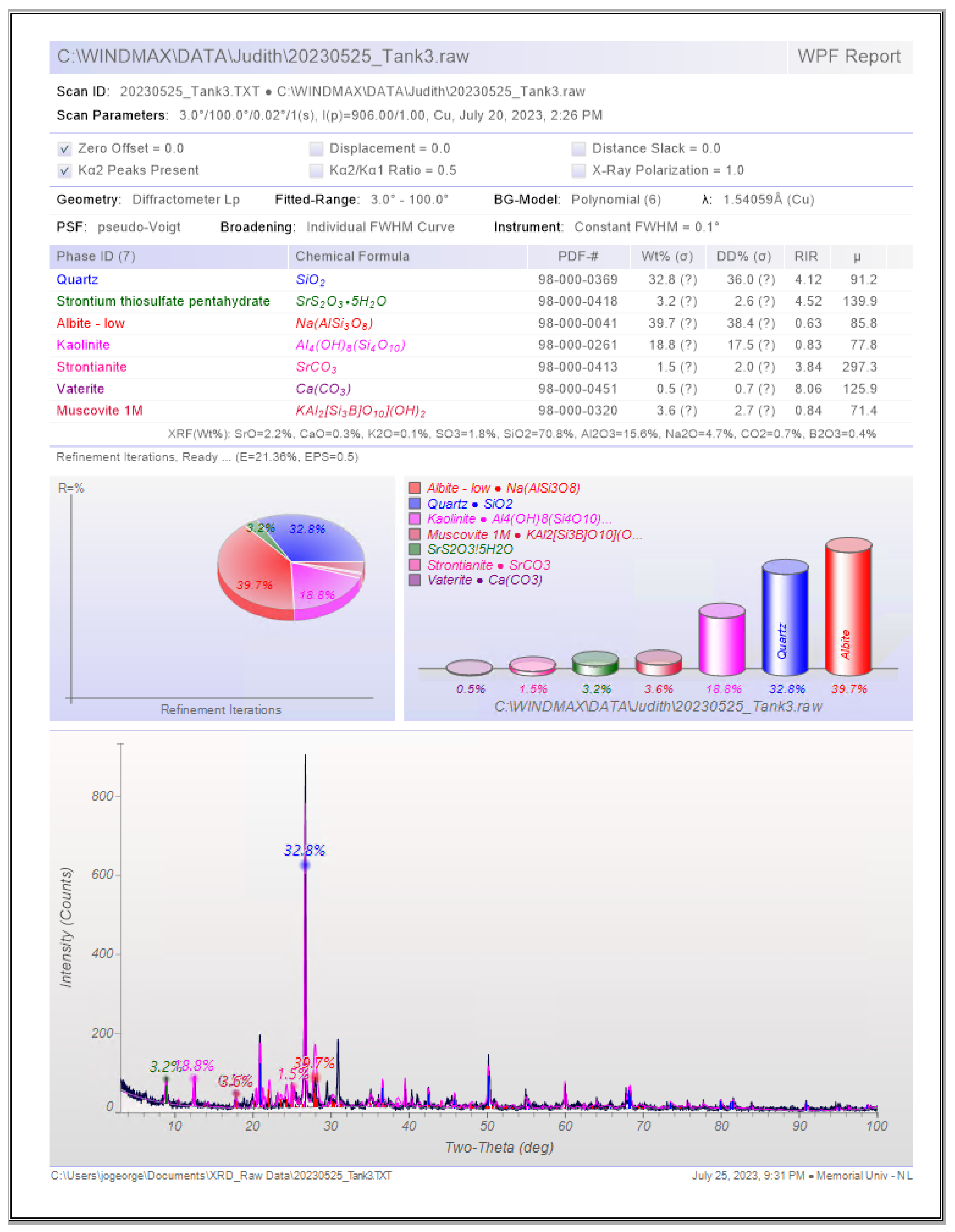

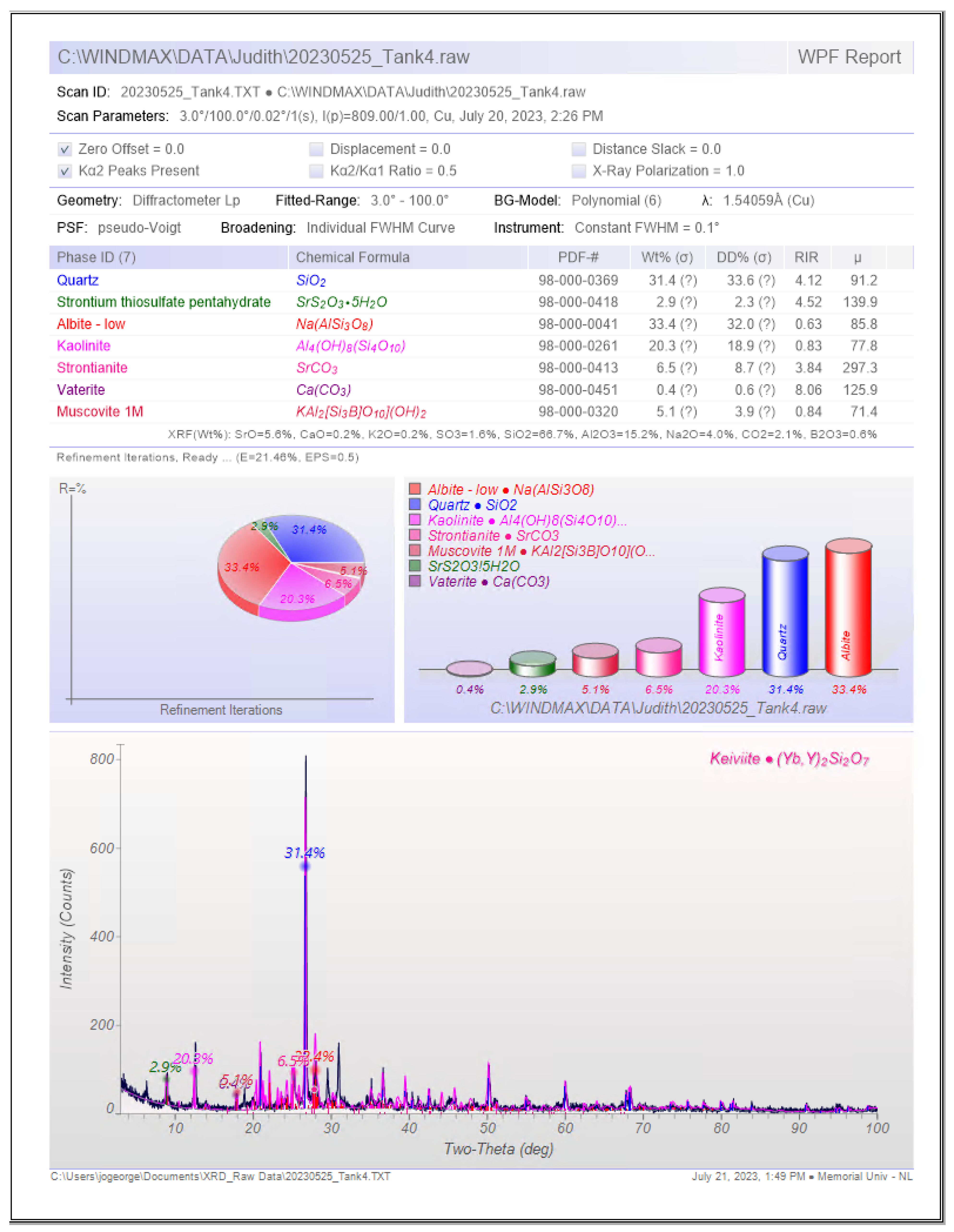

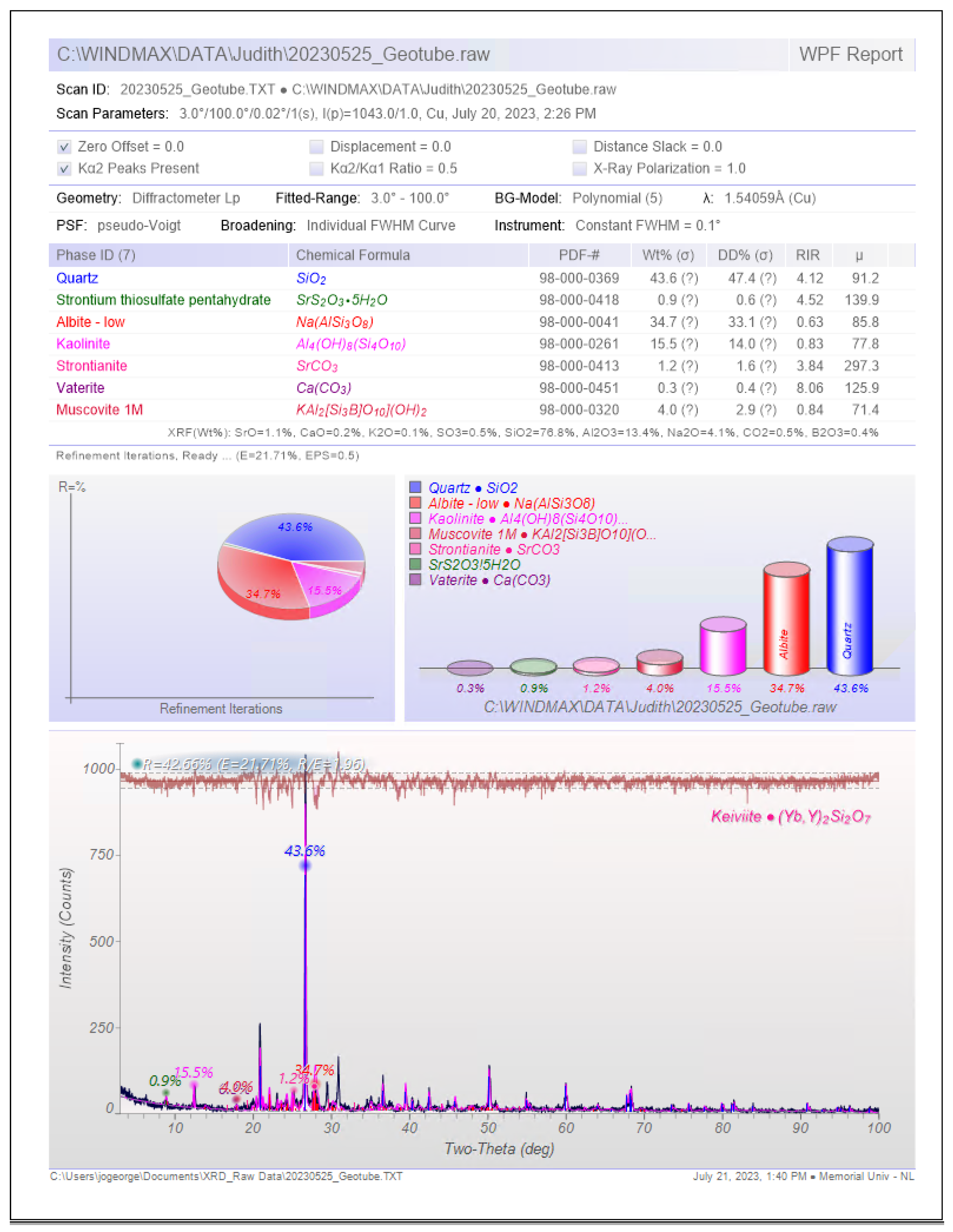

3.2. Results of X-Ray Diffraction of Fine Cuttings Samples

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| LD# | Circulation | Depth (m Along Hole) | Thrust (KN) | Rotary Speed (rpm) | Torque (KNm) | ROP (m/h) | Flow Rate (USgpm) | Air Flow Rate (m3/h) |

|---|---|---|---|---|---|---|---|---|

| 1 | DF | 0.98 | 75.81 | 9.00 | 32.64 | 0.820 | 1938 | - |

| 1 | DF | 1.08 | 70.18 | 9.50 | 32.64 | 0.324 | 1718 | - |

| 1 | DF | 3.16 | 98.43 | 9.90 | 37.39 | 0.396 | 2045 | - |

| 1 | RC | 4.02 | 93.85 | 13.06 | 36.35 | 0.432 | 510 | - |

| 1 | RC | 4.14 | 97.64 | 13.11 | 40.03 | 0.432 | 509 | - |

| 1 | RC | 4.45 | 119.14 | 13.07 | 44.05 | 0.468 | 510 | - |

| 1 | RC | 4.56 | 119.10 | 13.15 | 47.94 | 0.504 | 514 | - |

| 1 | RC | 5.26 | 117.72 | 10.48 | 42.49 | 0.432 | 515 | - |

| 1 | RC | 6.08 | 159.60 | 14.20 | 36.46 | 0.350 | 815 | - |

| 1 | RC | 6.16 | 159.60 | 13.00 | 36.97 | 0.300 | 813 | - |

| 1 | RC | 6.23 | 159.60 | 13.90 | 37.47 | 0.600 | 812 | - |

| 1 | RC | 6.31 | 159.60 | 13.50 | 6.87 | 0.430 | 812 | - |

| 1 | RC | 6.65 | 155.61 | 14.60 | 46.59 | 0.510 | 342 | - |

| 1 | RC | 6.70 | 159.60 | 13.50 | 49.12 | 0.270 | 343 | - |

| 1 | RC | 7.50 | 195.51 | 12.10 | 38.49 | 0.270 | 887 | - |

| 1 | RC | 7.65 | 211.47 | 13.80 | 40.01 | 0.220 | 883 | - |

| 1 | RC | 7.80 | 219.45 | 12.70 | 40.01 | 0.220 | 891 | - |

| 1 | RC | 8.20 | 219.45 | 12.70 | 40.01 | 0.220 | 891 | - |

| 1 | RC | 8.40 | 239.40 | 15.20 | 42.03 | 0.220 | 889 | - |

| 1 | RC | 8.56 | 259.35 | 15.10 | 42.54 | 0.360 | 889 | - |

| 1 | RC | 8.86 | 279.30 | 16.20 | 49.63 | 0.440 | 889 | - |

| 1 | RC | 11.74 | 339.15 | 16.70 | 49.12 | 0.800 | 1158 | - |

| 1 | RC | 12.10 | 339.15 | 16.40 | 49.12 | 0.680 | 1154 | - |

| 1 | RC | 12.47 | 339.15 | 16.50 | 49.12 | 0.720 | 1158 | - |

| 1 | RC | 12.83 | 339.15 | 14.70 | 49.63 | 0.760 | 1154 | - |

| 1 | RC | 13.17 | 339.15 | 15.90 | 50.64 | 0.560 | 1154 | - |

| 1 | RC | 13.53 | 331.17 | 9.50 | 44.06 | 0.180 | 955 | - |

| 1 | RC | 13.70 | 339.15 | 15.50 | 54.18 | 0.510 | 1129 | - |

| 1 | RC | 14.02 | 331.17 | 14.80 | 52.16 | 0.640 | 1131 | - |

| 1 | RC | 14.24 | 359.10 | 14.60 | 51.15 | 0.160 | 1132 | - |

| 1 | RC | 14.75 | 359.10 | 16.00 | 52.16 | 0.680 | 1310 | - |

| 1 | RC | 15.08 | 279.30 | 16.40 | 49.63 | 0.660 | 881 | - |

| 1 | RC | 15.47 | 275.31 | 15.10 | 49.63 | 1.000 | 955 | - |

| 1 | RC | 15.93 | 275.31 | 17.60 | 51.65 | 0.920 | 956 | - |

| 1 | RC | 16.42 | 279.30 | 15.10 | 50.64 | 1.040 | 955 | - |

| 1 | RC | 16.80 | 279.30 | 15.40 | 50.64 | 0.800 | 954 | - |

| 1 | RC | 17.00 | 279.30 | 15.40 | 50.64 | 0.800 | 954.00 | - |

| 1 | RC | 17.59 | 295.26 | 16.10 | 56.21 | 1.060 | 957 | - |

| 1 | RC | 17.59 | 295.26 | 16.10 | 56.21 | 1.060 | 957 | - |

| 1 | RC | 18.15 | 279.30 | 17.70 | 52.67 | 1.240 | 959 | - |

| 1 | RC | 18.46 | 279.30 | 14.30 | 55.70 | 0.620 | 1078 | - |

| 1 | RC | 19.01 | 299.25 | 15.90 | 54.69 | 0.800 | 1070 | - |

| 1 | RC | 19.37 | 295.26 | 16.30 | 52.16 | 0.720 | 1129 | - |

| 1 | RC | 19.68 | 295.26 | 15.10 | 56.72 | 0.620 | 1132 | - |

| 1 | RC | 20.12 | 303.24 | 15.00 | 51.15 | 0.760 | 1129 | - |

| 1 | RC | 20.16 | 299.25 | 10.00 | 48.11 | 0.120 | 1165 | - |

| 1 | RC | 20.54 | 295.26 | 14.90 | 57.22 | 0.760 | 1155 | - |

| 1 | RC | 20.79 | 291.27 | 15.10 | 55.70 | 0.500 | 1051 | - |

| 1 | RC | 21.13 | 315.21 | 16.20 | 52.67 | 0.680 | 1053 | - |

| 1 | RC | 21.13 | 315.21 | 16.20 | 52.67 | 0.680 | 1053 | - |

| 1 | RC | 21.46 | 323.19 | 15.90 | 52.16 | 0.640 | 1120 | - |

| 1 | RC | 21.81 | 323.19 | 15.90 | 53.68 | 0.470 | 1138 | - |

| 1 | RC | 21.90 | 323.19 | 17.60 | 51.65 | 0.360 | 1138 | - |

| 1 | RC | 22.18 | 359.10 | 17.00 | 56.21 | 0.600 | 1199 | - |

| 1 | RC | 22.50 | 359.10 | 14.70 | 55.70 | 0.640 | 1201 | - |

| 1 | RC | 22.72 | 339.15 | 13.90 | 58.24 | 0.440 | 1199 | - |

| 1 | RC | 23.07 | 359.10 | 14.90 | 53.17 | 0.560 | 1199 | - |

| 1 | RC | 23.36 | 355.11 | 14.90 | 52.67 | 0.600 | 1259 | - |

| 1 | RC | 23.62 | 351.12 | 16.30 | 52.16 | 0.520 | 1262 | - |

| 1 | RC | 23.88 | 359.10 | 15.50 | 57.73 | 0.520 | 1255 | - |

| 1 | RC | 24.21 | 359.10 | 16.90 | 57.73 | 0.560 | 1251 | - |

| 1 | RC | 24.61 | 355.11 | 15.10 | 53.17 | 0.480 | 1822 | - |

| 1 | RC | 24.61 | 355.11 | 15.10 | 53.17 | 0.480 | 1822 | - |

| 1 | RC | 24.85 | 351.12 | 17.70 | 59.25 | 0.480 | 1807 | - |

| 1 | RC | 25.16 | 339.15 | 17.10 | 55.70 | 0.620 | 1829 | - |

| 1 | RC | 25.45 | 359.10 | 17.30 | 58.74 | 0.560 | 1838 | - |

| 1 | RC | 25.70 | 355.11 | 14.00 | 55.20 | 0.500 | 1831 | - |

| 1 | RC | 26.00 | 335.16 | 14.00 | 64.82 | 0.600 | 1830 | - |

| 1 | RC | 26.22 | 355.11 | 15.30 | 55.20 | 0.150 | 1876 | - |

| 1 | RC | 26.49 | 355.11 | 17.40 | 59.76 | 0.640 | 1874 | - |

| 1 | RC | 26.80 | 363.09 | 16.40 | 61.78 | 0.620 | 1867 | - |

| 1 | RC | 27.11 | 359.10 | 9.70 | 68.87 | 0.680 | 1865 | - |

| 1 | RC | 27.24 | 139.65 | 9.70 | 56.21 | 0.170 | 1892 | - |

| 1 | RC | 27.31 | 199.50 | 10.20 | 47.60 | 0.280 | 1831 | - |

| 1 | RC | 27.74 | 319.20 | 17.00 | 58.24 | 0.860 | 1867 | - |

| 1 | RC | 28.20 | 283.29 | 15.40 | 62.79 | 0.960 | 1845 | - |

| 1 | RC | 29.25 | 303.24 | 16.10 | 60.77 | 0.690 | 1866 | - |

| 1 | RC | 29.53 | 299.25 | 9.00 | 58.24 | 1.120 | 1856 | - |

| 1 | RC | 29.82 | 199.50 | 11.90 | 61.30 | 0.100 | 1389 | - |

| 1 | RC | 30.09 | 195.50 | 13.60 | 51.70 | 0.540 | 1386 | - |

| 1 | RC | 30.09 | 195.50 | 13.60 | 51.70 | 0.540 | 1386 | - |

| 1 | RC | 30.82 | 259.40 | 15.30 | 56.70 | 0.740 | 1392 | - |

| 1 | RC | 30.82 | 259.40 | 15.30 | 56.70 | 0.740 | 1392 | - |

| 1 | RC | 31.16 | 279.30 | 14.40 | 57.20 | 0.700 | 1395 | - |

| 1 | RC | 31.46 | 299.30 | 16.10 | 55.70 | 0.670 | 1391 | - |

| 1 | RC | 31.46 | 299.30 | 16.10 | 55.70 | 0.670 | 1391 | |

| 1 | RC | 31.82 | 299.30 | 14.60 | 50.10 | 0.720 | 1386 | - |

| 1 | RC | 31.95 | 323.19 | 16.00 | 57.22 | 0.210 | 1384 | - |

| 1 | RC | 32.07 | 319.20 | 14.20 | 56.70 | 0.660 | 1386 | - |

| 1 | RC | 32.54 | 319.20 | 13.20 | 58.24 | 0.640 | 1378 | - |

| 1 | RC | 32.54 | 319.20 | 13.20 | 58.24 | 0.640 | 1378 | - |

| 1 | RC | 32.97 | 243.40 | 10.10 | 56.20 | 0.500 | 1383 | - |

| 1 | RC | 33.04 | 279.30 | 11.70 | 60.26 | 0.280 | 1458 | - |

| 1 | RC | 33.40 | 315.20 | 14.40 | 51.70 | 0.650 | 1486 | - |

| 1 | RC | 33.54 | 319.20 | 9.70 | 47.60 | 0.300 | 1486 | - |

| 1 | RC | 33.70 | 335.16 | 9.70 | 66.84 | 0.270 | 1390 | - |

| 1 | RC | 33.86 | 355.10 | 10.70 | 66.80 | 0.240 | 1390 | - |

| 1 | RC | 33.95 | 299.30 | 9.30 | 63.30 | 0.170 | 1382 | - |

| 1 | RC | 34.01 | 315.20 | 11.90 | 80.50 | 0.100 | 1544 | - |

| 1 | RC | 34.35 | 355.11 | 18.50 | 56.72 | 0.440 | 1545 | - |

| 1 | RC | 34.57 | 387.03 | 16.00 | 75.96 | 0.200 | 1540 | - |

| 1 | RC | 34.72 | 399.00 | 16.00 | 87.10 | 0.150 | 1950 | - |

| 1 | RC | 34.74 | 399.00 | 16.00 | 87.10 | 0.150 | 1950 | - |

| 1 | RC | 34.79 | 395.00 | 12.60 | 99.80 | 0.100 | 1920 | - |

| 1 | RC | 34.87 | 239.40 | 8.30 | 37.98 | 0.000 | 1548 | - |

| 1 | RC | 35.12 | 343.14 | 16.30 | 51.15 | 0.376 | 1541 | - |

| 1 | RC | 35.34 | 355.10 | 14.60 | 53.20 | 0.501 | 1541 | - |

| 1 | RC | 35.63 | 359.10 | 21.00 | 65.30 | 0.655 | 1594 | - |

| 1 | RC | 36.20 | 355.10 | 19.80 | 59.20 | 0.500 | 1602 | - |

| 1 | RC | 36.57 | 355.11 | 20.60 | 58.24 | 0.714 | 1590 | - |

| 1 | RC | 36.84 | 355.10 | 17.60 | 57.20 | 0.180 | 1391 | - |

| 1 | RC | 36.84 | 355.10 | 17.60 | 57.20 | 0.200 | 1391 | - |

| 1 | RC | 37.60 | 363.10 | 19.60 | 56.70 | 0.725 | 1391 | - |

| 1 | RC | 38.00 | 359.10 | 19.50 | 61.80 | 0.800 | 1391 | - |

| 1 | RC | 38.73 | 359.10 | 20.30 | 68.90 | 0.700 | 1392 | - |

| 1 | RC | 39.13 | 359.10 | 18.60 | 67.90 | 0.700 | 1587 | - |

| 1 | RC | 39.40 | 363.09 | 19.10 | 57.73 | 0.628 | 1391 | - |

| 1 | RC | 39.60 | 355.11 | 19.40 | 58.24 | 0.293 | 1587 | - |

| 1 | RC | 40.37 | 359.10 | 20.10 | 65.30 | 0.673 | 1533 | - |

| 1 | RC | 40.63 | 359.10 | 21.90 | 62.30 | 0.612 | 1530 | - |

| 1 | RC | 41.02 | 359.10 | 20.80 | 64.30 | 0.874 | 1535 | - |

| 1 | RC | 41.41 | 359.10 | 23.60 | 69.90 | 0.800 | 1536 | - |

| 1 | RC | 41.87 | 359.10 | 21.90 | 72.40 | 0.794 | 1532 | - |

| 1 | RC | 42.22 | 359.10 | 21.10 | 66.80 | 0.810 | 1533 | - |

| 1 | RC | 42.76 | 359.10 | 22.40 | 69.90 | 0.422 | 1674 | - |

| 1 | RC | 43.61 | 371.07 | 22.00 | 64.82 | 0.744 | 1584 | - |

| 1 | RC | 44.14 | 359.10 | 22.60 | 67.90 | 1.004 | 1584 | - |

| 1 | RC | 44.94 | 383.04 | 22.00 | 65.33 | 0.655 | 1591 | - |

| 1 | RC | 45.18 | 359.10 | 21.90 | 64.30 | 0.445 | 1590 | - |

| 1 | RC | 45.38 | 383.04 | 21.10 | 64.82 | 0.483 | 1581 | - |

| 1 | RC | 45.38 | 359.10 | 21.10 | 64.80 | 0.483 | 1581 | - |

| 1 | RC | 45.60 | 199.50 | 20.60 | 74.90 | 0.600 | 1606 | - |

| 1 | RC | 45.67 | 379.05 | 21.90 | 80.52 | 0.048 | 1394 | - |

| 1 | RC | 46.21 | 199.50 | 21.60 | 66.80 | 1.007 | 1599 | - |

| 1 | RC | 46.84 | 199.50 | 20.60 | 66.80 | 0.643 | 1686 | - |

| 1 | RC | 47.16 | 199.50 | 20.10 | 67.40 | 0.717 | 1699 | - |

| 1 | RC | 47.41 | 199.50 | 21.70 | 80.50 | 0.504 | 1696 | - |

| 1 | RC | 48.70 | 199.50 | 22.60 | 65.30 | 0.556 | 1877 | - |

| 1 | RC | 49.44 | 199.50 | 21.90 | 69.40 | 0.800 | 1878 | - |

| 1 | RC | 50.71 | 379.10 | 19.60 | 65.30 | 0.970 | 1897 | - |

| 1 | RC | 51.11 | 379.10 | 19.90 | 68.40 | 0.800 | 1892 | - |

| 1 | RC | 51.35 | 383.00 | 19.80 | 67.40 | 0.300 | 1894 | - |

| 1 | RC | 51.46 | 383.04 | 19.80 | 67.35 | 0.260 | 1886 | - |

| 1 | RC | 51.77 | 383.00 | 19.80 | 67.40 | 0.300 | 1904 | - |

| 1 | RC | 51.77 | 383.00 | 19.80 | 67.40 | 0.300 | 1904 | - |

| 1 | RC | 52.25 | 387.00 | 20.50 | 63.30 | 0.511 | 1904 | - |

| 1 | RC | 52.50 | 395.00 | 20.90 | 66.80 | 0.500 | 1911 | - |

| 1 | RC | 52.73 | 391.00 | 24.00 | 60.80 | 0.413 | 1894 | - |

| 1 | RC | 52.73 | 391.00 | 24.00 | 60.80 | 0.413 | 1894 | - |

| 1 | RC | 53.11 | 395.00 | 21.60 | 58.20 | 0.350 | 1907 | |

| 1 | RC | 53.39 | 391.02 | 22.20 | 62.29 | 0.265 | 1913 | - |

| 1 | RC | 53.61 | 379.10 | 20.30 | 58.20 | 0.177 | 1899 | - |

| 1 | RC | 53.70 | 379.10 | 20.50 | 59.80 | 0.166 | 2091 | - |

| 1 | RC | 53.79 | 379.10 | 20.70 | 58.20 | 0.177 | 2088 | - |

| 1 | RC | 53.93 | 391.00 | 23.50 | 63.30 | 0.381 | 2095 | - |

| 1 | RC | 54.19 | 395.00 | 19.90 | 54.20 | 0.280 | 2002 | - |

| 1 | RC | 54.21 | 391.00 | 10.10 | 44.60 | 0.000 | 1919 | - |

| 1 | RC | 54.34 | 395.00 | 22.50 | 59.20 | 0.158 | 1914 | 2364 |

| 1 | RC | 54.44 | 391.00 | 21.40 | 58.20 | 0.187 | 1901 | 2478 |

| 1 | RC | 54.73 | 387.00 | 21.20 | 59.80 | 0.253 | 1814 | 2302 |

| 1 | RC | 55.03 | 403.00 | 28.60 | 64.80 | 0.382 | 1803 | 2506 |

| 1 | RC | 55.28 | 403.00 | 21.10 | 61.30 | 0.590 | 1810 | - |

| 1 | RC | 55.60 | 407.00 | 20.40 | 70.40 | 0.642 | 1811 | - |

| 1 | RC | 56.51 | 419.00 | 23.00 | 58.70 | 0.529 | 1807 | 2424 |

| 1 | RC | 56.51 | 419.00 | 23.00 | 58.70 | 0.529 | 1807 | 2424 |

| 1 | RC | 58.08 | 434.90 | 21.30 | 68.40 | 0.883 | 1784 | - |

| 1 | RC | 59.29 | 438.90 | 22.20 | 73.90 | 0.849 | 1904 | - |

| 1 | RC | 59.72 | 438.90 | 21.80 | 80.00 | 0.822 | 1885 | - |

| 1 | RC | 60.09 | 434.90 | 22.40 | 69.40 | 0.839 | 2004 | - |

| 1 | RC | 60.51 | 442.90 | 22.70 | 68.40 | 0.817 | 1997 | 2538 |

| 1 | RC | 60.56 | 442.90 | 21.90 | 72.90 | 0.115 | 1395 | - |

| 1 | RC | 61.51 | 438.90 | 22.40 | 72.90 | 0.930 | 1995 | 2588 |

| 1 | RC | 61.99 | 438.90 | 22.50 | 69.90 | 1.031 | 1987 | 2416 |

| 1 | RC | 62.51 | 438.90 | 23.30 | 76.00 | 0.984 | 1994 | 2418 |

| 1 | RC | 63.01 | 434.90 | 23.90 | 63.80 | 1.000 | 1959 | - |

| 1 | RC | 63.30 | 434.91 | 21.60 | 65.83 | 0.496 | 1780 | 2438 |

| 1 | RC | 63.39 | 434.91 | 19.40 | 70.90 | 1.193 | 2008 | 2327 |

| 1 | RC | 66.90 | 430.90 | 23.10 | 77.00 | 1.094 | 1803 | 2320 |

| 1 | RC | 67.43 | 454.90 | 22.60 | 82.00 | 1.087 | 1899 | 2560 |

| 1 | RC | 68.18 | 379.10 | 22.40 | 86.60 | 0.771 | 2006 | 2400 |

| 1 | RC | 69.20 | 438.90 | 23.40 | 72.90 | 1.126 | 1994 | - |

| 1 | RC | 69.38 | 367.08 | 20.70 | 83.05 | 0.183 | 1994 | - |

| 1 | RC | 70.82 | 371.07 | 21.60 | 87.10 | 1.293 | 1900 | 2518 |

| 1 | RC | 71.78 | 399.00 | 21.70 | 73.43 | 1.010 | 1831 | - |

| 1 | RC | 73.30 | 442.89 | 23.30 | 76.97 | 1.067 | 1798 | 2516 |

| 1 | RC | 74.44 | 434.91 | 22.20 | 73.93 | 0.938 | 1769 | 2598 |

| 1 | RC | 76.02 | 335.16 | 22.10 | 80.01 | 0.409 | 1485 | - |

| 1 | RC | 76.27 | 259.35 | 21.30 | 81.53 | 0.474 | 1813 | - |

| 1 | RC | 76.66 | 351.12 | 22.20 | 74.95 | 0.566 | 1959 | - |

| 1 | RC | 77.37 | 418.95 | 21.40 | 77.48 | 1.033 | 1963 | - |

| 1 | RC | 78.21 | 446.88 | 22.10 | 73.43 | 1.016 | 1979 | - |

| 1 | RC | 78.62 | 295.26 | 20.30 | 83.05 | 0.164 | 1351 | - |

| 1 | RC | 81.31 | 363.09 | 20.70 | 87.61 | 1.322 | 1999 | 2568 |

| LD# | Circulation | Depth (m AH) | Thrust (KN) | Rotary Speed (rpm) | Torque (KNm) | ROP (m/h) | Flow Rate (USgpm) | Air Flow Rate (m3/h) |

|---|---|---|---|---|---|---|---|---|

| 2 | DF | 0.42 | 100 | 14.10 | 39.50 | 0.511 | 1770 | - |

| 2 | DF | 0.73 | 112 | 13.90 | 37.98 | 0.358 | 1757 | - |

| 2 | DF | 0.98 | 116 | 14.60 | 43.55 | 0.541 | 1837 | - |

| 2 | DF | 1.63 | 112 | 13.40 | 44.06 | 0.630 | 1842 | - |

| 2 | DF | 1.81 | 96 | 16.80 | 43.04 | 0.552 | 1869 | - |

| 2 | DF | 2.23 | 112 | 14.60 | 42.54 | 0.496 | 1869 | - |

| 2 | RC | 2.25 | 88 | 13.50 | 40.00 | 0.390 | 1274 | 1939 |

| 2 | RC | 2.38 | 52 | 13.50 | 34.44 | 0.381 | 576 | - |

| 2 | RC | 2.52 | 92 | 9.70 | 44.56 | 0.218 | 575 | 637 |

| 2 | RC | 2.65 | 48 | 11.50 | 31.90 | 0.234 | 576 | 2000 |

| 2 | RC | 2.85 | 100 | 13.40 | 32.92 | 0.454 | 574 | 1999 |

| 2 | RC | 3.06 | 96 | 13.30 | 32.41 | 0.389 | 572 | 2000 |

| 2 | RC | 3.23 | 160 | 11.70 | 33.42 | 0.489 | 569 | 2000 |

| 2 | RC | 3.23 | 156 | 13.40 | 32.92 | 0.689 | 572 | 2000 |

| 2 | RC | 3.82 | 108 | 12.90 | 43.55 | 0.543 | 572 | 1932 |

| 2 | RC | 4.13 | 160 | 12.40 | 41.02 | 0.588 | 576 | 2000 |

| 2 | RC | 4.43 | 120 | 14.40 | 41.02 | 0.640 | 574 | 2000 |

| 2 | RC | 4.68 | 120 | 14.90 | 36.97 | 0.497 | 574 | 2000 |

| 2 | RC | 5.12 | 239 | 14.60 | 95.20 | 1.070 | 576 | 2000 |

| 2 | RC | 5.39 | 120 | 8.80 | 75.45 | 0.216 | 577 | 2000 |

| 2 | RC | 5.46 | 52 | 7.60 | 95.71 | 0.044 | 576 | 2000 |

| 2 | RC | 6.04 | 192 | 22.20 | 48.11 | 0.691 | 573 | - |

| 2 | RC | 6.4 | 200 | 20.80 | 48.61 | 0.766 | 573 | 2584 |

| 2 | RC | 6.4 | 200 | 20.80 | 48.61 | 0.766 | 573 | 2584 |

| 2 | RC | 6.8 | 196 | 21.60 | 52.16 | 0.771 | 571 | 2592 |

| 2 | RC | 6.81 | 203 | 21.90 | 65.33 | 0.000 | 572 | - |

| 2 | RC | 7.09 | 215 | 21.40 | 54.18 | 0.773 | 568 | - |

| 2 | RC | 7.69 | 219 | 21.00 | 50.13 | 0.769 | 475 | - |

| 2 | RC | 7.98 | 219 | 25.40 | 53.17 | 0.446 | 475 | - |

| 2 | RC | 8.01 | 211 | 20.80 | 58.74 | 0.024 | 475 | - |

| 2 | RC | 8.22 | 311 | 20.90 | 70.39 | 0.392 | 473 | 2600 |

| 2 | RC | 8.51 | 335 | 25.00 | 52.67 | 0.731 | 472 | 2016 |

| 2 | RC | 8.88 | 335 | 21.70 | 51.65 | 0.805 | 470 | - |

| 2 | RC | 9.17 | 339 | 22.50 | 63.81 | 0.414 | 473 | - |

| 2 | RC | 9.9 | 463 | 14.60 | 58.74 | 0.564 | 607 | - |

| 2 | RC | 10.2 | 483 | 13.50 | 53.68 | 0.792 | 609 | - |

| 2 | RC | 10.61 | 479 | 13.90 | 50.64 | 0.823 | 609 | - |

| 2 | RC | 10.97 | 479 | 13.60 | 48.61 | 0.671 | 613 | - |

| 2 | RC | 11.79 | 479 | 12.70 | 57.22 | 0.859 | 609 | 2568 |

| 2 | RC | 12.14 | 439 | 13.20 | 47.10 | 0.612 | 540 | 2574 |

| 2 | RC | 12.46 | 515 | 14.70 | 53.17 | 0.668 | 538 | 2602 |

| 2 | RC | 12.66 | 519 | 14.40 | 56.72 | 0.688 | 510 | - |

| 2 | RC | 12.91 | 515 | 14.10 | 48.11 | 0.599 | 426 | 2602 |

| 2 | RC | 13.38 | 395 | 14.80 | 54.69 | 0.083 | 806 | - |

| 2 | RC | 13.66 | 479 | 13.80 | 59.25 | 0.654 | 709 | 2238 |

| 2 | RC | 13.88 | 479 | 11.10 | 50.64 | 0.280 | 590 | 2222 |

| 2 | RC | 14.24 | 523 | 13.50 | 64.82 | 0.154 | 586 | 1662 |

| 2 | RC | 15.18 | 519 | 14.90 | 50.64 | 0.797 | 286 | 1836 |

| 2 | RC | 15.18 | 519 | 14.90 | 50.64 | 0.797 | 286 | 1836 |

| 2 | RC | 15.45 | 519 | 14.90 | 55.70 | 0.609 | 286 | 1842 |

| 2 | RC | 15.71 | 479 | 13.40 | 79.00 | 0.455 | 447 | 1858 |

| 2 | RC | 16.08 | 327 | 11.10 | 51.65 | 0.355 | 455 | 1838 |

| 2 | RC | 16.32 | 319 | 12.70 | 49.63 | 0.453 | 514 | 1854 |

| 2 | RC | 16.32 | 319 | 12.70 | 49.63 | 0.453 | 514 | 1854 |

| 2 | RC | 16.59 | 303 | 13.50 | 92.67 | 0.487 | 514 | 1840 |

| 2 | RC | 16.59 | 255 | 13.50 | 52.67 | 0.389 | 482 | 2430 |

| 2 | RC | 16.69 | 279 | 15.80 | 49.12 | 0.404 | 481 | 2414 |

| 2 | RC | 16.83 | 299 | 14.00 | 50.13 | 0.537 | 481 | 2456 |

| 2 | RC | 17.15 | 295 | 13.20 | 54.69 | 0.658 | 484 | 2464 |

| 2 | RC | 17.45 | 323 | 13.00 | 44.56 | 0.700 | 486 | 2428 |

| 2 | RC | 17.82 | 387 | 13.00 | 51.65 | 0.829 | 465 | 2494 |

| LD# | Circulation | Depth (m Along Hole) | Thrust (KN) | Rotary Speed (rpm) | Torque (KNm) | ROP (m/h) | DOC (mm/rev) | Flow Rate (USgpm) |

|---|---|---|---|---|---|---|---|---|

| 3 | DF | 1.95 | 32.0 | 3.6 | 10.63 | 0.336 | 1.556 | 517 |

| 3 | DF | 2.18 | 32.0 | 3.4 | 10.13 | 0.300 | 1.471 | 1895 |

| 3 | DF | 2.24 | 32.0 | 3.5 | 10.63 | 0.053 | 0.252 | 1874 |

| 3 | DF | 2.32 | 36.0 | 7.3 | 20.76 | 0.026 | 0.059 | 1470 |

| 3 | DF | 2.37 | 60.0 | 6.7 | 20.76 | 0.110 | 0.274 | 2116 |

| 3 | DF | 2.44 | 72.0 | 7.6 | 24.31 | 0.120 | 0.263 | 2616 |

| 3 | DF | 2.61 | 56.0 | 7.4 | 21.78 | 0.120 | 0.270 | 2431 |

| 3 | DF | 2.9 | 52.0 | 5.5 | 20.76 | 0.260 | 0.788 | 2378 |

| 3 | DF | 3.34 | 32.0 | 5.8 | 22.28 | 0.420 | 1.207 | 1859 |

| 3 | DF | 3.49 | 64.0 | 6.9 | 25.32 | 0.150 | 0.362 | 2038 |

| 3 | DF | 3.8 | 119.7 | 8 | 27.85 | - | 2400 | |

| 3 | DF | 5.66 | 111.7 | 6.3 | 29.37 | 0.110 | 0.291 | 2550 |

| 3 | DF | 5.74 | 111.7 | 6.3 | 34.44 | 0.110 | 0.291 | 2200 |

| 3 | DF | 5.87 | 99.8 | 9.8 | 30.38 | 0.130 | 0.221 | 2200 |

| 3 | DF | 6.11 | 123.7 | 8.6 | 28.86 | 0.220 | 0.426 | 1850 |

| 3 | DF | 6.5 | 135.7 | 8.6 | 29.37 | 0.200 | 0.388 | 2400 |

| 3 | DF | 6.6 | 135.7 | 9.7 | 28.36 | 0.200 | 0.344 | 2307 |

| 3 | DF | 6.7 | 135.7 | 9.7 | 28.36 | 0.200 | 0.344 | 2460 |

| 3 | DF | 6.8 | 135.7 | 11 | 29.88 | 0.200 | 0.303 | 2460 |

| 3 | DF | 6.88 | 155.6 | 10.4 | 33.42 | 0.170 | 0.272 | 2400 |

| 3 | DF | 7.11 | 147.6 | 15.4 | 30.89 | 0.170 | 0.184 | 2400 |

| 3 | DF | 7.27 | 99.8 | 15.4 | 30.89 | 0.390 | 0.422 | 2400 |

| Date of Daily Production | LD# | Mode |

|---|---|---|

| 11 October 2021 | 1 | RC |

| 12 October 2021 | ||

| 13 October 2021 | ||

| 14 October 2021 | ||

| 20 October 2021 | ||

| 21 October 2021 | ||

| 26 October 2021 | ||

| 27 October 2021 | ||

| 28 October 2021 | ||

| 29 October 2021 | ||

| 30 October 2021 | ||

| 1 November 2021 | ||

| 2 November 2021 | ||

| 3 November 2021 | ||

| 4 November 2021 | ||

| 28 November 2021 | 2 | |

| 3 December 2021 |

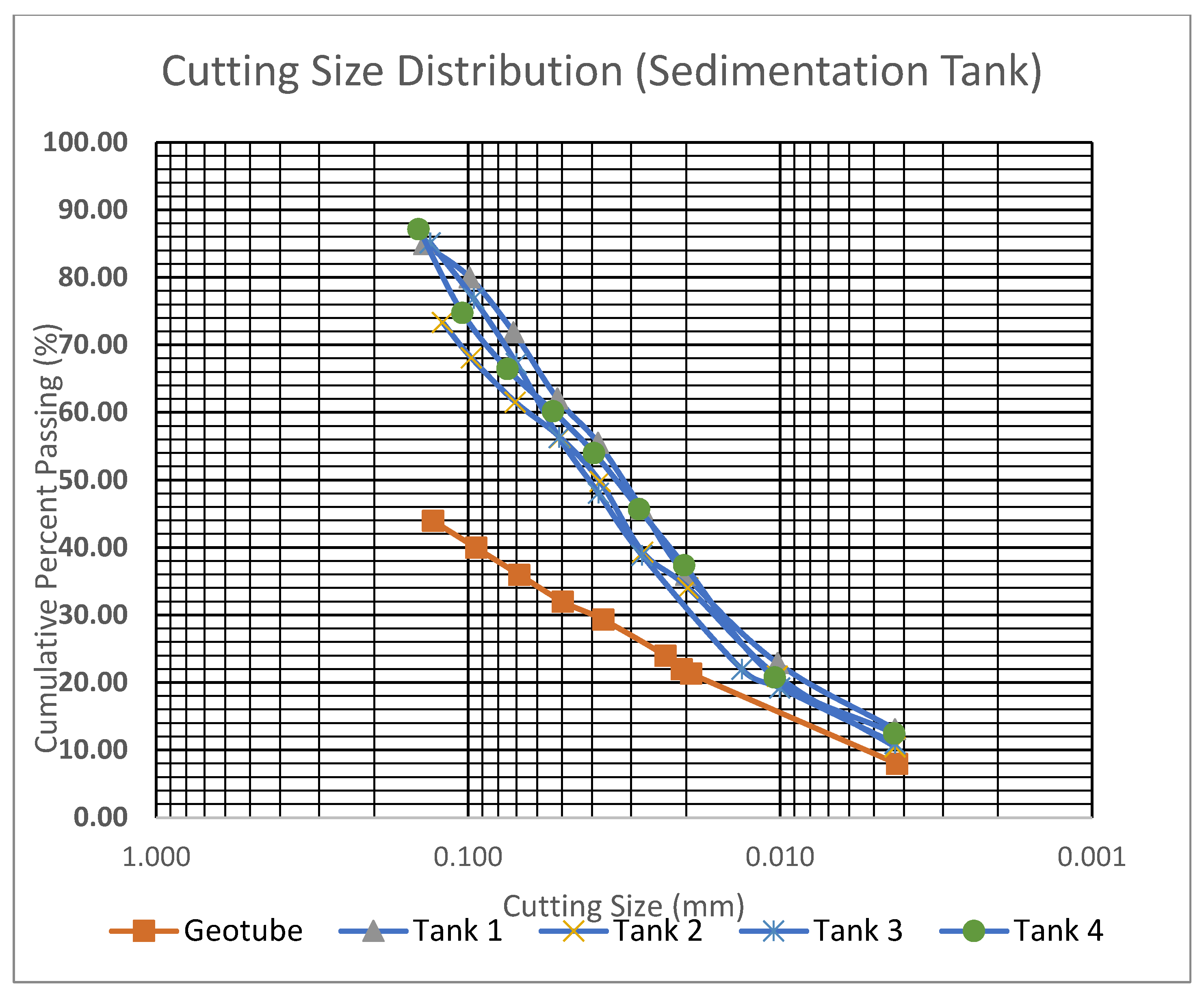

| S/N | Remarks | |

|---|---|---|

| 1 | Tank 1 | Fine-sized |

| 2 | Tank 2 | Fine-sized |

| 3 | Tank 3 | Fine-sized |

| 4 | Tank 4 | Fine-sized |

| 5 | Geotube® | Fine-sized |

| Depth (m AH) | Cutting Size or Sieve Size (mm) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 76.2 | 50.8 | 44.45 | 38.100 | 25.400 | 22.225 | 19.050 | 11.125 | 4.750 | 2.000 | 0.850 | 0.420 | 0.250 | 0.149 | 0.075 | |

| Cumulative Percent Passing | |||||||||||||||

| 0.98 | - | - | - | - | - | - | - | - | 100% | 78% | 5% | 1% | 1% | 1% | 0% |

| 1.08 | - | - | - | - | - | - | - | - | 100% | 81% | 3% | 1% | 1% | 1% | 0% |

| 3.16 | - | - | - | - | - | - | 100% | 92% | 57% | 23% | 3% | 1% | 1% | 1% | 0% |

| 4.02 | - | 100% | 100% | 100% | 100% | 97% | 95% | 69% | 4% | 1% | 1% | 1% | 1% | 1% | 1% |

| 4.14 | - | - | 100% | 100% | 97% | 95% | 92% | 64% | 17% | 7% | 3% | 1% | 1% | 0% | 0% |

| 4.45 | - | 100% | 100% | 100% | 97% | 97% | 94% | 64% | 7% | 4% | 2% | 1% | 1% | 1% | 0% |

| 4.56 | - | - | - | 100% | 100% | 99% | 96% | 57% | 6% | 2% | 1% | 0% | 0% | 0% | 0% |

| 5.26 | - | - | - | 100% | 100% | 98% | 97% | 72% | 26% | 15% | 8% | 4% | 3% | 2% | 1% |

| 6.08 | - | 100% | 100% | 100% | 100% | 100% | 100% | 95% | 60% | 24% | 2% | 1% | 0% | 0% | 0% |

| 6.16 | - | - | 100% | 100% | 100% | 100% | 100% | 95% | 63% | 27% | 4% | 2% | 1% | 1% | 0% |

| 6.23 | - | 100% | 100% | 100% | 100% | 100% | 100% | 96% | 56% | 26% | 4% | 2% | 2% | 2% | 1% |

| 6.31 | - | 100% | 100% | 100% | 100% | 100% | 100% | 95% | 47% | 22% | 4% | 2% | 1% | 1% | 0% |

| 6.65 | - | - | - | 100% | 100% | 100% | 98% | 95% | 55% | 24% | 3% | 1% | 1% | 0% | 0% |

| 6.70 | - | - | 100% | 100% | 100% | 100% | 100% | 95% | 60% | 24% | 2% | 1% | 0% | 0% | 0% |

| 7.50 | - | - | - | 100% | 100% | 96% | 94% | 87% | 55% | 22% | 2% | 1% | 0% | 0% | 0% |

| 7.65 | - | - | - | 100% | 100% | 100% | 100% | 93% | 59% | 26% | 5% | 3% | 2% | 2% | 2% |

| 7.80 | - | - | 100% | 100% | 96% | 96% | 96% | 88% | 51% | 20% | 2% | 1% | 1% | 1% | 0% |

| 8.20 | - | 100% | 100% | 100% | 100% | 97% | 97% | 90% | 60% | 27% | 6% | 3% | 3% | 2% | 2% |

| 8.40 | - | - | 100% | 100% | 100% | 100% | 100% | 95% | 55% | 25% | 4% | 2% | 1% | 1% | 0% |

| 8.56 | - | 100% | 100% | 100% | 97% | 97% | 97% | 91% | 53% | 22% | 5% | 3% | 2% | 2% | 1% |

| 8.86 | - | 100% | 100% | 100% | 100% | 97% | 95% | 89% | 54% | 23% | 5% | 2% | 1% | 1% | 0% |

| 11.74 | - | 100% | 100% | 100% | 100% | 100% | 100% | 93% | 61% | 29% | 7% | 4% | 3% | 2% | 1% |

| 12.10 | - | - | 100% | 100% | 100% | 100% | 99% | 92% | 60% | 27% | 6% | 3% | 2% | 2% | 1% |

| 12.47 | - | 100% | 100% | 100% | 100% | 100% | 100% | 91% | 51% | 21% | 6% | 4% | 3% | 3% | 3% |

| 12.83 | - | 100% | 100% | 100% | 100% | 100% | 100% | 87% | 50% | 19% | 4% | 2% | 2% | 2% | 1% |

| 13.17 | - | 100% | 100% | 100% | 100% | 98% | 98% | 87% | 49% | 18% | 5% | 3% | 3% | 2% | 2% |

| 13.53 | - | - | 100% | 100% | 100% | 100% | 100% | 82% | 35% | 11% | 2% | 1% | 1% | 1% | 1% |

| 13.70 | - | 100% | 100% | 100% | 94% | 93% | 91% | 79% | 47% | 21% | 7% | 5% | 4% | 3% | 2% |

| 14.02 | - | - | - | 100% | 94% | 94% | 94% | 82% | 46% | 21% | 5% | 2% | 2% | 1% | 1% |

| 14.24 | - | - | - | 100% | 100% | 100% | 100% | 88% | 47% | 20% | 4% | 2% | 2% | 2% | 1% |

| 14.75 | - | - | - | 100% | 100% | 100% | 97% | 93% | 57% | 27% | 6% | 3% | 2% | 1% | 1% |

| 15.08 | - | - | 100% | 100% | 100% | 100% | 100% | 87% | 35% | 14% | 3% | 2% | 1% | 1% | 1% |

| 15.47 | - | 100% | 100% | 100% | 100% | 100% | 98% | 64% | 48% | 16% | 3% | 2% | 1% | 1% | 1% |

| 15.93 | - | - | - | 100% | 100% | 100% | 100% | 85% | 46% | 20% | 4% | 2% | 2% | 2% | 1% |

| 16.42 | - | - | 100% | 100% | 100% | 100% | 100% | 88% | 51% | 25% | 5% | 2% | 1% | 1% | 1% |

| 16.80 | - | 100% | 100% | 100% | 100% | 100% | 97% | 85% | 47% | 22% | 5% | 3% | 2% | 2% | 1% |

| 17.00 | - | - | - | 100% | 100% | 100% | 100% | 88% | 48% | 22% | 4% | 2% | 1% | 1% | 1% |

| 17.59 | - | - | 100% | 97% | 97% | 94% | 83% | 46% | 19% | 5% | 3% | 3% | 2% | 2% | |

| 17.59 | - | - | - | 100% | 97% | 97% | 94% | 83% | 46% | 19% | 5% | 3% | 3% | 2% | 2% |

| 18.15 | - | 100% | 100% | 96% | 96% | 94% | 80% | 38% | 15% | 3% | 1% | 1% | 1% | 0% | |

| 18.46 | - | 100% | 100% | 100% | 71% | 67% | 62% | 51% | 25% | 12% | 4% | 3% | 2% | 2% | 2% |

| 19.01 | - | 100% | 100% | 79% | 79% | 72% | 59% | 28% | 9% | 1% | 0% | 0% | 0% | 0% | |

| 19.37 | - | 100% | 100% | 100% | 100% | 100% | 97% | 71% | 28% | 9% | 3% | 2% | 2% | 2% | 2% |

| 19.68 | - | - | - | 100% | 88% | 88% | 88% | 68% | 30% | 8% | 1% | 1% | 0% | 0% | 0% |

| 20.12 | - | - | - | 100% | 100% | 96% | 87% | 76% | 32% | 10% | 3% | 2% | 2% | 2% | 2% |

| 20.16 | - | - | - | 100% | 92% | 87% | 87% | 71% | 32% | 12% | 3% | 2% | 2% | 2% | 1% |

| 20.54 | - | - | - | 100% | 100% | 100% | 100% | 96% | 63% | 26% | 4% | 2% | 1% | 1% | 1% |

| 20.79 | - | - | - | 86% | 80% | 80% | 79% | 62% | 34% | 15% | 5% | 4% | 3% | 3% | 2% |

| 21.13 | - | - | - | 100% | 87% | 77% | 77% | 72% | 34% | 13% | 4% | 3% | 3% | 2% | 2% |

| 21.13 | - | - | - | 100% | 100% | 100% | 100% | 88% | 39% | 15% | 5% | 3% | 3% | 2% | 1% |

| 21.46 | - | - | - | 100% | 100% | 98% | 95% | 80% | 42% | 19% | 6% | 4% | 3% | 3% | 2% |

| 21.81 | - | - | - | 100% | 100% | 100% | 100% | 83% | 38% | 16% | 5% | 3% | 3% | 3% | 1% |

| 21.90 | - | - | 100% | 100% | 100% | 100% | 100% | 79% | 33% | 12% | 3% | 2% | 1% | 1% | 1% |

| 22.18 | - | - | - | 100% | 100% | 100% | 93% | 78% | 39% | 15% | 5% | 3% | 3% | 3% | 1% |

| 22.50 | - | - | - | 100% | 100% | 100% | 100% | 81% | 37% | 14% | 4% | 3% | 3% | 2% | 2% |

| 22.72 | - | 100% | 100% | 100% | 83% | 83% | 83% | 73% | 43% | 17% | 6% | 4% | 4% | 3% | 3% |

| 23.07 | - | - | - | 100% | 100% | 100% | 100% | 91% | 39% | 15% | 4% | 3% | 2% | 2% | 1% |

| 23.36 | - | 100% | 89% | 84% | 84% | 62% | 21% | 8% | 2% | 1% | 1% | 1% | 0% | ||

| 23.62 | - | 100% | 100% | 100% | 99% | 78% | 34% | 13% | 5% | 3% | 3% | 3% | 2% | ||

| 23.88 | - | - | - | 100% | 100% | 100% | 100% | 84% | 37% | 15% | 4% | 3% | 2% | 2% | 1% |

| 24.21 | - | - | - | 100% | 100% | 100% | 98% | 88% | 57% | 28% | 8% | 4% | 4% | 3% | 2% |

| 24.61 | - | - | - | 100% | 100% | 100% | 100% | 88% | 46% | 19% | 5% | 3% | 3% | 2% | 1% |

| 24.61 | - | - | - | 100% | 100% | 99% | 98% | 80% | 28% | 10% | 3% | 2% | 1% | 1% | 1% |

| 24.85 | - | - | - | 100% | 81% | 81% | 80% | 75% | 46% | 18% | 6% | 4% | 4% | 3% | 2% |

| 25.16 | - | - | - | 81% | 73% | 73% | 73% | 70% | 42% | 18% | 7% | 4% | 4% | 3% | 2% |

| 25.45 | - | - | - | 100% | 100% | 100% | 100% | 91% | 50% | 20% | 6% | 4% | 3% | 3% | 1% |

| 25.70 | - | - | - | 100% | 100% | 100% | 98% | 90% | 45% | 18% | 5% | 3% | 2% | 2% | 1% |

| 26.00 | - | - | - | 100% | 94% | 94% | 94% | 85% | 54% | 22% | 6% | 3% | 3% | 2% | 2% |

| 26.22 | - | - | - | 100% | 90% | 90% | 90% | 80% | 42% | 15% | 4% | 3% | 2% | 2% | 1% |

| 26.49 | - | - | - | 100% | 93% | 85% | 81% | 70% | 38% | 14% | 3% | 2% | 1% | 1% | 0% |

| 26.80 | - | - | - | 100% | 100% | 100% | 94% | 88% | 47% | 17% | 3% | 2% | 2% | 1% | 1% |

| 27.11 | - | - | - | 100% | 89% | 87% | 87% | 78% | 50% | 22% | 5% | 2% | 1% | 1% | 1% |

| 27.24 | - | - | - | 100% | 100% | 100% | 97% | 88% | 55% | 21% | 4% | 2% | 2% | 2% | 1% |

| 27.31 | - | - | - | 100% | 100% | 100% | 100% | 99% | 62% | 23% | 4% | 2% | 2% | 2% | 1% |

| 27.74 | - | - | - | 100% | 100% | 100% | 100% | 95% | 59% | 23% | 5% | 3% | 2% | 2% | 2% |

| 28.20 | - | - | - | 100% | 100% | 100% | 100% | 90% | 50% | 19% | 4% | 3% | 2% | 2% | 2% |

| 29.25 | - | - | - | 100% | 100% | 100% | 100% | 79% | 43% | 15% | 4% | 3% | 3% | 2% | 2% |

| 29.53 | - | - | - | 100% | 100% | 95% | 95% | 76% | 45% | 15% | 4% | 2% | 2% | 2% | 1% |

| 29.82 | - | - | - | 100% | 89% | 85% | 76% | 60% | 28% | 10% | 3% | 2% | 2% | 1% | 1% |

| 30.09 | - | - | - | 100% | 100% | 95% | 95% | 77% | 31% | 10% | 2% | 1% | 1% | 1% | 0% |

| 30.09 | - | - | - | 100% | 100% | 100% | 96% | 86% | 48% | 17% | 4% | 2% | 2% | 2% | 1% |

| 30.82 | - | - | - | 100% | 80% | 72% | 72% | 70% | 38% | 13% | 3% | 2% | 2% | 1% | 1% |

| 30.82 | - | - | - | 82% | 57% | 42% | 42% | 29% | 12% | 6% | 2% | 2% | 2% | 1% | 1% |

| 31.16 | - | - | - | 100% | 100% | 93% | 93% | 78% | 35% | 14% | 4% | 2% | 2% | 1% | 1% |

| 31.46 | - | - | - | 65% | 65% | 58% | 52% | 38% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 31.46 | - | - | - | 72% | 72% | 66% | 61% | 49% | 19% | 5% | 1% | 1% | 1% | 1% | 0% |

| 31.82 | - | - | - | 100% | 95% | 95% | 93% | 70% | 34% | 12% | 2% | 1% | 1% | 1% | 0% |

| 31.95 | - | - | - | 86% | 86% | 86% | 81% | 62% | 32% | 13% | 4% | 3% | 2% | 2% | 2% |

| 32.07 | - | - | - | 100% | 100% | 96% | 96% | 83% | 30% | 8% | 1% | 1% | 1% | 0% | 0% |

| 32.54 | - | - | - | 100% | 100% | 96% | 96% | 82% | 42% | 17% | 6% | 4% | 3% | 3% | 3% |

| 32.54 | - | - | - | 100% | 100% | 96% | 96% | 82% | 42% | 17% | 5% | 4% | 3% | 3% | 3% |

| 32.97 | - | - | - | 100% | 94% | 94% | 94% | 80% | 36% | 11% | 2% | 2% | 1% | 1% | 1% |

| 33.04 | - | - | - | 100% | 100% | 100% | 99% | 82% | 35% | 12% | 3% | 2% | 2% | 1% | 1% |

| 33.40 | - | - | - | 87% | 78% | 76% | 76% | 64% | 40% | 16% | 5% | 3% | 3% | 3% | 2% |

| 33.54 | - | - | - | 86% | 86% | 84% | 81% | 64% | 27% | 8% | 3% | 2% | 2% | 2% | 1% |

| 33.70 | - | - | - | 100% | 100% | 98% | 94% | 70% | 31% | 9% | 2% | 2% | 1% | 1% | 1% |

| 33.86 | - | - | - | 87% | 82% | 80% | 80% | 65% | 32% | 11% | 2% | 1% | 1% | 1% | 0% |

| 33.95 | - | - | - | 100% | 100% | 100% | 100% | 86% | 41% | 15% | 4% | 3% | 2% | 2% | 2% |

| 34.01 | - | - | - | 100% | 100% | 94% | 92% | 74% | 33% | 13% | 4% | 2% | 2% | 2% | 1% |

| 34.35 | - | - | - | 100% | 100% | 96% | 93% | 77% | 32% | 12% | 4% | 3% | 2% | 2% | 2% |

| 34.57 | - | - | - | 100% | 96% | 96% | 91% | 70% | 38% | 14% | 4% | 2% | 2% | 2% | 1% |

| 34.72 | - | - | - | 100% | 100% | 93% | 93% | 79% | 42% | 17% | 5% | 4% | 3% | 3% | 1% |

| 34.74 | - | - | - | 100% | 100% | 100% | 97% | 79% | 28% | 9% | 3% | 2% | 2% | 1% | 1% |

| 34.79 | - | - | - | 100% | 100% | 97% | 94% | 79% | 29% | 8% | 2% | 2% | 1% | 1% | 1% |

| 34.87 | 100% | 100% | 100% | 83% | 83% | 82% | 70% | 47% | 22% | 6% | 4% | 3% | 3% | 2% | |

| 35.12 | 100% | 100% | 100% | 100% | 100% | 100% | 87% | 48% | 20% | 5% | 3% | 2% | 2% | 1% | |

| 35.34 | - | - | - | 100% | 96% | 96% | 96% | 81% | 42% | 20% | 6% | 3% | 2% | 1% | 1% |

| 35.63 | - | - | - | 100% | 100% | 97% | 97% | 84% | 37% | 13% | 2% | 1% | 1% | 0% | 0% |

| 36.20 | 100% | 100% | 100% | 100% | 100% | 100% | 88% | 45% | 18% | 5% | 4% | 3% | 3% | 3% | |

| 36.57 | 100% | 100% | 100% | 100% | 100% | 100% | 78% | 42% | 15% | 3% | 2% | 2% | 1% | 1% | |

| 36.84 | - | - | - | 100% | 96% | 96% | 96% | 85% | 38% | 13% | 3% | 2% | 1% | 1% | 1% |

| 36.84 | 100% | 100% | 100% | 97% | 97% | 97% | 83% | 41% | 15% | 5% | 3% | 3% | 3% | 2% | |

| 37.60 | - | - | - | 100% | 100% | 100% | 98% | 83% | 43% | 16% | 5% | 3% | 2% | 2% | 2% |

| 38.00 | 100% | 100% | 100% | 93% | 93% | 92% | 79% | 41% | 15% | 3% | 2% | 2% | 1% | 1% | |

| 38.73 | 100% | 100% | 100% | 95% | 95% | 94% | 77% | 37% | 14% | 5% | 3% | 3% | 3% | 2% | |

| 39.13 | - | - | - | 91% | 88% | 87% | 87% | 72% | 37% | 14% | 4% | 3% | 2% | 2% | 2% |

| 39.40 | 100% | 100% | 100% | 90% | 90% | 88% | 65% | 24% | 8% | 2% | 2% | 1% | 1% | 1% | |

| 39.60 | 100% | 100% | 100% | 100% | 100% | 98% | 82% | 38% | 16% | 4% | 2% | 2% | 2% | 1% | |

| 40.37 | 100% | 100% | 100% | 93% | 93% | 91% | 76% | 38% | 15% | 3% | 2% | 2% | 2% | 1% | |

| 40.63 | 100% | 100% | 100% | 84% | 82% | 80% | 71% | 39% | 17% | 4% | 3% | 2% | 2% | 1% | |

| 41.02 | 100% | 100% | 100% | 96% | 96% | 91% | 78% | 43% | 16% | 4% | 3% | 2% | 2% | 1% | |

| 41.41 | - | - | - | 81% | 81% | 81% | 81% | 72% | 42% | 19% | 5% | 3% | 3% | 2% | 2% |

| 41.87 | 100% | 77% | 77% | 72% | 72% | 70% | 62% | 38% | 18% | 3% | 2% | 1% | 1% | 1% | |

| 42.22 | - | - | - | 88% | 88% | 88% | 88% | 76% | 49% | 24% | 5% | 2% | 2% | 1% | 1% |

| 42.76 | 100% | 100% | 100% | 100% | 100% | 100% | 95% | 64% | 28% | 6% | 3% | 3% | 2% | 1% | |

| 43.61 | 100% | 100% | 84% | 63% | 63% | 63% | 53% | 37% | 20% | 4% | 2% | 2% | 1% | 1% | |

| 44.14 | 100% | 100% | 83% | 68% | 68% | 65% | 57% | 38% | 20% | 5% | 3% | 2% | 2% | 1% | |

| 44.94 | 100% | 100% | 100% | 100% | 100% | 97% | 88% | 50% | 24% | 5% | 2% | 2% | 1% | 1% | |

| 45.18 | 100% | 73% | 73% | 66% | 64% | 64% | 59% | 36% | 18% | 5% | 3% | 2% | 2% | 1% | |

| 45.38 | - | - | - | 89% | 89% | 89% | 87% | 80% | 47% | 20% | 5% | 3% | 3% | 3% | 2% |

| 45.38 | 100% | 100% | 92% | 87% | 84% | 79% | 61% | 27% | 13% | 3% | 2% | 1% | 1% | 0% | |

| 45.60 | 100% | 100% | 100% | 100% | 100% | 95% | 76% | 40% | 15% | 4% | 3% | 2% | 2% | 2% | |

| 45.67 | 100% | 100% | 100% | 100% | 100% | 100% | 88% | 50% | 20% | 4% | 2% | 1% | 1% | 1% | |

| 46.21 | - | - | - | 100% | 100% | 97% | 94% | 78% | 40% | 14% | 3% | 2% | 2% | 2% | 1% |

| 46.84 | - | - | - | 91% | 91% | 87% | 87% | 79% | 52% | 36% | 7% | 4% | 3% | 2% | 1% |

| 47.16 | - | - | - | 73% | 73% | 69% | 69% | 62% | 62% | 13% | 5% | 3% | 3% | 2% | 2% |

| 47.41 | - | - | - | 100% | 89% | 88% | 88% | 76% | 34% | 11% | 3% | 2% | 2% | 1% | 1% |

| 48.70 | - | - | - | 100% | 100% | 100% | 100% | 86% | 38% | 16% | 6% | 5% | 2% | 1% | 1% |

| 49.44 | 100% | 100% | 100% | 100% | 100% | 100% | 88% | 48% | 16% | 4% | 2% | 2% | 2% | 1% | |

| 50.71 | - | - | - | 100% | 100% | 100% | 70% | 57% | 51% | 25% | 7% | 4% | 4% | 3% | 1% |

| 51.11 | - | 90% | 90% | 80% | 79% | 75% | 72% | 55% | 25% | 10% | 3% | 1% | 1% | 1% | 0% |

| 51.35 | - | 100% | 100% | 89% | 89% | 88% | 88% | 71% | 35% | 15% | 4% | 2% | 1% | 1% | 1% |

| 51.46 | 100% | 100% | 100% | 94% | 94% | 92% | 82% | 51% | 22% | 7% | 5% | 4% | 4% | 3% | |

| 51.77 | - | 100% | 100% | 100% | 100% | 98% | 97% | 84% | 38% | 15% | 5% | 3% | 3% | 3% | 2% |

| 51.77 | 100% | 100% | 81% | 75% | 71% | 70% | 57% | 26% | 11% | 2% | 1% | 1% | 1% | 0% | |

| 52.25 | - | - | - | 100% | 98% | 93% | 91% | 74% | 28% | 9% | 2% | 1% | 1% | 1% | 1% |

| 52.50 | 100% | 100% | 100% | 100% | 100% | 100% | 89% | 49% | 21% | 5% | 3% | 2% | 1% | 1% | |

| 52.73 | - | - | - | 87% | 80% | 80% | 79% | 65% | 25% | 8% | 2% | 2% | 1% | 1% | 1% |

| 52.73 | - | - | - | 100% | 94% | 94% | 94% | 79% | 32% | 10% | 3% | 2% | 2% | 2% | 1% |

| 53.11 | 100% | 100% | 100% | 79% | 79% | 78% | 66% | 36% | 15% | 4% | 2% | 2% | 1% | 1% | |

| 53.39 | - | - | - | 89% | 86% | 84% | 84% | 77% | 41% | 16% | 5% | 3% | 3% | 3% | 1% |

| 53.61 | - | - | - | 100% | 100% | 98% | 96% | 79% | 34% | 13% | 5% | 3% | 3% | 3% | 2% |

| 53.70 | 100% | 100% | 100% | 100% | 100% | 100% | 91% | 47% | 19% | 6% | 3% | 3% | 2% | 1% | |

| 53.79 | - | - | - | 76% | 69% | 69% | 67% | 54% | 23% | 8% | 3% | 2% | 2% | 2% | 1% |

| 53.93 | - | - | - | 100% | 100% | 98% | 97% | 84% | 41% | 17% | 5% | 3% | 2% | 2% | 1% |

| 54.19 | - | - | - | 100% | 90% | 90% | 86% | 74% | 27% | 10% | 4% | 3% | 3% | 3% | 2% |

| 54.21 | - | - | - | 100% | 100% | 100% | 93% | 81% | 33% | 13% | 4% | 3% | 2% | 2% | 2% |

| 54.34 | - | - | - | 100% | 100% | 100% | 98% | 84% | 31% | 11% | 3% | 2% | 1% | 1% | 1% |

| 54.44 | - | - | - | 100% | 91% | 91% | 91% | 78% | 29% | 10% | 3% | 1% | 1% | 1% | 1% |

| 54.73 | - | - | - | 100% | 100% | 100% | 95% | 84% | 39% | 9% | 2% | 1% | 1% | 1% | 1% |

| 55.03 | - | - | - | 100% | 100% | 96% | 96% | 83% | 34% | 11% | 3% | 2% | 2% | 2% | 1% |

| 55.28 | - | - | - | 100% | 100% | 100% | 95% | 67% | 17% | 6% | 3% | 2% | 2% | 2% | 2% |

| 55.60 | - | - | - | 100% | 73% | 73% | 73% | 58% | 18% | 5% | 1% | 1% | 1% | 1% | 1% |

| 56.51 | - | - | - | 100% | 100% | 99% | 97% | 82% | 32% | 10% | 2% | 2% | 1% | 1% | 1% |

| 56.51 | - | - | - | 100% | 87% | 81% | 81% | 63% | 26% | 11% | 3% | 2% | 2% | 2% | 1% |

| 58.08 | - | - | - | 100% | 100% | 100% | 100% | 82% | 32% | 11% | 2% | 1% | 1% | 1% | 1% |

| 59.29 | 100% | 100% | 100% | 100% | 100% | 100% | 85% | 41% | 16% | 5% | 3% | 2% | 2% | 1% | |

| 59.72 | 100% | 100% | 100% | 100% | 100% | 100% | 91% | 42% | 17% | 5% | 3% | 3% | 3% | 2% | |

| 60.09 | 100% | 100% | 100% | 100% | 100% | 100% | 81% | 18% | 5% | 1% | 1% | 1% | 1% | 0% | |

| 60.51 | 100% | 100% | 100% | 100% | 97% | 96% | 80% | 21% | 8% | 3% | 2% | 2% | 2% | 1% | |

| 60.56 | 100% | 100% | 100% | 96% | 92% | 92% | 74% | 24% | 9% | 2% | 1% | 1% | 1% | 1% | |

| 61.51 | 100% | 100% | 100% | 94% | 94% | 94% | 77% | 25% | 9% | 4% | 3% | 2% | 2% | 2% | |

| 61.99 | 100% | 100% | 88% | 85% | 84% | 84% | 64% | 19% | 8% | 3% | 2% | 1% | 1% | 1% | |

| 62.51 | 100% | 100% | 100% | 89% | 86% | 86% | 56% | 20% | 7% | 2% | 1% | 1% | 1% | 1% | |

| 63.01 | 100% | 100% | 100% | 97% | 97% | 96% | 78% | 28% | 12% | 4% | 3% | 2% | 2% | 1% | |

| 63.30 | 100% | 100% | 100% | 100% | 100% | 99% | 83% | 31% | 12% | 5% | 4% | 3% | 3% | 2% | |

| 63.39 | 100% | 100% | 100% | 100% | 100% | 97% | 74% | 18% | 6% | 2% | 2% | 1% | 1% | 1% | |

| 66.90 | 100% | 100% | 100% | 83% | 83% | 83% | 71% | 36% | 13% | 4% | 3% | 3% | 2% | 2% | |

| 67.43 | 100% | 100% | 100% | 90% | 90% | 87% | 76% | 42% | 18% | 5% | 3% | 3% | 2% | 1% | |

| 68.18 | 100% | 100% | 100% | 90% | 90% | 88% | 81% | 39% | 13% | 2% | 1% | 1% | 1% | 0% | |

| 69.20 | 100% | 100% | 100% | 95% | 95% | 95% | 84% | 49% | 21% | 6% | 4% | 4% | 4% | 3% | |

| 69.38 | 100% | 100% | 100% | 100% | 95% | 93% | 84% | 46% | 17% | 3% | 2% | 1% | 1% | 1% | |

| 70.82 | 100% | 100% | 84% | 84% | 84% | 82% | 75% | 41% | 16% | 5% | 4% | 3% | 3% | 2% | |

| 71.78 | 100% | 100% | 100% | 100% | 92% | 92% | 92% | 80% | 41% | 15% | 3% | 2% | 1% | 1% | 1% |

| 73.30 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 90% | 46% | 18% | 4% | 3% | 3% | 2% | 1% |

| 74.44 | - | - | - | 100% | 100% | 100% | 100% | 86% | 35% | 12% | 3% | 2% | 2% | 2% | 1% |

| 76.02 | - | - | - | 100% | 100% | 100% | 100% | 89% | 53% | 22% | 4% | 3% | 2% | 2% | 1% |

| 76.27 | 100% | 66% | 66% | 66% | 66% | 62% | 62% | 52% | 26% | 10% | 2% | 1% | 1% | 1% | 0% |

| 76.66 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 89% | 46% | 18% | 5% | 4% | 3% | 3% | 2% |

| 77.37 | 100% | 100% | 100% | 85% | 85% | 85% | 83% | 71% | 35% | 13% | 3% | 2% | 1% | 1% | 1% |

| 78.21 | 100% | 100% | 100% | 100% | 100% | 95% | 95% | 81% | 43% | 16% | 5% | 4% | 4% | 3% | 2% |

| 78.62 | - | - | - | 100% | 100% | 100% | 100% | 85% | 41% | 17% | 4% | 3% | 2% | 2% | 2% |

| 81.31 | 100% | 100% | 100% | 75% | 75% | 75% | 75% | 64% | 34% | 12% | 3% | 2% | 1% | 1% | 1% |

| Depth (m AH) | Cutting Size or Sieve Size (mm) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 76.2 | 50.8 | 44.45 | 38.100 | 25.400 | 22.225 | 19.050 | 11.125 | 4.750 | 2.000 | 0.850 | 0.420 | 0.250 | 0.149 | 0.075 | |

| Cumulative Percent Passing | |||||||||||||||

| 0.42 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 76% | 3% | 1% | 1% | 0% | 0% |

| 0.73 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 78% | 4% | 1% | 0% | 0% | 0% |

| 0.98 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 78% | 5% | 1% | 1% | 1% | 0% |

| 1.63 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 76% | 3% | 1% | 1% | 0% | 0% |

| 1.81 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 97% | 20% | 6% | 3% | 1% | 1% |

| 2.23 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 98% | 94% | 93% | 20% | 4% | 2% | 2% | 1% |

| 2.25 | 100% | 100% | 100% | 94% | 92% | 92% | 81% | 61% | 36% | 3% | 1% | 0% | 0% | 0% | |

| 2.38 | 100% | 100% | 100% | 100% | 91% | 87% | 66% | 31% | 11% | 2% | 1% | 1% | 0% | 0% | |

| 2.52 | 100% | 100% | 100% | 100% | 97% | 96% | 68% | 30% | 12% | 5% | 3% | 2% | 2% | 1% | |

| 2.65 | 100% | 100% | 100% | 89% | 86% | 73% | 51% | 18% | 6% | 2% | 1% | 0% | 0% | 0% | |

| 2.85 | 100% | 100% | 100% | 92% | 83% | 80% | 45% | 15% | 5% | 2% | 2% | 1% | 1% | 1% | |

| 3.06 | 100% | 100% | 100% | 91% | 80% | 77% | 50% | 15% | 5% | 1% | 0% | 0% | 0% | 0% | |

| 3.23 | 100% | 79% | 79% | 79% | 79% | 76% | 57% | 28% | 8% | 1% | 1% | 1% | 1% | 0% | |

| 3.23 | 100% | 100% | 77% | 70% | 66% | 63% | 54% | 32% | 13% | 4% | 2% | 1% | 1% | 0% | |

| 3.82 | 100% | 100% | 100% | 100% | 100% | 100% | 96% | 69% | 31% | 5% | 1% | 1% | 1% | 0% | |

| 4.13 | 100% | 100% | 100% | 100% | 100% | 97% | 90% | 62% | 28% | 6% | 2% | 1% | 1% | 1% | |

| 4.43 | 100% | 100% | 100% | 100% | 100% | 100% | 91% | 67% | 36% | 10% | 4% | 2% | 2% | 1% | |

| 4.68 | 100% | 100% | 100% | 100% | 99% | 99% | 92% | 61% | 28% | 6% | 2% | 1% | 1% | 0% | |

| 5.12 | 100% | 100% | 100% | 100% | 100% | 100% | 93% | 60% | 30% | 5% | 1% | 1% | 0% | 0% | |

| 5.39 | 100% | 100% | 100% | 100% | 98% | 98% | 92% | 62% | 30% | 6% | 3% | 2% | 1% | 1% | |

| 5.46 | 100% | 100% | 100% | 100% | 100% | 100% | 80% | 25% | 8% | 2% | 1% | 1% | 1% | 1% | |

| 6.04 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 96% | 60% | 26% | 5% | 2% | 1% | 1% | 1% |

| 6.4 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 96% | 60% | 27% | 5% | 2% | 1% | 1% | 0% |

| 6.4 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 97% | 78% | 40% | 8% | 3% | 2% | 2% | 1% |

| 6.8 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 96% | 65% | 30% | 6% | 2% | 1% | 1% | 0% |

| 6.81 | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 76% | 39% | 7% | 3% | 2% | 1% | 1% | |

| 7.09 | 100% | 100% | 100% | 100% | 100% | 100% | 95% | 70% | 34% | 7% | 2% | 1% | 1% | 0% | |

| 7.69 | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 75% | 35% | 6% | 3% | 2% | 1% | 1% | |

| 7.98 | 100% | 100% | 100% | 100% | 100% | 100% | 98% | 62% | 20% | 1% | 0% | 0% | 0% | 0% | |

| 8.01 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 90% | 49% | 5% | 2% | 1% | 1% | 1% | |

| 8.22 | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 81% | 36% | 3% | 1% | 1% | 0% | 0% | |

| 8.51 | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 88% | 56% | 11% | 4% | 2% | 2% | 1% | |

| 8.88 | 100% | 100% | 100% | 100% | 100% | 100% | 98% | 66% | 27% | 6% | 2% | 1% | 1% | 0% | |

| 9.17 | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 82% | 44% | 7% | 3% | 2% | 1% | 0% | |

| 9.9 | 100% | 100% | 100% | 100% | 100% | 100% | 97% | 71% | 32% | 3% | 1% | 1% | 1% | 0% | |

| 10.2 | 100% | 100% | 100% | 100% | 100% | 100% | 97% | 70% | 33% | 5% | 2% | 1% | 1% | 1% | |

| 10.61 | 100% | 100% | 100% | 100% | 100% | 100% | 97% | 75% | 35% | 5% | 2% | 1% | 1% | 0% | |

| 10.97 | 100% | 100% | 100% | 100% | 100% | 99% | 94% | 72% | 36% | 7% | 3% | 2% | 2% | 1% | |

| 11.79 | 100% | 100% | 100% | 100% | 100% | 100% | 93% | 57% | 23% | 4% | 1% | 0% | 0% | 0% | |

| 12.14 | 100% | 100% | 100% | 100% | 96% | 96% | 91% | 57% | 21% | 3% | 1% | 0% | 0% | 0% | |

| 12.46 | 100% | 100% | 100% | 100% | 100% | 98% | 96% | 62% | 24% | 2% | 1% | 1% | 0% | 0% | |

| 12.66 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 98% | 72% | 30% | 2% | 1% | 0% | 0% | 0% |

| 12.91 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 96% | 72% | 38% | 9% | 3% | 1% | 1% | 0% |

| 13.38 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 65% | 29% | 6% | 2% | 1% | 1% | 1% |

| 13.66 | 100% | 100% | 100% | 100% | 94% | 94% | 90% | 75% | 60% | 29% | 5% | 1% | 1% | 1% | 0% |

| 13.88 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 93% | 63% | 35% | 4% | 1% | 0% | 0% | 0% |

| 14.24 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 95% | 60% | 25% | 1% | 0% | 0% | 0% | 0% |

| 15.18 | 100% | 100% | 100% | 100% | 90% | 90% | 90% | 84% | 57% | 22% | 2% | 0% | 0% | 0% | 0% |

| 15.18 | 100% | 100% | 100% | 100% | 89% | 89% | 89% | 88% | 67% | 35% | 6% | 1% | 0% | 0% | 0% |

| 15.45 | 100% | 100% | 100% | 100% | 100% | 98% | 98% | 95% | 67% | 30% | 4% | 1% | 1% | 0% | 0% |

| 15.71 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 97% | 75% | 39% | 6% | 0% | 0% | 0% | 0% |

| 16.08 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 72% | 26% | 1% | 0% | 0% | 0% | 0% |

| 16.32 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 95% | 73% | 28% | 3% | 1% | 0% | 0% | 0% |

| 16.32 | 100% | 100% | 100% | 100% | 100% | 100% | 98% | 91% | 54% | 21% | 1% | 1% | 0% | 0% | 0% |

| 16.59 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 93% | 69% | 30% | 4% | 1% | 0% | 0% | 0% |

| 16.59 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 91% | 49% | 7% | 2% | 1% | 0% | 0% |

| 16.69 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 93% | 47% | 6% | 2% | 1% | 1% | 0% |

| 16.83 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 98% | 87% | 41% | 4% | 1% | 1% | 0% | 0% |

| 17.15 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 84% | 36% | 3% | 1% | 1% | 1% | 0% |

| 17.45 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 92% | 51% | 4% | 1% | 1% | 0% | 0% |

| 17.82 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 98% | 83% | 40% | 5% | 1% | 1% | 0% | 0% |

| Depth (m Along Hole) | Cutting Size or Sieve Size (mm) | ||||||

|---|---|---|---|---|---|---|---|

| 4.750 | 2.000 | 0.850 | 0.420 | 0.250 | 0.149 | 0.075 | |

| Cumulative Percent Passing | |||||||

| 1.95 | 100% | 93% | 40% | 3% | 1% | 0% | 0% |

| 2.18 | 100% | 93% | 31% | 1% | 0% | 0% | 0% |

| 2.24 | 100% | 89% | 27% | 2% | 0% | 0% | 0% |

| 2.32 | 100% | 78% | 21% | 1% | 0% | 0% | 0% |

| 2.37 | 97% | 54% | 9% | 2% | 1% | 1% | 1% |

| 2.44 | 100% | 79% | 18% | 3% | 1% | 1% | 0% |

| 2.61 | 98% | 43% | 6% | 1% | 0% | 0% | 0% |

| 2.9 | 100% | 88% | 22% | 1% | 0% | 0% | 0% |

| 3.34 | 100% | 95% | 31% | 1% | 0% | 0% | 0% |

| 3.49 | 100% | 90% | 13% | 1% | 0% | 0% | 0% |

| 3.8 | 100% | 100% | 54% | 1% | 1% | 1% | 1% |

| 5.66 | 100% | 99% | 42% | 4% | 2% | 2% | 1% |

| 5.74 | 100% | 100% | 52% | 2% | 1% | 1% | 0% |

| 5.87 | 100% | 99% | 36% | 1% | 1% | 0% | 0% |

| 6.11 | 100% | 99% | 43% | 3% | 1% | 1% | 0% |

| 6.5 | 100% | 100% | 79% | 8% | 2% | 1% | 1% |

| 6.6 | 100% | 100% | 79% | 6% | 3% | 2% | 1% |

| 6.7 | 100% | 100% | 76% | 4% | 2% | 1% | 1% |

| 6.8 | 100% | 100% | 61% | 1% | 1% | 0% | 0% |

| 6.88 | 100% | 99% | 50% | 3% | 1% | 1% | 1% |

| 7.11 | 100% | 100% | 78% | 5% | 1% | 1% | 1% |

| 7.27 | 100% | 100% | 67% | 15% | 2% | 2% | 1% |

| Cumulative Percent Passing Sieves of Size (mm) (Settling Pit) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 76.2 | 50.8 | 44.45 | 38.1 | 25.4 | 22.225 | 19.05 | 11.1252 | 4.75 | 2 | 0.85 | 0.42 | 0.25 | 0.149 | 0.075 | |

| 3 December 2021_LD2 | 100% | 98% | 97% | 94% | 83% | 80% | 78% | 68% | 32% | 7% | 2% | 1% | 1% | 1% | 0% |

| 28 November 2021 (LD #2) | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 97% | 78% | 51% | 28% | 14% | 9% | 4% | 1% |

| 1 November 2021 (LD #1) | 100% | 100% | 98% | 98% | 97% | 97% | 96% | 86% | 57% | 38% | 24% | 15% | 11% | 7% | 3% |

| 11 October 2021 (LD#1) | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 96% | 74% | 48% | 26% | 13% | 8% | 5% | 2% |

| 4 November 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 89% | 55% | 30% | 15% | 9% | 6% | 5% | 2% |

| 3 November 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 99% | 98% | 92% | 65% | 42% | 23% | 12% | 7% | 4% | 1% |

| 2 November 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 100% | 99% | 94% | 66% | 40% | 22% | 14% | 11% | 7% | 3% |

| 21 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 99% | 97% | 90% | 64% | 42% | 27% | 16% | 10% | 6% | 3% |

| 30 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 99% | 99% | 89% | 44% | 22% | 11% | 6% | 5% | 4% | 2% |

| 29 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 99% | 98% | 85% | 48% | 23% | 10% | 5% | 4% | 3% | 2% |

| 27 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 100% | 97% | 85% | 53% | 29% | 15% | 9% | 7% | 6% | 3% |

| 26 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 99% | 99% | 95% | 85% | 58% | 39% | 25% | 14% | 10% | 6% | 3% |

| 14 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 99% | 98% | 97% | 90% | 62% | 39% | 23% | 13% | 8% | 5% | 2% |

| 12 October 2021 (LD #1) | 100% | 100% | 97% | 97% | 96% | 96% | 95% | 88% | 61% | 35% | 17% | 8% | 5% | 4% | 2% |

| 13 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 97% | 95% | 94% | 86% | 69% | 57% | 45% | 33% | 25% | 17% | 10% |

| 20 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 92% | 92% | 88% | 79% | 52% | 27% | 12% | 6% | 4% | 3% | 2% |

| Sample Source | Mass Percent Finer (%) | Maximum Particle Diameter in Suspension, (mm) |

|---|---|---|

| Tank 1 | 75 | 0.132 |

| 68 | 0.096 | |

| 60 | 0.070 | |

| 56 | 0.050 | |

| 50 | 0.037 | |

| 42 | 0.027 | |

| 34 | 0.020 | |

| 22 | 0.010 | |

| 10 | 0.004 | |

| Tank 2 | 62 | 0.140 |

| 57 | 0.101 | |

| 52 | 0.073 | |

| 47 | 0.052 | |

| 41 | 0.039 | |

| 36 | 0.027 | |

| 30 | 0.020 | |

| 19 | 0.010 | |

| 10 | 0.004 | |

| Tank 3 | 75 | 0.146 |

| 67 | 0.105 | |

| 63 | 0.075 | |

| 51 | 0.054 | |

| 44 | 0.040 | |

| 38 | 0.029 | |

| 32 | 0.020 | |

| 20 | 0.010 | |

| 12 | 0.004 | |

| Tank 4 | 63 | 0.145 |

| 60 | 0.103 | |

| 57 | 0.074 | |

| 50 | 0.053 | |

| 44 | 0.039 | |

| 38 | 0.028 | |

| 32 | 0.020 | |

| 22 | 0.010 | |

| 9 | 0.004 | |

| Geotube | 54 | 0.145 |

| 49 | 0.104 | |

| 46 | 0.074 | |

| 38 | 0.054 | |

| 33 | 0.040 | |

| 28 | 0.028 | |

| 22 | 0.020 | |

| 14 | 0.010 | |

| 8 | 0.004 |

| Cumulative Percent Passing Sieves of Size (mm) (Effluent Line) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 76.2 | 50.8 | 44.45 | 38.1 | 25.4 | 22.225 | 19.05 | 11.1252 | 4.75 | 2 | 0.85 | 0.42 | 0.25 | 0.149 | 0.075 | |

| 3 December 2021 (LD #2) | No Collected Sample | ||||||||||||||

| 28 November 2021 (LD #2) | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 97% | 72% | 34% | 5% | 2% | 1% | 1% | 0% |

| 1 November 2021 (LD #1) | 100% | 100% | 100% | 100% | 96% | 95% | 93% | 77% | 30% | 10% | 3% | 2% | 1% | 1% | 1% |

| 11 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 99% | 99% | 90% | 54% | 23% | 5% | 3% | 2% | 2% | 1% |

| 4 November 2021 (LD #1) | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 87% | 48% | 20% | 4% | 3% | 2% | 2% | 1% |

| 3 November 2021 (LD #1) | 100% | 100% | 100% | 96% | 93% | 92% | 91% | 81% | 41% | 15% | 4% | 2% | 2% | 2% | 1% |

| 2 November 2021 (LD #1) | 100% | 100% | 100% | 99% | 94% | 94% | 93% | 76% | 28% | 11% | 4% | 2% | 2% | 2% | 1% |

| 21 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 99% | 96% | 93% | 76% | 34% | 12% | 4% | 2% | 2% | 2% | 1% |

| 30 October 2021 (LD #1) | 100% | 99% | 99% | 93% | 89% | 88% | 85% | 72% | 35% | 14% | 4% | 3% | 2% | 2% | 1% |

| 29 October 2021 (LD #1) | 100% | 100% | 100% | 95% | 93% | 92% | 91% | 79% | 45% | 19% | 5% | 3% | 2% | 2% | 1% |

| 27 October 2021 (LD #1) | 100% | 100% | 95% | 89% | 82% | 81% | 79% | 69% | 41% | 19% | 4% | 2% | 2% | 2% | 1% |

| 26 October 2021 (LD #1) | 100% | 100% | 100% | 99% | 95% | 95% | 94% | 79% | 39% | 15% | 4% | 3% | 2% | 2% | 1% |

| 14 October 2021 (LD #1) | 100% | 100% | 100% | 99% | 94% | 93% | 92% | 84% | 47% | 18% | 5% | 3% | 2% | 2% | 1% |

| 12 October 2021 (LD #1) | 100% | 100% | 100% | 100% | 96% | 95% | 93% | 79% | 42% | 17% | 4% | 2% | 2% | 2% | 1% |

| 13 October 2021 (LD #1) | 100% | 100% | 100% | 99% | 95% | 94% | 93% | 78% | 38% | 16% | 5% | 3% | 3% | 2% | 2% |

| 20 October 2021 (LD #1) | 100% | 100% | 100% | 93% | 90% | 87% | 86% | 71% | 34% | 12% | 3% | 2% | 2% | 2% | 1% |

| Circulation | Depth (m Along Hole) | Percentiles of Cutting Size | Coarseness Index | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| D10 (mm) | D30 (mm) | D50 (mm) | D60 (mm) | D80 (mm) | D90 (mm) | Cu | Cc | |||

| DF | 0.98 | 0.9 | 1.2 | 1.6 | 1.7 | 2.2 | 3.5 | 1.84 | 0.97 | 513 |

| DF | 1.08 | 1.0 | 1.2 | 1.5 | 1.7 | 2.0 | 3.3 | 1.77 | 0.97 | 513 |

| DF | 3.16 | 1.3 | 2.6 | 4.2 | 5.3 | 8.9 | 10.7 | 4.25 | 1.00 | 622 |

| RC | 4.02 | 5.4 | 7.3 | 9.3 | 10.2 | 14.5 | 17.6 | 1.91 | 0.97 | 731 |

| RC | 4.14 | 2.8 | 6.5 | 9.3 | 10.6 | 15.6 | 18.4 | 3.74 | 1.40 | 723 |

| RC | 4.45 | 5.1 | 7.3 | 9.6 | 10.7 | 15.4 | 18.0 | 2.11 | 0.99 | 731 |

| RC | 4.56 | 5.3 | 7.8 | 10.3 | 11.8 | 15.9 | 17.9 | 2.24 | 0.97 | 740 |

| RC | 5.26 | 1.2 | 5.4 | 8.1 | 9.5 | 13.7 | 16.9 | 7.98 | 2.53 | 675 |

| RC | 6.08 | 1.3 | 2.4 | 4.0 | 4.7 | 8.4 | 10.2 | 3.76 | 1.00 | 617 |

| RC | 6.16 | 1.1 | 2.2 | 3.7 | 4.5 | 8.0 | 10.0 | 3.92 | 0.98 | 607 |

| RC | 6.23 | 1.2 | 2.4 | 4.2 | 5.3 | 8.5 | 10.2 | 4.55 | 0.93 | 611 |

| RC | 6.31 | 1.3 | 2.9 | 5.2 | 6.5 | 9.1 | 10.5 | 5.18 | 1.04 | 628 |

| RC | 6.65 | 1.2 | 2.6 | 4.3 | 5.6 | 8.8 | 10.4 | 4.48 | 0.95 | 624 |

| RC | 6.70 | 1.1 | 2.5 | 4.4 | 5.7 | 8.7 | 10.2 | 4.98 | 0.98 | 617 |

| RC | 7.50 | 1.3 | 2.7 | 4.4 | 5.8 | 9.8 | 14.9 | 4.49 | 0.93 | 644 |

| RC | 7.65 | 1.1 | 2.4 | 4.0 | 4.9 | 8.6 | 10.5 | 4.36 | 1.01 | 608 |

| RC | 7.80 | 1.4 | 2.9 | 4.7 | 6.3 | 9.7 | 13.0 | 4.65 | 0.99 | 648 |

| RC | 8.20 | 1.1 | 2.3 | 3.9 | 4.8 | 9.0 | 11.3 | 4.41 | 1.02 | 614 |

| RC | 8.40 | 1.2 | 2.5 | 4.3 | 5.5 | 8.7 | 10.4 | 4.63 | 0.93 | 617 |

| RC | 8.56 | 1.2 | 2.7 | 4.5 | 5.9 | 9.3 | 10.9 | 5.03 | 1.06 | 629 |

| RC | 8.86 | 1.2 | 2.6 | 4.4 | 5.9 | 9.5 | 12.6 | 5.04 | 0.99 | 632 |

| RC | 11.74 | 1.0 | 2.1 | 3.8 | 4.7 | 8.6 | 10.6 | 4.76 | 0.91 | 600 |

| RC | 12.10 | 1.1 | 2.3 | 3.9 | 4.7 | 8.7 | 10.7 | 4.35 | 1.00 | 608 |

| RC | 12.47 | 1.1 | 2.8 | 4.7 | 6.2 | 9.4 | 11.0 | 5.45 | 1.12 | 617 |

| RC | 12.83 | 1.3 | 3.0 | 4.8 | 6.5 | 9.9 | 13.0 | 5.06 | 1.05 | 633 |

| RC | 13.17 | 1.3 | 3.1 | 5.0 | 6.6 | 10.0 | 13.3 | 5.10 | 1.10 | 634 |

| RC | 13.53 | 1.9 | 4.1 | 6.4 | 8.1 | 10.9 | 14.7 | 4.37 | 1.14 | 666 |

| RC | 13.70 | 1.1 | 2.9 | 5.3 | 7.3 | 12.0 | 18.3 | 6.67 | 1.07 | 654 |

| RC | 14.02 | 1.2 | 3.0 | 5.4 | 7.2 | 10.8 | 16.2 | 5.89 | 1.01 | 656 |

| RC | 14.24 | 1.3 | 3.0 | 5.3 | 6.8 | 9.8 | 12.2 | 5.30 | 1.05 | 633 |

| RC | 14.75 | 1.1 | 2.2 | 4.1 | 5.2 | 8.8 | 10.6 | 4.94 | 0.91 | 612 |

| RC | 15.08 | 1.6 | 4.1 | 6.6 | 7.9 | 10.3 | 13.1 | 4.90 | 1.35 | 658 |

| RC | 15.47 | 1.5 | 3.2 | 5.4 | 9.5 | 14.9 | 17.3 | 6.36 | 0.72 | 666 |

| RC | 15.93 | 1.3 | 3.1 | 5.4 | 7.0 | 10.3 | 13.6 | 5.48 | 1.04 | 638 |

| RC | 16.42 | 1.2 | 2.6 | 4.6 | 6.3 | 9.7 | 12.3 | 5.44 | 0.91 | 626 |

| RC | 16.80 | 1.2 | 2.9 | 5.2 | 6.9 | 10.3 | 14.5 | 5.67 | 1.00 | 636 |

| RC | 17.00 | 1.3 | 2.9 | 5.1 | 6.7 | 9.9 | 12.5 | 5.31 | 0.98 | 635 |

| RC | 17.59 | 1.3 | 3.1 | 5.5 | 7.2 | 10.7 | 16.4 | 5.62 | 1.07 | 651 |

| RC | 17.59 | 1.3 | 3.1 | 5.5 | 7.2 | 10.7 | 16.4 | 5.62 | 1.07 | 651 |

| RC | 18.15 | 1.5 | 3.8 | 6.6 | 8.1 | 11.1 | 16.8 | 5.30 | 1.18 | 676 |

| RC | 18.46 | 1.8 | 6.0 | 10.8 | 17.3 | 29.2 | 33.7 | 9.86 | 1.19 | 799 |

| RC | 19.01 | 2.2 | 5.2 | 9.3 | 11.8 | 25.9 | 32.0 | 5.39 | 1.04 | 772 |

| RC | 19.37 | 2.1 | 5.0 | 8.0 | 9.5 | 13.9 | 16.9 | 4.49 | 1.23 | 684 |

| RC | 19.68 | 2.3 | 4.8 | 8.1 | 9.8 | 15.9 | 27.9 | 4.32 | 1.05 | 729 |

| RC | 20.12 | 2.0 | 4.5 | 7.3 | 8.8 | 13.9 | 20.2 | 4.33 | 1.15 | 689 |

| RC | 20.16 | 1.8 | 4.5 | 7.7 | 9.3 | 15.5 | 24.3 | 5.24 | 1.22 | 709 |

| RC | 20.54 | 1.2 | 2.3 | 3.8 | 4.5 | 8.0 | 9.9 | 3.89 | 0.99 | 606 |

| RC | 20.79 | 1.4 | 4.2 | 8.4 | 10.7 | 21.4 | 40.0 | 7.44 | 1.16 | 747 |

| RC | 21.13 | 1.6 | 4.3 | 7.4 | 9.1 | 23.2 | 28.4 | 5.53 | 1.22 | 727 |

| RC | 21.13 | 1.4 | 3.7 | 6.1 | 7.4 | 10.0 | 12.3 | 5.19 | 1.27 | 644 |

| RC | 21.46 | 1.2 | 3.3 | 6.0 | 7.7 | 11.1 | 16.4 | 6.42 | 1.18 | 648 |

| RC | 21.81 | 1.4 | 3.8 | 6.5 | 7.9 | 10.7 | 14.3 | 5.79 | 1.33 | 648 |

| RC | 21.90 | 1.7 | 4.4 | 7.1 | 8.5 | 11.4 | 15.2 | 4.89 | 1.30 | 668 |

| RC | 22.18 | 1.4 | 3.7 | 6.5 | 8.2 | 12.4 | 17.4 | 5.70 | 1.15 | 660 |

| RC | 22.50 | 1.5 | 3.9 | 6.7 | 8.1 | 11.0 | 14.9 | 5.28 | 1.25 | 655 |

| RC | 22.72 | 1.2 | 3.3 | 6.2 | 8.3 | 16.4 | 30.4 | 6.71 | 1.08 | 695 |

| RC | 23.07 | 1.5 | 3.7 | 6.1 | 7.3 | 9.7 | 11.0 | 5.00 | 1.29 | 642 |

| RC | 23.36 | 2.3 | 6.1 | 9.3 | 10.9 | 17.6 | 26.1 | 4.67 | 1.47 | 747 |

| RC | 23.62 | 1.6 | 4.2 | 7.1 | 8.5 | 11.9 | 15.6 | 5.35 | 1.32 | 661 |

| RC | 23.88 | 1.5 | 3.8 | 6.5 | 7.8 | 10.6 | 14.1 | 5.34 | 1.28 | 652 |

| RC | 24.21 | 1.0 | 2.2 | 4.1 | 5.4 | 9.5 | 13.0 | 5.42 | 0.91 | 610 |

| RC | 24.61 | 1.2 | 3.1 | 5.3 | 6.8 | 9.9 | 12.3 | 5.48 | 1.13 | 632 |

| RC | 24.61 | 2.0 | 5.0 | 7.4 | 8.6 | 11.1 | 15.6 | 4.38 | 1.45 | 677 |

| RC | 24.85 | 1.2 | 3.2 | 5.6 | 7.8 | 18.7 | 31.3 | 6.31 | 1.05 | 699 |

| RC | 25.16 | 1.1 | 3.4 | 6.6 | 8.8 | 37.0 | 7.88 | 1.13 | 749 | |

| RC | 25.45 | 1.2 | 2.9 | 4.8 | 6.3 | 9.4 | 10.9 | 5.29 | 1.15 | 622 |

| RC | 25.70 | 1.3 | 3.2 | 5.4 | 6.9 | 9.7 | 11.4 | 5.24 | 1.14 | 636 |

| RC | 26.00 | 1.2 | 2.7 | 4.4 | 6.0 | 10.1 | 15.5 | 5.15 | 1.04 | 641 |

| RC | 26.22 | 1.4 | 3.5 | 6.1 | 7.7 | 11.0 | 25.7 | 5.33 | 1.10 | 681 |

| RC | 26.49 | 1.6 | 3.8 | 7.1 | 9.1 | 18.6 | 24.1 | 5.76 | 1.01 | 712 |

| RC | 26.80 | 1.4 | 3.2 | 5.2 | 6.8 | 9.9 | 14.0 | 4.83 | 1.07 | 645 |

| RC | 27.11 | 1.2 | 2.8 | 4.8 | 7.0 | 13.0 | 26.2 | 5.83 | 0.92 | 678 |

| RC | 27.24 | 1.2 | 2.7 | 4.3 | 5.7 | 9.6 | 12.9 | 4.58 | 1.03 | 626 |

| RC | 27.31 | 1.2 | 2.5 | 3.9 | 4.6 | 7.9 | 9.6 | 3.78 | 1.11 | 606 |

| RC | 27.74 | 1.2 | 2.6 | 4.1 | 4.9 | 8.5 | 10.3 | 4.13 | 1.14 | 609 |

| RC | 28.20 | 1.3 | 3.0 | 4.7 | 6.3 | 9.5 | 11.1 | 4.90 | 1.08 | 628 |

| RC | 29.25 | 1.5 | 3.5 | 6.0 | 7.7 | 11.4 | 15.2 | 5.31 | 1.06 | 649 |

| RC | 29.53 | 1.5 | 3.4 | 5.8 | 7.9 | 12.8 | 17.0 | 5.27 | 0.97 | 664 |

| RC | 29.82 | 1.9 | 5.1 | 9.1 | 11.1 | 20.5 | 26.1 | 5.77 | 1.20 | 742 |

| RC | 30.09 | 2.0 | 4.7 | 7.4 | 8.7 | 12.3 | 16.9 | 4.39 | 1.25 | 668 |

| RC | 30.09 | 1.4 | 3.1 | 5.1 | 6.8 | 10.1 | 14.1 | 4.96 | 1.07 | 641 |

| RC | 30.82 | 1.6 | 3.8 | 7.1 | 9.2 | 25.2 | 31.6 | 5.60 | 0.99 | 745 |

| RC | 30.82 | 3.8 | 11.5 | 23.9 | 26.9 | 36.9 | 7.10 | 1.29 | 922 | |

| RC | 31.16 | 1.5 | 4.1 | 7.0 | 8.5 | 12.4 | 17.4 | 5.62 | 1.31 | 676 |

| RC | 31.46 | 6.4 | 9.8 | 18.0 | 23.1 | 3.61 | 0.65 | 921 | ||

| RC | 31.46 | 3.0 | 7.1 | 11.7 | 18.6 | 6.27 | 0.93 | 853 | ||

| RC | 31.82 | 1.7 | 4.3 | 7.6 | 9.4 | 14.7 | 18.1 | 5.42 | 1.12 | 695 |

| RC | 31.95 | 1.6 | 4.4 | 8.5 | 10.7 | 18.8 | 6.74 | 1.14 | 741 | |

| RC | 32.07 | 2.3 | 4.8 | 7.2 | 8.4 | 10.8 | 15.5 | 3.65 | 1.18 | 685 |

| RC | 32.54 | 1.3 | 3.4 | 6.0 | 7.6 | 10.8 | 15.6 | 5.91 | 1.19 | 648 |

| RC | 32.54 | 1.3 | 3.4 | 6.1 | 7.6 | 10.8 | 15.6 | 5.89 | 1.20 | 649 |

| RC | 32.97 | 1.9 | 4.1 | 6.8 | 8.2 | 11.1 | 16.6 | 4.45 | 1.12 | 682 |

| RC | 33.04 | 1.8 | 4.1 | 6.7 | 8.1 | 10.8 | 14.8 | 4.61 | 1.19 | 663 |

| RC | 33.40 | 1.4 | 3.6 | 7.4 | 10.0 | 28.0 | 7.37 | 0.95 | 745 | |

| RC | 33.54 | 2.3 | 5.3 | 8.8 | 10.5 | 18.5 | 4.67 | 1.18 | 755 | |

| RC | 33.70 | 2.1 | 4.6 | 7.9 | 9.5 | 14.5 | 17.9 | 4.59 | 1.07 | 690 |

| RC | 33.86 | 1.8 | 4.4 | 8.2 | 10.1 | 22.6 | 39.5 | 5.56 | 1.07 | 757 |

| RC | 33.95 | 1.5 | 3.6 | 6.0 | 7.4 | 10.2 | 13.2 | 4.87 | 1.15 | 645 |

| RC | 34.01 | 1.6 | 4.3 | 7.4 | 8.9 | 13.7 | 18.1 | 5.50 | 1.30 | 682 |

| RC | 34.35 | 1.7 | 4.5 | 7.3 | 8.8 | 12.8 | 17.7 | 5.11 | 1.34 | 678 |

| RC | 34.57 | 1.5 | 3.8 | 7.2 | 9.2 | 15.0 | 18.6 | 5.96 | 1.03 | 686 |

| RC | 34.72 | 1.3 | 3.4 | 6.1 | 7.8 | 11.5 | 17.5 | 6.03 | 1.15 | 659 |

| RC | 34.74 | 2.2 | 5.0 | 7.5 | 8.8 | 11.8 | 16.2 | 4.03 | 1.29 | 680 |

| RC | 34.79 | 2.3 | 4.9 | 7.4 | 8.7 | 11.8 | 16.8 | 3.83 | 1.20 | 685 |

| RC | 34.87 | 1.1 | 2.9 | 5.7 | 8.3 | 17.8 | 30.6 | 7.44 | 0.89 | 696 |

| RC | 35.12 | 1.2 | 3.0 | 5.1 | 6.8 | 10.0 | 12.9 | 5.58 | 1.08 | 632 |

| RC | 35.34 | 1.2 | 3.2 | 6.0 | 7.6 | 10.9 | 15.9 | 6.42 | 1.14 | 656 |

| RC | 35.63 | 1.7 | 3.9 | 6.5 | 7.9 | 10.6 | 14.8 | 4.62 | 1.16 | 668 |

| RC | 36.20 | 1.3 | 3.2 | 5.5 | 7.0 | 10.0 | 12.5 | 5.51 | 1.16 | 631 |

| RC | 36.57 | 1.5 | 3.5 | 6.1 | 7.9 | 11.7 | 15.4 | 5.29 | 1.04 | 655 |

| RC | 36.84 | 1.6 | 3.9 | 6.4 | 7.8 | 10.5 | 14.8 | 4.70 | 1.17 | 667 |

| RC | 36.84 | 1.5 | 3.6 | 6.1 | 7.6 | 10.7 | 15.3 | 5.26 | 1.16 | 656 |

| RC | 37.60 | 1.3 | 3.4 | 5.9 | 7.5 | 10.7 | 15.0 | 5.57 | 1.16 | 646 |

| RC | 38.00 | 1.5 | 3.6 | 6.2 | 7.9 | 11.8 | 17.7 | 5.34 | 1.07 | 678 |

| RC | 38.73 | 1.5 | 3.9 | 6.9 | 8.4 | 12.5 | 17.3 | 5.61 | 1.23 | 673 |

| RC | 39.13 | 1.5 | 3.9 | 7.1 | 8.9 | 15.5 | 32.5 | 5.89 | 1.11 | 710 |

| RC | 39.40 | 2.3 | 5.7 | 8.7 | 10.3 | 16.2 | 21.7 | 4.49 | 1.36 | 726 |

| RC | 39.60 | 1.4 | 3.7 | 6.5 | 7.9 | 10.9 | 15.3 | 5.55 | 1.23 | 656 |

| RC | 40.37 | 1.5 | 3.8 | 6.8 | 8.5 | 13.3 | 18.4 | 5.52 | 1.13 | 685 |

| RC | 40.63 | 1.4 | 3.6 | 6.9 | 8.9 | 19.4 | 30.2 | 6.47 | 1.06 | 715 |

| RC | 41.02 | 1.4 | 3.4 | 6.0 | 7.8 | 12.4 | 18.6 | 5.54 | 1.05 | 668 |

| RC | 41.41 | 1.3 | 3.3 | 6.4 | 8.6 | 18.1 | 6.75 | 1.01 | 729 | |

| RC | 41.87 | 1.4 | 3.6 | 7.8 | 10.5 | 45.3 | 48.1 | 7.68 | 0.91 | 805 |

| RC | 42.22 | 1.2 | 2.7 | 5.0 | 7.4 | 13.7 | 6.36 | 0.85 | 686 | |

| RC | 42.76 | 1.1 | 2.1 | 3.7 | 4.4 | 8.0 | 10.0 | 4.21 | 0.98 | 597 |

| RC | 43.61 | 1.3 | 3.6 | 9.8 | 16.5 | 35.7 | 40.5 | 13.03 | 0.63 | 806 |

| RC | 44.14 | 1.2 | 3.6 | 8.9 | 14.4 | 35.3 | 40.6 | 11.63 | 0.72 | 789 |

| RC | 44.94 | 1.2 | 2.6 | 4.7 | 6.4 | 9.8 | 13.0 | 5.51 | 0.90 | 630 |

| RC | 45.18 | 1.3 | 3.9 | 8.7 | 13.0 | 46.2 | 48.5 | 9.95 | 0.87 | 834 |

| RC | 45.38 | 1.2 | 3.0 | 5.3 | 7.2 | 11.6 | 5.96 | 1.02 | 684 | |

| RC | 45.38 | 1.7 | 5.3 | 9.1 | 11.0 | 19.9 | 34.0 | 6.50 | 1.49 | 751 |

| RC | 45.60 | 1.5 | 3.6 | 6.5 | 8.3 | 12.8 | 16.9 | 5.64 | 1.08 | 661 |

| RC | 45.67 | 1.3 | 2.9 | 4.7 | 6.4 | 9.8 | 12.5 | 5.03 | 1.02 | 633 |

| RC | 46.21 | 1.6 | 3.7 | 6.5 | 8.1 | 11.9 | 16.9 | 5.19 | 1.09 | 667 |

| RC | 46.84 | 1.0 | 1.8 | 4.4 | 6.6 | 11.7 | 24.5 | 6.76 | 0.48 | 659 |

| RC | 47.16 | 1.6 | 3.0 | 4.1 | 4.7 | 2.91 | 1.18 | 763 | ||

| RC | 47.41 | 1.8 | 4.2 | 7.1 | 8.7 | 13.9 | 26.3 | 4.79 | 1.13 | 705 |

| RC | 48.70 | 1.3 | 3.7 | 6.3 | 7.6 | 10.3 | 13.2 | 5.93 | 1.42 | 644 |

| RC | 49.44 | 1.4 | 3.2 | 5.1 | 6.7 | 9.9 | 12.7 | 4.67 | 1.06 | 638 |

| RC | 50.71 | 1.0 | 2.5 | 4.6 | 12.9 | 20.1 | 21.1 | 12.63 | 0.47 | 676 |

| RC | 51.11 | 2.1 | 5.9 | 10.0 | 13.3 | 35.0 | 44.4 | 6.47 | 1.26 | 797 |

| RC | 51.35 | 1.5 | 4.0 | 7.4 | 9.2 | 15.3 | 38.6 | 6.30 | 1.21 | 715 |

| RC | 51.46 | 1.1 | 2.8 | 4.6 | 6.6 | 10.8 | 17.8 | 5.99 | 1.05 | 643 |

| RC | 51.77 | 1.5 | 3.8 | 6.4 | 7.8 | 10.6 | 14.8 | 5.30 | 1.25 | 653 |

| RC | 51.77 | 1.8 | 5.5 | 9.6 | 12.8 | 36.0 | 41.1 | 6.99 | 1.28 | 803 |

| RC | 52.25 | 2.1 | 5.0 | 7.7 | 9.1 | 13.8 | 18.5 | 4.27 | 1.27 | 701 |

| RC | 52.50 | 1.2 | 2.8 | 4.9 | 6.5 | 9.7 | 12.1 | 5.40 | 1.03 | 629 |

| RC | 52.73 | 2.3 | 5.5 | 8.7 | 10.4 | 22.7 | 4.52 | 1.27 | 769 | |

| RC | 52.73 | 2.0 | 4.5 | 7.2 | 8.5 | 11.7 | 16.9 | 4.32 | 1.18 | 686 |

| RC | 53.11 | 1.5 | 4.0 | 7.7 | 9.9 | 26.1 | 32.1 | 6.56 | 1.06 | 738 |

| RC | 53.39 | 1.4 | 3.5 | 6.3 | 8.1 | 14.2 | 5.74 | 1.11 | 707 | |

| RC | 53.61 | 1.6 | 4.2 | 7.0 | 8.4 | 11.6 | 16.4 | 5.40 | 1.33 | 663 |

| RC | 53.70 | 1.2 | 3.1 | 5.2 | 6.6 | 9.5 | 9.8 | 5.31 | 1.17 | 628 |

| RC | 53.79 | 2.3 | 6.2 | 10.3 | 14.7 | 6.27 | 1.11 | 823 | ||

| RC | 53.93 | 1.3 | 3.5 | 6.1 | 7.6 | 10.5 | 14.8 | 5.65 | 1.20 | 650 |

| RC | 54.19 | 1.9 | 5.2 | 7.9 | 9.2 | 15.1 | 26.0 | 4.74 | 1.48 | 709 |

| RC | 54.21 | 1.6 | 4.3 | 7.0 | 8.4 | 11.0 | 17.1 | 5.14 | 1.38 | 668 |

| RC | 54.34 | 1.9 | 4.6 | 7.0 | 8.2 | 10.6 | 14.4 | 4.28 | 1.37 | 668 |

| RC | 54.44 | 2.1 | 4.9 | 7.5 | 8.8 | 12.2 | 18.2 | 4.23 | 1.34 | 703 |

| RC | 54.73 | 2.1 | 3.9 | 6.3 | 7.7 | 10.6 | 15.3 | 3.66 | 0.94 | 666 |

| RC | 55.03 | 1.8 | 4.3 | 6.8 | 8.1 | 10.8 | 15.3 | 4.53 | 1.24 | 668 |

| RC | 55.28 | 3.0 | 6.4 | 9.0 | 10.3 | 14.8 | 17.6 | 3.46 | 1.35 | 704 |

| RC | 55.60 | 3.1 | 6.7 | 9.9 | 12.1 | 28.6 | 33.3 | 3.94 | 1.21 | 795 |

| RC | 56.51 | 2.0 | 4.5 | 7.0 | 8.3 | 10.9 | 15.4 | 4.18 | 1.21 | 673 |

| RC | 56.51 | 1.9 | 5.5 | 8.9 | 10.6 | 18.7 | 28.1 | 5.52 | 1.47 | 742 |

| RC | 58.08 | 1.9 | 4.5 | 7.0 | 8.3 | 10.9 | 14.7 | 4.48 | 1.30 | 669 |

| RC | 59.29 | 1.4 | 3.5 | 6.0 | 7.5 | 10.4 | 13.9 | 5.40 | 1.19 | 646 |

| RC | 59.72 | 1.3 | 3.4 | 5.8 | 7.1 | 9.7 | 11.0 | 5.49 | 1.27 | 634 |

| RC | 60.09 | 3.1 | 6.0 | 8.0 | 9.0 | 11.0 | 14.8 | 2.88 | 1.28 | 692 |

| RC | 60.51 | 2.5 | 5.7 | 7.9 | 9.0 | 11.1 | 16.2 | 3.59 | 1.45 | 689 |

| RC | 60.56 | 2.2 | 5.5 | 8.0 | 9.3 | 13.7 | 18.2 | 4.20 | 1.45 | 706 |

| RC | 61.51 | 2.2 | 5.4 | 7.8 | 9.0 | 12.5 | 17.2 | 4.07 | 1.43 | 695 |

| RC | 61.99 | 2.5 | 6.3 | 9.1 | 10.6 | 17.6 | 39.3 | 4.14 | 1.47 | 761 |

| RC | 62.51 | 2.6 | 6.5 | 10.1 | 12.3 | 17.5 | 26.4 | 4.64 | 1.31 | 751 |

| RC | 63.01 | 1.7 | 5.1 | 7.6 | 8.9 | 12.1 | 16.4 | 5.27 | 1.72 | 680 |

| RC | 63.30 | 1.6 | 4.6 | 7.1 | 8.3 | 10.7 | 14.4 | 5.14 | 1.62 | 658 |

| RC | 63.39 | 2.9 | 6.1 | 8.4 | 9.5 | 13.1 | 16.6 | 3.24 | 1.35 | 698 |

| RC | 66.90 | 1.6 | 4.0 | 7.3 | 9.1 | 16.9 | 30.5 | 5.67 | 1.11 | 716 |

| RC | 67.43 | 1.3 | 3.4 | 6.3 | 8.2 | 14.3 | 22.2 | 6.20 | 1.06 | 684 |

| RC | 68.18 | 1.7 | 3.8 | 6.4 | 8.0 | 11.0 | 25.7 | 4.63 | 1.06 | 695 |

| RC | 69.20 | 1.2 | 2.9 | 4.9 | 6.7 | 10.5 | 15.4 | 5.76 | 1.07 | 640 |

| RC | 69.38 | 1.4 | 3.2 | 5.4 | 7.0 | 10.4 | 16.3 | 4.98 | 1.03 | 656 |

| RC | 70.82 | 1.4 | 3.6 | 6.5 | 8.4 | 17.0 | 40.4 | 6.14 | 1.11 | 716 |

| RC | 71.78 | 1.5 | 3.5 | 6.2 | 7.9 | 11.4 | 18.0 | 5.24 | 1.07 | 681 |

| RC | 73.30 | 1.3 | 3.2 | 5.3 | 6.8 | 9.7 | 11.5 | 5.13 | 1.12 | 632 |

| RC | 74.44 | 1.7 | 4.1 | 6.6 | 7.9 | 10.4 | 13.5 | 4.59 | 1.26 | 657 |

| RC | 76.02 | 1.2 | 2.7 | 4.5 | 6.0 | 9.6 | 12.1 | 4.86 | 1.00 | 624 |

| RC | 76.27 | 2.1 | 5.7 | 10.7 | 17.4 | 61.3 | 68.7 | 8.41 | 0.92 | 919 |

| RC | 76.66 | 1.3 | 3.2 | 5.3 | 6.8 | 9.8 | 11.7 | 5.28 | 1.15 | 629 |

| RC | 77.37 | 1.7 | 4.1 | 7.4 | 9.2 | 17.1 | 40.3 | 5.54 | 1.12 | 736 |

| RC | 78.21 | 1.3 | 3.4 | 6.0 | 7.6 | 10.9 | 16.0 | 5.72 | 1.16 | 651 |

| RC | 78.62 | 1.4 | 3.5 | 6.0 | 7.5 | 10.4 | 13.9 | 5.49 | 1.18 | 644 |

| RC | 81.31 | 4.1 | 4.3 | 8.2 | 10.3 | 39.4 | 41.9 | 2.51 | 0.43 | 784 |

| Circulation | Depth (m AH) | Percentiles of Cutting Size | Coarseness Index (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| D10 (mm) | D30 (mm) | D50 (mm) | D60 (mm) | D80 (mm) | D90 (mm) | Cu | Cc | |||

| DF | 0.42 | 0.963 | 1.746 | 1.746 | 1.746 | 2.460 | 3.669 | 1.81 | 1.81 | 520.00 |

| DF | 0.73 | 0.948 | 1.259 | 1.571 | 1.726 | 2.305 | 3.580 | 1.82 | 0.97 | 517.80 |

| DF | 0.98 | 0.939 | 1.253 | 1.567 | 1.724 | 2.315 | 3.606 | 1.84 | 0.97 | 513.10 |

| DF | 1.63 | 0.598 | 1.029 | 1.328 | 1.478 | 1.778 | 1.928 | 2.47 | 1.20 | 520.00 |

| DF | 1.81 | 0.549 | 0.995 | 1.294 | 1.444 | 1.744 | 1.894 | 2.63 | 1.25 | 473.80 |

| DF | 2.23 | 0.578 | 1.010 | 1.324 | 1.480 | 1.793 | 1.950 | 2.56 | 1.19 | 485.90 |

| RC | 2.25 | 1.101 | 1.803 | 3.541 | 4.613 | 10.946 | 17.738 | 4.19 | 0.64 | 640.60 |

| RC | 2.38 | 1.869 | 4.617 | 8.247 | 10.084 | 16.554 | 21.563 | 5.40 | 1.13 | 709.80 |

| RC | 2.52 | 1.639 | 4.677 | 8.039 | 9.723 | 14.491 | 17.373 | 5.93 | 1.37 | 683.00 |

| RC | 2.65 | 2.874 | 7.086 | 10.966 | 14.361 | 20.733 | 26.699 | 5.00 | 1.22 | 773.90 |

| RC | 2.85 | 3.353 | 7.930 | 12.193 | 14.457 | 18.986 | 24.723 | 4.31 | 1.30 | 772.00 |

| RC | 3.06 | 3.381 | 7.402 | 11.046 | 13.951 | 22.283 | 25.084 | 4.13 | 1.16 | 779.90 |

| RC | 3.23 | 2.258 | 5.258 | 9.637 | 12.478 | 44.793 | 47.796 | 5.53 | 0.98 | 817.80 |

| RC | 3.23 | 1.638 | 4.489 | 10.083 | 16.479 | 38.888 | 41.669 | 10.06 | 0.75 | 817.80 |

| RC | 3.82 | 1.08 | 1.97 | 3.38 | 4.10 | 7.33 | 9.71 | 3.81 | 0.88 | 596.10 |

| RC | 4.13 | 1.050 | 2.182 | 3.805 | 4.616 | 8.861 | 11.101 | 4.39 | 0.98 | 611.40 |

| RC | 4.43 | 0.828 | 1.722 | 3.232 | 4.130 | 8.174 | 10.789 | 4.99 | 0.87 | 586.30 |

| RC | 4.68 | 1.046 | 2.152 | 3.845 | 4.692 | 8.686 | 10.725 | 4.49 | 0.94 | 610.90 |

| RC | 5.12 | 1.07 | 1.99 | 3.86 | 4.84 | 8.62 | 10.51 | 4.55 | 0.77 | 609.10 |

| RC | 5.39 | 1.03 | 2.01 | 3.74 | 4.60 | 8.55 | 10.64 | 4.45 | 0.85 | 607.00 |

| RC | 5.46 | 2.375 | 5.376 | 7.674 | 8.823 | 11.122 | 15.081 | 3.72 | 1.38 | 681.20 |

| RC | 6.04 | 1.129 | 2.290 | 3.927 | 4.745 | 8.333 | 10.130 | 4.20 | 0.98 | 609.00 |

| RC | 6.4 | 1.127 | 2.267 | 3.898 | 4.714 | 8.268 | 10.067 | 4.18 | 0.97 | 608.70 |

| RC | 6.4 | 0.937 | 1.642 | 2.706 | 3.423 | 5.279 | 8.762 | 3.65 | 0.84 | 569.60 |

| RC | 6.8 | 1.043 | 2.014 | 3.583 | 4.367 | 7.800 | 9.818 | 4.19 | 0.89 | 598.60 |

| RC | 6.81 | 0.95 | 1.67 | 2.80 | 3.54 | 5.78 | 8.58 | 3.72 | 0.83 | 571.30 |

| RC | 7.09 | 0.99 | 1.82 | 3.21 | 3.98 | 7.26 | 9.77 | 4.03 | 0.84 | 589.80 |

| RC | 7.69 | 0.99 | 1.79 | 3.01 | 3.70 | 5.97 | 8.63 | 3.73 | 0.88 | 577.60 |

| RC | 7.98 | 1.410 | 2.674 | 3.976 | 4.627 | 7.960 | 9.732 | 3.28 | 1.10 | 619.20 |

| RC | 8.01 | 0.980 | 1.503 | 2.068 | 2.744 | 4.098 | 4.976 | 2.80 | 0.84 | 551.10 |

| RC | 8.22 | 1.10 | 1.79 | 2.87 | 3.48 | 4.71 | 7.95 | 3.16 | 0.84 | 579.30 |

| RC | 8.51 | 0.83 | 1.34 | 1.85 | 2.36 | 4.07 | 5.96 | 2.86 | 0.92 | 537.90 |

| RC | 8.88 | 1.08 | 2.21 | 3.62 | 4.32 | 7.53 | 9.52 | 3.99 | 1.04 | 599.00 |

| RC | 9.17 | 0.94 | 1.57 | 2.45 | 3.17 | 4.60 | 7.79 | 3.38 | 0.83 | 562.40 |

| RC | 9.9 | 1.118 | 1.928 | 3.264 | 3.957 | 6.905 | 9.420 | 3.54 | 0.84 | 593.80 |

| RC | 10.2 | 0.95 | 1.67 | 2.80 | 3.54 | 5.78 | 8.58 | 3.72 | 0.83 | 589.40 |

| RC | 10.61 | 1.04 | 1.80 | 3.00 | 3.69 | 6.12 | 9.05 | 3.53 | 0.84 | 583.60 |

| RC | 10.97 | 0.98 | 1.77 | 3.07 | 3.83 | 6.98 | 9.85 | 3.92 | 0.84 | 584.50 |

| RC | 11.79 | 1.225 | 2.530 | 4.145 | 5.197 | 8.759 | 10.540 | 4.24 | 1.01 | 620.60 |

| RC | 12.14 | 1.303 | 2.687 | 4.241 | 5.380 | 9.029 | 10.853 | 4.13 | 1.03 | 635.50 |

| RC | 12.46 | 1.258 | 2.406 | 3.861 | 4.588 | 8.132 | 10.034 | 3.65 | 1.00 | 615.60 |

| RC | 12.66 | 1.172 | 1.997 | 3.310 | 3.967 | 6.728 | 9.173 | 3.39 | 0.86 | 596.60 |

| RC | 12.91 | 0.871 | 1.683 | 2.978 | 3.781 | 6.897 | 9.601 | 4.34 | 0.86 | 579.40 |

| RC | 13.38 | 1.044 | 2.084 | 3.603 | 4.363 | 7.580 | 9.479 | 4.18 | 0.95 | 596.40 |

| RC | 13.66 | 1.078 | 2.048 | 3.848 | 4.747 | 13.825 | 19.219 | 4.40 | 0.82 | 650.20 |

| RC | 13.88 | 1.060 | 1.805 | 3.469 | 4.464 | 8.328 | 10.417 | 4.21 | 0.69 | 602.20 |

| RC | 14.24 | 1.297 | 2.424 | 3.981 | 4.772 | 8.411 | 10.231 | 3.68 | 0.95 | 619.50 |

| RC | 15.18 | 1.319 | 2.612 | 4.169 | 5.358 | 10.155 | 18.658 | 4.06 | 0.97 | 662.90 |

| RC | 15.18 | 1.004 | 1.787 | 3.264 | 4.132 | 8.735 | 26.979 | 4.12 | 0.77 | 636.20 |

| RC | 15.45 | 1.123 | 2.004 | 3.473 | 4.207 | 7.612 | 9.882 | 3.75 | 0.85 | 605.10 |

| RC | 15.71 | 0.997 | 1.678 | 2.816 | 3.592 | 6.237 | 9.169 | 3.60 | 0.79 | 582.60 |

| RC | 16.08 | 1.256 | 2.247 | 3.453 | 4.056 | 6.676 | 8.943 | 3.23 | 0.99 | 601.00 |

| RC | 16.32 | 1.170 | 2.098 | 3.324 | 3.936 | 6.710 | 9.625 | 3.37 | 0.96 | 599.40 |

| RC | 16.32 | 1.347 | 2.727 | 4.395 | 5.759 | 9.272 | 11.028 | 4.28 | 0.96 | 632.30 |

| RC | 16.59 | 1.121 | 1.992 | 3.389 | 4.090 | 7.619 | 10.329 | 3.65 | 0.87 | 602.20 |

| RC | 16.59 | 0.924 | 1.482 | 2.094 | 2.748 | 4.055 | 4.709 | 2.97 | 0.87 | 550.30 |

| RC | 16.69 | 0.973 | 1.534 | 2.202 | 2.796 | 3.984 | 4.578 | 2.87 | 0.87 | 551.60 |

| RC | 16.83 | 1.035 | 1.666 | 2.558 | 3.151 | 4.338 | 6.439 | 3.04 | 0.85 | 567.60 |

| RC | 17.15 | 1.082 | 1.788 | 2.798 | 3.369 | 4.511 | 7.261 | 3.11 | 0.88 | 574.90 |

| RC | 17.45 | 0.986 | 1.478 | 1.970 | 2.589 | 3.932 | 4.603 | 2.63 | 0.86 | 550.20 |

| RC | 17.82 | 1.027 | 1.684 | 2.665 | 3.305 | 4.584 | 7.774 | 3.22 | 0.84 | 572.30 |

| Depth (m Along Hole) | Percentiles of Cutting Size | Coarseness Index (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| D10 (mm) | D30 (mm) | D50 (mm) | D60 (mm) | D80 (mm) | D90 (mm) | Cu | Cc | ||

| 1.95 | 0.51 | 0.74 | 1.07 | 1.29 | 1.71 | 1.93 | 2.53 | 0.84 | 463 |

| 2.18 | 0.55 | 0.83 | 1.20 | 1.38 | 1.75 | 1.94 | 2.51 | 0.91 | 474 |

| 2.24 | 0.56 | 0.90 | 1.27 | 1.46 | 1.83 | 2.20 | 2.59 | 0.99 | 499 |

| 2.32 | 0.61 | 1.03 | 1.44 | 1.64 | 2.27 | 3.51 | 2.68 | 1.06 | 482 |

| 2.37 | 0.87 | 1.38 | 1.90 | 2.39 | 3.66 | 4.30 | 2.76 | 0.92 | 500 |

| 2.44 | 0.63 | 1.08 | 1.45 | 1.64 | 2.09 | 3.42 | 2.60 | 1.12 | 499 |

| 2.61 | 0.96 | 1.58 | 2.33 | 2.84 | 3.85 | 4.36 | 2.95 | 0.92 | 552 |

| 2.9 | 0.61 | 0.99 | 1.34 | 1.51 | 1.85 | 2.37 | 2.47 | 1.06 | 489 |

| 3.34 | 0.55 | 0.84 | 1.19 | 1.37 | 1.72 | 1.90 | 2.49 | 0.93 | 472 |

| 3.49 | 0.74 | 1.10 | 1.40 | 1.55 | 1.85 | 2.00 | 2.11 | 1.06 | 496 |

| 3.8 | 0.50 | 0.66 | 0.82 | 1.00 | 1.50 | 1.75 | 2.02 | 0.87 | 443 |

| 5.66 | 0.50 | 0.72 | 1.02 | 1.22 | 1.62 | 1.82 | 2.46 | 0.86 | 451 |

| 5.74 | 0.49 | 0.66 | 0.83 | 1.04 | 1.53 | 1.77 | 2.10 | 0.86 | 444 |

| 5.87 | 0.53 | 0.78 | 1.11 | 1.29 | 1.66 | 1.84 | 2.42 | 0.88 | 463 |

| 6.11 | 0.50 | 0.68 | 0.95 | 1.09 | 1.60 | 2.18 | 0.85 | 453 | |

| 6.5 | 0.44 | 0.56 | 0.67 | 0.73 | 0.88 | 1.44 | 1.69 | 0.96 | 408 |

| 6.6 | 0.45 | 0.56 | 0.68 | 0.74 | 0.90 | 1.46 | 1.65 | 0.96 | 409 |

| 6.7 | 0.46 | 0.58 | 0.70 | 0.76 | 1.05 | 1.52 | 1.64 | 0.96 | 417 |

| 6.8 | 0.49 | 0.63 | 0.77 | 0.84 | 1.41 | 1.71 | 1.73 | 0.96 | 436 |

| 6.88 | 0.49 | 0.67 | 0.85 | 1.09 | 1.55 | 1.78 | 2.22 | 0.85 | 445 |

| 7.11 | 0.46 | 0.57 | 0.69 | 0.74 | 0.93 | 1.47 | 1.63 | 0.96 | 413 |

| 7.27 | 0.36 | 0.55 | 0.71 | 0.79 | 1.30 | 1.65 | 2.23 | 1.06 | 413 |

| Particle Size (mm) | LD# | Mode | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Settling Pit—Daily Production | D10 | D30 | D50 | D60 | D80 | D90 | Cu | Cc | Coarseness Index (%) | ||

| 11 October 2021 | 0.33 | 1.06 | 2.18 | 3.24 | 6.40 | 9.29 | 9.94 | 1.07 | 528.80 | 1 | RC |

| 12 October 2021 | 0.51 | 1.67 | 3.55 | 4.60 | 9.13 | 13.00 | 8.99 | 1.18 | 598.70 | ||

| 13 October 2021 | 0.07 | 0.35 | 1.35 | 2.72 | 8.74 | 14.78 | 37.74 | 0.63 | 471.20 | ||

| 14 October 2021 | 0.31 | 1.34 | 3.31 | 4.52 | 8.93 | 11.60 | 14.48 | 1.28 | 564.00 | ||

| 20 October 2021 | 0.68 | 2.35 | 4.53 | 6.63 | 11.77 | 20.58 | 9.82 | 1.24 | 641.60 | ||

| 21 October 2021 | 0.24 | 1.09 | 3.00 | 4.27 | 8.72 | 11.33 | 17.82 | 1.16 | 546.00 | ||

| 26 October 2021 | 0.26 | 1.27 | 3.57 | 5.24 | 10.03 | 15.19 | 20.10 | 1.18 | 567.50 | ||

| 27 October 2021 | 0.46 | 2.10 | 4.42 | 6.15 | 10.10 | 14.47 | 13.36 | 1.56 | 595.70 | ||

| 28 October 2021 | 1.23 | 3.63 | 6.82 | 8.69 | 15.30 | 33.09 | 7.05 | 1.23 | |||

| 29 October 2021 | 0.85 | 2.79 | 5.13 | 6.82 | 10.21 | 13.98 | 8.07 | 1.35 | 622.50 | ||

| 30 October 2021 | 0.79 | 3.02 | 5.56 | 6.99 | 9.86 | 12.04 | 8.87 | 1.65 | 618.40 | ||

| 1 November 2021 | 0.22 | 1.32 | 3.68 | 5.33 | 9.72 | 14.05 | 23.71 | 1.47 | 571.60 | ||

| 2 November 2021 | 0.22 | 1.35 | 3.08 | 4.13 | 7.94 | 10.19 | 18.57 | 1.99 | 542.70 | ||

| 3 November 2021 | 0.36 | 1.27 | 2.98 | 4.16 | 8.23 | 10.55 | 11.47 | 1.07 | 556.70 | ||

| 4 November 2021 | 0.53 | 2.02 | 4.17 | 5.63 | 9.40 | 11.82 | 10.71 | 1.38 | 590.60 | ||

| 28 November 2021 | 0.29 | 0.94 | 1.89 | 2.92 | 5.45 | 8.74 | 9.91 | 1.02 | 517.80 | 2 | |

| 3 December 2021 | 2.31 | 4.56 | 7.97 | 9.73 | 21.76 | 33.88 | 4.22 | 0.93 | 759.50 | ||