State of the Art of Renewable Sources Potentialities in the Middle East: A Case Study in the Kingdom of Saudi Arabia

Abstract

1. Introduction

2. Renewable Energy Source Technologies

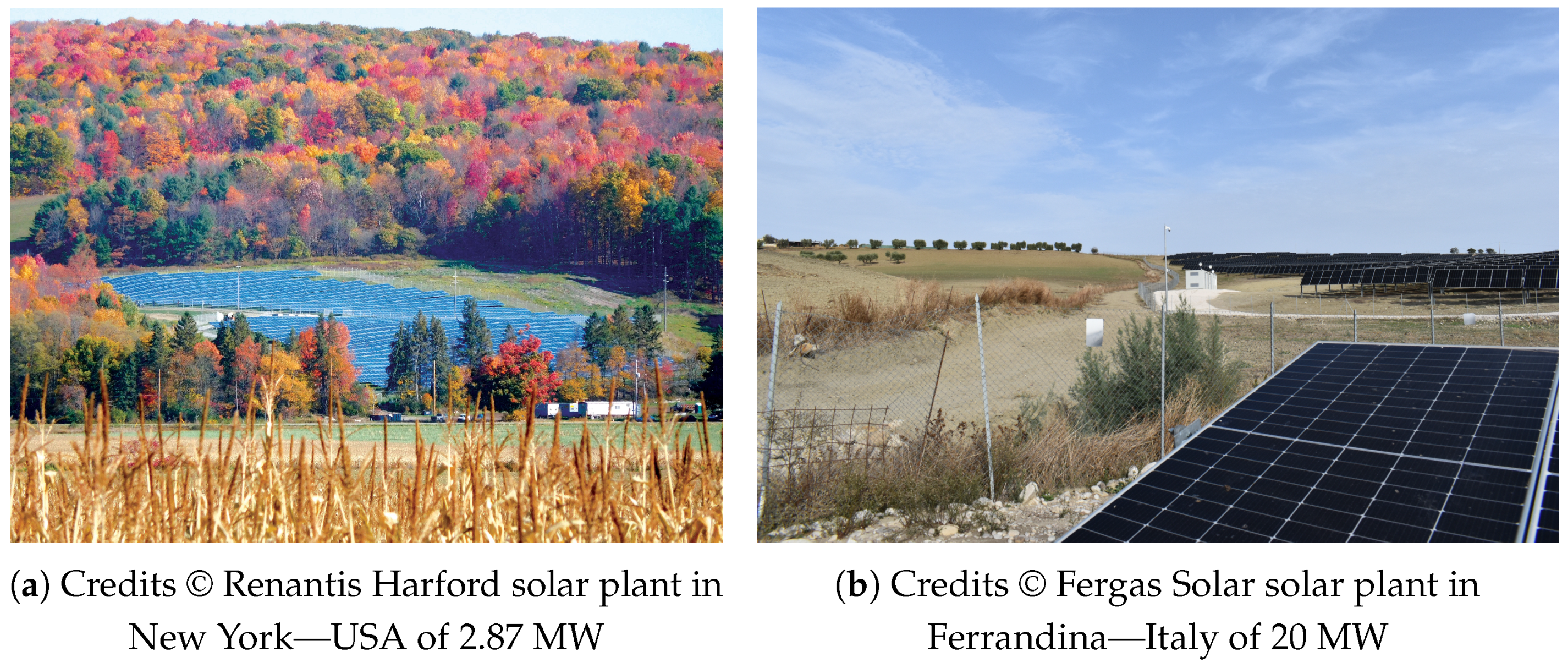

2.1. Photovoltaic Plant

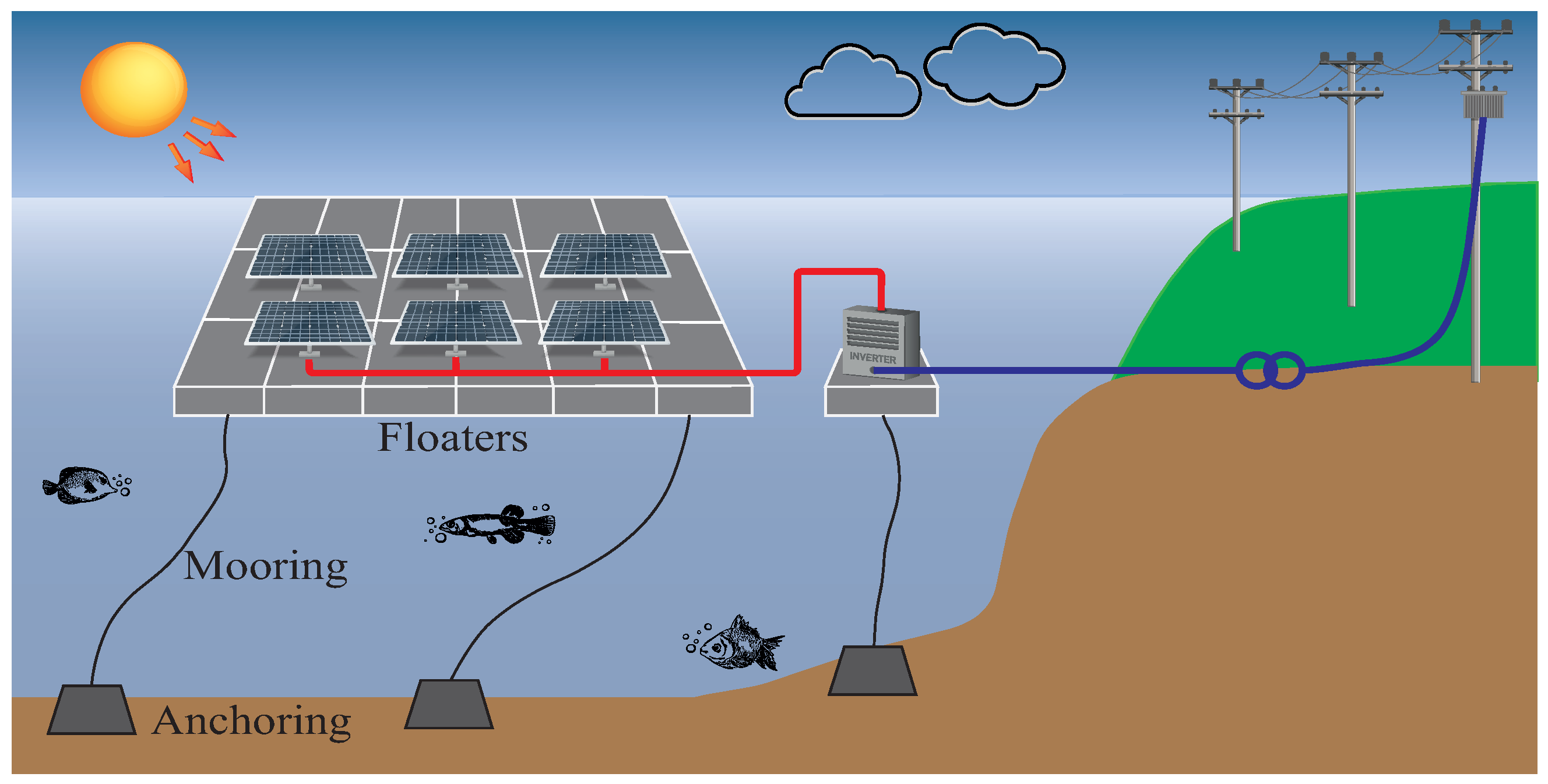

2.2. Floating Photovoltaic Systems

- Class 1 consists of large rafts made of high-density polyethylene (HDPE) pipes and steel, aluminium or composite components. On the one hand, the HDPE pipes provide the buoyancy force, on the other hand, the aluminium or steel rafts ensure an optimal panel inclination. This type of structure does not cover completely the water surface, minimizing the positive effect on water evaporation [40];

- Class 2 consists of single-module rafts that are connected by pins to form floating platforms [39]. The main problem of this technology is the lightness of the structure itself, whose connecting pins, made of HDPE, can break under very strong stress due to wind or wave action [41]. Despite the limitations that make this class unsuitable for marine applications, nearshore FPV systems have been realized in the Persian Gulf using this technology [42].

- Class 3 consists of floating pontoons made of plastic but with a low risk of releasing microplastics into the water, in compliance with environmental regulations. The pontoons can be joined in order to form a safe, stable, and easily maintained floating platform [43].

2.3. Concentrating Solar Power

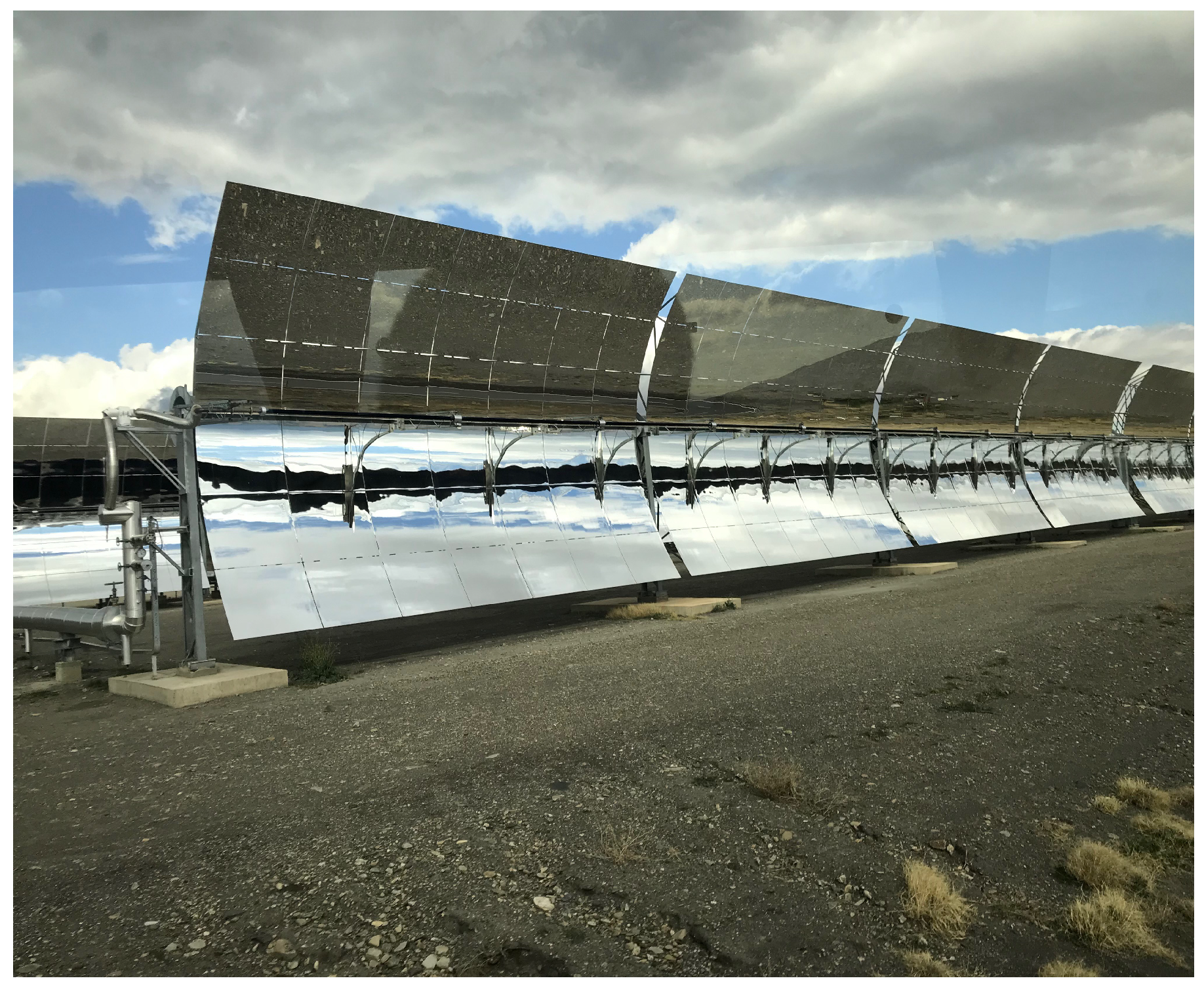

2.3.1. Parabolic Trough Systems

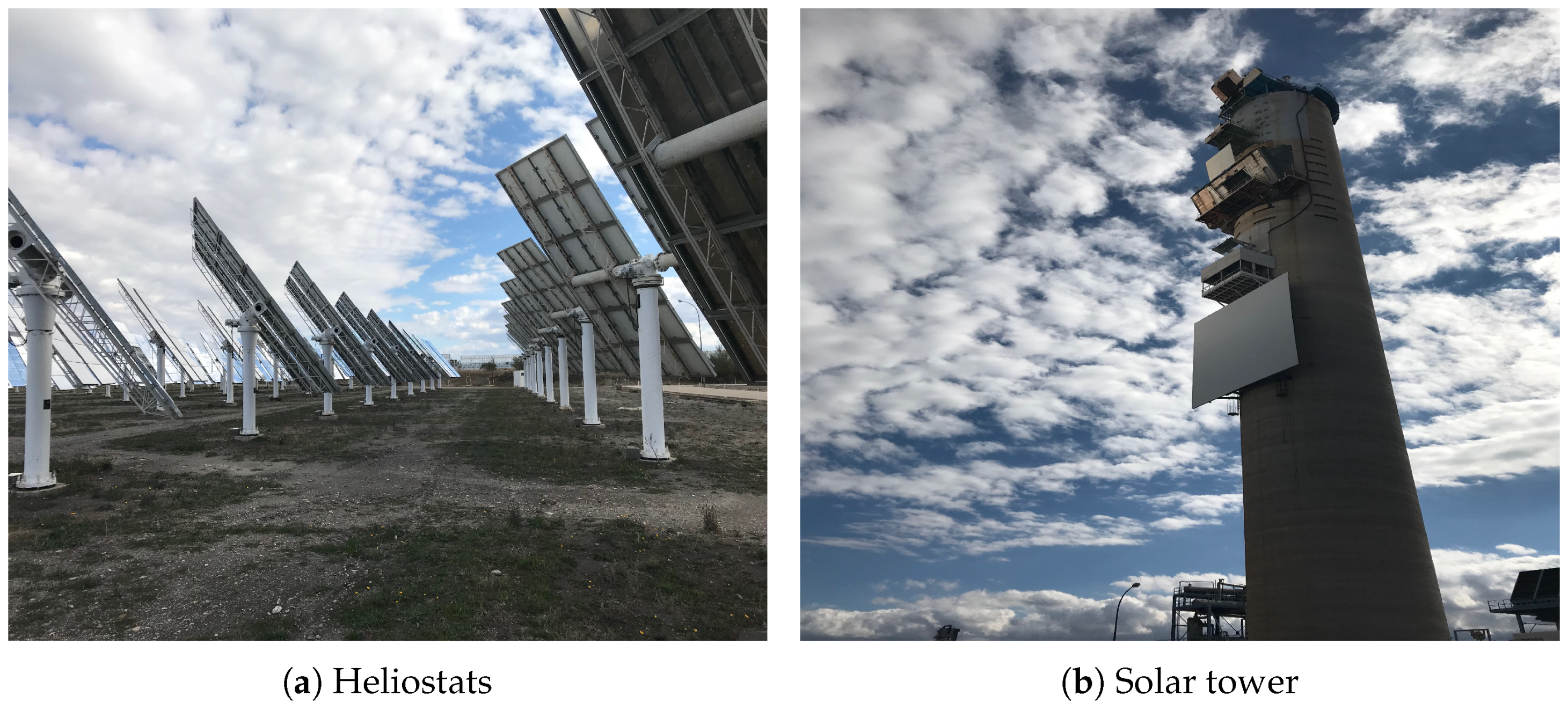

2.3.2. Concentrating Solar Tower

- In the indirect configuration, a non-aqueous or non-gaseous working fluid is heated in the receiver. If a thermal energy storage (TES) system is present, the fluid is held there before being sent to a steam generator train. The steam produced by the train is then used to power a conventional turbine generator, which generates electricity. Commercial designs employing this concept utilize molten nitrate salts as the working fluid due to their exceptional heat transfer and energy-storage characteristics;

- In the alternative arrangement, known as the direct configuration, water or steam are employed as the working substance. It is heated in the receiver and directed straight to the inlet of the Rankine turbine. The direct steam solar receiver can be equipped with distinct receiver parts dedicated to steam generation, superheating, and, if necessary, reheating. Another alternative architecture, which has yet to be made available for commercial use, involves utilizing a gaseous working fluid such as air or to propel a power system based on the Brayton or Rankine cycle.

- Elevated temperatures can enhance the efficiency of the steam cycle and decrease the amount of water needed for cooling the condenser [59];

- The increased temperature also enhances the desirability of utilizing thermal energy storage to enable predictable power generation [59];

- Elevated temperatures will also provide more significant temperature gradients in the storage system, reducing the cost or enabling increased storage capacity at the exact same cost [59].

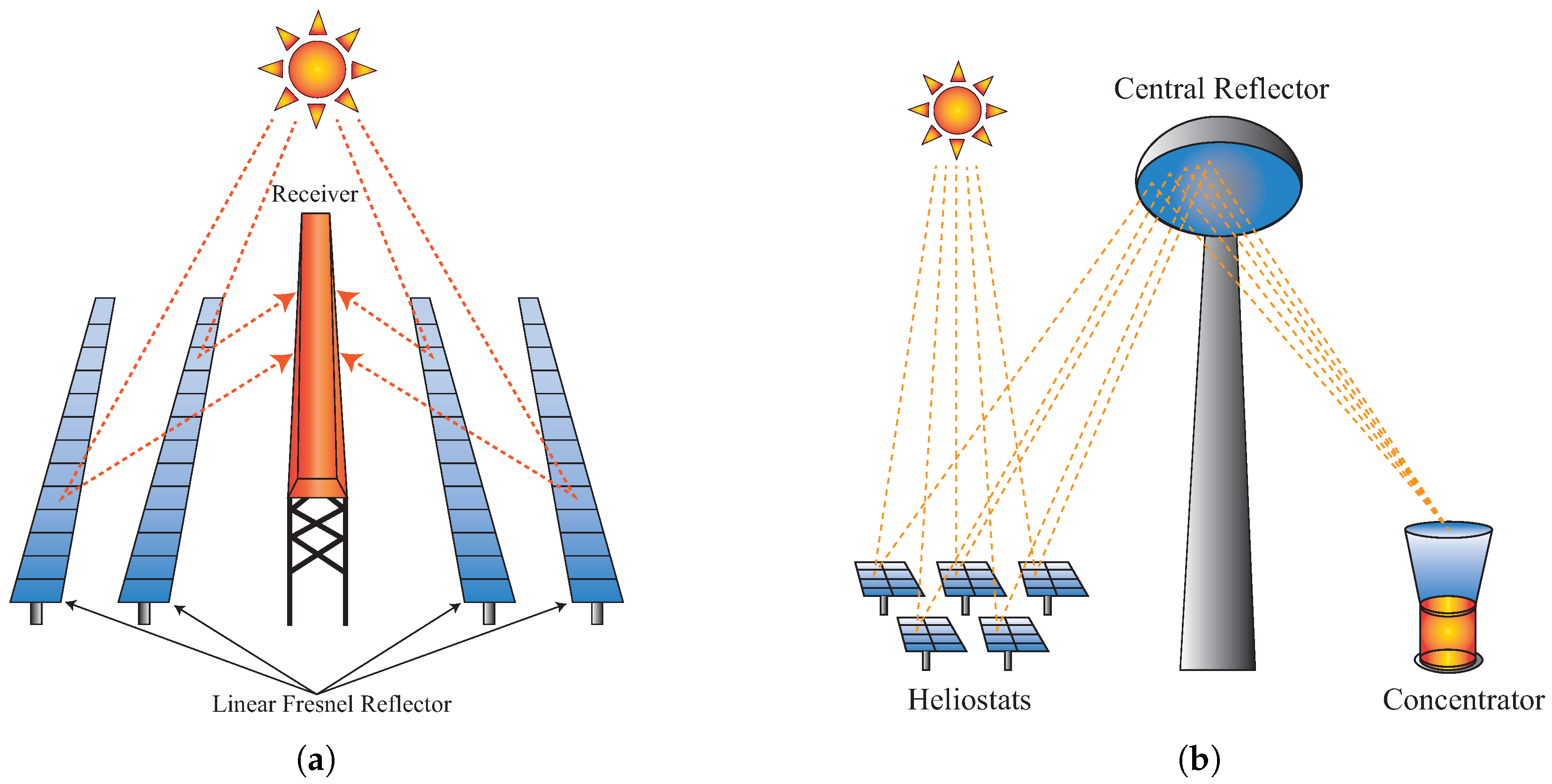

2.3.3. Linear Fresnel Reflector

- LFCs have the advantage of utilizing cost-effective flat glass mirrors, readily available as a widely produced commodity [52];

- LFCs necessitate a reduced amount of steel and concrete due to the lighter weight of the metal support framework. Additionally, this facilitates the assembly process [52];

- LFCs experience lower wind stresses, leading to enhanced structural stability, decreased optical losses, and reduced risk of mirror-glass breakage [52];

- The mirror surface area per receiver is greater in LFCs than in PTCs, which is significant considering that the receiver is the costliest element in both PTC and LFC systems [52].

2.3.4. Beam down Solar Thermal Concentrator

2.3.5. Dish/Engine Systems

- The generator is usually located in the receiver of each dish, which minimizes heat losses. This design allows for tiny individual dish-generating capacity, ranging from 5 to 50 kW, making it very modular and suited for distributed generation;

- Stirling dish technology has the best efficiency among all forms of CSP systems;

- Stirling dishes employ dry cooling methods and do not require extensive cooling systems or towers, enabling CSP to generate power in areas with limited water resources;

- Stirling dishes, due to their compact size and self-contained nature, can be installed on slopes or uneven ground, which is impossible with PTC, LFC, and solar towers.

2.4. Wind Power Plants

2.5. Hybrid Systems

2.5.1. CSP and Desalination

- Small-scale decentralized desalination plants directly powered by concentrating solar thermal collectors, specifically the multi-effect desalination (MED) plants [71];

- Concentrating solar power stations that generate electricity for reverse osmosis (RO) membrane desalination, known as CSP/RO [72];

- Combined electricity and heat generation for thermal multi-effect desalination systems, referred to as CSP/MED [73].

2.5.2. CSP and Gas Systems

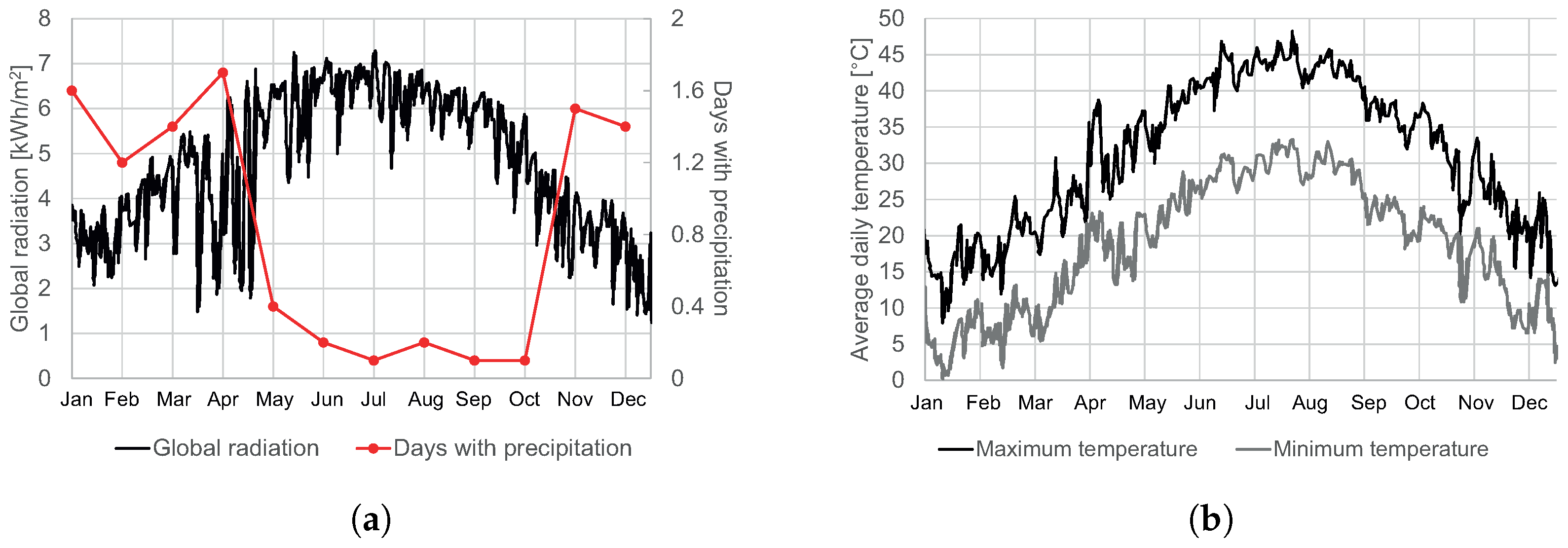

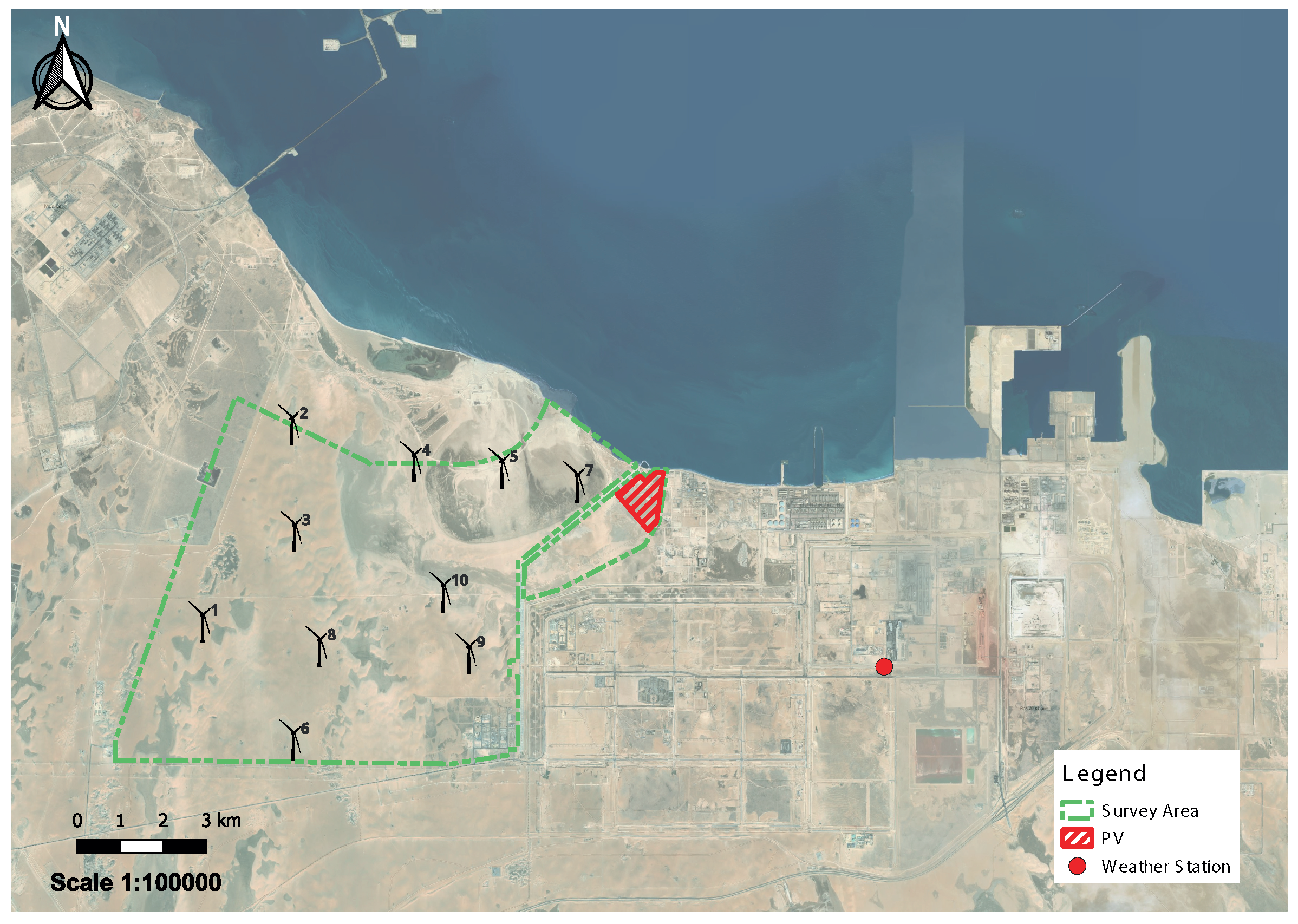

3. Case Study: Utility-Scale Renewable Power Plants in Saudi Arabia

- Land use: an issue that mainly concerns the PV plant, whose layout was chosen so as to avoid shading between parallel rows of modules;

- Power density: a fundamental characteristic for selecting the installation site of a wind turbine and strictly dependent on wind speed;

- Energy produced: estimated by means of globally recognized software.

3.1. Modeling Software and Tools Used for the Analysis

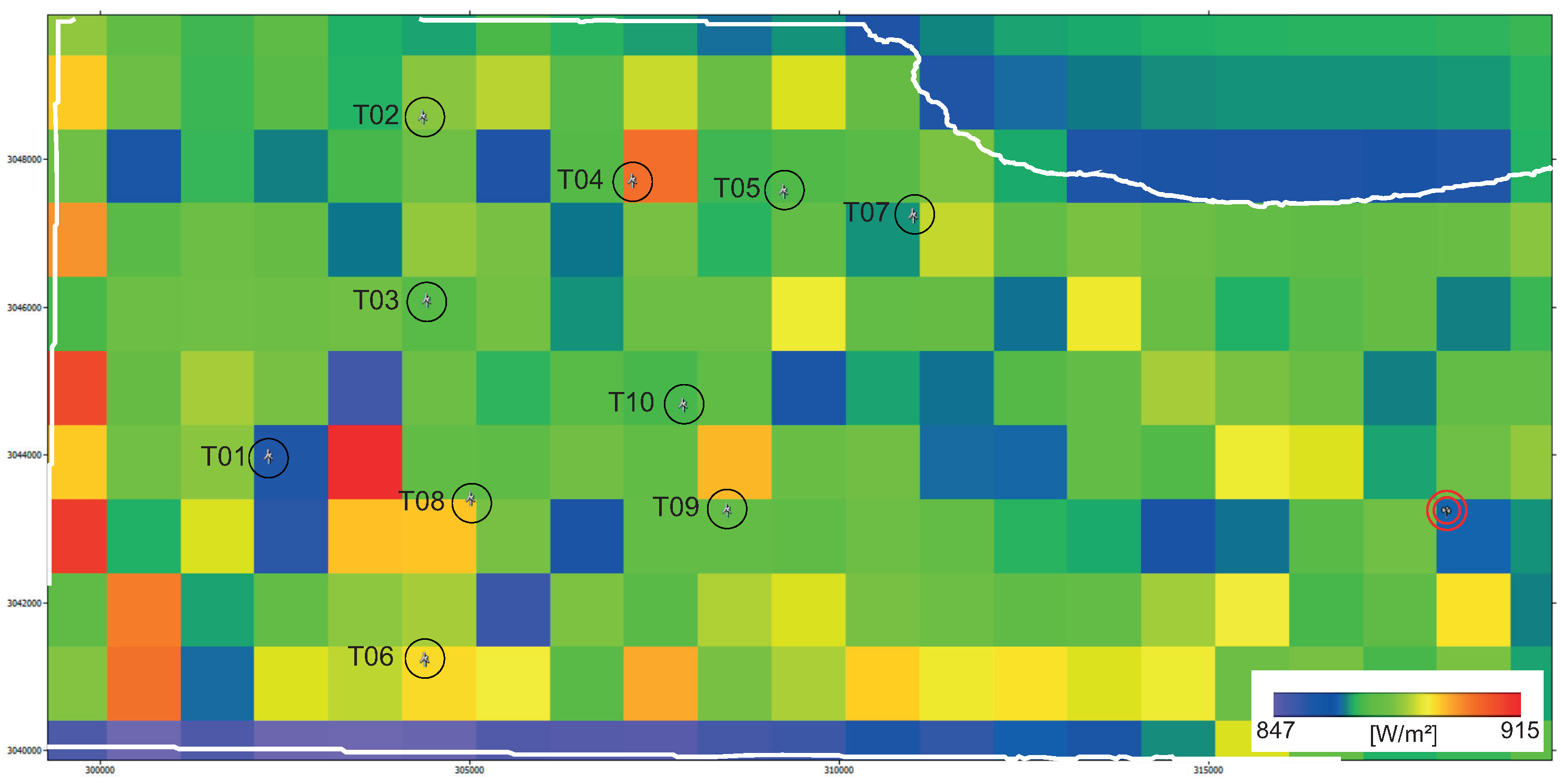

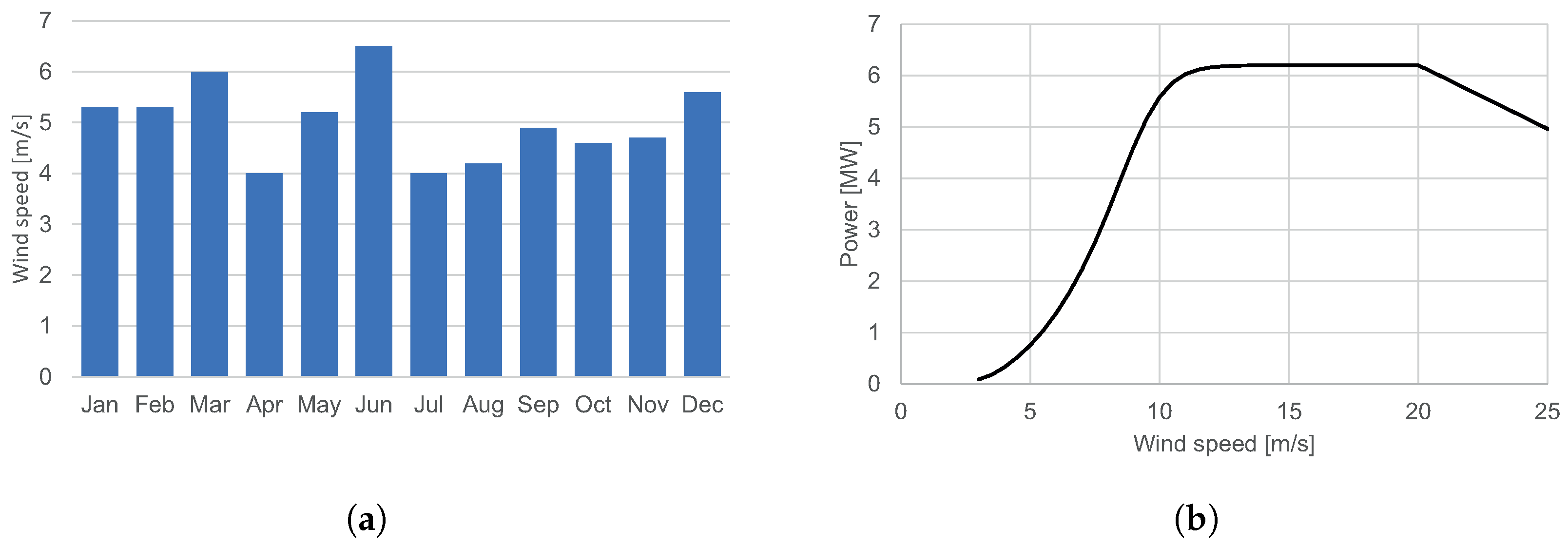

3.2. Wind Farm

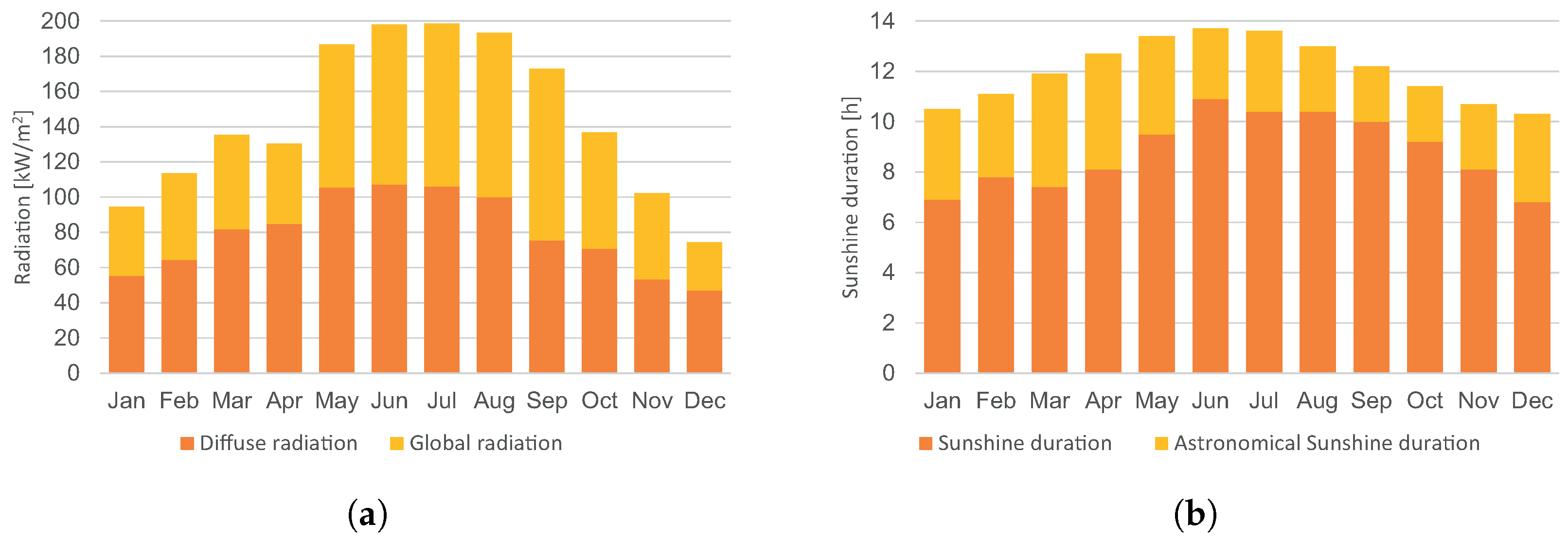

3.3. Photovoltaic Plant

3.4. Floating PV

- A waterless brush-based cleaning system (BCS) that acts on the surface of the modules by means of electromechanical devices controlled by an electronic controller. The system, which is extremely simple and lightweight, consists of a cleaning apparatus that can move on the panel surface through rails. The overall simplicity of this technology makes it possible to minimize human intervention while reducing the maintenance costs. The brush replacement frequency of the BCS is strongly influenced by environmental conditions. Furthermore, in the case of bonded dust, the cleaning of the panel must be performed manually to avoid damage to the surface due to friction between the brush and the surface itself [85]. The BCS can exploit different control systems, such as Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controller (PLC), or Arduino [86,87];

- An electrodynamic cleaning system (ECS) that uses the force generated by electrodes installed on the panel, to which a single-phase or multi-phase voltage is applied to generate a travelling or standing wave. These waves generate an electric field whose vertical component can lift charged particles and transport them towards the edge of the panel [84,85]. The efficiency of the cleaning system depends on the width and distance of the electrodes, the voltages and frequencies used, and the inclination of the PV panel [88]. This technology allows to remove more than 90% of dirt in a short time [89];

- Robotic cleaning systems (RCS), which can operate in dry or wet conditions, are the best solution for large-scale installations. RCS are lightweight, efficient, and ideal for arid and desert regions due to the reduced water consumption in the water-based configuration [90]. Most robots exploit control units based on Arduino [91] or Raspberry Pi [92], thus avoiding connections to external devices. The system uses soft plastic wheels powered by DC motors to move, thus avoiding possible scratches or abrasions on the surface of the modules. Furthermore, some robots are equipped with infrared dust sensors that can detect the level of dirt on the panel [93]. The robots are powered by batteries that are charged by means of a docking station or can be connected to the panel’s output battery. The cleaning system generally uses brushes or roller brushes to remove dust, also in combination with a wiper or pad and water for better results [94]. Although their initial and maintenance cost is high, RCS are very efficient in cleaning and can also be used without water [95,96].

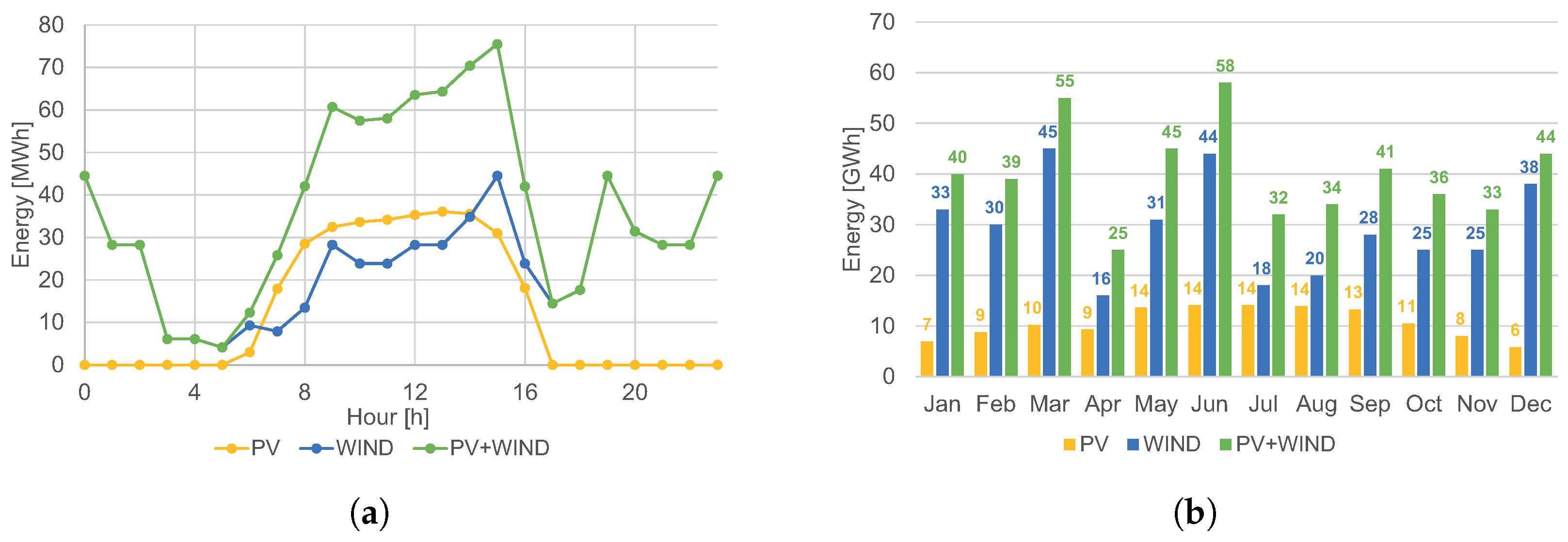

3.5. Proposed Hybrid Farm

3.6. Discussion

- Economic Sustainability Indicator: it considers economic sustainability by highlighting the performance of the proposed solution from the perspective of the installation, operation, maintenance, and management costs;

- Environmental Sustainability Indicator: it considers environmental sustainability by highlighting the performance of the proposed solution from the perspective of energy efficiency and emission of pollutants;

- Technical Sustainability Indicator: it considers technical sustainability by highlighting the performance of the proposed solution from the perspective of functionality, robustness, and reliability.

- Constructability;

- Maintainability;

- Operability;

- Satisfying environmental requirements;

- Cost minimization.

- Concentrated RESs should be adopted and sized to offer concentrated and non-dispatchable power generation according to renewable resources. Concentrated RES identifies utility-scale renewable power plants usually installed near conventional power plants in large dedicated areas. The concentrated RES plants should be sized and operated to support the conventional generation;

- Distributed RESs should be adopted and sized to offer a distributed (local) power generation integrated into smart microgrids with flexible and managed load, which permits the optimization of the power and energy flows locally, reducing the peaks and keeping the power demand from the system as flat as possible. Distributed RESs should identify the renewable power plants usually installed over buildings, infrastructures, or nearby. These plants are sized and operated to optimize the local power flows and minimize the exchange of power with the transmission lines. Distributed RES power plants are considered to operate in integration with the end-users systems by a supervisory system with the digitalization of the controls to optimize the power flows locally.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Damoom, M.M.; Hashim, S.; Aljohani, M.S.; Saleh, M.A. Adding sustainable sources to the Saudi Arabian electricity sector. Electr. J. 2018, 31, 20–28. [Google Scholar] [CrossRef]

- Stracqualursi, E.; Rosato, A.; Di Lorenzo, G.; Panella, M.; Araneo, R. Systematic review of energy theft practices and autonomous detection through artificial intelligence methods. Renew. Sustain. Energy Rev. 2023, 184, 113544. [Google Scholar] [CrossRef]

- Lashin, A.; Al Arifi, N. Geothermal energy potential of southwestern of Saudi Arabia “exploration and possible power generation”: A case study at Al Khouba area—Jizan. Renew. Sustain. Energy Rev. 2014, 30, 771–789. [Google Scholar] [CrossRef]

- Nematollahi, O.; Hoghooghi, H.; Rasti, M.; Sedaghat, A. Energy demands and renewable energy resources in the Middle East. Renew. Sustain. Energy Rev. 2016, 54, 1172–1181. [Google Scholar] [CrossRef]

- Bayomi, N.; Fernandez, J.E. Towards sustainable energy trends in the Middle East: A study of four major emitters. Energies 2019, 12, 1615. [Google Scholar] [CrossRef]

- Nathaniel, S.; Anyanwu, O.; Shah, M. Renewable energy, urbanization, and ecological footprint in the Middle East and North Africa region. Environ. Sci. Pollut. Res. 2020, 27, 14601–14613. [Google Scholar] [CrossRef] [PubMed]

- Alnatheer, O. The potential contribution of renewable energy to electricity supply in Saudi Arabia. Energy Policy 2005, 33, 2298–2312. [Google Scholar] [CrossRef]

- Alaqeel, T.; Suryanarayanan, S. A comprehensive cost-benefit analysis of the penetration of Smart Grid technologies in the Saudi Arabian electricity infrastructure. Util. Policy 2019, 60, 100933. [Google Scholar] [CrossRef]

- Ramli, M.A.; Hiendro, A.; Sedraoui, K.; Twaha, S. Optimal sizing of grid-connected photovoltaic energy system in Saudi Arabia. Renew. Energy 2015, 75, 489–495. [Google Scholar] [CrossRef]

- Baseer, M.; Meyer, J.; Alam, M.M.; Rehman, S. Wind speed and power characteristics for Jubail industrial city, Saudi Arabia. Renew. Sustain. Energy Rev. 2015, 52, 1193–1204. [Google Scholar] [CrossRef]

- Barashid, K.; Munshi, A.; Alhindi, A. Wind Farm Power Prediction Considering Layout and Wake Effect: Case Study of Saudi Arabia. Energies 2023, 16, 938. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2019; Technical Report; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2020. [Google Scholar]

- Bahrampour, H.; Beheshti Marnani, A.K.; Askari, M.B.; Bahrampour, M.R. Evaluation of renewable energies production potential in the Middle East: Confronting the world’s energy crisis. Front. Energy 2020, 14, 42–56. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2022. Available online: https://mc-cd8320d4-36a1-40ac-83cc-3389-cdn-endpoint.azureedge.net/-/media/Files/IRENA/Agency/Publication/2023/Aug/IRENA_Renewable_power_generation_costs_in_2022.pdf?rev=cccb713bf8294cc5bec3f870e1fa15c2 (accessed on 4 January 2024).

- Amran, Y.A.; Amran, Y.M.; Alyousef, R.; Alabduljabbar, H. Renewable and sustainable energy production in Saudi Arabia according to Saudi Vision 2030; Current status and future prospects. J. Clean. Prod. 2020, 247, 119602. [Google Scholar] [CrossRef]

- Alrammah, I.A. Analysis of nuclear accident scenarios and emergency planning zones for a proposed Advanced Power Reactor 1400 (APR1400). Nucl. Eng. Des. 2023, 407, 112275. [Google Scholar] [CrossRef]

- Johari, J.; Dewayatna, W.; Sarjono, S.; Rianto, S.; Yusnitha, E.; Adhi, A.; Suryaman, G.; Rahmadi, G.; Langenati, R.; Rachmawati, M. Preliminary assessment of sustainability of HTR fuel programme for newcomer countries. Nucl. Eng. Des. 2022, 398, 111971. [Google Scholar] [CrossRef]

- Oettingen, M.; Kim, J. Detection of Numerical Power Shift Anomalies in Burnup Modeling of a PWR Reactor. Sustainability 2023, 15, 3373. [Google Scholar] [CrossRef]

- Kępisty, G.; Oettingen, M.; Stanisz, P.; Cetnar, J. Statistical error propagation in HTR burnup model. Ann. Nucl. Energy 2017, 105, 355–360. [Google Scholar] [CrossRef]

- Baek, J. A panel cointegration analysis of CO2 emissions, nuclear energy and income in major nuclear generating countries. Appl. Energy 2015, 145, 133–138. [Google Scholar] [CrossRef]

- Kartal, M.T. The role of consumption of energy, fossil sources, nuclear energy, and renewable energy on environmental degradation in top-five carbon producing countries. Renew. Energy 2022, 184, 871–880. [Google Scholar] [CrossRef]

- Di Lorenzo, G.; Stracqualursi, E.; Araneo, R. The Journey Towards the Energy Transition: Perspectives from the International Conference on Environment and Electrical Engineering (EEEIC). Energies 2022, 15, 6652. [Google Scholar] [CrossRef]

- Di Lorenzo, G.; Stracqualursi, E.; Micheli, L.; Martirano, L.; Araneo, R. Challenges in Energy Communities: State of the Art and Future Perspectives. Energies 2022, 15, 7384. [Google Scholar] [CrossRef]

- stergaard, P.A.; Duic, N.; Noorollahi, Y.; Mikulcic, H.; Kalogirou, S. Sustainable development using renewable energy technology. Renew. Energy 2020, 146, 2430–2437. [Google Scholar] [CrossRef]

- Rosato, A.; Altilio, R.; Araneo, R.; Panella, M. Prediction in Photovoltaic Power by Neural Network. Energies 2017, 10, 1003. [Google Scholar] [CrossRef]

- Rosato, A.; Panella, M.; Araneo, R.; Andreotti, A. A neural network-based prediction system of distributed generation for the management of microgrids. IEEE Trans. Ind. Appl. 2019, 55, 7092–7102. [Google Scholar] [CrossRef]

- Rosato, A.; Panella, M.; Araneo, R. A distributed algorithm for the cooperative prediction of power production in PV plants. IEEE Trans. Energy Convers. 2019, 34, 497–508. [Google Scholar] [CrossRef]

- Succetti, F.; Rosato, A.; Araneo, R.; Panella, M. Deep Neural Networks for Multivariate Prediction of Photovoltaic Power Time Series. IEEE Access 2020, 8, 211490–211505. [Google Scholar] [CrossRef]

- Rosato, A.; Panella, M.; Andreotti, A.; Mohammed, O.A.; Araneo, R. Two-stage dynamic management in energy communities using a decision system based on elastic net regularization. Appl. Energy 2021, 291, 116852. [Google Scholar] [CrossRef]

- Østergaard, P.A.; Duic, N.; Noorollahi, Y.; Kalogirou, S. Renewable energy for sustainable development. Renew. Energy 2022, 199, 1145–1152. [Google Scholar] [CrossRef]

- Kopecek, R.; Libal, J. Bifacial photovoltaics 2021: Status, opportunities and challenges. Energies 2021, 14, 2076. [Google Scholar] [CrossRef]

- Di Lorenzo, G.; Araneo, R.; Mitolo, M.; Niccolai, A.; Grimaccia, F. Review of O&M Practices in PV Plants: Failures, Solutions, Remote Control, and Monitoring Tools. IEEE J. Photovolt. 2020, 10, 914–926. [Google Scholar]

- Di Lorenzo, G.; Stracqualursi, E.; Micheli, L.; Celozzi, S.; Araneo, R. Prognostic Methods for Photovoltaic Systems’ Underperformance and Degradation: Status, Perspectives, and Challenges. Energies 2022, 15, 6413. [Google Scholar] [CrossRef]

- Rodríguez-Gallegos, C.D.; Liu, H.; Gandhi, O.; Singh, J.P.; Krishnamurthy, V.; Kumar, A.; Stein, J.S.; Wang, S.; Li, L.; Reindl, T.; et al. Global techno-economic performance of bifacial and tracking photovoltaic systems. Joule 2020, 4, 1514–1541. [Google Scholar] [CrossRef]

- Wang, S.; Shen, Y.; Zhou, J.; Li, C.; Ma, L. Efficiency Enhancement of Tilted Bifacial Photovoltaic Modules with Horizontal Single-Axis Tracker—The Bifacial Companion Method. Energies 2022, 15, 1262. [Google Scholar] [CrossRef]

- Gorjian, S.; Sharon, H.; Ebadi, H.; Kant, K.; Scavo, F.B.; Tina, G.M. Recent technical advancements, economics and environmental impacts of floating photovoltaic solar energy conversion systems. J. Clean. Prod. 2021, 278, 124285. [Google Scholar] [CrossRef]

- Niccolai, A.; Grimaccia, F.; Di Lorenzo, G.; Araneo, R.; Ughi, F.; Polenghi, M. A Review of Floating PV Systems with a Techno-Economic Analysis. IEEE J. Photovolt. 2023, 14, 23–24. [Google Scholar] [CrossRef]

- Ghigo, A.; Faraggiana, E.; Sirigu, M.; Mattiazzo, G.; Bracco, G. Design and analysis of a floating photovoltaic system for offshore installation: The case study of Lampedusa. Energies 2022, 15, 8804. [Google Scholar] [CrossRef]

- Claus, R.; López, M. Key issues in the design of floating photovoltaic structures for the marine environment. Renew. Sustain. Energy Rev. 2022, 164, 112502. [Google Scholar] [CrossRef]

- Kumar, M.; Niyaz, H.M.; Gupta, R. Challenges and opportunities towards the development of floating photovoltaic systems. Sol. Energy Mater. Sol. Cells 2021, 233, 111408. [Google Scholar] [CrossRef]

- Nguyen, D. The Global Evolution of Floating Solar PV; Technical report, Working Paper; IFC: Washington, DC, USA, 2017. [Google Scholar]

- Emiliano, B. Floating PV in the Persian Gulf. Available online: https://www.pv-magazine.com/2020/02/17/floating-pv-in-the-persian-gulf/ (accessed on 4 January 2024).

- Cazzaniga, R. Chapter 4—Floating PV Structures. In Floating PV Plants; Rosa-Clot, M., Marco Tina, G., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 33–45. [Google Scholar] [CrossRef]

- SERIS. Where Sun Meets Water—Floating Solar Market Report. Available online: http://hdl.handle.net/10986/31880 (accessed on 4 January 2024).

- Idier, D.; Bertin, X.; Thompson, P.; Pickering, M.D. Interactions between mean sea level, tide, surge, waves and flooding: Mechanisms and contributions to sea level variations at the coast. Surv. Geophys. 2019, 40, 1603–1630. [Google Scholar] [CrossRef]

- Acharya, M.; Devraj, S. Floating Solar Photovoltaic (FSPV): A Third Pillar to Solar PV Sector; The Energy and Resources Institute: New Delhi, India, 2019. [Google Scholar]

- Rashid, K.; Mohammadi, K.; Powell, K. Dynamic simulation and techno-economic analysis of a concentrated solar power (CSP) plant hybridized with both thermal energy storage and natural gas. J. Clean. Prod. 2020, 248, 119193. [Google Scholar] [CrossRef]

- Rohani, S.; Went, J.; Duvenhage, D.F.; Gerards, R.; Wittwer, C.; Fluri, T. Optimization of water management plans for CSP plants through simulation of water consumption and cost of treatment based on operational data. Sol. Energy 2021, 223, 278–292. [Google Scholar] [CrossRef]

- Awan, A.B.; Khan, M.; Zubair, M.; Bellos, E. Commercial parabolic trough CSP plants: Research trends and technological advancements. Sol. Energy 2020, 211, 1422–1458. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Mdallal, A.; Rezk, A.; Radwan, A.; Rahman, S.M.A.; Shah, S.K.; Abdelkareem, M.A. Concentrating solar power (CSP) technologies: Status and analysis. Int. J. Thermofluids 2023, 18, 100340. [Google Scholar] [CrossRef]

- Arnaoutakis, G.E.; Katsaprakakis, D.A. Concentrating Solar Power Advances in Geometric Optics, Materials and System Integration. Energies 2021, 14, 6229. [Google Scholar] [CrossRef]

- Gielen, D. Renewable Energy Technologies: Cost Analysis Series; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2012; Volume 1. [Google Scholar]

- Dhaou, M.H.; Mellouli, S.; Alresheedi, F.; El-Ghoul, Y. Numerical assessment of an innovative design of an evacuated tube solar collector incorporated with PCM embedded metal foam/plate fins. Sustainability 2021, 13, 10632. [Google Scholar] [CrossRef]

- Saini, P.; Singh, S.; Kajal, P.; Dhar, A.; Khot, N.; Mohamed, M.; Powar, S. A review of the techno-economic potential and environmental impact analysis through life cycle assessment of parabolic trough collector towards the contribution of sustainable energy. Heliyon 2023, 9, e17626. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Lu, Z.; Yu, W.; Zhang, H.; Wang, Z. Tracking and ray tracing equations for the target-aligned heliostat for solar tower power plants. Renew. Energy 2011, 36, 2687–2693. [Google Scholar] [CrossRef]

- Alam, M.I.; Nuhash, M.M.; Zihad, A.; Nakib, T.H.; Ehsan, M.M. Conventional and Emerging CSP Technologies and Design Modifications: Research Status and Recent Advancements. Int. J. Thermofluids 2023, 20, 100406. [Google Scholar] [CrossRef]

- Kearney, D. Utility-Scale Power Tower Solar Systems: Performance Acceptance Test Guidelines; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2013.

- Singer, C.; Giuliano, S.; Buck, R. Assessment of improved molten salt solar tower plants. Energy Procedia 2014, 49, 1553–1562. [Google Scholar] [CrossRef]

- Zhang, H.; Baeyens, J.; Degrève, J.; Cacères, G. Concentrated solar power plants: Review and design methodology. Renew. Sustain. Energy Rev. 2013, 22, 466–481. [Google Scholar] [CrossRef]

- Ortega, J.I.; Burgaleta, J.I.; Téllez, F.M. Central receiver system solar power plant using molten salt as heat transfer fluid. J. Sol. Energy Eng. 2008, 130, 024501. [Google Scholar] [CrossRef]

- González-Mora, E.; Durán García, M.D. Methodology for an opto-geometric optimization of a linear Fresnel reflector for direct steam generation. Energies 2020, 13, 355. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2014; Technical report; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2015. [Google Scholar]

- Rungasamy, A.; Craig, K.; Meyer, J.P. A review of linear Fresnel primary optical design methodologies. Sol. Energy 2021, 224, 833–854. [Google Scholar] [CrossRef]

- Hachicha, A.A. Numerical Modelling of a Parabolic trough Solar Collector. Ph.D. Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2013. [Google Scholar]

- Mokhtar, M.B. The Beam-Down Solar Thermal Concentrator: Experimental Characterization and Modeling. Master’s Thesis, Masdar Institute of Science and Technology, Masdar City, United Arab Emirates, 2011. [Google Scholar]

- Concentrating Solar Power Basics. Available online: https://www.nrel.gov/research/re-csp.html (accessed on 4 January 2024).

- Guarino, S.; Buscemi, A.; Messineo, A.; Lo Brano, V. Energy and Environmental Assessment of a Hybrid Dish-Stirling Concentrating Solar Power Plant. Sustainability 2022, 14, 6098. [Google Scholar] [CrossRef]

- IRENA. Renewable Energy and Jobs: Annual Review 2023. Available online: https://mc-cd8320d4-36a1-40ac-83cc-3389-cdn-endpoint.azureedge.net/-/media/Files/IRENA/Agency/Publication/2023/Sep/IRENA_Renewable_energy_and_jobs_2023.pdf?rev=4c35bf5a1222429e8f0bf932a641f818 (accessed on 4 January 2024).

- European Commision. EU Wind Energy. Available online: https://energy.ec.europa.eu/topics/renewable-energy/eu-wind-energy_en (accessed on 4 January 2024).

- Musial, W.; Green, R.; DeMeo, E.; Cooperman, A.; Housner, S.; Marquis, M.; MacDonald, S.; McDowell, B.; Hein, C.; Rolph, R.; et al. Great Lakes Wind Energy Challenges and Opportunities Assessment; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2023.

- Liponi, A.; Tempesti, C.; Baccioli, A.; Ferrari, L. Small-scale desalination plant driven by solar energy for isolated communities. Energies 2020, 13, 3864. [Google Scholar] [CrossRef]

- Mohammadi, K.; Saghafifar, M.; Ellingwood, K.; Powell, K. Hybrid concentrated solar power (CSP)-desalination systems: A review. Desalination 2019, 468, 114083. [Google Scholar] [CrossRef]

- Gohil, P.P.; Desai, H.; Kumar, A.; Kumar, R. Current Status and Advancement in Thermal and Membrane-Based Hybrid Seawater Desalination Technologies. Water 2023, 15, 2274. [Google Scholar] [CrossRef]

- Power, C.S. Clean Power on Demand 24/7; World Bank: Washington, DC, USA, 2021. [Google Scholar]

- Saudi & Middle East Green Initiative. Available online: https://www.greeninitiatives.gov.sa/about-sgi/sgi-targets/reduce-carbon-emissions/ (accessed on 4 January 2024).

- Almulhim, A.I. Understanding public awareness and attitudes toward renewable energy resources in Saudi Arabia. Renew. Energy 2022, 192, 572–582. [Google Scholar] [CrossRef]

- Hepbasli, A.; Alsuhaibani, Z. A key review on present status and future directions of solar energy studies and applications in Saudi Arabia. Renew. Sustain. Energy Rev. 2011, 15, 5021–5050. [Google Scholar] [CrossRef]

- Lazaroiu, G.C.; Longo, M.; Roscia, M.; Pagano, M. Comparative analysis of fixed and sun tracking low power PV systems considering energy consumption. Energy Convers. Manag. 2015, 92, 143–148. [Google Scholar] [CrossRef]

- Bontempo Scavo, F.; Tina, G.M.; Gagliano, A.; Nižetić, S. An assessment study of evaporation rate models on a water basin with floating photovoltaic plants. Int. J. Energy Res. 2021, 45, 167–188. [Google Scholar] [CrossRef]

- Majumder, A.; Innamorati, R.; Frattolillo, A.; Kumar, A.; Gatto, G. Performance analysis of a floating photovoltaic system and estimation of the evaporation losses reduction. Energies 2021, 14, 8336. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Zobel, P.B.; De Marcellis, A.; Palange, E. Autonomous robot for cleaning photovoltaic panels in desert zones. Mechatronics 2020, 68, 102372. [Google Scholar] [CrossRef]

- Alghamdi, A.S.; Bahaj, A.S.; Blunden, L.S.; Wu, Y. Dust removal from solar PV modules by automated cleaning systems. Energies 2019, 12, 2923. [Google Scholar] [CrossRef]

- Shah, A.H.; Hassan, A.; Laghari, M.S.; Alraeesi, A. The influence of cleaning frequency of photovoltaic modules on power losses in the desert climate. Sustainability 2020, 12, 9750. [Google Scholar] [CrossRef]

- Zahedi, R.; Ranjbaran, P.; Gharehpetian, G.B.; Mohammadi, F.; Ahmadiahangar, R. Cleaning of floating photovoltaic systems: A critical review on approaches from technical and economic perspectives. Energies 2021, 14, 2018. [Google Scholar] [CrossRef]

- Derakhshandeh, J.F.; AlLuqman, R.; Mohammad, S.; AlHussain, H.; AlHendi, G.; AlEid, D.; Ahmad, Z. A comprehensive review of automatic cleaning systems of solar panels. Sustain. Energy Technol. Assess. 2021, 47, 101518. [Google Scholar] [CrossRef]

- Sivan, A.; Sivan, A.; Lakshmi Priya, G.; Mathew, S. Automatic Self Cleaning Solar Panel. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 2035–2037. [Google Scholar]

- Sreega, R.; Nithyananthan, K.; Nandhini, B. Design and development of automated solar panel cleaner and cooler. Int. J. Electr. Electron. Eng. 2017, 9, 186–197. [Google Scholar]

- Wu, G.; Inderbitzin, A.; Bening, C. Total cost of ownership of electric vehicles compared to conventional vehicles: A probabilistic analysis and projection across market segments. Energy Policy 2015, 80, 196–214. [Google Scholar] [CrossRef]

- Mazumder, M.; Horenstein, M.N.; Stark, J.W.; Girouard, P.; Sumner, R.; Henderson, B.; Sadder, O.; Hidetaka, I.; Biris, A.S.; Sharma, R. Characterization of electrodynamic screen performance for dust removal from solar panels and solar hydrogen generators. IEEE Trans. Ind. Appl. 2013, 49, 1793–1800. [Google Scholar] [CrossRef]

- Anderson, M.; Grandy, A.; Hastie, J.; Sweezey, A.; Ranky, R.; Mavroidis, C.; Markopoulos, Y.P. Robotic device for cleaning photovoltaic panel arrays. In Mobile Robotics: Solutions and Challenges; World Scientific: Singapore, 2010; pp. 367–377. [Google Scholar]

- Jawale, J.; Karra, V.; Patil, B.; Singh, P.; Singh, S.; Atre, S. Solar panel cleaning bot for enhancement of efficiency—An innovative approach. In Proceedings of the 2016 3rd International Conference on Devices, Circuits and Systems (ICDCS), Coimbatore, India, 3–5 March 2016; pp. 103–108. [Google Scholar]

- Divya, R.; Sheeba, K.; Gayadhiri Dhevi, J.; Sandhiya, S.; Vennila, S. Automatic cleaning of solar panel with maximum power tracking by using Arduino. Int. J. Adv. Res. Ideas Innov. Technol. 2018, 2, 5. [Google Scholar]

- Hadipour, M.; Derakhshandeh, J.F.; Rezaei, R. Fully automatic cleaning system of smart street lights: A new design via Alf and vegard’s RISC processor. SN Appl. Sci. 2020, 2, 1212. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, Q.; Hu, J. A linear piezoelectric actuator based solar panel cleaning system. Energy 2013, 60, 401–406. [Google Scholar] [CrossRef]

- Parrott, B.; Zanini, P.C.; Shehri, A.; Kotsovos, K.; Gereige, I. Automated, robotic dry-cleaning of solar panels in Thuwal, Saudi Arabia using a silicone rubber brush. Sol. Energy 2018, 171, 526–533. [Google Scholar] [CrossRef]

- Jaradat, M.A.; Tauseef, M.; Altaf, Y.; Saab, R.; Adel, H.; Yousuf, N.; Zurigat, Y.H. A fully portable robot system for cleaning solar panels. In Proceedings of the 2015 10th International Symposium on Mechatronics and its Applications (ISMA), Sharjah, United Arab Emirates, 8–10 December 2015; pp. 1–6. [Google Scholar]

- Sukarso, A.P.; Kim, K.N. Cooling effect on the floating solar PV: Performance and economic analysis on the case of west Java province in Indonesia. Energies 2020, 13, 2126. [Google Scholar] [CrossRef]

- Liu, H.; Krishna, V.; Lun Leung, J.; Reindl, T.; Zhao, L. Field experience and performance analysis of floating PV technologies in the tropics. Prog. Photovolt. Res. Appl. 2018, 26, 957–967. [Google Scholar] [CrossRef]

- Sahu, A.; Yadav, N.; Sudhakar, K. Floating photovoltaic power plant: A review. Renew. Sustain. Energy Rev. 2016, 66, 815–824. [Google Scholar] [CrossRef]

- Micheli, L. The temperature of floating photovoltaics: Case studies, models and recent findings. Sol. Energy 2022, 242, 234–245. [Google Scholar] [CrossRef]

- Roy, P.; He, J. Grid-connected hybrid wind-solar farm hourly dispatching with battery and supercapacitor energy storage. In Proceedings of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 1831–1836. [Google Scholar]

| Parameter | Unit | Value (Market) | |

|---|---|---|---|

| Net capacity factor | Utility scale | % | 25.1 |

| Commercial | % | 16.0 | |

| Residential | % | 15.3 | |

| LCOE | Utility scale | $/MWh | 30.67 |

| Commercial | $/MWh | 48.34 | |

| Residential | $/MWh | 79.88 | |

| Life Cycle GHG | g /kWh | 46 | |

| Land use (>1 MW) | Utility scale fixed | MW/km2 | 87.5 |

| Specific productivity | MWh/(MW × yr) | 1900 | |

| Parameter | Unit | Value | |

|---|---|---|---|

| Net capacity factor | % | 63.0 | |

| LCOE | $/MWh | 57.73 | |

| Life Cycle GHG | g CO2eq/kWh | 36.00 | |

| Specific productivity | MWh/(MW × year) | 2850 | |

| Land use | Parabolic trough systems | MWe/km2 | 300 |

| Concentrating solar power | MWe/km2 | 400 | |

| Linear Fresnel reflector | MWe/km2 | 150 | |

| Dish | MWe/km2 | 30 | |

| Technology | Direct Area | Total Area | ||

|---|---|---|---|---|

| Capacity-Weighted Average Land Use | Generation Weighted Average Land Use | Capacity-Weighted Average Land Use | Generation Weighted Average Land Use | |

| (acres/MWac) | (acres/GWh/yr) | (acres/MWac) | (acres/GWh/yr) | |

| Small PV (>1 MW, <20 MW) 1 | 5.9 | 3.1 | 8.3 | 4.1 |

| Fixed | 5.5 | 3.2 | 7.6 | 4.4 |

| 1-axis | 6.3 | 2.9 | 8.7 | 3.8 |

| 2-axis flat panel | 9.4 | 4.1 | 13.0 | 5.5 |

| 2-axis CPV | 6.9 | 2.3 | 9.1 | 3.1 |

| Large PV (>20 MW) 1 | 7.2 | 3.1 | 7.9 | 3.4 |

| Fixed | 5.8 | 2.8 | 7.5 | 3.7 |

| 1-axis | 9 | 3.5 | 8.3 | 3.3 |

| 2-axis CPV | 6.1 | 2.0 | 8.1 | 2.8 |

| CSP 1 | 7.7 | 2.7 | 10.0 | 3.5 |

| Parabolic through | 6.2 | 2.5 | 9.5 | 3.9 |

| Tower | 8.9 | 2.8 | 10.0 | 3.2 |

| Dish Stirling | 2.8 | 1.5 | 10 | 5.3 |

| Linear Fresnel | 2.0 | 1.7 | 4.7 | 4.0 |

| Parameter | Unit | Value | |

|---|---|---|---|

| Net capacity factor | Land based | % | 47.0 |

| Offshore | % | 51.0 | |

| Offshore | % | 46.7 | |

| LCOE | Land based | $/MWh | 21.51 |

| Offshore | $/MWh | 61.96 | |

| Life Cycle GHG | g CO2eq/kWh | 126 | |

| Specific productivity | Land based | MWh/(MW × year) | 3660 |

| Offshore | MWh/(MW × year) | 4295 | |

| Land use | MWe/km2 | 35 | |

| Type | 3-Bladed, Horizontal Axis |

| Rated power | 6.2 MW |

| Blade length | 83.5 m |

| Hub height | 165 m |

| Cut-in wind speed | 3 m/s |

| Cut-out wind speed | 25 m/s |

| Turbine ID | Gross AEP | Net AEP | Efficiency |

|---|---|---|---|

| [GWh] | [GWh] | [%] | |

| T01 | 35.5 | 35.4 | 99.6 |

| T02 | 35.8 | 35.7 | 99.8 |

| T03 | 35.6 | 35.4 | 99.3 |

| T04 | 35.7 | 35.5 | 99.4 |

| T05 | 35.6 | 35.4 | 99.3 |

| T06 | 35.7 | 35.4 | 99.2 |

| T07 | 35.6 | 35.4 | 99.4 |

| T08 | 35.8 | 35.4 | 99.1 |

| T09 | 35.5 | 35.0 | 98.6 |

| T10 | 35.6 | 35.3 | 99.0 |

| Wind farm | 356.4 | 353.8 | 99.3 |

| Modules Type | Bifacial |

| Number of modules | 26 |

| Open circuit voltage | 1338.22 V |

| Short circuit current | 14.37 A |

| Maximum power point voltage | 1107.34 V |

| Maximum power point current | 13.620 A |

| Peak nominal power | 15.08 kWp |

| Rated power | 4400 kVA |

| Max input voltage | 1500 V |

| AC power frequency | 50–60 Hz |

| Max efficiency | 98.8% |

| Typical nominal AC voltages | 10 kV to 35 kV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Lorenzo, G.; Stracqualursi, E.; Vescio, G.; Araneo, R. State of the Art of Renewable Sources Potentialities in the Middle East: A Case Study in the Kingdom of Saudi Arabia. Energies 2024, 17, 1816. https://doi.org/10.3390/en17081816

Di Lorenzo G, Stracqualursi E, Vescio G, Araneo R. State of the Art of Renewable Sources Potentialities in the Middle East: A Case Study in the Kingdom of Saudi Arabia. Energies. 2024; 17(8):1816. https://doi.org/10.3390/en17081816

Chicago/Turabian StyleDi Lorenzo, Gianfranco, Erika Stracqualursi, Giovanni Vescio, and Rodolfo Araneo. 2024. "State of the Art of Renewable Sources Potentialities in the Middle East: A Case Study in the Kingdom of Saudi Arabia" Energies 17, no. 8: 1816. https://doi.org/10.3390/en17081816

APA StyleDi Lorenzo, G., Stracqualursi, E., Vescio, G., & Araneo, R. (2024). State of the Art of Renewable Sources Potentialities in the Middle East: A Case Study in the Kingdom of Saudi Arabia. Energies, 17(8), 1816. https://doi.org/10.3390/en17081816