1. Introduction

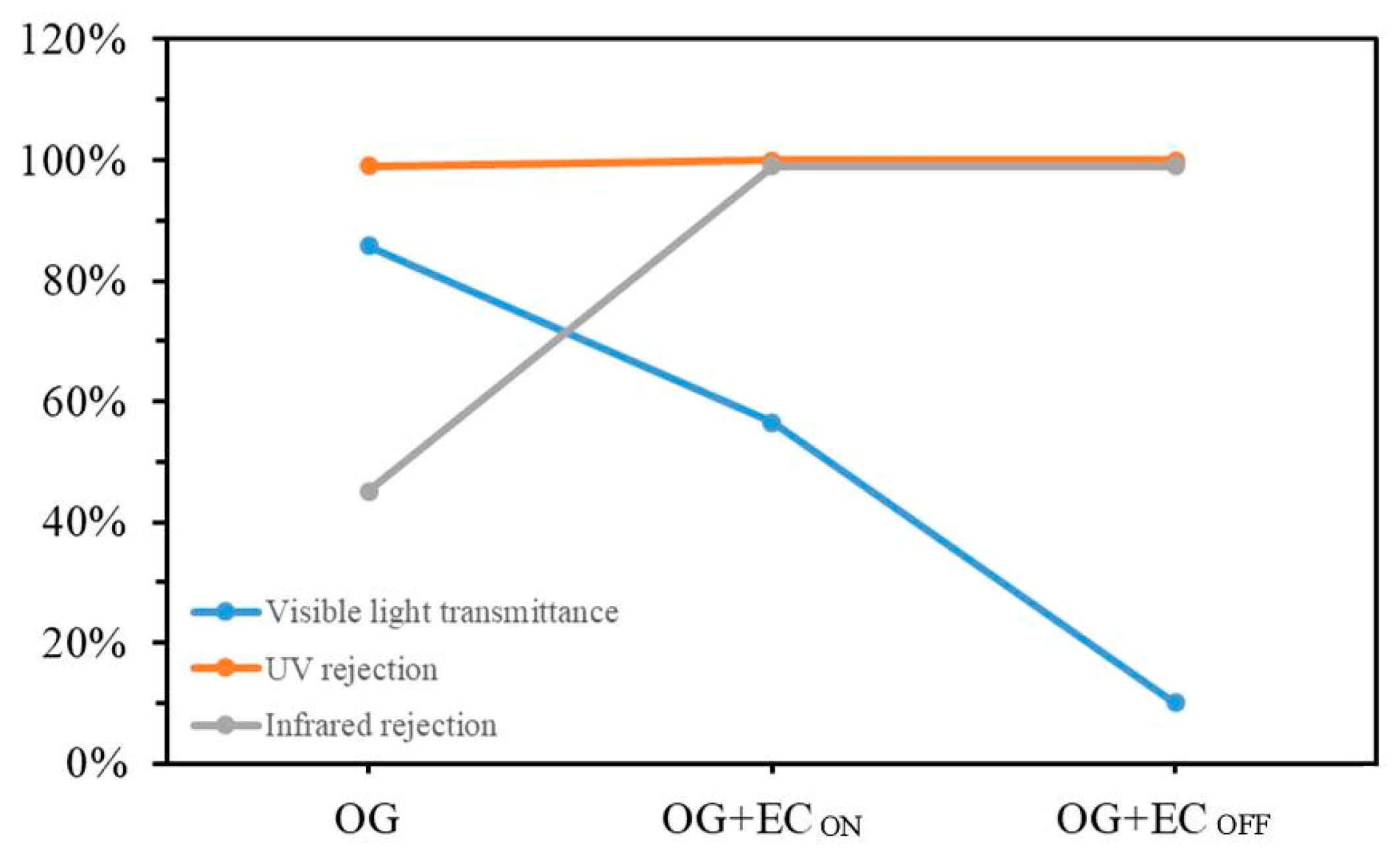

The majority of building energy consumption is influenced by the heat entering through walls, windows, and ceilings, with windows being the most susceptible to heat ingress. Therefore, the thermal insulation efficiency of windows has a significant impact. Over the past few years, numerous thermal insulation facilities have been developed, including external shading, heat-insulating films, Low-E glass, electrochromic film, etc., with many scholars also comparing the thermal insulation effects of different types of glass. The optical properties of glass also play a crucial role in determining its insulation effectiveness. Thermal insulation films enhance the glass’s solar reflectance and absorption, thereby reducing its solar transmittance and subsequently lowering the heat entering indoors. Solar radiation consists of ultraviolet light, visible light, and infrared light. However, reducing visible light transmittance simultaneously reduces indoor brightness, and increasing solar absorption raises the film temperature, leading to secondary radiation and reducing the lifespan of the film. Many scholars have explored the effects of thermal insulation film application through practical experiments or by building energy simulations.

Smart photochromic glass is a material that can alter its optical properties based on external conditions, and includes piezochromic, thermochromic, and electrochromic glass. Among these, electrochromic glass can change its color and transparency level by applying an electric current, thereby regulating environmental temperature. There are three types of electrochromic technology: electrochromic, suspended particle device (SPD), and polymer-dispersed liquid crystal (PDLC), which we will introduce in detail in the following sections.

Electrochromic glass consists of two layers of tungsten oxide or nickel oxide as the electrochromic layer, with an electrolyte sandwiched in between [

1]. The principle involves applying a direct current to the transparent conductive layer, which attracts ions from the electrolyte into the electrochromic layer, initiating a reduction reaction with electrons. Reversing the voltage causes the glass to transition from an opaque state back to a transparent state. Here are some simulated or experimental comparisons between electrochromic glass and other shading methods found in the literature.

Aste et al. [

2] compared the effects of electrochromic glass, regular glass, and external blinds systems in an office building in Milan using EnergyPlus simulations. The results showed that electrochromic glass reduced energy consumption by 39.5% compared to regular glass and by 26.2% compared to external blinds.

Sbar et al. [

3] evaluated the energy-saving effect of using electrochromic glass in buildings with a window to wall ratio of 60% in different climate zones of the United States. Simulation results using eQuest indicated that compared to static glass, electrochromic glass could reduce energy consumption by over 45% and decrease the demand on air conditioning systems, resulting in cost savings.

Piccolo et al. [

4] conducted experiments and simulations on a building located in Messina, Italy. The results indicated that the temperature difference between the inner and outer surfaces of the glass was greater in the opaque state compared to the transparent state. This is attributed to the electrochromic (EC) effect, which increases absorption of thermal radiation, resulting in secondary solar heat generation. The author also analyzed the different heat components entering the interior through opaque glass, observing an 83% reduction in direct radiation, a 46% increase in thermal radiation, and a 14% increase in convective heat transfer. Simulation results showed that in climates with predominant cooling demands, EC glass effectively reduces building energy consumption, whereas in climates with predominant heating demands, the energy-saving effects are less evident.

Ardakan et al. [

5] compared the glare control performance of two case sites using fritted glass (an opaque ceramic material deposited on glass during heat treatment) and electrochromic (EC) windows, one being a skylight and the other a vertical glass panel. They found that in both cases, transparent Low-E glass and fritted glass were insufficient for adequate sunlight glare control. In contrast, EC glass provided suitable glare control and daylight utilization, while maintaining clear external visibility at all times.

Wang et al. [

6] studied the Meditation Hall at the New Materials Research Institute in Jinwan District, Zhuhai City, China, and simulated three glass configurations: electrochromic windows, Low-E windows, and regular glass windows. The results showed that the shading performance of the electrochromic windows surpassed that of the regular and Low-E windows, particularly during summer days, reducing approximately 40% of the total solar radiation. Compared to regular glass windows, electrochromic windows could save about 90% of energy consumption annually and effectively reduce the annual cooling energy consumption of buildings in subtropical regions.

Another type of electrochromic technology is the Suspended Particle Device (SPD). Its principle involves placing SPD material between two glass panes. When no voltage is applied, the SPD particles are randomly suspended, blocking light. When voltage is applied, the particles align vertically within the glass, allowing light to pass through.

Ghosh and Norton [

7] explored the performance and advantages of SPD when powered by a photovoltaic (PV) device supplying alternating current (AC) and under electrically switchable direct current (DC) power. Ghosh et al. [

8] also tested the optical properties of SPD switchable glazing using an outdoor test cell in Dublin, Ireland. The experimental results showed that the overall heat transfer coefficient (U-value) for both opaque and transparent states was very similar, approximately 5.9 W/m

2 K. The light transmittance was about 5% in the opaque state and 55% in the transparent state.

Another type of electrochromic material is polymer-dispersed liquid crystal (PDLC), which consists of a polymer base and tiny liquid crystal droplets [

9]. By applying a small voltage, the orientation of the liquid crystals can be changed, resulting in two states: “transparent” and “translucent/opaque”. When the electrochromic film is in the translucent/opaque state, PDLC scatters light due to the refractive index mismatch between the droplets and the polymer base [

10].

Through experiments and simulations, Mesloub et al. [

11] analyzed the thermal and optical properties and building energy consumption of PDLC windows applied in hot climates. The results showed that both the transparent and opaque states of PDLC windows have significant advantages in terms of thermal and optical performance. Additionally, simulation results demonstrated that PDLC windows contribute to energy savings and carbon reduction.

Using a spectrometer (Perkin Elmer

® Lambda 1050 UV/VIS/NIR, Waltham, MA, USA) and experimental analysis, Hemaida et al. [

12] investigated the optical and thermal properties of PDLC glass windows. Results revealed that the SHGC of the PDLC glass system was 0.68 in its transparent state and 0.63 in its opaque state, with corresponding U-values of 2.79 W/m

2 K and 2.44 W/m

2 K, respectively. This suggests its potential to effectively reduce heating loads in cold climates. However, caution is warranted due to the higher temperature of the glass inner surface, which may lead to secondary heat radiation.

Ghosh and Mallick [

13] also investigated the optical properties of PDLC glass using a spectrophotometer. The experimental results showed that the total solar transmittance in transparent and opaque states were 41% and 23%, respectively. Additionally, due to the scattering phenomenon of liquid crystal particles, the opaque state exhibited high diffuse transmission, with a haze value of 82.6%, providing a high level of protection for human skin. The author also suggested that when applying PDLC in buildings, consideration should be given to the durability of the glass and its performance under switching cycles.

Oh et al. [

14] proposed two retrofit methods using PDLC film to regulate solar radiation in old office buildings. Additionally, the energy-saving effects and daylight performance after the retrofit were analyzed. The first method involved applying PDLC film on the existing double-glazed curtain walls. The second method entailed sandwiching PDLC film between two glass substrates and installing a separate frame on the indoor side for new windows. Simulation results demonstrated the effectiveness of both retrofit methods using PDLC film in reducing heating and cooling energy consumption and improving daylight performance. Specifically, the retrofit with PDLC windows showed a greater performance improvement compared to simply applying PDLC film.

Field and Ghosh [

15] investigated various glass configurations, including vacuum windows, aerogel windows, vacuum–aerogel windows, and switchable smart windows, including PDLC, PDLC–aerogel, and PDLC–vacuum. Taking into account heating, cooling, and lighting considerations, the overall findings suggest that PDLC–vacuum is the most effective strategy for attaining Nearly Zero Energy Buildings (NZEB), boasting a U-value ranging from 0.810 to 0.831 W/m

2 K and offering the greatest reduction in building energy consumption. However, its performance is influenced by factors such as window-to-wall ratio and building orientation. Furthermore, PDLC stands out for its affordability, having the shortest payback period among the options, with less than 25 years required for return on investment.

Chidubem Iluyemi et al. [

16] examined the energy-saving benefits of electrochromic glass and PDLC glass compared to traditional clear glass in residential construction. The results indicate that smart windows offer improved optical characteristics over clear glass. Specifically, electrochromic glass with daylight control demonstrated the highest overall energy savings, reducing energy consumption by 23.56% when compared to single-pane glass windows. Moreover, in PDLC window setups, utilizing silver-coated glass for the inner pane of double-glazed windows further decreased energy usage.

Alghamdi and Almawgani [

17] implemented a smart energy-saving system using PDLC film combined with programming and sensors, which can adjust the glass state according to weather changes. Compared to traditional shading systems, it saved approximately 39% of energy consumption, with lower installation and maintenance costs than curtains or blinds. The authors also suggest that PDLC film can reduce reflection by absorbing sunlight, thereby converting heat pollution factors into thermal energy that can be utilized for solar power generation.

According to the relevant literature, electrochromic glass consists of two layers of tungsten oxide or nickel oxide as the electrochromic layer, with an electrolyte sandwiched in between [

1]. The principle of Suspended Particle Device (SPD) involves placing SPD material between two glass panes. Both of these technologies incorporate a color-changing layer or material between layers of glass. Another type of electrochromic material is polymer-dispersed liquid crystal (PDLC), which consists of a polymer base and tiny liquid crystal droplets [

9]. PDLC can be made into a thin film that can be attached to other glass surfaces, similar to heat insulation films. Therefore, PDLC films have greater potential for application. However, when applied to glass windows, the effects of PDLC films on indoor temperature, air conditioning electricity consumption, and indoor environment have not yet been fully studied.

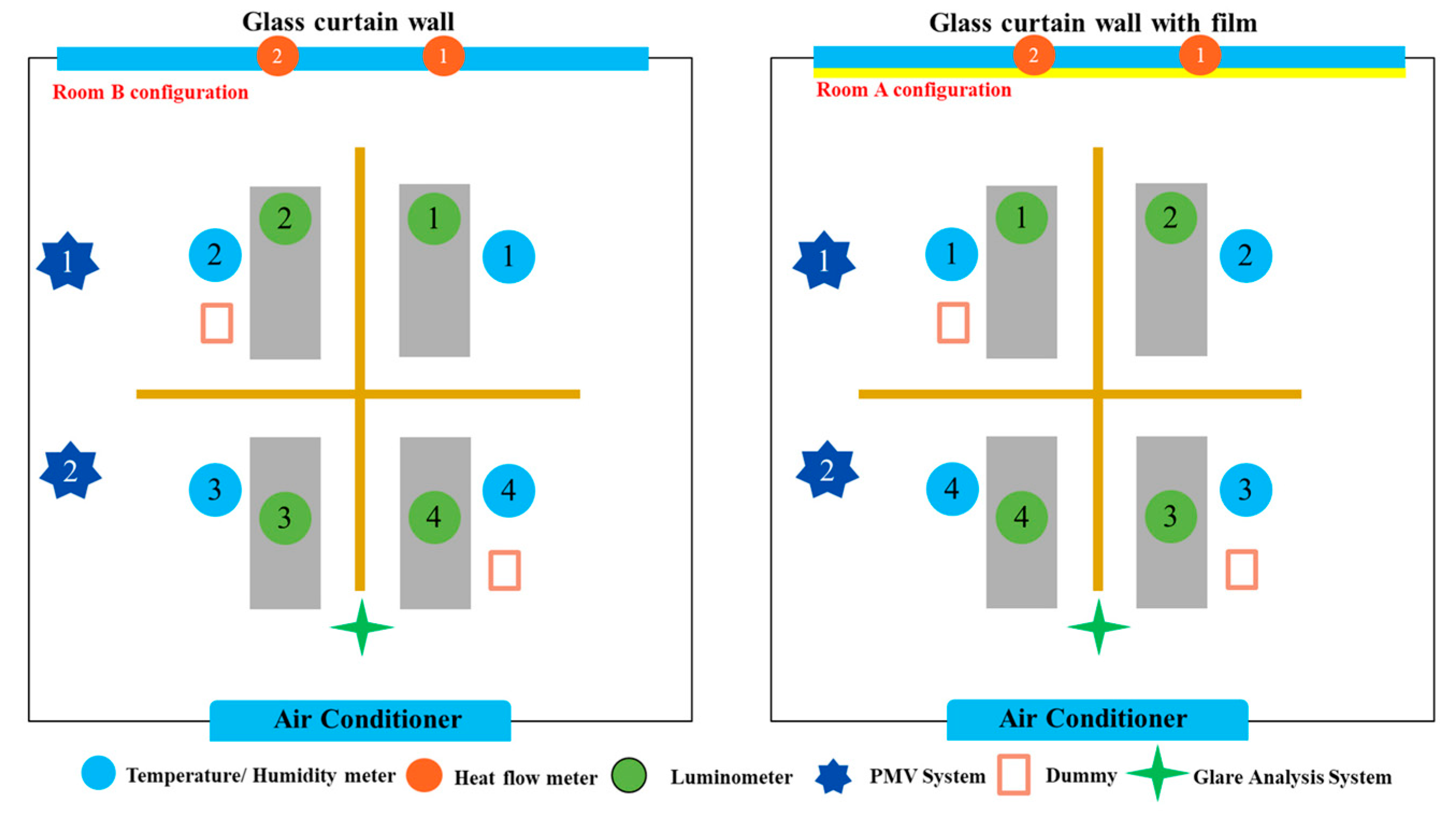

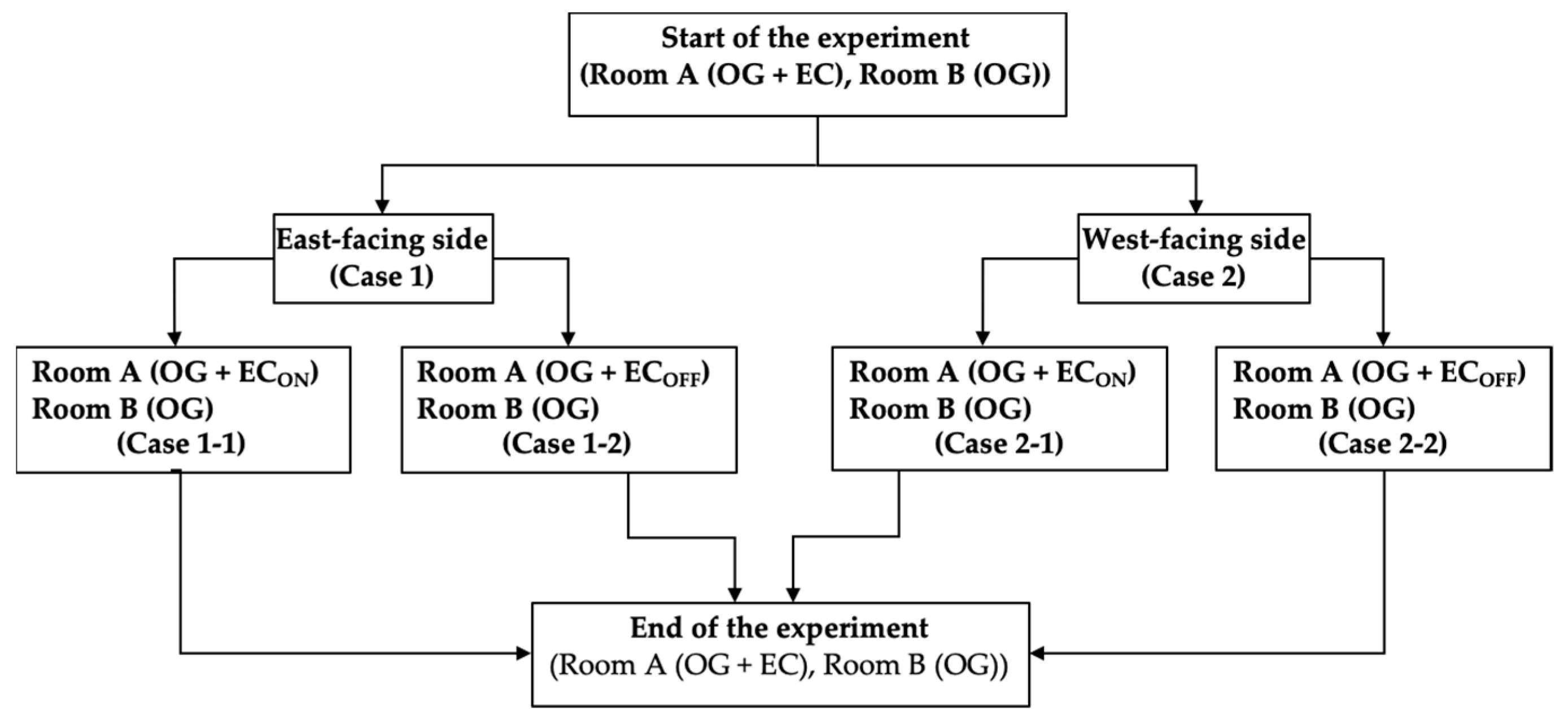

The objective of this study is to use SPINLab [

18,

19,

20] as an experimental platform to investigate the effects of using clear glass or clear glass with electrochromic film on indoor environmental quality, electricity consumption of air conditioning, indoor thermal comfort, and visual comfort in various building façades (east-facing side or west-facing side). These research efforts aim to reduce building energy consumption, improve indoor environments, and enhance the comfort and livability of residential and office spaces.

The electrochromic film used in this study is based on PDLC technology. However, for convenience, we will refer to it as “electrochromic film” in the following discussion. The transparent state will be denoted as OG + ECON, while the opaque state will be referred to as OG + ECOFF.

The following sections, respectively, detail the experimental equipment and the research parameters, and examine the effects of OG, OG + ECON, and OG + ECOFF on indoor environment, electricity consumption of air conditioning, indoor thermal comfort, and indoor visual comfort.

3. Results and Discussion

3.1. Analysis of Indoor Environment

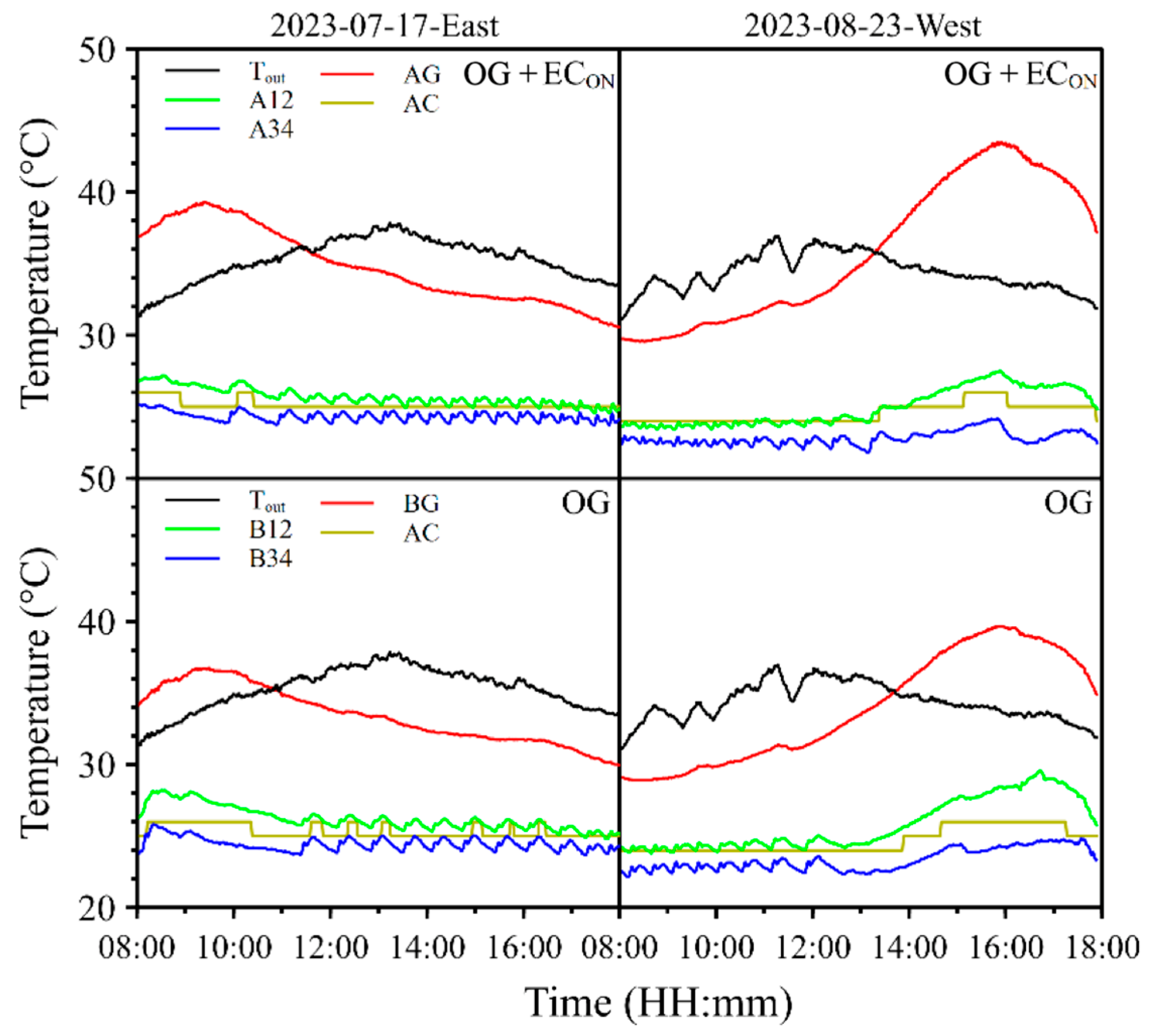

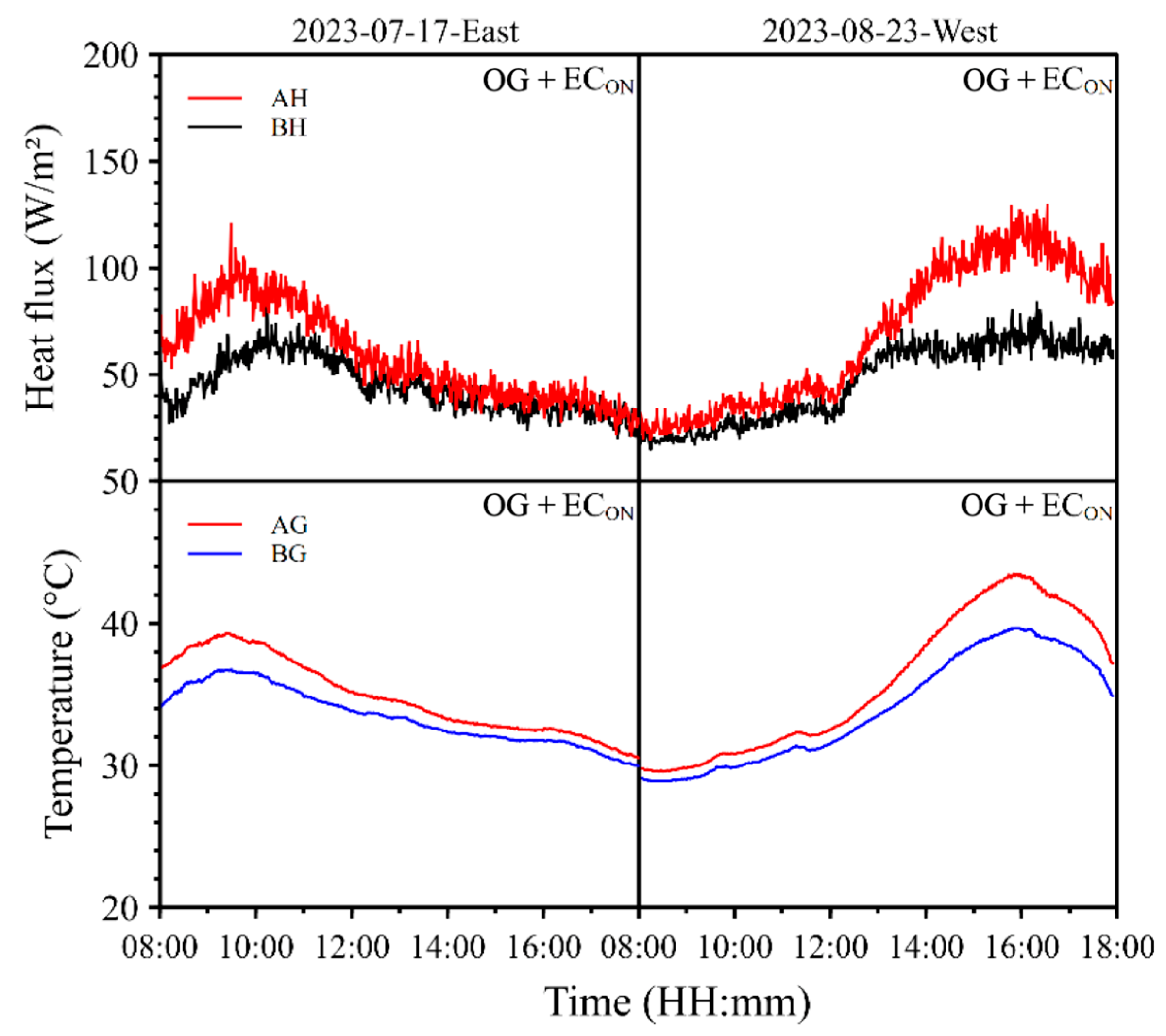

Figure 4 shows that due to direct sunlight, the indoor temperatures and surface temperatures of the glass (OG, OG + EC

ON) in both rooms on the east-facing side in the morning and the west-facing side in the afternoon are higher than at other times. The period during which direct sunlight enters an east-facing side is from 7:00 to 10:00. For a west-facing side, direct sunlight enters the interior from 14:00 to 17:00 p.m. During these times, more heat is transmitted into the indoor space due to direct sunlight. On an east-facing side, the glass temperatures in rooms A and B increase significantly between 7:00 and 10:00. On a west-facing side, the glass temperatures in rooms A and B show a noticeable rise between 14:00 and 16:00. After 16:00, the impact of direct sunlight on the interior decreases, and the glass temperatures in rooms A and B gradually decline.

The outdoor temperature is denoted as Tout. The temperature of the air conditioner sensor is denoted as AC. The indoor temperature of room A and room B was controlled by the air conditioner to remain at 26 °C.

In room A (OG + ECON), the indoor temperatures (A12, A34, AC) reach maximums of 27.2 °C and 27.5 °C, respectively, while in room B (OG) (B12, B34, AC), they reach maximums of 28.2 °C and 29.55 °C. Additionally, during periods of direct sunlight, the temperatures (A12, B12) around the windows are notably higher than those around the air conditioner compared to other times.

Figure 5 illustrates that in the morning on the east-facing side and in the afternoon on the west-facing side, the glass temperatures (AG) in room A reach maximums of 39.3 °C and 43.55 °C, respectively, while in room B (BG), they reach maximums of 36.75 °C and 39.7 °C, all significantly higher than the outdoor temperatures. Moreover, the glass heat flux in room A (AH) reaches maximums of 121 W/m

2 and 130 W/m

2, respectively, while in room B (BH), it reaches maximums of 84 W/m

2 and 84.5 W/m

2. It can be observed that, compared to the OG alone, the application of OG + EC

ON results in a further increase in glass temperature and glass heat flux, especially during periods of direct sunlight.

Figure 6 shows that due to direct sunlight, the indoor temperatures in both rooms (room A and room B), with the east-facing side in the morning and the west-facing side in the afternoon, are higher compared to other times of the day. In room A (OG + EC

ON), the indoor temperatures (A12, A34, AC) reach maximum values of 28 °C and 27.7 °C, while in room B (OG) (B12, B34, AC), they reach maximum values of 29.05 °C and 30 °C respectively. During periods of direct sunlight, the temperatures (A12, B12) around the windows are notably higher than those around the air conditioner.

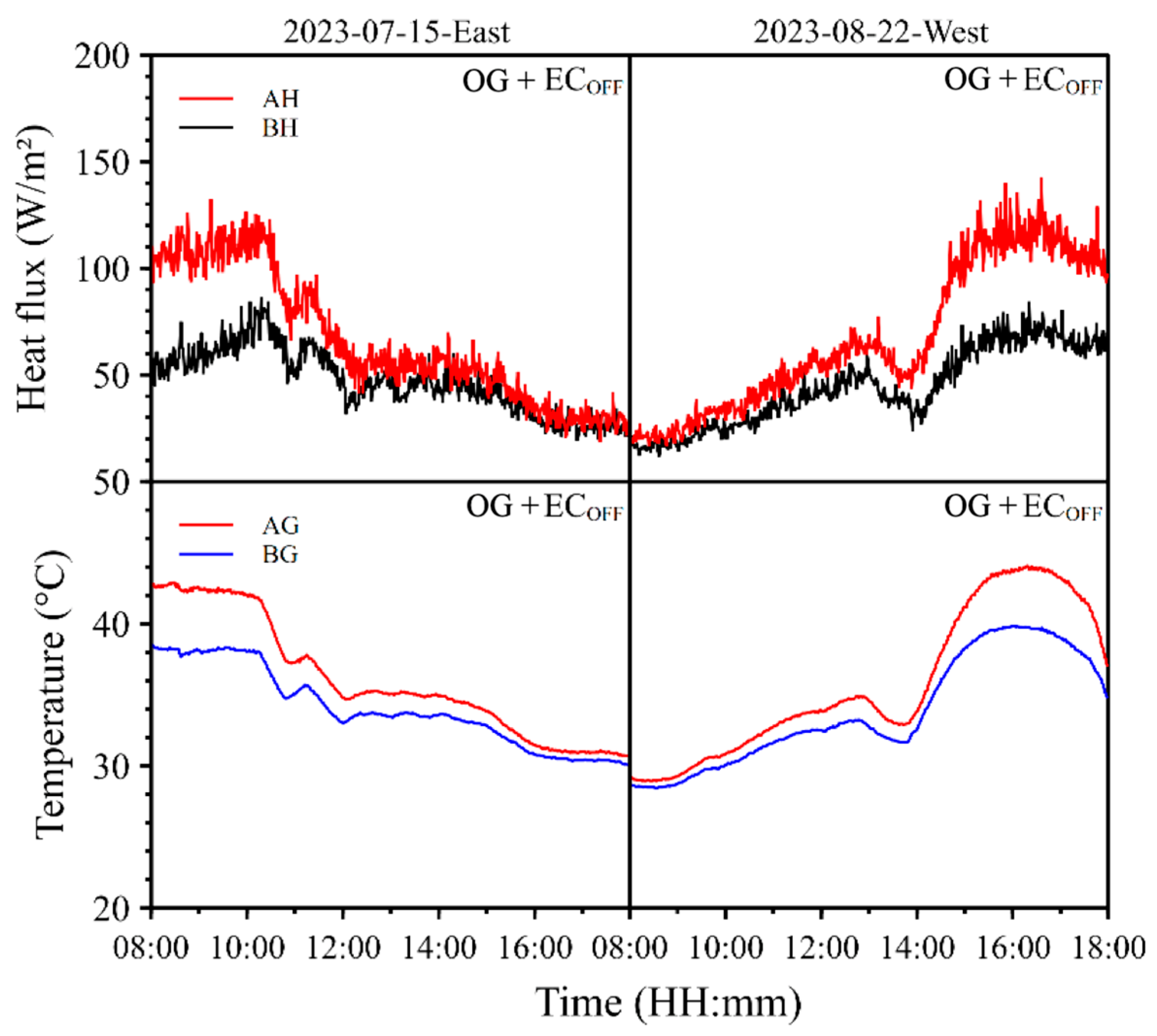

Figure 7 shows that during the morning on the east-facing side and the afternoon on the west-facing side, the glass temperatures (AG) in room A reach maximums of 42.95 °C and 44.1 °C, respectively. In room B (BG), they reach maximums of 38.5 °C and 39.85 °C, all significantly higher than the outdoor temperatures. The glass heat flux in room A (AH) peaks at 132.5 W/m

2 and 142.5 W/m

2, respectively, while in room B (BH), it peaks at 86.5 W/m

2 and 84.5 W/m

2. It is evident that, compared to the OG, OG + EC

OFF results in a further increase in both glass temperature and glass heat flux, especially during periods of direct sunlight irradiation.

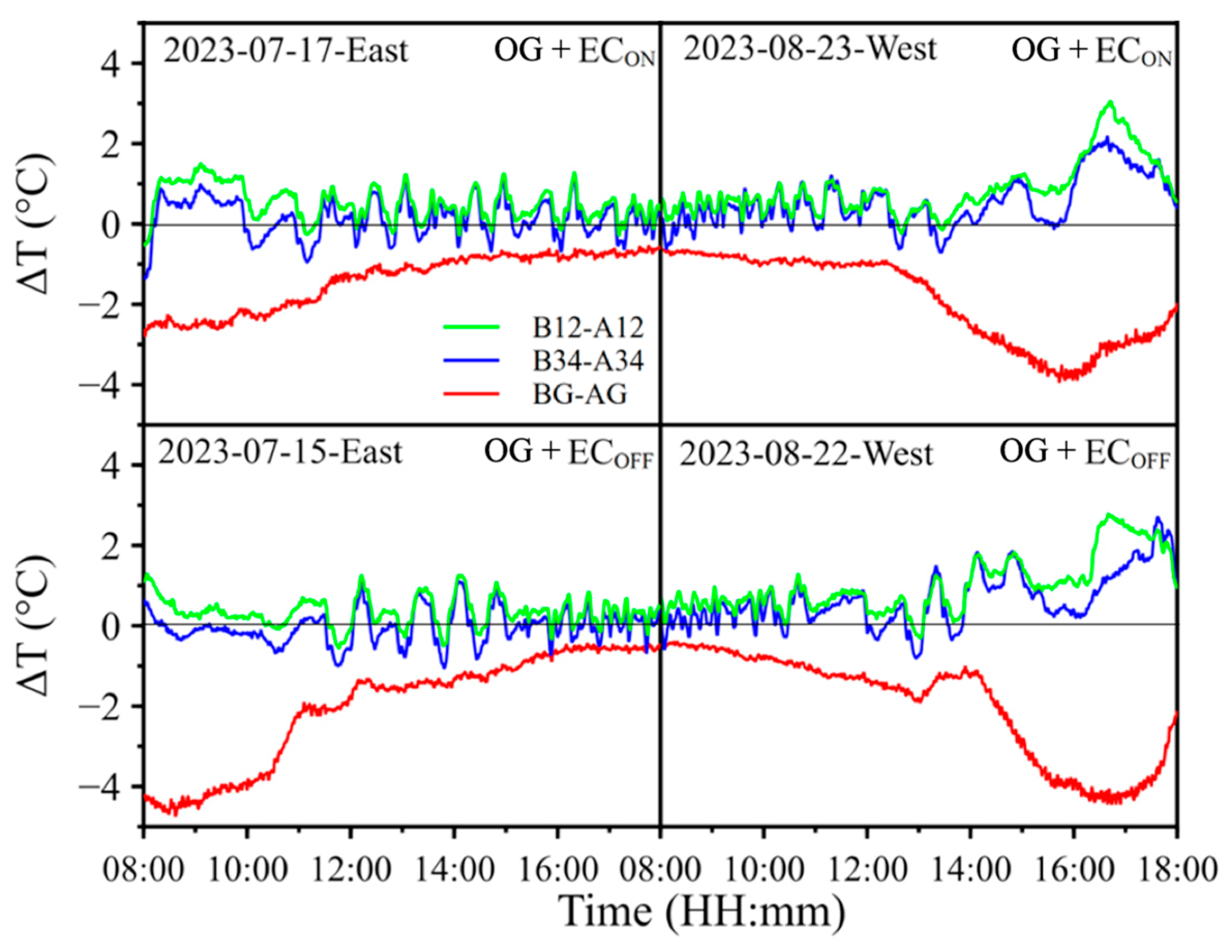

Figure 8 shows that when the building’s façade faces East, before approximately 11:00 in the morning, and faces West in the afternoon after 14:00, the indoor temperature difference between room A and room B (green and blue lines) mostly ranges between 0 °C and 2 °C. There is a noticeable gap between the temperature differences near the windows (green line, B12-A12) and near the air conditioning (blue line, B34-A34) in both rooms. This indicates that compared to clear glass (OG), the electrochromic film (OG + EC

ON or OG + EC

OFF) can effectively lower the indoor temperature during periods of direct sunlight, with the cooling effect near the windows often being better than near the air conditioning. In contrast, during other times when sunlight is not directly entering the rooms, both the green and blue lines oscillate between −1 °C and 1 °C, with the temperature difference near the windows (green line, B12-A12) being only slightly higher than that near the air conditioning (blue line, B34-A34). This shows that the indoor environment is controlled by the air conditioning, and electrochromic film (OG + EC

ON and OG + EC

OFF) does not have a significant cooling effect indoors during these periods.

The electrochromic films (OG + EC

ON or OG + EC

OFF) can lower indoor temperatures due to their lower solar transmittance compared to clear glass (OG), which reduces the heat radiation entering the room. However, because their solar absorptance is higher than that of clear glass (OG), the inner surface temperature of the glass increases.

Figure 6 shows that when the building’s façade faces East before approximately 11:00 in the morning and faces West in the afternoon after 14:00, the temperature difference of the glass in rooms A and B (red line) mostly ranges between −2 °C and −4 °C. This indicates that compared to clear glass (OG), electrochromic film (OG + EC

ON or OG + EC

OFF) significantly increases the glass temperature during periods of direct sunlight. The glass temperature of OG + EC

OFF is higher than OG + EC

ON.

During periods when sunlight is not directly entering the room, the glass temperature difference in rooms A and B (red line) mostly ranges between 0 °C and −2 °C. This shows that, regardless of direct sunlight, the electrochromic film increases the glass temperature compared to clear glass, with a more pronounced effect during periods of direct sunlight.

3.2. The Electricity Consumption of Air Conditioning

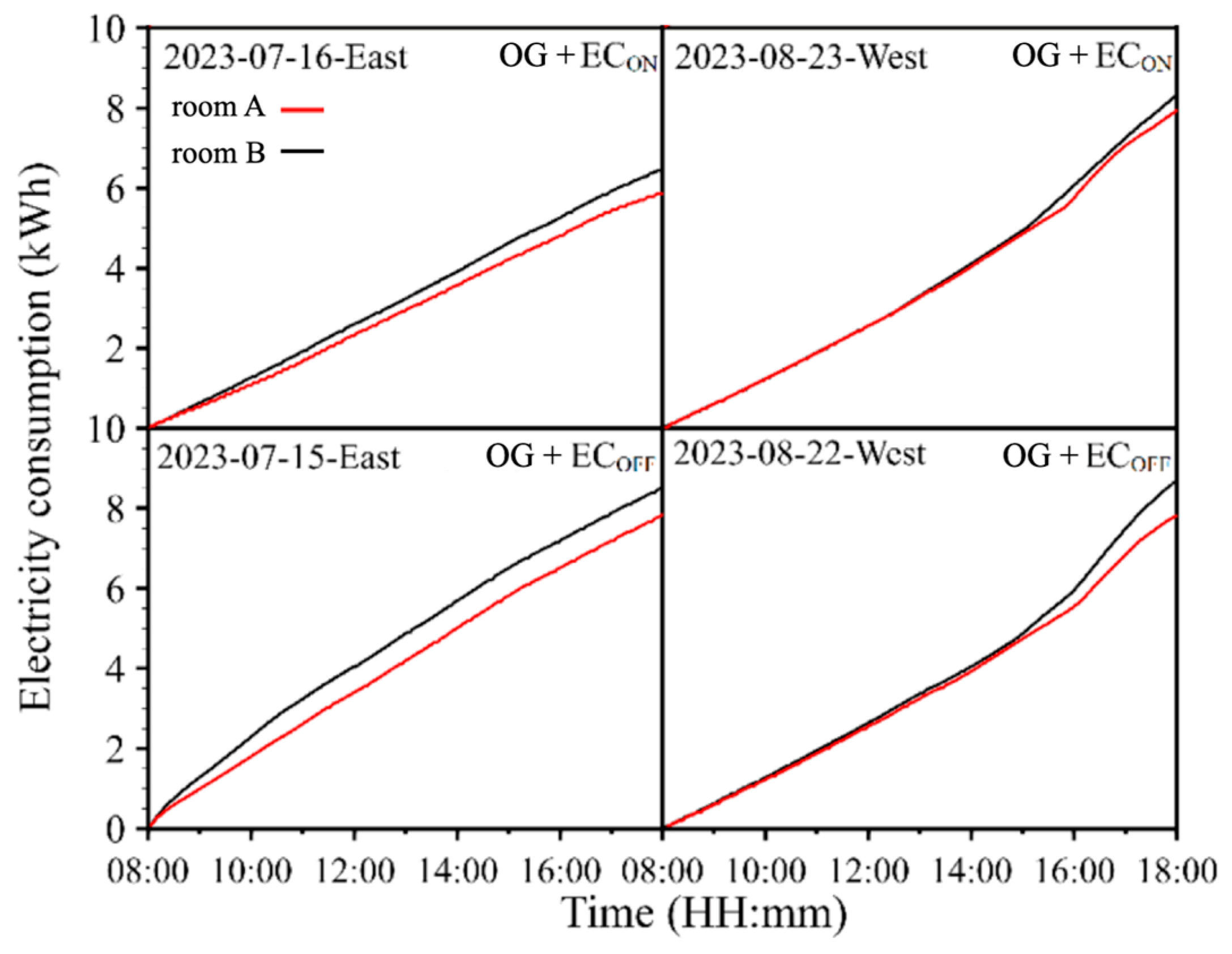

Figure 9 depicts the air conditioning electricity consumption of electrochromic film (OG + EC

ON or OG + EC

OFF) (represented by the red line for room A) and their corresponding clear glass (OG) (represented by the black line for room B) on the east- or west-facing side. The electrochromic films can reduce the amount of solar heat entering indoor spaces, thereby lowering the operation and electricity consumption of air conditioning systems. Compared to the OG + EC

ON configuration, the OG + EC

OFF setup is more effective at minimizing solar heat gain, resulting in greater electricity savings.

The electrochromic film (OG + ECON or OG + ECOFF) showed significant electricity-saving effects. On the east-facing side, electricity-saving benefits are noticeable in the morning, with the slopes of the red and black lines nearly identical in the afternoon, indicating similar electricity consumption levels for rooms A and B. On the east-facing side, the air conditioning electricity consumption of room A (OG + ECON) and room B (OG) is almost the same from 08:00 to 10:00. After 10:00, the air conditioning electricity consumption of room A (OG + ECON) starts to be lower than that of room B (OG). At 16:00, the air conditioning electricity consumption of room A (OG + ECON) is about 6% lower than that of room B (OG), and this difference remains around 6% from 16:00 to 18:00.

For room A (OG + ECOFF) and room B (OG), the air conditioning electricity consumption is almost the same from 08:00 to 08:30. After 08:30, the air conditioning electricity consumption of room A (OG + ECOFF) starts to be lower than that of room B (OG). At 11:00, the air conditioning electricity consumption of room A (OG + ECOFF) is about 9% lower than that of room B (OG), and this difference remains around 9% from 11:00 to 18:00.

On the west-facing side, the air conditioning electricity consumption of room A (OG + ECON) and room B (OG) is almost the same from 08:00 to 15:00. After 15:00, the air conditioning electricity consumption of room A (OG + ECON) starts to be lower than that of room B (OG). At 18:00, the air conditioning electricity consumption of room A (OG + ECON) is about 5% lower than that of room B (OG).

For room A (OG + ECOFF) and room B (OG), the air conditioning electricity consumption is almost the same from 08:00 to 15:00. After 15:00, the air conditioning electricity consumption of room A (OG + ECOFF) starts to be lower than that of room B (OG). At 16:00, the air conditioning electricity consumption of room A (OG + ECOFF) is about 7% lower than that of room B (OG). At 18:00, the air conditioning electricity consumption of room A (OG + ECOFF) is about 10% lower than that of room B (OG).

Conversely, on the west-facing side, the red and black lines overlap in the morning, indicating similar electricity consumption for both rooms until around 15:00, when an electricity consumption difference emerges. This result shows that the electrochromic film (OG + ECON or OG + ECOFF) has significant power-saving benefits only during periods of direct sunlight.

To make a more comprehensive comparison of the electricity-saving benefits of electrochromic film versus clear glass, we conducted a 2- to 3-day average electricity savings analysis for each orientation to minimize potential errors, as shown in

Figure 8. On the east-facing side, the average electricity savings for OG + EC

ON and OG + EC

OFF are 4.5% and 5.1%, respectively, while on the west-facing side, the average electricity savings for EC

ON and EC

OFF are 9.2% and 9.4%, respectively.

Figure 10 indicates that the electricity-saving ratio on the west-facing side (9.2–9.4%) is significantly higher than that on the east-facing side (4.5–5.1%). Moreover, in terms of electricity-saving effectiveness, EC

OFF outperforms EC

ON.

3.3. Analysis of Indoor Thermal Comfort and Indoor Visual Comfort

Figure 11 illustrates the predicted mean vote (PMV) values for electrochromic films (OG + EC

ON or OG + EC

OFF) along with their corresponding clear glass (OG) under air conditioning operation. The left column represents the east-facing side, while the right column represents the west-facing side. From top to bottom, they show EC

ON and EC

OFF, respectively. A1 and A2 denote the PMV values around the window and air conditioner in room A (OG + EC

ON or OG + EC

OFF), while B1 and B2 denote the PMV values around the window and air conditioner in room B (OG).

The parameters used for calculating the predicted mean vote (PMV) index include wet bulb temperature, black bulb temperature, air temperature, radiation temperature, wind speed, and indoor humidity. The results of this study indicate that the application of electrochromic window film leads to reductions in air temperature (as shown in

Figure 7), black bulb temperature, and radiation temperature. Consequently, the PMV values associated with electrochromic films are lower than those observed with clear glass.

A comparison between the OG + ECOFF and OG + ECON configurations reveals that OG + ECOFF, with a lower visible light transmittance of 10%, compared to 56.5% in the “OG + ECON” state, is more effective in mitigating solar penetration into the indoor space. During periods of direct solar exposure, the PMV values under the OG + ECOFF condition are slightly lower than those under the OG + ECON condition.

The PMV values near the window (A1 or B1) in rooms A and B are consistently higher than the PMV values near the air conditioning (A2 or B2). This is because positions closer to the window are more susceptible to outdoor temperature and direct sunlight, while positions closer to the air conditioning are more influenced by the air conditioning system, making them relatively more comfortable. Additionally, it is evident that the PMV values in room B (B1 or B2) are consistently higher than the PMV values in the corresponding positions in room A (A1 or A2). This indicates that, compared to clear glass, electrochromic film contributes to improving overall thermal comfort indoors throughout the day.

When the building’s façade faces east in the morning (before approximately 11:00) and west in the afternoon (after 14:00), the PMV values near the window (B1) in room B mostly range between 1 and 4, indicating a hot environment in room B.

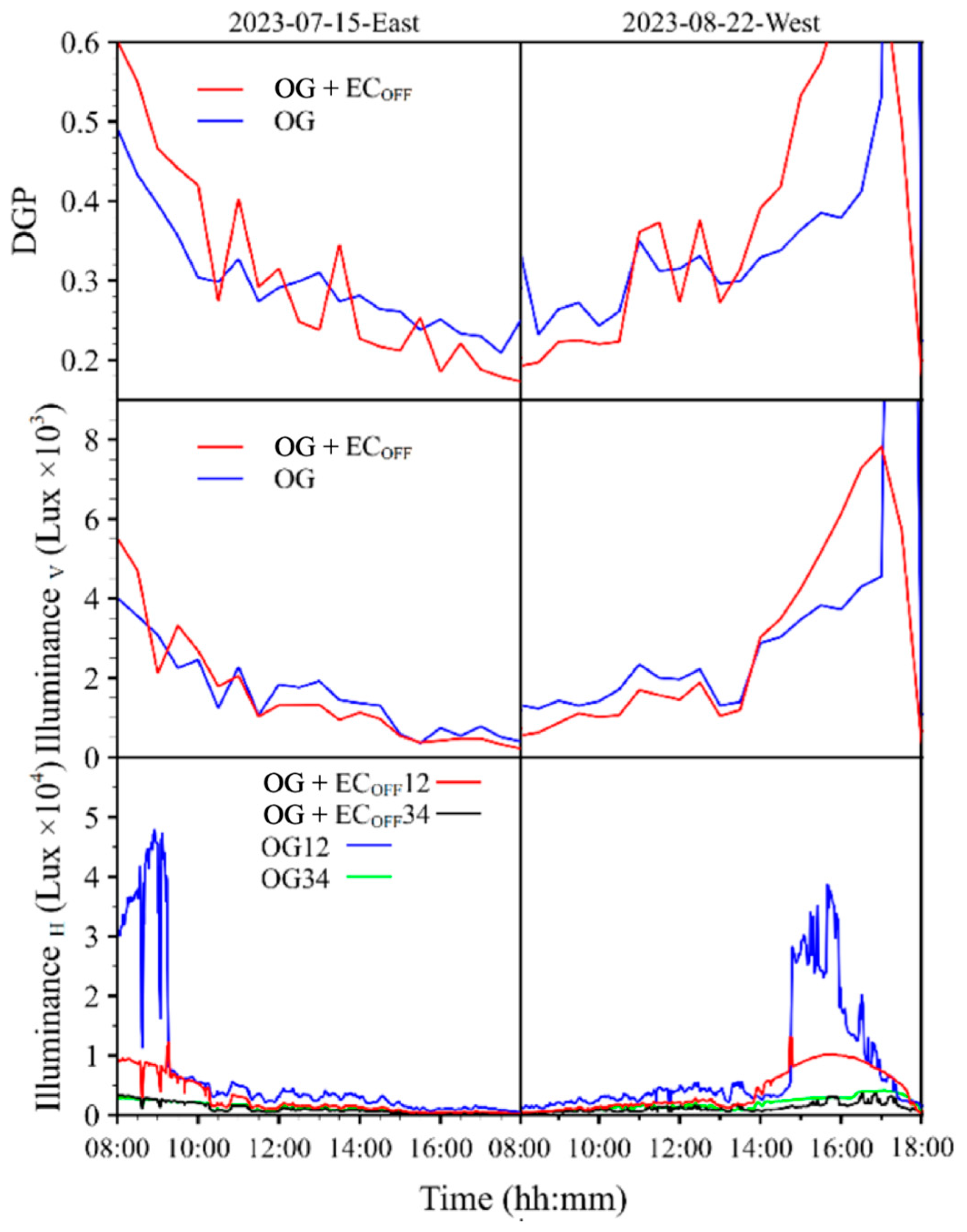

Figure 12 and

Figure 13 present the daylight glare probability (DGP) values and illuminance data for EC

ON and EC

OFF across the east and west building façades. An important parameter influencing visual comfort is indoor illuminance, particularly during periods of direct sunlight, which significantly increases both horizontal and vertical illuminance levels. This study found that variations in vertical illuminance have a greater impact on indoor glare indices.

Under the OG + ECON configuration, when vertical indoor illuminance exceeds 2300 lux, the daylight glare probability (DGP) surpasses 0.35, indicating the onset of glare discomfort. Similarly, in the OG + ECOFF configuration, glare effects begin to occur when vertical illuminance exceeds 2000 lux, as the DGP also rises above 0.35.

The first and second columns, respectively, show the DGP values and vertical illuminance, recorded at 30 min intervals. In the graphs, the red line represents the electrochromic film, while the blue line represents the clear glass. The third column shows horizontal illuminance, recorded every minute. The red and black lines represent the average illuminance values around the window and the air conditioner for the electrochromic film, respectively, while the blue and green lines represent the average illuminance values around the window and the air conditioner for the clear glass. Despite the lower sensitivity of DGP and vertical illuminance data compared to horizontal illuminance, they still effectively illustrate the differences between the rooms.

Figure 12 illustrates that in the morning on the east-facing side and in the afternoon on the west-facing side, horizontal illuminance around the window increases due to direct sunlight entering the room. The impact of direct sunlight on the west-facing side is particularly pronounced, with both rooms A and B experiencing DGP values exceeding 0.4 starting from 15:30. Comparing the data for rooms A and B in both orientations (east-facing side and west-facing side), it is evident that EC

ON, compared to OG, reduces both vertical and horizontal illuminance, thereby also lowering the DGP values.

Figure 13 also demonstrates a similar phenomenon. In the morning on the east-facing side and in the afternoon on the west-facing side, both rooms A and B experience increases in DGP and illuminance due to direct sunlight. On the east-facing side, OG’s DGP values exceed 0.4 before 9:00, while for EC

OFF, this occurs before 10:00. On the west facing side in the afternoon, OG’s DGP exceeds 0.4 after 16:30, whereas for EC

OFF, it surpasses 0.4 as early as 14:00. This indicates that EC

OFF is affected by direct sunlight earlier and for a longer duration compared to OG. The reason is that the thermal insulation mechanism of the electrochromic film scatters incoming light. Instead of allowing sunlight to concentrate on the window-side floor or desk, EC

OFF diffuses it throughout the room, resulting in elevated DGP values persisting for a longer period.

Under the OG + ECON configuration, when vertical indoor illuminance exceeds 2300 lux, the daylight glare probability (DGP) surpasses 0.35, indicating the onset of glare discomfort. Similarly, in the OG + ECOFF configuration, glare effects begin to occur when vertical illuminance exceeds 2000 lux, as the DGP also rises above 0.35.

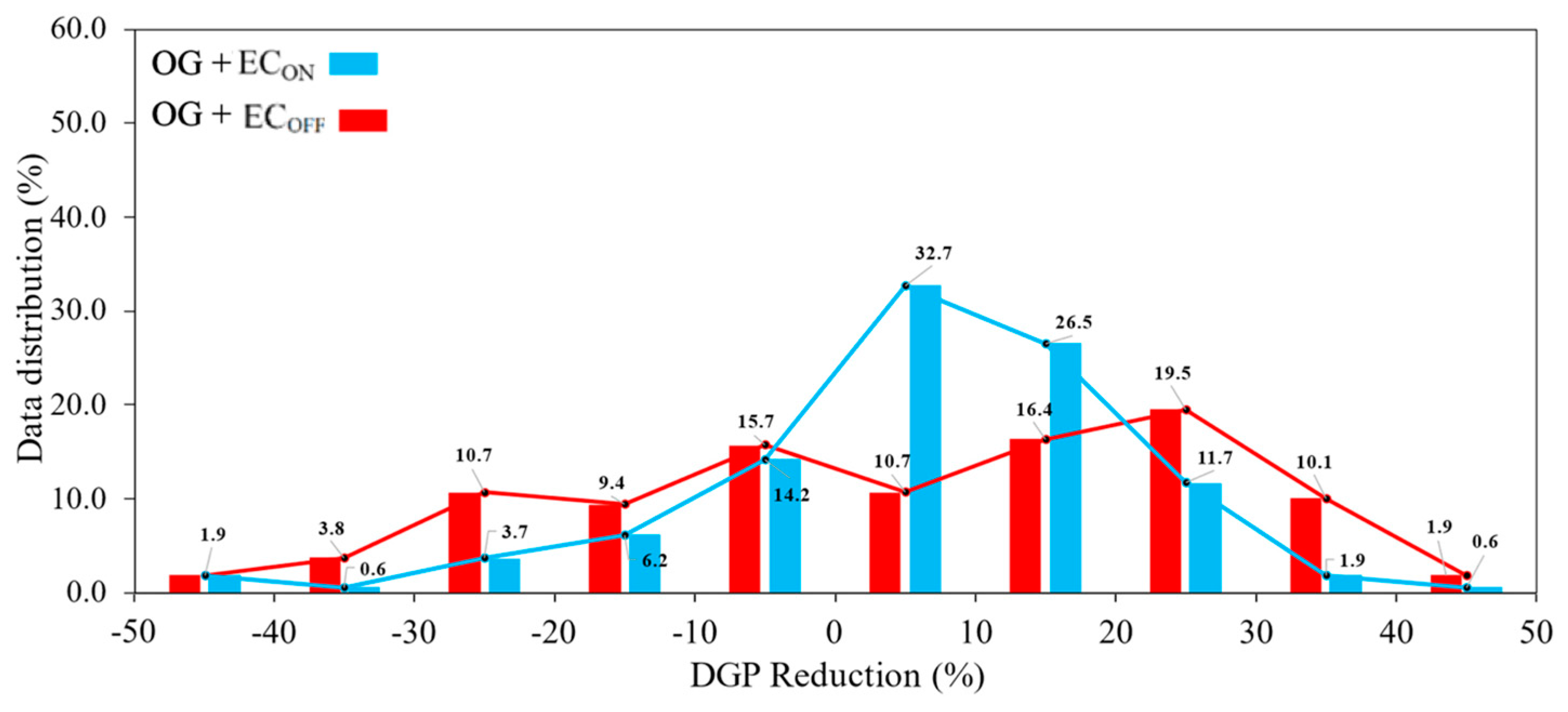

Next, we analyzed the DGP reduction effect of electrochromic film compared to clear glass. The DGP reduction at each time point was calculated by subtracting the DGP value of room A (with electrochromic film) from that of room B (with clear glass), and then standardizing it by dividing by the DGP value of room B. The results are presented in

Figure 14, which shows the distribution of DGP reduction percentages for electrochromic film (OG + EC

ON or OG + EC

OFF). It can be observed that EC

OFF shows a reduction in DGP values in 58.6% of the data (10.7 + 16.4 + 19.5 + 10.1 + 1.9 = 58.6%), with 31.5% (19.5 + 10.1 + 1.9 = 31.5%) exhibiting a reduction greater than 20%. However, 41.4% of the data (1.8 + 3.8 + 10.7 + 9.7 + 15.7 = 41.4%) show an increase in DGP values.

On the other hand, ECON shows a reduction in DGP values in 73.4% of the data (32.7 + 26.5 + 11.7 + 1.9 + 0.6 = 73.4%), with 14.2% (11.7 + 1.9 + 0.6 = 14.2%) showing a reduction greater than 20%. However, 26.6% of the data (1.9 + 0.6 + 3.7 + 6.2 + 14.2 = 26.6%) show an increase in DGP values.