1. Introduction

According to a ship application, a specific diesel engine exhibits black smoke emissions under low-speed operating conditions, which significantly impairs acceleration performance. Consequently, when confronted with larger hulls and propeller shafts, issues such as inertia, black smoke emissions, and prolonged acceleration times may become more pronounced. The literature and empirical analyses [

1,

2,

3,

4,

5] indicate that the occurrence of black smoke is primarily due to insufficient combustion resulting from inadequate air intake at low speeds. The limited air intake in this type of diesel engine can be attributed to the ‘hysteresis’ effect stemming from the original turbocharger’s high moment of inertia and sluggish response characteristics. Furthermore, the extent of matching between the ship’s machinery and propeller plays a substantial role in exacerbating black smoke issues during marine diesel engine operation.

Researchers have conducted extensive investigations in the field of diesel engine black smoke control [

6,

7,

8,

9,

10]. Hunicz et al. examined the combustion stability of Spark-Assisted Compression Ignition (SACL) with the aim of enhancing thermal efficiency and reducing NOx emissions by exploring the SACL/Homogeneous Charge Compression Ignition (HCCL) transition [

11]. Zhang et al. [

12] discovered that while an increase in compressed air supply led to higher soot emissions at elevated pressures, it resulted in a decrease at higher temperatures; furthermore, NOx emissions exhibited a non-monotonic dependence on pressure. The system achieved a peak indicated thermal efficiency of 44.3% (+19.7% compared to baseline) at 300 KPa/303 K, surpassing hybrid configurations by 6.64% in overall efficiency under optimized pneumatic conditions. Sun et al. [

13] reported that water injection reduced NOx emissions by 72.8%, albeit with a power loss of 2.08%. In contrast, steam injection yielded a reduction of 38.9% in NOx emissions along with a power gain of 24.7% at 20 g/500 K, thereby demonstrating steam’s dual advantages for emission control and efficiency enhancement over water-based methods under optimized Waste Heat Recovery (WHR) conditions [

14]. Cernat et al. [

15] verified the feasibility of hydrogen fuel substitution technology, achieving a 50% reduction in NOx emissions and a 73.8% decrease in smoke levels with a hydrogen blending ratio of 34%. Fayad and Yokomura proposed enhancements regarding injection strategies and EGR control: delayed main injection combined with high-pressure injection effectively reduces both smoke and NOx emissions simultaneously [

16]; additionally, a transient EGR control strategy based on λ significantly mitigates carbon smoke generation [

17]. In terms of system matching optimization, Tadros’ team innovatively shifted the propeller selection criteria from traditional open water efficiency to an orientation focused on fuel consumption rates, optimizing fuel consumption across full operating conditions by suppressing air bubble performance [

18]. The ship–engine–propeller coupling model developed by Nelson et al. offers a systematic solution for controlling whole-life fuel costs [

19]. Significant advancements have been made in intelligent prediction technologies; notably, Wang’s black smoke prediction model constructed using the random forest algorithm demonstrates markedly greater accuracy compared to traditional empirical formulas [

20].

Currently, research on diesel engine emission control, both domestically and internationally, predominantly focuses on optimizing fuel injection strategies, developing novel fuels, and advancing particulate matter capture technologies. However, there is a notable lack of systematic investigations into the evaluation of black smoke phenomena during the low-speed loading process of medium-speed diesel engines and the mechanisms linking these phenomena to the transient response performance of turbochargers. Simultaneously, while advancements have been made in theoretical modeling, numerical simulation, and experimental validation regarding ship–engine–propeller matching technology, its practical application still faces significant challenges. Traditional matching approaches are largely limited to the static optimization of mechanical parameters (such as power, rotational speed, and torque) for selecting ship machinery equipment. These methods do not comprehensively incorporate adjustments to dynamic control strategies for actual ship operations nor adequately consider how thermodynamic parameters of diesel engines influence system matching. This predominantly mechanically oriented matching paradigm makes it difficult for existing research to effectively predict or mitigate transient black smoke issues in diesel engines during coordinated operation within ship–engine–propeller systems. Particularly under low-speed operating conditions, the imbalance in air–fuel ratios and combustion deterioration resulting from sluggish turbocharger responses have not been thoroughly analyzed or managed from an engineering perspective.

This study innovatively develops a cross-scale coupled black smoke control technology system specifically designed for marine medium-speed diesel engines. At the diesel engine level, an engineering smoke emission assessment model is proposed for the first time. This model is based on collaborative verification through GT-Power(V2016) simulations and opacity bench tests. By designing a low-rotational inertia B/C dual turbocharger scheme, the excess air coefficient under transient conditions is significantly enhanced, effectively overcoming the bottleneck of black smoke deterioration caused by response delays in traditional single turbocharging systems. At the system level, this research transcends the limitations of conventional ship–engine–propeller matching technologies that primarily focus on mechanical parameters. By integrating the thermodynamic parameters of diesel engines (specifically exhaust smoke density) with dynamic characteristics of the propulsion system within a Matlab/Simulink(R2022a) framework, we establish a multiphysical-field coupling simulation model of ship–engine–propeller that incorporates a black smoke prediction function. This model not only facilitates collaborative optimization between mechanical performance and emission characteristics but also proposes a two-dimensional power control strategy aimed at balancing ship maneuverability with black smoke suppression. Consequently, this provides an innovative methodology for addressing multi-objective conflicts among “transient response, combustion emissions, and propulsion efficiency” under low-speed loading conditions.

2. Materials and Methods

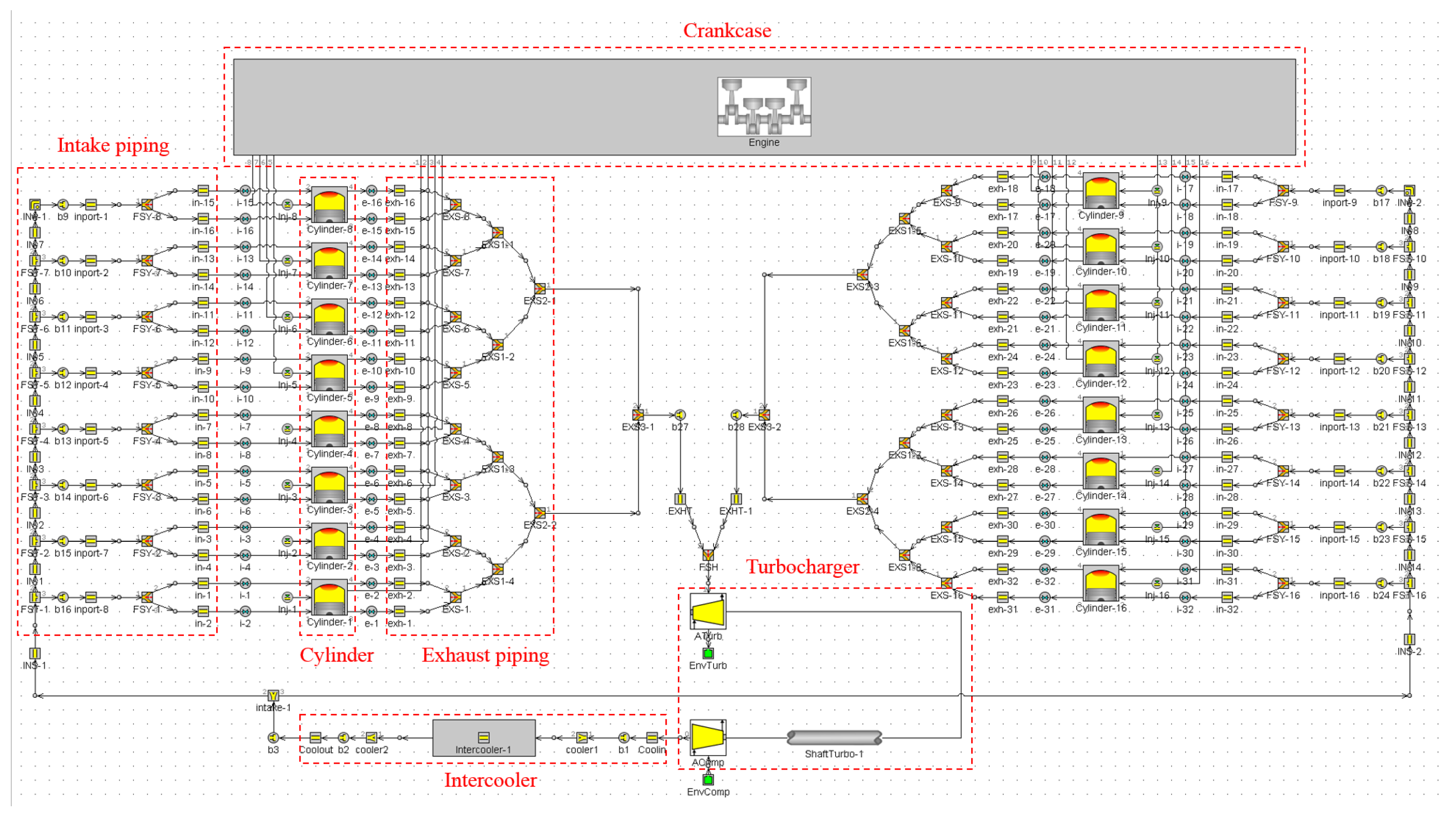

To study this type of diesel engine in depth, the modular modeling feature of GT-Power software was utilized to construct simulation models for key components, including the intercooler, turbocharger, crankcase, and cylinder, respectively, connecting the configurations according to the actual structural order. The main technical parameters of this type of diesel engine are shown in

Table 1.

The simulation model of the original A turbocharger compatible with the diesel engine has been established, as shown in

Figure 1.

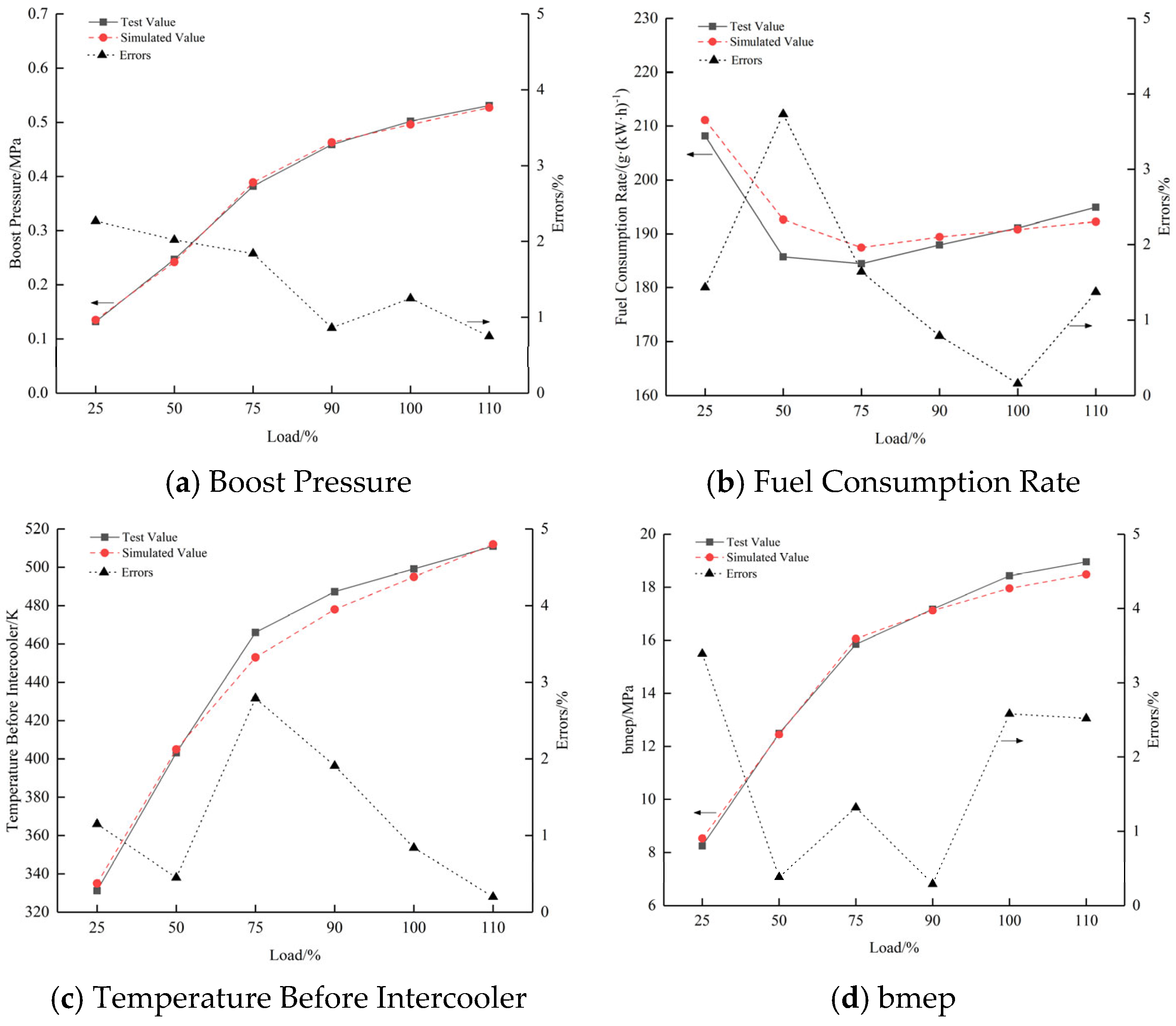

To further improve the accuracy and credibility of the diesel engine simulation model, matching calculations were carried out for 25~110% steady-state load operating points of the diesel engine propulsion characteristics. At the same time, combined with the measured results provided by the diesel engine manufacturer, the simulation calculation results of boost pressure, fuel consumption rate, temperature before intercooler, and brake mean effective pressure (bmep) at each working condition point are calibrated to ensure that the simulation model can comprehensively assess the performance of the diesel engine under different load conditions and accurately reflect the actual operating status of the diesel engine, as shown in

Figure 2.

Analyzing the measured data and simulation data shows that the multi-parameter calibration deviation of the constructed diesel engine simulation model is minimal. The maximum error range of key parameters is effectively maintained within the 5% threshold acceptable in the engineering field. Specifically, the maximum errors for boost pressure, fuel consumption rate, temperature before intercooler, and bmep are 3.39%, 3.73%, 2.79%, and 2.27%, respectively. Moreover, the overall trend of change demonstrates a high degree of consistency, leading to the conclusion that the model is relatively accurate.

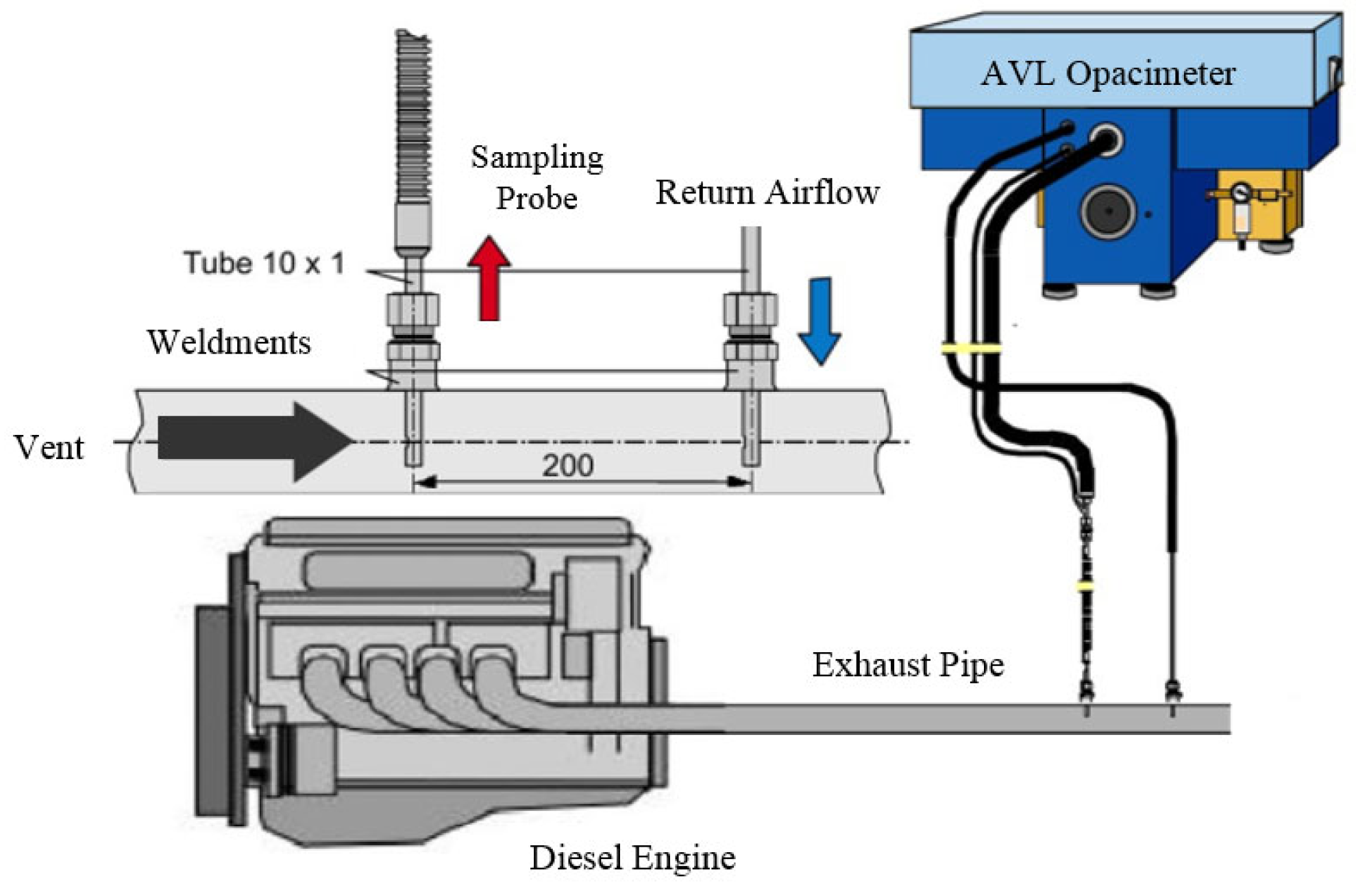

The bench test recorded the dynamic measurement of the opacity of the exhaust smoke in the pipe by using an AVL opacity test instrument on the exhaust pipe of the original A diesel engine system. The sampling point was set on the longest and straightest possible section of the pipe to reduce the interference of the airflow disturbance on the measurement results, as shown in

Figure 3.

The instrument is based on the principle of light attenuation. It determines the opacity by detecting the amount of light attenuation after penetrating the exhaust gas, which directly reflects the concentration of particulate matter and the intensity of black smoke emission. Compared with the traditional steady-state test, its advantage lies in the real-time monitoring of the diesel engine’s dynamic emission characteristics under transient operating conditions (acceleration/deceleration/load change), which provides key data support for combustion analysis and control optimization.

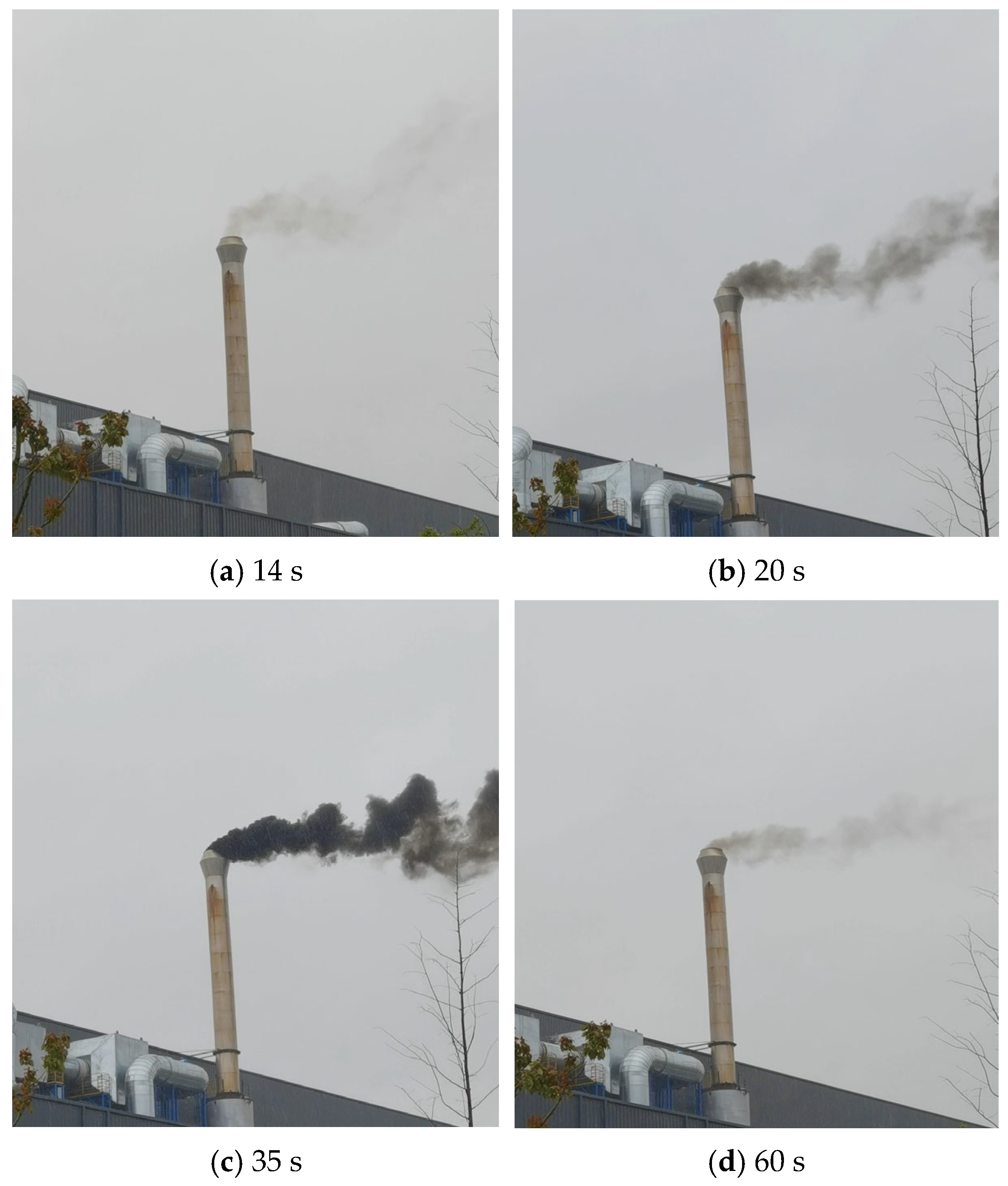

Meanwhile, during the test, the emission at the exhaust pipe outlet was video recorded under favorable weather conditions.

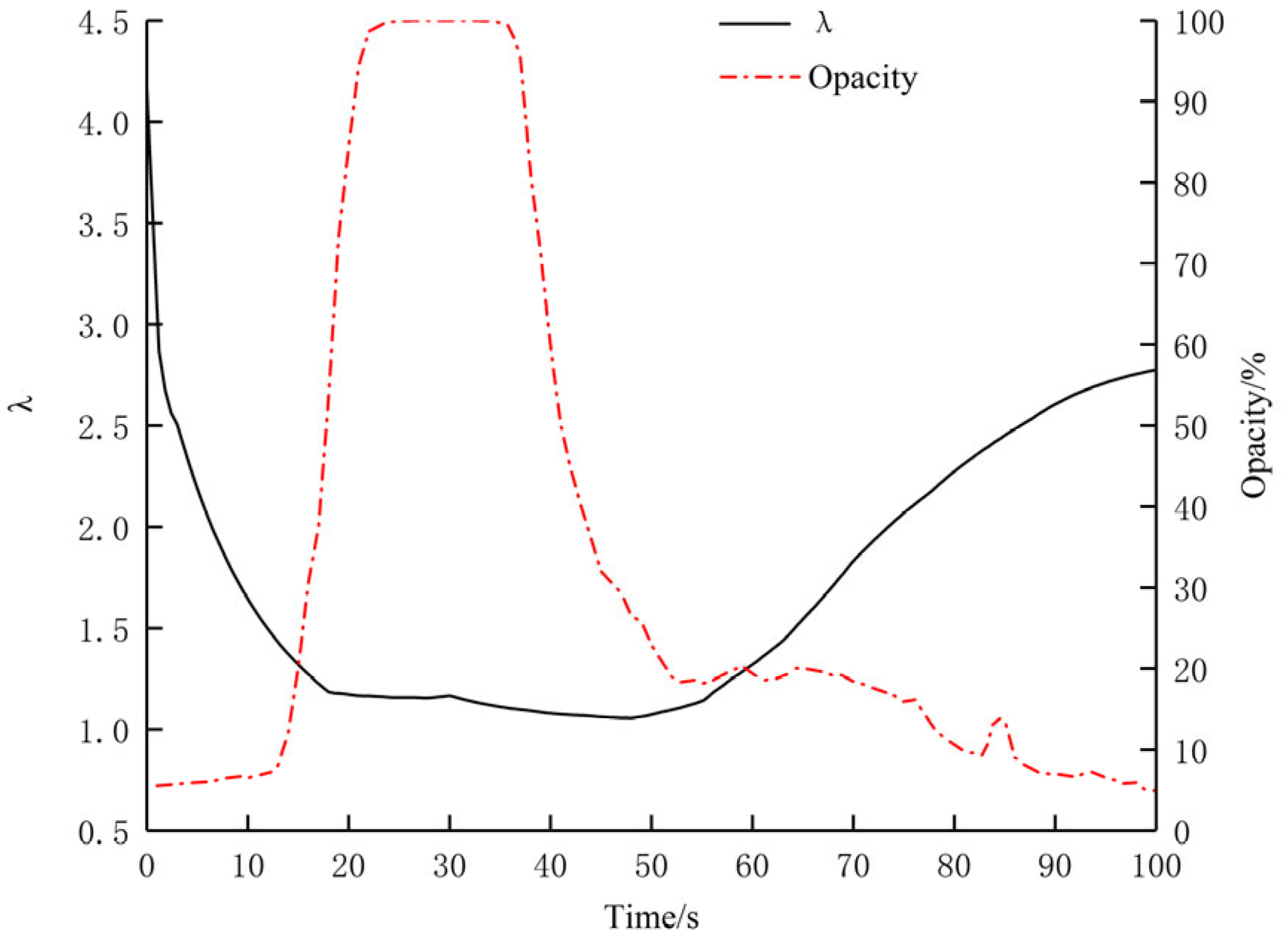

Figure 4 shows that the diesel engine was loaded at low speed for 14–65 s: at 14 s, the opacity was 20%, which corresponded to a trace amount of black smoke that was hardly visible to the naked eye; at 20 s, it rose to 60%, and the black smoke became visible; at 25–40 s, it continued to be 100% opaque, presenting a thick smoke that was completely obscured; after 40 s, the value gradually fell back, and the black smoke was dissipated to the point that it was unobservable. The dynamic curve reveals the fluctuation characteristics of diesel engine emissions under transient conditions.

According to the smoke condition of the diesel engine recorded in the video, it can be found that this type of diesel engine has a more serious exhaust smoke problem when it is running in low-speed conditions. When it is applied in the real ship, the diesel engine needs to bear the greater load of the ship’s operation, and its exhaust smoke problem may be more prominent, so it is necessary to optimize the exhaust smoke problem of this type of diesel engine when it is running empty first.

The GT-Power model of the diesel engine established in this paper mainly combines the λ model, which can characterize the exhaust smoke, and the opacity, which is an important indicator for recording and evaluating the emission of black smoke, to quantify and analyze the relationship between λ, opacity, and black smoke, so that we can reasonably analyze the improvement of the dual-boosting scheme on the black smoke problem. The GT-Power simulation model of the original Type-A single turbocharger of the diesel engine was simulated and calculated according to the loading procedure of the opacity bench test.

The opacity of the bench test and the simulation model λ are recorded separately during the loading procedure, as shown in

Figure 5. From the curves, it can be found that λ corresponds well with the trend of opacity change, indicating that the two are strongly correlated. When λ is lower than 1.5, the opacity rises rapidly, peaks quickly, falls sharply, and stabilizes after λ rises back. Under this loading procedure, λ remains below 1.5 from 12 s to 64 s, and the opacity is below 20% from 14 s to 65 s, which indicates that the simulation model can reasonably evaluate the black smoke condition of this type of diesel engine. Therefore, it can be quantitatively concluded that when λ is below the critical value of 1.5, there is a risk of producing black smoke in this type of diesel engine.

In the in-depth simulation analysis, the correlation between the risk of diesel exhaust black smoke and λ is scientifically defined based on the previous research results and the detailed mapping test data from the equipment plant. A smoke risk assessment system with λ as the core indicator was established: when λ is less than 1.5, it is regarded as a high-risk area, which indicates that the risk of diesel exhaust black smoke is significantly higher and intervention measures need to be taken immediately to reduce the emission; when λ falls within the range of 1.5 to 2.0, it is defined as a medium-risk area, which means that although there is a certain degree of risk of black smoke, the risk has been mitigated in comparison with that of the high-risk area, and continuous monitoring and timely optimization of operation strategies are still required.

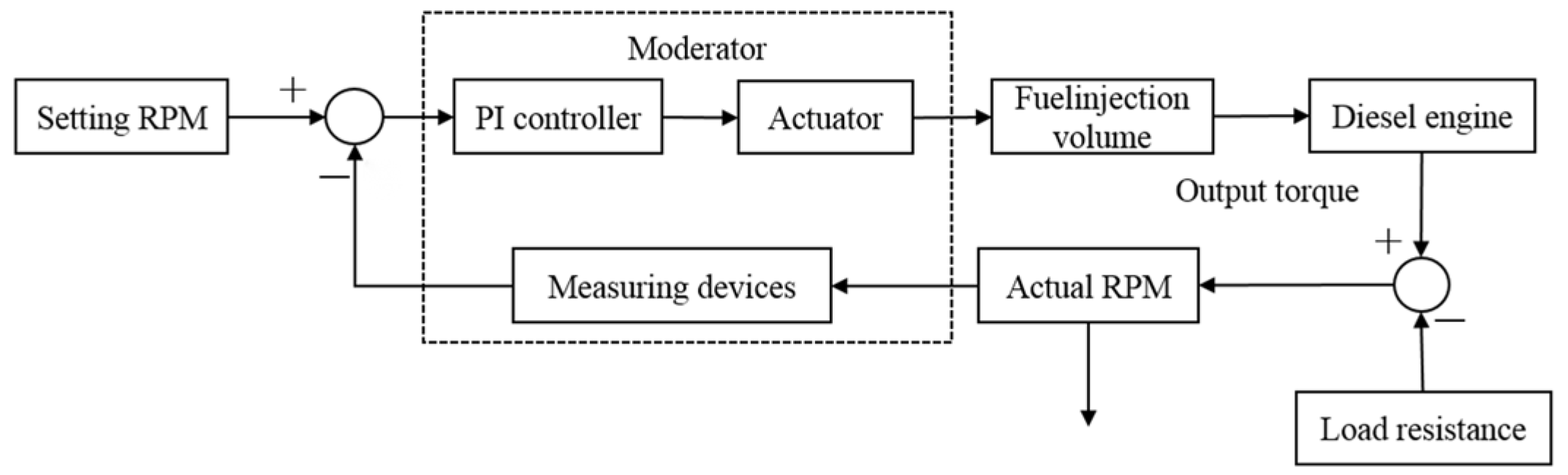

Based on the classical dynamics and engineering thermodynamics theory, the hull drag module, propeller module, shaft system drive, and diesel engine governor module are established.

The governor module is benchmarked for initial parameter estimation using the classical Ziegler–Nichols method, which provides a systematic set of guidelines for parameter selection based on system response characteristics. The initial parameters were established with Kp = 3.69 and Ti = 10.38. While these values effectively maintained the system’s stability, further optimization was essential to meet the dynamic performance requirements. Considering the specific characteristics of the diesel engine system, both the proportional gain Kp and integral time Ti underwent meticulous fine-tuning. Through a series of iterative adjustments, the final parameters were refined to Kp = 4.2 and Ti = 8.5. This modification resulted in a significant reduction in overshoot and a corresponding decrease in regulation time. The control principle of the PI controller obtained accordingly for the shaft system speed is shown in

Figure 6.

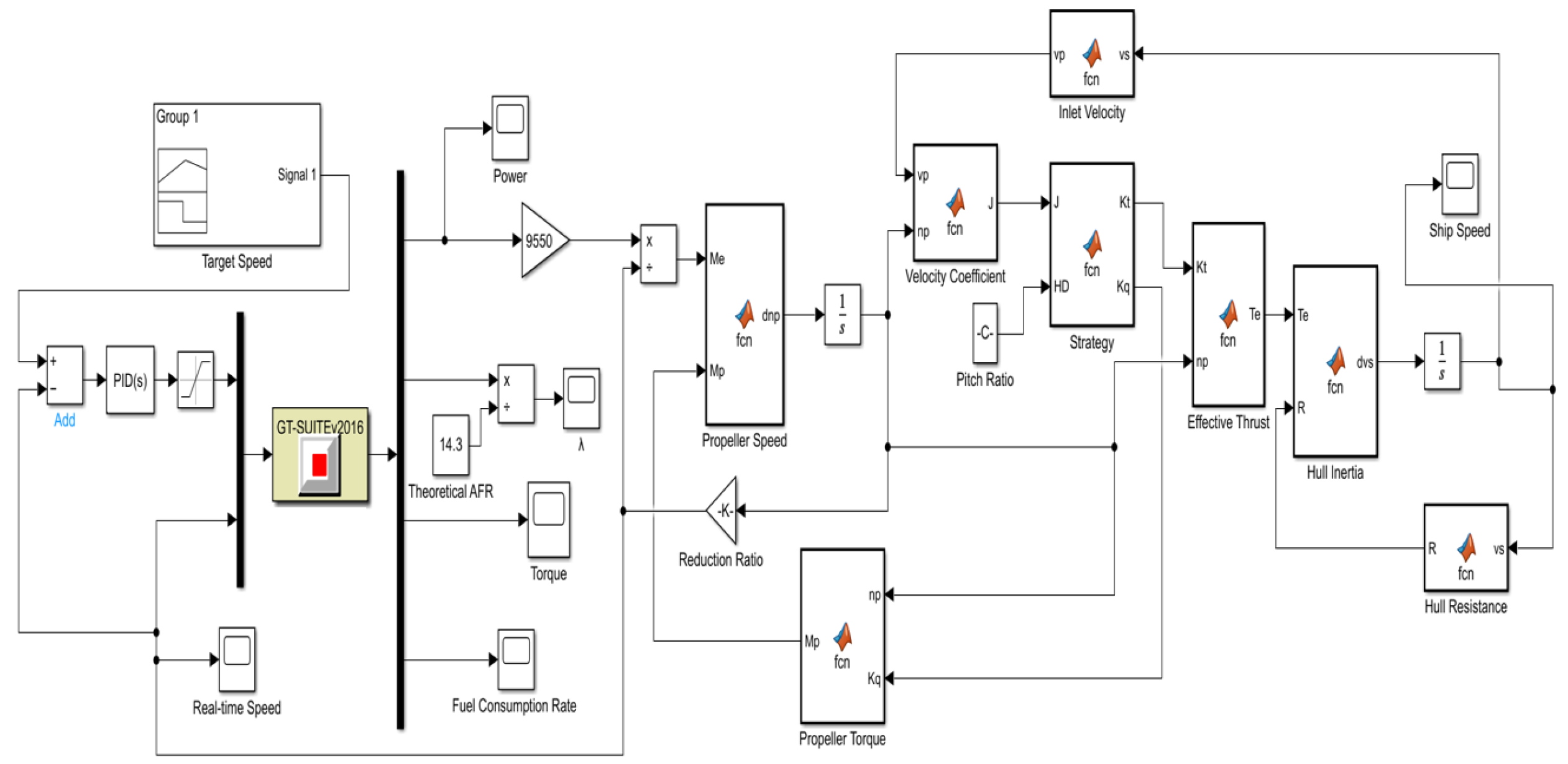

Based on classical dynamics and engineering thermodynamics, this framework integrates several key modules: a hull resistance module for calculating hydrodynamic resistance during vessel navigation; a propeller module that generates thrust through propeller pitch ratio and open-water characteristics; a shafting transmission module encompassing gearboxes and couplings to analyze power transfer efficiency; and a diesel engine governor module aimed at optimizing engine speed and load responses. Dynamic evaluation of smoke opacity is achieved through co-simulation between GT-Power and MATLAB/Simulink, as illustrated in

Figure 7. The rotational speed and power output parameters from the main engine are transmitted via the shafting system to drive both propeller rotation and vessel motion. Control signals generated within Simulink dynamically modulate the engine simulations in GT-Power, with output data providing not only final model outputs but also closed-loop feedback signals that iteratively refine control algorithms. This multidimensional framework facilitates simultaneous simulation of power transmission dynamics, propulsion performance assessment, and real-time operational adjustments. Consequently, it enhances the accuracy and applicability of marine propulsion system design and optimization.

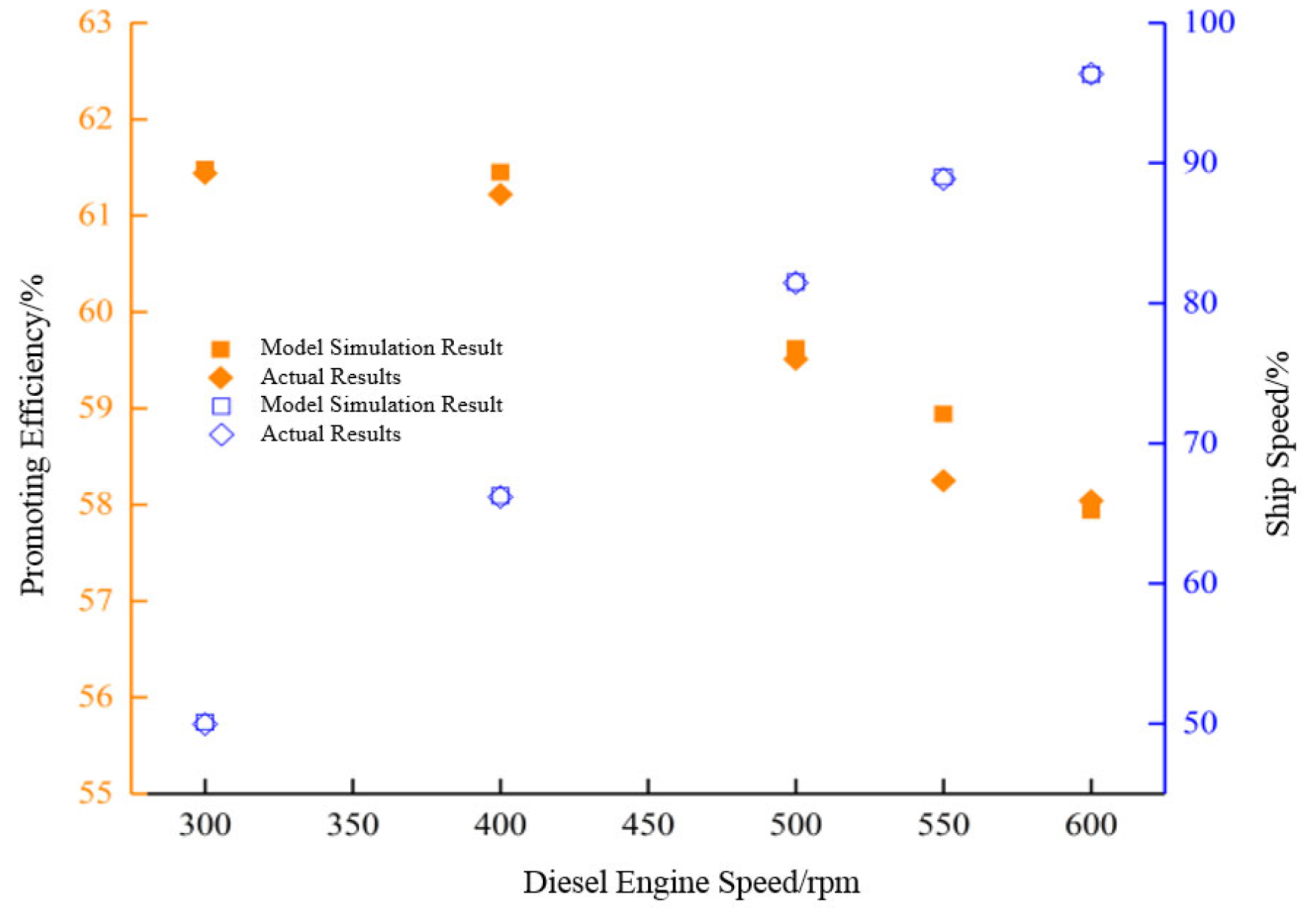

By comparing the steady-state simulation with the real ship test data, it can be seen from

Figure 8 that the comparison trend of the simulation and calculation results of this model is the same. The error of the model propulsion efficiency is less than 1.18%. The error of the sailing speed is less than 0.25%, which verifies the credibility of the model and lays a foundation for the subsequent research on the dynamic control strategy.

Considering that the moment of inertia of the turbocharger is not infinitely small due to material and technical reasons, it was decided to match a dual turbocharger solution with a total moment of inertia of about 20% of the original single turbocharger. At the same time, in order to further determine the specific type of turbocharger, a detailed numerical matching calculation was carried out. In the calculation process, the autonomous control requirements and cost control factors are fully considered. At the same time, they are closely combined with the main technical parameters of the diesel engine to ensure the best match between the turbocharger and the diesel engine. This paper initially selected three turbocharger models, including the original turbocharger, as shown in

Table 2.

Based on the combined advantages of the Type-C dual turbocharger in terms of emission control and fuel economy, it is identified as the core solution for the ship–machine–propeller matching control strategy study. To evaluate the dynamic working condition performance, this study designed differentiated control strategies for two types of scenarios: extreme emergency maneuvers (extreme loading) and regular sailing (normal loading). By comparing the three-speed acceleration strategies of 1, 2, and 7 rpm/s, it is found that the marginal effect of diesel engine power gain decreases significantly when the speed increase rate exceeds 2 rpm/s. Therefore, 2 rpm/s is finally selected as the balance point, which can not only improve the ship’s sailing efficiency by optimizing the matching between the propeller pitch ratio and the power loading rate but also reduce the mechanical load and energy consumption caused by the power fluctuation, and prolong the service life of the diesel engine. The 7 rpm/s as the maximum speed-up strategy under the acceleration limit is used to adjust to the best state under emergency working conditions quickly, ensuring the ship has efficient response capability in unexpected situations. This strategy system takes into account the economy of regular operation and the maneuverability demand of extreme conditions and provides a practical basis for ship–engine–propeller cooperative control. The boundary parameters of the control strategy are shown in

Table 3 below.

3. Results

3.1. Optimization of the Black Smoke Problem Under the Dual Turbocharger Scheme

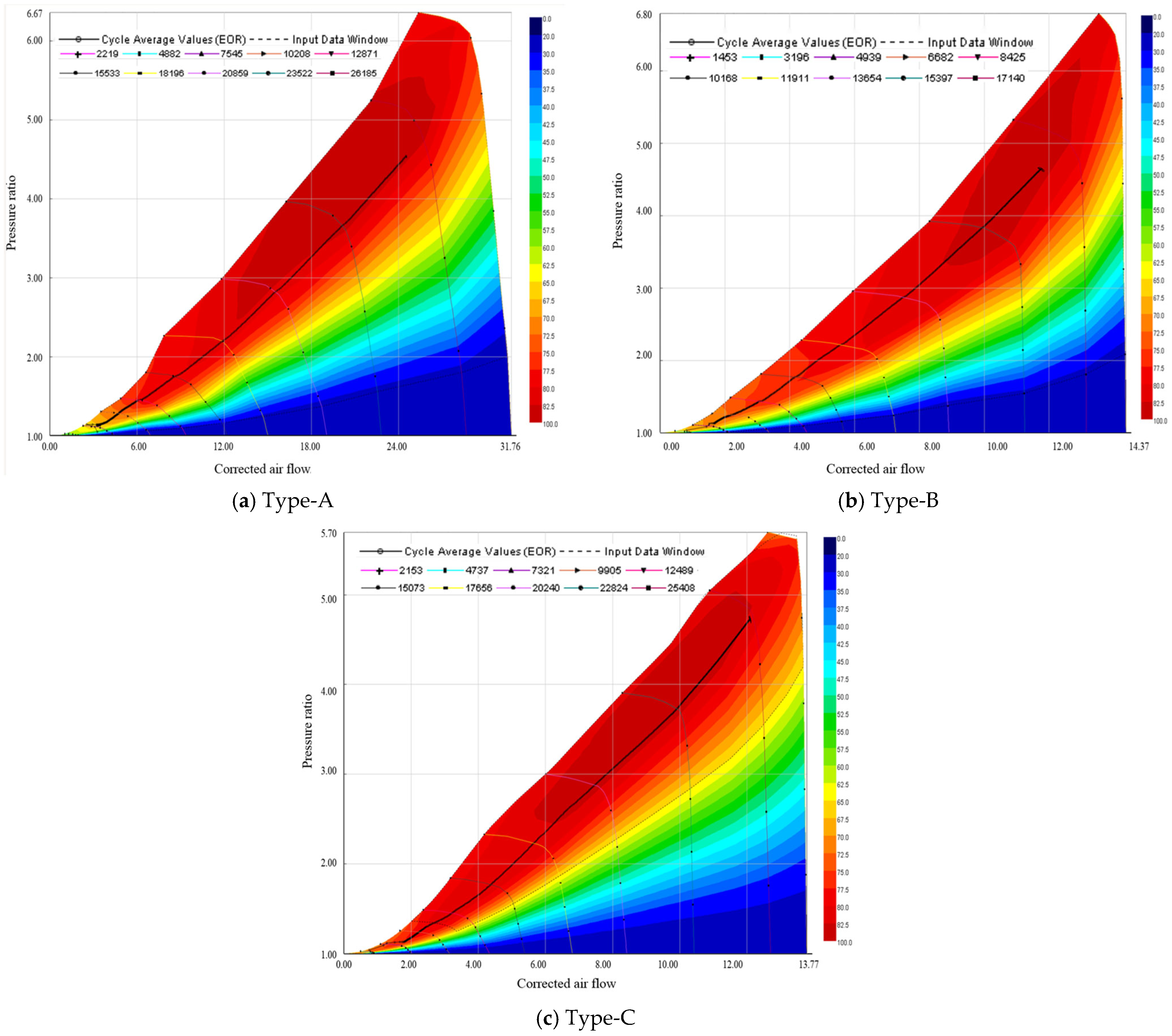

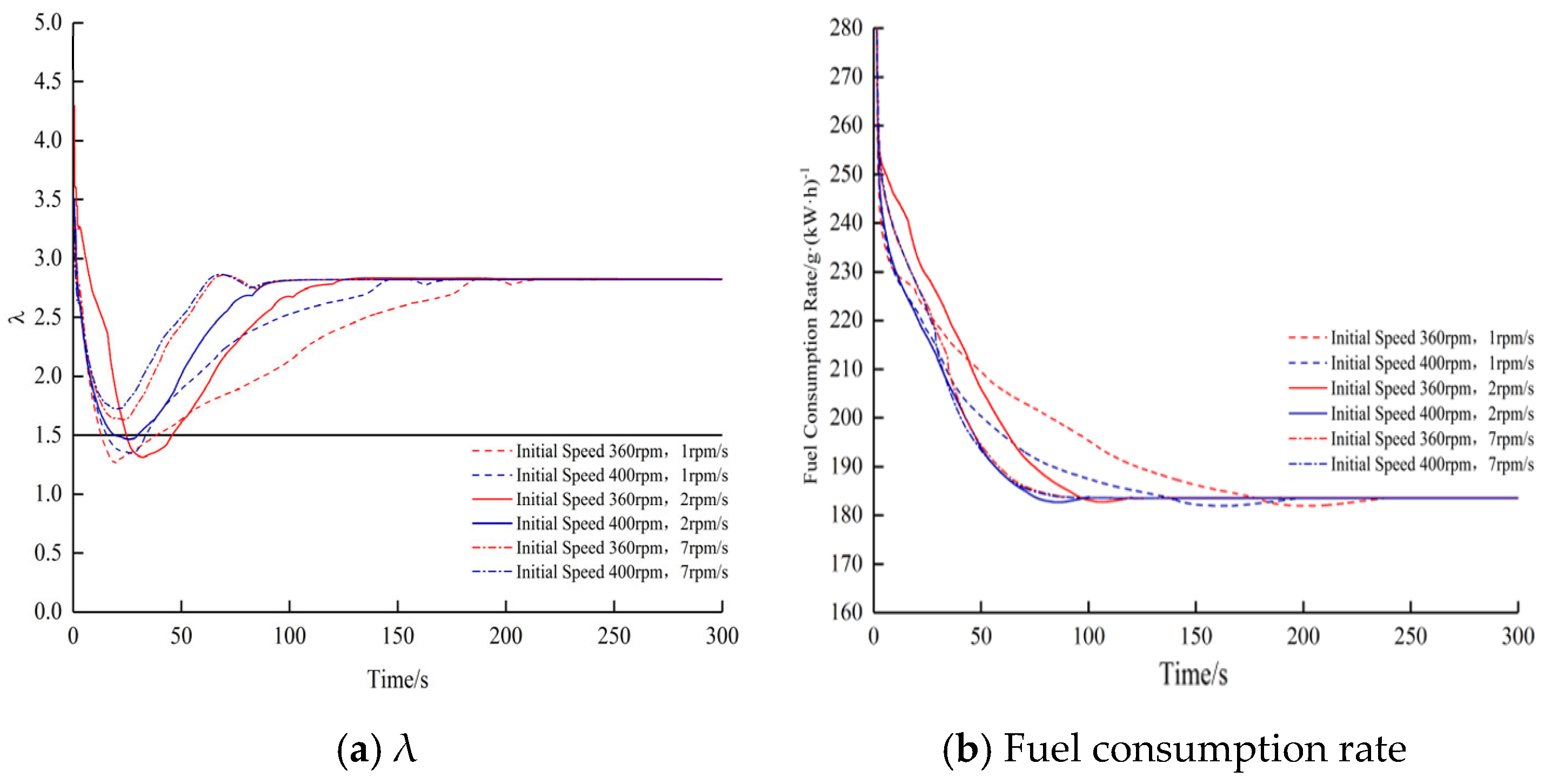

In the diesel engine simulation model, as shown in

Figure 9, the numerical simulation results of the three turbocharger schemes, A, B, and C, under low-speed transient loading conditions show that all the schemes can cover the high-efficiency working area of the MAP diagram of the pressurized engine and achieve a balanced optimization of efficiency and power output. Among them, by virtue of higher overall efficiency, the Type-A and Type-C turbochargers make the diesel engine operating line biased towards the upper power region of the MAP diagram, which shows a significant ability to expand the power of the high load. In contrast, the Type-B turbocharger, due to the conservative performance parameters, has its operating point stabilized at the center of the highest efficiency region, which maximizes the efficiency but restricts the potential of the power output. It is worth noting that the Type-C turbocharger has a longer duration when crossing the high-efficiency zone, which not only prolongs the high-efficiency operation cycle but also broadens the power regulation margin, making the diesel engine more adaptable under complex operating conditions, which is crucial for improving the overall performance competitiveness in practical applications.

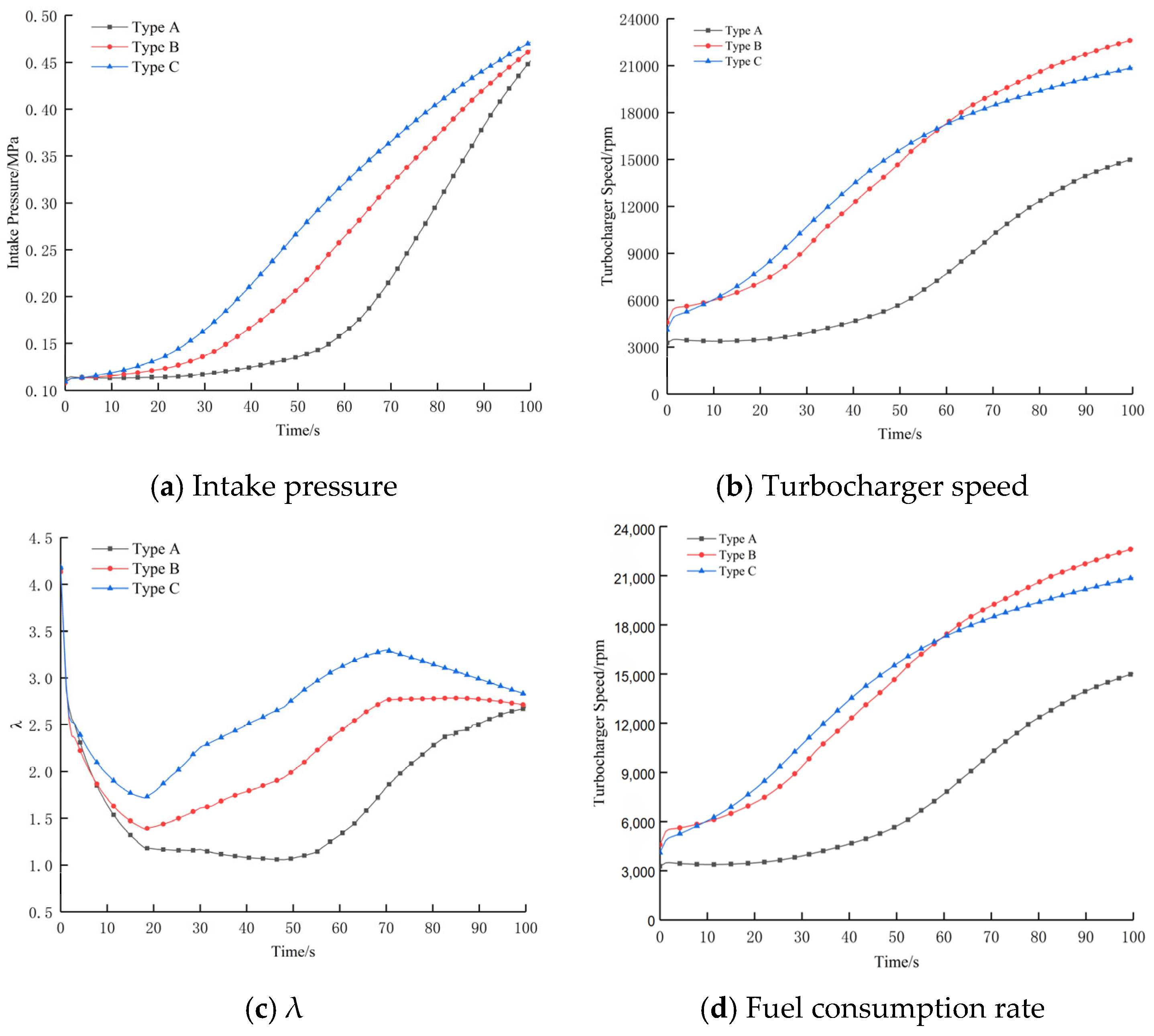

By analyzing the performance of different turbocharger solutions during diesel engine loading, it is found that they have a significant effect on intake pressure establishment, combustion efficiency, and fuel economy.

Figure 10a shows that all three turbochargers show a trend of slow increase in intake pressure at the beginning of the loading process. However, the response speeds differ significantly: it takes 57 s for the Type-A single turbocharger to reach the 0.15 MPa threshold, while the Type-B and Type-C dual turbochargers with low moment of inertia shorten the time to 35 and 25.8 s, respectively, and the response efficiencies are improved by 38.6% and 54.7%. Although the moment of inertia of the Type-C is slightly higher than that of the Type-B, it still achieves a better transient response by its higher overall efficiency, confirming that the combination of low moment of inertia and high efficiency of the dual turbocharger solution can quickly establish a stable intake pressure to ensure the supply of combustion air.

In terms of combustion optimization,

Figure 10b,c show that the λ value drops rapidly at the beginning of the loading period due to the sudden increase in fuel injection caused by the restricted air supply from the under-speed turbocharger. The dual turbocharger schemes (B and C) make the λ value steadily recover and stabilize by quickly building up the intake pressure. In contrast, the single turbocharger of Type-A has a continuous decline in λ value up to 50 s before it slowly recovers due to the lag in response. Among them, the λ value of the Type-C scheme did not fall below the 1.5 threshold throughout the whole process, completely avoiding the generation of black smoke; the λ value of the Type-A fell below the threshold within 52 s, leading to significant black smoke emission; although the Type-B exceeded the standard for a short period, the duration of the process was shortened by 78.8% compared with that of the Type-A, which verifies the advantage of the dual turbocharger scheme in suppressing emissions.

Fuel economy analysis (

Figure 10d) shows that the fuel consumption rates of dual-boost solutions B and C show a stable downward trend. In contrast, Type-A shows a rebound due to insufficient combustion at the initial stage. At the critical 30 and 70 s rev points, the fuel consumption rates of Type-B are reduced by 16 and 27.7 g·(kW·h)

−1, respectively, while those of Type-C are reduced by 9.7 and 12.9 g·(kW·h)

−1, which significantly improves the economy. Taken together, the Type-C solution provides an effective solution for optimizing performance under complex operating conditions through efficient intake pressure regulation, precise combustion control, and low fuel consumption, demonstrating comprehensive advantages in terms of improved diesel engine transient response, reduced emissions, and optimized operating costs.

3.2. Optimization Effect of Extreme Loading Strategy

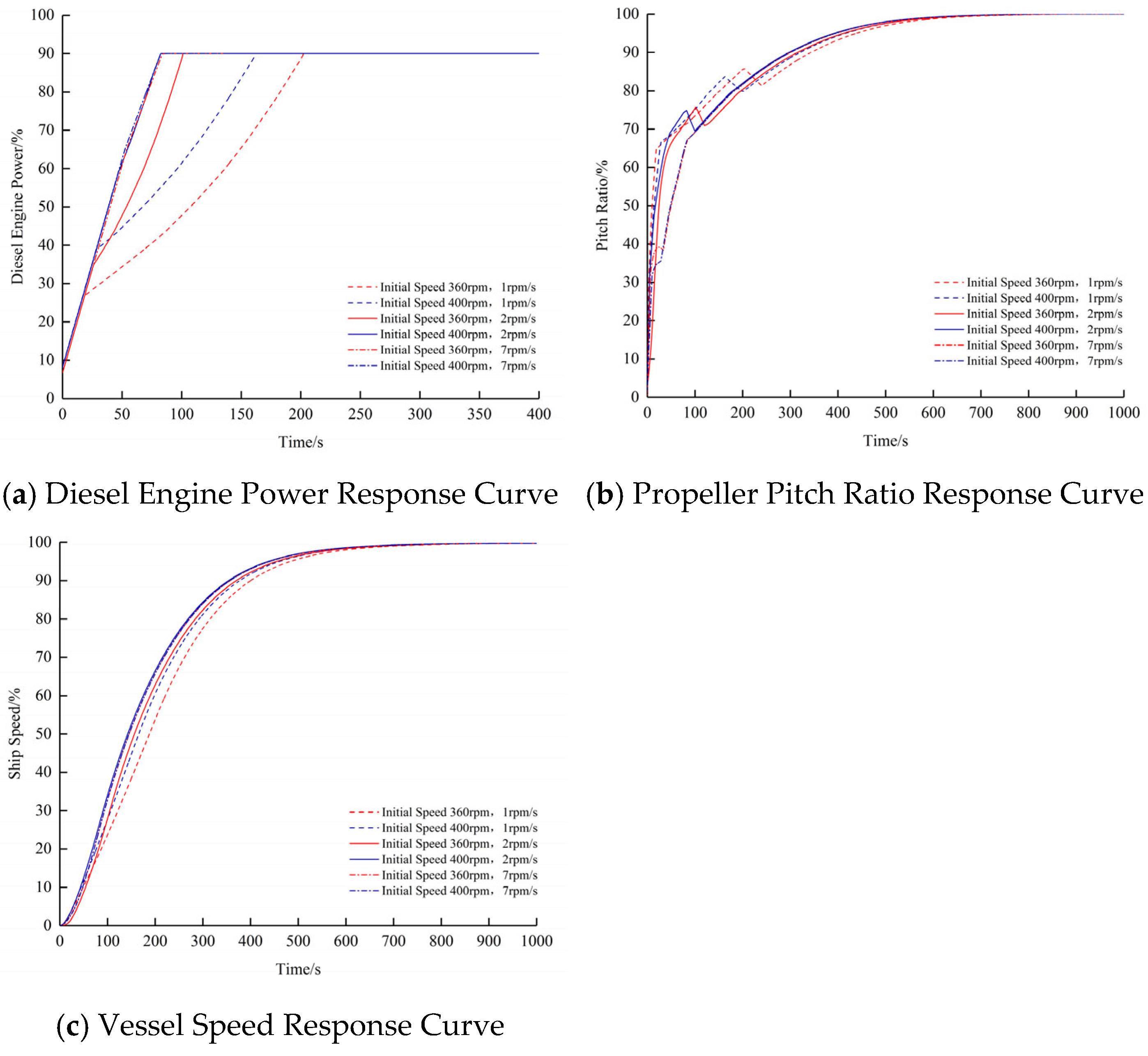

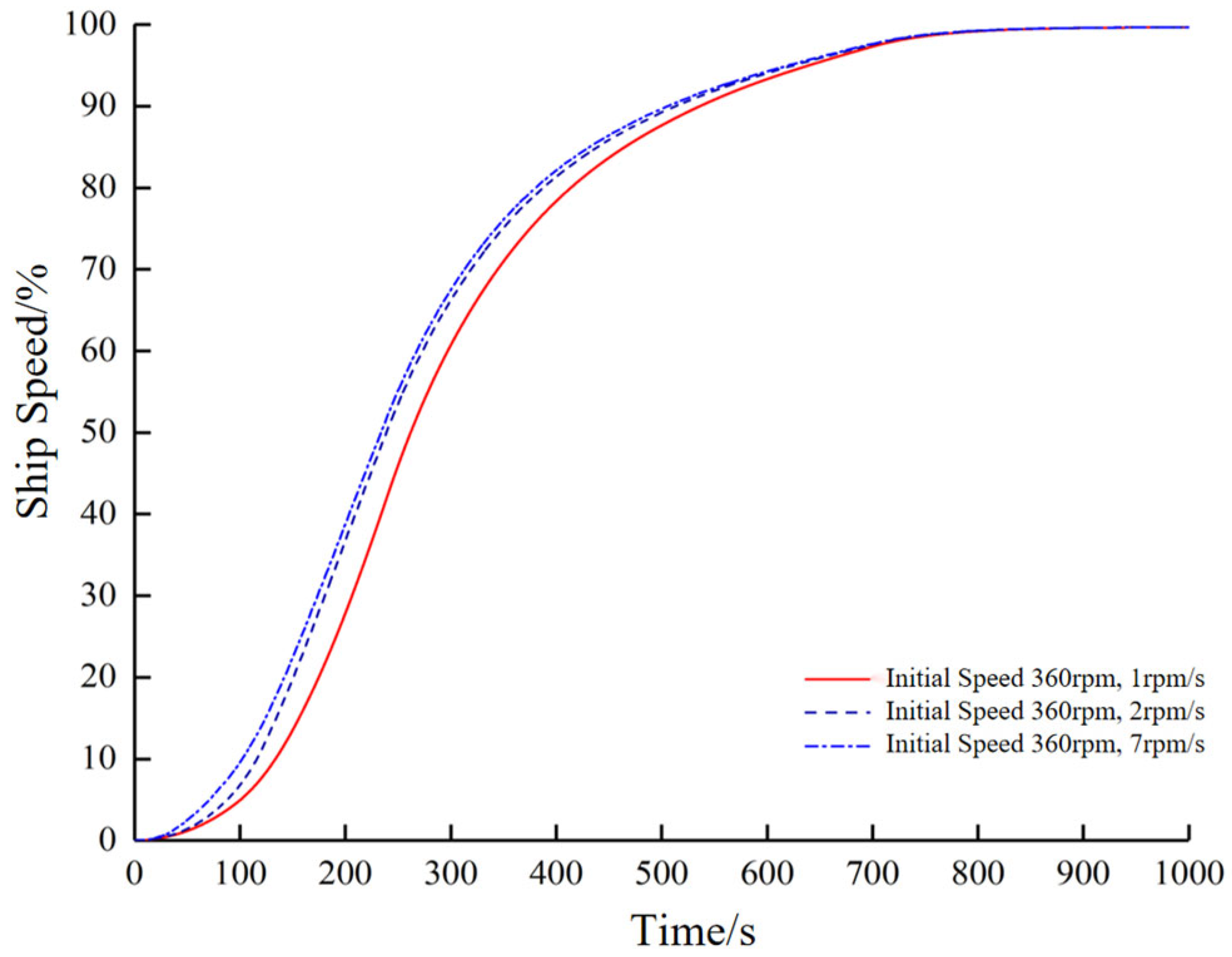

The relationship curves of diesel engine power, propeller pitch ratio, and vessel speed with loading time obtained based on the limit loading strategy for the four-engine, two-propeller starting strategy are shown in

Figure 11.

Based on the simulation results, the system parameter response is considered to have reached stability when the rate of change of the matching parameter over time, normalized by the simulation parameters, at adjacent time steps is less than 0.02%. From this, the response stabilization times for diesel engine speed, diesel engine power, propeller pitch ratio, and vessel speed are determined as shown in

Table 4 below.

During the diesel engine loading process, the effects of the initial speed and the rate of speed increase on the system response and ship performance must be weighed comprehensively. The low-speed increase rate (e.g., 1 rpm/s) is constrained by the power–speed limit line, which leads to an extension of the loading time and a decrease in the ship’s maneuverability in reaching the target power and speed. In comparison, the high-speed increase rate (e.g., 7 rpm/s) can significantly shorten the time to load to the rated power, with the shortest time being 82.5 s. However, the marginal effect of the power gain needs to be taken into account. Based on the simulation analysis, 2 rpm/s is used as a balanced strategy, which improves navigation efficiency by optimizing the matching of propeller and power loading and reduces mechanical load and energy consumption to prolong the life of the diesel engine.

The choice of initial speed directly affects the economy and safety: 360 rpm, as the lowest speed in the restricted area, has a lower real-time power demand for ship handling and a better economy, while 400 rpm, with a higher power margin, is safer for ship-handling and takes less time to load to the rated condition, which makes the maneuverability better, but its higher idling speed intensifies the vibration and noise. Therefore, the initial rotational speed should be chosen according to the ship’s priority of economy, safety, and quiet performance.

The ship–machine–propeller simulation, comparing performance under single and double turbocharger conditions (

Figure 12 and

Figure 13), shows that the fuel consumption rate is higher at the beginning of the start-up period, primarily due to frictional resistance and inertial consumption. It then decreases rapidly and tends to stabilize. The effect of turbocharger rate on fuel consumption is significant: at the same initial speed, the higher the rate (e.g., 7 rpm/s), the faster the fuel consumption rate decreases and the lower the stable value is, which indicates that a high turbocharger rate promotes combustion adequacy by increasing the intake pressure and air density, thus optimizing fuel economy. In addition, the direct effect of initial speed on fuel consumption is reflected in the fact that, under the same boost rate, the initial fuel consumption is higher at a high initial speed (400 rpm) due to the greater start-up energy demand. However, the gap between the stabilized stage and the low speed (360 rpm) is gradually narrowed. It is demonstrated that a reasonable match between the initial speed and boost rate can account for the dynamic response efficiency of the diesel engine, fuel economy, and the comprehensive performance requirements of the ship, providing a theoretical basis for optimizing the parameters under actual working conditions.

Under extreme loading conditions, the dual turbocharger significantly optimizes the exhaust black smoke characteristics by boosting the combustion air supply.

Table 5 shows that the λ values of the dual turbochargers are considerably higher than those of the single turbocharger for all combinations of initial speed and rate of increase, indicating that they are more effective in promoting complete fuel combustion. Taking the initial speed of 360 rpm/min and the rate of growth of 1 rpm/s as an example, the dual turbocharger improves λ from 0.9482 to 1.2591 compared to the single turbocharger, representing a 32.8% increase in λ. Additionally, it shortens the duration of the high-risk area from 101.3 to 25.9 s, a decrease of 74.4%. As the rate of growth is raised to 7 rpm/s, the single turbocharger increases λ by 25.6% to 1.0675 through the compensation of the fuel injection strategy. However, its mid-risk duration is still 2.1 times that of the dual turbocharger, highlighting the dual turbocharger system’s ability to improve response hysteresis to transient conditions. In addition, the dual turbocharger can eliminate the high-risk region time under several operating conditions, proving that it not only shortens the combustion deterioration phase but also significantly suppresses black smoke generation by rapidly building up intake pressure. Comprehensively, it is demonstrated that the dual turbocharger program substantially reduces the duration of medium and high-risk combustion through enhanced air supply and dynamic response, providing key technical support for transient emission control in diesel engines.

Increasing the initial speed can help improve black smoke emission, but the matching characteristics of the turbocharger system limit its effectiveness. The system matching analysis shows that at 360 r/min, the Type-C turbocharger reduces the high-risk time to one-quarter of the Type-A solution’s time by virtue of its air supply efficiency advantage, as λ is 33% higher than that of the Type-A. The Type-A turbocharger has a low value of λ, resulting in a medium-risk time that is 83% longer than that of the Type-C, even though the Type-A turbocharger partially optimizes combustion due to the turbulence enhancement achieved when the initial rotational speed is increased to 400 r/min. Under extreme operating conditions (7 rpm/s growth rate), the dual turbocharger, through the optimal matching of the high-efficiency zone of the compressor and the speed domain, combined with the enhancement of the mixture formation by the high-revolution turbulence, raises the λ to 1.7239 (52.8% higher than that of the single turbocharger), eliminating the high-risk time. This indicates that the dual turbocharger not only improves transient response through mechanical structure optimization but also enhances combustion completeness by using the speed–turbulence synergy effect, achieving a systematic breakthrough in black smoke suppression capability.

3.3. Optimization Effect of Normal Loading Strategy

Figure 14 below shows the vessel speed response curves for normal loading conditions of four engines and two propellers under different strategies. In this case, the rate of increase in the ship’s speed at the front end of the accelerating process is slightly lower than that at the high-speed increasing rate condition due to the slower rise in the diesel engine’s output power.

The simulation results of ship–machine–propeller matching in normal loading mode are shown in

Table 6 below.

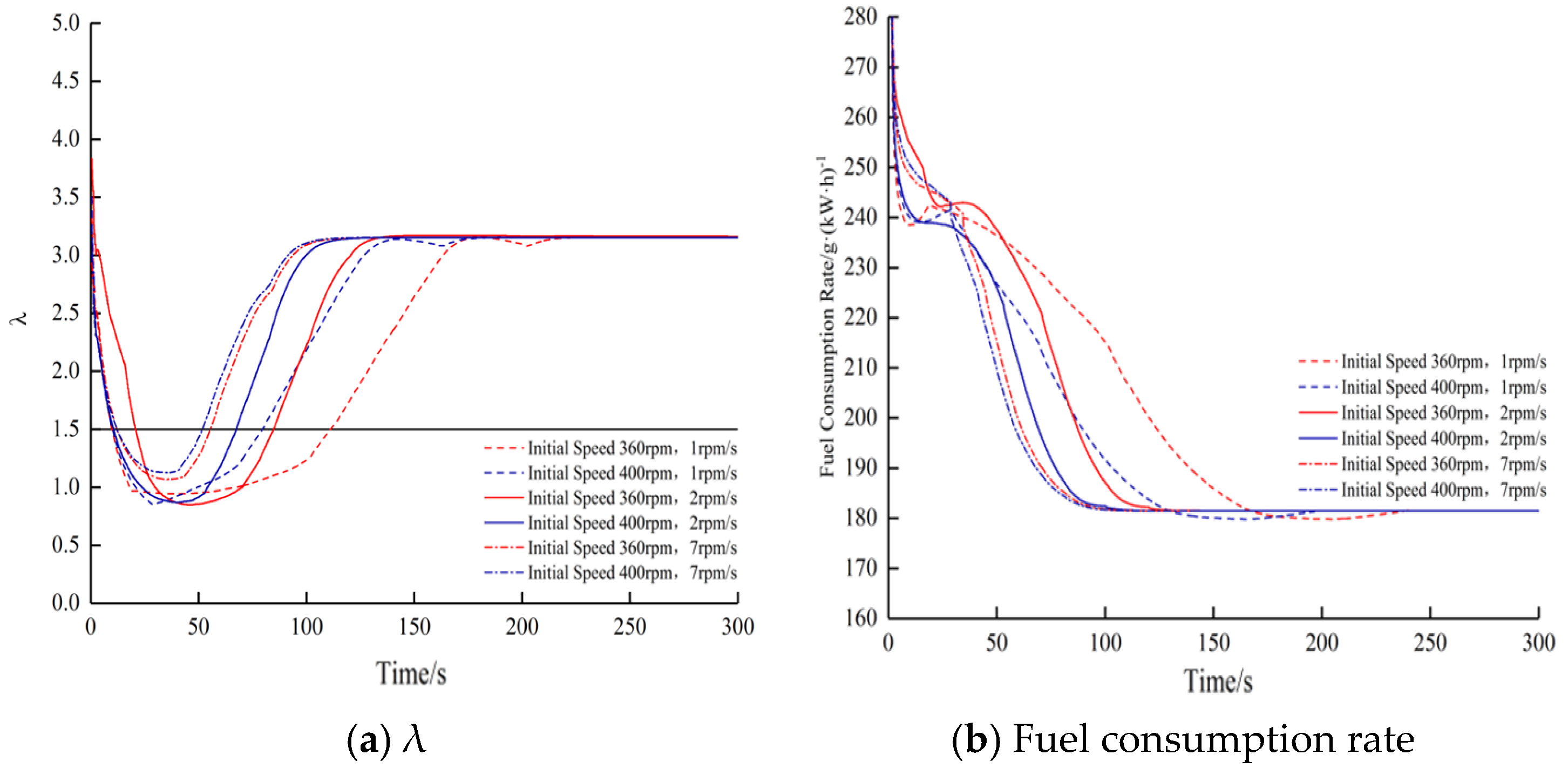

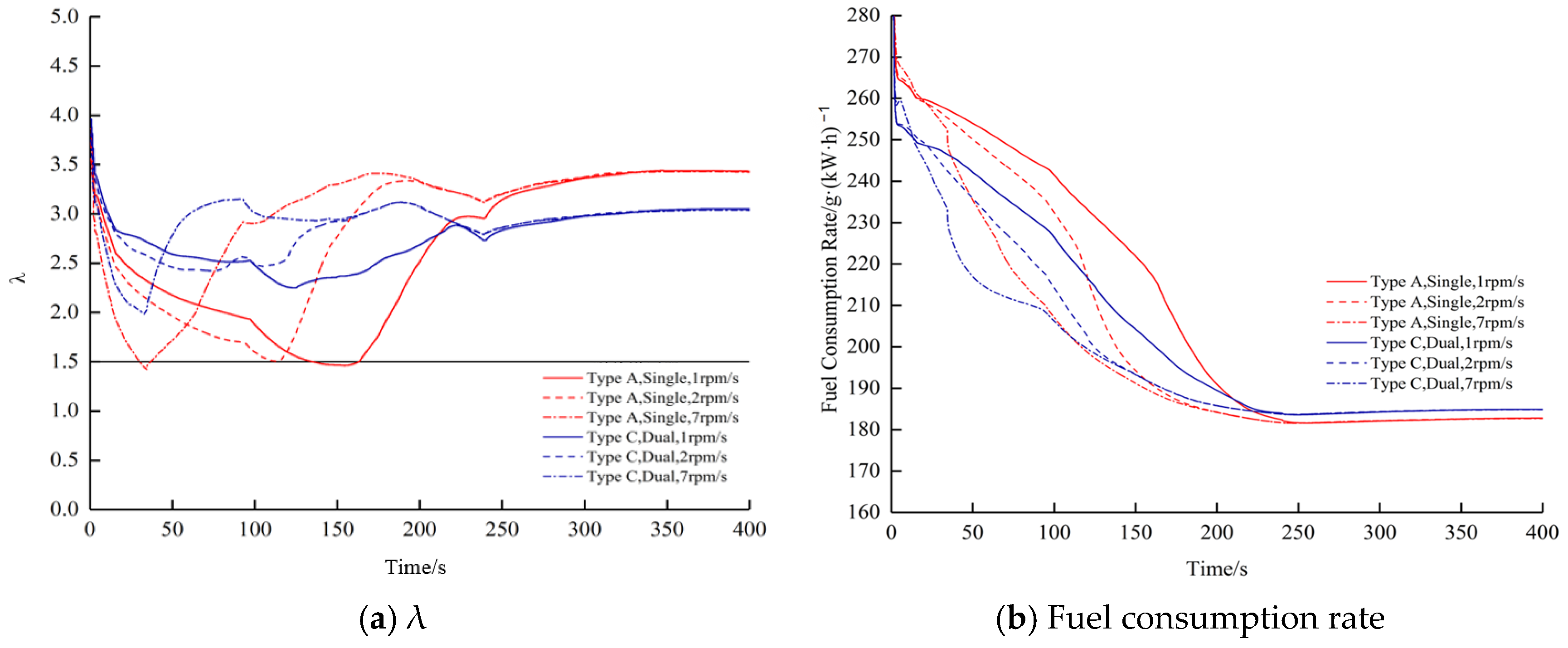

Based on the boat–machine–propeller simulation results, the simulation analyses of λ changes during emergency loading of the diesel engine in Type-A single turbocharger state and Type-C double turbocharger state were carried out.

Under normal loading conditions, the dual turbochargers are equally effective in suppressing the risk of exhaust black smoke. As shown in

Figure 15, there are some state points in the high-risk area under the single turbocharger configuration. In contrast, the dual turbochargers only leave a few medium-risk points in the fast-loading condition at a 7 rpm/s growth rate, and the risk of black smoke is eliminated under the remaining conditions. The data in

Table 7 further reveal that, under the same initial speed and growth rate conditions, the lowest λ of the single turbocharger (Type-A) falls below the 1.5 threshold several times due to insufficient intake efficiency. The duration of the medium–high-risk area is significantly prolonged, which exposes the core defect of inadequate combustion, especially in the low-load stage. After adopting the Type-C dual turbocharger, the minimum λ is lifted overall, and the duration of the medium–high risk area is essentially eliminated, which verifies its technical advantage of significantly improving combustion completeness by enhancing the dynamic response of intake pressure. Even at a high growth rate of 7 rpm/s, although the minimum λ of the dual turbocharger is slightly reduced due to the fast power loading rate, the medium-risk time is still significantly lower than that of the single turbocharger, demonstrating that it maintains stable combustion control capability under high dynamic working conditions. The comparison highlights that the dual turbochargers, through mechanical synergistic design and dynamic response optimization, achieve black smoke suppression across the entire operating range, from limited loading to conventional conditions, providing a systematic solution for clean combustion and emission control in diesel engines.

The improved dual turbocharger significantly reduces the risk of exhaust black smoke of the diesel engine under various loading modes by reducing rotational inertia. Under the 1 rpm/s and 2 rpm/s loading strategies, the lowest λ value remains stable above 2.0, achieving zero generation of black smoke. However, in the 7 rpm/s high growth rate condition, although λ does not fall below 2.0, dynamic fluctuation may lead to a potential stability problem in emission. For this reason, it is recommended to prioritize the 2 rpm/s acceleration strategy for normal loading conditions, which not only balances power loading rate and emission control requirements but also shortens acceleration time and optimizes fuel economy, thereby avoiding the potential risk associated with the 7 rpm/s strategy. By matching the dynamic response and combustion stability, the program can enhance the overall operating efficiency of the diesel engine while ensuring compliance with emission standards. This strategy offers a framework for sustainable shipping by striking a balance between emission control and fuel efficiency.

4. Discussion

This study undertakes simulation modeling and calculations of the dynamic process of ship–engine–propeller matching under emergency and normal navigation scenarios. It analyzes the correlations among the ship’s acceleration time, the exhaust smoke density of the diesel engine, the rotational speed of the diesel engine, and the acceleration and deceleration rates of the pitch ratio of the controllable-pitch propeller. The research delves into the transient characteristics of the diesel engine during the processes of loading, exhaust emission, and the ship’s acceleration. Moreover, optimization recommendations for the ship–engine–propeller matching power–control strategy are put forward, aiming to balance both maneuverability and the control of diesel engine exhaust black smoke.

The research findings indicate that the transient operating state of the diesel engine plays a decisive role in the generation of exhaust black smoke. Particularly under emergency loading conditions, the rapid increase in diesel engine power frequently leads to a deterioration in the quality of the fuel–air mixture. This, in turn, gives rise to incomplete combustion, thereby increasing the risk of exhaust black smoke. Through comparative analysis, it has been found that the Type-C dual turbocharger demonstrates remarkable advantages in enhancing fuel mixing and reducing the risk of black smoke, effectively eliminating high-risk exhaust regions. Furthermore, this study conducts an in-depth exploration of the mechanism by which the initial stable rotational speed after connection impacts the exhaust black smoke characteristics of the diesel engine. The analysis results suggest that although increasing the initial stable rotational speed can, to some extent, suppress the generation of exhaust black smoke, the suppression effect is not substantial. This is mainly because as the rotational speed rises, while the intake air volume increases, which promotes the improvement of the combustion process, the fuel supply also concomitantly increases. As a result, the improvement in combustion conditions is limited. Regarding the normal loading process, this study recommends a comprehensive consideration of the trade-off between the power loading rate and the black smoke risk. It is proposed that a rotational speed increase rate exceeding 7 rpm/s should be avoided to ensure the stable operation of the diesel engine and compliance with stringent emission standards. Additionally, a rotational speed increase rate of 2 rpm/s is preferably considered to achieve the desired ship speed more rapidly and attain a lower fuel-consumption rate.

To deepen and expand the scope of this research, the following investigations will be conducted in the future:

- (1)

Building upon the established dual turbocharger configuration, emphasis will be placed on the optimization of the intake and exhaust systems of this medium-speed diesel engine. Additionally, meticulous calibration of valve timing will be carried out. The objective is to explore and implement a comprehensive strategy that can effectively enhance the power output, fuel efficiency, and low speed response of the diesel engine, thereby significantly improving its overall performance.

- (2)

With respect to the control logic of the PI governor, a more comprehensive set of factors will be taken into account. These factors include, but are not limited to, the temperature and pressure thresholds of the intake and exhaust systems, as well as the operational status of the turbocharger. These parameters will serve as input information for the governor’s decision-making process. By comprehensively evaluating the operational constraints of key components within the diesel engine, precise regulation and optimal control of fuel injection quantity can be achieved.

- (3)

Leveraging a profound understanding of the ship’s operating characteristics across all working conditions, simulation analyses of the ship–engine–propeller system will be conducted under various navigation modes, such as reverse operation, turning maneuvers, towing operations, and mooring conditions. The purpose of these analyses is to validate and optimize the collaborative efficiency of the system under each condition. Based on these findings, a highly adaptable control strategy will be proposed to ensure the stable operation and efficient maneuverability of the ship in diverse and complex operational environments.