Immunological AI Optimizer Deployment in a 330 MW Lignite-Fired Unit for NOx Abatement

Abstract

:1. Introduction

- Narrow temperature operating windows (especially for SNCR);

- High reagent costs and ammonia slip risks;

- Limited adaptability to fuel quality variations or boiler aging effects.

- Deploying the SILO combustion optimization system;

- Integrating AGAM acoustic thermometry for real-time fireball profiling;

- Enhancing SNCR performance by ensuring ideal temperature zones;

- Achieving strict compliance with NOx emission limits (<200 mg/Nm3) across all operating loads using only native lignite fuel.

2. Background and Literature Review

2.1. Advanced Combustion Control

2.2. SILO—Immunological AI Combustion Optimizer

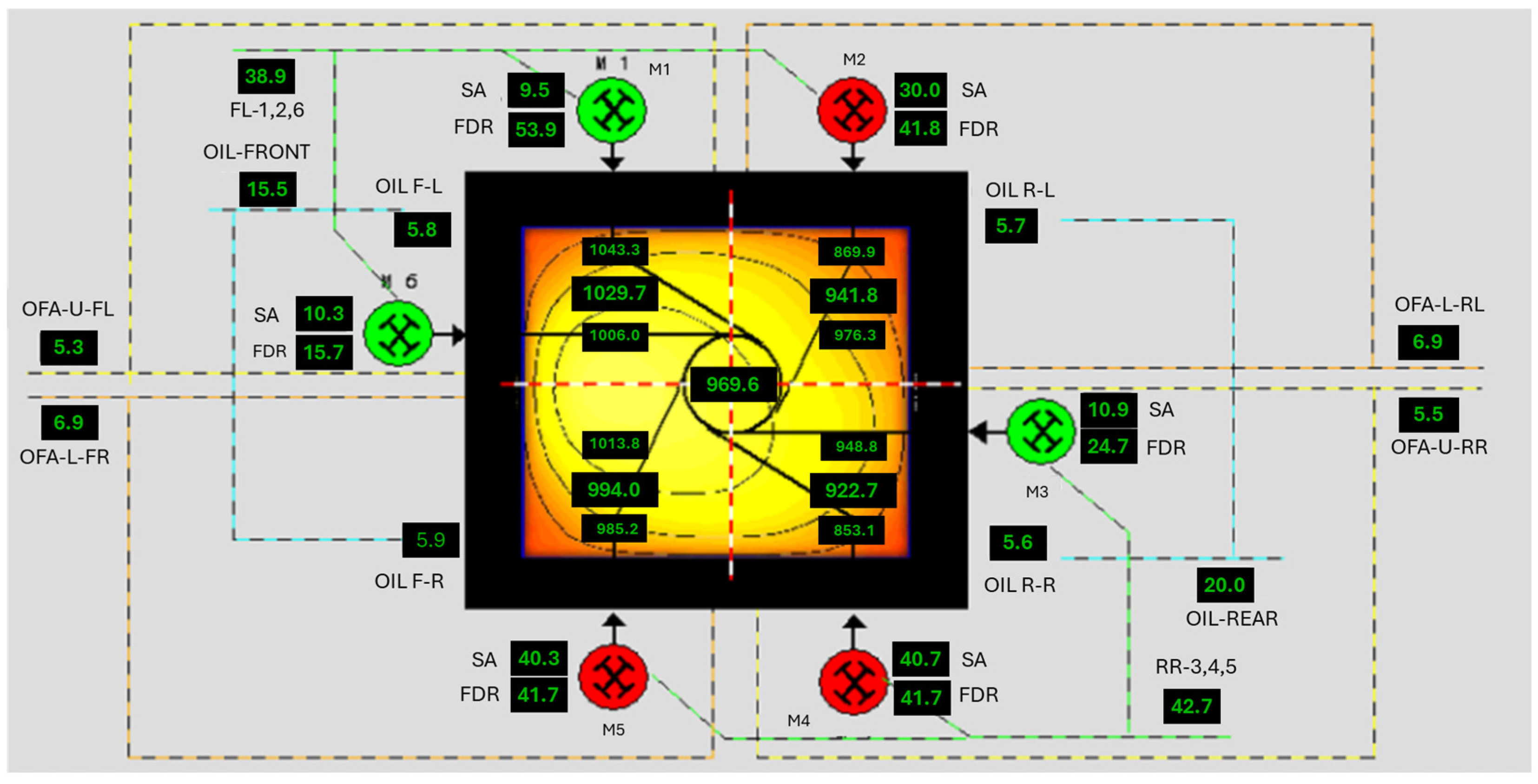

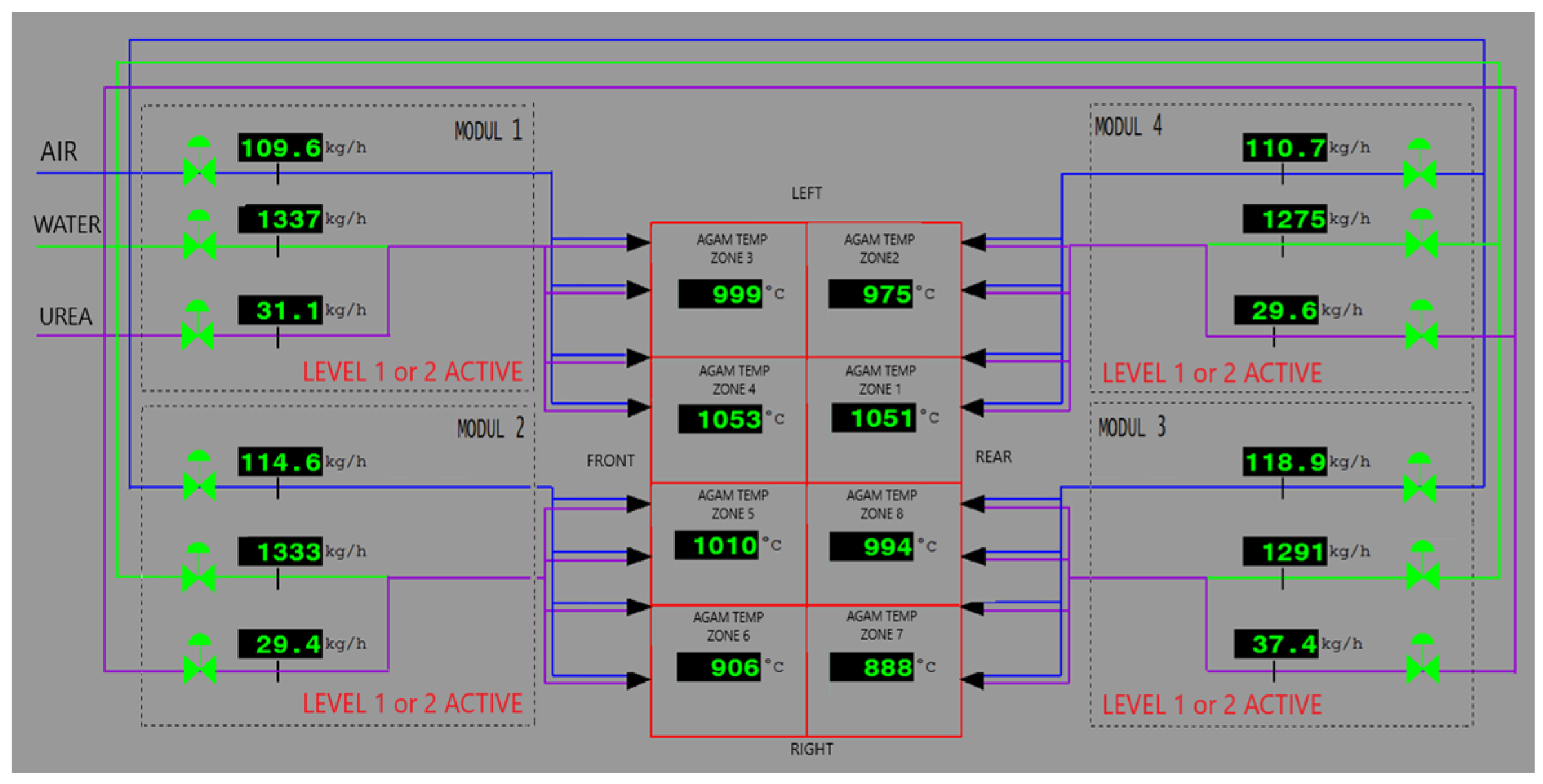

2.3. Acoustic Gas Temperature Measurement (AGAM)

2.4. SNCR: Urea-Based Mechanisms, Limitations, and Temperature Sensitivity

2.5. Gaps in Current Research and Contributions of This Work

- Real-time application of NOx formation models under varying load and coal quality;

- Dynamic combustion optimization integrating spatial furnace temperature profiling (e.g., acoustic thermometry) with intelligent setpoints;

- Seamless coordination of primary NOx control (combustion tuning) and secondary SNCR strategies under transient conditions;

- Limited integration of AI-driven systems (MPC, RL) with direct in-furnace temperature measurements for enhanced control responsiveness.

- Prioritizing primary NOx reduction via intelligent combustion and air staging;

- Creating a self-adaptive, data-driven optimization framework reacting to furnace asymmetries and NOx generation zones;

- Validating the approach on a 330 MW lignite-fired boiler, achieving NOx emissions consistently below 200 mg/Nm3 across varying loads.

3. Project Objectives

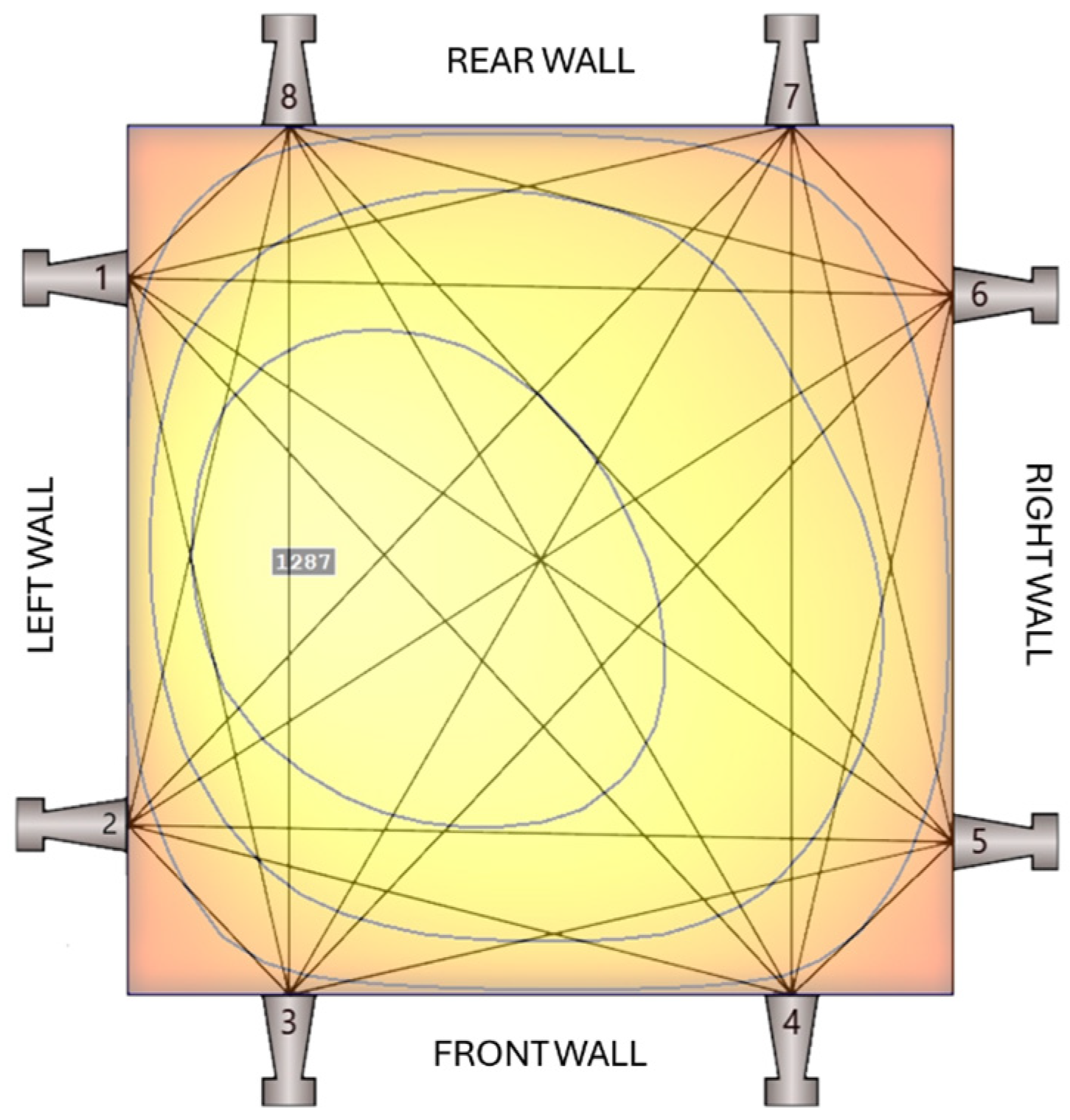

4. Boiler Configuration and Research Platform

4.1. Immunological AI Combustion Optimization System—SILO

- Twenty-five MVs, including 6 × coal feeders, 6 × secondary air dampers, 2 × general air dampers, 4 × OFA dampers, 6 × oil dampers, and 1 × oxygen setpoint bias;

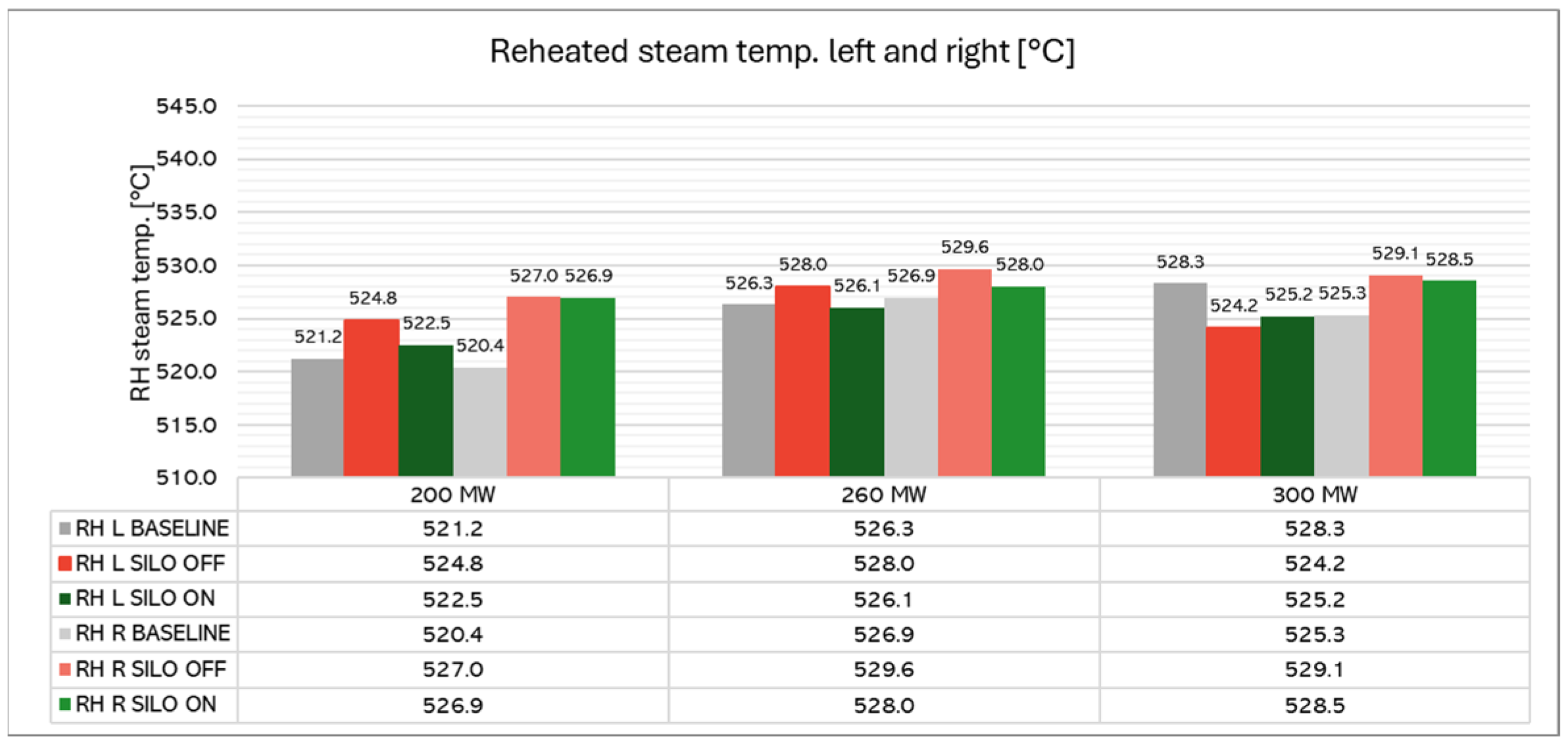

- Fifteen CVs, including NOX and CO emission, urea flow, O2 content in flue gases—left and right flue gas duct, superheated and reheated steam temperatures, gas temperatures from AGAM system—8 temperatures for 8 zones;

- Three DVs: unit load, pulverizers’ configuration, and estimated fuel quality.

4.2. SNCR Installation

5. Results and Discussion

5.1. Performance Testing Methodology

- An initial test (baseline) prior to any system upgrades;

- A final test after commissioning the SNCR installation and the SILO combustion optimization system.

- Phase 1: SNCR operational, SILO deactivated;

- Phase 2: both SNCR and SILO operational.

- Boiler load control maintained in AUTO mode with a stable load ± 5%;

- Collection of fly ash and bottom ash samples hourly;

- Automatic operation of other control loops (airflow, steam pressure, feedwater, etc.);

- No adjustments permitted to mill configurations;

- No sootblower operations allowed during the test;

- SILO combustion optimizer and SNCR systems active (only final performance test).

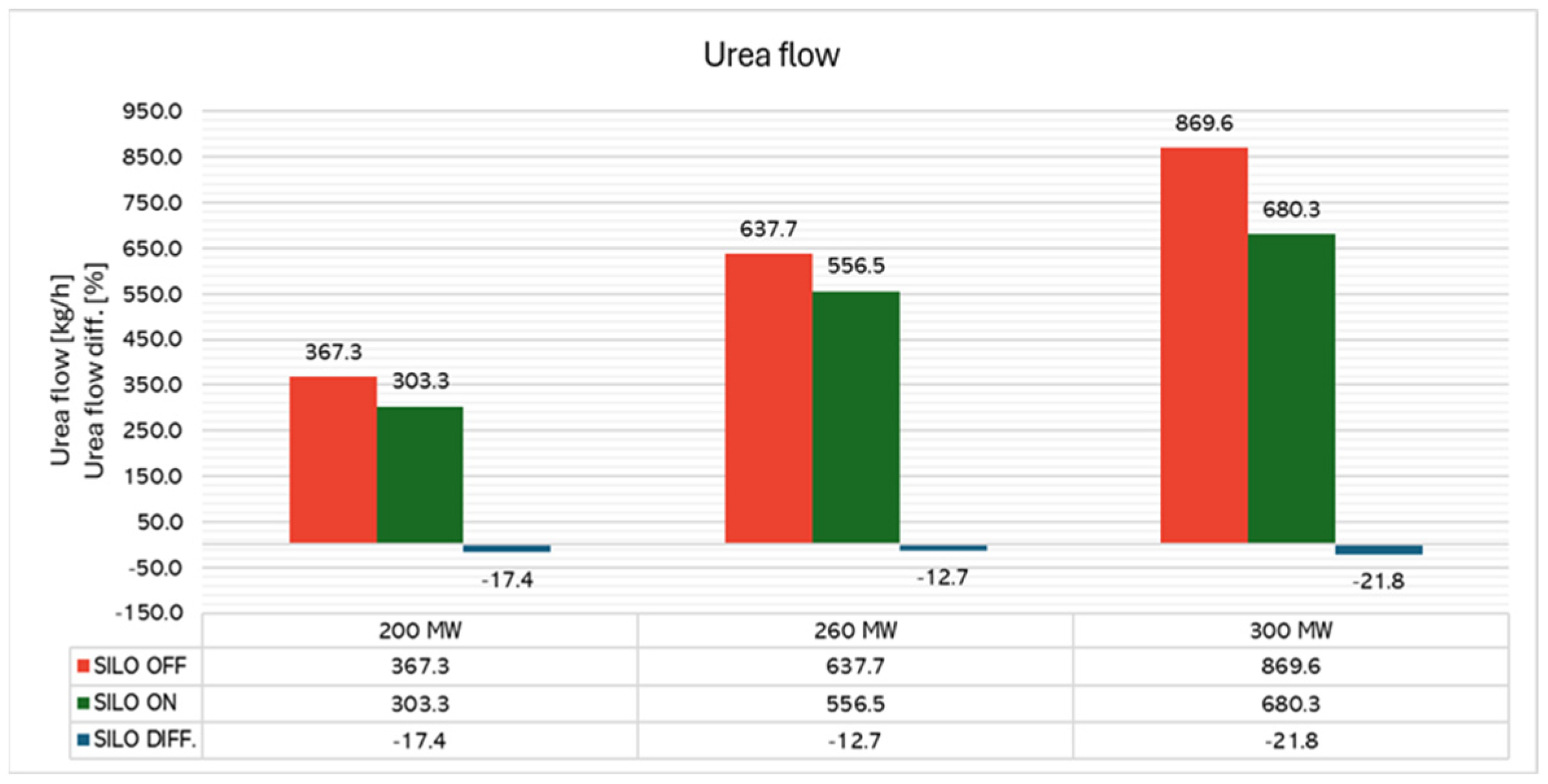

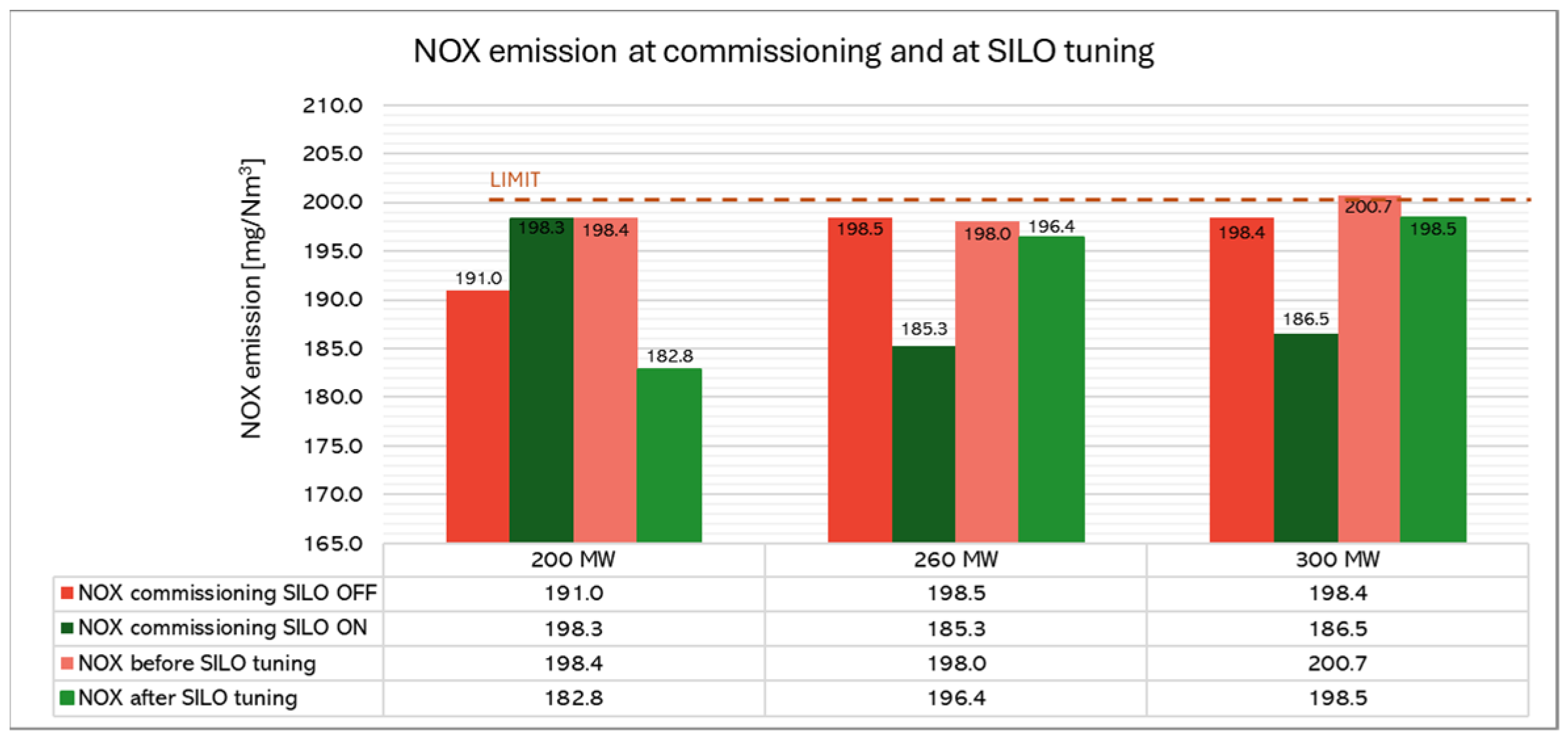

5.2. Project Results

- Average load: 246.5 MW;

- NOx emissions (corrected to 6% O2): 194.38 mg/Nm3;

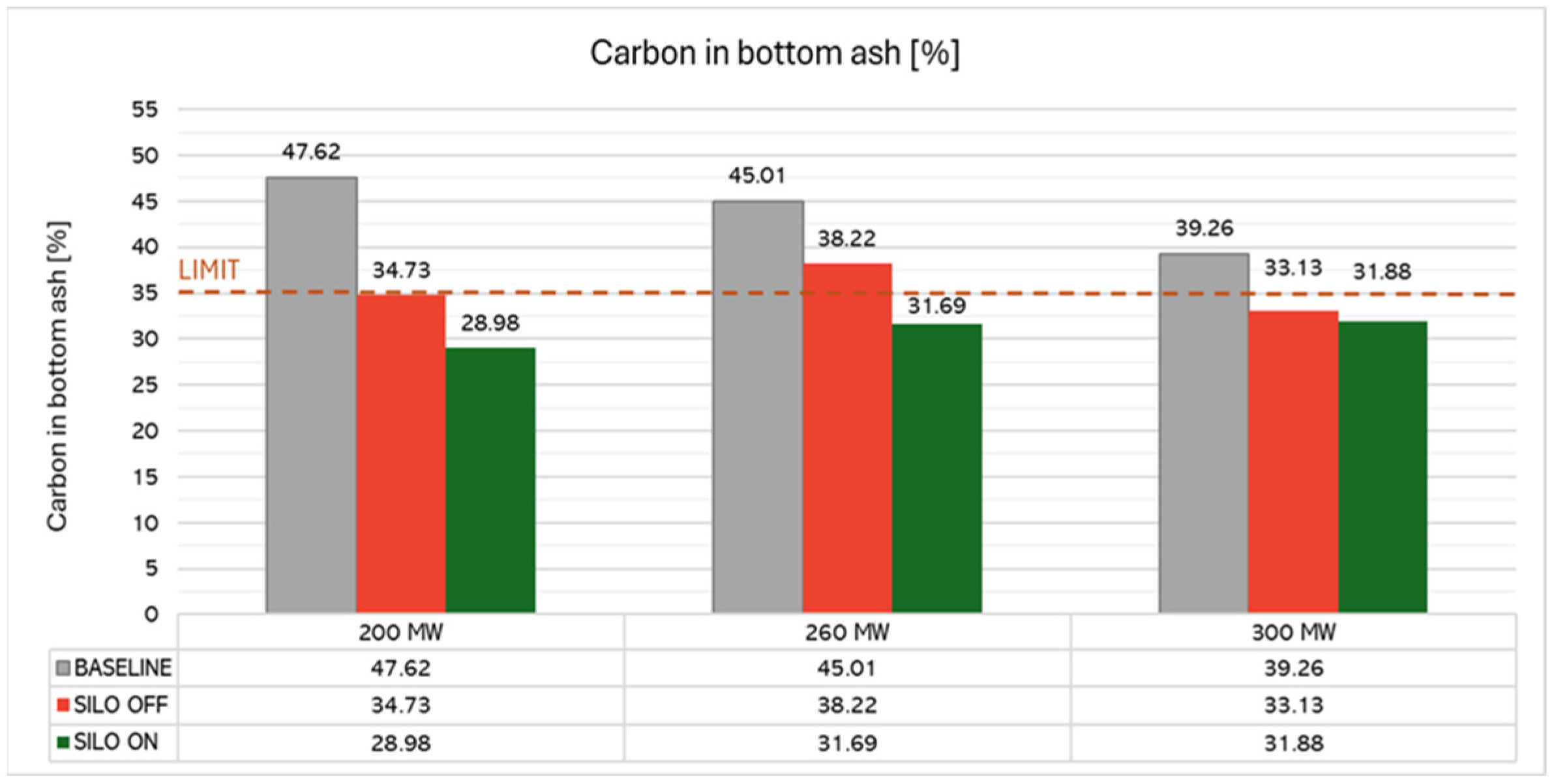

- Unburned carbon in bottom ash: 30.85%;

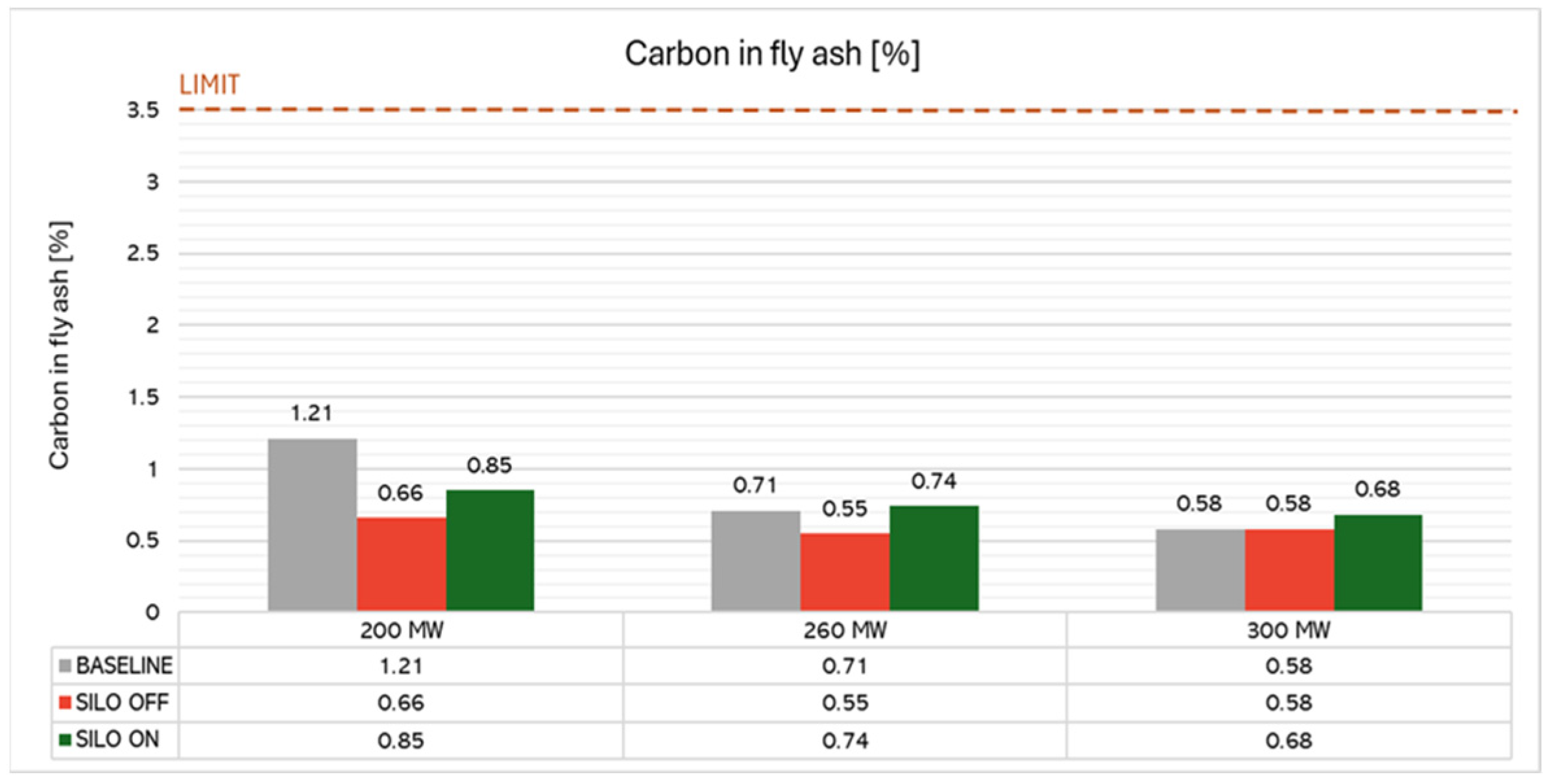

- Unburned carbon in fly ash: 0.75%;

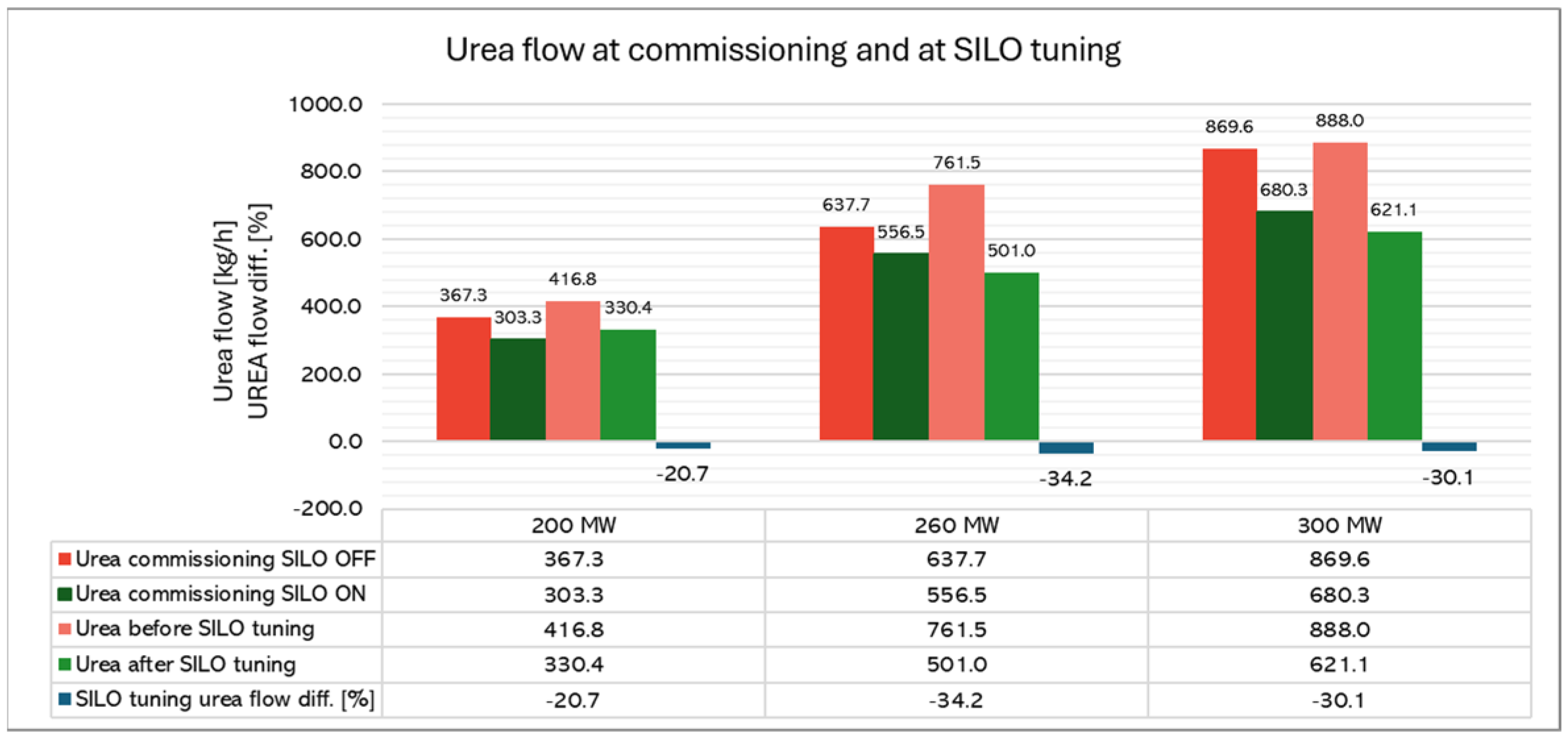

- Average urea flow: 788.5 kg/h (solid urea equivalent: 315.4 kg/h);

- Water consumption: 78.48 hl/h;

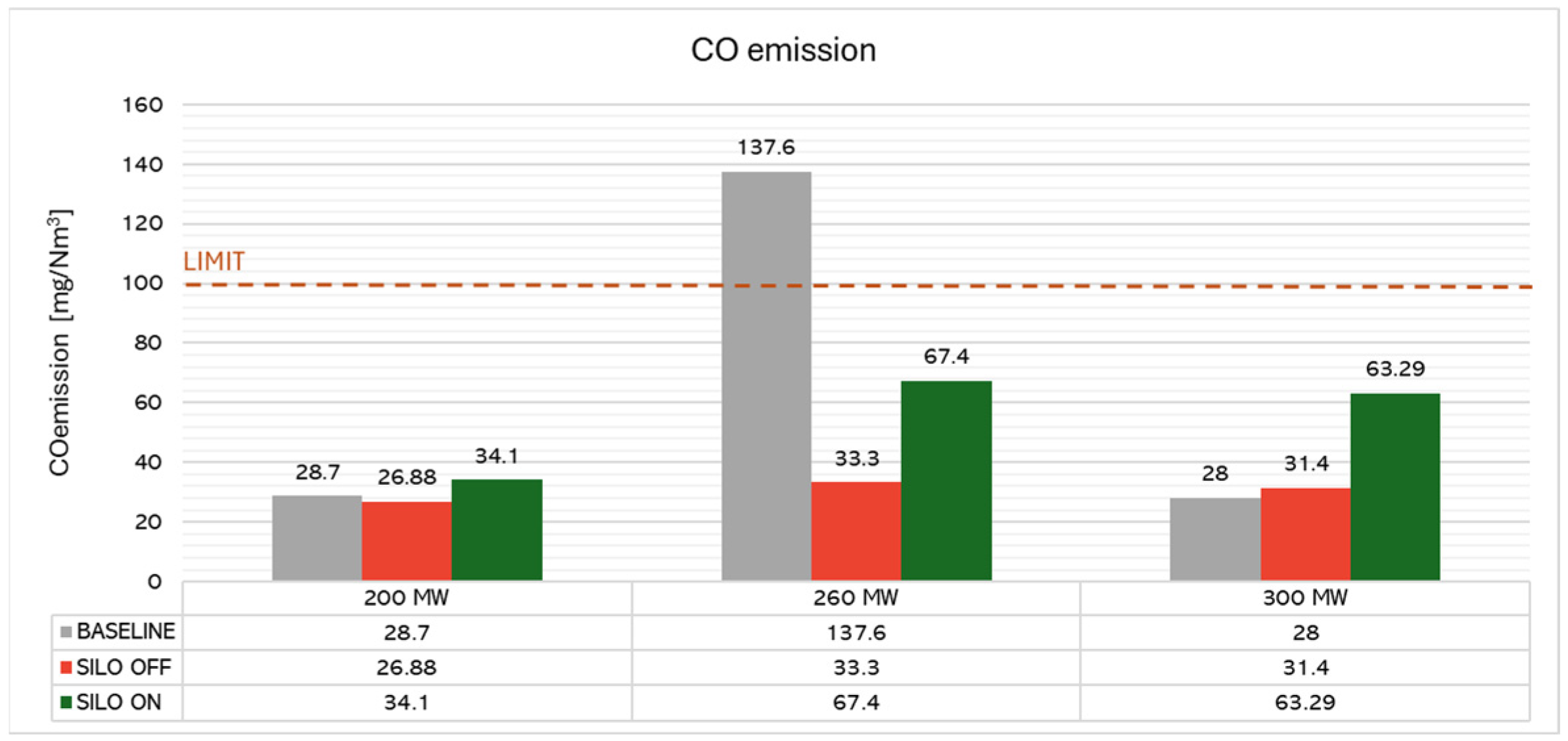

- CO emissions: 54.9 mg/Nm3;

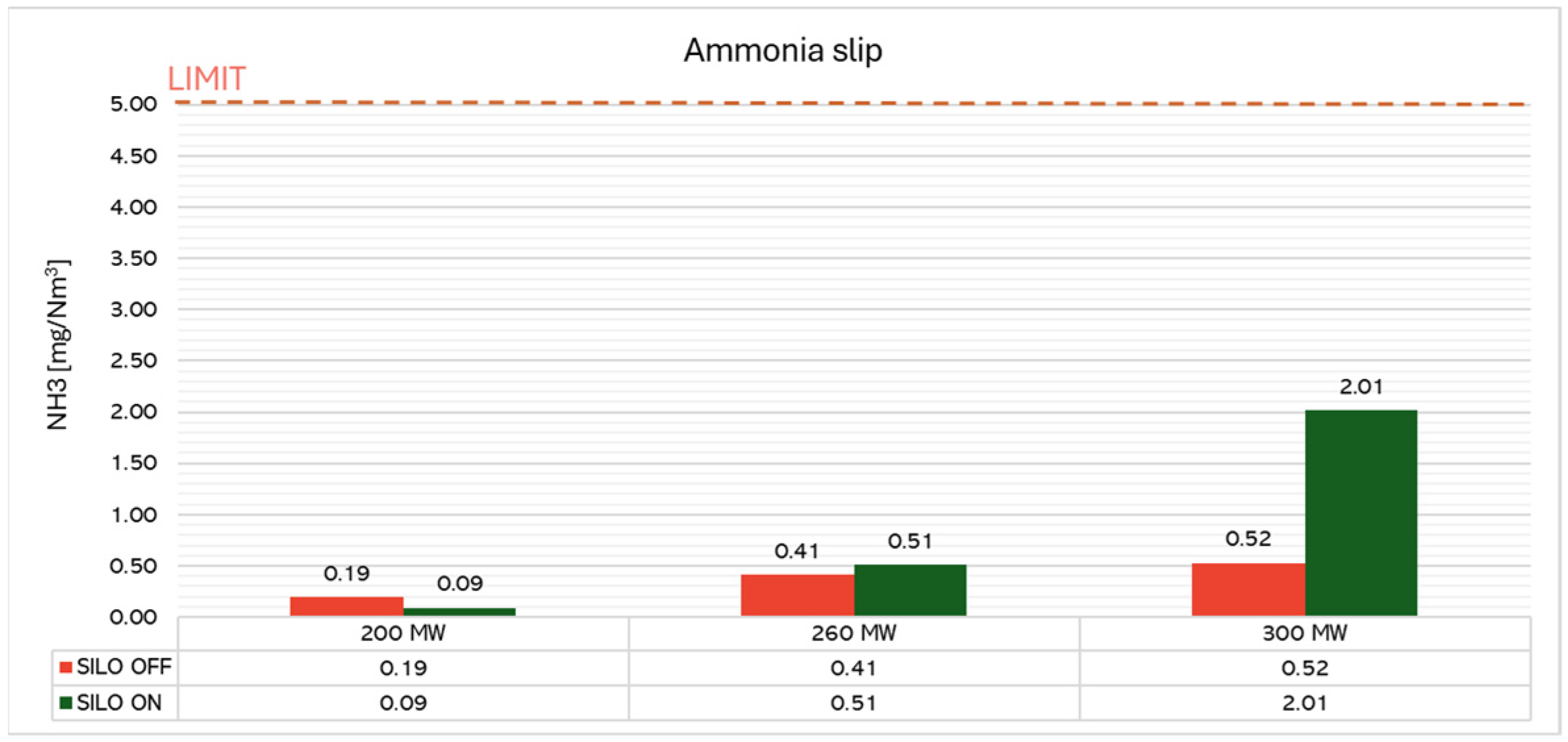

- NH3 slip: 1.05 mg/Nm3;

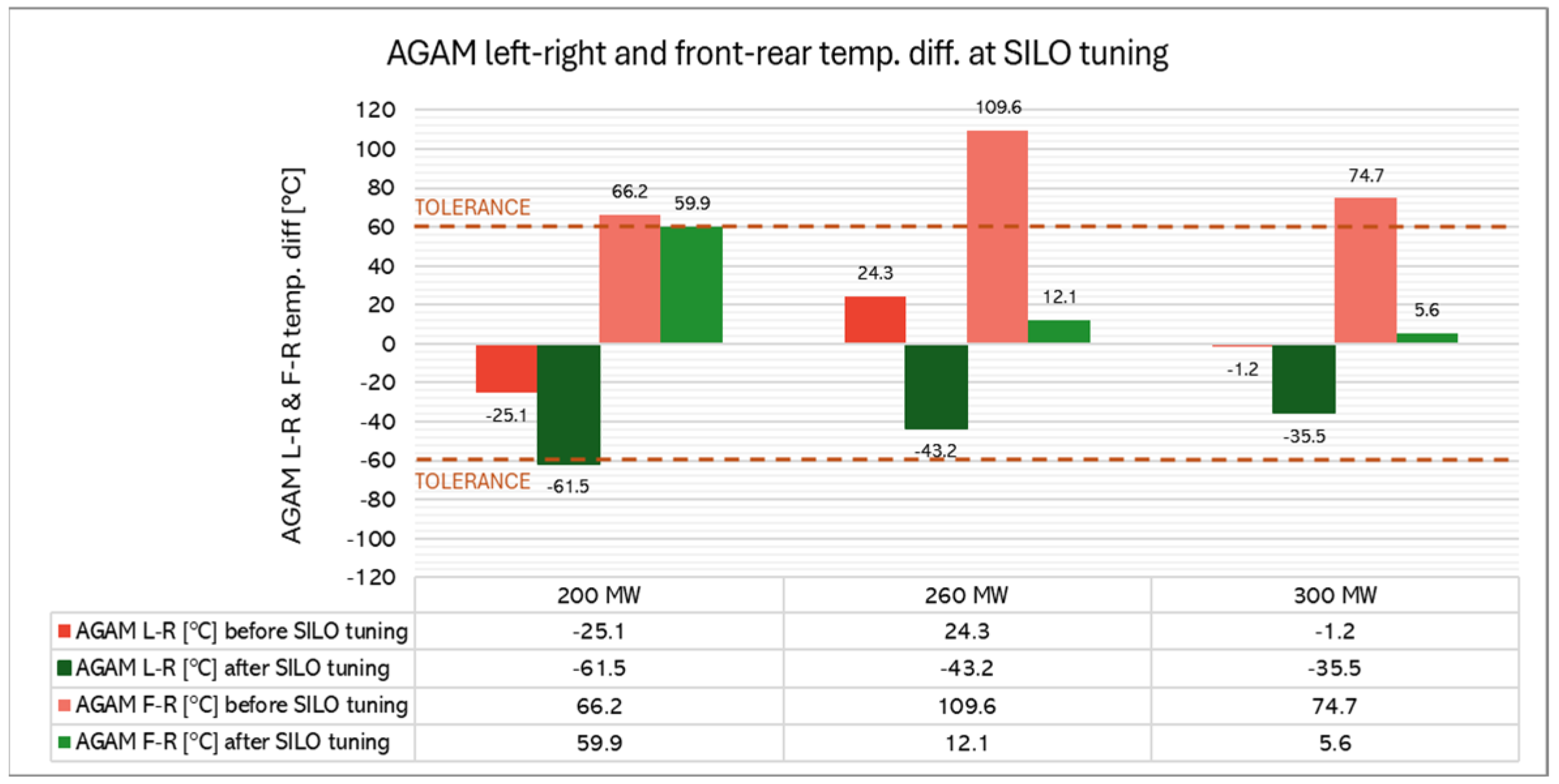

5.3. Post-Commissioning Tuning of SILO Combustion Optimizer

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SILO | Stochastic Immune Layer Optimizer |

| OFA | Over Fire Air |

| AGAM | Acoustic Gas Temperature Measurement |

| SNCR | Selective Non-Catalytic Reduction |

| DCS | Distributed Control System |

| PID | Proportional–Integral–Derivative |

| MPC | Model Predictive Control |

| J | Quality indicator |

| Linear penalty coefficient for k-th manipulated variable—MV | |

| Demand for k-th manipulated variable—MV | |

| Current value for k-th manipulated variable—MV | |

| Insensibility zone for linear penalty for k-th manipulated variable—MV | |

| Square penalty coefficient for k-th manipulated variable—MV | |

| Insensibility zone for square penalty for k-th manipulated variable—MV | |

| Linear penalty coefficient for k-th controlled variable—CV | |

| Demand value for k-th controlled variable—CV | |

| Current value for k-th controlled variable—CV | |

| Insensibility zone for linear penalty for k-th controlled variable—CV | |

| Square penalty coefficient for k-th controlled variable—CV | |

| Insensibility zone for square penalty for k-th controlled variable—CV | |

| Optimal change vector of manipulated variables—MV | |

| Matrix of the automatically identified input–output gains of the process | |

| T | Gas temperature [K] |

| Distance between particular transmitter and particular receiver [m] | |

| κ | Adiabatic coefficient [-] |

| ] | |

| Flight time [s] |

References

- International Energy Agency. Europe Energy Mix. Available online: https://www.iea.org/regions/europe/energy-mix (accessed on 28 April 2025).

- Skalska, K.; Miller, J.S.; Ledakowicz, S. Trends in NO x abatement: A review. Sci. Total Environ. 2010, 408, 3976–3989. [Google Scholar] [CrossRef] [PubMed]

- Kaya, H.; Tüfekci, P.; Uzun, E. Predicting CO and NOx emissions from gas turbines: Novel data and a benchmark PEMS. Turk. J. Electr. Eng. Comput. Sci. 2019, 27, 4696–4709. [Google Scholar]

- Fagerli, H.; Tsyro, S.; Jonson, J.E.; Nyíri, Á.; Gauss, M. Transboundary particulate matter, photo-oxidants, acidifying and eutrophying components. In 2019 NILU & EMEP Report; Norwegian Meteorological Institute: Oslo, Norway, 2019. [Google Scholar]

- Ziaja, J.; Lichota, J. Experimental results and minimizing NOX emissions’ analysis from the fluidized bed boiler of type OE700. Rynek Energii 2021, 6, 76–89. [Google Scholar]

- Zhao, S.; Peng, J.; Ge, R.; Wu, S.; Zeng, K.; Huang, H.; Yang, K.; Sun, Z. Research progress on selective catalytic reduction (SCR) catalysts for NOx removal from coal-fired flue gas. Fuel Process. Technol. 2022, 236, 107432. [Google Scholar] [CrossRef]

- Brodeck, M.; Deuster, M.; Filipowski, K.; Gancarczyk, E. Acoustic gas temperature measurement–an advanced online monitoring system for the diagnosis and improvement of the boiler operation and SNCR. In Proceedings of the 14th International Conference on Boiler Technology Poland 2022, Szczyrk, Poland, 25–28 October 2022. [Google Scholar]

- Śladewski, Ł.; Wojdan, K.; Świrski, K.; Janda, T.; Nabagło, D.; Chachuła, J. Optimization of combustion process in coal-fired power plant with utilization of acoustic system for in-furnace temperature measurement. Appl. Therm. Eng. 2017, 123, 711–720. [Google Scholar] [CrossRef]

- Hu, Z.; Fang, J.; Zheng, R.; Li, M.; Gao, B.; Zhang, L. Efficient model predictive control of boiler coal combustion based on NARX neutral network. J. Process Control 2024, 134, 103158. [Google Scholar] [CrossRef]

- QY Research. Combustion Control Optimization Solutions: Global Market Share and Ranking, Overall Sales and Demand Forecast 2025–2031; QY Research Group: Pune, India, 2025. [Google Scholar]

- Global Industry Analysts, Inc. Industrial Combustion Control Components and Systems: Market Research Report, April 2025; GIA Publications: Chicago, IL, USA, 2025. [Google Scholar]

- Dukelow, S.G. Control of Boilers, 2nd ed.; International Society of Automation (ISA): Research Triangle Park, NC, USA, 1991. [Google Scholar]

- Liang, J.; Guo, H.; Chen, K.; Yu, K.; Yue, C.; Ma, Y. A Survey on Intelligent Optimization Approaches to Boiler Combustion Optimization. CAAI Artif. Intell. Res. 2023, 2, 9150014. [Google Scholar] [CrossRef]

- Wei, H.; Liu, S.; He, J.; Liu, Y.; Zhang, G. Research on Model Predictive Control of a 130 t/h Biomass Circulating Fluidized Bed Boiler Combustion System Based on Subspace Identification. Energies 2023, 16, 3421. [Google Scholar] [CrossRef]

- Zhan, X.; Xu, H.; Zhang, Y.; Zhu, X.; Yin, H.; Zheng, Y. DeepThermal: Combustion Optimization for Thermal Power Generating Units Using Offline Reinforcement Learning. In Proceedings of the Thirty-Sixth AAAI Conference on Artificial Intelligence (AAAI2022), Virtual, 22 February–1 March 2022. [Google Scholar]

- Yan, X.; Zhao, C.; Li, X.; Wang, S.; Xiao, G. Combustion Optimization Test of "W" Flame Furnace Based on Orthogonal Experimental Design; IOP conference series. Earth Environ. Sci. 2019, 371, 32042. [Google Scholar]

- Yao, Z.; Romero, C.; Baltrusaitis, J. Combustion optimization of a coal-fired power plant boiler using artificial intelligence neural networks. Fuel 2023, 344, 128145. [Google Scholar] [CrossRef]

- Xu, W.; Huang, Y.; Song, S.; Chen, B.; Qi, X. A novel online combustion optimization method for boiler combining dynamic modeling, multi-objective optimization and improved case-based reasoning. Fuel 2023, 337, 126854. [Google Scholar] [CrossRef]

- Li, Q.; He, Q.; Liu, Z. Low NOx combustion optimization based on partial dimension opposition-based learning particle swarm optimization. Fuel 2022, 310, 122352. [Google Scholar] [CrossRef]

- Wang, Z.; Xue, W.; Li, K.; Tang, Z.; Liu, Y.; Zhang, F.; Cao, S.; Peng, X.; Wu, E.Q.; Zhou, H. Dynamic combustion optimization of a pulverized coal boiler considering the wall temperature constraints: A deep reinforcement learning-based framework. Appl. Therm. Eng. 2025, 259, 124923. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, C.; Liu, D. Data-driven based multi-objective combustion optimization covering static and dynamic states. Expert Syst. Appl. 2022, 210, 118531. [Google Scholar] [CrossRef]

- Xu, W.; Huang, Y.; Song, S. On-line combustion optimization framework for coal-fired boiler combining improved cultural algorithm, deep learning, multi-objective evolutionary algorithm with improved case-based reasoning technology. Fuel 2024, 358, 130225. [Google Scholar] [CrossRef]

- Xu, W.; Huang, Y.; Song, S.; Yue, J.; Chen, B.; Liu, Y.; Zou, Y. A new on-line combustion optimization approach for ultra-supercritical coal-fired boiler to improve boiler efficiency, reduce NOx emission and enhance operating safety. Energy 2023, 282, 128748. [Google Scholar] [CrossRef]

- Tatjewski, P. Advanced Control of Industrial Processes: Structures and Aglorithms; Springer: London, UK, 2007. [Google Scholar]

- Wojdan, K. System of Optimizing Steady-State Control of Technical Processes Inspired by Operation of an Immune System. Ph.D. Thesis, Warsaw University of Technology, Warsaw, Poland, 2008. [Google Scholar]

- Wojdan, K.; Świrski, K.; Warchoł, M.; Maciorowski, M. Conditioning of Model Identification Task in Immune Inspired Optimizer SILO. In IAENG Transactions on Engineering Technologies Volume 3; American Institute of Physics (AIP): College Park, MD, USA, 2009. [Google Scholar]

- Husson, D.; Bennett, S.D.; Kino, G.S. Remote temperature measurement using an acoustic probe. Appl. Phys. Lett. 1982, 41, 915–917. [Google Scholar] [CrossRef]

- Yan, H.; Peng, Z.; Cui, K.; Zhang, L. Acoustic Travel-time Measurement in Acoustic Temperature Field Monitoring. In Proceedings of the 2008 7th World Congress on Intelligent Control and Automation, Chongqing, China, 25–27 June 2008; pp. 4947–4951. [Google Scholar]

- Kudo, K.; Mizutani, K. Temperature Measurement Using Acoustic Reflectors. Jpn. J. Appl. Phys. 2004, 43, 3095–3098. [Google Scholar] [CrossRef]

- Deuster, M. Acoustic gas temperature measurement. In Proceedings of the Wissenforum: Temperature Measurement Technique Conference, Aldenhoven, Germany, 29–30 September 2009. [Google Scholar]

- Hill, S.C.; Douglas Smoot, L. Modeling of nitrogen oxides formation and destruction in combustion systems. Prog. Energy Combust. Sci. 2000, 26, 417–458. [Google Scholar] [CrossRef]

- Reid, I.A.B. Retrofitting Lignite Plants to Improve Efficiency and Performance; IEA Clean Coal Centre: London, UK, 2016. [Google Scholar]

- Hernik, B. Numerical Research of Flue Gas Denitrification Using the SNCR Method in an OP 650 Boiler. Energies 2022, 15, 3427. [Google Scholar] [CrossRef]

- Krawczyk, P.; Kurkus-Gruszecka, M.; Dzido, A. Numerical and Experimental Analysis of SNCR Installation Performance in a Power Stoker Boiler. Appl. Sci. 2024, 14, 8508. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Fatehi, H.; Bai, X.-S. Numerical study of the combustion and application of SNCR for NOx reduction in a lab-scale biomass boiler. Fuel 2021, 293, 120154. [Google Scholar] [CrossRef]

- Ziaja, J.; Lichota, J. Urea injection: New method for reducing NOX emissions from CFB boilers. Rynek Energii 2023, 5, 64–69. [Google Scholar]

- Locci, C.; Vervisch, L.; Benjamin, F.; Pascale, D.; Nicolas, P. Selective Non-catalytic Reduction (SNCR) of Nitrogen Oxide Emissions: A Perspective from Numerical Modeling. Flow Turbul. Combust. 2018, 100, 301–340. [Google Scholar] [CrossRef]

| Category | Indicator | Target/Requirement |

|---|---|---|

| Operational Range | Load range | 50–100% |

| Fuel type | Domestic lignite only | |

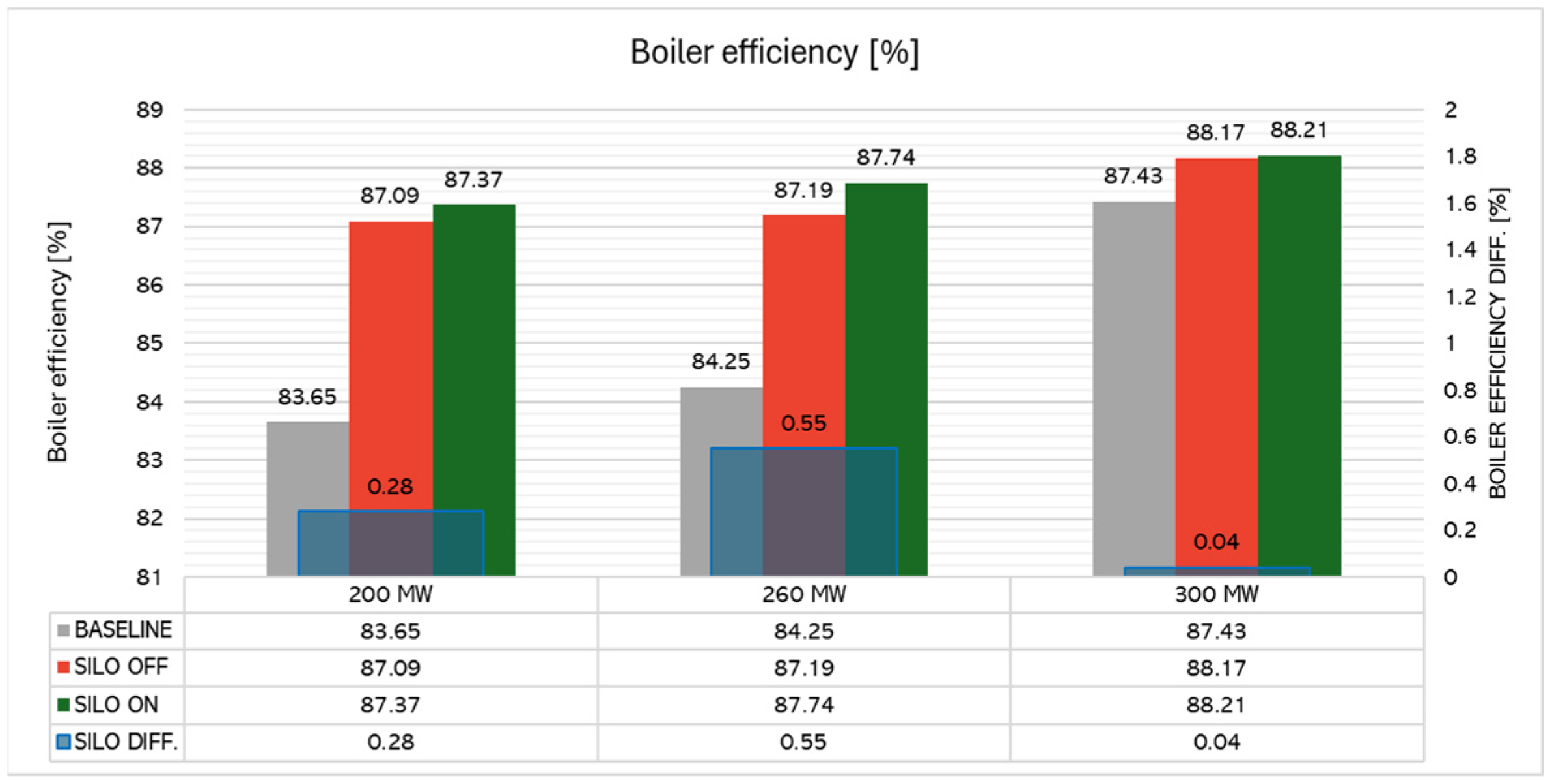

| Efficiency | Boiler thermal efficiency | ≥88.5% (rated conditions) |

| Specific fuel consumption | ≤design value | |

| Emissions | NOx emissions | ≤200 mg/Nm3 (6% O2) across all load conditions |

| CO emissions | ≤100 mg/Nm3 (Best Available Techniques (BAT) Reference Document for Large Combustion Plants) | |

| Ammonia slip | ≤5 mg/Nm3 (Best Available Techniques (BAT) Reference Document for Large Combustion Plants) | |

| Ash Quality | Unburned fuel in bottom ash | <35% |

| Unburned fuel in fly ash | <3.5% | |

| Reagent Use | Solid urea consumption for SNCR | ≤382.3 kg/h (equivalent to 955.75 kg/h of 40% urea solution) (SNCR design parameter for optimized combustion) |

| Water consumption for urea solution preparation | ≤86.4 hectoliters/hour (SNCR design parameter for optimized combustion) | |

| Cost Optimization | SNCR operation and maintenance costs | Minimized through adaptive control |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Świrski, K.; Śladewski, Ł.; Wojdan, K.; Peng, X. Immunological AI Optimizer Deployment in a 330 MW Lignite-Fired Unit for NOx Abatement. Energies 2025, 18, 3032. https://doi.org/10.3390/en18123032

Świrski K, Śladewski Ł, Wojdan K, Peng X. Immunological AI Optimizer Deployment in a 330 MW Lignite-Fired Unit for NOx Abatement. Energies. 2025; 18(12):3032. https://doi.org/10.3390/en18123032

Chicago/Turabian StyleŚwirski, Konrad, Łukasz Śladewski, Konrad Wojdan, and Xianyong Peng. 2025. "Immunological AI Optimizer Deployment in a 330 MW Lignite-Fired Unit for NOx Abatement" Energies 18, no. 12: 3032. https://doi.org/10.3390/en18123032

APA StyleŚwirski, K., Śladewski, Ł., Wojdan, K., & Peng, X. (2025). Immunological AI Optimizer Deployment in a 330 MW Lignite-Fired Unit for NOx Abatement. Energies, 18(12), 3032. https://doi.org/10.3390/en18123032