Optimization of Volumetric Fracturing Stages and Clusters in Continental Shale Oil Reservoirs Based on Geology-Engineering Integration

Abstract

1. Introduction

2. Establishment of the Integrated Geology-Engineering Model of the Gulong Shale

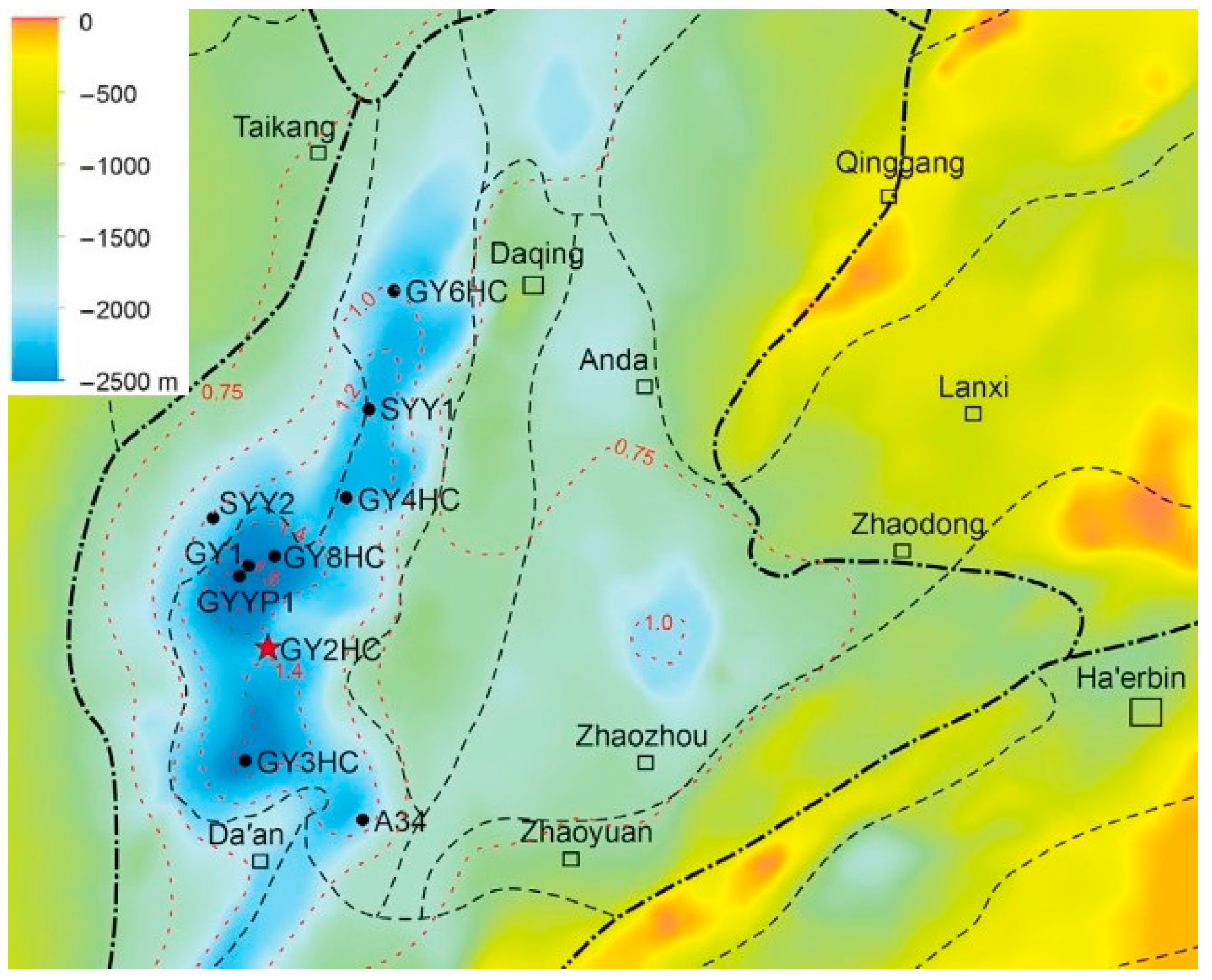

2.1. Study Area

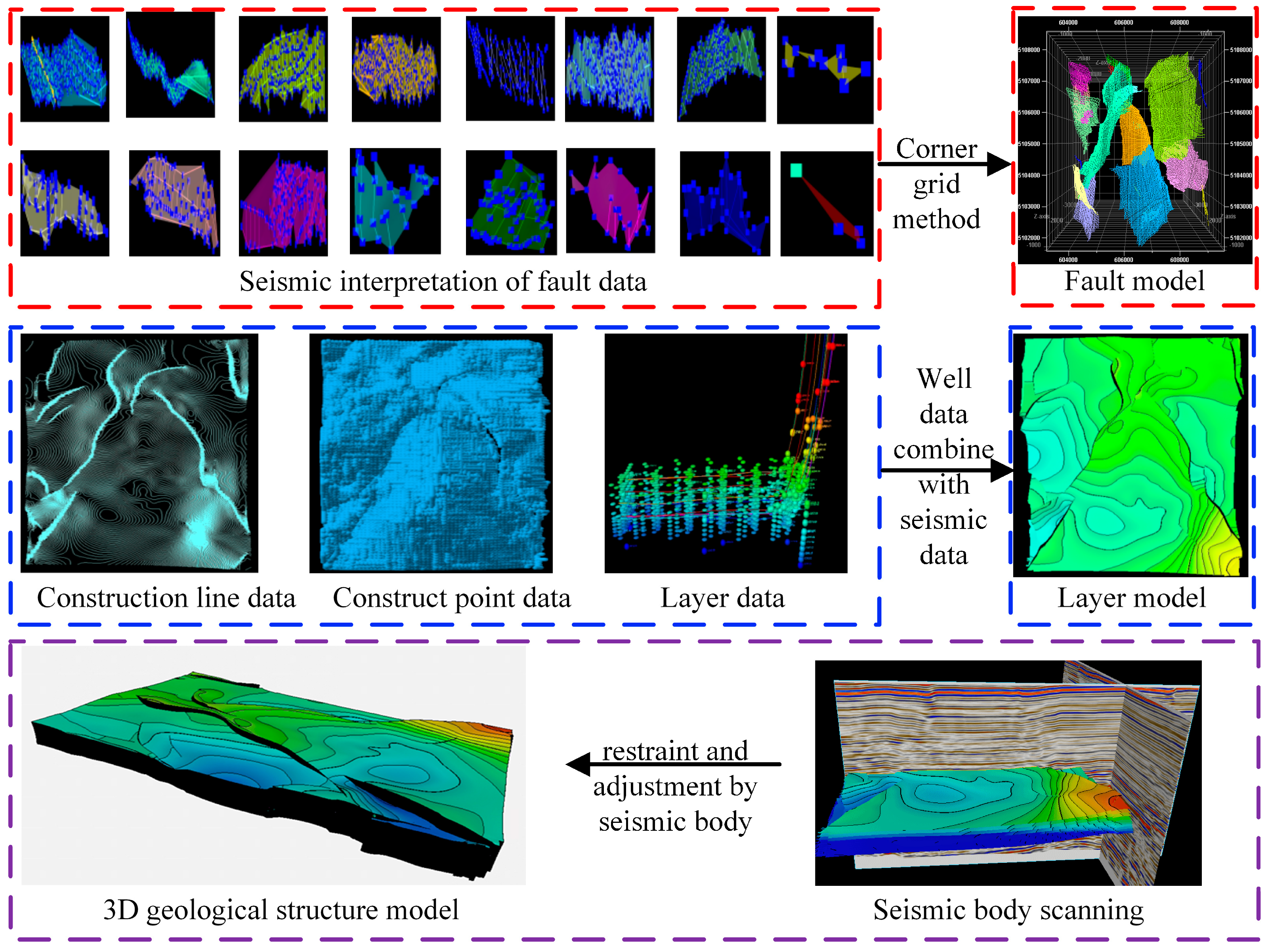

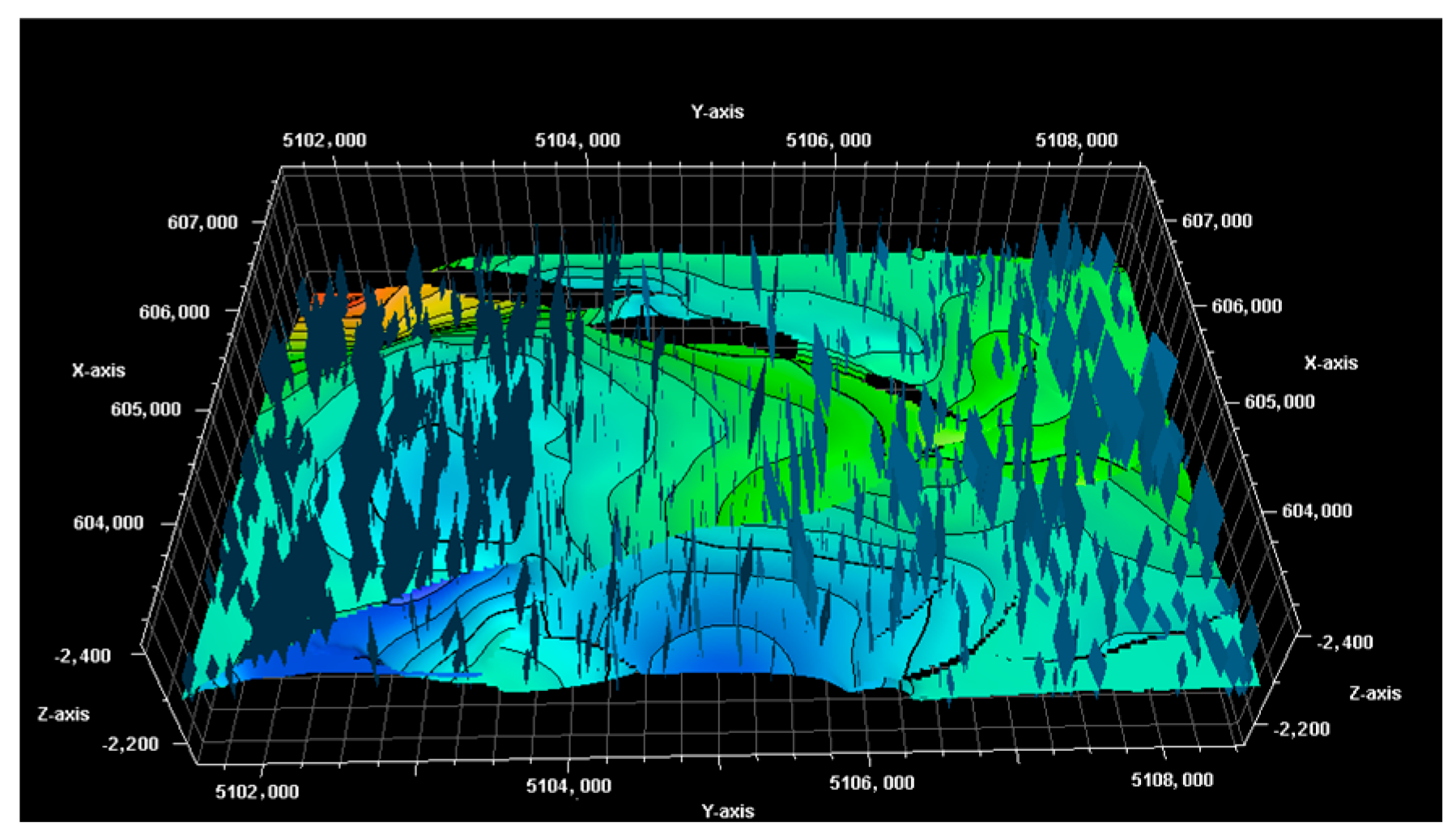

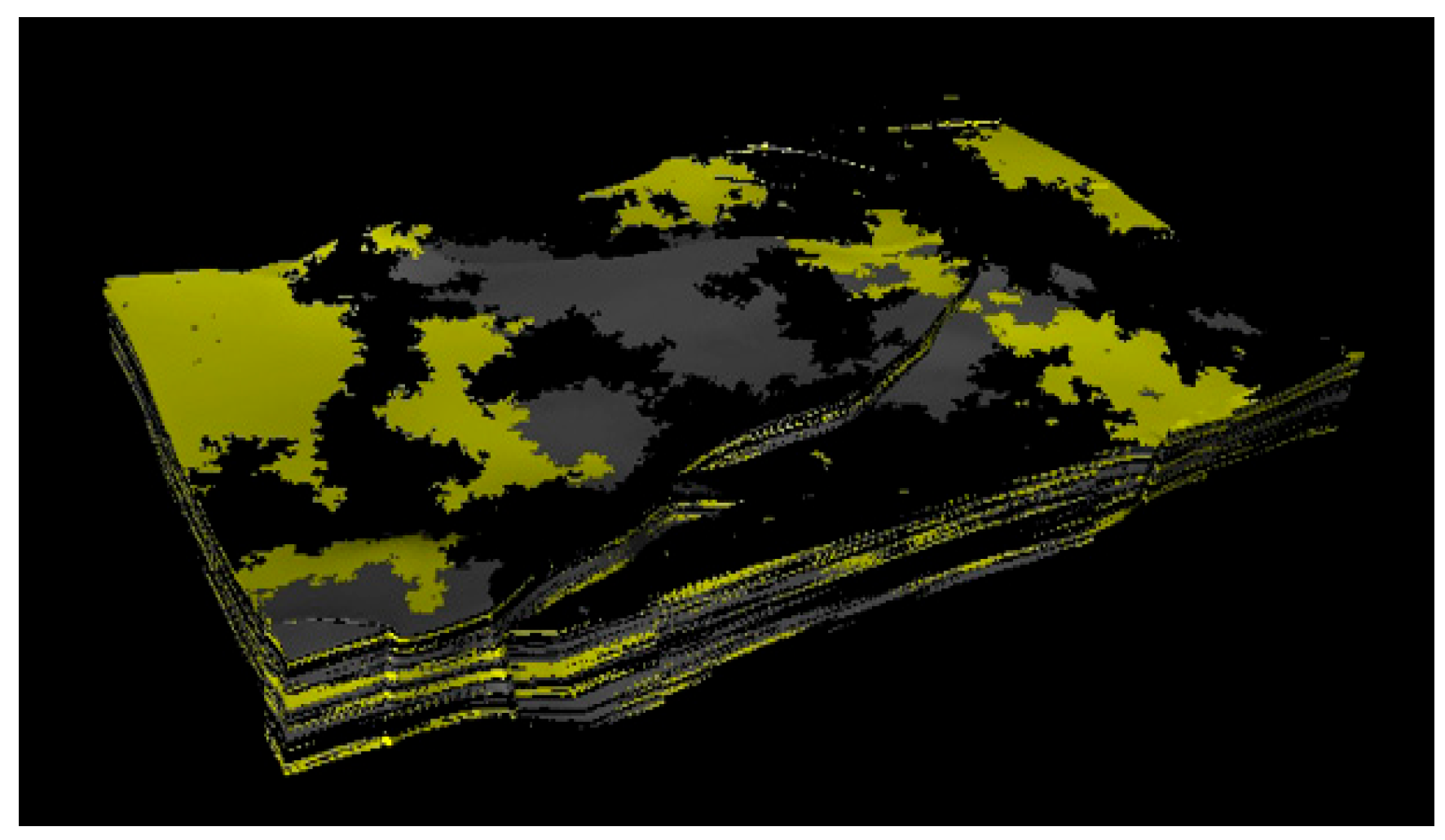

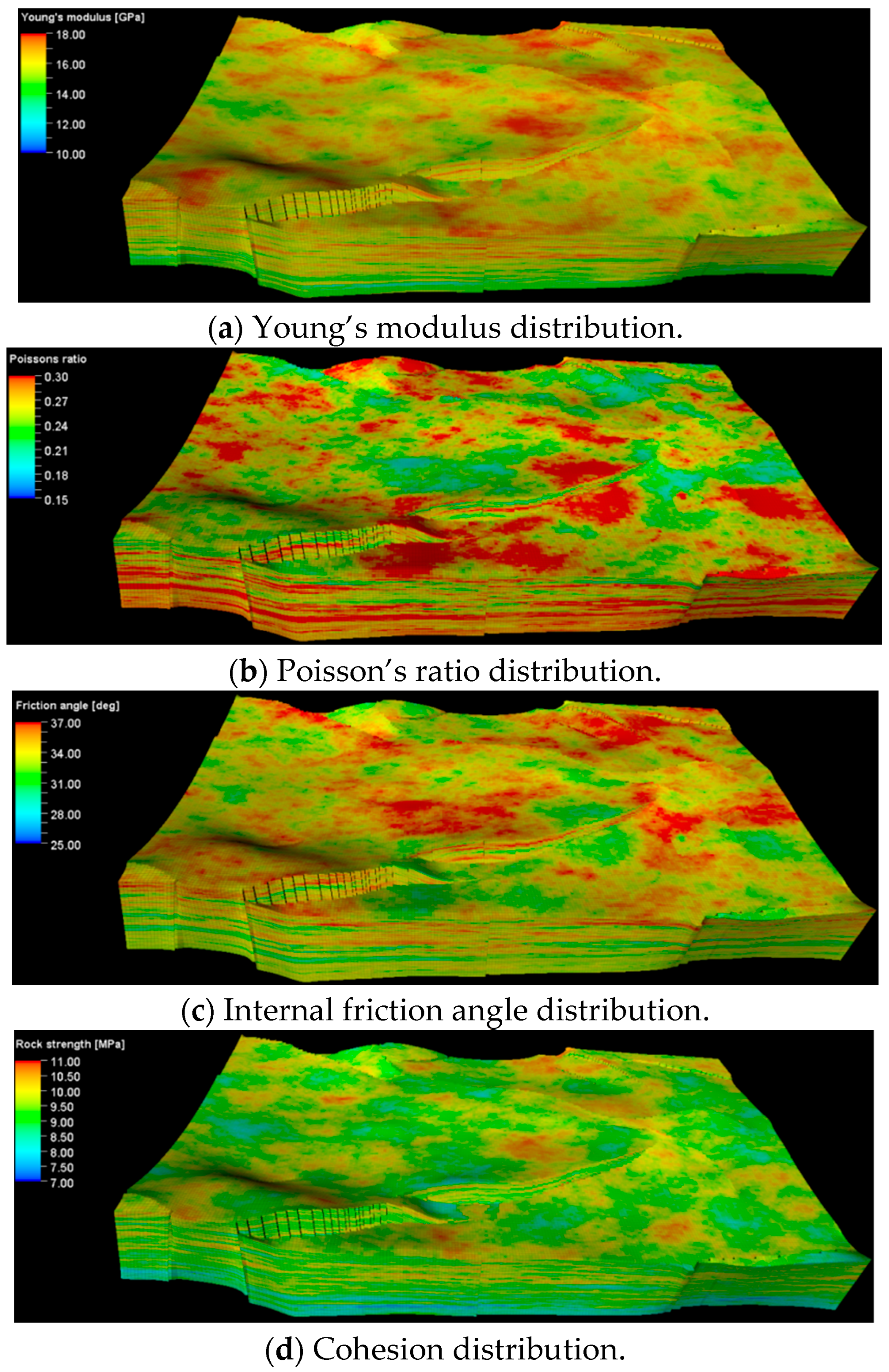

2.2. Establishment of Geology-Engineering Integration

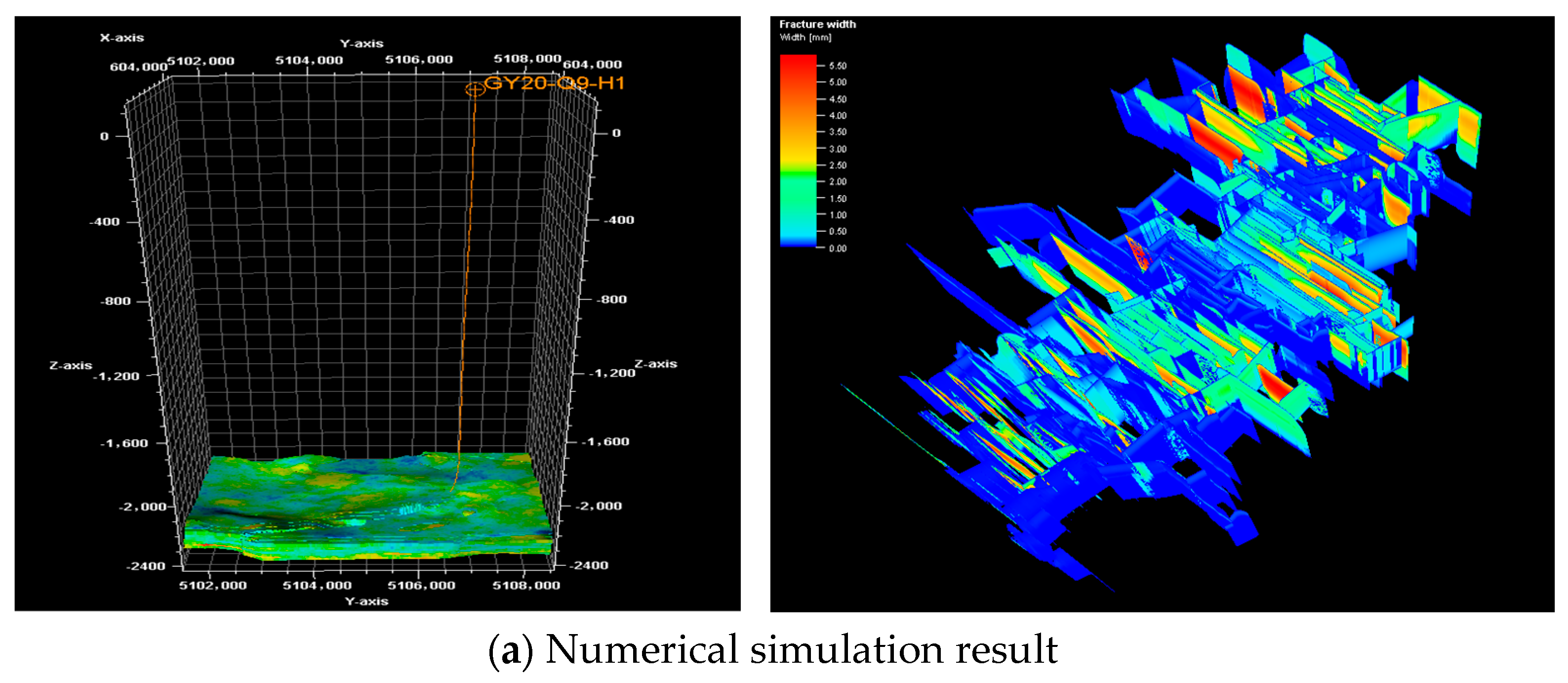

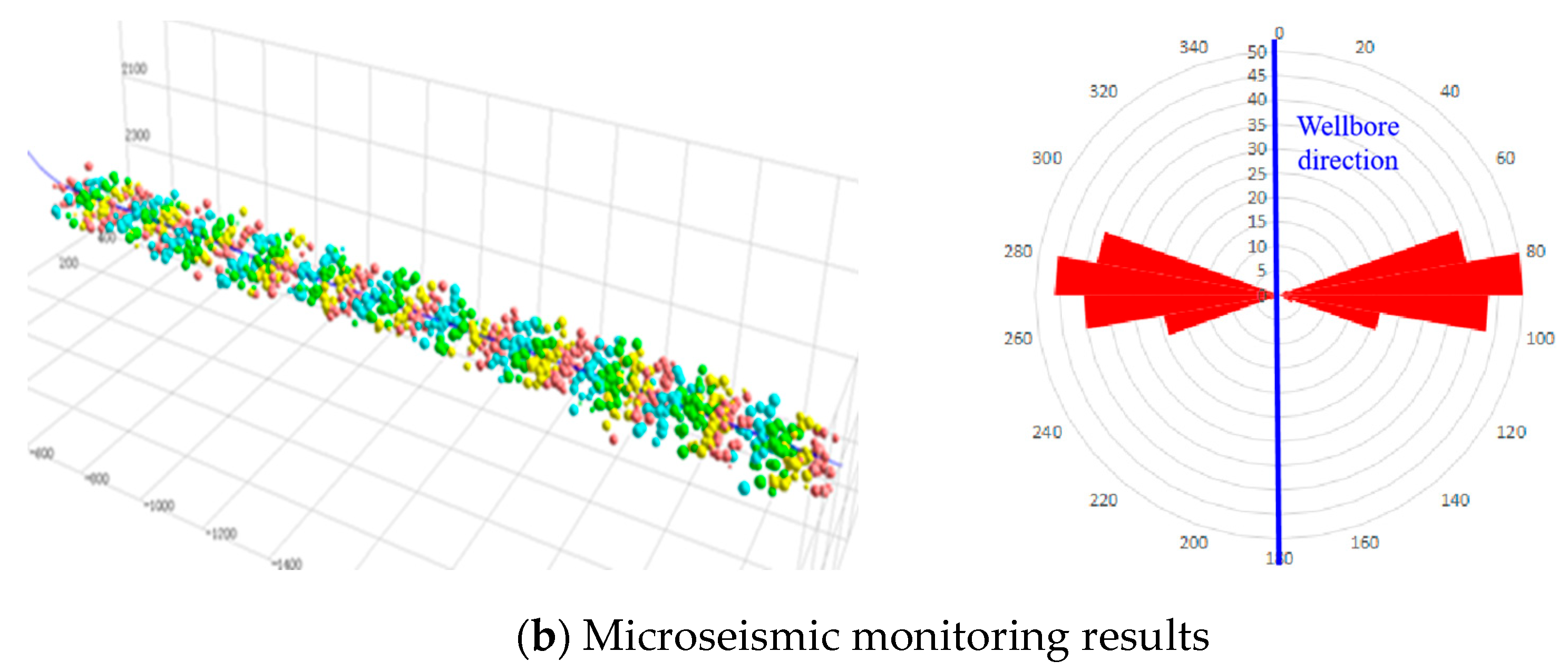

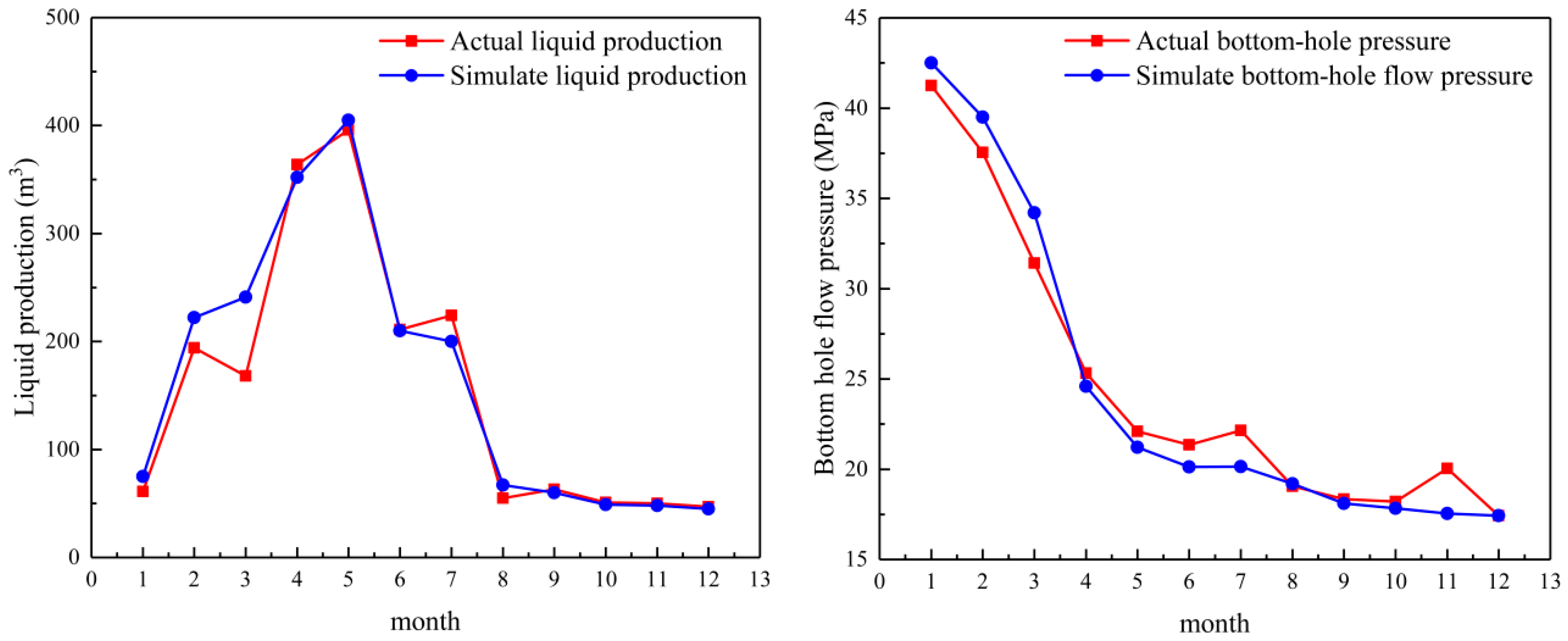

2.3. Model Verification

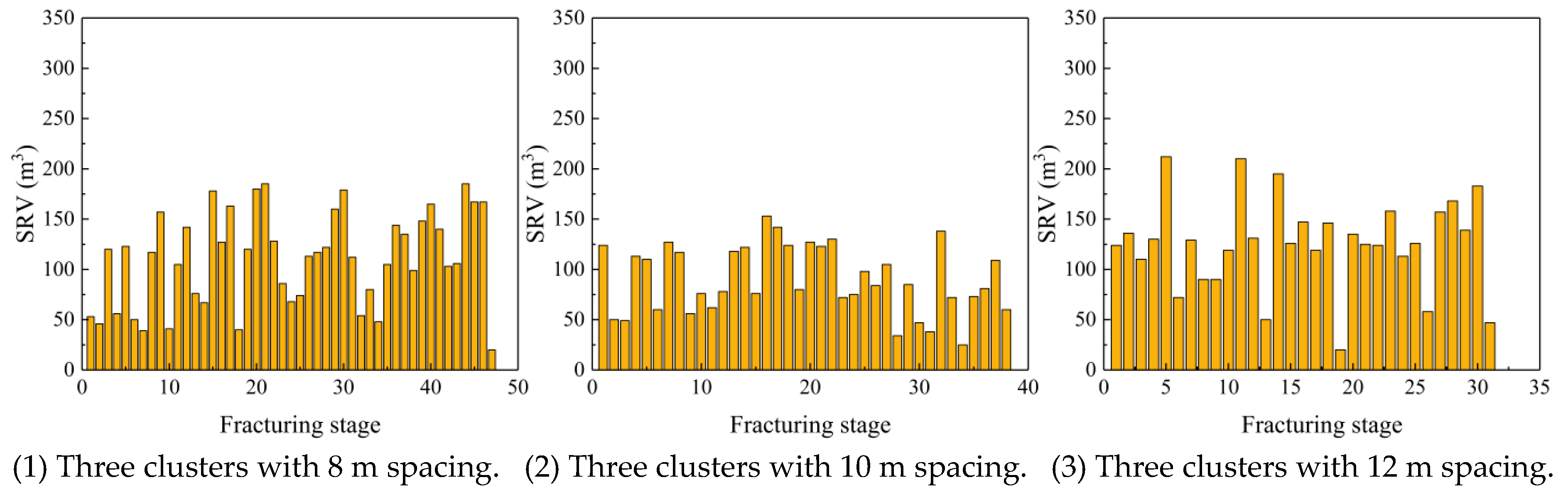

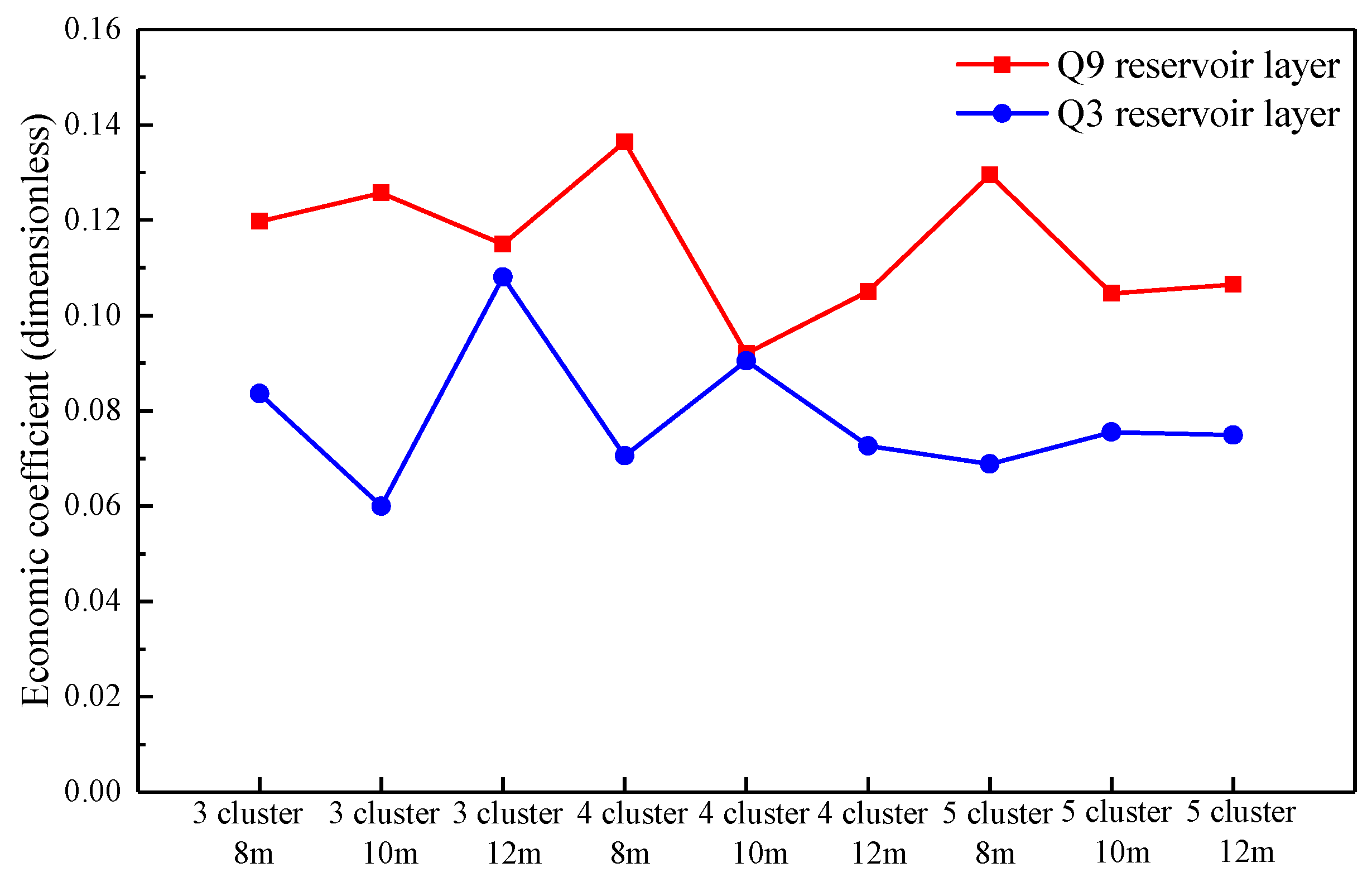

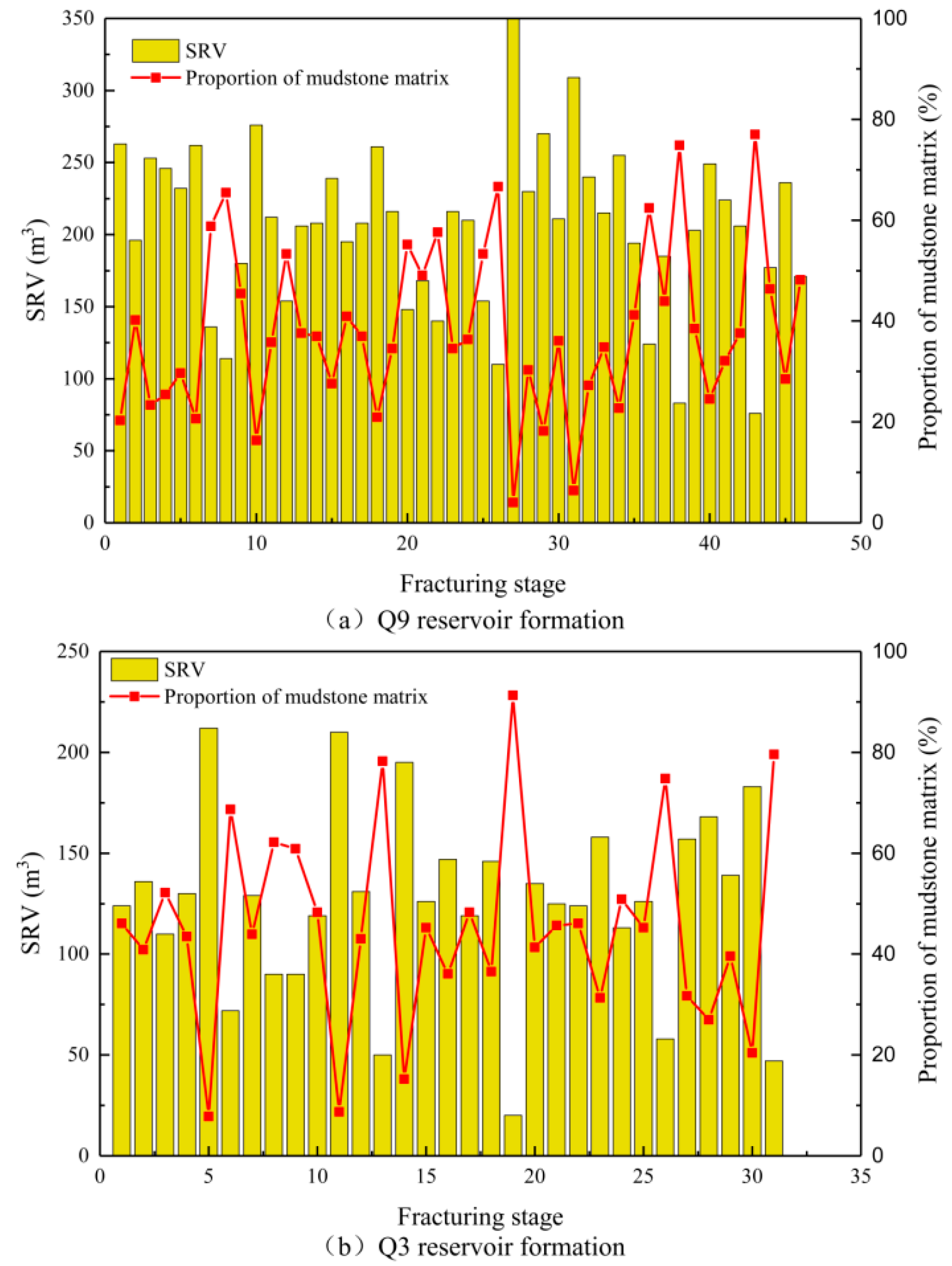

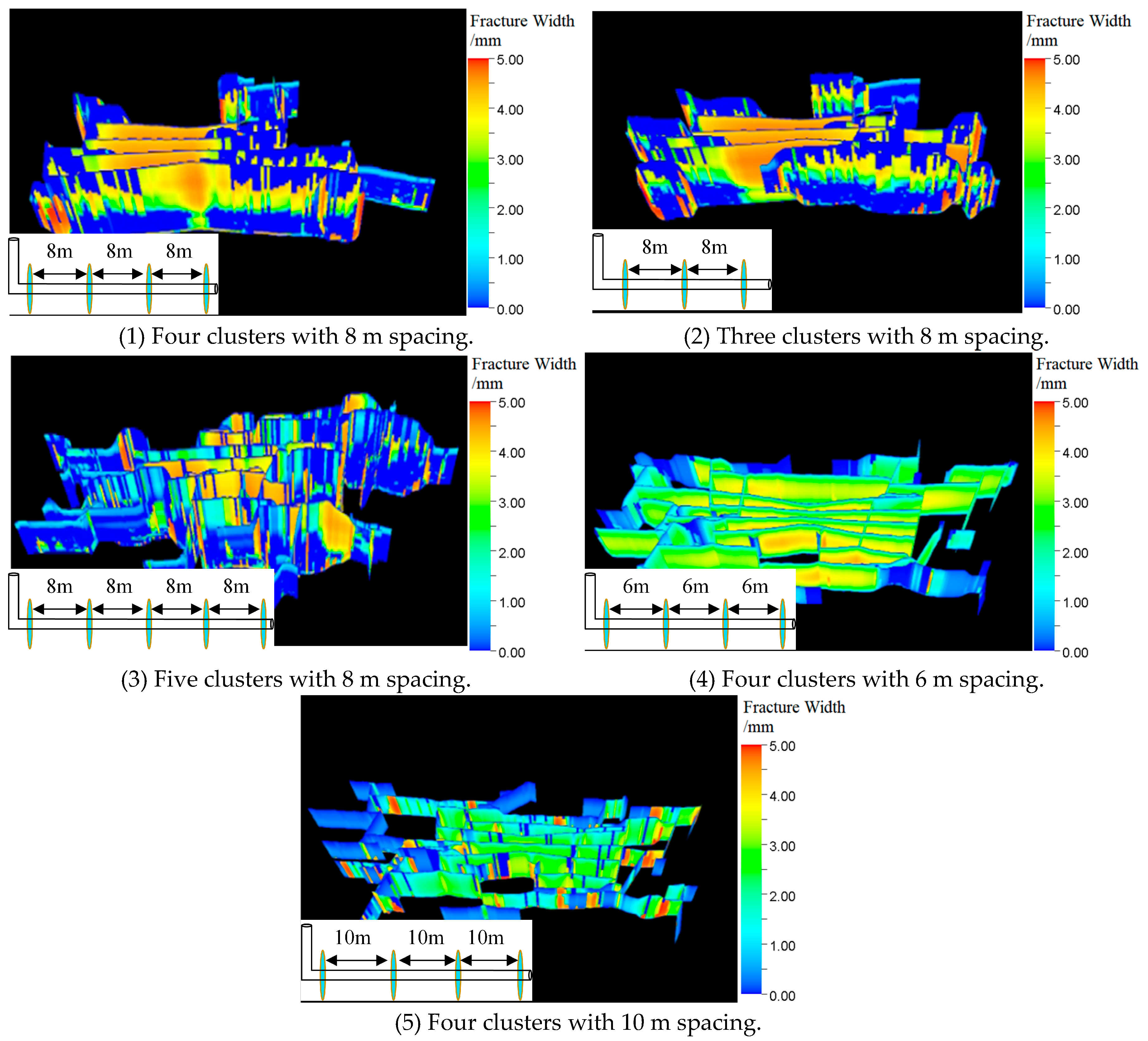

3. Optimal Design of the Fracturing Stages and Clusters

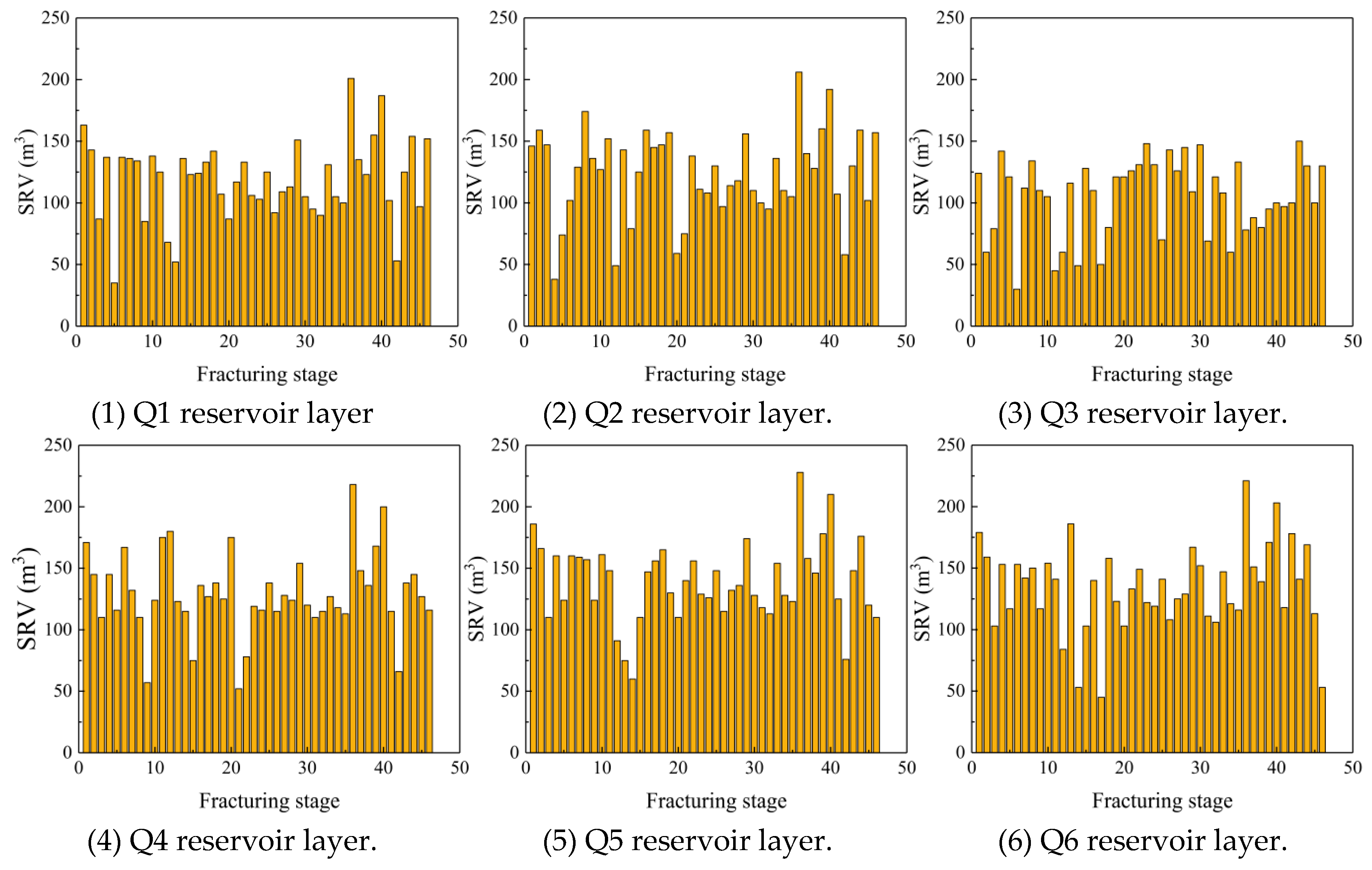

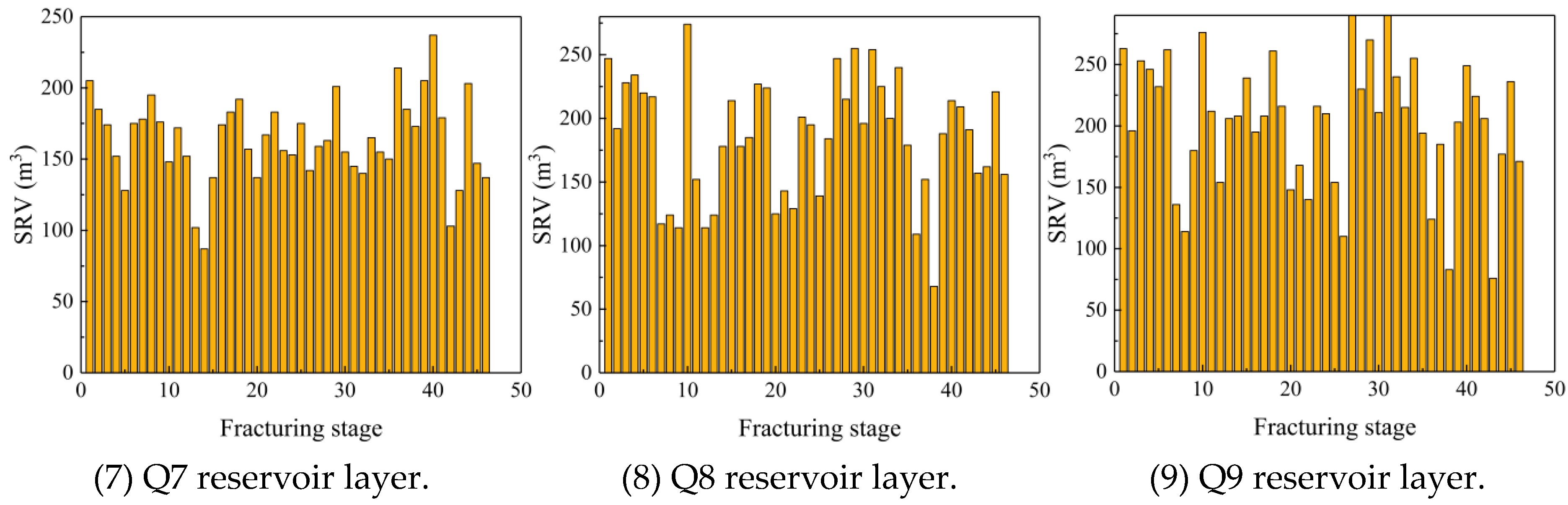

3.1. Evaluation of the Compressibility of the Different Reservoir Layers

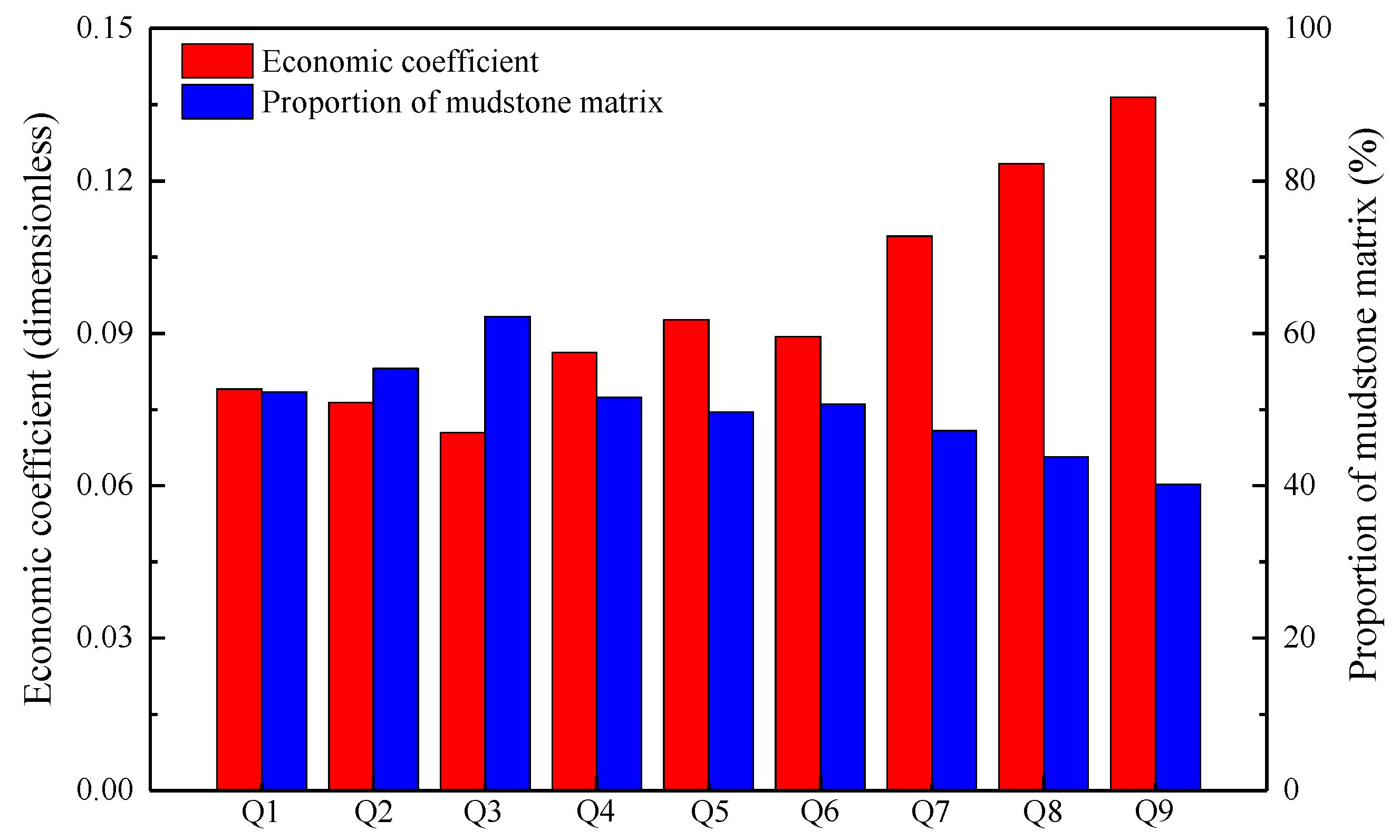

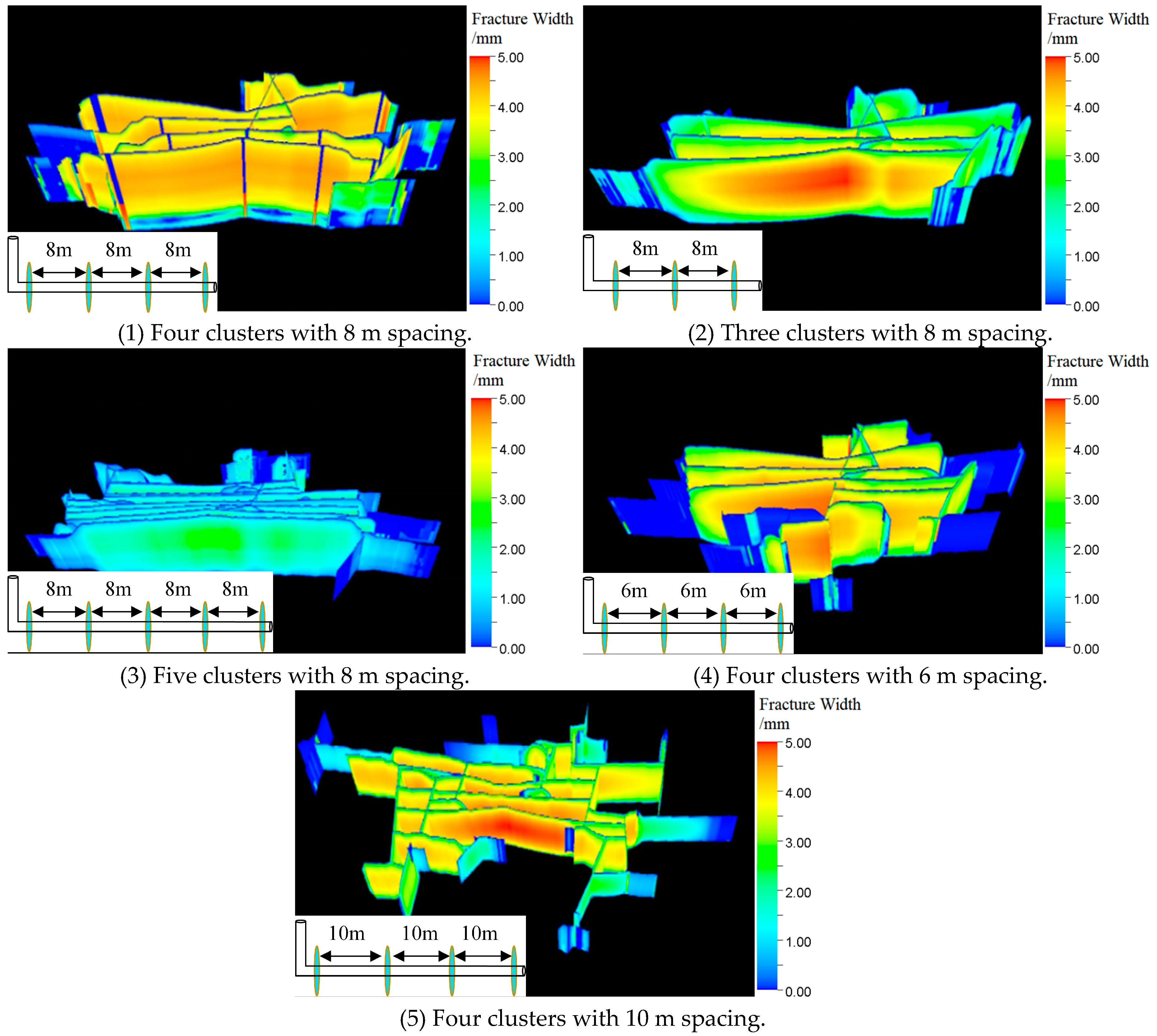

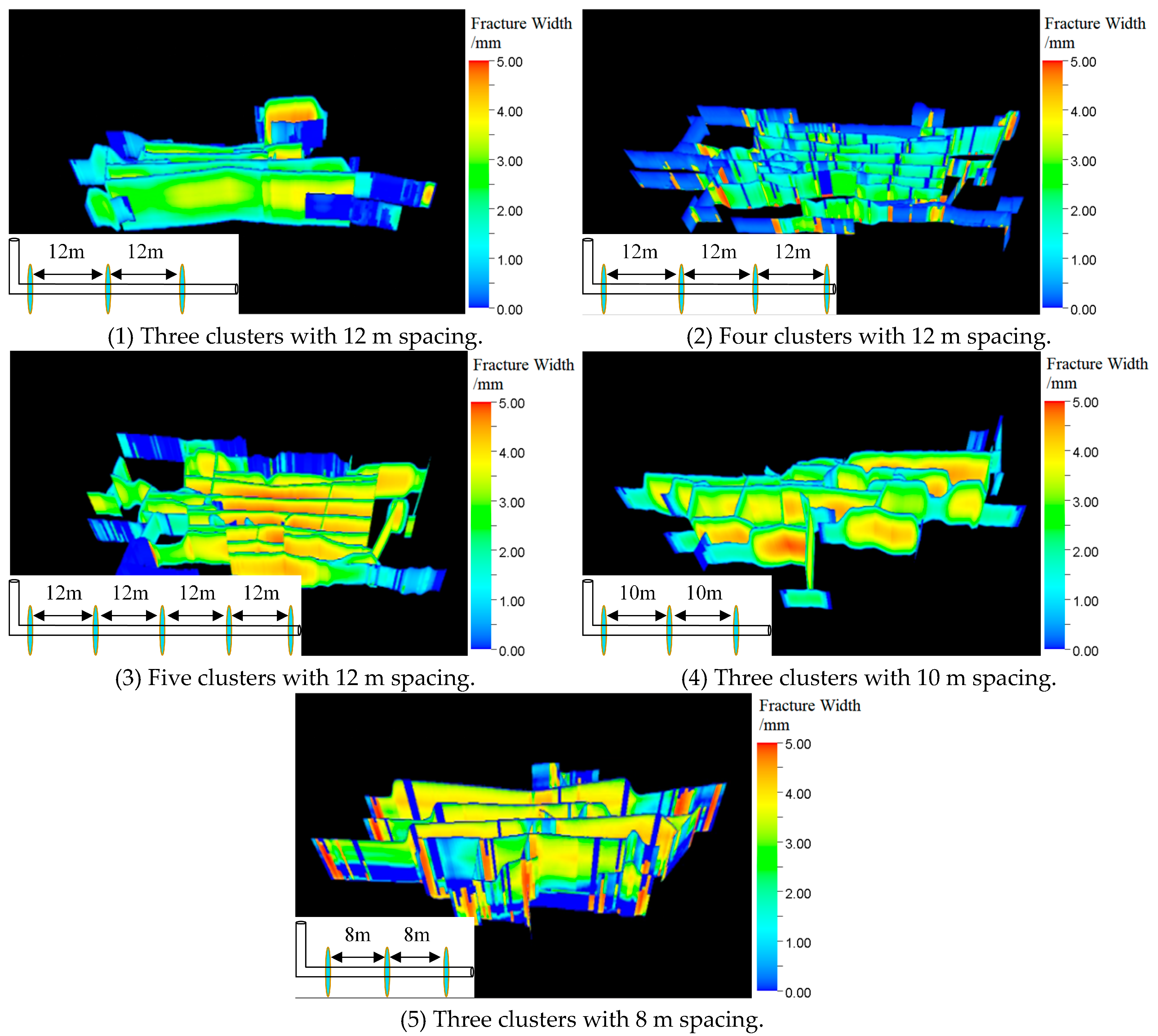

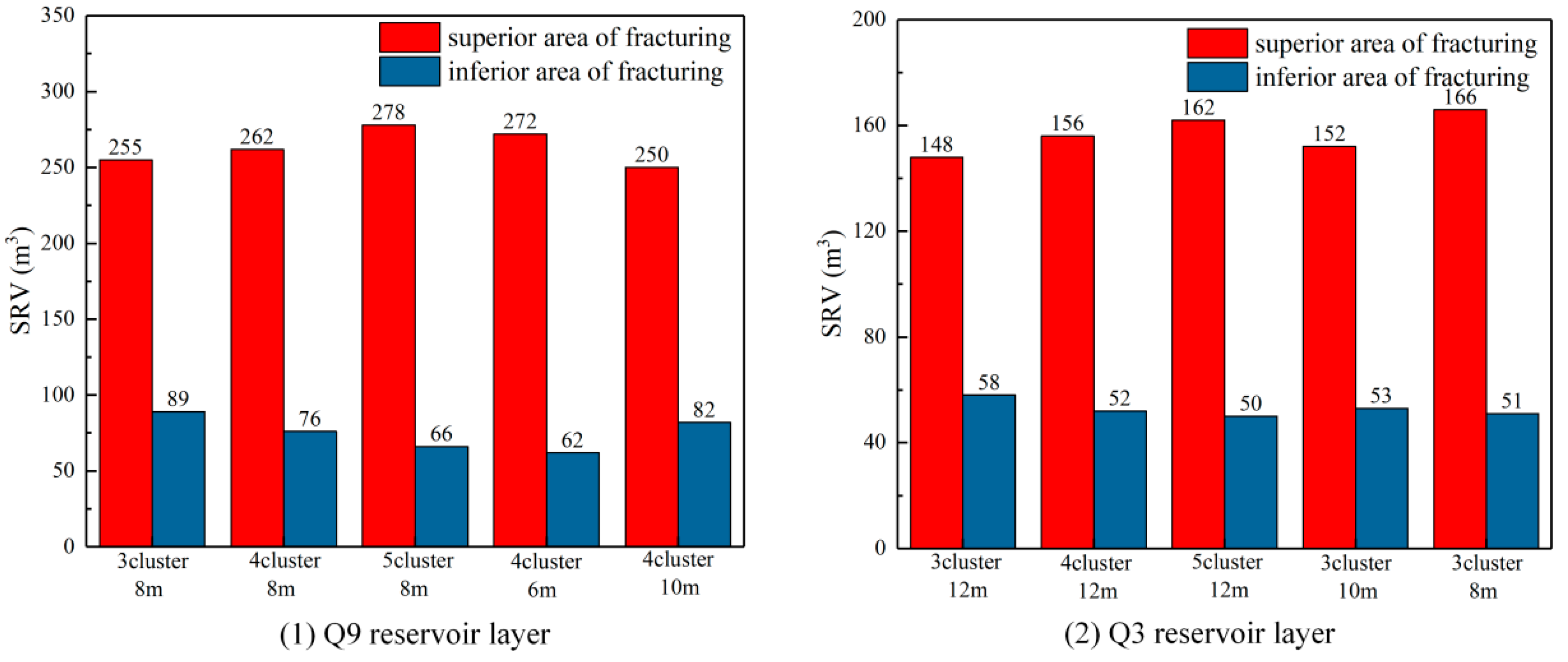

3.2. Differences and Optimization of the Fracturing in the Q9 and Q3 Reservoir Layers

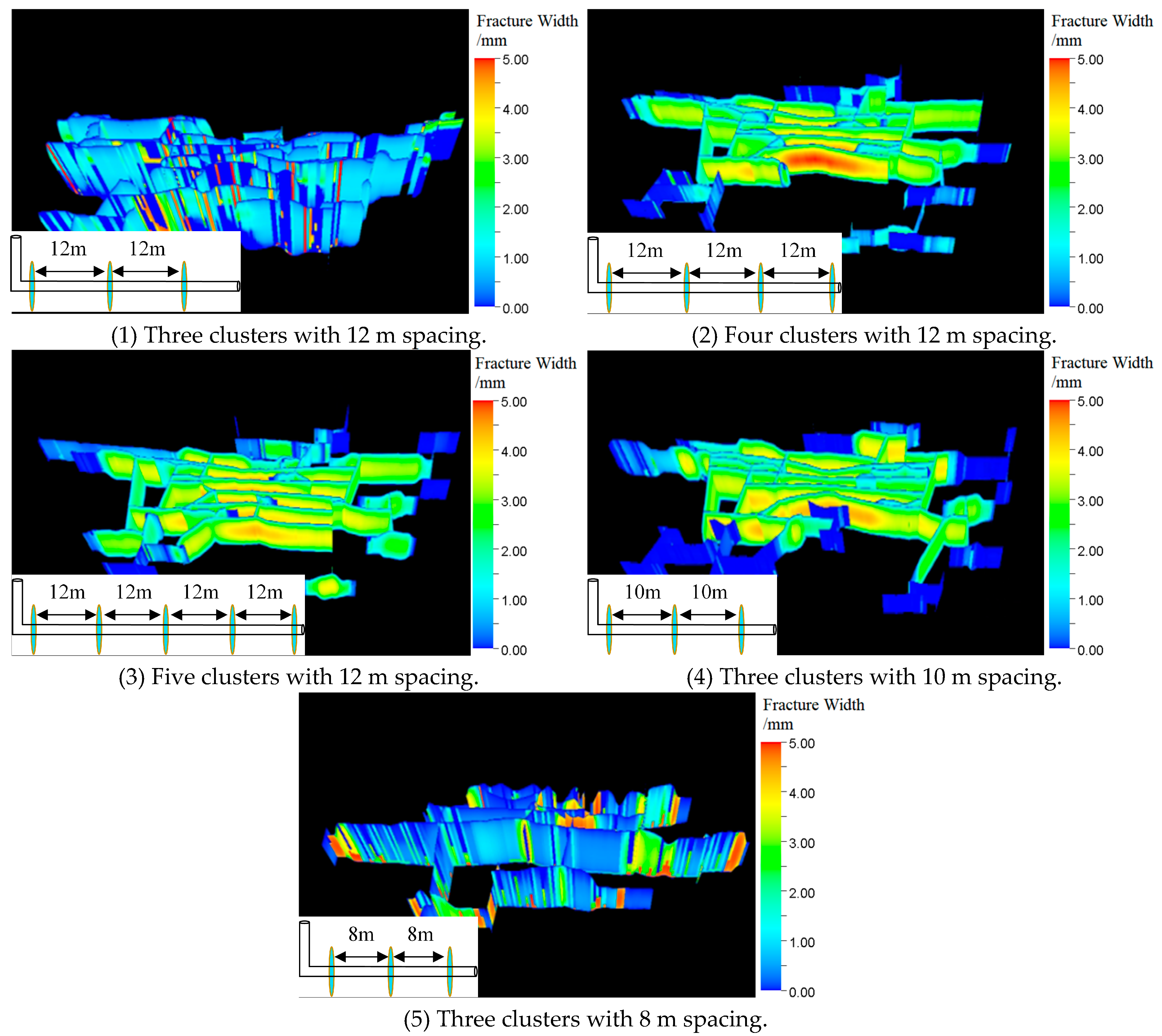

3.3. Differences and Optimization of the Superior and Inferior Fracturing Areas in the Reservoir Layers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Wu, J.; Li, Q.; Zhou, X.; Li, Y.; Chi, P.; Han, Y.; Ansari, U.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-Bearing Sediment in Northern South China Sea by Horizontal Wellbore: Sensitivity Analysis. Nat. Resour. Res. 2025, 34, 1667–1699. [Google Scholar]

- Li, Q.; Li, Y.; Cheng, Y.; Li, Q.; Wang, F.; Wei, J.; Liu, Y.; Zhang, C.; Song, B.; Yan, C.; et al. Numerical simulation of fracture reorientation during hydraulic fracturing in perforated horizontal well in shale reservoirs. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1807–1813. [Google Scholar] [CrossRef]

- Sun, L.; Zhu, R.; Zhang, T.; Cai, Y.; Feng, Z.; Bai, B.; Jiang, H.; Wang, B. Advances and trends of non-marine shale sedimentology: A case study from Gulong Shale of Daqing Oilfield, Songliao Basin, NE China. Pet. Explor. Dev. 2024, 51, 1367–1385. [Google Scholar] [CrossRef]

- Yuan, S.; Lei, Z.; Li, J.; Yao, Z.; Li, B.; Wang, R.; Liu, Y.; Wang, Q. Key theoretical and technical issues and countermeasures for effective development of Gulong shale oil, Daqing Oilfield, NE China. Pet. Explor. Dev. 2023, 50, 638–650. [Google Scholar] [CrossRef]

- Liu, H.; Huang, Y.; Cai, M.; Meng, S.; Tao, J. Practice and development suggestions of hydraulic fracturing technology in the Gulong shale oil reservoirs of Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 688–698. [Google Scholar] [CrossRef]

- Wang, X.; Cui, B.; Feng, Z.; Shao, H.; Huo, Q.; Zhang, B.; Gao, B.; Zeng, H. In-situ hydrocarbon formation and accumulation mechanisms of micro- and nano-scale pore-fracture in Gulong shale, Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 1269–1281. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Zhu, R.K.; Wu, S.T.; Jiang, X.-H.; Liu, C.; Cai, Y.; Zhang, S.-R.; Zhang, T.-S. Microscopic oil occurrence in high-maturity lacustrine shales: Qingshankou Formation, Gulong Sag, Songliao Basin. Pet. Sci. 2023, 20, 2726–2746. [Google Scholar] [CrossRef]

- Meng, S.; Zhang, Z.; Xu, W.; Yu, H.; Wu, H.; Liu, H. A mixed phase-field model for fracture propagation behavior in Gulong shale with complex wavy bedding. J. Rock Mech. Geotech. Eng. 2025. [Google Scholar] [CrossRef]

- Han, Z.; Wang, G.; Wu, H.; Feng, Z.; Tian, H.; Xie, Y.; Wu, H. Lithofacies Characteristics of Gulong Shale and Its Influence on Reservoir Physical Properties. Energies 2024, 17, 779. [Google Scholar] [CrossRef]

- Meng, S.W.; Tao, J.P.; Li, T.J.; Li, D.-X.; Wang, S.-L.; Yang, L.; Liu, X.; Liang, L.-H.; Liu, H. Mechanical characteristics and reservoir stimulation mechanisms of the Gulong shale oil reservoirs, the northern Songliao Basin. Pet. Sci. 2024, 21, 2023–2036. [Google Scholar] [CrossRef]

- Sun, G.; Dong, W.; Zhang, X.; Zhong, J.; Sun, N. Study on Dolomite Thin Layers and Nodules in the Qingshankou Formation Shale Oil Reservoir of Gulong Sag. Energies 2023, 16, 3981. [Google Scholar] [CrossRef]

- Gu, M. Impact of anisotropy induced by shale lamination and natural fractures on reservoir development and operational designs. SPE Reserv. Eval. Eng. 2018, 21, 850–862. [Google Scholar] [CrossRef]

- Yan, W.; Wang, C.; Yin, S.; Wen, Z.; Zheng, J.; Fu, X.; Feng, Z.; Zhang, Z.; Zhu, J. A log-based method for fine-scale evaluation of lithofacies and its applications to the Gulong shale in the Songliao Basin, Northeast China. Energy Geosci. 2024, 5, 100291. [Google Scholar] [CrossRef]

- Alsuwaidi, E.S.; Xi, G.F.; Zimmerman, R.W. Mechanical characterization of Laffan and Nahr Umr anisotropic shales. J. Pet. Sci. Eng. 2021, 200, 108195. [Google Scholar] [CrossRef]

- Dong, Z.; Tian, S.; Xue, H.; Lu, S.; Liu, B.; Erastova, V.; Chen, G.; Zhang, Y. A novel method for automatic quantification of different pore types in shale based on SEM-EDS calibration. Mar. Pet. Geol. 2025, 173, 107278. [Google Scholar] [CrossRef]

- Dong, Z.; Tian, S.; Xue, H.; Lu, S.; Liu, B.; Erastova, V.; Wu, M.; Wu, R. Analysis of Pore Types in Lower Cretaceous Qingshankou Shale Influenced by Electric Heating. Energy Fuels 2024, 38, 20577–20590. [Google Scholar] [CrossRef]

- Liu, G.; Liu, G.; Shang, D.; Du, X. Characterization of brittleness index of gas shale and its influence on favorable block exploitation in southwest China. Front. Earth Sci. 2024, 12, 9378. [Google Scholar] [CrossRef]

- Shuoshi, W.; Zheng, G.; Ping, G.; Zhao, W. Comparative Laboratory Wettability Study of Sandstone, Tuff, and Shale Using 12-MHz NMR T1-T2 Fluid Typing: Insight of Shale. SPE J. 2024, 29, 4781–4803. [Google Scholar]

- Zhou, Y.; Guan, W.; Sun, Q.; Zou, X.; He, Z. Effect of multi-scale rough surfaces on oil-phase trapping in fractures: Pore-scale modeling accelerated by wavelet decomposition. Comput. Geotech. 2025, 179, 106951. [Google Scholar] [CrossRef]

- Gan, B.; Li, Z.; Huo, W.; Zhang, Y.; Li, Z.; Fan, R.; Zhang, H.; Xu, Y.; He, Y. Phase transitions of CH4 hydrates in mud-bearing sediments with oceanic laminar distribution: Mechanical response and stabilization-type evolution. Fuel 2025, 380, 133185. [Google Scholar] [CrossRef]

- Ren, Q.Q.; Li, L.F.; Wang, J.; Jiang, R.T.; Li, M.P.; Feng, J.W. Dynamic evolution mechanism of the fracturing fracture system—Enlightenments from hydraulic fracturing physical experiments and finite element numerical simulation. Pet. Sci. 2024, 21, 3839–3866. [Google Scholar] [CrossRef]

- Niu, Q.; Hu, M.; Chang, J.; Wang, W.; Yuan, W.; Wang, Q.; Zheng, Y.; Shang, S. Explosive fracturing mechanism in low-permeability sandstone-type uranium deposits considering different acidification reactions. Energy 2024, 312, 133676. [Google Scholar] [CrossRef]

- Dehghan, A.N.; Goshtasbi, K.; Ahangari, K.; Jin, Y. The effect of natural fracture dip and strike on hydraulic fracture propagation. Int. J. Rock Mech. Min. Sci. 2015, 75, 210–215. [Google Scholar] [CrossRef]

- Zhang, R.X.; Hou, B.; Han, H.F.; Fan, M.; Chen, M. Experimental investigation on fracture morphology in laminated shale formation by hydraulic fracturing. J. Pet. Sci. Eng. 2019, 177, 442–451. [Google Scholar] [CrossRef]

- Tan, P.; Pang, H.; Zhang, R.X.; Jin, Y.; Zhou, Y.; Kao, J.; Fan, M. Experimental investigation into hydraulic fracture geometry and proppant migration characteristics for southeastern Sichuan deep shale reservoirs. J. Pet. Sci. Eng. 2019, 184, 106517. [Google Scholar] [CrossRef]

- Huang, B.X.; Liu, J.W. Experimental investigation of the effect of bedding planes on hydraulic fracturing under true triaxial stress. Rock Mech. Rock Eng. 2017, 50, 2627–2643. [Google Scholar] [CrossRef]

- Li, M.; Zhou, F.; Sun, Z.; Dong, E.; Zhuang, X.; Yuan, L.; Wang, B. Experimental study on plugging performance and diverted fracture geometry during different temporary plugging and diverting fracturing in Jimusar shale. J. Pet. Sci. Eng. 2022, 215, 110580. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.; Dong, K.; Meng, S.; Lu, Q.; Li, Z. Effects of in-situ temperature in deep reservoirs on shale fracture properties. Energy Rep. 2023, 9, 73–83. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, D.Q.; Zhao, Z.H.; Wang, H.J. Investigation on the effect of confining pressure on the geomechanical and ultrasonic properties of black shale using ultrasonic transmission and post-test CT visualization. J. Pet. Sci. Eng. 2020, 185, 106630. [Google Scholar] [CrossRef]

- Li, J.; Xie, M.; Wang, S.; Meng, S.; Dong, K.; Lu, Q. Study on the influence of thermo-pressure coupling environment on the fracture properties of shale in deep reservoirs. Theor. Appl. Fract. Mech. 2024, 131, 104440. [Google Scholar] [CrossRef]

- Wei, M.D.; Dai, F.; Xu, N.W.; Zhao, T.; Xia, K.W. Experimental and numerical study on the fracture process zone and fracture toughness determination for ISRM-suggested semi-circular bend rock specimen. Eng. Fract. Mech. 2016, 154, 43–56. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Wang, D.; Guo, Z.; Tang, H.; Zhang, L. A 3D fully coupled numerical model for multi-cluster fracturing with perforation erosion. Geoenergy Sci. Eng. 2025, 250, 213805. [Google Scholar] [CrossRef]

- Suo, Y.; Li, Z.-H.; Fu, X.-F.; Zhang, C.-C.; Jia, Z.-J.; Peng, D.-Z.; He, W.-Y.; Pan, Z.-J. Comprehensive study of hydraulic fracturing in shale oil reservoirs comprising shale–sandstone transitions. Phys. Fluids 2024, 36, 077161. [Google Scholar] [CrossRef]

- Li, M.-H.; Zhou, F.-J.; Wang, B.; Hu, X.-D.; Wang, D.-B.; Zhuang, X.-Y.; Han, S.-B.; Huang, G.-P. Numerical simulation on the multiple planar fracture propagation with perforation plugging in horizontal wells. Pet. Sci. 2022, 19, 2253–2267. [Google Scholar] [CrossRef]

- Feng, M.J.; Li, H.L.; Liu, H.J.; Zhou, L.; Chen, J.; Ren, X. 3d numerical investigation of hydraulic fracture network propagation in a shale gas reservoir with natural and layered discontinuities under fully hydromechanical coupling. J. Porous Media 2021, 24, 51–75. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, J.; Li, Z.; Hu, H.; Mei, Y. Numerical Simulation of Multi-cluster Fracturing Using the Triaxiality Dependent Cohesive Zone Model in a Shale Reservoir with Mineral Heterogeneity. Rock Mech. Rock Eng. 2023, 57, 1–25. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, S.C.; Xu, Y. A numerical method for simulating planar 3D multi-fracture propagation in multi-stage fracturing of horizontal wells. Pet. Explor. Dev. 2020, 47, 171–183. [Google Scholar] [CrossRef]

- Cheng, Y. Mechanical interaction of multiple fractures-exploring impacts of the spacing/number of perforation clusters on horizontal shale-gas wells. SPE J. 2012, 17, 992–1001. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Jin, X.C.; Guo, J.C.; An, F.C.; Wang, Y.H.; Lai, X. Coupled flow stress and damage modelling of interactions between hydraulic fractures and natural fractures in shale gas reservoirs. Oil Gas Coal Technol. 2016, 13, 359–390. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, X.; Tang, M.; Du, X.; Xu, C.; Tang, J.; Damjanac, B. Numerical Investigation on Hydraulic Fracturing of Extreme Limited Entry Perforating in Plug-and-Perforation Completion of Shale Oil Reservoir in Changqing Oilfield, China. Rock Mech. Rock Eng. 2021, 54, 2925–2941. [Google Scholar] [CrossRef]

- Chen, H.; Liu, H.; Shen, C.; Xie, W.; Liu, T.; Zhang, J.; Lu, J.; Li, Z.; Peng, Y. Research on Geological-Engineering Integration Numerical Simulation Based on EUR Maximization Objective. Energies 2024, 17, 3644. [Google Scholar] [CrossRef]

- Tang, J.; Wang, X.; Du, X.; Xianfei, D.U.; Bing, M.A. Optimization of integrated geological-engineering design of volume fracturing with fan-shaped well pattern. Pet. Explor. Dev. 2023, 50, 971–978. [Google Scholar] [CrossRef]

- Zeng, J.; Li, W.; Fang, H.; Huang, X.; Wang, T.; Zhang, D.; Yuan, S. The hydraulic fracturing design technology and application of geological-engineering integration for tight gas in jinqiu gas field. Front. Energy Res. 2022, 1003660. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Zhang, X.; Guo, W.; Kang, L.; Yu, R.; Sun, Y. 3D geological model-based hydraulic fracturing parameters optimization using geology-engineering integration of a shale gas reservoir: A case study. Energy Rep. 2022, 8, 10048–10060. [Google Scholar] [CrossRef]

- Bo, L.; Suoliang, C.; Sheng, Z.; Chen, Q.; Zhang, J.; Li, Y.; Liu, J. Coalbed methane gas content and its geological controls: Research based on seismic-geological integrated method. J. Nat. Gas Sci. Eng. 2022, 101, 104510. [Google Scholar]

- Ashraf, U.; Zhang, H.; Anees, A.; Zhang, X.; Duan, L. Assessment of lake-level variations to decipher geological controlling factors and depositional architecture of Lake Fuxian, Yunnan Plateau: Preliminary insights from geophysical data. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 1–26. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, X.; Jin, Y.; Yan, K.; Li, Z.; Fu, H.; Li, S. Prediction model and real-time diagnostics of hydraulic fracturing pressure for highly deviated wells in deep oil and gas reservoirs. Sci. Rep. 2025, 15, 3559. [Google Scholar] [CrossRef]

- Ashraf, U.; Zhang, H.; Anees, A.; Nasir Mangi, H.; Ali, M.; Ullah, Z.; Zhang, X. Application of Unconventional Seismic Attributes and Unsupervised Machine Learning for the Identification of Fault and Fracture Network. Appl. Sci. 2020, 10, 3864. [Google Scholar] [CrossRef]

- Cao, D.; Zeng, L.; Gomez-Rivas, E.; Gong, L.; Liu, G.; Lu, G.; Bons, P.D. Correction of linear fracture density and error analysis using underground borehole data. J. Struct. Geol. 2024, 184, 105152. [Google Scholar] [CrossRef]

- Ren, J.; Lun, Z.; Anzhu, X.; Ashraf, U.; Yin, J.; Song, H.; Su, N.; Du, B.; Anees, A. Sweet spots prediction through fracture genesis using multi-scale geological and geophysical data in the karst reservoirs of Cambrian Longwangmiao Carbonate Formation, Moxi-Gaoshiti area in Sichuan Basin, South China. J. Pet. Explor. Prod. Technol. 2022, 12, 1313–1328. [Google Scholar]

- Lei, Z.; Meng, S.; Peng, Y.; Tao, J.; Liu, Y.; Liu, H. Evaluation of the adaptability of CO2 pre-fracturing to Gulong shale oil reservoirs. Pet. Explor. Dev. 2025, 52, 1–11. [Google Scholar] [CrossRef]

- Wang, S. Optimization of fracturing construction parameters for Gulong Shale Oil with horizontal wells in Songliao Bain. Pet. Geol. Eng. 2023, 37, 94–99. [Google Scholar]

| Well | Average Fracture Length (Simulation)/m | Average Fracture Length (Actual) /m | Average Fracture Height (Simulation) /m | Average Fracture Height (Actual) /m | Cumulative Fluid Production (Simulation)/m3 | Cumulative Fluid Production (Actual)/m3 |

|---|---|---|---|---|---|---|

| Q9-X | 180 | 185 | 8 | 8.5 | 1937 | 1884 |

| Q8-X | 178 | 181 | 7.6 | 8.2 | 1910 | 1871 |

| Q6-X | 161 | 166 | 6.8 | 7.1 | 1812 | 1795 |

| Q5-X | 165 | 172 | 7.2 | 7.7 | 1846 | 1811 |

| Q3-X | 140 | 144 | 6.2 | 6.5 | 1654 | 1613 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Cai, M.; Li, J.; Guo, Z.; Jiang, X.; Dong, G. Optimization of Volumetric Fracturing Stages and Clusters in Continental Shale Oil Reservoirs Based on Geology-Engineering Integration. Energies 2025, 18, 3066. https://doi.org/10.3390/en18123066

Cao J, Cai M, Li J, Guo Z, Jiang X, Dong G. Optimization of Volumetric Fracturing Stages and Clusters in Continental Shale Oil Reservoirs Based on Geology-Engineering Integration. Energies. 2025; 18(12):3066. https://doi.org/10.3390/en18123066

Chicago/Turabian StyleCao, Jiangang, Meng Cai, Jinbo Li, Zheng Guo, Xuepeng Jiang, and Guohao Dong. 2025. "Optimization of Volumetric Fracturing Stages and Clusters in Continental Shale Oil Reservoirs Based on Geology-Engineering Integration" Energies 18, no. 12: 3066. https://doi.org/10.3390/en18123066

APA StyleCao, J., Cai, M., Li, J., Guo, Z., Jiang, X., & Dong, G. (2025). Optimization of Volumetric Fracturing Stages and Clusters in Continental Shale Oil Reservoirs Based on Geology-Engineering Integration. Energies, 18(12), 3066. https://doi.org/10.3390/en18123066