A Review of Heat Dissipation and Absorption Technologies for Enhancing Performance in Photovoltaic–Thermal Systems

Abstract

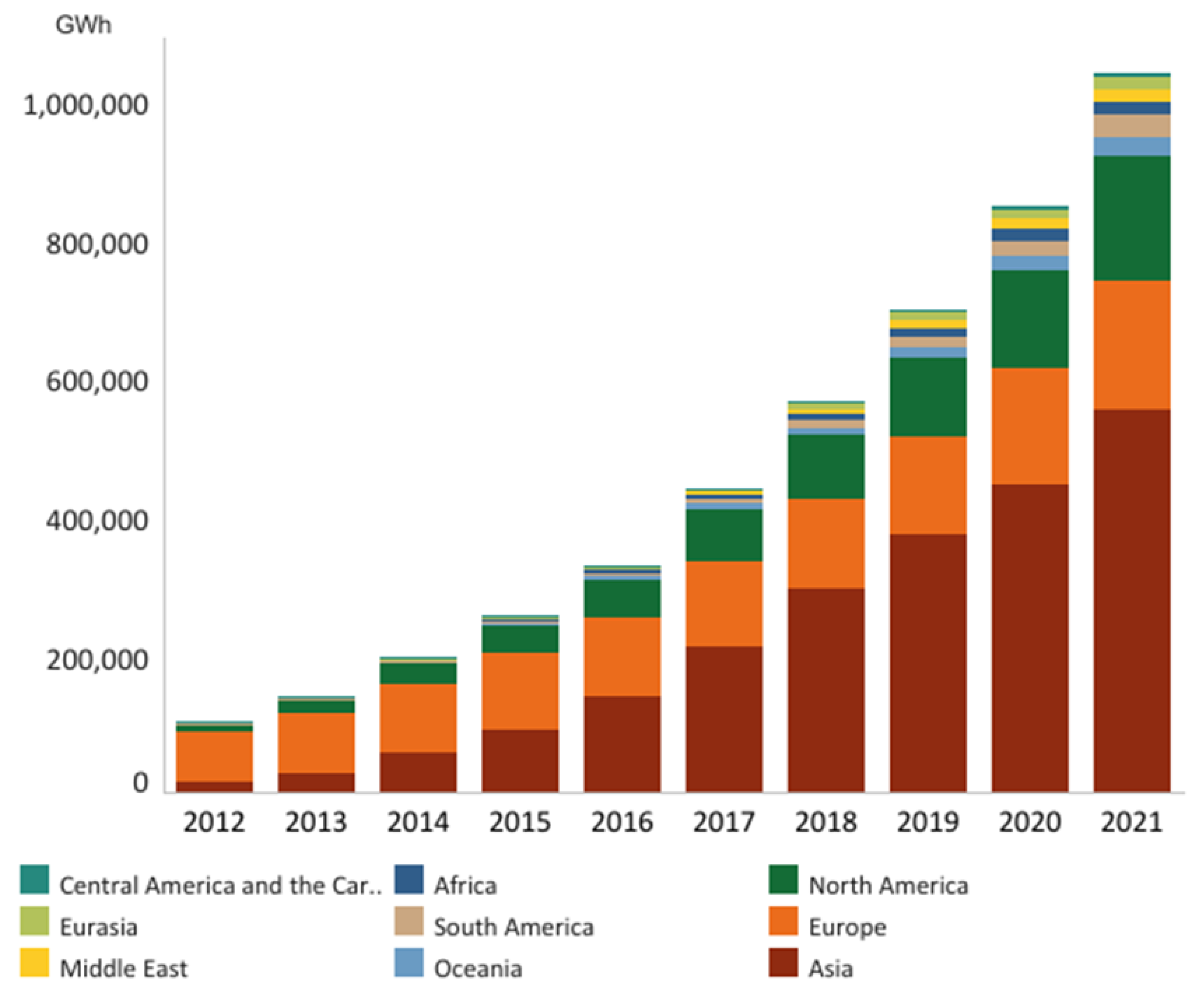

1. Introduction

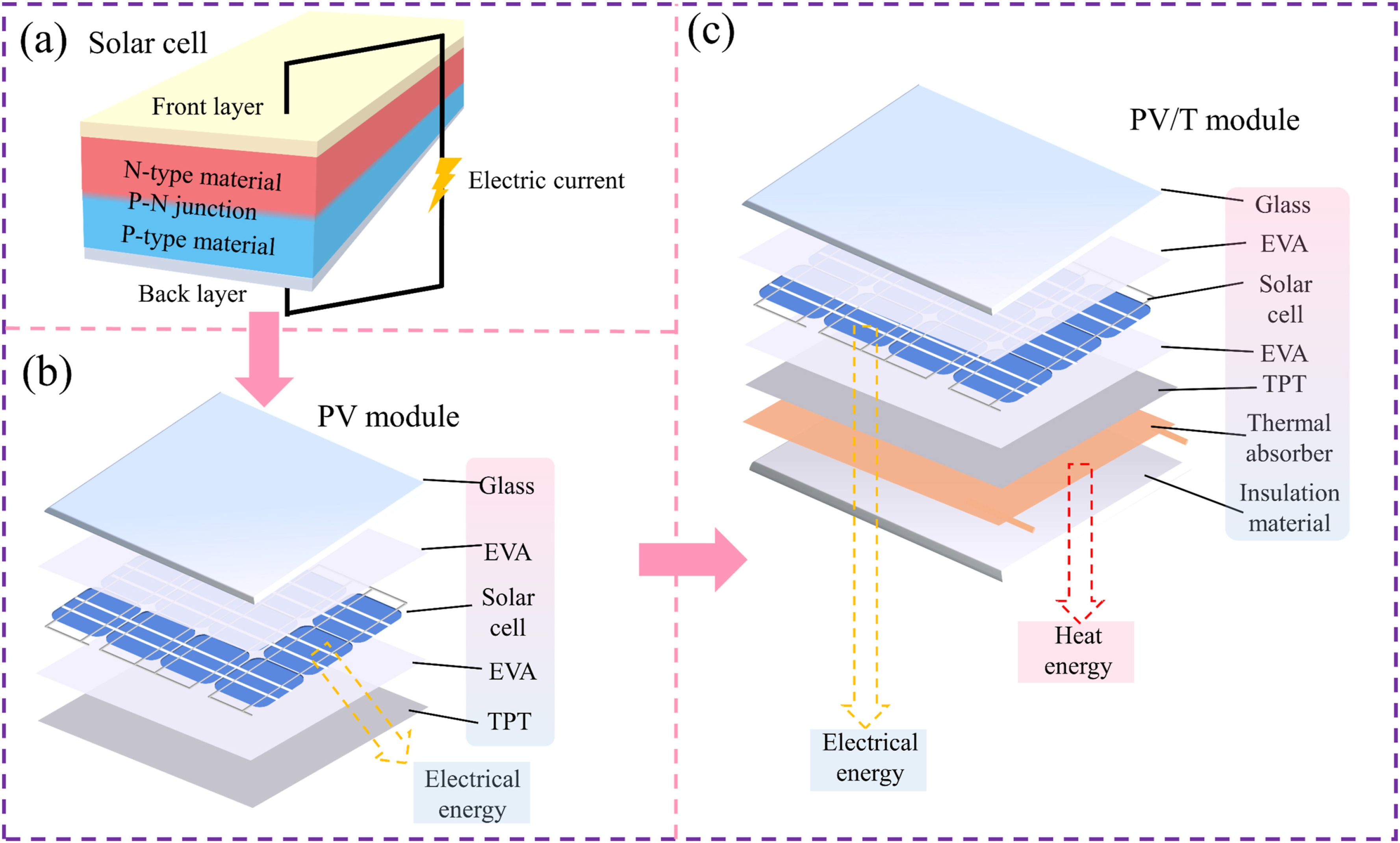

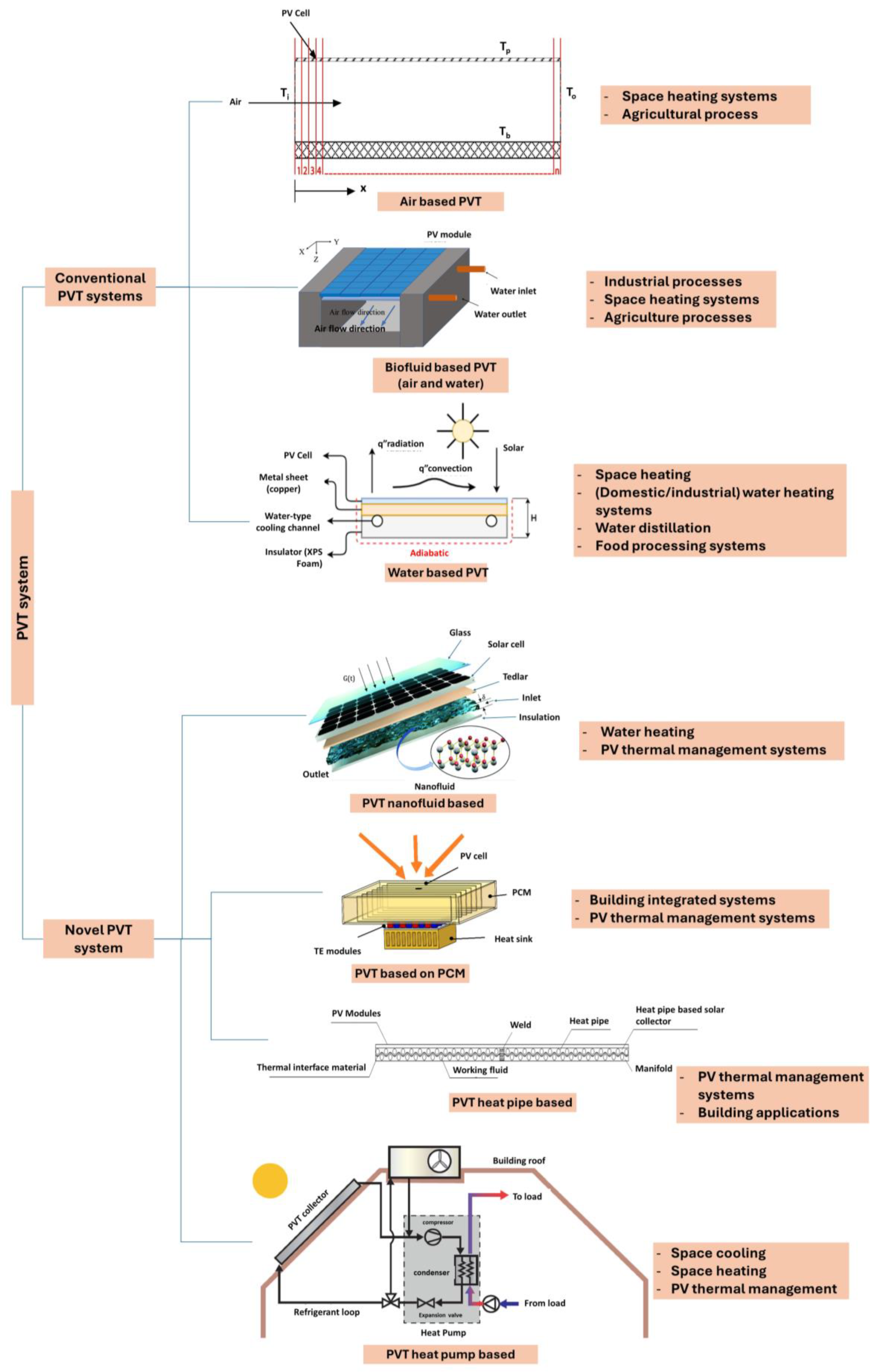

2. Fundamentals of PVT Systems

2.1. Principle of PVT Systems

2.2. Critical Factors Affecting PVT Systems

3. Developments in Heat Dissipation and Absorption Technologies for Improving Overall Performance of PVT Systems

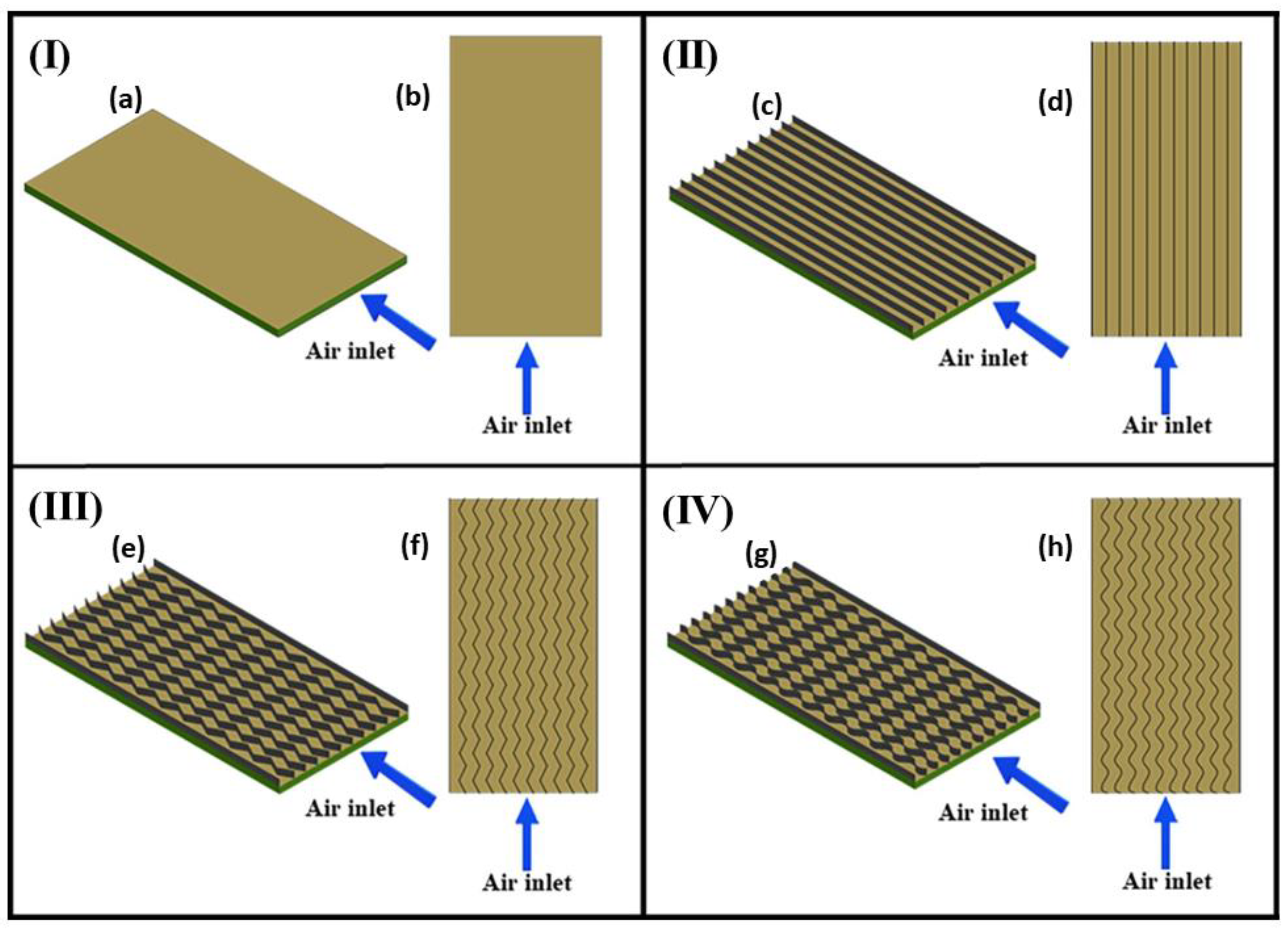

3.1. Absorber Design

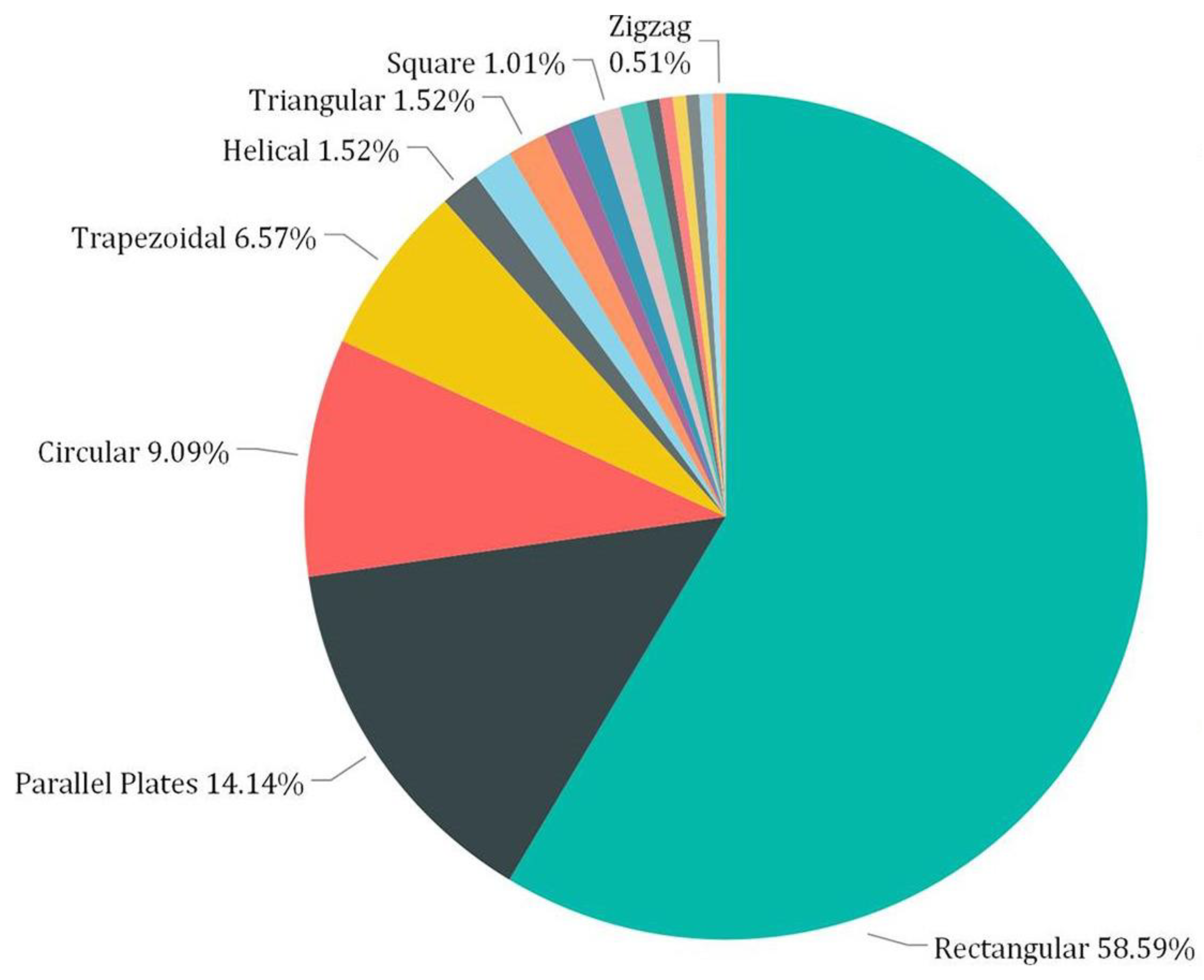

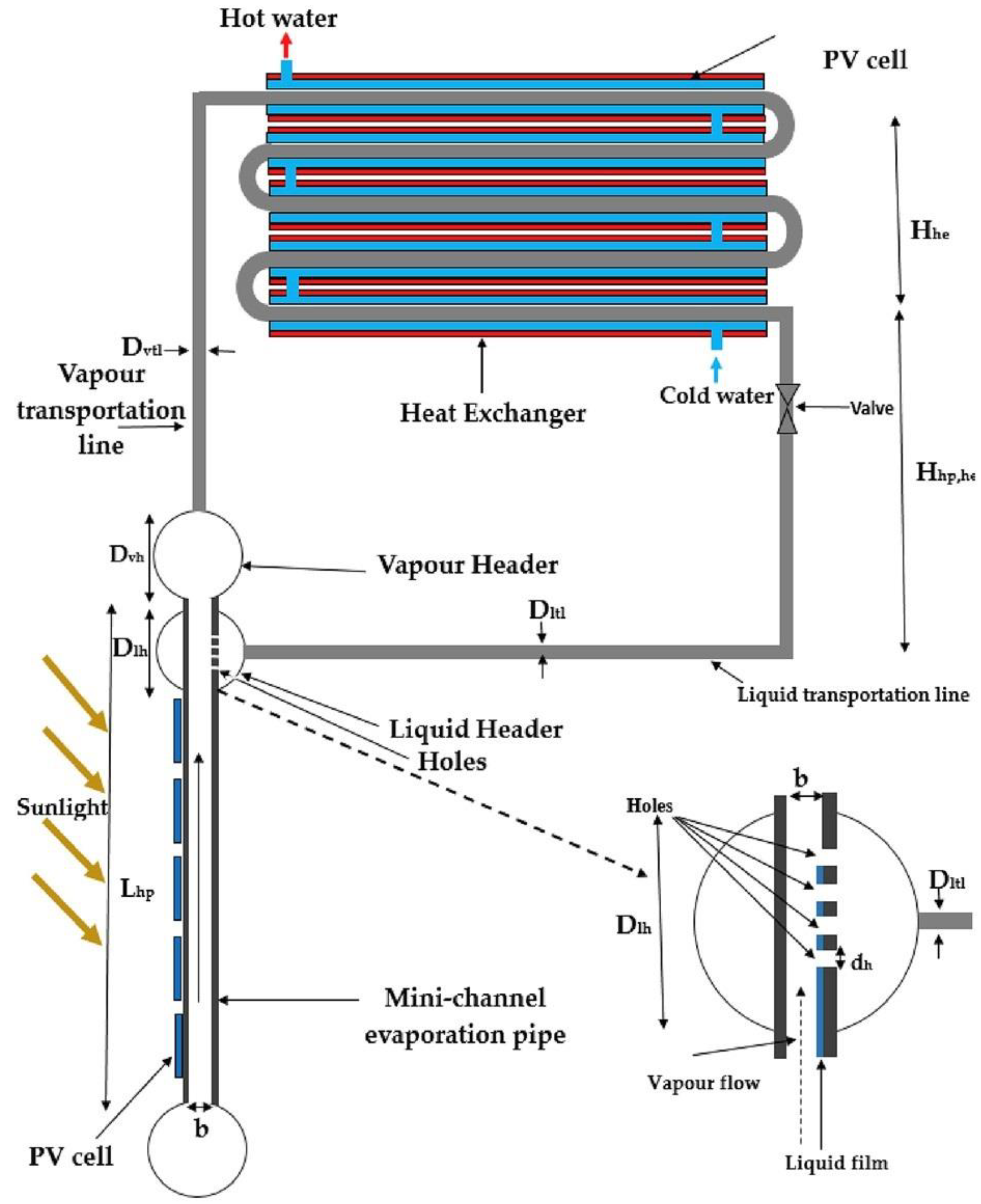

3.2. Mini/Microchannels

3.3. Polymer Materials

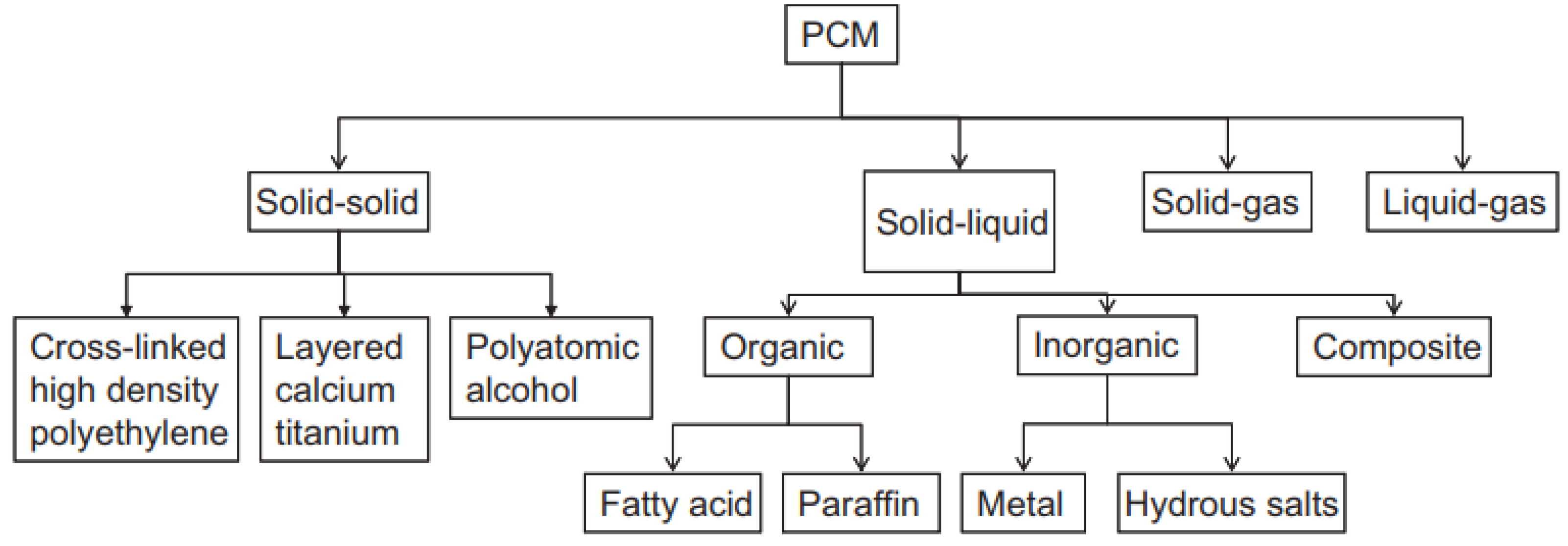

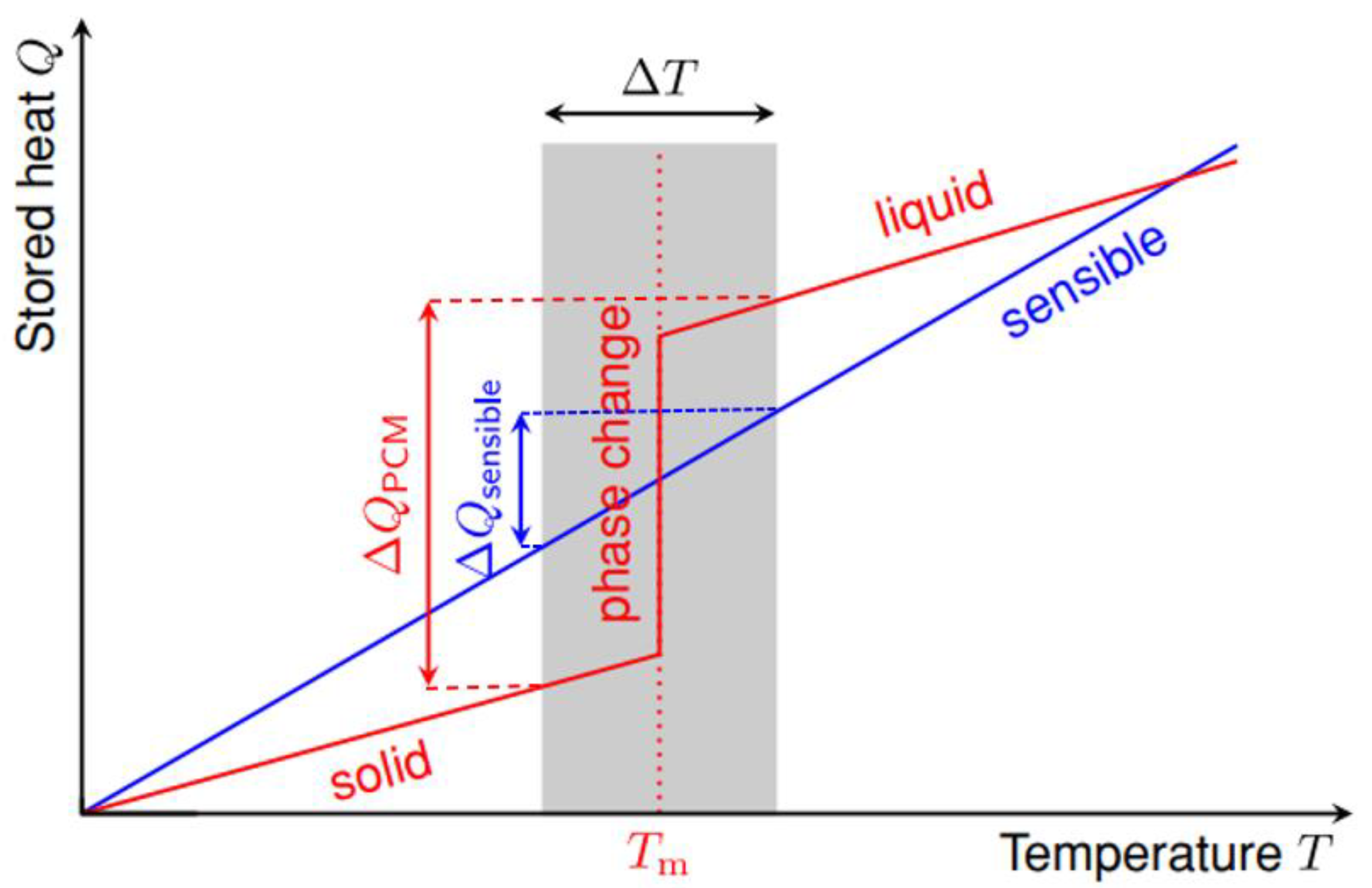

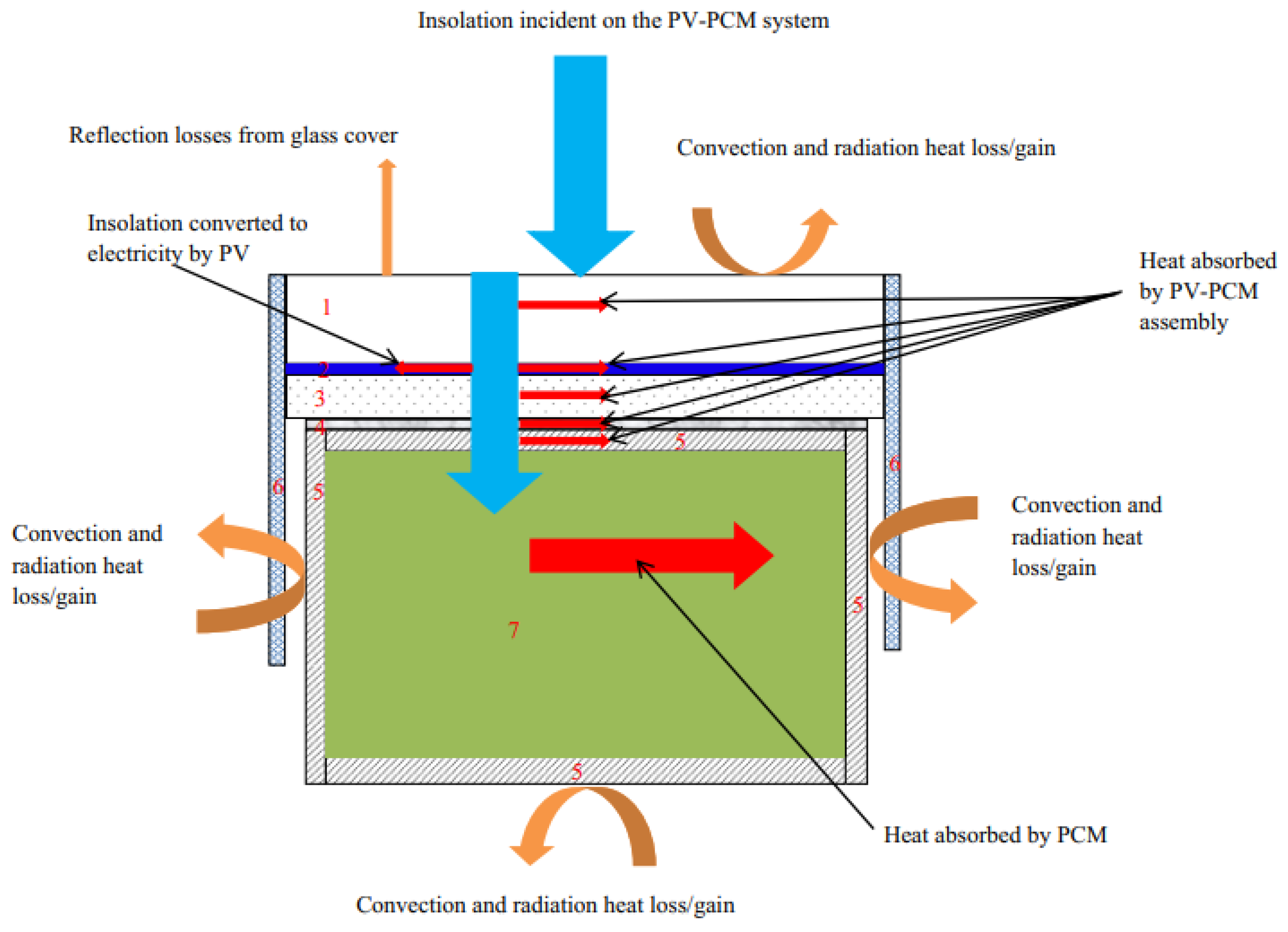

3.4. Phase Change Materials

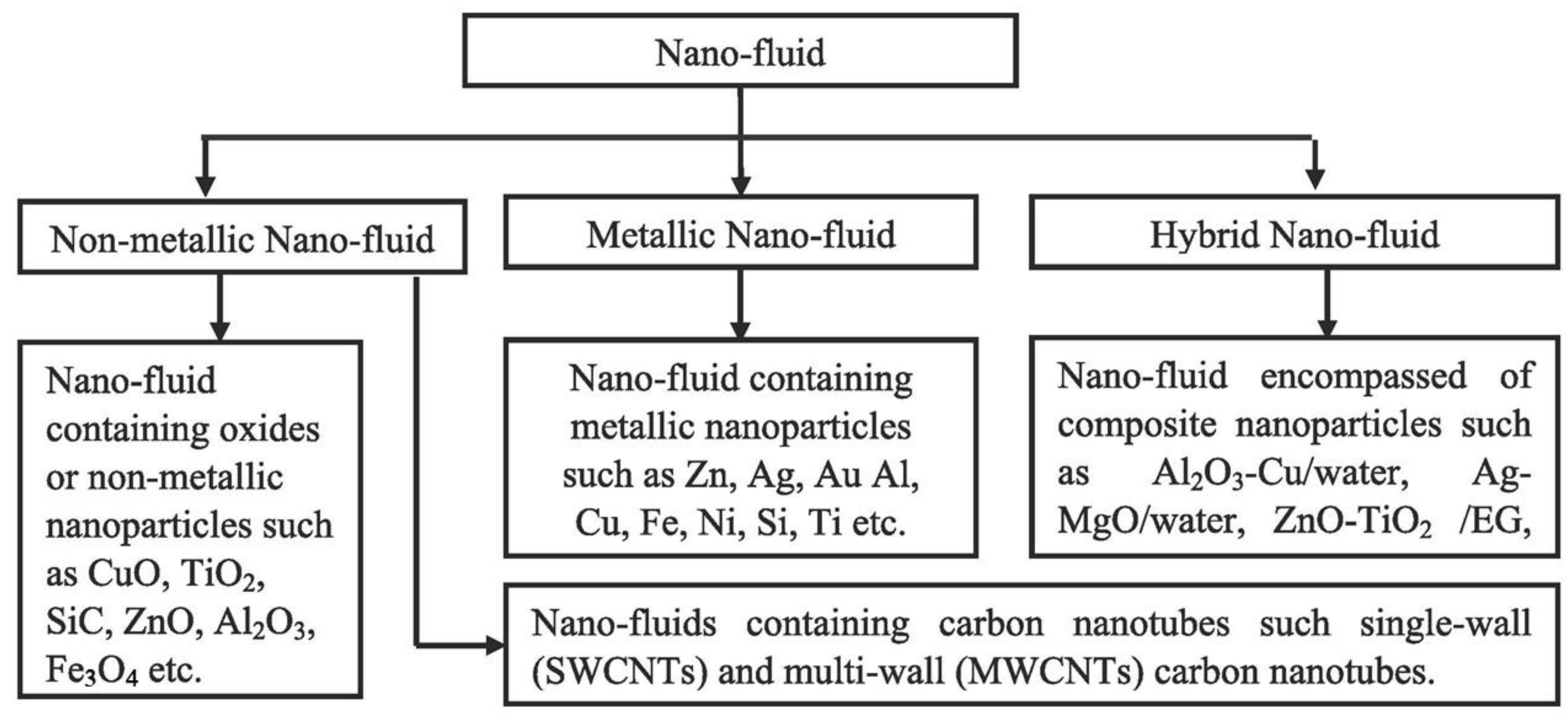

3.5. Nanofluids

3.6. Comparison between Various Cooling Technologies

4. Conclusions

- Absorber design: Optimal PVT performance can be achieved by increasing the heat transfer contact area. This can be realized through longer collectors, strategic riser tube placement, homogenizing fluid flow with fins, and arranging pipes to minimize flow distance between each other.

- Mini/microchannels: While mini/microchannels, owing to their small dimensions, can enhance heat transfer from solid materials to the flowing fluid, they also present a higher risk of power loss. Modifications have primarily focused on channel pipe arrays, utilizing plain or grooved external channels and diameter adjustments.

- Polymer materials: Considering the high cost of conventional metal-based PVT systems, polymers have been explored as an alternative. Despite their lower thermal conductivity compared to metals, polymers offer flexibility in design to maximize heat transfer through increased contact area. Polymers are useful not only as absorber materials but also to replace the glass cover. While polymer-based PVTs have not yet surpassed conventional PVT systems in performance, their cost-effectiveness and versatility make them a promising option for future development.

- PCMs: PCMs can absorb significant amounts of heat through latent heat storage. The efficiency of PCMs integration depends on factors such as thickness, type, and placement within the system. Considering latent heat utilization, PCM can be a more effective solution than changing absorber materials.

- Nanofluids: As coolants, nanofluids demonstrate superior performance compared to pure water owing to their higher thermal conductivity. Various nanofluid types and combinations thereof have been explored to increase thermal conductivity. Generally, higher volume concentrations lead to greater heat rejection and improved electrical efficiency. However, the preparation of nanofluids is crucial as it affects stability and heat absorption capabilities.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, J.; Yu, Y.; Ma, T.; Zhang, C.; Wang, Q. Evolution of energy and metal demand driven by industrial revolutions and its trend analysis. Chin. J. Popul. Resour. Environ. 2021, 19, 256–264. [Google Scholar] [CrossRef]

- Ritchie, H.; Rosado, P. Our World in Data. 2017. Available online: https://ourworldindata.org/fossil-fuels (accessed on 18 December 2023).

- Tiseo, I. Annual Carbon Dioxide (CO2) Emissions Worldwide from 1940 to 2022. 2023. Available online: https://www.statista.com/statistics/276629/global-co2-emissions/ (accessed on 18 December 2023).

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- UC Davis. 2021. Available online: https://www.ucdavis.edu/climate/definitions/how-is-solar-power-generated (accessed on 18 December 2023).

- IRENA, International-Renewable-Energy-Agency. 2023. Available online: https://www.irena.org/Data/View-data-by-topic/Capacity-and-Generation/Regional-Trends (accessed on 18 November 2023).

- Hao, D.; Qi, L.; Tairab, A.M.; Ahmed, A.; Azam, A.; Luo, D.; Pan, Y.; Zhang, Z.; Yan, J. Solar energy harvesting technologies for PV self-powered applications: A comprehensive review. Renew. Energy 2022, 188, 678–697. [Google Scholar] [CrossRef]

- Gao, Y.; Wu, D.; Dai, Z.; Wang, C.; Chen, B.; Zhang, X. A comprehensive review of the current status, developments, and outlooks of heat pipe photovoltaic and photovoltaic/thermal systems. Renew. Energy 2023, 207, 539–574. [Google Scholar] [CrossRef]

- Ennemri, A.; Logerais, P.; Balistrou, M.; Durastanti, J.; Belaidi, I. Cracks in silicon photovoltaic modules: A review. J. Optoelectron. Adv. Mater. 2019, 21, 74–92. [Google Scholar]

- Tatsi, E.; Griffini, G. Polymeric materials for photon management in photovoltaics. Sol. Energy Mater. Sol. Cells 2019, 196, 43–56. [Google Scholar] [CrossRef]

- Leem, J.W.; Choi, M.; Yu, J.S. Multifunctional microstructured polymer films for boosting solar power generation of silicon-based photovoltaic modules. ACS Appl. Mater. Interfaces 2015, 7, 2349–2358. [Google Scholar] [CrossRef] [PubMed]

- Helseth, L. Harvesting energy from light and water droplets by covering photovoltaic cells with transparent polymers. Appl. Energy 2021, 300, 117394. [Google Scholar] [CrossRef]

- Li, M.; Liu, W.; Zhang, F.; Zhang, X.; Omer, A.A.A.; Zhang, Z.; Liu, Y.; Zhao, S. Polymer multilayer film with excellent UV-resistance & high transmittance and its application for glass-free photovoltaic modules. Sol. Energy Mater. Sol. Cells 2021, 229, 111103. [Google Scholar] [CrossRef]

- Singh, A.; Umakanth, V.; Tyagi, N.; Kumar, S. A comparative study of different polymer materials for the development of flexible crystalline silicon modules. Sol. Energy Mater. Sol. Cells 2023, 255, 112259. [Google Scholar] [CrossRef]

- Shubbak, M.H. Advances in solar photovoltaics: Technology review and patent trends. Renew. Sustain. Energy Rev. 2019, 115, 109383. [Google Scholar] [CrossRef]

- Tharamuttam, J.K.; Ng, A.K. Design and development of an automatic solar tracker. Energy Procedia 2017, 143, 629–634. [Google Scholar] [CrossRef]

- Thomas, A.; Racherla, P. Constructing statutory energy goal compliant wind and solar PV infrastructure pathways. Renew. Energy 2020, 161, 1–19. [Google Scholar] [CrossRef]

- Meral, M.E.; Dinçer, F. A review of the factors affecting operation and efficiency of photovoltaic based electricity generation systems. Renew. Sustain. Energy Rev. 2011, 15, 2176–2184. [Google Scholar] [CrossRef]

- Sudhakar, P.; Santosh, R.; Asthalakshmi, B.; Kumaresan, G.; Velraj, R. Performance augmentation of solar photovoltaic panel through PCM integrated natural water circulation cooling technique. Renew. Energy 2020, 172, 1433–1448. [Google Scholar] [CrossRef]

- Adinoyi, M.J.; Said, S.A.M. Effect of dust accumulation on the power outputs of solar photovoltaic modules. Renew. Energy 2013, 60, 633–636. [Google Scholar] [CrossRef]

- Salamah, T.; Ramahi, A.; Alamara, K.; Juaidi, A.; Abdallah, R.; Abdelkareem, M.A.; Amer, E.-C.; Olabi, A.G. Effect of dust and methods of cleaning on the performance of solar PV module for different climate regions: Comprehensive review. Sci. Total. Environ. 2022, 827, 154050. [Google Scholar] [CrossRef]

- Badiee, A.; Ashcroft, I.; Wildman, R. The thermo-mechanical degradation of ethylene vinyl acetate used as a solar panel adhesive and encapsulant. Int. J. Adhes. Adhes. 2016, 68, 212–218. [Google Scholar] [CrossRef]

- Lämmle, M.; Hermann, M.; Kramer, K.; Panzer, C.; Piekarczyk, A.; Thoma, C.; Fahr, S. Development of highly efficient, glazed PVT collectors with overheating protection to increase reliability and enhance energy yields. Sol. Energy 2018, 176, 87–97. [Google Scholar] [CrossRef]

- Zhou, Q.; Dong, P.; Li, M.; Wang, Z. Analyzing the interactions between photovoltaic system and its ambient environment using CFD techniques: A review. Energy Build. 2023, 296, 113394. [Google Scholar] [CrossRef]

- Raj, A.B.S.; Kumar, S.P.; Manikandan, G.; Titus, P.J. An experimental study on the performance of concentrated photovoltaic system with cooling system for domestic applications. Int. J. Eng. Adv. Technol. (IJEAT) 2014, 3, 2249–8958. [Google Scholar]

- Abdolzadeh, M.; Ameri, M. Improving the effectiveness of a photovoltaic water pumping system by spraying water over the front of photovoltaic cells. Renew. Energy 2009, 34, 91–96. [Google Scholar] [CrossRef]

- Salem, M.; Elsayed, M.; Abd-Elaziz, A.; Elshazly, K. Performance enhancement of the photovoltaic cells using Al2O3/PCM mixture and/or water cooling-techniques. Renew. Energy 2019, 138, 876–890. [Google Scholar] [CrossRef]

- Abdallah, S.R.; Saidani-Scott, H.; Abdellatif, O.E. Performance analysis for hybrid PV/T system using low concentration MWCNT (water-based) nanofluid. Sol. Energy 2019, 181, 108–115. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M. Floating tracking cooling concentrating (FTCC) systems. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference (PVSC), Austin, TX, USA, 3–8 June 2012. [Google Scholar]

- Mehrotra, S.; Rawat, P.; Debbarma, M.; Sudhakar, K. Performance of a solar panel with water immersion cooling technique. Int. J. Sci. Environ. Technol. 2014, 3, 1161–1172. [Google Scholar]

- Hadipour, A.; Zargarabadi, M.R.; Rashidi, S. An efficient pulsed- spray water cooling system for photovoltaic panels: Experimental study and cost analysis. Renew. Energy 2020, 164, 867–875. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Senthilkumar, T. Experimental demonstration of enhanced solar energy utilization in flat PV (photovoltaic) modules cooled by heat spreaders in conjunction with cotton wick structures. Energy 2015, 90, 1401–1410. [Google Scholar] [CrossRef]

- Alami, A.H. Effects of evaporative cooling on efficiency of photovoltaic modules. Energy Convers. Manag. 2014, 77, 668–679. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Senthilkumar, T. Five decades of evolution of solar photovoltaic thermal (PVT) technology—A critical insight on review articles. J. Clean. Prod. 2021, 322, 128997. [Google Scholar] [CrossRef]

- Sandnes, B.; Rekstad, J. A photovoltaic/thermal (PV/T) collector with a polymer absorber plate. Experimental study and analytical model. Sol. Energy 2002, 72, 63–73. [Google Scholar] [CrossRef]

- Othman, M.Y.H.; Yatim, B.; Sopian, K.; Abu Bakar, M.N. Performance analysis of a double-pass photovoltaic/thermal (PV/T) solar collector with CPC and fins. Renew. Energy 2005, 30, 2005–2017. [Google Scholar] [CrossRef]

- Noro, M.; Lazzarin, R.; Bagarella, G. Advancements in hybrid photovoltaic-thermal systems: Performance evaluations and applications. Energy Procedia 2016, 101, 496–503. [Google Scholar] [CrossRef]

- Oh, J.; Bae, S.; Chae, H.; Jeong, J.; Nam, Y. Photovoltaic–thermal advanced technology for real applications: Review and case study. Energy Rep. 2023, 10, 1409–1433. [Google Scholar] [CrossRef]

- Sathe, T.M.; Dhoble, A. A review on recent advancements in photovoltaic thermal techniques. Renew. Sustain. Energy Rev. 2017, 76, 645–672. [Google Scholar] [CrossRef]

- Sohel, M.I.; Ma, Z.; Cooper, P.; Adams, J.; Scott, R. A dynamic model for air-based photovoltaic thermal systems working under real operating conditions. Appl. Energy 2014, 132, 216–225. [Google Scholar] [CrossRef]

- Korkut, T.B.; Gören, A.; Rachid, A. Numerical and Experimental Study of a PVT Water System under Daily Weather Conditions. Energies 2022, 15, 6538. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Design configuration and operational parameters of bi-fluid PVT collectors: An updated review. Environ. Sci. Pollut. Res. 2023, 30, 81474–81492. [Google Scholar] [CrossRef] [PubMed]

- Zarei, A.; Izadpanah, E.; Rabiee, M.B. Using a nanofluid-based photovoltaic thermal (PVT) collector and eco-friendly refrigerant for solar compression cooling system. J. Therm. Anal. Calorim. 2022, 148, 2041–2055. [Google Scholar] [CrossRef]

- Cui, T.; Xuan, Y.; Li, Q. Design of a novel concentrating photovoltaic–thermoelectric system incorporated with phase change materials. Energy Convers. Manag. 2016, 112, 49–60. [Google Scholar] [CrossRef]

- Jouhara, H.; Szulgowska-Zgrzywa, M.; Sayegh, M.; Milko, J.; Danielewicz, J.; Nannou, T.; Lester, S. The performance of a heat pipe based solar PV/T roof collector and its potential contribution in district heating applications. Energy 2017, 136, 117–125. [Google Scholar] [CrossRef]

- Miglioli, A.; Aste, N.; Del Pero, C.; Leonforte, F. Photovoltaic-thermal solar-assisted heat pump systems for building applications: Integration and design methods. Energy Built Environ. 2023, 4, 39–56. [Google Scholar] [CrossRef]

- Kandeal, A.; Thakur, A.K.; Elkadeem, M.; Elmorshedy, M.F.; Ullah, Z.; Sathyamurthy, R.; Sharshir, S.W. Photovoltaics performance improvement using different cooling methodologies: A state-of-art review. J. Clean. Prod. 2020, 273, 122772. [Google Scholar] [CrossRef]

- Nasrin, R.; Hasanuzzaman, M.; Rahim, N. Effect of high irradiation and cooling on power, energy and performance of a PVT system. Renew. Energy 2018, 116, 552–569. [Google Scholar] [CrossRef]

- Abdul-Ganiyu, S.; Quansah, D.A.; Ramde, E.W.; Seidu, R.; Adaramola, M.S. Study effect of flow rate on flat-plate water-based photovoltaic-thermal (PVT) system performance by analytical technique. J. Clean. Prod. 2021, 321, 128985. [Google Scholar] [CrossRef]

- Zhao, S.; Li, W.; El-Samie, M.M.A.; Ju, X.; Xu, C. Numerical simulation to study the effect of spectral division of solar irradiance on the spectral splitting photovoltaic/thermal system. Renew. Energy 2022, 182, 634–646. [Google Scholar] [CrossRef]

- Nasrin, R.; Rahim, N.A.; Fayaz, H.; Hasanuzzaman, M. Water/MWCNT nanofluid based cooling system of PVT: Experimental and numerical research. Renew. Energy 2018, 121, 286–300. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.; Al-Badi, R.; Fayad, M.A.; Gholami, A. Dust impact on photovoltaic/thermal system in harsh weather conditions. Sol. Energy 2022, 245, 308–321. [Google Scholar] [CrossRef]

- Said, S.A.; Walwil, H.M. Fundamental studies on dust fouling effects on PV module performance. Sol. Energy 2014, 107, 328–337. [Google Scholar] [CrossRef]

- Ahmadinejad, M.; Moosavi, R. Energy and exergy evaluation of a baffled-nanofluid-based photovoltaic thermal system (PVT). Int. J. Heat Mass Transf. 2023, 203, 123775. [Google Scholar] [CrossRef]

- Hassan, A.; Abbas, S.; Yousuf, S.; Abbas, F.; Amin, N.; Ali, S.; Mastoi, M.S. An experimental and numerical study on the impact of various parameters in improving the heat transfer performance characteristics of a water based photovoltaic thermal system. Renew. Energy 2023, 202, 499–512. [Google Scholar] [CrossRef]

- Nishioka, K.; Hatayama, T.; Uraoka, Y.; Fuyuki, T.; Hagihara, R.; Watanabe, M. Field-test analysis of PV system output characteristics focusing on module temperature. Sol. Energy Mater. Sol. Cells 2003, 75, 665–671. [Google Scholar] [CrossRef]

- Bazilian, M.D.; Prasad, D. Modelling of a photovoltaic heat recovery system and its role in a design decision support tool for building professionals. Renew. Energy 2002, 27, 57–68. [Google Scholar] [CrossRef]

- Chow, T.; Pei, G.; Fong, K.; Lin, Z.; Chan, A.; Ji, J. Energy and exergy analysis of photovoltaic–thermal collector with and without glass cover. Appl. Energy 2009, 86, 310–316. [Google Scholar] [CrossRef]

- Madas, S.R.; Narayanan, R.; Gudimetla, P. Numerical investigation on the optimum performance output of photovoltaic thermal (PVT) systems using nano-copper oxide (CuO) coolant. Sol. Energy 2023, 255, 222–235. [Google Scholar] [CrossRef]

- Gholampour, M.; Ameri, M.; Samani, M.S. Experimental study of performance of Photovoltaic–Thermal Unglazed Transpired Solar Collectors (PV/UTCs): Energy, exergy, and electrical-to-thermal rational approaches. Sol. Energy 2014, 110, 636–647. [Google Scholar] [CrossRef]

- Haddad, S.; Touafek, K.; Khelifa, A. Investigation of the Electrical and Thermal Performance of a PVT Hybrid System. In Proceedings of the 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 31 March–2 April 2015. [Google Scholar]

- Leong, K.; Saidur, R.; Mahlia, T.; Yau, Y. Entropy generation analysis of nanofluid flow in a circular tube subjected to constant wall temperature. Int. Commun. Heat Mass Transf. 2012, 39, 1169–1175. [Google Scholar] [CrossRef]

- Marulasiddeshi, H.B.; Kanti, P.K.; Prakash, S.B.; Sridhara, S.N. Investigation of entropy generation and Thermohydraulic Characteristics Al2O3–CuO hybrid nanofluid flow in a pipe at different inlet fluid temperatures. Int. J. Therm. Sci. 2023, 193, 108541. [Google Scholar] [CrossRef]

- Liu, L.; Shalwan, A.; Teng, J.; Liu, C.; Li, Z. The entropy generation analysis of a PVT solar collector with internally needle finned serpentine absorber tube. Eng. Anal. Bound. Elem. 2023, 155, 1123–1130. [Google Scholar] [CrossRef]

- Elbreki, A.; Alghoul, M.A.; Al-Shamani, A.N.; Ammar, A.A.; Yegani, B.; Aboghrara, A.M.; Rusaln, M.; Sopian, K. The role of climatic-design-operational parameters on combined PV/T collector performance: A critical review. Renew. Sustain. Energy Rev. 2016, 57, 602–647. [Google Scholar] [CrossRef]

- Bahrehmand, D.; Ameri, M. Energy and exergy analysis of different solar air collector systems with natural convection. Renew. Energy 2015, 74, 357–368. [Google Scholar] [CrossRef]

- Ibrahim, A.; Jin, G.L.; Daghigh, R.; Salleh, M.H.M.; Othman, M.Y.; Ruslan, M.H.; Mat, S.; Sopian, K. Hybrid photovoltaic thermal (PVT) air and water based solar collectors suitable for building integrated applications. Am. J. Environ. Sci. 2009, 5, 618–624. [Google Scholar] [CrossRef]

- Ghale, Z.Y.; Haghshenasfard, M.; Esfahany, M.N. Investigation of nanofluids heat transfer in a ribbed microchannel heat sink using single-phase and multiphase CFD models. Int. Commun. Heat Mass Transf. 2015, 68, 122–129. [Google Scholar] [CrossRef]

- Verma, S.K.; Gupta, N.K.; Rakshit, D. A comprehensive analysis on advances in application of solar collectors considering design, process and working fluid parameters for solar to thermal conversion. Sol. Energy 2020, 208, 1114–1150. [Google Scholar] [CrossRef]

- Pandey, K.M.; Chaurasiya, R. A review on analysis and development of solar flat plate collector. Renew. Sustain. Energy Rev. 2017, 67, 641–650. [Google Scholar] [CrossRef]

- Vengadesan, E.; Senthil, R. A review on recent developments in thermal performance enhancement methods of flat plate solar air collector. Renew. Sustain. Energy Rev. 2020, 134, 110315. [Google Scholar] [CrossRef]

- Koech, R.K.; Ondieki, H.O.; Tonui, J.K.; Rotich, S.K. A steady state thermal model for photovoltaic/thermal (PV/T) system under various condition. Int. J. Sci. Eng. Technol. Res. 2012, 1, 1–5. [Google Scholar]

- Ali, A.; Alhussein, M.; Aurangzeb, K.; Akbar, F. The numerical analysis of Al2O3-Cu/water hybrid nanofluid flow inside the serpentine absorber channel of a PVT; the overall efficiency intelligent forecasting. Eng. Anal. Bound. Elem. 2023, 157, 82–91. [Google Scholar] [CrossRef]

- Ibrahim, A.; Othman, M.; Ruslan, M.; Alghoul, M.; Yahya, M.; Sopian, K. Performance of photovoltaic thermal collector (PVT) with different absorbers design. Wseas Trans. Environ. Dev. 2009, 5, 321–330. [Google Scholar]

- Ekramian, E.; Etemad, S.; Haghshenasfard, M. Numerical analysis of heat transfer performance of flat plate solar collectors. J. Fluid Flow Heat Mass Transf. 2014, 1, 38–42. [Google Scholar] [CrossRef]

- Kumar, R.; Rosen, M.A. Performance evaluation of a double pass PV/T solar air heater with and without fins. Appl. Therm. Eng. 2011, 31, 1402–1410. [Google Scholar] [CrossRef]

- Cetina-Quiñones, A.; Polanco-Ortiz, I.; Alonzo, P.M.; Hernandez-Perez, J.; Bassam, A. Innovative heat dissipation design incorporated into a solar photovoltaic thermal (PV/T) air collector: An optimization approach based on 9E analysis. Therm. Sci. Eng. Prog. 2023, 38, 101635. [Google Scholar] [CrossRef]

- Kazem, H.A.; Al-Waeli, A.H.; Chaichan, M.T.; Al-Waeli, K.H.; Al-Aasam, A.B.; Sopian, K. Evaluation and comparison of different flow configurations PVT systems in Oman: A numerical and experimental investigation. Sol. Energy 2020, 208, 58–88. [Google Scholar] [CrossRef]

- Missirlis, D.; Martinopoulos, G.; Tsilingiridis, G.; Yakinthos, K.; Kyriakis, N. Investigation of the heat transfer behaviour of a polymer solar collector for different manifold configurations. Renew. Energy 2014, 68, 715–723. [Google Scholar] [CrossRef]

- Joshi, R.; Khandwawala, D.A. A comparative study of the effect of variation of inside diameter of condenser and mass flow rate on the heat transfer coefficient in a domestic refrigerator. Int. J. Eng. Res. Appl. 2014, 4, 514–518. [Google Scholar]

- Tuckerman, D.; Pease, R. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Sriharan, G.; Harikrishnan, S.; Oztop, H.F. A review on thermophysical properties, preparation, and heat transfer enhancement of conventional and hybrid nanofluids utilized in micro and mini channel heat sink. Sustain. Energy Technol. Assess. 2023, 58, 103327. [Google Scholar] [CrossRef]

- Chamkha, A.J.; Molana, M.; Rahnama, A.; Ghadami, F. On the nanofluids applications in microchannels: A comprehensive review. Powder Technol. 2018, 332, 287–322. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, Y.; Wang, W.; Quan, Z.; Wang, L.; Yu, D. Experimental investigation of performance for the novel flat plate solar collector with micro-channel heat pipe array (MHPA-FPC). Appl. Therm. Eng. 2013, 54, 440–449. [Google Scholar] [CrossRef]

- Shahsavar, A.; Jha, P.; Askari, I.B. Experimental study of a nanofluid-based photovoltaic/thermal collector equipped with a grooved helical microchannel heat sink. Appl. Therm. Eng. 2022, 217, 119281. [Google Scholar] [CrossRef]

- Mansour, M.K. Thermal analysis of novel minichannel-based solar flat-plate collector. Energy 2013, 60, 333–343. [Google Scholar] [CrossRef]

- Sharma, N.; Diaz, G. Performance model of a novel evacuated-tube solar collector based on minichannels. Sol. Energy 2011, 85, 881–890. [Google Scholar] [CrossRef]

- Wei, L.; Yuan, D.; Tang, D.; Wu, B. A study on a flat-plate type of solar heat collector with an integrated heat pipe. Sol. Energy 2013, 97, 19–25. [Google Scholar] [CrossRef]

- Oyinlola, M.; Shire, G.; Moss, R. Thermal analysis of a solar collector absorber plate with microchannels. Exp. Therm. Fluid Sci. 2014, 67, 102–109. [Google Scholar] [CrossRef]

- Radwan, A.; Ookawara, S.; Ahmed, M. Analysis and simulation of concentrating photovoltaic systems with a microchannel heat sink. Sol. Energy 2016, 136, 35–48. [Google Scholar] [CrossRef]

- Agrawal, S.; Tiwari, G. Energy and exergy analysis of hybrid micro-channel photovoltaic thermal module. Sol. Energy 2011, 85, 356–370. [Google Scholar] [CrossRef]

- Köhl, M. Solar Heating & Cooling Programme International Energy Agency. 2015. Available online: https://task39.iea-shc.org/ (accessed on 14 November 2023).

- Isravel, R.S.; Saravanan, S.; Vijayan, V. A review of material and coatings in solar collectors. Mater. Today Proc. 2020, 21, 497–499. [Google Scholar] [CrossRef]

- Jia, P.; Lamm, M.E.; Sha, Y.; Ma, Y.; Kurnaz, L.B.; Zhou, Y. Thiol-ene eugenol polymer networks with chemical Degradation, thermal degradation and biodegradability. Chem. Eng. J. 2023, 454, 140051. [Google Scholar] [CrossRef]

- Gijsman, P.; Fiorio, R. Long term thermo-oxidative degradation and stabilization of polypropylene (PP) and the implications for its recyclability. Polym. Degrad. Stab. 2023, 208, 110260. [Google Scholar] [CrossRef]

- Ceretti, D.V.A.; Edeleva, M.; Cardon, L.; D’hooge, D.R. Molecular Pathways for Polymer Degradation during Conventional Processing, Additive Manufacturing, and Mechanical Recycling. Molecules 2023, 28, 2344. [Google Scholar] [CrossRef] [PubMed]

- Thakur, B.; Singh, J.; Singh, J.; Angmo, D.; Vig, A.P. Biodegradation of different types of microplastics: Molecular mechanism and degradation efficiency. Sci. Total. Environ. 2023, 877, 162912. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Brassart, L. A reaction-diffusion framework for hydrolytic degradation of amorphous polymers based on a discrete chain scission model. Acta Biomater. 2023, 167, 361–373. [Google Scholar] [CrossRef] [PubMed]

- Torres, M.; Burdin, L.; Rentería-Rodríguez, A.V.; Franco-Urquiza, E.A. Degradation of epoxy-particles composites exposed to UV and gamma radiation. Chemistry 2023, 5, 559–570. [Google Scholar] [CrossRef]

- Chow, T.T. A review on photovoltaic/thermal hybrid solar technology. Appl. Energy 2010, 87, 365–379. [Google Scholar] [CrossRef]

- Lee, S.H.; Luvnish, A.; Su, X.; Meng, Q.; Liu, M.; Kuan, H.-C.; Saman, W.; Bostrom, M.; Ma, J. Advancements in polymer (Nano)composites for phase change material-based thermal storage: A focus on thermoplastic matrices and ceramic/carbon fillers. Smart Mater. Manuf. 2024, 2, 100044. [Google Scholar] [CrossRef]

- Maqbool, M.; Aftab, W.; Bashir, A.; Usman, A.; Guo, H.; Bai, S. Engineering of polymer-based materials for thermal management solutions. Compos. Commun. 2022, 29, 101048. [Google Scholar] [CrossRef]

- Yandri, E. Development and experiment on the performance of polymeric hybrid photovoltaic thermal (PVT) collector with halogen solar simulator. Sol. Energy Mater. Sol. Cells 2019, 201, 110066. [Google Scholar] [CrossRef]

- Filipović, P.; Dović, D.; Horvat, I.; Ranilović, B. Evaluation of a novel polymer solar collector using numerical and experimental methods. Energy 2023, 284, 128558. [Google Scholar] [CrossRef]

- Selikhov, Y.; Klemeš, J.J.; Kapustenko, P.; Arsenyeva, O. The study of flat plate solar collector with absorbing elements from a polymer material. Energy 2022, 256, 124677. [Google Scholar] [CrossRef]

- Nishit, J.; Bekal, S. Experimental investigation on polymer solar water heater using Al2O3 nanofluid for performance improvement. Mater. Today Proc. 2023, 92, 249–257. [Google Scholar] [CrossRef]

- Ariyawiriyanan, W.; Meekaew, T.; Yamphang, M.; Tuenpusa, P.; Boonwan, J.; Euaphantasate, N.; Muangchareon, P.; Chungpaibulpatana, S. Thermal efficiency of solar collector made from thermoplastics. Energy Procedia 2013, 34, 500–505. [Google Scholar] [CrossRef][Green Version]

- Ango, A.M.D.; Medale, M.; Abid, C. Optimization of the design of a polymer flat plate solar collector. Sol. Energy 2013, 87, 64–75. [Google Scholar] [CrossRef]

- Chen, G.; Shestopalov, K.; Doroshenko, A.; Koltun, P. Polymeric materials for solar energy utilization: A comparative experimental study and environmental aspects. Polym. Technol. Eng. 2014, 54, 796–805. [Google Scholar] [CrossRef]

- Kim, S.; Kissick, S.; Spence, S.; Boyle, C. Design, Analysis and Performance of a Polymer–Carbon Nanotubes Based Economic Solar Collector. Sol. Energy 2016, 134, 251–263. [Google Scholar] [CrossRef]

- Pugsley, A.; Zacharopoulos, A.; Smyth, M.; Mondol, J. Performance evaluation of the senergy polycarbonate and asphalt carbon nanotube solar water heating collectors for building integration. Renew. Energy 2019, 137, 2–9. [Google Scholar] [CrossRef]

- Resch-Fauster, K.; Hengstberger, F.; Zauner, C.; Holper, S. Overheating protection of solar thermal façades with latent heat storages based on paraffin-polymer compounds. Energy Build. 2018, 169, 254–259. [Google Scholar] [CrossRef]

- Telkes, M.; Raymond, E. Storing Solar Heat in Chemicals; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 1949. [Google Scholar]

- Wang, Z.; Qiu, F.; Yang, W.; Zhao, X. Applications of solar water heating system with phase change material. Renew. Sustain. Energy Rev. 2015, 52, 645–652. [Google Scholar] [CrossRef]

- Günther, E.; Hiebler, S.; Mehling, H.; Redlich, R. Enthalpy of Phase Change Materials as a Function of Temperature: Required Accuracy and Suitable Measurement Methods. Int. J. Thermophys. 2009, 30, 1257–1269. [Google Scholar] [CrossRef]

- Velmurugan, K.; Elavarasan, R.M.; Van De, P.; Karthikeyan, V.; Korukonda, T.B.; Dhanraj, J.A.; Emsaeng, K.; Chowdhury, S.; Techato, K.; El Khier, B.S.A.; et al. A Review of Heat Batteries Based PV Module Cooling—Case Studies on Performance Enhancement of Large-Scale Solar PV System. Sustainability 2022, 14, 1963. [Google Scholar] [CrossRef]

- Velmurugan, K.; Karthikeyan, V.; Korukonda, T.B.; Madhan, K.; Emsaeng, K.; Sukchai, S.; Sirisamphanwong, C.; Wongwuttanasatian, T.; Elavarasan, R.M.; Alhelou, H.H.; et al. Experimental Studies on PV Module Cooling With Radiation Source PCM Matrix. IEEE Access 2020, 8, 145936–145949. [Google Scholar] [CrossRef]

- Velmurugan, K.; Karthikeyan, V.; Sharma, K.; Korukonda, T.B.; Kannan, V.; Balasubramanian, D.; Wongwuttanasatian, T. Contactless phase change material based photovoltaic module cooling: A statistical approach by clustering and correlation algorithm. J. Energy Storage 2022, 53, 105139. [Google Scholar] [CrossRef]

- Rekha, S.S.; Karthikeyan, V.; Thuy, L.T.T.; Binh, Q.A.; Techato, K.; Kannan, V.; Roy, V.A.; Sukchai, S.; Velmurugan, K. Efficient heat batteries for performance boosting in solar thermal cooking module. J. Clean. Prod. 2021, 324, 129223. [Google Scholar] [CrossRef]

- Alsaqoor, S.; Alqatamin, A.; Alahmer, A.; Nan, Z.; Al-Husban, Y.; Jouhara, H. The impact of phase change material on photovoltaic thermal (PVT) systems: A numerical study. Int. J. Thermofluids 2023, 18, 100365. [Google Scholar] [CrossRef]

- Sardarabadi, M.; Passandideh-Fard, M.; Maghrebi, M.-J.; Ghazikhani, M. Experimental study of using both ZnO/water nanofluid and phase change material (PCM) in photovoltaic thermal systems. Sol. Energy Mater. Sol. Cells 2017, 161, 62–69. [Google Scholar] [CrossRef]

- Yazdanifard, F.; Ameri, M.; Taylor, R.A. Numerical modeling of a concentrated photovoltaic/thermal system which utilizes a PCM and nanofluid spectral splitting. Energy Convers. Manag. 2020, 215, 112927. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Hemedah, M.A.; Sorour, M.; El-Maghlany, W.M. Novel enhanced conduction model for predicting performance of a PV panel cooled by PCM. Energy Convers. Manag. 2020, 205, 112456. [Google Scholar] [CrossRef]

- Chaabane, M.; Mhiri, H.; Bournot, P. Thermal performance of an integrated collector storage solar water heater (ICSSWH) with phase change materials (PCM). Energy Convers. Manag. 2014, 78, 897–903. [Google Scholar] [CrossRef]

- Diallo, T.M.; Yu, M.; Zhou, J.; Zhao, X.; Shittu, S.; Li, G.; Ji, J.; Hardy, D. Energy performance analysis of a novel solar PVT loop heat pipe employing a microchannel heat pipe evaporator and a PCM triple heat exchanger. Energy 2018, 167, 866–888. [Google Scholar] [CrossRef]

- Fayaz, H.; Rahim, N.; Hasanuzzaman, M.; Rivai, A.; Nasrin, R. Numerical and outdoor real time experimental investigation of performance of PCM based PVT system. Sol. Energy 2019, 179, 135–150. [Google Scholar] [CrossRef]

- Simón-Allué, R.; Guedea, I.; Villén, R.; Brun, G. Experimental study of Phase Change Material influence on different models of Photovoltaic-Thermal collectors. Sol. Energy 2019, 190, 1–9. [Google Scholar] [CrossRef]

- Ren, H.; Lin, W.; Ma, Z.; Fan, W.; Wang, X. Thermal performance evaluation of an integrated photovoltaic thermal-phase change material system using Taguchi method. Energy Procedia 2017, 121, 118–125. [Google Scholar] [CrossRef]

- Su, D.; Jia, Y.; Lin, Y.; Fang, G. Maximizing the energy output of a photovoltaic–thermal solar collector incorporating phase change materials. Energy Build. 2017, 153, 382–391. [Google Scholar] [CrossRef]

- Yang, X.; Sun, L.; Yuan, Y.; Zhao, X.; Cao, X. Experimental investigation on performance comparison of PV/T-PCM system and PV/T system. Renew. Energy 2018, 119, 152–159. [Google Scholar] [CrossRef]

- Hasan, A.; McCormack, S.; Huang, M.; Sarwar, J.; Norton, B. Increased photovoltaic performance through temperature regulation by phase change materials: Materials comparison in different climates. Sol. Energy 2015, 115, 264–276. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Farshad, S.A.; Ebrahimpour, Z.; Said, Z. Recent progress on flat plate solar collectors and photovoltaic systems in the presence of nanofluid: A review. J. Clean. Prod. 2021, 293, 126119. [Google Scholar] [CrossRef]

- Younis, A.; Elsarrag, E.; Alhorr, Y.; Onsa, M. The influence of Al2O3-ZnO-H2O nanofluid on the thermodynamic performance of photovoltaic-thermal hybrid solar collector system. Innov. Energy Res. 2018, 7, 2576-1463. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Sardarabadi, M.; Passandideh-Fard, M. Energy and exergy analysis of nanofluid based photovoltaic thermal system integrated with phase change material. Energy 2018, 147, 636–647. [Google Scholar] [CrossRef]

- Fudholi, A.; Razali, N.F.M.; Yazdi, M.H.; Ibrahim, A.; Ruslan, M.H.; Othman, M.Y.; Sopian, K. TiO2/water-based photovoltaic thermal (PVT) collector: Novel theoretical approach. Energy 2019, 183, 305–314. [Google Scholar] [CrossRef]

- Awais, M.; Saad, M.; Ayaz, H.; Ehsan, M.; Bhuiyan, A.A. Computational assessment of Nano-particulate (Al2O3/Water) utilization for enhancement of heat transfer with varying straight section lengths in a serpentine tube heat exchanger. Therm. Sci. Eng. Prog. 2020, 20, 100521. [Google Scholar] [CrossRef]

- Tian, M.-W.; Khetib, Y.; Yan, S.-R.; Rawa, M.; Sharifpur, M.; Cheraghian, G.; Melaibari, A.A. Energy, exergy and economics study of a solar/thermal panel cooled by nanofluid. Case Stud. Therm. Eng. 2021, 28, 101481. [Google Scholar] [CrossRef]

- Menon, G.S.; Murali, S.; Elias, J.; Delfiya, D.A.; Alfiya, P.; Samuel, M.P. Experimental investigations on unglazed photovoltaic-thermal (PVT) system using water and nanofluid cooling medium. Renew. Energy 2022, 188, 986–996. [Google Scholar] [CrossRef]

- Bassam, A.M.; Sopian, K.; Ibrahim, A.; Al-Aasam, A.B.; Dayer, M. Experimental analysis of photovoltaic thermal collector (PVT) with nano PCM and micro-fins tube counterclockwise twisted tape nanofluid. Case Stud. Therm. Eng. 2023, 45, 102883. [Google Scholar] [CrossRef]

- Geovo, L.; Ri, G.D.; Kumar, R.; Verma, S.K.; Roberts, J.J.; Mendiburu, A.Z. Theoretical model for flat plate solar collectors operating with nanofluids: Case study for Porto Alegre, Brazil. Energy 2023, 263, 125698. [Google Scholar] [CrossRef]

- Adun, H.; Adedeji, M.; Ruwa, T.; Senol, M.; Kavaz, D.; Dagbasi, M. Energy, exergy, economic, environmental (4E) approach to assessing the performance of a photovoltaic-thermal system using a novel ternary nanofluid. Sustain. Energy Technol. Assess. 2021, 50, 101804. [Google Scholar] [CrossRef]

- Fayaz, H.; Nasrin, R.; Rahim, N.; Hasanuzzaman, M. Energy and exergy analysis of the PVT system: Effect of nanofluid flow rate. Sol. Energy 2018, 169, 217–230. [Google Scholar] [CrossRef]

- Hooshmandzade, N.; Motevali, A.; Seyedi, S.R.M.; Biparva, P. Influence of single and hybrid water-based nanofluids on performance of microgrid photovoltaic/thermal system. Appl. Energy 2021, 304, 117769. [Google Scholar] [CrossRef]

- Shen, T.; Xie, H.; Gavurová, B.; Sangeetha, M.; Karthikeyan, C.; Praveenkumar, T.R.; Xia, C.; Manigandan, S. Experimental analysis of photovoltaic thermal system assisted with nanofluids for efficient electrical performance and hydrogen production through electrolysis. Int. J. Hydrogen Energy 2023, 48, 21029–21037. [Google Scholar] [CrossRef]

- Murtadha, T.K. Effect of using Al2O3/TiO2 hybrid nanofluids on improving the photovoltaic performance. Case Stud. Therm. Eng. 2023, 47, 103112. [Google Scholar] [CrossRef]

- Alktranee, M.; Shehab, M.A.; Németh, Z.; Bencs, P.; Hernadi, K. Experimental study for improving photovoltaic thermal system performance using hybrid titanium oxide-copper oxide nanofluid. Arab. J. Chem. 2023, 16, 105102. [Google Scholar] [CrossRef]

- Parsa, S.M.; Yazdani, A.; Aberoumand, H.; Farhadi, Y.; Ansari, A.; Aberoumand, S.; Karimi, N.; Afrand, M.; Cheraghian, G.; Ali, H.M. A critical analysis on the energy and exergy performance of photovoltaic/thermal (PV/T) system: The role of nanofluids stability and synthesizing method. Sustain. Energy Technol. Assess. 2022, 51, 101887. [Google Scholar] [CrossRef]

- Said, Z.; Sundar, L.S.; Tiwari, A.K.; Ali, H.M.; Sheikholeslami, M.; Bellos, E.; Babar, H. Recent advances on the fundamental physical phenomena behind stability, dynamic motion, thermophysical properties, heat transport, applications, and challenges of nanofluids. Phys. Rep. 2022, 946, 1–94. [Google Scholar] [CrossRef]

- Baek, S.; Shin, D.; Noh, J.; Choi, B.; Huh, S.; Jeong, H.; Sung, Y. Influence of surfactants on thermal performance of Al2O3/water nanofluids in a two-phase closed thermosyphon. Case Stud. Therm. Eng. 2021, 28, 101586. [Google Scholar] [CrossRef]

- Torii, S. Turbulent heat transfer behavior of nanofluid in a circular tube heated under constant heat flux. Adv. Mech. Eng. 2010, 2, 917612. [Google Scholar] [CrossRef]

- Kia, S.; Khanmohammadi, S.; Jahangiri, A. Experimental and numerical investigation on heat transfer and pressure drop of SiO2 and Al2O3 oil-based nanofluid characteristics through the different helical tubes under constant heat fluxes. Int. J. Therm. Sci. 2023, 185, 108082. [Google Scholar] [CrossRef]

- Sajid, M.U.; Ali, H.M. Recent advances in application of nanofluids in heat transfer devices: A critical review. Renew. Sustain. Energy Rev. 2019, 103, 556–592. [Google Scholar] [CrossRef]

| Refs. | Types | Electrical Efficiency | Thermal Efficiency | Remarks |

|---|---|---|---|---|

| Koech et al. [72] | Varying collector length while keeping the number of PV cells constant | 31% | Extending collector length reduces the packing factor and enhances heat loss. | |

| Ali et al. [73] | Single and double serpentine | 15.22% | 43% | Double serpentine increases the heat transfer coefficient. |

| Ibrahim et al. [74] | Direct, oscillatory, serpentine, web, spiral, parallel-serpentine, modified serpentine-parallel | 50.12% | Heat absorption increases with a tighter spacing between tubes. | |

| Ekramian et al. [75] | Five positions and four different shapes of riser | Riser tubes with sharp corners in cross-section weaken convective heat transfer. | ||

| Kumar and Rosen [76] | With and without fin | Extending heat transfer by utilizing fins excessively reduce cell temperature. | ||

| Cetina-Quinones et al. [77] | Linear fins, zig-zag fins, wavy fins | Wavy fins create turbulent flow, enhancing convective heat transfer. | ||

| Kazem et al. [78] | Direct flow, web flow, spiral flow | 9.17% | 26% | The spiral flow tube in the absorber demonstrates superior performance in thermal evaluations. |

| Missirlis et al. [79] | 3 different inlet and outlet pipe manifold | The different manifold of inlet and outlet produces different temperature distribution. |

| Refs. | Types | Electrical Efficiency | Thermal Efficiency | Remarks |

|---|---|---|---|---|

| Deng et al. [84] | Microchannel heat pipe array | MHPA–FPC responds to generate temperature difference in less than 2 min. | ||

| Shahsavar et al. [85] | Plain, parallel, staggered groove | 53.7% | Staggered grooves achieved the best performance than other types in energetic and exergetic terms. | |

| Mansour [86] | Square | Displacing tube to minichannel as heat-reducing tools boosts the heat removal process. | ||

| Sharma and Diaz [87] | Minichannel brings better performance; operational condition needs to be considered. | |||

| Wei et al. [88] | Integrated heat pipe with 15 vertical pipes, having two horizontal connected pipes at both ends | 73% | Vacuum insulation inside solar heat collectors improves thermal performance. | |

| Oyinlola et al. [89] | Sixty microchannels measuring 0.5 mm × 2 mm × 270 mm | Insulation on each side of the plate minimizes heat loss. | ||

| Radwan et al. [90] | 19% | 62% | Employing microchannel in low-concentration photovoltaic was proven can significantly reduce cell temperature. | |

| Agrawal and Tiwar [91] | Microchannel outperforms single-channel in efficiency. |

| Degradation | Main Factor |

|---|---|

| Thermal degradation [94] | Temperature increase |

| Oxidative degradation [95] | Water and temperature |

| Chemical degradation [96] | Chemicals |

| Biodegradation [97] | Microorganism enzyme |

| Hydrolytic degradation [98] | Water and temperature |

| Mechanical degradation [96] | Mechanical stress |

| Photo-oxidative degradation [99] | UV radiation and oxygen |

| Refs. | Types | Electrical Efficiency | Thermal Efficiency | Remarks |

|---|---|---|---|---|

| Erkata Yandri [103] | Polymethyl methacrylate | 7.9% | 82.56% | Electrical and thermal efficiency react oppositely to increases in solar temperature. |

| Filipovi’c et al. [104] | Chlorinated poly, polyamide | 76.8% | The number of air gaps and base material thermal conductivity showed opposing effects on thermal efficiency. | |

| Selikhov et al. [105] | Polyethylene | Mass flow rate determines heat flux value. | ||

| Nishit and Bekal [106] | Al2O3 application significantly enhances system performance to compensate for polymer limitations. | |||

| Ariyawiriyanan et al. [107] | Polyvinyl chloride-blue (PVC-B), polybutene (PB), polypropylene random copolymer (PP-R), and polyvinyl chloride–carbon black (PVC–CB) | 50% | Thermal conductivity varies among polymer types and surface areas, influencing heat rejection. | |

| Mintsa Do Ango et al. [108] | Polycarbonate | Optimal efficiency is achieved with a 10 mm air-gap thickness. | ||

| Chen et al. [109] | Polycarbonate | In thermal efficiency, aluminum solar collectors outperform polymer ones. | ||

| Kim et al. [110] | Polycarbonate | Length extension does not affect thermal efficiency or absorber optical properties. | ||

| Pugsley et al. [111] | Polycarbonate | 32% | Polycarbonate and CNT performance still falls short of conventional collector performance. | |

| Resch-Fauster et al. [112] | Paraffin wax | At peak irradiation, PCM–polymer maintains the surface temperature below the threshold. |

| Refs. | Types | Electrical Efficiency | Thermal Efficiency | Remarks |

|---|---|---|---|---|

| Alsaqoor et al. [120] | Lauric acid | 13.5% | 71.7%% | Inclusion of PCM on PVT and storage tanks leads the better temperature degradation. |

| Sardarabadi et al. [121] | Paraffin wax | PCM application outperforms nanofluid application. | ||

| Yazdanifard, et al. [122] | RT25 (paraffin) and S27 | 14.5% | 46.5% | Higher melting point PCM facilitates faster heat transfer, leading to quicker system stabilization to a steady state. |

| Elsheniti, et al. [123] | RT25HC | PCM usage in cold weather proved to be less effective. PCM usage in cold weather proved to be less effective. | ||

| Chaabane et al. [124] | RT42-graphite and myristic acid | Myristic acid with a higher melting temperature performs better in daily operation. | ||

| Diallo et al. [125] | 12.2% | 55.6% | Increasing water inlet temperature results in heat loss and reduced useful heat. | |

| Fayaz et al. [126] | Paraffin (A44) | 13.98% | 76.1% | Utilizing PCM can boost PVT system in overall evaluated performance values. |

| Simón-Allué, et al. [127] | RT50, C48 | PCM does not significantly change thermal performance but improves heat production distribution. | ||

| Ren et al. [128] | SP24E & SP26E | Thermal energy storage performance strongly depends on design variables. | ||

| Su et al. [129] | Different melting points of PCM respond variably over time under various operational conditions. | |||

| Yang et al. [130] | Capric acid | 8.16% | PCM absorbs both sensible and latent heat, distributing it when solar radiation is absent. | |

| Hasan et al. [131] | Eutectic of capric–palmitic acid and calcium chloride hexahydrate | PCM demonstrates significant benefits in hotter environments. |

| Refs. | Types | Electrical Efficiency | Thermal Efficiency | Remarks |

|---|---|---|---|---|

| Tian et al. [137] | MgO | Higher nanofluid concentration enhances exergy output. | ||

| Menon et al. [138] | CuO | 35.67% | 78.41% | Nanofluid, as a coolant medium, stores sensible heat more efficiently during PVT operation. |

| Bassam et al. [139] | SiC | 9.6% | SiC nanofluid prevents microcracking but does not significantly increase system efficiency. | |

| Ahmadinejad and Moosavi [54] | CuO and CNT | 17.85% | 64.5% | CNT holds the greatest outcome over CuO and pure water at any different irradiation conditions. |

| Geovo et al. [140] | MgO | Applying nanofluids as cooling fluids can reduce the size of solar collectors. | ||

| Adun et al. [141] | Al2O3–ZnO–Fe3O4 | 13.74% | Ternary nanofluid improves heat transfer, but pumping power considerations are essential. | |

| Fayaz et al. [142] | MWCNT | 12.50% | 81.24% | Higher mass flow rates maintain temperature gradient, enhancing convective heat transfer. |

| Hooshmandzade et al. [143] | Hybrid (Al2O3 + SiO2) | 62.50% | Nanofluid lowers temperature due to high thermal capacity and increases open-circuit voltage output. | |

| Shen et al. [144] | ZnO | 8.7% | 34% | Voltage generation continues to rise over time, even if temperatures decrease after an initial increase. |

| Murtadha [145] | Hybrid (Al2O3 + TiO2) | 17.6% | Al2O3 with TiO2 combination outperforms standalone Al2O3 as a working fluid. | |

| Alktranee et al. [146] | TiO2–CuO | 9.20% | 50.2% | Enhanced performance considering system capacity, dimensions, and nanofluid concentrations. |

| Parsa et al. [147] | Ag | 12.28% | 65.5% | Nanofluid stability is more influential than volume concentration. |

| PVT System | Strength | Weakness |

|---|---|---|

| Absorber design | -Easily install in conventional PV system | -High cost |

| -High efficiency | -Consume external power for using liquid cooling | |

| -Absorbed heat can be reused | -Non-uniform cooling effect | |

| -Variative modification | -Need larger space | |

| Mini/microchannels | -Uniform temperature distribution | -Increasing pumping power |

| -Effective space | -Mostly applied in concentrated PV | |

| -High efficiency | -High cost | |

| Polymers | -Low cost | -Less performance enhancement |

| -Easy fabrication | -Should be combined with other techniques | |

| -Corrosion resistance | -Absorbed heat is wasted | |

| -Light-weight | ||

| PCMs | -No need to circulate fluid | -Physical contact with PV material can cause damage |

| -Easily attach | -Risk damage by leakage | |

| -Low cost | -Degradation performance for outdoor exposure | |

| -Able to absorb more heat | ||

| Nanofluids | -Significant efficiency enhancement | -Increase pumping power |

| -Low cost | -Need additional heat exchanger | |

| -Can be applied and integrated with other cooling techniques | -Challenge of nanofluid stability and conglomeration |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurniawati, I.; Sung, Y. A Review of Heat Dissipation and Absorption Technologies for Enhancing Performance in Photovoltaic–Thermal Systems. Energies 2024, 17, 1721. https://doi.org/10.3390/en17071721

Kurniawati I, Sung Y. A Review of Heat Dissipation and Absorption Technologies for Enhancing Performance in Photovoltaic–Thermal Systems. Energies. 2024; 17(7):1721. https://doi.org/10.3390/en17071721

Chicago/Turabian StyleKurniawati, Ischia, and Yonmo Sung. 2024. "A Review of Heat Dissipation and Absorption Technologies for Enhancing Performance in Photovoltaic–Thermal Systems" Energies 17, no. 7: 1721. https://doi.org/10.3390/en17071721

APA StyleKurniawati, I., & Sung, Y. (2024). A Review of Heat Dissipation and Absorption Technologies for Enhancing Performance in Photovoltaic–Thermal Systems. Energies, 17(7), 1721. https://doi.org/10.3390/en17071721