Characterization of Particle Emissions from GTM 400 Fueled with HEFA-SPK Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Engine and Fuels

2.2. Apparatus and Procedures

3. Results

3.1. Particle-Number-Emission Indices

3.2. Particulate-Mass-Emission Indices

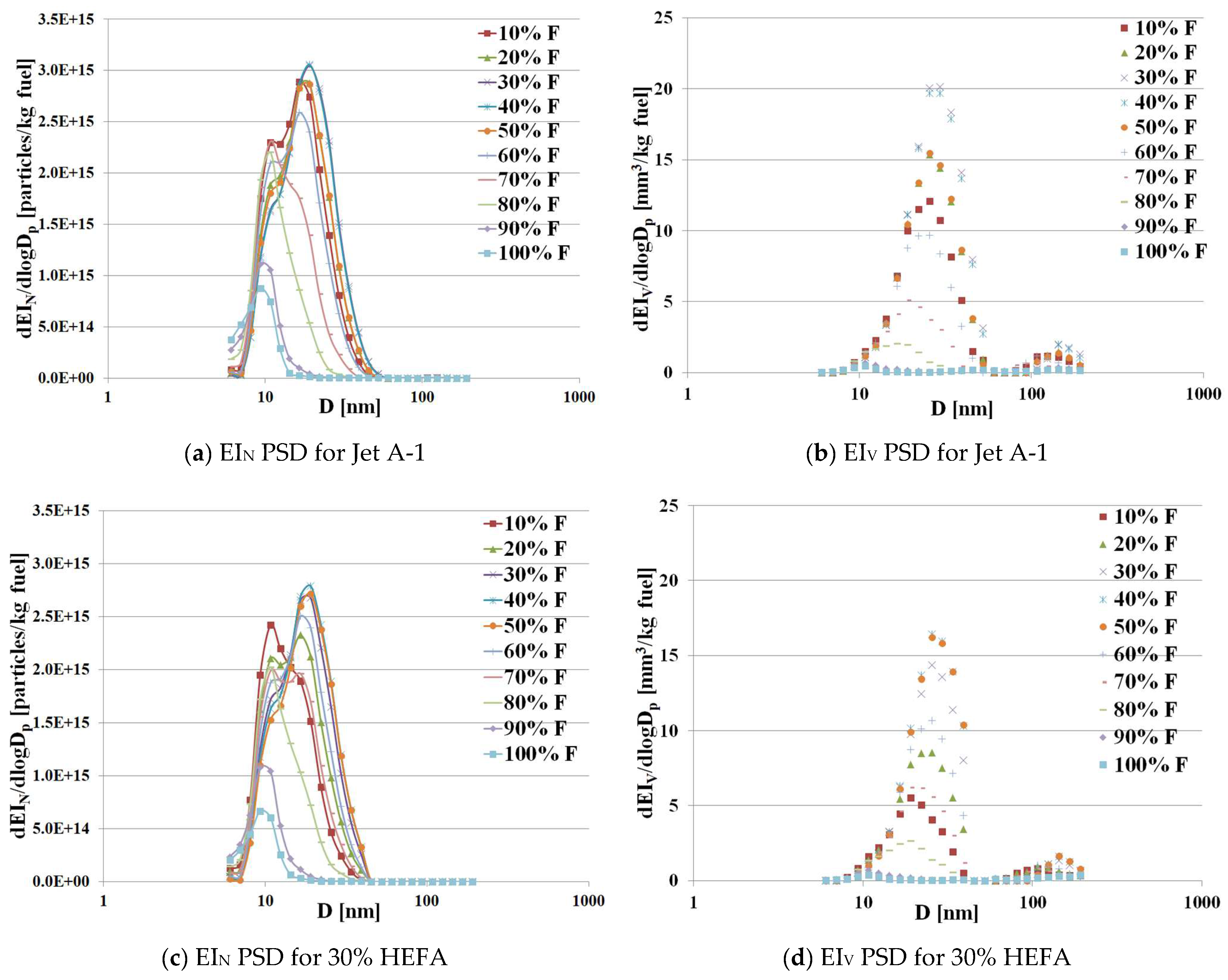

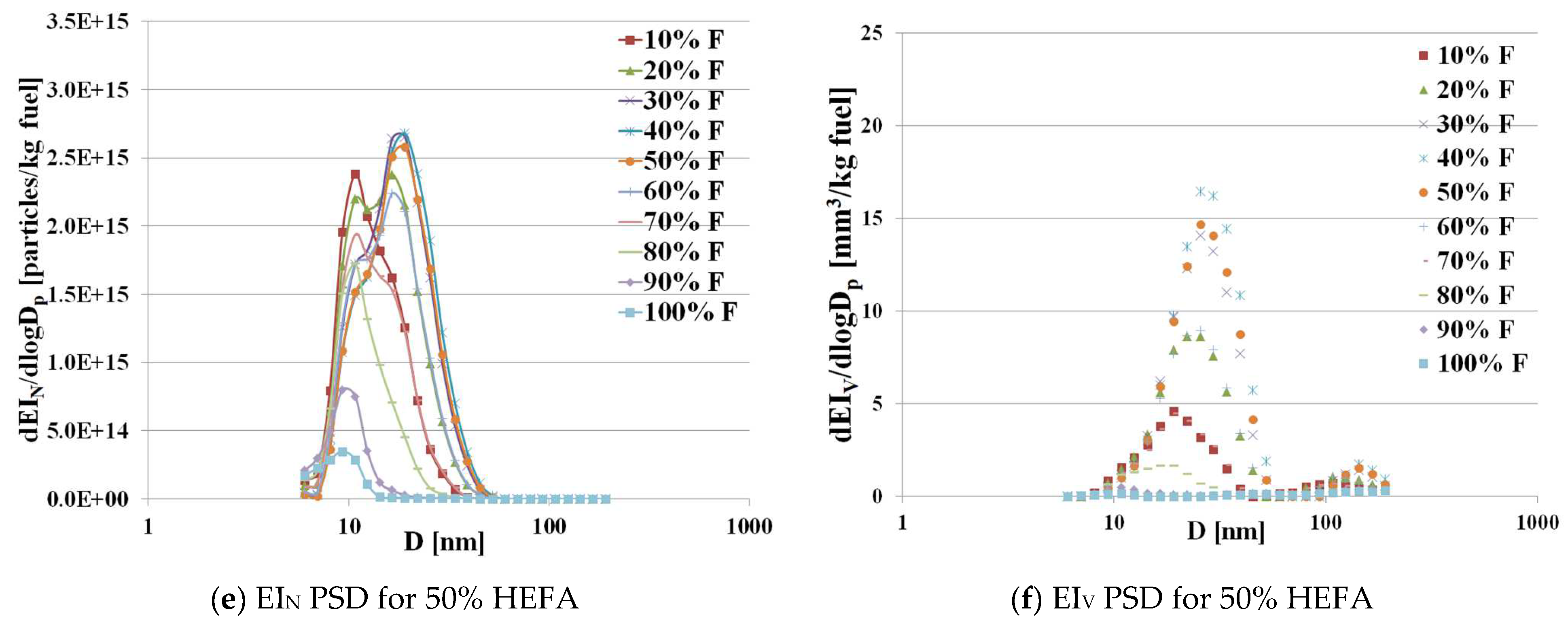

3.3. Particle-Size Distribution

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hasan, M.A.; Mamun, A.A.; Rahman, S.M.; Malik, K.; Al Amran, M.I.U.; Khondaker, A.N.; Reshi, O.; Tiwari, S.P.; Alismail, F.S. Climate change mitigation pathways for the aviation sector. Sustainability 2021, 13, 3656. [Google Scholar] [CrossRef]

- Galant-Gołębiewska, M.; Jasiński, R.; Nowak, M.; Kurzawska, P.; Maciejewska, M.; Ginter, M. Methodical aspects of the LTO cycle use for environmental impact assessment of air operations based on the Warsaw Chopin Airport. Aviation 2021, 25, 86–91. [Google Scholar] [CrossRef]

- EASA. Updated Analysis of the Non-CO2 Climate Impacts of Aviation and Potential Policy Measures Pursuant to the EU Emissions Trading System Directive Article 30(4); EASA: Cologne, Germany, 2020. [Google Scholar]

- ICAO. ICAO International Standards and Recommended Practices, Annex 16 to the Convention on International Civil Aviation, Environmental Protection: Volume II—Aircraft Engine Emissions, 4th ed.; ICAO: Montreal, QC, Canada, 2017. [Google Scholar]

- Wang, J.; Zu, L.; Zhang, S.; Jiang, H.; Ni, H.; Wang, Y.; Zhang, H.; Ding, Y. Recent Advances and Implications for Aviation Emission Inventory Compilation Methods. Sustainability 2024, 16, 8507. [Google Scholar] [CrossRef]

- Owen, B.; Anet, J.G.; Bertier, N.; Christie, S.; Cremaschi, M.; Dellaert, S.; Edebeli, J.; Janicke, U.; Kuenen, J.; Lim, L.; et al. Review: Particulate matter emissions from aircraft. Atmosphere 2022, 13, 1230. [Google Scholar] [CrossRef]

- Monroig, O.R.; Corporan, E.; DeWitt, M.J.; Striebich, R.; Wagner, M. Effects of aromatic and sulfur concentration in jet fuel on the emissions of a T63 engine. In Proceedings of the 9th International Conference on Stability, Handling and Use of Liquid Fuels, Sitges, Spain, 14–19 September 2005; Volume 3, pp. 1839–1848. [Google Scholar]

- Monroig, O.; Corporan, E.; DeWitt, M.J.; Mortimer, B.; Ostdiek, D.; Wagner, M. Effects of jet fuel aromatic concentration on the emissions of a T63 engine. ACS Div. Fuel Chem. Prepr. 2005, 50, 335–337. [Google Scholar]

- Brem, B.T.; Durdina, L.; Siegerist, F.; Beyerle, P.; Bruderer, K.; Rindlisbacher, T.; Rocci-Denis, S.; Andac, M.G.; Zelina, J.; Penanhoat, O.; et al. Effects of Fuel Aromatic Content on Nonvolatile Particulate Emissions of an In-Production Aircraft Gas Turbine. Environ. Sci. Technol. 2015, 49, 13149–13157. [Google Scholar] [CrossRef]

- Moore, R.H.; Shook, M.; Beyersdorf, A.; Corr, C.; Herndon, S.; Knighton, W.B.; Miake-Lye, R.; Thornhill, K.L.; Winstead, E.L.; Yu, Z.; et al. Influence of jet fuel composition on aircraft engine emissions: A synthesis of aerosol emissions data from the NASA APEX, AAFEX, and ACCESS missions. Energy Fuels 2015, 29, 2591–2600. [Google Scholar] [CrossRef]

- Timko, M.T.; Yu, Z.; Onasch, T.B.; Wong, H.-W.; Miake-Lye, R.C.; Beyersdorf, A.J.; Anderson, B.E.; Thornhill, K.L.; Winstead, E.L.; Corporan, E.; et al. Particulate emissions of gas turbine engine combustion of a fischer-tropsch synthetic fuel. Energy Fuels 2010, 24, 5883–5896. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Sustainable Aviation Fuel: Review of Technical Pathways; Office of Energy Efficiency & Renewable, Energy: Washington, DC, USA, 2020. [Google Scholar]

- Kurzawska-Pietrowicz, P.; Jasiński, R. A Review of Alternative Aviation Fuels. Energies 2024, 17, 3890. [Google Scholar] [CrossRef]

- ICAO. ICAO Document, CORSIA Default Life Cycle Emissions Values for CORSIA Eligible Fuels; ICAO: Montreal, QC, Canada, 2022. [Google Scholar]

- Gawron, B.; Białecki, T.; Janicka, A.; Suchocki, T. Combustion and emissions characteristics of the turbine engine fueled with HEFAblends from different feedstocks. Energies 2020, 13, 1277. [Google Scholar] [CrossRef]

- Undavalli, V.K.; Hamilton, J.; Ubogu, E.A.; Ahmed, I.; Khandelwal, B. Impact of HEFA Fuel Properties on Gaseous Emissions and Smoke Number in a Gas Turbine Engine. In Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition. Volume 3B: Combustion, Fuels, and Emissions, Rotterdam, The Netherlands, 13–17 June 2022. [Google Scholar] [CrossRef]

- Roiger, A.; Harlaß, T.; Bräuer, T.; Schlager, H.; Schumann, U.; Sauer, D.; Voigt, C.; Dörnbrack, A.; Märkl, R.; Dischl, R.; et al. In-flight and ground-based measurements of nitrogen oxide emissions from latest generation jet engines and 100% sustainable aviation fuel. In Proceedings of the EGU General Assembly 2024, Vienna, Austria, 14–19 April 2024. [Google Scholar] [CrossRef]

- Merkisz, J.; Pielecha, J. The on-road exhaust emissions characteristics of SUV vehicles fitted with diesel engines. Combust. Engines 2011, 145, 58–72. [Google Scholar] [CrossRef]

- Jasiński, R.; Kurzawska, P.; Przysowa, R. Characterization of particle emissions from a DGEN 380 small turbofan fueled with ATJ blends. Energies 2021, 14, 3368. [Google Scholar] [CrossRef]

- Schripp, T.; Anderson, B.; Crosbie, E.C.; Moore, R.H.; Herrmann, F.; Oßwald, P.; Wahl, C.; Kapernaum, M.; Köhler, M.; le Clercq, P.; et al. Impact of Alternative Jet Fuels on Engine Exhaust Composition during the 2015 ECLIF Ground-Based Measurements Campaign. Environ. Sci. Technol. 2018, 52, 4969–4978. [Google Scholar] [CrossRef]

- Rojo, C.; Vancassel, X.; Mirabel, P.; Ponche, J.-L.; Garnier, F. Impact of alternative jet fuels on aircraft-induced aerosols. Fuel 2015, 144, 335–341. [Google Scholar] [CrossRef]

- Moore, R.H.; Thornhill, K.L.; Weinzierl, B.; Sauer, D.; D’Ascoli, E.; Kim, J.; Lichtenstern, M.; Scheibe, M.; Beaton, B.; Beyersdorf, A.J.; et al. Biofuel blending reduces particle emissions from aircraft engines at cruise conditions. Nature 2017, 543, 411–415. [Google Scholar] [CrossRef]

- Jasiński, R. Analysis of Particle Emissions from a Jet Engine Including Conditions of Afterburner Use. Energies 2022, 15, 7696. [Google Scholar] [CrossRef]

- Durdina, L.; Brem, B.T.; Elser, M.; Schönenberger, D.; Siegerist, F.; Anet, J.G. Reduction of nonvolatile particulate matter emissions of a commercial turbofan engine at the ground level from the use of a sustainable aviation fuel blend. Environ. Sci. Technol. 2021, 55, 14576–14585. [Google Scholar] [CrossRef]

- Chan, T.W.; Chishty, W.A.; Canteenwalla, P.; Buote, D.; Davison, C.R. Characterization of emissions from the use of alternative aviation fuels. J. Eng. Gas. Turbine Power 2016, 138, 011506. [Google Scholar] [CrossRef]

- Jasiński, R.; Przysowa, R. Evaluating the Impact of Using HEFA Fuel on the Particulate Matter Emissions from a Turbine Engine. Energies 2024, 17, 1077. [Google Scholar] [CrossRef]

- Durdina, L.; Brem, B.T.; Setyan, A.; Siegerist, F.; Rindlisbacher, T.; Wang, J. Assessment of Particle Pollution from Jetliners: FromSmoke Visibility to Nanoparticle Counting. Environ. Sci. Technol. 2017, 51, 3534–3541. [Google Scholar] [CrossRef]

- Durdina, L.; Decker, Z.C.J.; Edebeli, J.; Spirig, C.; Frischknecht, T.; Anet, J.G.; Brem, B.T.; Siegerist, F.; Rindlisbacher, T. Gaseous and Particulate Emissions from a Small Business Jet Using Conventional Jet A-1 and a 30% SAF Blend. ACS EST Air 2025, 2, 967–978. [Google Scholar] [CrossRef]

- Timko, M.T.; Herndon, S.C.; de la Rosa Blanco, E.; Wood, E.C.; Yu, Z.; Miake-Lye, R.C.; Corporan, E. Combustion products of petroleum jet fuel, a Fischer-Tropsch synthetic fuel, and a biomass fatty acid methyl ester fuel for a gas turbine engine. Combust. Sci. Technol. 2011, 183, 1039–1068. [Google Scholar] [CrossRef]

- Jonsdottir, H.R.; Delaval, M.; Leni, Z.; Keller, A.; Brem, B.T.; Siegerist, F.; Schönenberger, D.; Durdina, L.; Elser, M.; Burtscher, H.; et al. Non-volatile particle emissions from aircraft turbine engines at ground-idle induce oxidative stress in bronchial cells. Commun. Biol. 2019, 2, 90. [Google Scholar] [CrossRef] [PubMed]

- Lobo, P.; Condevaux, J.; Yu, Z.; Kuhlmann, J.; Hagen, D.E.; Miake-Lye, R.C.; Whitefield, P.D.; Raper, D.W. Demonstration of a Regulatory Method for Aircraft Engine Nonvolatile PM Emissions Measurements with Conventional and Isoparaffinic Kerosene fuels. Energy Fuels 2016, 30, 7770–7777. [Google Scholar] [CrossRef]

- Beyersdorf, A.J.; Timko, M.T.; Ziemba, L.D.; Bulzan, D.; Corporan, E.; Herndon, S.C.; Howard, R.; Miake-Lye, R.; Thornhill, K.L.; Winstead, E.; et al. Reductions in aircraft particulate emissions due to the use of Fischer–Tropsch fuels. Atmos. Chem. Phys. 2014, 14, 11–23. [Google Scholar] [CrossRef]

- Schripp, T.; Herrmann, F.; Oßwald, P.; Köhler, M.; Zschocke, A.; Weigelt, D.; Mroch, M.; Werner-Spatz, C. Particle emissions of two unblended alternative jet fuels in a full scale jet engine. Fuel 2019, 256, 115903. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Thrust max. | N | 400 |

| Thrust min. | N | 15 |

| RPM max | rpm | 85,000 |

| RPM min | rpm | 27,000 |

| Compression ratio | - | 3.3:1 |

| Mass air flow rate | g/s | 770 |

| Exhaust gas temperature | °C | 750 |

| Fuel consumption | g/min | 1200 |

| Parameter | Value |

|---|---|

| Diameter range | 5.6–560 nm |

| Number of measurement channels per decade | 16 |

| Resolution | 10 Hz |

| Exhaust sample volume flow rate | 0.6 m3/h |

| Compressed air volume flow rate | 2.4 m3/h |

| Input sample temperature | 10–52 °C |

| Fuel Type | RC [%] | Thrust [N] | Fuel Flow [kg/h] | T3 [°C] | P2 [hPa] | Total Mass Flow [kg/s] | RPM [1/min] |

|---|---|---|---|---|---|---|---|

| Jet A-1 | 10 | 22 | 11.91 | 966.29 | 174.85 | 0.186 | 32,305 |

| 30 | 48.8 | 16.25 | 893.26 | 333.95 | 0.257 | 42,903 | |

| 50 | 88.9 | 21.45 | 892.20 | 569.13 | 0.337 | 53,624 | |

| 70 | 156.8 | 28.23 | 928.23 | 892.48 | 0.422 | 64,020 | |

| 100 | 321 | 43.39 | 1089.40 | 1554.24 | 0.555 | 78,475 | |

| 30% HEFA | 10 | 23 | 12.09 | 958.57 | 175 | 0.183 | 32,373 |

| 30 | 47.5 | 16.38 | 893.25 | 329.65 | 0.253 | 42,770 | |

| 50 | 89.4 | 21.82 | 885.81 | 578.63 | 0.340 | 54,013 | |

| 70 | 152.2 | 28.31 | 914.81 | 890.15 | 0.422 | 63,995 | |

| 100 | 315 | 46.15 | 1067.97 | 1528.33 | 0.558 | 78,765 | |

| 50% HEFA | 10 | 22.0 | 12.12 | 942.30 | 176.58 | 0.179 | 32,342 |

| 30 | 49.5 | 16.70 | 885.91 | 342.03 | 0.261 | 43,388 | |

| 50 | 89.9 | 21.63 | 879.79 | 563.40 | 0.334 | 53,446 | |

| 70 | 156.3 | 28.51 | 911.73 | 890.93 | 0.422 | 64,055 | |

| 100 | 323 | 47.16 | 1061.27 | 1554.75 | 0.550 | 79,150 |

| F | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% | Mean |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Jet A-1 | 2.01 × 1016 | 2.00 × 1016 | 2.13 × 1016 | 2.12 × 1016 | 1.98 × 1016 | 1.76 × 1016 | 1.39 × 1016 | 1.01 × 1016 | 4.41 × 1015 | 3.44 × 1015 | - |

| 30% HEFA | −27% | −17% | −13% | −10% | −6% | −3% | +1% | 0% | −3% | −24% | −10% |

| 50% HEFA | −32% | −14% | −14% | −13% | −11% | −14% | −14% | −20% | −28% | −56% | −22% |

| 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% | Mean | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Jet A-1 | 88.108 | 106.402 | 138.516 | 136.027 | 106.308 | 71.922 | 37.429 | 16.699 | 4.899 | 3.471 | - |

| 30% HEFA | −54% | −39% | −31% | −21% | −1% | +4% | +24% | +23% | −8% | −20% | −12% |

| 50% HEFA | −60% | −37% | −29% | −17% | −5% | −8% | −11% | −14% | −17% | −34% | −23% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurzawska-Pietrowicz, P.; Jasiński, R. Characterization of Particle Emissions from GTM 400 Fueled with HEFA-SPK Blends. Energies 2025, 18, 2696. https://doi.org/10.3390/en18112696

Kurzawska-Pietrowicz P, Jasiński R. Characterization of Particle Emissions from GTM 400 Fueled with HEFA-SPK Blends. Energies. 2025; 18(11):2696. https://doi.org/10.3390/en18112696

Chicago/Turabian StyleKurzawska-Pietrowicz, Paula, and Remigiusz Jasiński. 2025. "Characterization of Particle Emissions from GTM 400 Fueled with HEFA-SPK Blends" Energies 18, no. 11: 2696. https://doi.org/10.3390/en18112696

APA StyleKurzawska-Pietrowicz, P., & Jasiński, R. (2025). Characterization of Particle Emissions from GTM 400 Fueled with HEFA-SPK Blends. Energies, 18(11), 2696. https://doi.org/10.3390/en18112696