CO2 Capture Cost Reduction Potential of the Coal-Fired Power Plants under High Penetration of Renewable Power in China

Abstract

1. Introduction

2. System Description and Evaluation

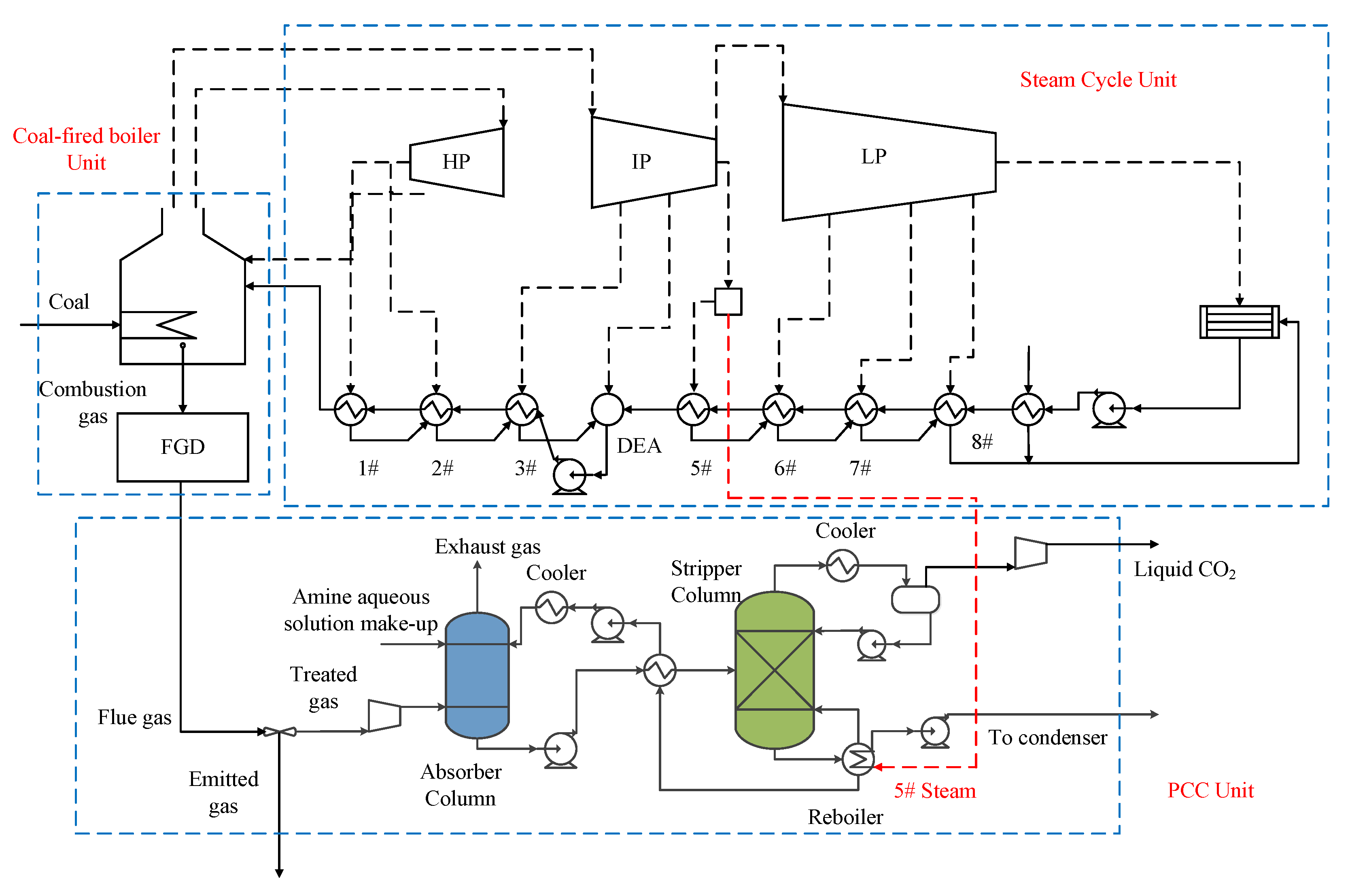

2.1. System Description

2.2. Techno-Economic Performance Evaluation

2.3. Potential Evaluation Based on Learning Curves

3. System Simulation and Model Validation

3.1. Reference Plant

3.2. PCC Unit

4. Results and Discussion

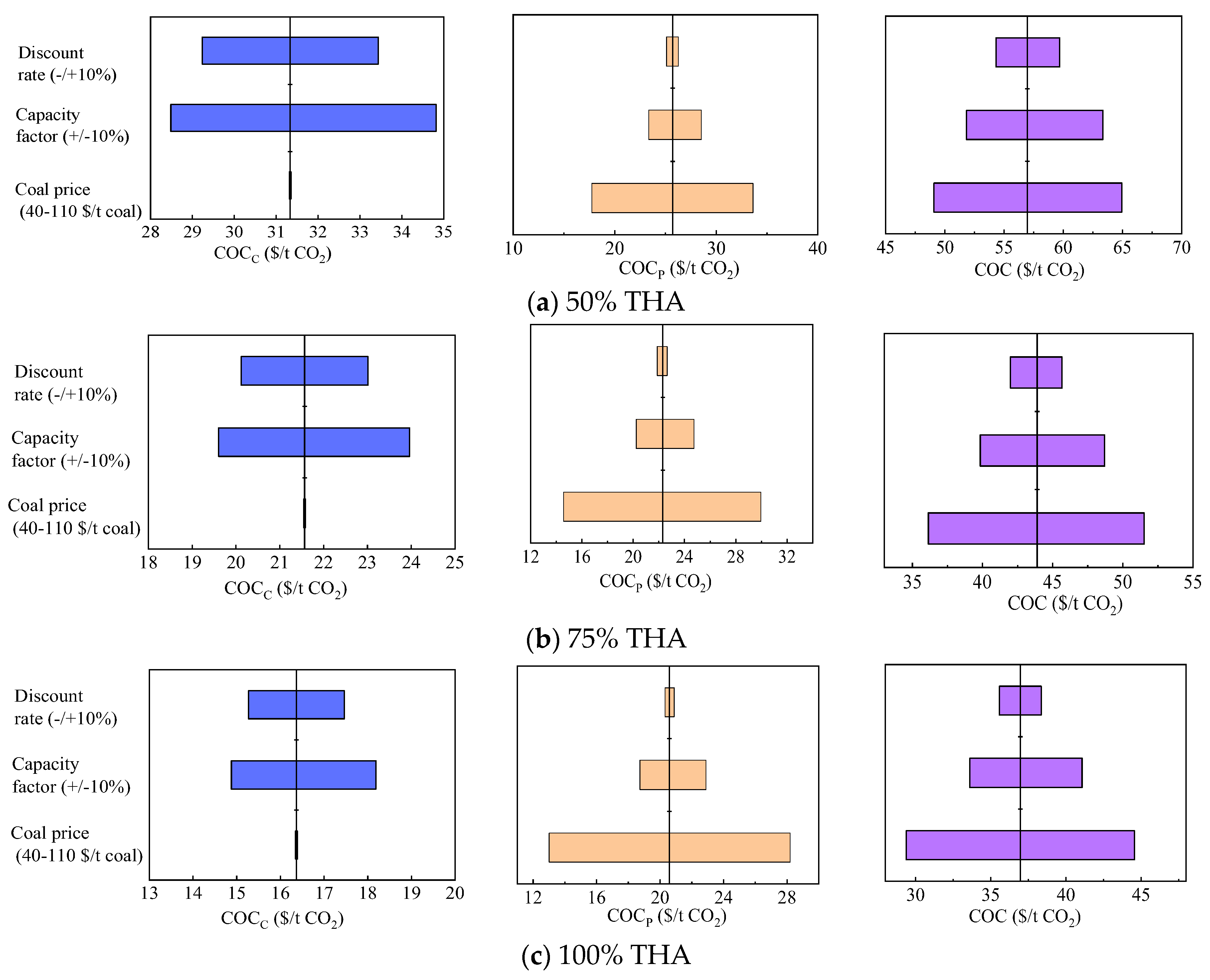

4.1. Techno-Economic Performance of the Retrofitted Plant Operating under Variable Conditions

4.2. CO2 Capture Cost Reduction Potential

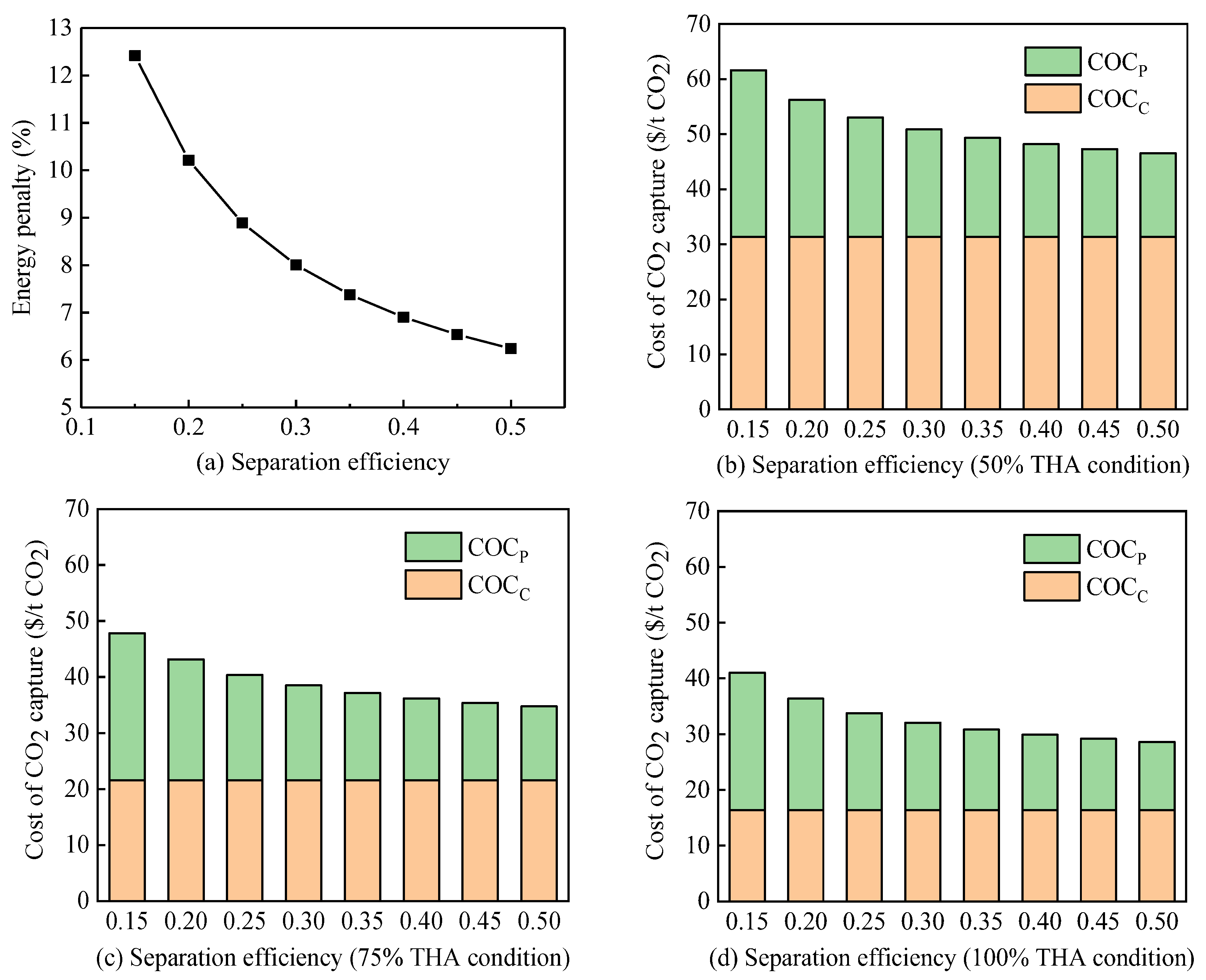

4.2.1. Cost Reduction Potential of Improving Separation Efficiency

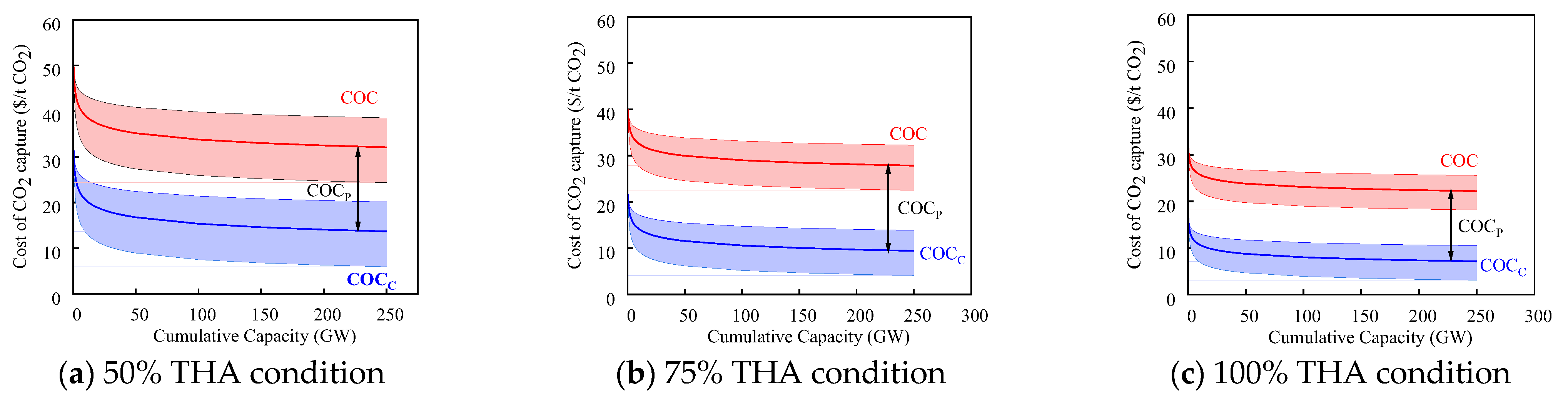

4.2.2. Cost Reduction Potential of Large-Scale Commercial Deployment

4.3. Early Demonstration Opportunities and Policy Suggestions

5. Conclusions

- (1)

- The cost contribution of extra capital investment (COCC) increased as the boiler load decreased, while the cost contribution of energy penalty (COCP) increased slightly. When the boiler load decreased from 100% THA condition to 50% THA condition, the cost of CO2 capture (COC) increased from 37.0 $/t CO2 to 57.0 $/t CO2. The COCP and COCC also increased from 20.6 $/t CO2 to 25.7 $/t CO2 and from 16.4 $/t CO2 to 31.3 $/t CO2, respectively. The offset from the design condition contributed to the increase in cost.

- (2)

- The cost reduction potential under variable operation conditions was further analyzed by improving separation efficiency and large-scale commercial deployment. With the range of separation efficiency from 0.15 to 0.5, a 25 to 30% reduction of COC during variable operation conditions can be achieved. Besides, large-scale commercial deployment could realize a 42.2–50.5% reduction of COC during variable operation conditions at a high investment learning rate case.

- (3)

- The COC during flexible operation is expected to decline the scope from 11.6 $/t CO2 to 15.7 $/t CO2 in the northern region as the technology matures after large-scale commercial deployment. According to the distribution of coal prices and renewable energy sources in China, the early demonstration projects of a multi-energy supply system should prioritize the northern region. With the increasing penetration of renewable power into the power grid, policy support in the form of subsidies and market mechanisms should be established to provide external and internal market driving forces for CCS technology.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| b | Experience ratio |

| C0 | Cost for the first unit |

| Ccum | unit cost of cumulative output |

| Cum | Cumulative output |

| CFUEL | Annual fuel cost |

| CCR | CO2 capture ratio |

| CCS | CO2 capture and storage |

| CF | Capacity factor |

| COE | Cost of electricity |

| COC | Cost of CO2 capture |

| COCC | Cost contribution of extra capital investment |

| COCP | Cost contribution of energy penalty |

| CRF | Capital recovery factor |

| DEA | Deaerator |

| FGD | Flue gas desulfurization |

| fi | Scale factor |

| GHG | Greenhouse gas |

| HP | High-pressure |

| Ii | Fixed capital investment requirement of ith equipment |

| Ii,r | Reference fixed capital investment requirement of ith equipment |

| i | Discount rate |

| LP | Low-pressure |

| LR | Learning rate |

| LRC | Learning rate of CO2 compression unit |

| LRS | Learning rate of CO2 separation unit |

| MCO2,captured | Mass flow rate of CO2 captured |

| Mm | Mass flow rate of model value |

| Mo | Mass flow rate of operating value |

| MP | Medium-pressure |

| n | Life of equipment |

| P | Power output |

| PCC | Post-combustion CO2 capture |

| PV | Photovoltaic |

| Si | Scale of ith equipment |

| Si,r | Reference scale of ith equipment |

| T | Annual operation hours |

| Tm | Temperature of model value |

| To | Temperature of operating value |

| THA | Turbine heat acceptance |

| TCR | Total capital requirement |

| XOM | Coefficient annual operating and maintenance cost |

| λC | Share of CO2 compression investment cost |

| λS | Share of CO2 separation investment cost |

References

- Masson-Delmotte, V.; Zhai, P.; Pörtner, H.O.; Roberts, D.; Skea, J.; Shukla, P.R.; Pirani, A.; Moufouma-Okia, W.; Péan, C.; Pidcock, R.; et al. Global Warming of 1.5 °C; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Pirani, A.; Fuglestvedt, J.S.; Byers, E.; O’neill, B.; Riahi, K.; Lee, J.-Y.; Marotzke, J.; Rose, S.K.; Schaeffer, R.; Tebaldi, C. Scenarios in IPCC assessments: Lessons from AR6 and opportunities for AR7. Npj Clim. Action 2024, 3, 1. [Google Scholar] [CrossRef]

- Luo, F.; Guo, Y.; Yao, M.; Cai, W.; Wang, M.; Wei, W. Carbon emissions and driving forces of China’s power sector: Input-output model based on the disaggregated power sector. J. Clean. Prod. 2020, 268, 121925. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, J.; Liu, J.; He, S.; Zeng, X.; Yang, D.; Yang, G.; Li, L. Tracing the carbon capture energy distribution in a natural gas combined cycle power plant under variable operating conditions. Appl. Therm. Eng. 2024, 246, 123000. [Google Scholar] [CrossRef]

- BP Statistical Review of World Energy. 2019. Available online: https://www.bp.com/content/dam/bp/businesssites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2019-full-report.pdf (accessed on 1 November 2019).

- IEA. An Energy Sector Roadmap to Carbon Neutrality in China; IEA: Paris, France, 2021. [Google Scholar]

- van der Wijk, P.C.; Brouwer, A.S.; van den Broek, M.; Slot, T.; Stienstra, G.; van der Veen, W.; Faaij, A.P. Benefits of coal-fired power generation with flexible CCS in a future northwest European power system with large scale wind power. Int. J. Greenh. Gas Control 2014, 28, 216–233. [Google Scholar] [CrossRef]

- Szima, S.; del Pozo, C.A.; Cloete, S.; Chiesa, P.; Alvaro, J.; Cormos, A.-M.; Amini, S. Finding synergy between renewables and coal: Flexible power and hydrogen production from advanced IGCC plants with integrated CO2 capture. Energy Convers. Manag. 2021, 231, 113866. [Google Scholar] [CrossRef]

- Xu, G.; Liang, F.; Wu, Y.; Yang, Y.; Zhang, K.; Liu, W. A new proposed approach for future large-scale de-carbonization coal-fired power plants. Appl. Therm. Eng. 2015, 87, 316–327. [Google Scholar] [CrossRef]

- Boot-Handford, M.E.; Abanades, J.C.; Anthony, E.J.; Blunt, M.J.; Brandani, S.; Mac Dowell, N.; Fernández, J.R.; Ferrari, M.C.; Gross, R.; Hallett, J.P.; et al. Carbon capture and storage update. Energy Environ. Sci. 2014, 7, 130–189. [Google Scholar] [CrossRef]

- Bui, M.; Adjiman, C.S.; Bardow, A.; Anthony, E.J.; Boston, A.; Brown, S.; Fennell, P.S.; Fuss, S.; Galindo, A.; Hackett, L.A.; et al. Carbon capture and storage (CCS): The way forward. Energy Environ. Sci. 2018, 11, 1062–1176. [Google Scholar]

- Wu, X.; Wang, M.; Liao, P.; Shen, J.; Li, Y. Solvent-based post-combustion CO2 capture for power plants: A critical review and perspective on dynamic modelling, system identification, process control and flexible operation. Appl. Energy 2020, 257, 113941. [Google Scholar] [CrossRef]

- Li, K.; Leigh, W.; Feron, P.; Yu, H.; Tade, M. Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: Techno-economic assessment of the MEA process and its improvements. Appl. Energy 2016, 165, 648–659. [Google Scholar] [CrossRef]

- Chalmers, H.; Gibbins, J. Initial evaluation of the impact of post-combustion capture of carbon dioxide on supercritical pulverised coal power plant part load performance. Fuel 2007, 86, 2109–2123. [Google Scholar] [CrossRef]

- Chalmers, H.; Lucquiaud, M.; Gibbins, J.; Leach, M. Flexible operation of coal fired power plants with postcombustion capture of carbon dioxide. J. Environ. Eng. 2009, 135, 449–458. [Google Scholar] [CrossRef]

- Chalmers, H.; Leach, M.; Lucquiaud, M.; Gibbins, J. Valuing flexible operation of power plants with CO2 capture. Energy Procedia 2009, 1, 4289–4296. [Google Scholar] [CrossRef]

- Fernandez, E.S.; del Rio, M.S.; Chalmers, H.; Khakharia, P.; Goetheer, E.; Gibbins, J.; Lucquiaud, M. Operational flexibility options in power plants with integrated post-combustion capture. Int. J. Greenh. Gas Control 2016, 48, 275–289. [Google Scholar] [CrossRef]

- Rúa, J.; Bui, M.; Nord, L.O.; Mac Dowell, N. Does CCS reduce power generation flexibility? A dynamic study of combined cycles with post-combustion CO2 capture. Int. J. Greenh. Gas Control 2020, 95, 102984. [Google Scholar] [CrossRef]

- China Power Engineering Consulting Group Corporation. Reference Price Index of Thermal Power Engineering Design; China Electric Power Press: Beijing, China, 2016. (In Chinese) [Google Scholar]

- Hu, Y.; Xu, G.; Xu, C.; Yang, Y. Thermodynamic analysis and techno-economic evaluation of an integrated natural gas combined cycle (NGCC) power plant with post-combustion CO2 capture. Appl. Therm. Eng. 2017, 111, 308–316. [Google Scholar] [CrossRef]

- Exchange Rates.org. Available online: https://www.exchange-rates.org/zh/exchange-rate-history/usd-cny-2023 (accessed on 20 April 2024).

- Coalchina.org. Available online: http://www.coalchina.org.cn/index.php?m=content&c=index&a=show&catid=28&id=115461 (accessed on 15 December 2023).

- Zhou, Y.; Xu, Z.; Zhang, J.; Xing, J.; Jia, J.; Cui, P. Development and techno-economic evaluation of coal to ethylene glycol process and Allam power cycle and carbon capture and storage and integration process. Fuel 2023, 332, 126121. [Google Scholar] [CrossRef]

- Wang, D.; Li, S.; Liu, F.; Gao, L.; Sui, J. Post combustion CO2 capture in power plant using low temperature steam upgraded by double absorption heat transformer. Appl. Energy 2018, 227, 603–612. [Google Scholar] [CrossRef]

- Xu, C.; Li, X.; Xin, T.; Liu, X.; Xu, G.; Wang, M.; Yang, Y. A thermodynamic analysis and economic assessment of a modified de-carbonization coal-fired power plant incorporating a supercritical CO2 power cycle and an absorption heat transformer. Energy 2019, 179, 30–45. [Google Scholar] [CrossRef]

- Xu, C.; Li, X.; Xin, T.; Liu, X.; Xu, G.; Wang, M.; Yang, Y. Energy, exergy and economic analyses of a novel solar-lignite hybrid power generation process using lignite pre-drying. Energy Convers. Manag. 2018, 170, 19–33. [Google Scholar] [CrossRef]

- Kang, J.N.; Wei, Y.M.; Liu, L.; Han, R.; Chen, H.; Li, J.; Wang, J.W.; Yu, B.Y. The Prospects of Carbon Capture and Storage in China’s Power Sector under the 2 °C Target: A Component-based Learning Curve Approach. Int. J. Greenh. Gas Control 2020, 101, 103149. [Google Scholar] [CrossRef]

- Wang, D.; Li, S.; He, S.; Gao, L. Coal to substitute natural gas based on combined coal-steam gasification and one-step methanation. Appl. Energy 2019, 240, 851–859. [Google Scholar] [CrossRef]

- Moser, P.; Schmidt, S.; Sieder, G.; Garcia, H.; Stoffregen, T. Performance of MEA in a long-term test at the post-combustion capture pilot plant in Niederaussem. Int. J. Greenh. Gas Control 2011, 5, 620–627. [Google Scholar] [CrossRef]

- Duan, L.; Zhao, M.; Yang, Y. Integration and optimization study on the coal-fired power plant with CO2 capture using MEA. Energy 2012, 45, 107–116. [Google Scholar] [CrossRef]

- Oh, S.-Y.; Yun, S.; Kim, J.-K. Process integration and design for maximizing energy efficiency of a coal-fired power plant integrated with amine-based CO2 capture process. Appl. Energy 2018, 216, 311–322. [Google Scholar] [CrossRef]

- Rochelle, G.T. Amine scrubbing for CO2 capture. Science 2009, 325, 1652–1654. [Google Scholar] [CrossRef] [PubMed]

- Idem, R.; Supap, T.; Shi, H.; Gelowitz, D.; Ball, M.; Campbell, C.; Tontiwachwuthikul, P. Practical experience in post-combustion CO2 capture using reactive solvents in large pilot and demonstration plants. Int. J. Greenh. Gas Control 2015, 40, 6–25. [Google Scholar] [CrossRef]

- Chen, Q.; Lv, M.; Gu, Y.; Yang, X.; Tang, Z.; Sun, Y.; Jiang, M. Hybrid energy system for a coal-based chemical industry. Joule 2018, 2, 607–620. [Google Scholar] [CrossRef]

- Chai, S.; Liu, Q.; Yang, J. Renewable power generation policies in China: Policy instrument choices and influencing factors from the central and local government perspectives. Renew. Sustain. Energy Rev. 2023, 174, 113126. [Google Scholar] [CrossRef]

- Liu, L.; Fang, M.; Xu, S.; Wang, J.; Guo, D. Development and testing of a new post-combustion CO2 capture solvent in pilot and demonstration plant. Int. J. Greenh. Gas Control 2022, 113, 103513. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, Y.; Zhang, S.; Li, Y.; Han, T.; Gao, L. The full chain demonstration project in China—Status of the CCS development in coal-fired power generation in GuoNeng Jinjie. Int. J. Greenh. Gas Control 2021, 110, 103432. [Google Scholar] [CrossRef]

| Items | Value |

|---|---|

| Exchange rate ($/¥) | 7.08 [21] |

| Actual interest rate for the credit (%) | 4.9 [24] |

| Discount rate (%) | 12 [24] |

| Share of investment obtained from commercial credit (%) | 70 [24] |

| Capacity factor, CF | 0.85 [24] |

| Annual operation time (hours/year) | 7446 [24] |

| Coal price ($/t) | 75 [22] |

| Depreciation times (years) | 15 [24] |

| Operation times (years) | 30 [25] |

| Construction times (years) | 3 [24] |

| Share of investment cost in respective years of construction (%) | 30/40/30 [24] |

| Operation and Maintenance Cost | 4% of the TCR [25,26] |

| Ultimate Analysis, wt% | |||||||

|---|---|---|---|---|---|---|---|

| Car 1 | Har 1 | Oar 1 | Nar 1 | Sar 1 | ASHar 1 | Mar 1 | LHV, MJ/kg |

| 43.21 | 2.62 | 8.64 | 0.57 | 0.17 | 15.49 | 29.30 | 15.75 |

| Items | 100% THA | 75% THA | 50% THA |

|---|---|---|---|

| Main stream flow rate (t/h) | 994.2 | 717.7 | 473.6 |

| Inlet pressure of main steam (MPa) | 24.2 | 19.1 | 12.7 |

| Inlet temperature of main steam (°C) | 566 | 566 | 566 |

| Mass flow rate of reheated steam (t/h) | 840.7 | 619.3 | 416.5 |

| Inlet temperature of reheated steam (°C) | 566 | 566 | 566 |

| Inlet pressure of reheated steam (MPa) | 4.214 | 3.121 | 2.103 |

| Operating Conditions | 100% THA Condition | 75% THA Condition | 50% THA Condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Physical Parameters | To (°C) a | Tm (°C) a | Mo (t/h) a | Mm (t/h) a | To (°C) a | Tm (°C) a | Mo (t/h) a | Mo (t/h) a | To (°C) a | Tm (°C) a | Mo (t/h) a | Mm (t/h) a |

| Inlet of HP cylinder | 566.0 | 566.0 | 991.9 | 995.1 | 566.0 | 566.0 | 717.7 | 714.0 | 566.0 | 566.0 | 472.3 | 471.0 |

| Inlet of IP cylinder | 566.0 | 566.0 | 840.7 | 857.3 | 566.0 | 566.0 | 619.3 | 626.9 | 555.0 | 555.0 | 416.5 | 421.9 |

| Inlet of reheater | 313.8 | 313.7 | 840.7 | 857.3 | 312.8 | 312.7 | 619.3 | 626.9 | 321.7 | 321.5 | 416.5 | 421.9 |

| 1# high-pressure heater b | 251.6 | 240.5 | 994.2 | 995.1 | 234.3 | 222.9 | 717.7 | 714.0 | 213.4 | 209.7 | 473.5 | 471.0 |

| 2# high-pressure heater b | 213.8 | 208.5 | 777.8 | 778.7 | 199.4 | 192.5 | 717.7 | 714.0 | 181.7 | 182.0 | 473.5 | 471.0 |

| 3# high-pressure heater b | 176.6 | 172.1 | 777.8 | 778.7 | 164.5 | 157.8 | 717.7 | 714.0 | 149.6 | 150.1 | 473.5 | 471.0 |

| Inlet of deaerator b | 150.6 | 143.7 | 777.8 | 778.7 | 140.4 | 134.9 | 577.0 | 577.0 | 127.8 | 122.7 | 391.3 | 391.3 |

| 5# low-pressure heater b | 118.4 | 113.8 | 777.8 | 778.7 | 109.9 | 106.2 | 577.0 | 577.0 | 99.4 | 96.4 | 391.3 | 391.3 |

| 6# low-pressure heater b | 85.4 | 82.7 | 777.8 | 778.7 | 78.3 | 76.0 | 577.0 | 577.0 | 69.4 | 67.3 | 391.3 | 391.3 |

| 7# low-pressure heater b | 60.6 | 59.1 | 777.8 | 778.7 | 54.8 | 53.4 | 577.0 | 577.0 | 47.5 | 46.2 | 391.3 | 391.3 |

| 8# low-pressure heater b | 33.7 | 32.8 | 777.8 | 778.7 | 33.9 | 32.9 | 577.0 | 577.0 | 34 | 32.8 | 391.3 | 391.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Zheng, Y. CO2 Capture Cost Reduction Potential of the Coal-Fired Power Plants under High Penetration of Renewable Power in China. Energies 2024, 17, 2050. https://doi.org/10.3390/en17092050

He S, Zheng Y. CO2 Capture Cost Reduction Potential of the Coal-Fired Power Plants under High Penetration of Renewable Power in China. Energies. 2024; 17(9):2050. https://doi.org/10.3390/en17092050

Chicago/Turabian StyleHe, Song, and Yawen Zheng. 2024. "CO2 Capture Cost Reduction Potential of the Coal-Fired Power Plants under High Penetration of Renewable Power in China" Energies 17, no. 9: 2050. https://doi.org/10.3390/en17092050

APA StyleHe, S., & Zheng, Y. (2024). CO2 Capture Cost Reduction Potential of the Coal-Fired Power Plants under High Penetration of Renewable Power in China. Energies, 17(9), 2050. https://doi.org/10.3390/en17092050