1. Introduction

Stricter global legislation regarding CO

2, particulate, and NO

x emissions from motor vehicles call for drive types that, in contrast to internal combustion engines, can be operated largely free of pollutants [

1,

2,

3]. To this end, green hydrogen, which is generated from the overproduction of electricity from renewable energies, could be used as an energy source in the vehicle. Using a fuel cell, the hydrogen can be converted into electricity on board of a vehicle. The electricity produced can then be used to power electric motors with a high degree of efficiency, simultaneously almost exclusively emitting air and water. In these fuel cell electric vehicles, the hydrogen is stored in hydrogen tanks, which have a high gravimetric and volumetric energy density compared to batteries [

4]. This results in an advantage over battery electric vehicles (BEV) wherever a large amount of energy has to be stored in the vehicle; for example, use-cases with high total weight or where large distances need to be overcome without the possibility to recharge. Following the introduction of series-produced passenger cars such as the Hyundai Nexo [

5] and the Toyota Mirai [

6], which demonstrate the maturity of the technology, other vehicles such as the Honda CR-V [

7] or Opel Movano [

8] are about to enter the market.

Due to its quick-start capability and high durability, polymer electrolyte membrane fuel cells (PEMFCs) are typically used for vehicles, which convert hydrogen into electric power for the drive system. The central component of the PEMFC is a synthetic membrane that is impermeable to electrons but conducts protons oxidized from hydrogen. In addition, catalytic materials are applied to the electrodes of the PEMFC to accelerate the desired cell reaction and thus increase cell efficiency. However, in addition to the low availability of green hydrogen and a currently limited supply infrastructure, there are also challenges regarding the thermal management of FCEV: The chemical stability of the described components, as well as the membrane humidification to maintain the proton transport mechanisms and hence efficient operation of the cell, are strongly temperature-dependent. Depending on the pressure level, state of health and efficiency suffer from excessive temperatures outside the usual temperature window of 65–80 °C in relation to the coolant outlet temperature at the stack. To protect these components and the functionality of the fuel cell stack, the operating temperature must therefore be controlled and limited. For this purpose, liquid coolant is usually passed between the bipolar plates of each cell, which electrically couples the individual cells of the stack together. Due to the low material thickness of the cells coming with short heat transfer paths from the reaction layer to the coolant, and due to limited possibilities to directly measure the temperature within the cells of the stack, the coolant temperature is used as the representative operating temperature. However, since the heat is generated in the reaction zone near the catalyst, the actual temperature in the solid material must be higher than the coolant temperature.

One challenge of the thermal management system is the operation of the fuel cell system in regions where sub-zero ambient temperatures occur since the water within the system can be present in its solid form, impeding the operation of the stack until a certain operating temperature is exceeded. In order to overcome this challenge, recent research focuses on two strategies, either avoiding ice formation [

9] or actively supporting the heat-up procedure [

10].

Another challenge is the possible overheating of the fuel cell stack when operating the vehicle in hot climate zones: compared to combustion engines, which have to dissipate a similar amount of heat via the cooling water, the maximum cooling water temperature is reduced by roughly 30 °C at the outlet of the fuel cell stack. Following the heat exchanger equation for cross-flow heat exchangers, the heat flow that can be dissipated from the cooling water to the environment is determined by the inlet temperature differential

(ITD), as described in Equation (

1):

with the operation characteristic

for cross-flow heat exchangers and the minimum heat capacity flow

of the two fluids. Therefore, the reduced cooling water temperature at the radiator inlet in vehicles with a fuel cell drive results in a lower dissipatable heat flow. In order to still be able to dissipate sufficient heat from the system, the cooling surfaces or the heat transfer factor needs to be increased. This is not possible for vehicles based on the current platforms without considerable effort or changes to the overall vehicle design. If the heat dissipated by the vehicle radiator is no longer sufficient to compensate for the heat production of the stack, there is a risk of the stack overheating, resulting in accelerated aging or reduced efficiency, as described above. This is particularly to be expected at operating points like uphill driving, where high ambient temperatures occur in addition to high wheel power and low air volume flow. In this case, monitoring of the stack reduces the electrical power produced by the stack and thus leads to a shift to more efficient operating points with lower heat dissipation rates, known as thermal derating. The full rated power of the drivetrain is no longer available to the driver of the vehicle, resulting in reduced acceleration and maximum velocity if the hybridization battery cannot compensate for the lack of electrical power. If one considers not only the short-term deviation from the usual vehicle performance—which means losses in driving function and also in safety when overtaking—but also long-lasting power reductions due to the temperature limits, which have an influence on the payload-distance of a vehicle in a specific time, this problem represents a major challenge in the commercial introduction of fuel cell drives.

Though thermal management of FCEVs in general [

11,

12] and cooling of the fuel cell stack in detail [

13,

14,

15,

16,

17,

18] are the subject of the current research, few specific studies exist on the cooling performance of a FCEV cooling module: Lee et al. conducted an evaluation of the cooling performance of the stack radiator in a fuel cell vehicle under real-world driving conditions at an ambient temperature of 35 °C [

19]. Their study involved the use of 12 anemometers positioned downstream of the stack radiator, though details regarding the specific measurement technique were not provided. The presented graphs illustrate the relationship between vehicle driving speed and frontal air velocity; however, additional data on the corresponding fan speed could further enhance the interpretation. Furthermore, the heat rejection rates of the stack radiator were derived from simulations, although the results for maximum coolant flow rates were not explicitly shown. Gong et al. investigated the flow and heat transfer characteristics of two fuel cell vehicles, Roewe 950 and Toyota Mirai, with focus on the intake grilles and opening angle of the radiator fins [

20]. The boundary conditions of their 3D computational model included high ambient temperatures of between 300

and 320

, whereas the coolant flow rates varied between 45.6

and 76

. A comparison with experimental results were not provided. Doppler et al. presented a methodology for sizing heat exchangers for fuel cell trucks, also including the influence of the ambient temperature [

21]. Their work is based on stationary calculations as well as dynamic simulations, though comparison with experimental investigations was not given.

Regarding the experimental investigation of the fuel cell system of FCEVs, Di Pierro et al. characterized the Hyundai Nexo for three different dynamic drive cycles [

22]. Their study focused on the electrical powertrain behavior in order to deliver validation data for vehicle modeling. Investigation of the thermal management system is left open for future studies. The same research group also points out the problem of assessing how FCEVs perform under various real-world operating conditions, with special focus on the energy consumption and efficiency [

23]. They also provided a new formulation of overall efficiency of FCEVs, including different energy sources as an extension to the Society of Automotive Engineers (SAE) vehicle efficiency method and applying the method in comparison to BEVs. Dynamic tests were performed in the laboratory as well as on the road with ambient temperatures of up to 35 °C. The influence of ambient temperature was evaluated on a vehicle system level, not providing the detailed information necessary to model the effects of climatic conditions on the fuel cell system or cooling system. Sery and Leduc studied different methods for measuring hydrogen consumption of the Hyundai Nexo on various mission profiles on a chassis dynamometer [

24]. Their study considered different steady states regarding fuel cell stack and systempower but did not consider varying boundary conditions like change in ambient temperature. Lohse-Busch et al. studied stack and system efficiency at up to 35 °C ambient temperature with a solar loading of 850

[

25]. For these conditions, a reduction in stack power was observed depending on road grade and cooling conditions. The vehicle used was a Toyota Mirai of the 1st generation, which is not state-of-the-art anymore. Wang et al. studied the environmental adaptability of a Hyundai Nexo in cold start and high-temperature scenarios [

26]. They provided a heat balance analysis for two continuous hill-climbs with 40 °C ambient temperature and compared the results with a vehicle simulation model. The same research group also considered dynamic drive cycles for FCEV tests, though they did not focus on high-temperature conditions [

27,

28].

In addition to experimental studies, models of both the fuel cell system and thermal management of FCEVs are often used in order to make predictions for thermal limitations. Haraldsson and Alvfors studied the effects of ambient conditions on the FCEV efficiency up to a temperature of 40 °C using a vehicle model in ADVISOR [

29]. They found an influence of ambient air temperature and relative humidity on vehicle performance as well as high altitude. Liu et al. investigated the influence of ambient temperatures on the stack performance using a simulation model [

30]. They found that a higher working temperature would benefit peak power output and efficiency. The results on the fuel cell system or at vehicle level were not shown. Anselma et al. studied the optimal thermal management strategy used in FCEVs, including detailed modeling of single BoP components [

31]. An ambient temperature of 40 °C was taken into account when analyzing WLTCs that were run several times in succession.

Thermal derating of FCEV in particular is rarely considered in scientific publications. Gilles and Peissner included a limit for thermal derating in the thermal management strategy of their overall vehicle model [

32]. The focus of the work was on the derivation of thermally demanding load cases for FCEV based on fleet data. Hahn et al. set up a model predictive control (MPC)-based fuel cell model with a detailed air system in order to show the ability of the MPC to maintain stable operation while realizing a thermal derating strategy [

33]. They assumed a maximum temperature limit of 80 °C, after which thermal derating was applied.

In order to overcome the limitations of the cooling module radiator, spray cooling has been the focus of research in the last years: while Wagenblast et al. [

34] and Lee et al. [

35] studied radiator spray cooling for a FCEV truck, Park et al. [

36] tested spray cooling in a climate chamber heated up to 45 °C ambient temperature with the aim of reducing the effect of thermal derating for a passenger car with fuel cell drive. Furthermore, Souby et al. [

37] focused on the general performance of spray cooling while Prakabaran et al. [

38] investigated intermittent spray cooling in contrast to continuous spray cooling with regard to application in FCEVs.

To summarize the above studies, the influence of ambient temperature on the efficiency of the fuel cell systems used in vehicles needs to be further explored experimentally. Moreover, the issue of thermal derating of FCEVs is solely addressed in simulation studies, yet the strategy employed remains unspecified. The objective of this study is to address this research gap of lacking experimental data regarding thermal derating and specifically contribute to the field in the following manner:

Identification of the heat rejection of the cooling module of a series-produced fuel cell vehicle as a function of vehicle speed;

Determination of the effect of ambient air temperature on the fuel cell system and stack performance of a FCEV;

Examination of the derating strategy of series-production vehicle;

Description of the occurrence of derating during a dynamic driving cycle on a chassis dynamometer.

For this purpose, a new method for determining the average cooling air velocity at the vehicle radiator is introduced, which is not found in the literature in this form. Similarly, the influence of the ambient temperature on the efficiency of the fuel cell stack and system for a production vehicle has not yet been investigated at the vehicle level. A method for detecting thermal derating of an FCEV on a chassis dynamometer adds to the novelty of this study and can be used in future extended studies aiming to answer the research question of whether and to what extent there are limits to the use of FCEVs in hot climate conditions due to limitations of the thermal management system.

3. Results and Analysis

If the heat rejection at the radiator balances the heat flow from the stack to the cooling water, the condition for a stationary operating temperature of the fuel cell stack is fulfilled. If the inlet temperature of the cooling water at the stack increases due to insufficient heat rejection at the radiator, as shown in Equation (

1), the heat transferred from the stack to the cooling water is reduced, and the stack heats up. When the temperature of the fuel cell increases, degradation processes also increase. In order to avoid damage to the fuel cell, the fuel cell control unit reduces the power output of the fuel cell, called thermal derating. In the following, the maximum heat rejection of the HT-radiator as the largest heat sink is described, as well as the influence of ambient conditions on the fuel cell stack acting as the largest heat source within the vehicle system. All error bars presented show the repeatability error based on one standard deviation. The evaluation of thermal derating during a real driving scenario is described in the final subsection.

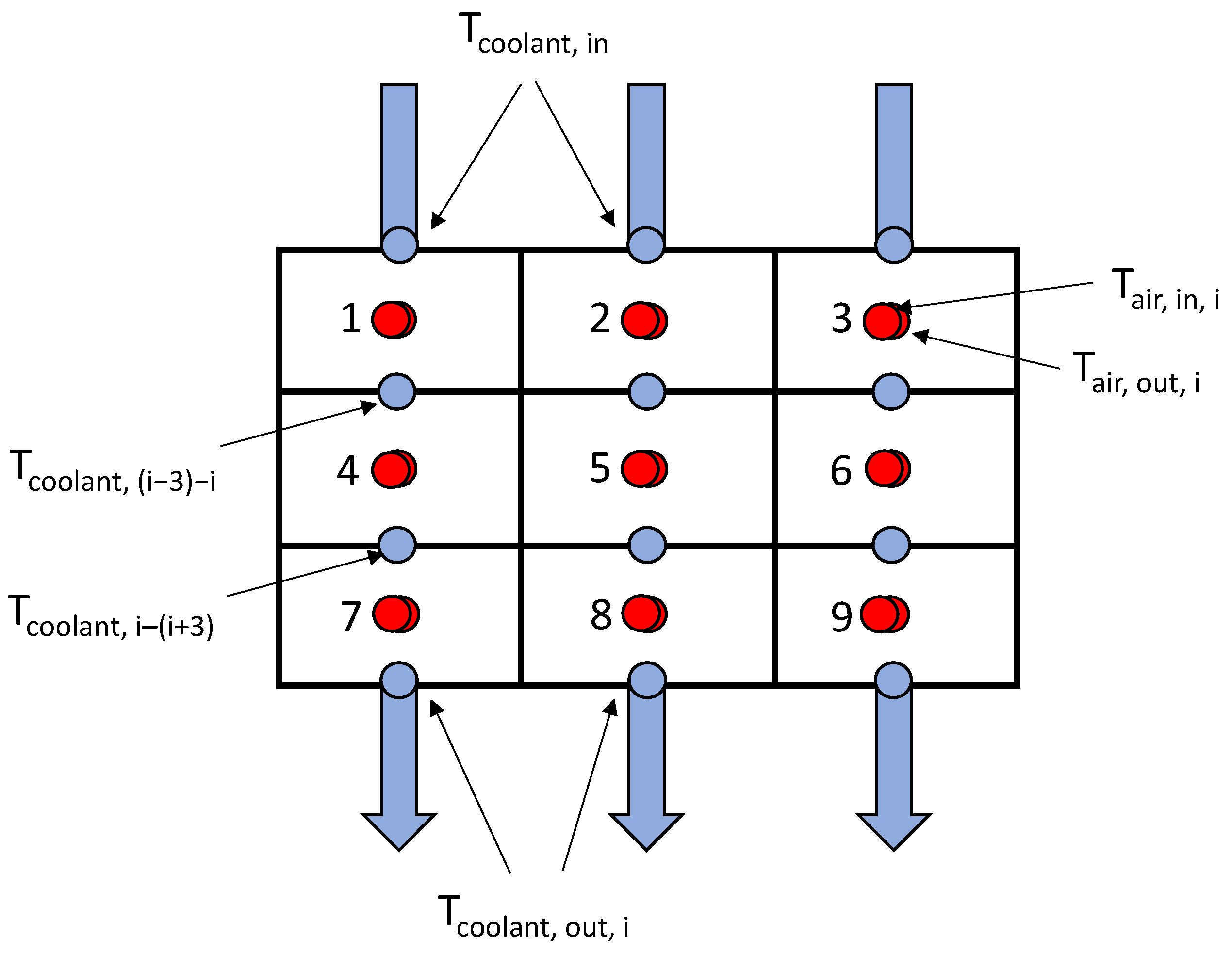

3.1. Cooling Module

At a stationary operating point, the heat absorbed by the cooling air corresponds to the heat of the fuel cell removed by the coolant. The corresponding energy balance is defined as follows:

Combining Equations (

8) and (

9) with Equation (

10), it can be seen that due to the lower heat capacity flow of the cooling air, the temperature change in the cooling air is significantly higher than for the liquid coolant, hence reducing the available heat transfer rate at the radiator according to Equation (

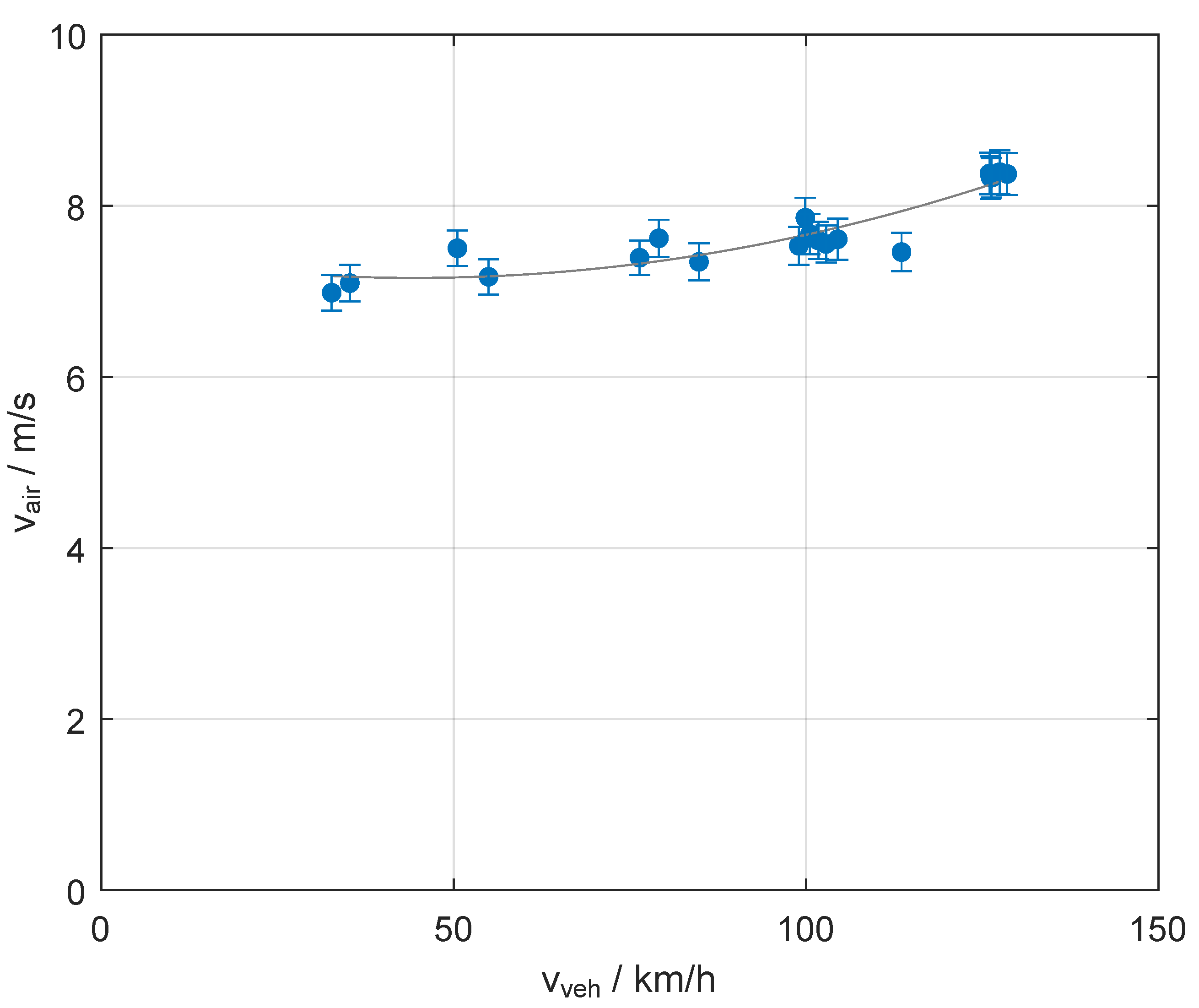

1). The heat capacity flow of the cooling air can be increased by increasing the cooling air velocity through the cooling module. In

Figure 3, the mean velocity of the cooling air flowing through the HT-radiator is shown, depending on the vehicle speed. The entire cooling module consists of an LT-radiator, refrigerant condenser, HT-radiator, and two high-voltage cooling fans of 1.73

electrical power each.

The two radiator fans were at a maximum speed of 4200 rpm for the operating points presented. The cooling air velocity based on an energy balance at the radiator walls was averaged over a minimum time window of 20

, for which a constant operating point of the vehicle was observed. Vehicle speeds lower than 30

were not examined since they are not expected to be critical for the thermal management system, and wind speeds lower than 20

cannot be provided. Between 30 and 130

, the dependency of the cooling air velocity from the vehicle speed is expected to be a quadratic relationship. However, the increase in cooling air velocity is very limited with increasing vehicle speed and therefore could also be linearized in the range from 30 to 100

. This observation is in contradiction with other studies, e.g., from Gilles and Peissner, where the driving speed is expected to largely contribute to the cooling air velocity [

32]. The underlying reason for these contrasting observations probably lies in the high-voltage fans, which are expected to have a large influence on the cooling airflow compared to typical 12

radiator fans with electrical power consumption significantly lower than 1

.

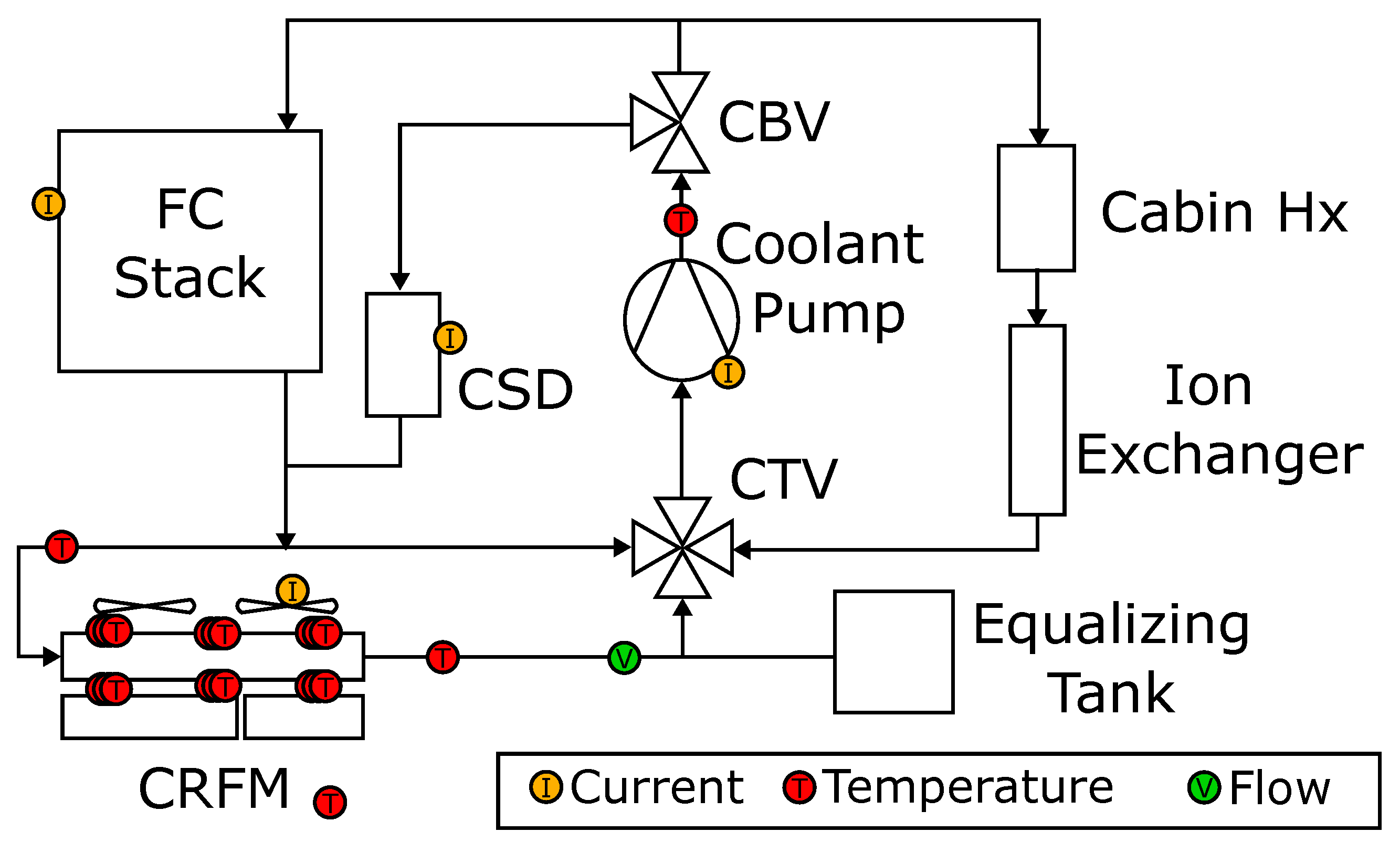

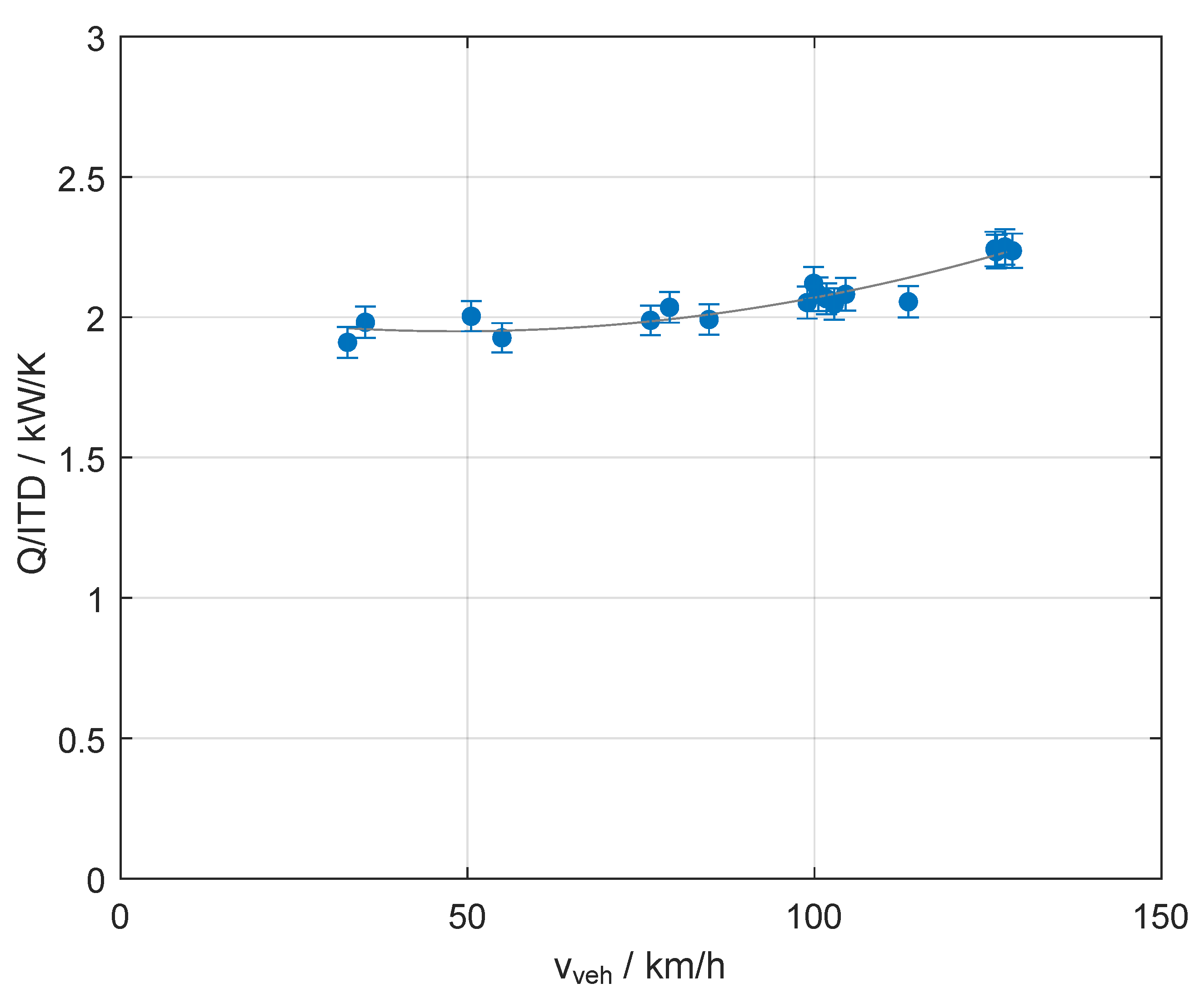

The influence of the predominantly speed-independent cooling airflow is also reflected in the heat rejection of the cooling module in relation to the inlet temperature differential, as shown in

Figure 4. Considering ITD allows the maximum heat transferred to the environment to be analyzed independently of ambient temperature and preheating effects by the LT-radiator and condenser. In addition to operation at maximum fan speeds, the operating points shown have been determined at maximum coolant flow to ensure that the maximum heat rejection for each distinct vehicle speed is determined.

Similar to

Figure 3, the heat transfer at the radiator is mainly independent from the vehicle speed in a range from 30 to 100

. For vehicle speeds exceeding 100

, an increase in heat rejection can be observed. In this operating range, the influence of the driving speed on the cooling airflow also increases. In addition to the findings described above, the results could also be used to validate an underhood flow model as, e.g., a 1D-model described by Navaneeth et al. [

42].

Compared to the literature [

19], the results shown here indicate that the installation of high-power fans is beneficial in terms of heat rejection over a large range of vehicle speeds with a heat rejection per inlet temperature differential of approximately

. The installation of even more powerful fans might additionally increase the cooling capability, though the higher cost of fans as well as nonlinear flow resistances should be considered for this decision.

The results found can also help to predict the system behavior in driving conditions not investigated in this paper. In stop-and-go traffic, for example, the cooling air volume flow must be provided by the fans alone due to the low vehicle speed. If one extrapolates a constant value of around 2 for low speeds to standstill, the air inlet temperature could rise to 60 °C without causing the stack to heat up when assuming a heat production lower than 10 for idle power and a stack outlet temperature of 65 °C.

3.2. Fuel Cell System

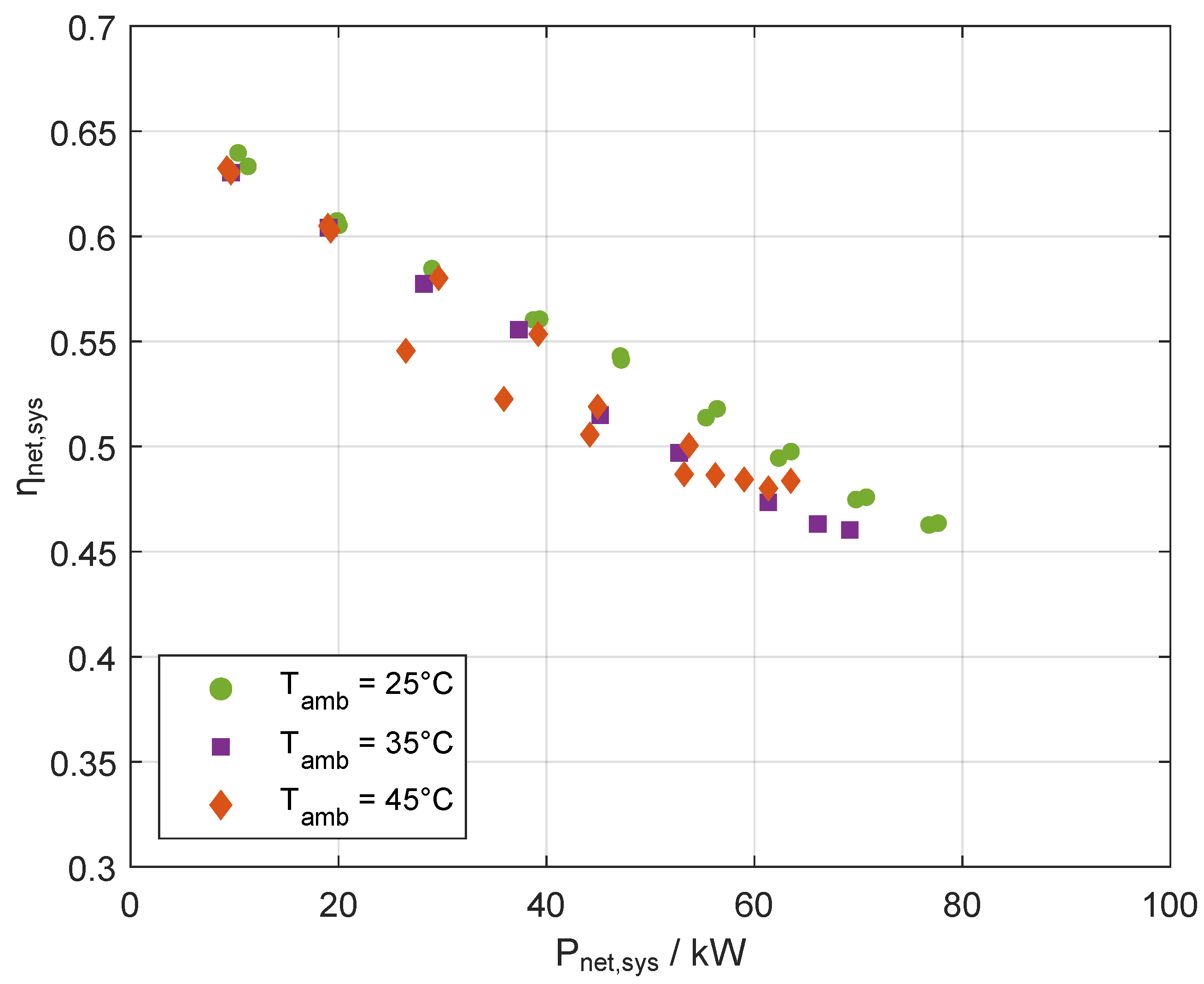

In the following, the fuel cell stack is examined, as it is the largest heat source of the thermal management system of an FCEV. In

Figure 5, the system efficiency, as defined in Equation (

6), dependent on the ambient temperature, is plotted against the net electrical power output of the system.

An effect of the ambient temperature can be observed, though a clear trend with increasing ambient temperatures is not recognizable. An ambient air temperature of 25 °C seems to be best in terms of efficiency over the whole range, indicating that higher temperatures than that are not beneficial for fuel consumption. In general, efficiency differences up to 5% occur. The differences observed result from the power consumption of the EAC and the components of the HT cooling system: at high ambient temperatures, the air density and thus the mass flow conveyed by the EAC decreases. However, in order to supply the cathode side of the reaction layer with sufficient air for the reaction, the EAC must be operated at a higher load operating point, which leads to higher auxiliary consumption in the fuel cell system. On the other hand, the coolant temperature increases with increasing ambient temperature, resulting in the multi-level controllers demanding higher electrical power consumption of cooling pump

and fans

in order to increase heat transfer. According to Equation (

5), the power of BoP

increases, resulting in a lower system efficiency. System efficiencies can therefore only be inadequately described by a single characteristic curve, especially during dynamic operation and under changing ambient conditions.

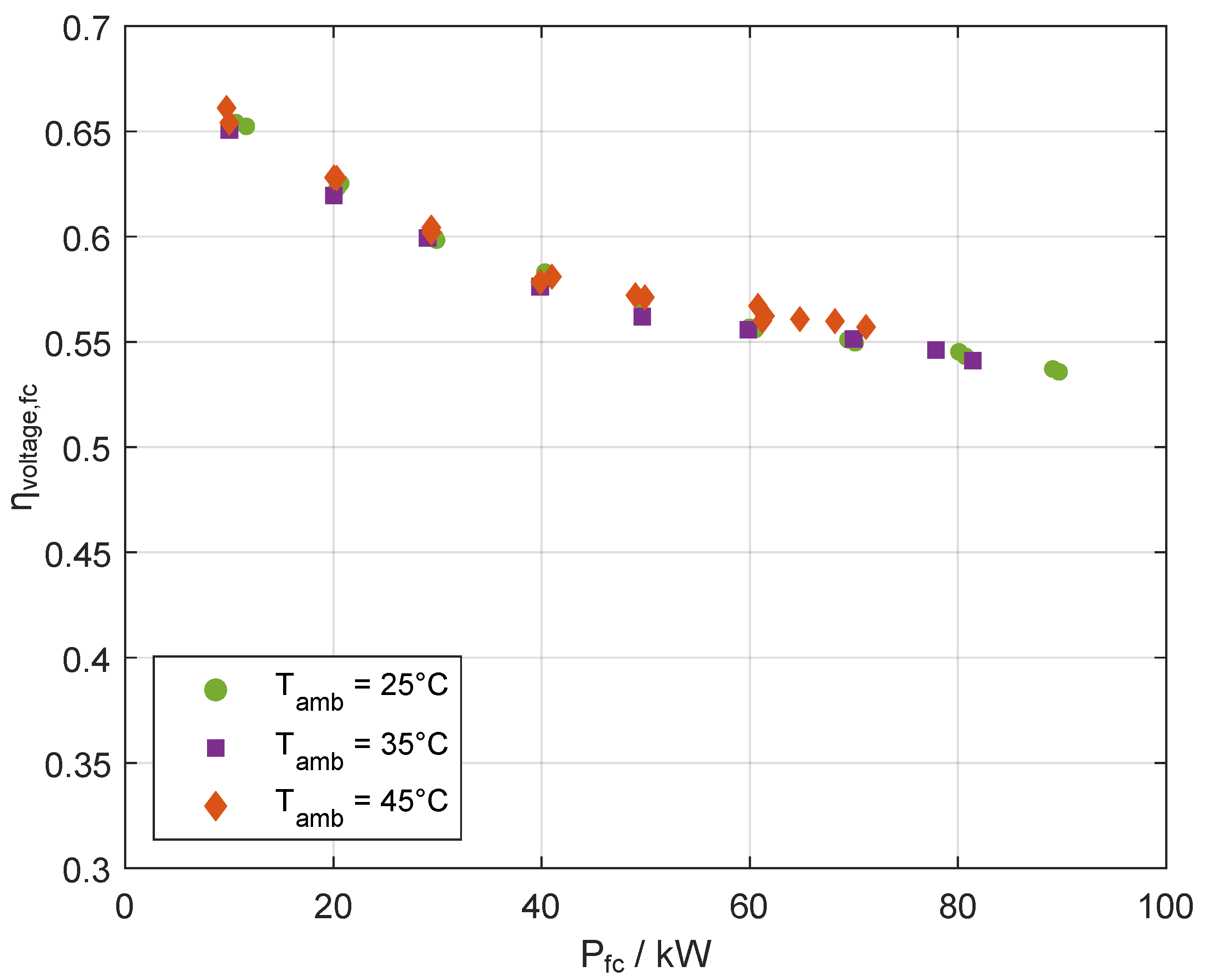

The voltage efficiency of the stack depending on the stack power is shown in

Figure 6 for the different ambient temperatures as well in a similar presentation as in

Figure 5. In contrast to the effects on system efficiency, it can be seen that a single characteristic curve is formed across the stationary points examined, regardless of the ambient temperature. This indicates that the BoP components are capable of delivering the same inlet conditions for the stack within the observed high ambient temperature conditions resulting in differences in stack efficiency with less that 1.5%. Humidification of the membranes of the single fuel cells seems to be of no concern for the observed operating points. Additionally, the maximum electrical power output could not be maintained constant for higher ambient temperatures. This implies a connection between ambient temperature and derating of the fuel cell, resulting in a maximum of 72

electrical power output at 45 °C ambient air temperature.

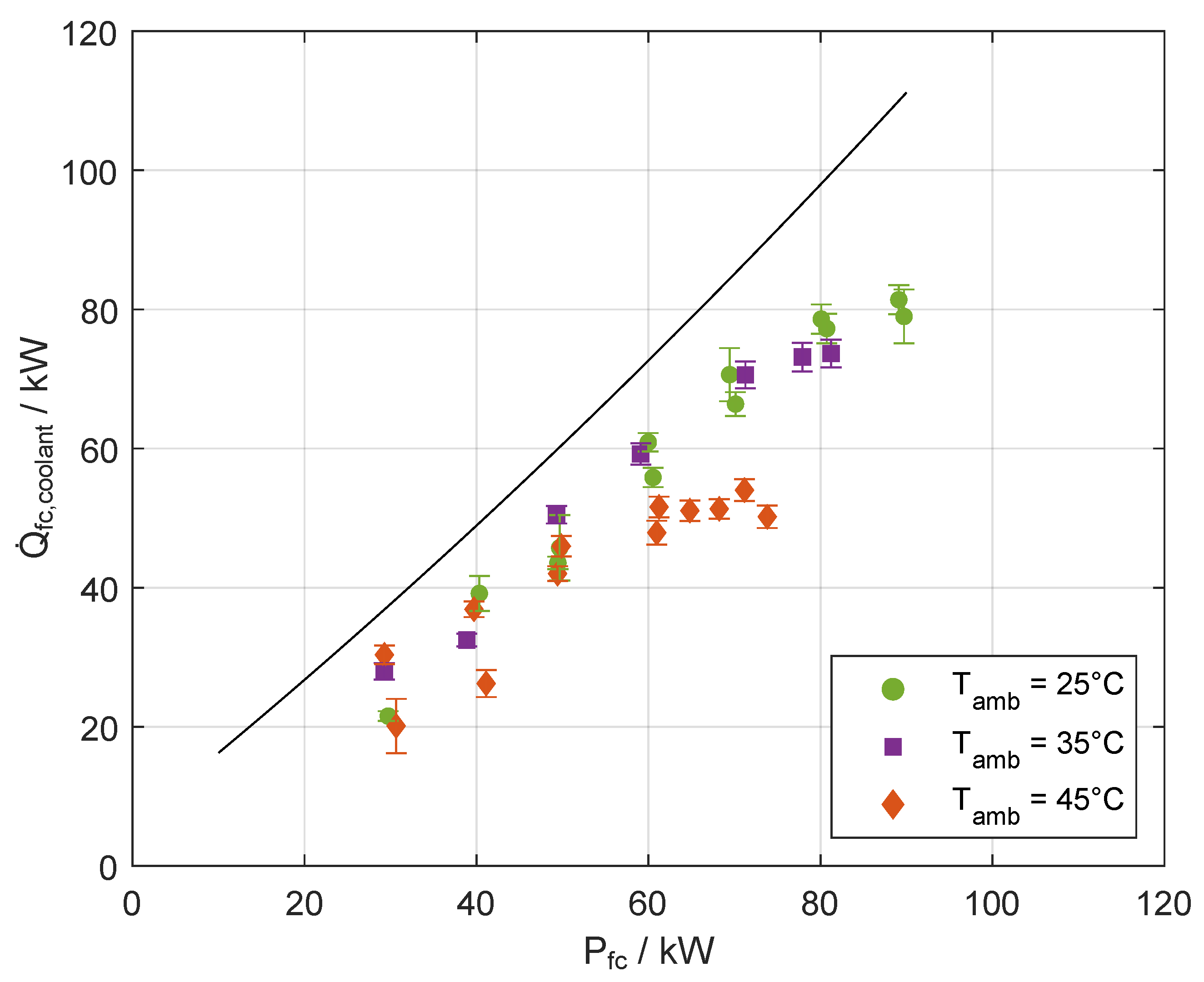

Since the efficiencies shown in

Figure 5 and

Figure 6 are based on the lower heating value (LHV), the overall heat production and the heat transferred to the HT cooling system cannot be derived directly from the presented data. In order to describe the absolute heat produced as well as the proportion dissipated by the HT cooling circuit, the actual heat transferred from the stack to the coolant is shown in

Figure 7 together with the theoretical maximum heat produced within the stack. Related data are given in

Appendix A.3.

The theoretical maximum is based on the maximum electrical current flow observed dependent on fuel cell stack power and the higher heating value (HHV) of hydrogen, as described in Equation (

11):

where

is the equivalent potential of a single cell corresponding to the HHV and

is the number of active fuel cells within the stack. It is assumed that all product water is liquid so that the entire energy stored in the chemical connection of the hydrogen molecule could be released as heat to the cooling system. No heat loss through heat sinks other than the cooling channels within the stack is presumed for the theoretical limit value. The actual heat transferred to the coolant is determined using Equation (

8). Since the coolant volume flow for some operating points with stack power lower than 40

were not in the range of the volume flow sensor, the corresponding heat flows could not be reliably determined.

As expected, the observed heat flows to the coolant are lower than the theoretical maximum of the generated heat. However, it was shown in

Figure 6 that the stack efficiency—and therefore stack heat production—is independent of the ambient temperature and stack power output, as the heat flow from the stack to the coolant is scattered: the further the observed operating points are below the theoretical maximum, the more heat is dissipated by other cooling mechanisms within the stack, e.g., by evaporation of water within the stack or increase of cathode air enthalpy along the flow path. Heat transfer up to 80

was observed for stack power close to 90

.

Summarizing the results above, a significant effect of ambient temperature on the fuel cell system efficiency was found, though the ambient temperature has no significant effect on the stack efficiency between 25 and 45 °C, probably due to significant humidification of the cell membranes within the stack. The results found here can help in modeling a FCEV with a thermal management system by indicating that for the temperature ranges observed, the use of a blackbox model for stack efficiency is sufficient, though the power consumption of the BoP components have to be modeled dependent on the ambient air temperature.

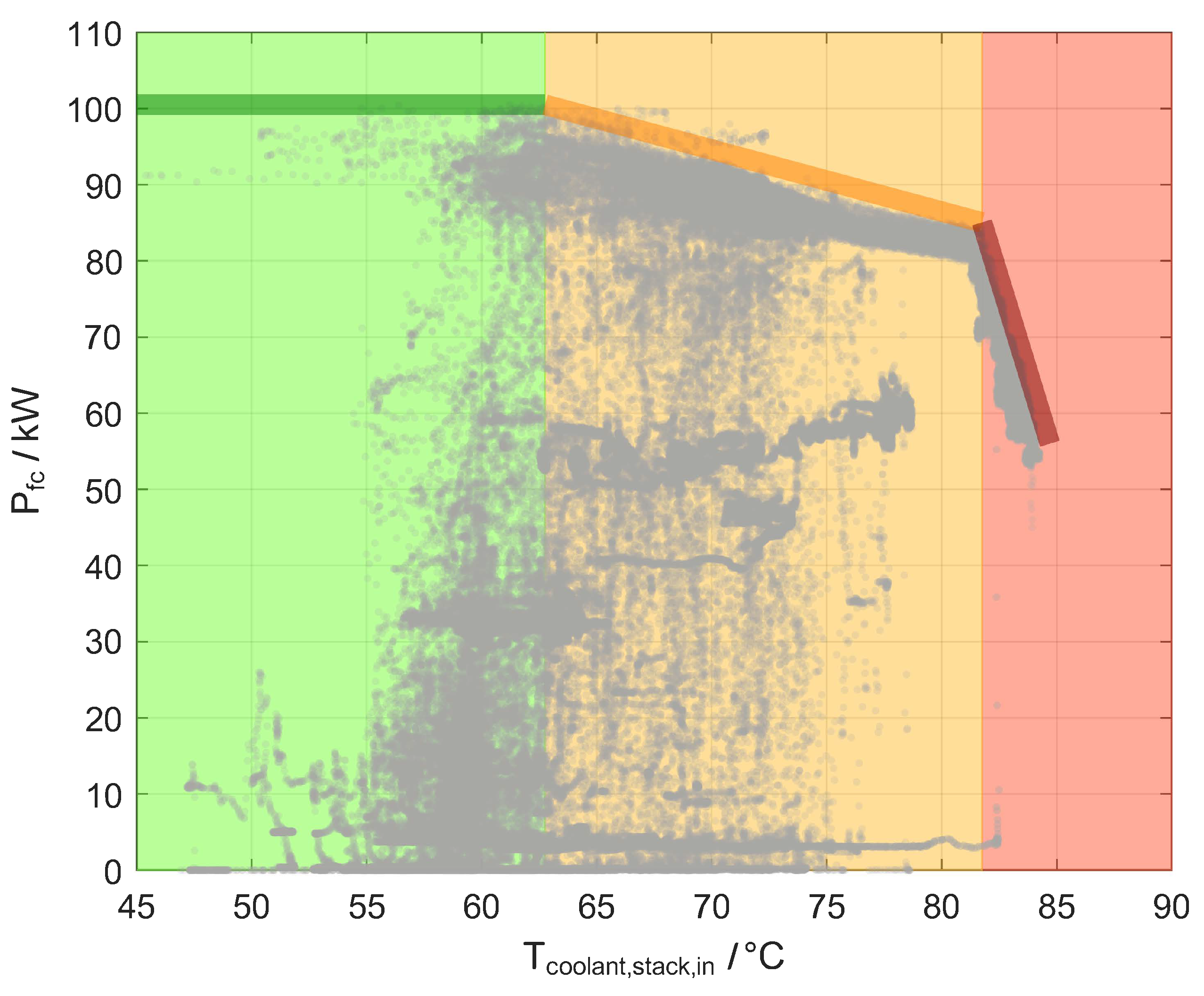

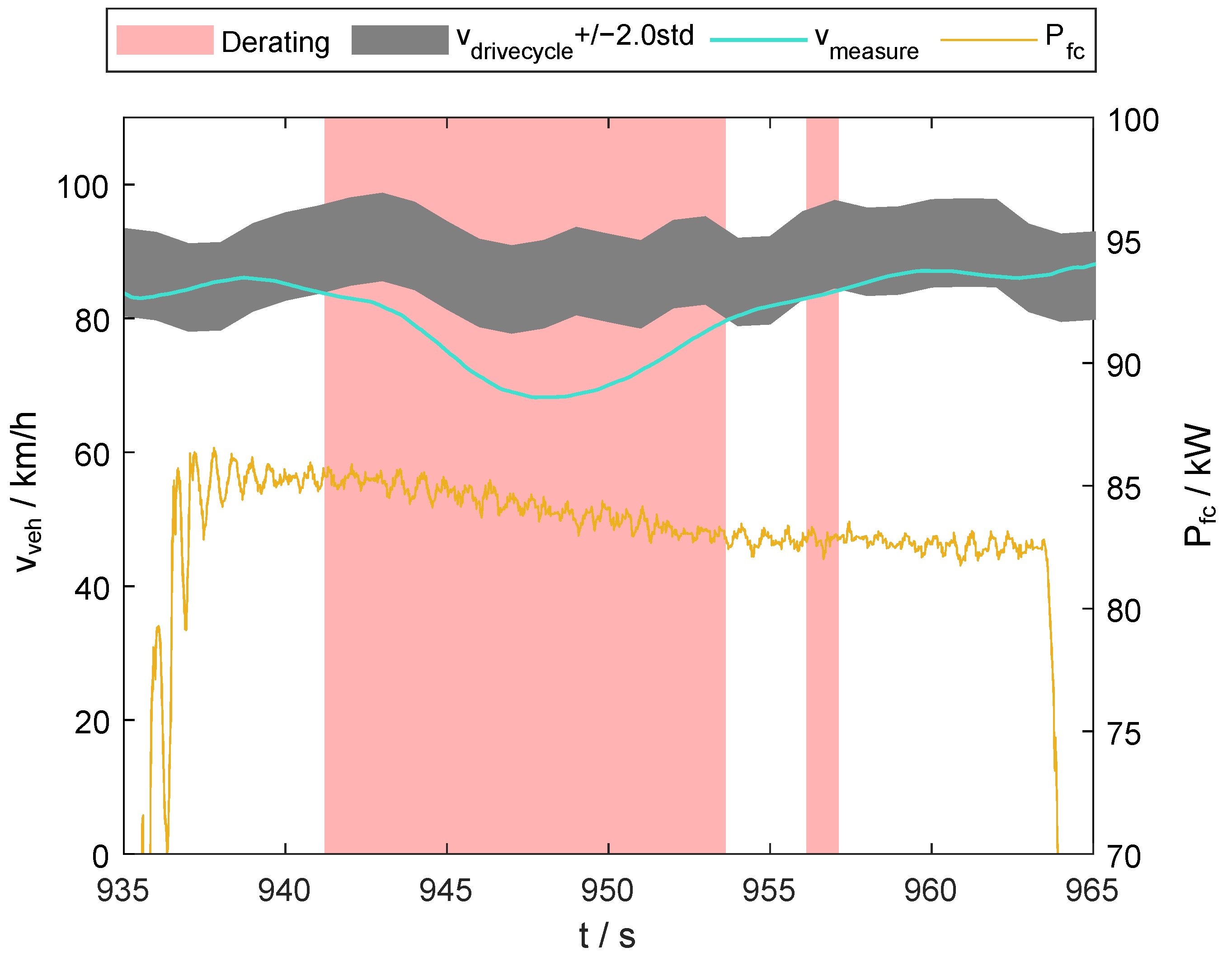

3.3. Thermal Derating

If the waste heat from the fuel cell exceeds the heat that can be dissipated from the vehicle radiator, the thermal masses of the cooling system, such as the coolant, heat up. As a result, the coolant enters the stack at a higher temperature, and the coolant can dissipate less heat from the reactive catalyst layer due to the low temperature difference to the solid components of the cells, assuming that the massflow of the coolant cannot be increased any further. The coolant temperature at the stack inlet is therefore a relevant parameter to control overheating of the stack. In

Figure 8, the coolant temperature at the stack inlet is shown over the operating points of the fuel cell, represented by the gross stack power for all stationary and dynamic measurements performed.

For some operating points, the stack power can overcome the rated power of 95 but never exceed 100 . It can be seen that no operating points fall within the area of high fuel cell outputs with simultaneously high inlet temperatures. This indicates that the control unit intervenes to reduce the current density and thus the waste heat if the stack overheats. In addition, two boundary lines can be identified at the boundary between the operating area and the area to be avoided. These boundary lines can be used to identify three temperature ranges: in the green marked range of up to 62.75 °C, the maximum stack power is available. In the orange marked range from 62.75 °C to 81.75 °C, there is a moderate reduction in fuel cell power. The maximum power of the stack is no longer permanently available. in the red marked range from an inlet temperature of 81.75 °C, massive thermal derating can be observed. The illustration reveals that thermal derating is taken into account in the operating strategy of the vehicle.

The effect of thermal derating on vehicle speed will be investigated below, as vehicle speed, together with acceleration, is the quantity most likely to be perceived by the driver. For this purpose, a real hill climb was followed on the chassis dynamometer at an average ambient temperature of 40.85 °C with only the weight of 70 kg of the driver as an additional load. Due to the measurement setup including a human driver, there are deviations between the target speed from the simulation

and the actual speed during the roller dynamometer test

. In order to clearly separate thermal derating from this influence, the standard deviation between the target speed

and the measured speed

was determined as a reference. The areas in which the measured speed was 2.0 standard deviations below the target speed—therefore representing a significantly greater deviation than the typical error caused by the driver—were assigned to thermal derating, as shown in

Figure 9.

In addition, the ranges were compared with the fuel cell power in order to be able to attribute the reduction in speed directly to the reduction or limitation of the fuel cell power and thus rule out other causes. At the selected time period in

Figure 9, it can also be seen that a short period between two areas marked with derating was not reliably recognized as derating, although the fuel cell power was limited. Reducing the threshold from 2.0 to 1.2 standard deviations, for example, could remedy this situation, but this would result in more errors originating from the driver being recognized as derating. Therefore, 2.0 standard deviations were set as the threshold value, as all events could be clearly assigned to thermal derating. The following considerations are therefore best-case considerations.

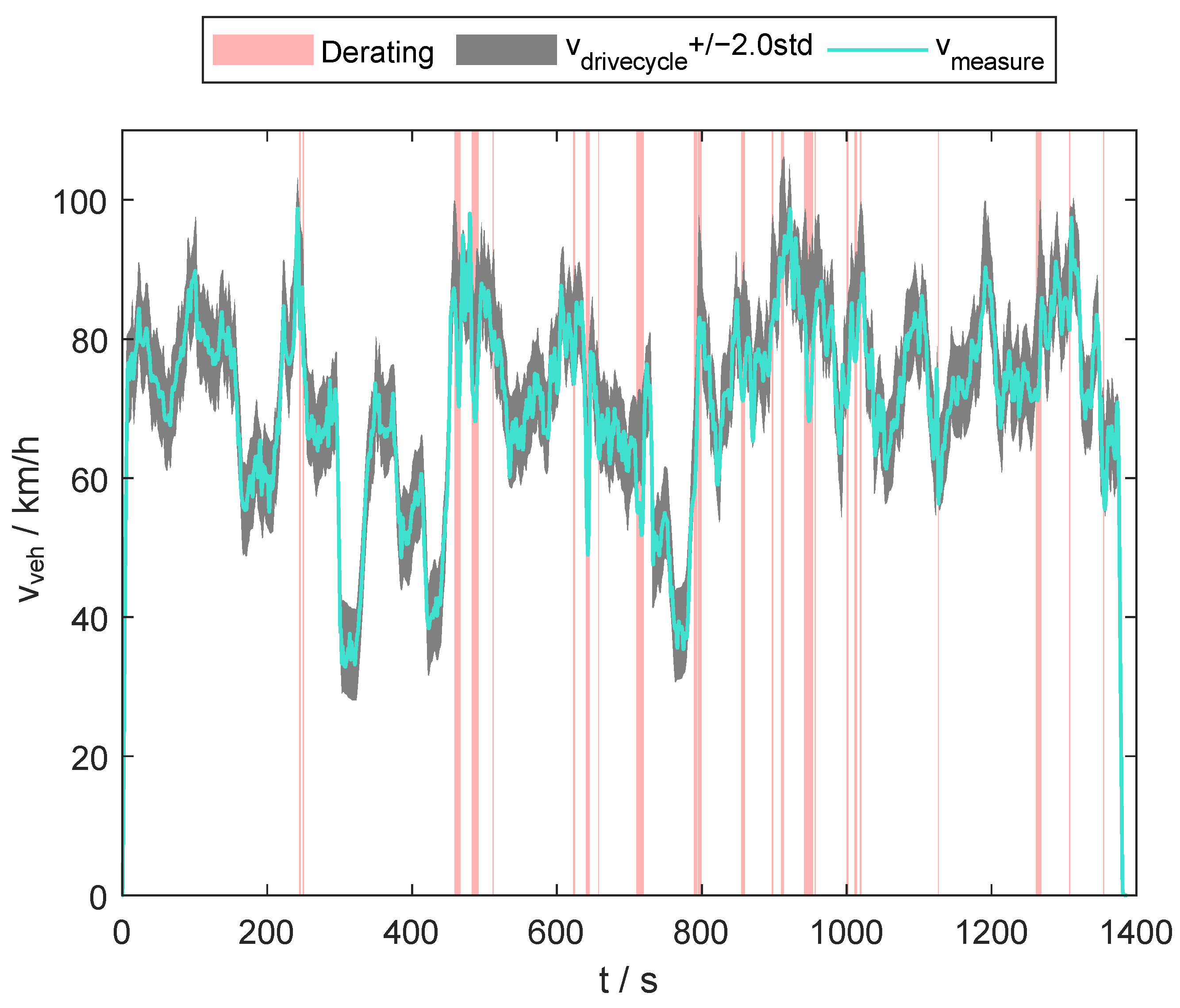

In

Figure 10, the derating events are shown for the whole uphill climb.

It can be seen that there are a few derating events in the beginning when the coolant temperature is not already heated up. Derating often occurs at points where the vehicle has to accelerate out of a low speed hairpin bend on a serpentine road. With a journey time of 1382 , the vehicle was 94.9 s in thermal derating, equivalent to 6.3% of the time. The average driving speed during the 27.61 long trip was 69.5 , which is a reduction of 3.4% compared to the target of 71.9 .

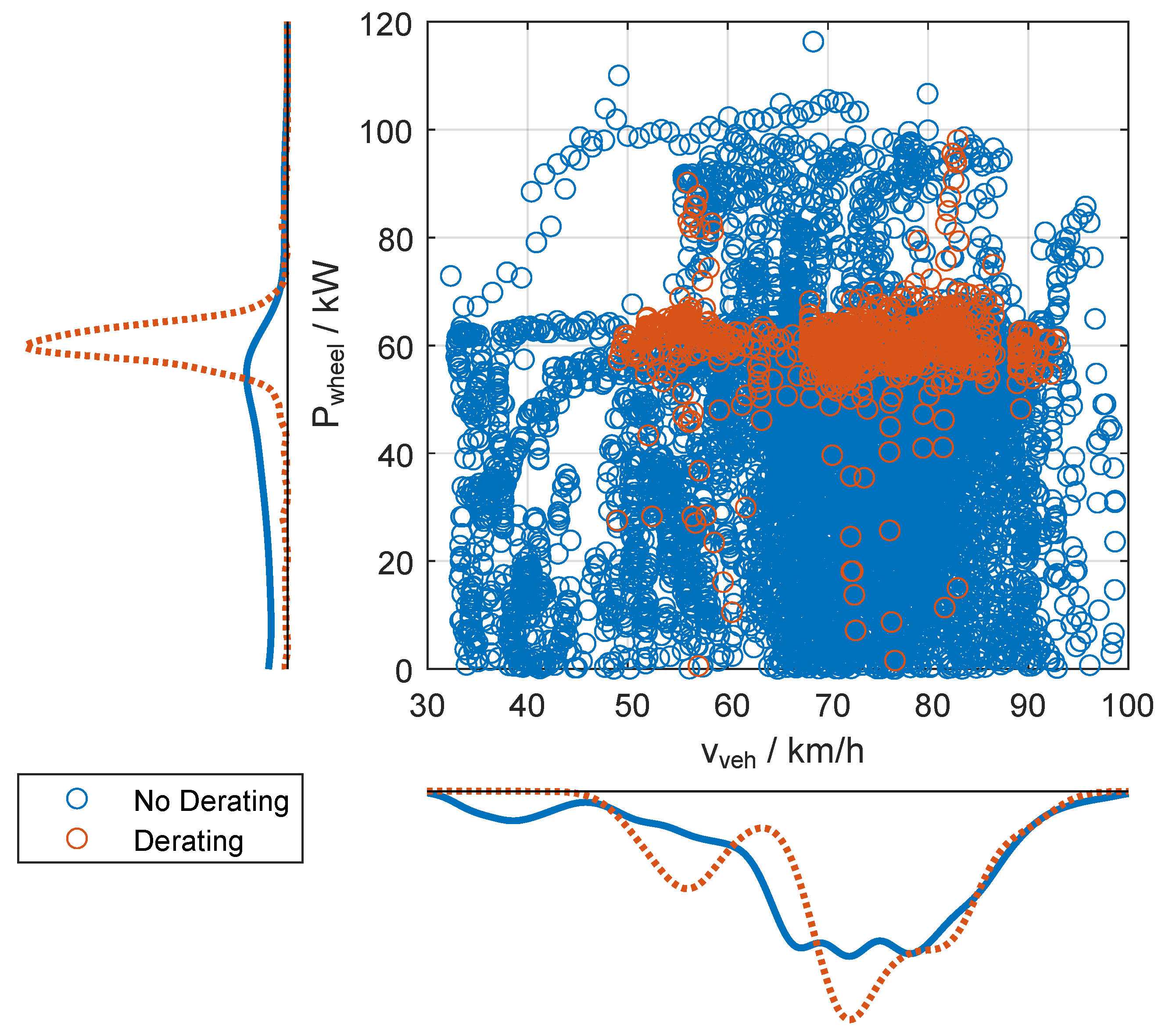

To find out which driving conditions cause derating in particular, the power transmitted from the wheels to the roller dynamometer is plotted against the vehicle speed for all operating points with and without derating in

Figure 11. The histograms for the distribution of wheel power and vehicle speed reveal the range in which the operating points with derating differ from the set of points without derating.

Vehicle speeds lower than 30

are not shown since they only occur during the initial start up and final stop of the vehicle and do not contribute to derating events. It can be seen that no derating occurs below 50 km/h. Isolated events that lead to the indication of derating at wheel power below 50

are due to the definition of thermal derating in this work, which allows for classification as derating even if the driver reduces the wheel power. However, those operating points are scarce and do not contribute much to the overall derating, as shown in the histogram for the wheel power. Above 50 km/h, derating appears to be largely independent of the vehicle speed. This is also consistent with the findings from

Figure 2, which show that the heat that can be dissipated at the vehicle radiator is largely independent of the vehicle speed due to the powerful design of the radiator fans.

Two areas in which derating occurs can be identified at 90 wheel power. The basic distribution of wheel power with and without thermal derating reveals that most operating points are in the range of around 60 . The fact that derating occurs to a large extent at wheel outputs that are significantly below the maximum e-machine output of 120 and the maximum stack output of 95 is likely due to the fact that short power peaks not only cause a significant increase in temperature but also gradual heating of the thermal masses involved due to permanently high wheel loads, which lead to temperatures that should be avoided during fuel cell operation.

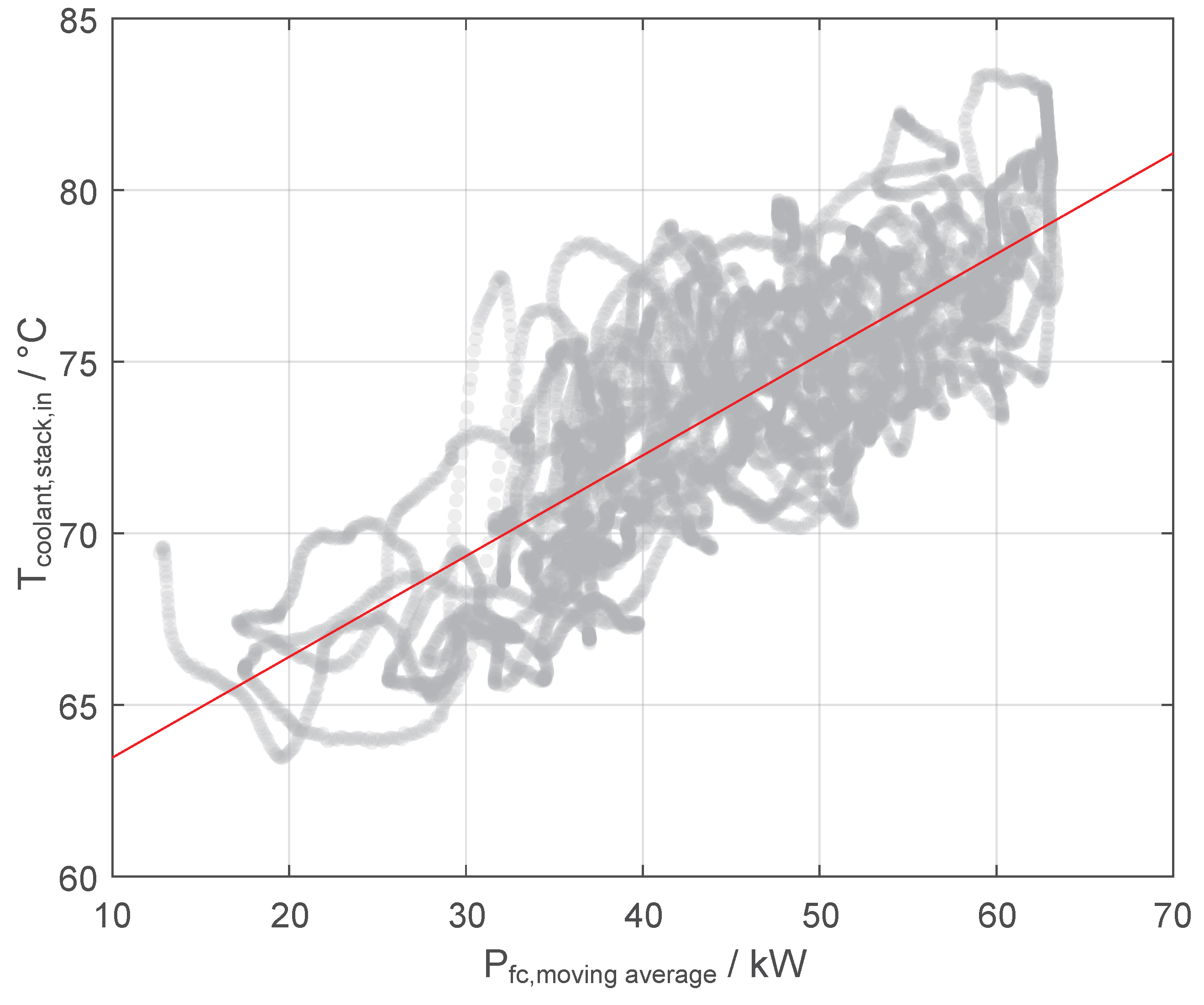

In order to examine the relationship between the coolant temperature at the stack inlet and a longer phase of high fuel cell power output, the correlation between the temperature and a moving average of the fuel cell stack power

was investigated. For this purpose, the correlation was examined for different time windows of the moving average from 10 to 200

in 5

steps. The highest correlation was found for a time window of 50

. The corresponding distribution is shown in

Figure 12.

Compared to the correlation with the immediate stack power, the correlation coefficient between stack power and coolant temperature could be increased from 0.30 to 0.79. The result supports the previously made assumption that long-term operation at high fuel cell power can lead to high coolant temperatures and thus is more likely to result in derating, which can be critical in addition to power peaks at nominal power. The time window found coincides very well with the findings of Gilles and Peissner [

32], who also found an observation period of 50

for the load integral they introduced, which provided the best correlation between load integral and coolant temperatures.

To summarize, it can be stated that thermal derating occurs to a significant extent for a production vehicle with fuel cell drive, even during a demanding driving cycle. However, we did not investigate a worst case with a fully aged stack or full load. High accelerations increase the coolant temperature at the stack inlet, resulting in the fuel cell stack power to be reduced with either a moderate or more severe approach depending on the temperature level. The comparison of target and measured vehicle speed was found to be a suitable indicator to determine thermal derating for roller dynamometer tests assuming a uncertainty band of two standard deviations. Furthermore, it was shown that the thermal time constants of the investigated fuel cell system were on the order of 50 .

4. Conclusions

In this study, the influence of climatic conditions with a focus on ambient temperature and driving conditions on the thermal management system of an FCEV was investigated with a focus on thermal derating of the fuel cell stack. Using an energy-based approach as a compromise between locally resolved and overall averaged airflows, the cooling air speed and the resulting maximum waste heat at the vehicle radiator were determined depending on the vehicle speed. It was found that the high-voltage radiator fans as part of the cooling module were powerful enough in supporting the cooling airflow. This results in the heat transfer at the HT-radiator being largely independent of the vehicle speed between 30 and 100 . Even more powerful fans might help to extend the thermal limits of FCEVs, though cost and effectiveness should be balanced carefully.

The effect of ambient temperature ranging from 25 to 45 °C was insignificant for the fuel cell stack efficiency, likely due to sufficient humidification of the fuel cell membranes. However, with regard to the overall fuel cell system, an efficiency difference of up to 5% was found. Thermal modeling of the overall system should therefore consider simulating the influence of ambient temperature on electrical consumption of the EAC, cooling pump, and radiator fans, which significantly contribute to the parasitic consumption of the BoP at high ambient temperatures.

The coolant temperature at the stack inlet was identified as a critical parameter for thermal derating of the system. While moderate derating was specified by the vehicle control system in the range of 66 to 82 °C inlet temperature, above 82 °C, the available fuel cell stack power is severely restricted, resulting in reduced transport performance or even safety issues.

A new criteria for determining thermal derating on roller dynamometer tests was successfully introduced and in good accordance with reduction of the fuel cell stack power as a result of the derating strategy. For the driving cycle investigated, which simulates a challenging uphill drive at high ambient temperatures, thermal derating of FCEVs has been demonstrated experimentally and found to occur 6.3% of the duration of the driving cycle, though a worst-case with aged stack or maximum payload has not been considered.

It has been shown that thermal derating is largely independent of the vehicle speed and tends to occur at moderate wheel powers of around 60 , where the duration over which the power is demanded is very relevant here. Time constants found with 50 for relating average fuel cell stack power and coolant inlet temperature are in accordance with the literature and might help to tune the thermal masses of a fuel cell stack model that could be used to predict thermal derating.

5. Limitations and Future Work

Though the results for the average cooling air speed are in a plausible range, the presented indirect measurement method of cooling air speed is subject to multiplication of errors based on the usage of multiple sensor signals. In contrast to pitot pipes, rapid local pressure fluctuations that occur due to the expected turbulent flow at high vehicle speeds—and hence air velocity fluctuations—cannot be sufficiently detected due to the thermal inertia of the temperature sensors. In addition, the method only detects local air velocities and is based on simplifying assumptions regarding the spatial inhomogeneities of the cooling air velocity. Therefore, future studies might benefit from adding more temperature sensor positions and additionally comparing the energy-based method introduced in this study with a more established method with a larger detection area, e.g., axial turbine anemometers, to be able to estimate the measurement errors based on local inhomogeneities in the turbulent flow. In addition, thermocouples placed within the radiator piping can help to check whether the assumption of an approximately linear change in cooling water temperature in flow direction is appropriate. Finally, the range of investigated vehicle speeds should be extended to a larger range, starting from 0 , in order to be able to confirm the observations for very low vehicle speeds.

In addition to the ambient temperature, the ambient air humidity also has a major influence on the thermal system of an FCEV. Therefore, studies on fuel cell stack and system efficiency should be extended to include humidity variations that reach into the limits of the ambient conditions in the real world. Humidity sensors in the supply and exhaust gas from the anode and cathode side could also provide more information about the humidification of the cell membranes in the studies described here.

The results shown regarding the occurrence of thermal derating during a dynamic drive cycle are strongly dependent on the driving cycle under consideration, the fuel cell system design, and the vehicle payload. Investigations with maximum payload as well as other challenging driving maneuvers should be considered to study the significance of derating in even more extreme cases and, e.g., confirm the performance of the thermal management system in stop-and-go traffic with even lower velocities than those presented in this study.

Disturbances like system vibrations in general or nonlinear friction were not considered during the dynamic drive cycle. In order to validate the relevance of derating, real street tests should be performed to also evaluate the influence of those disturbances on the results found. Due to the lower stack efficiency and therefore higher heat production, a fuel cell stack in end-of-life condition will be considered in future studies. Future studies should also consider ambient air pressure influences on the investigated low-pressure system as well as studying a high-pressure system, e.g., that used in the Toyota Mirai, to evaluate the performance of the two different fuel cell system designs. For a more general consideration of the relevance of thermal derating in FCEVs, it is recommended to use vehicle simulation models due to there flexibility and cost. The results shown here and future planned experimental studies can help to accurately describe the relevant variables in a FCEV thermal management model in order to predict thermal derating under challenging driving conditions.