Exploring the Environmental Benefits of an Open-Loop Circular Economy Strategy for Automotive Batteries in Industrial Applications

Abstract

1. Introduction

2. Materials and Methods

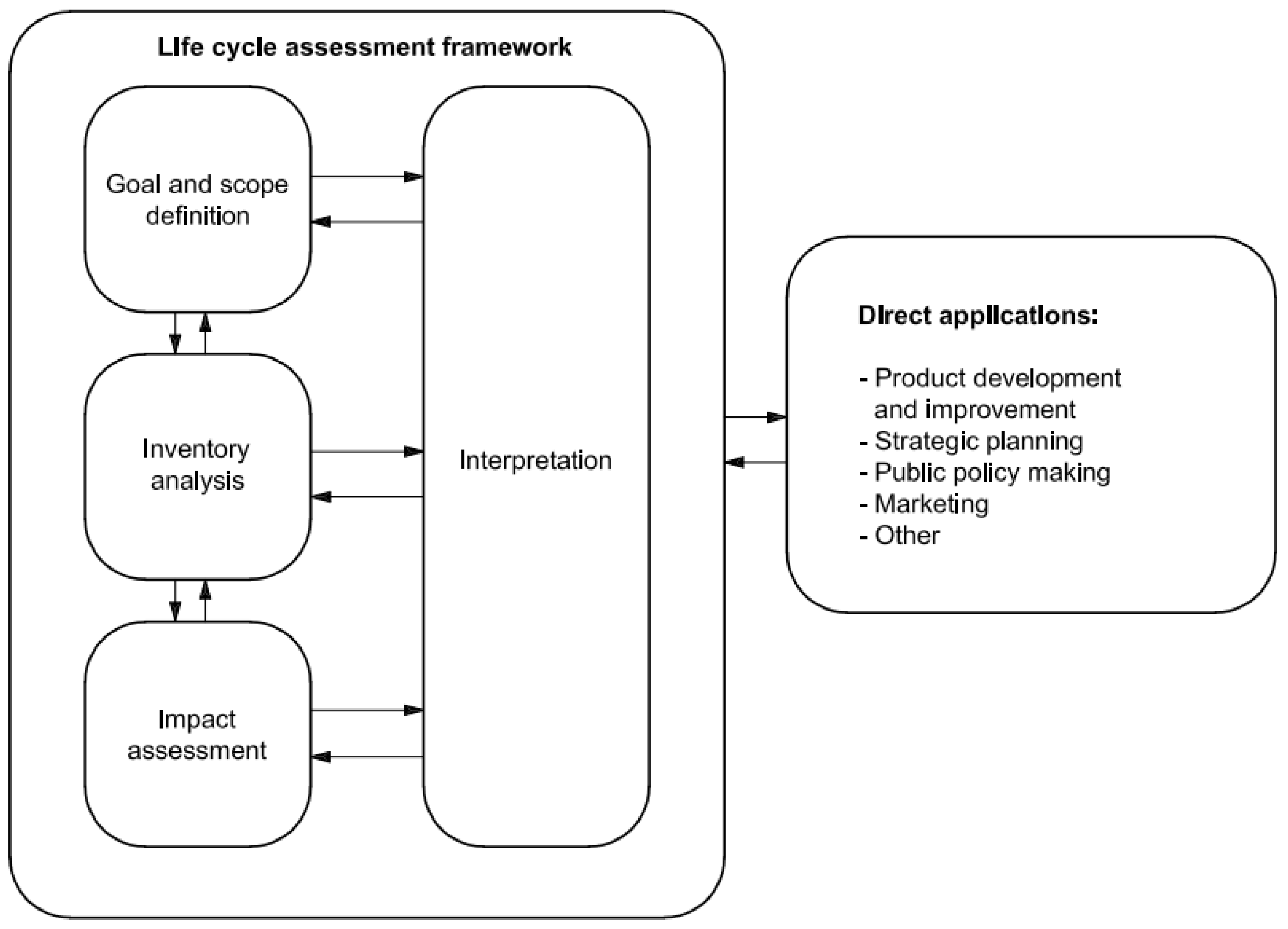

2.1. Phases of Life Cycle Assessment

- Step 1. Goal and scope definition. This step identifies the total objectives and gives a picture of the system in terms of system boundary and functional unit (FU);

- Step 2. Life cycle inventory analysis (LCI). This step includes the data collection on raw materials and energy consumption, environmental emissions, and waste generation;

- Step 3. Life cycle impact assessment (LCIA). This phase results in the classification of the environmental impacts of all processes previously collected and modeled in the LCI phase and transforms them into environmental themes such as global warming or human health.

- Step 4. Interpretation. This last step allows the LCIA results to be comparable and comprehensible.

2.2. Life Cycle Assessment: Goal and Scope

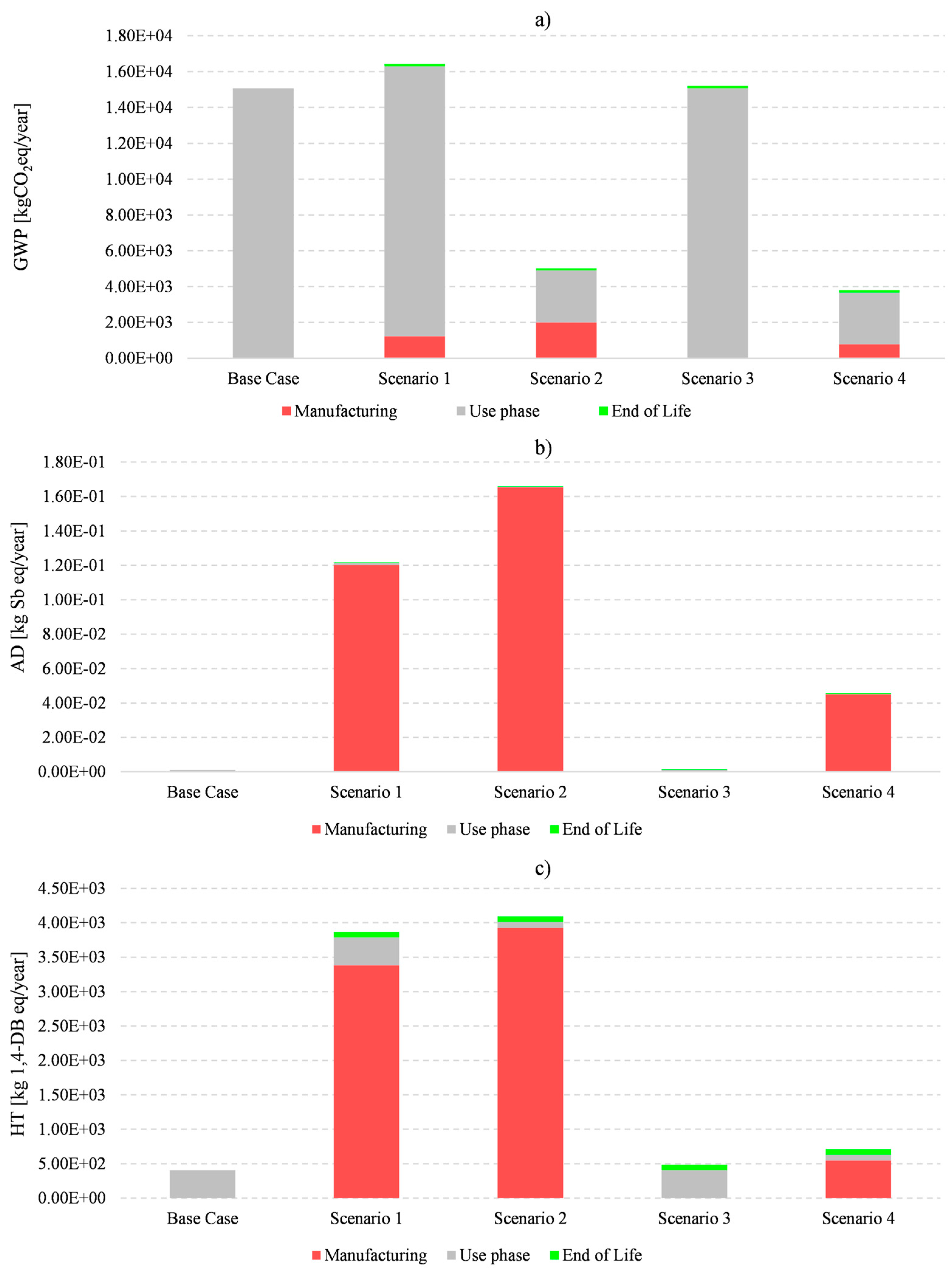

- Base Case: the ball mill machine is entirely served by the grid supply;

- Scenario 1: the ball mill machine is served by a BESS made of new batteries connected to the grid;

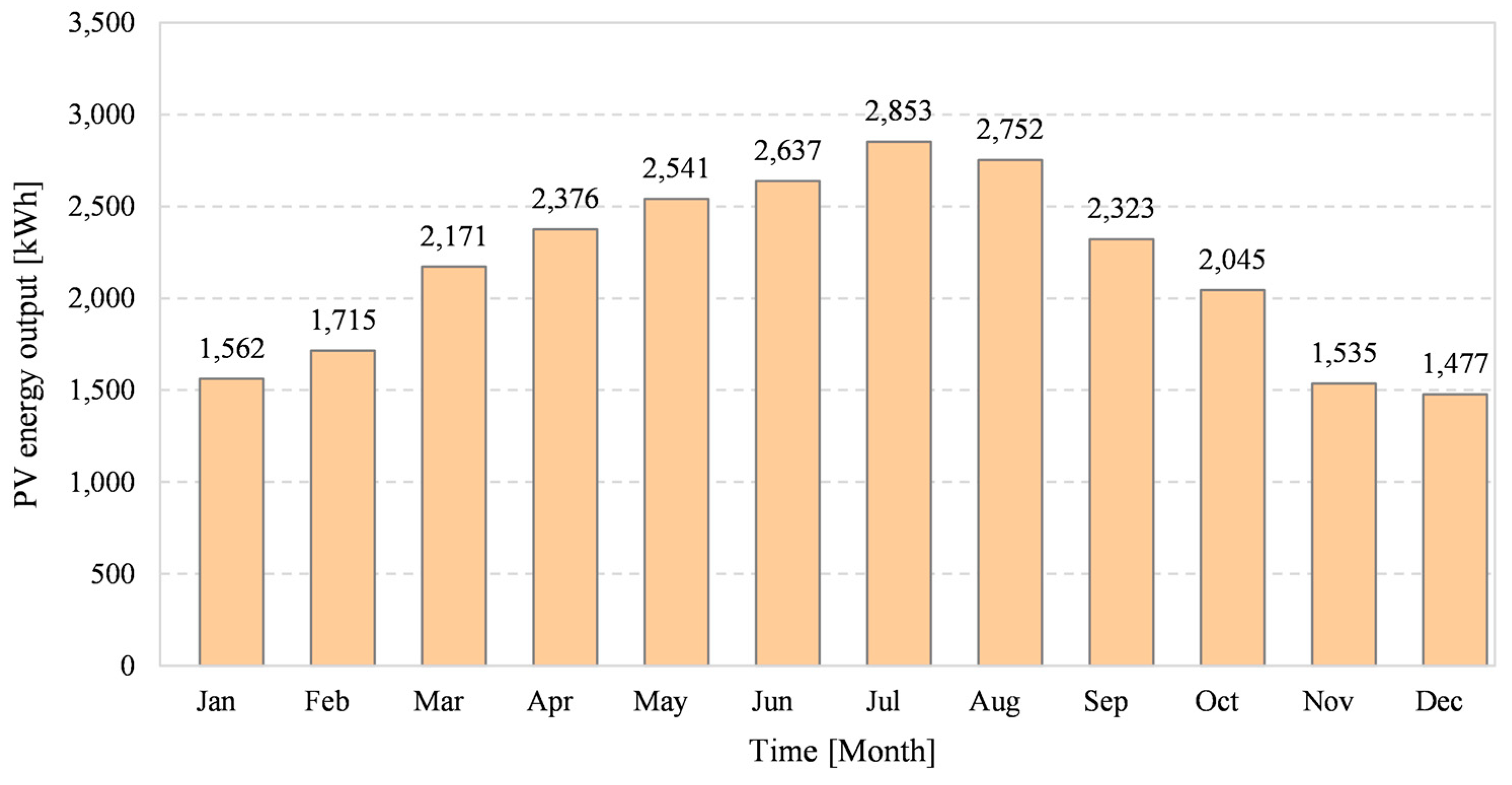

- Scenario 2: the ball mill machine is served by a BESS made of new batteries connected to a standalone PV system;

- Scenario 3: the ball mill machine is served by a SL-BESS made of decommissioned automotive batteries connected to the grid;

- Scenario 4: the ball mill machine is served by a SL-BESS made of decommissioned automotive batteries connected to a standalone PV system.

| Impact Category Group | Name of the Impact Category | Acronym | Unit of Measurement |

|---|---|---|---|

| Depletion of abiotic resources | Depletion of abiotic resources (elements, ultimate reserves) | AD | kg Sb eq. |

| Depletion of abiotic resources (fossil fuels) | AD(ff) | MJ | |

| Climate change | Climate change (global warming potential) | GWP | kg CO2 eq. |

| Ozone layer depletion | Ozone layer depletion | ODP | kg CFC-11 eq. |

| Human toxicity | Human toxicity | HT | kg 1,4-DB eq. |

| Ecotoxicity | Fresh water aquatic ecotoxicity | FWAE | kg 1,4-DB eq. |

| Marine aquatic ecotoxicity | MAE | kg 1,4-DB eq. | |

| Terrestrial ecotoxicity | TE | kg 1,4-DB eq. | |

| Photochemical oxidation | Photochemical oxidation | POC | kg C2H4 eq. |

| Acidification | Acidification potential | A | kg SO2 eq. |

| Eutrophication | Eutrophication | E | kg PO4 eq. |

2.3. Data Collection and Key Assumptions

2.3.1. Manufacturing and Recycling of BESS

2.3.2. Manufacturing and Recycling of PV System

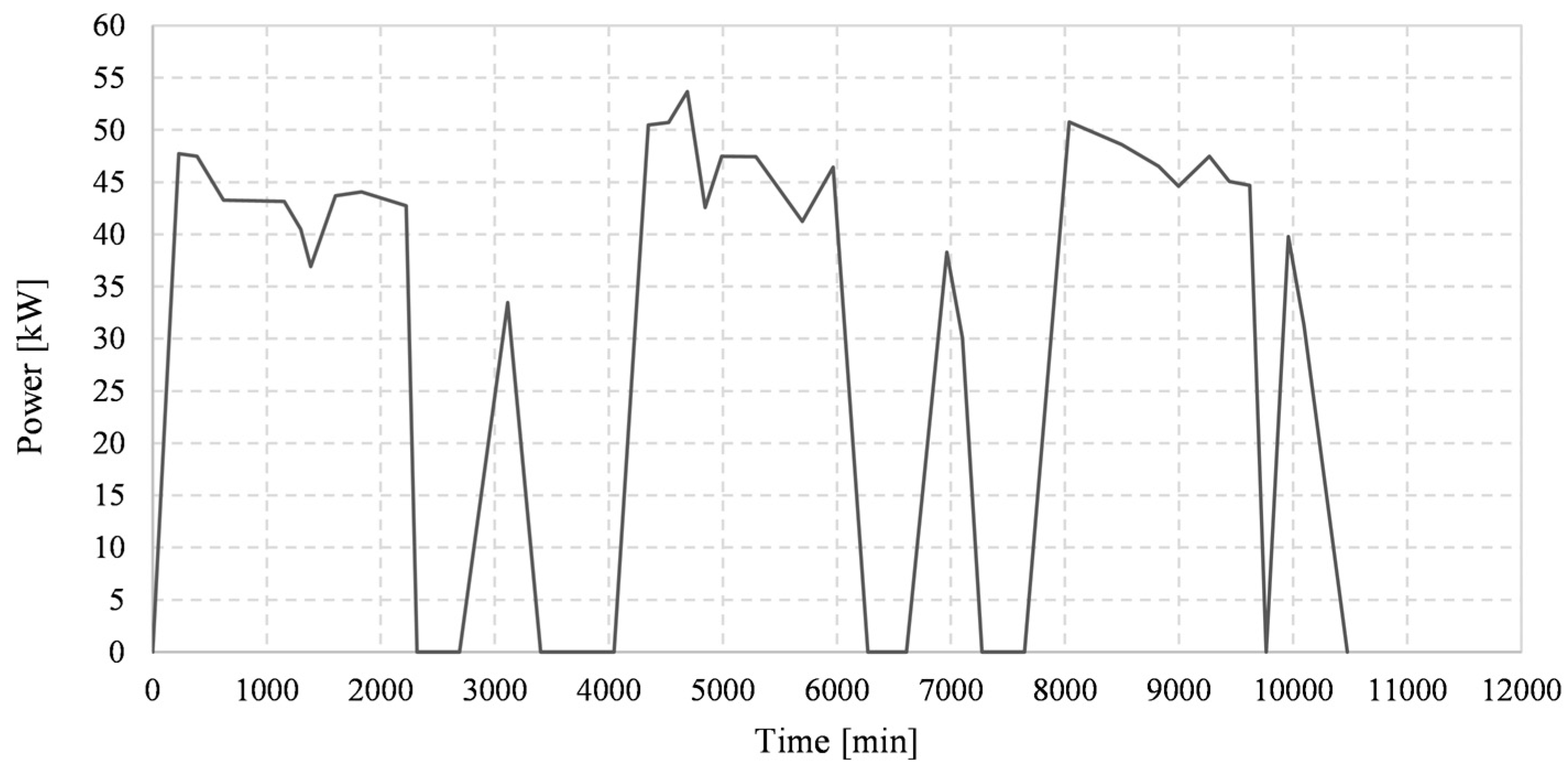

2.3.3. Use Phase

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xing, M.; Luo, F.; Fang, Y. Research on the sustainability promotion mechanisms of industries in China’s resource-based cities—From an ecological perspective. J. Clean. Prod. 2021, 315, 128114. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Di Bona, G.; Silvestri, C. Circular economy strategy of reusing olive mill wastewater in the ceramic industry: How the plant location can benefit environmental and economic performance. J. Clean. Prod. 2021, 326, 129388. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Gusmerotti, N.M.; Testa, F.; Corsini, F.; Pretner, G.; Iraldo, F. Drivers and approaches to the circular economy in manufacturing firms. J. Clean. Prod. 2019, 230, 314–327. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N. A Comprehensive Review on Second-Life Batteries: Current State, Manufacturing Considerations, Applications, Impacts, Barriers & Potential Solutions, Business Strategies, and Policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- International Energy Agency, 2020. Global EV Outlook 2020. Entering the Decade of Electric Drive? Available online: https://www.iea.org/reports/global-ev-outlook-2020 (accessed on 21 August 2020).

- Silvestri, L.; Forcina, A.; Arcese, G.; Bella, G. Recycling technologies of nickel–metal hydride batteries: An LCA based analysis. J. Clean. Prod. 2020, 273, 123083. [Google Scholar] [CrossRef]

- Faessler, B. Stationary, Second Use Battery Energy Storage Systems and Their Applications: A Research Review. Energies 2021, 14, 2335. [Google Scholar] [CrossRef]

- Pinegar, H.; Smith, Y.R. Recycling of End-of-Life Lithium Ion Batteries, Part I: Commercial Processes. J. Sustain. Metall. 2019, 5, 402–416. [Google Scholar] [CrossRef]

- Global Energy & Environment Research Team. Global Industrial Battery Market, Forecast to 2023: Growth in Renewable Energy and Distributed Generation to Drive the Global Industrial Battery Market; Frost & Sullivan: San Antonio, TX, USA, 2018; p. 196. [Google Scholar]

- Dunn, B.; Kamath, H.; Tarascon, J.-M. Electrical Energy Storage for the Grid: A Battery of Choices. Science 2011, 334, 928–935. [Google Scholar] [CrossRef]

- Yang, P.; Tarascon, J.-M. Towards systems materials engineering. Nat. Mater. 2012, 11, 560–563. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Silvestri, C.; Traverso, M. Circularity potential of rare earths for sustainable mobility: Recent developments, challenges and future prospects. J. Clean. Prod. 2021, 292, 126089. [Google Scholar] [CrossRef]

- Deutsche, B. Autos & Auto Parts Electric Cars: Plugged in 2; Deutsche Bank: Frankfurt, Germany, 2009. [Google Scholar]

- Garole, D.J.; Hossain, R.; Garole, V.J.; Sahajwalla, V.; Nerkar, J.; Dubal, D.P. Recycle, Recover and Repurpose Strategy of Spent Li-ion Batteries and Catalysts: Current Status and Future Opportunities. ChemSusChem 2020, 13, 3079–3100. [Google Scholar] [CrossRef]

- Zeng, X.; Li, J.; Ren, Y. Prediction of various discarded lithium batteries in China. In Proceedings of the 2012 IEEE International Symposium on Sustainable Systems and Technology (ISSST), Boston, MA, USA, 16–18 May 2012; pp. 1–4. [Google Scholar]

- Haupt, M.; Vadenbo, C.; Hellweg, S. Do We Have the Right Performance Indicators for the Circular Economy?: Insight into the Swiss Waste Management System. J. Ind. Ecol. 2017, 21, 615–627. [Google Scholar] [CrossRef]

- Berlin, D.; Feldmann, A.; Nuur, C. The relatedness of open- and closed-loop supply chains in the context of the circular economy; Framing a continuum. Clean. Logist. Supply Chain 2022, 4, 100048. [Google Scholar] [CrossRef]

- Innocenzi, V.; Ippolito, N.M.; De Michelis, I.; Prisciandaro, M.; Medici, F.; Vegliò, F. A review of the processes and lab-scale techniques for the treatment of spent rechargeable NiMH batteries. J. Power Sources 2017, 362, 202–218. [Google Scholar] [CrossRef]

- Tunsu, C.; Petranikova, M.; Gergorić, M.; Ekberg, C.; Retegan, T. Reclaiming rare earth elements from end-of-life products: A review of the perspectives for urban mining using hydrometallurgical unit operations. Hydrometallurgy 2015, 156, 239–258. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Secretariat, S.P. EU SET-Plan ACTION n°7 –Declaration of Intent “Become competitive in the global battery sector to drive e-mobility forward”. Transformation 2016, 100, 6317. [Google Scholar]

- European Union. Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on End-of Life Vehicles. Official Journal L; European Union: Maastricht, The Netherlands, 2000. [Google Scholar]

- Heymans, C.; Walker, S.B.; Young, S.B.; Fowler, M. Economic analysis of second use electric vehicle batteries for residential energy storage and load-levelling. Energy Policy 2014, 71, 22–30. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Ferraro, M.; Cellura, M. Energy and environmental benefits of circular economy strategies: The case study of reusing used batteries from electric vehicles. J. Energy Storage 2019, 25, 100845. [Google Scholar] [CrossRef]

- Silvestri, L.; De Santis, M.; Bella, G. A Preliminary Techno-Economic and Environmental Performance Analysis of Using Second-Life EV Batteries in an Industrial Application. In Proceedings of the 2022 6th International Conference on Green Energy and Applications (ICGEA), Singapore, 4–6 March 2022; pp. 99–102. [Google Scholar]

- Silvestri, L.; De Santis, M.; Bella, G. Techno-economic Evaluation of a Second-life Battery Energy Storage System Enabling Peak Shaving and PV Integration in a Ceramic Manufacturing Plant. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 13–16 December 2021; pp. 1566–1570. [Google Scholar]

- Silvestri, L.; De Santis, M. Renewable-based load shifting system for demand response to enhance energy-economic-environmental performance of industrial enterprises. Appl. Energy 2024, 358, 122562. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2021, 168, 105249. [Google Scholar] [CrossRef]

- Gu, X.; Bai, H.; Cui, X.; Zhu, J.; Zhuang, W.; Li, Z.; Hu, X.; Song, Z. Challenges and opportunities for second-life batteries: Key technologies and economy. Renew. Sustain. Energy Rev. 2024, 192, 114191. [Google Scholar] [CrossRef]

- Shu, X.; Guo, Y.; Yang, W.; Wei, K.; Zhu, G. Life-cycle assessment of the environmental impact of the batteries used in pure electric passenger cars. Energy Rep. 2021, 7, 2302–2315. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, B.; Shen, M.; Wu, Y.; Qu, S.; Hu, Y.; Feng, Y. Environmental impact assessment of second life and recycling for LiFePO4 power batteries in China. J. Environ. Manag. 2022, 314, 115083. [Google Scholar] [CrossRef]

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Hendrickson, T.P.; Kavvada, O.; Shah, N.; Sathre, R.; Scown, C.D. Life-cycle implications and supply chain logistics of electric vehicle battery recycling in California. Environ. Res. Lett. 2015, 10, 14011. [Google Scholar] [CrossRef]

- Raugei, M.; Winfield, P. Prospective LCA of the production and EoL recycling of a novel type of Li-ion battery for electric vehicles. J. Clean. Prod. 2019, 213, 926–932. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Kelly, J.C.; James, C.; Gallagher, K.G. The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy Environ. Sci. 2015, 8, 158–168. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Raugei, M.; Steubing, B.; Hartwell, A.; Anderson, P.A.; Heidrich, O. Life cycle assessment of lithium-ion battery recycling using pyrometallurgical technologies. J. Ind. Ecol. 2021, 25, 1560–1571. [Google Scholar] [CrossRef]

- Peters, J.F. Best practices for life cycle assessment of batteries. Nat. Sustain. 2023, 6, 614–616. [Google Scholar] [CrossRef]

- Ember Climate. 2023. Available online: https://ember-climate.org/insights/research/european-electricity-review-2023/ (accessed on 28 March 2024).

- Bin Wali, S.; Hannan, M.A.; Reza, M.S.; Ker, P.J.; Begum, R.A.; Rahman, M.S.A.; Mansor, M. Battery storage systems integrated renewable energy sources: A biblio metric analysis towards future directions. J. Energy Storage 2021, 35, 102296. [Google Scholar] [CrossRef]

- Venettacci, S.; Cozzolino, R.; Ponticelli, G.S.; Guarino, S. Environmental and economic life cycle assessment of thermal energy storage based on organic phase change material embedded in open-cell copper foams. Sustain. Prod. Consum. 2022, 29, 387–405. [Google Scholar] [CrossRef]

- Neumann, J.; Petranikova, M.; Meeus, M.; Gamarra, J.D.; Younesi, R.; Winter, M.; Nowak, S. Recycling of Lithium-Ion Batteries—Current State of the Art, Circular Economy, and Next Generation Recycling. Adv. Energy Mater. 2022, 12, 2102917. [Google Scholar] [CrossRef]

- Han, X.; Li, Y.; Nie, L.; Huang, X.; Deng, Y.; Yan, J.; Kourkoumpas, D.-S.; Karellas, S. Comparative life cycle greenhouse gas emissions assessment of battery energy storage technologies for grid applications. J. Clean. Prod. 2023, 392, 136251. [Google Scholar] [CrossRef]

- Gandiglio, M.; Marocco, P.; Bianco, I.; Lovera, D.; Blengini, G.A.; Santarelli, M. Life cycle assessment of a renewable energy system with hydrogen-battery storage for a remote off-grid community. Int. J. Hydrogen Energy 2022, 47, 32822–32834. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Arcese, G.; Bella, G. Environmental Analysis Based on Life Cycle Assessment: An Empirical Investigation on the Conventional and Hybrid Powertrain. In Proceedings of the Conference on Sustainable Mobility; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- de Souza, L.L.P.; Lora, E.E.S.; Palacio, J.C.E.; Rocha, M.H.; Renó, M.L.G.; Venturini, O.J. Comparative environmental life cycle assessment of conventional vehicles with different fuel options, plug-in hybrid and electric vehicles for a sustainable transportation system in Brazil. J. Clean. Prod. 2018, 203, 444–468. [Google Scholar] [CrossRef]

- Peña, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Pires, A.C.; Weidema, B.; Mieras, E.; Wang, F.; Fava, J.; Canals, L.M.i.; et al. Using life cycle assessment to achieve a circular economy. Int. J. Life Cycle Assess. 2021, 26, 215–220. [Google Scholar] [CrossRef]

- Spreafico, C. An analysis of design strategies for circular economy through life cycle assessment. Environ. Monit. Assess. 2022, 194, 180. [Google Scholar] [CrossRef]

- UNI EN ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006/Amd 1:2017; Environmental Management—Life Cycle Assessment—Requirements and Guidelines—Amendment 1. International Organization for Standardization: Geneva, Switzerland, 2006.

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; De Koning, A.; Van Oers, L.; Sleeswijk, A.W.; Suh, S.; de Haes, H.A.; et al. Life Cycle Assessment—An Operational Guide to the ISO Standards—Part 3: Scientific Background; Ministry Housing, Spatial Planning Environmental Center Environmental Science (CML): Den Haag Leiden, The Netherlands, 2001. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; De Koning, A.; Van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; de Haes, H.A.; et al. Life Cycle Assessment; An Operational Guide to the ISO Standards; Parts 1 and 2; Ministry Housing, Spatial Planning Environmental Center Environmental Science (CML): Den Haag Leiden, The Netherlands, 2001. [Google Scholar]

- PRé-Consultants. LCA Software and Database Manual; PRé Sustainability: Amersfoort, The Netherlands, 2014. [Google Scholar]

- Ecoinvent. The LifeCycle Inventory Data, Version 3.9.1. Swiss Centre for Life CycleInventories. In Proceedings of the Swiss Centre for Life Cycle Inventories; Ecoinvent: Duebendorf, Switzerland, 2023. [Google Scholar]

- SimaPro. SimaPro Database Manual—Methods Library; SimaPro: 2018. Available online: https://simapro.com/wp-content/uploads/2022/07/DatabaseManualMethods.pdf (accessed on 28 March 2024).

- Zeng, A.; Chen, W.; Rasmussen, K.D.; Zhu, X.; Lundhaug, M.; Müller, D.B.; Tan, J.; Keiding, J.K.; Liu, L.; Dai, T.; et al. Battery technology and recycling alone will not save the electric mobility transition from future cobalt shortages. Nat. Commun. 2022, 13, 1341. [Google Scholar] [CrossRef] [PubMed]

- Majeau-Bettez, G.; Hawkins, T.R.; Strømman, A.H. Life Cycle Environmental Assessment of Lithium-Ion and Nickel Metal Hydride Batteries for Plug-In Hybrid and Battery Electric Vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef] [PubMed]

- Tytgat, J. Umicore—Recycling of NiMH and Li-Ion Batteries a Sustainable New Business; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Morel, H. Ultra High Temperature (UHT) Technology at Technology at Umicore. 2010. Available online: http://www.lusitana.umicore.com/img/uploads/irpresentations/35/2010CMD_UHT.pdf (accessed on 28 March 2024).

- Silvestri, L.; Forcina, A.; Silvestri, C.; Ioppolo, G. Life cycle assessment of sanitaryware production: A case study in Italy. J. Clean. Prod. 2020, 251, 119708. [Google Scholar] [CrossRef]

- Photovoltaic Geographical Information System. PVGIS (C). 2023. Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/ (accessed on 28 March 2024).

- Lv, J.; Wang, Z.; Ma, S. Calculation method and its application for energy consumption of ball mills in ceramic industry based on power feature deployment. Adv. Appl. Ceram. 2020, 119, 183–194. [Google Scholar] [CrossRef]

- Fragoso, A.; Martins, R.F.; Soares, A.C. Failure analysis of a ball mill located in a cement’s production line. Eng. Fail. Anal. 2022, 138, 106339. [Google Scholar] [CrossRef]

- Little, L.; Mainza, A.N.; Becker, M.; Wiese, J. Fine grinding: How mill type affects particle shape characteristics and mineral liberation. Miner. Eng. 2017, 111, 148–157. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, S.; Yang, H.; Lv, J.; Liu, Y. A big data driven analytical framework for energy-intensive manufacturing industries. J. Clean. Prod. 2018, 197, 57–72. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Liu, Y.; Yang, H.; Lv, J.; Ren, S. Data-driven sustainable intelligent manufacturing based on demand response for energy-intensive industries. J. Clean. Prod. 2020, 274, 123155. [Google Scholar] [CrossRef]

- Li, H.; Yang, H.; Yang, B.; Zhu, C.; Yin, S. Modelling and simulation of energy consumption of ceramic production chains with mixed flows using hybrid Petri nets. Int. J. Prod. Res. 2018, 56, 3007–3024. [Google Scholar] [CrossRef]

- Shi, F.; Xie, W. A specific energy-based ball mill model: From batch grinding to continuous operation. Miner. Eng. 2016, 86, 66–74. [Google Scholar] [CrossRef]

- Xu, B.; Oudalov, A.; Ulbig, A.; Andersson, G.; Kirschen, D.S. Modeling of Lithium-Ion Battery Degradation for Cell Life Assessment. IEEE Trans. Smart Grid 2018, 9, 1131–1140. [Google Scholar] [CrossRef]

- Colucci, R.; Mahgoub, I.; Yousefizadeh, H.; Al-Najada, H. Survey of Strategies to Optimize Battery Operation to Minimize the Electricity Cost in a Microgrid With Renewable Energy Sources and Electric Vehicles. IEEE Access 2024, 12, 8246–8261. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Kim, H.C. Life cycle assessment of high-concentration photovoltaic systems. Prog. Photovolt. Res. Appl. 2013, 21, 379–388. [Google Scholar] [CrossRef]

- Warrier, G.A.; Palaniappan, S.; Habert, G. Classification of sources of uncertainty in building LCA. Energy Build. 2024, 305, 113892. [Google Scholar] [CrossRef]

- Scarlat, N.; Prussi, M.; Padella, M. Quantification of the carbon intensity of electricity produced and used in Europe. Appl. Energy 2022, 305, 117901. [Google Scholar] [CrossRef]

- Iranshahi, K.; Rubinetti, D.; Onwude, D.I.; Psarianos, M.; Schlüter, O.K.; Defraeye, T. Electrohydrodynamic drying versus conventional drying methods: A comparison of key performance indicators. Energy Convers. Manag. 2023, 279, 116661. [Google Scholar] [CrossRef]

| PV Panel Manuf. | PV Panel O&M | PV Panel End-of-Life | BESS Manuf. | BESS End-of-Life | |||||

|---|---|---|---|---|---|---|---|---|---|

| Glass (kg) | 1096.9 | Water demin. (kg) | 2.41 × 100 | Tap water (kg) | 453.0 | Water, decarb. (l) | 3.80 × 102 | Water (l) | 9.75 × 102 |

| Polymer (kg) | 146.3 | Hydraulic oil (kg) | 2.05 × 10−2 | Nitric acid (kg) | 10.4 | Deionized water (kg) | 2.50 × 102 | Coke (kg) | 3.93 × 103 |

| Aluminum (kg) | 117.0 | Polyester (kg) | 1.36 × 10−3 | Lime, hydrated (kg) | 53.4 | Positive electrode paste (kg) | 6.25 × 100 | H2SO4 (kg) | 1.11 × 104 |

| Silicon (kg) | 73.1 | Co-polymer plastic (kg) | 9.10 × 10−4 | Iron sulphate (FeSO4) (kg) | 5.44 × 100 | Li2CO3 (kg) | 1.90 × 103 | ||

| Copper (kg) | 14.6 | Lubricating oil (kg) | 5.69 × 10−4 | Cell container, tab and terminals (kg) | 2.00 × 10−1 | H2O2 (kg) | 1.98 × 103 | ||

| Polyurethane (kg) | 2.05 × 10−4 | Module and battery packaging (kg) | 1.70 × 10−1 | Limestone (kg) | 3.32 × 104 | ||||

| Silica gel (kg) | 2.05 × 10−4 | Phosphoric acid (H3PO4) (kg) | 3.53 × 100 | ||||||

| Stainless steel (kg) | 1.59 × 10−4 | Electrolyte for li-ion battery (kg) | 1.20 × 10−1 | ||||||

| Glass fiber (kg) | 1.59 × 10−4 | ||||||||

| Poly carbonate (kg) | 6.82 × 10−5 | ||||||||

| Poly amide (kg) | 2.27 × 10−5 |

| Base Case | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | |

|---|---|---|---|---|---|

| Electricity from grid [kWh/y] | 32,120 | 32,120 | 6135 | 32,120 | 6135 |

| Use Phase (Ball Mill) | ||

|---|---|---|

| AD | kg Sb eq | 1.07 × 10−3 |

| AD(ff) | MJ | 1.69 × 105 |

| GWP | kg CO2 eq | 1.51 × 104 |

| ODP | kg CFC-11 eq | 9.58 × 10−4 |

| HT | kg 1,4-DB eq | 4.04 × 102 |

| FWAE | kg 1,4-DB eq | 2.42 × 101 |

| MAE | kg 1,4-DB eq | 1.45 × 106 |

| TE | kg 1,4-DB eq | 7.98 × 100 |

| POC | kg C2H4 eq | 3.39 × 100 |

| A | kg SO2 eq | 6.15 × 101 |

| E | kg PO4 eq | 3.46 × 100 |

| S1 | Manuf. (New-BESS) | Use Phase (Ball Mill) | End-of-Life (New-BESS) | Total | |

|---|---|---|---|---|---|

| AD | kg Sb eq | 1.20 × 10−1 | 1.07 × 10−3 | 4.66 × 10−4 | 1.22 × 10−1 |

| AD(ff) | MJ | 1.21 × 104 | 1.69 × 105 | 1.68 × 103 | 1.83 × 105 |

| GWP | kg CO2 eq | 1.22 × 103 | 1.51 × 104 | 1.34 × 102 | 1.64 × 104 |

| ODP | kg CFC-11 eq | 8.13 × 10−3 | 9.58 × 10−4 | 1.05 × 10−5 | 9.10 × 10−3 |

| HT | kg 1,4-DB eq | 3.38 × 103 | 4.04 × 102 | 8.10 × 101 | 3.87 × 103 |

| FWAE | kg 1,4-DB eq | 1.66 × 103 | 2.42 × 101 | 5.52 × 101 | 1.74 × 103 |

| MAE | kg 1,4-DB eq | 5.58 × 106 | 1.45 × 106 | 2.26 × 105 | 7.25 × 106 |

| TE | kg 1,4-DB eq | 5.62 × 100 | 7.98 × 100 | 1.90 × 10−1 | 1.38 × 101 |

| POC | kg C2H4 eq | 3.79 × 10−1 | 3.39 × 100 | 1.23 × 10−1 | 3.89 × 100 |

| A | kg SO2 eq | 7.56 × 100 | 6.15 × 101 | 9.95 × 10−1 | 7.01 × 101 |

| E | kg PO4 eq | 6.20 × 100 | 3.46 × 100 | 2.41 × 10−1 | 9.90 × 100 |

| S2 | Manuf. (New-BESS) | Manuf. (PV) | Use Phase (Ball Mill) | Use Phase (PV O&M) | End-of-Life (New-BESS) | End-of-Life (PV) | Total | |

|---|---|---|---|---|---|---|---|---|

| AD | kg Sb eq | 1.20 × 10−1 | 4.50 × 10−2 | 2.05 × 10−4 | 4.17 × 10−6 | 4.66 × 10−4 | 6.00 × 10−6 | 1.66 × 10−1 |

| AD(ff) | MJ | 1.21 × 104 | 8.62 × 103 | 3.23 × 104 | 1.18 × 102 | 1.68 × 103 | 2.14 × 101 | 5.49 × 104 |

| GWP | kg CO2 eq | 1.22 × 103 | 7.83 × 102 | 2.88 × 103 | 3.37 × 100 | 1.34 × 102 | 4.67 × 100 | 5.03 × 103 |

| ODP | kg CFC-11 eq | 8.13 × 10−3 | 4.76 × 10−5 | 1.83 × 10−4 | 9.09 × 10−8 | 1.05 × 10−5 | 1.91 × 10−7 | 8.38 × 10−3 |

| HT | kg 1,4-DB eq | 3.38 × 103 | 5.47 × 102 | 7.72 × 101 | 7.06 × 100 | 8.10 × 101 | 8.44 × 10−1 | 4.09 × 103 |

| FWAE | kg 1,4-DB eq | 1.66 × 103 | 4.38 × 102 | 4.61 × 100 | 2.39 × 100 | 5.52 × 101 | 5.72 × 10−1 | 2.16 × 103 |

| MAE | kg 1,4-DB eq | 5.58 × 106 | 1.71 × 106 | 2.77 × 105 | 9.03 × 103 | 2.26 × 105 | 1.28 × 103 | 7.80 × 106 |

| TE | kg 1,4-DB eq | 5.62 × 100 | 1.39 × 100 | 1.52 × 100 | 3.88 × 10−3 | 1.90 × 10−1 | 8.10 × 10−3 | 8.74 × 100 |

| POC | kg C2H4 eq | 3.79 × 10−1 | 1.83 × 10−1 | 6.48 × 10−1 | 2.20 × 10−3 | 1.23 × 10−1 | 6.06 × 10−4 | 1.34 × 100 |

| A | kg SO2 eq | 7.56 × 100 | 3.98 × 100 | 1.17 × 101 | 2.68 × 10−2 | 9.95 × 10−1 | 1.01 × 10−2 | 2.43 × 101 |

| E | kg PO4 eq | 6.20 × 100 | 1.97 × 100 | 6.62 × 10−1 | 2.49 × 10−3 | 2.41 × 10−1 | 3.38 × 10−3 | 9.07 × 100 |

| Use Phase (Ball Mill) | End-of-Life (SL-BESS) | Total | ||

|---|---|---|---|---|

| AD | kg Sb eq | 1.07 × 10−3 | 4.66 × 10−4 | 1.54 × 10−3 |

| AD(ff) | MJ | 1.69 × 105 | 1.68 × 103 | 1.71 × 105 |

| GWP | kg CO2 eq | 1.51 × 104 | 1.34 × 102 | 1.52 × 104 |

| ODP | kg CFC-11 eq | 9.58 × 10−4 | 1.05 × 10−5 | 9.68 × 10−4 |

| HT | kg 1,4-DB eq | 4.04 × 102 | 8.10 × 101 | 4.85 × 102 |

| FWAE | kg 1,4-DB eq | 2.42 × 101 | 5.52 × 101 | 7.93 × 101 |

| MAE | kg 1,4-DB eq | 1.45 × 106 | 2.26 × 105 | 1.68 × 106 |

| TE | kg 1,4-DB eq | 7.98 × 100 | 1.90 × 10−1 | 8.17 × 100 |

| POC | kg C2H4 eq | 3.39 × 100 | 1.23 × 10−1 | 3.52 × 100 |

| A | kg SO2 eq | 6.15 × 101 | 9.95 × 10−1 | 6.25 × 101 |

| E | kg PO4 eq | 3.46 × 100 | 2.41 × 10−1 | 3.71 × 100 |

| Manuf. (PV) | Use Phase (Ball Mill) | Use Phase (PV O&M) | End-of-Life (SL-BESS) | End-of-Life (PV) | Total | ||

|---|---|---|---|---|---|---|---|

| AD | kg Sb eq | 4.50 × 10−2 | 2.05 × 10−4 | 4.17 × 10−6 | 4.66 × 10−4 | 6.00 × 10−6 | 4.57 × 10−2 |

| AD(ff) | MJ | 8.62 × 103 | 3.23 × 104 | 118.1996 | 1.68 × 103 | 2.14 × 101 | 4.27 × 104 |

| GWP | kg CO2 eq | 7.83 × 102 | 2.88 × 103 | 3.365216 | 1.34 × 102 | 4.67 × 100 | 3.80 × 103 |

| ODP | kg CFC-11 eq | 4.76 × 10−5 | 1.83 × 10−4 | 9.09 × 10−8 | 1.05 × 10−5 | 1.91 × 10−7 | 2.41 × 10−4 |

| HT | kg 1,4-DB eq | 5.47 × 102 | 7.72 × 101 | 7.059923 | 8.10 × 101 | 8.44 × 10−1 | 7.13 × 102 |

| FWAE | kg 1,4-DB eq | 4.38 × 102 | 4.61 × 100 | 2.387827 | 5.52 × 101 | 5.72 × 10−1 | 5.01 × 102 |

| MAE | kg 1,4-DB eq | 1.71 × 106 | 2.77 × 105 | 9034.775 | 2.26 × 105 | 1.28 × 103 | 2.23 × 106 |

| TE | kg 1,4-DB eq | 1.39 × 100 | 1.52 × 100 | 0.003878 | 1.90 × 10−1 | 8.10 × 10−3 | 3.12 × 100 |

| POC | kg C2H4 eq | 1.83 × 10−1 | 6.48 × 10−1 | 0.002205 | 1.23 × 10−1 | 6.06 × 10−4 | 9.57 × 10−1 |

| A | kg SO2 eq | 3.98 × 100 | 1.17 × 101 | 0.026822 | 9.95 × 10−1 | 1.01 × 10−2 | 1.68 × 101 |

| E | kg PO4 eq | 1.97 × 100 | 0.002486 | 2.41 × 10−1 | 3.38 × 10−3 | 2.21 × 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silvestri, L.; Forcina, A.; Silvestri, C.; Arcese, G.; Falcone, D. Exploring the Environmental Benefits of an Open-Loop Circular Economy Strategy for Automotive Batteries in Industrial Applications. Energies 2024, 17, 1720. https://doi.org/10.3390/en17071720

Silvestri L, Forcina A, Silvestri C, Arcese G, Falcone D. Exploring the Environmental Benefits of an Open-Loop Circular Economy Strategy for Automotive Batteries in Industrial Applications. Energies. 2024; 17(7):1720. https://doi.org/10.3390/en17071720

Chicago/Turabian StyleSilvestri, Luca, Antonio Forcina, Cecilia Silvestri, Gabriella Arcese, and Domenico Falcone. 2024. "Exploring the Environmental Benefits of an Open-Loop Circular Economy Strategy for Automotive Batteries in Industrial Applications" Energies 17, no. 7: 1720. https://doi.org/10.3390/en17071720

APA StyleSilvestri, L., Forcina, A., Silvestri, C., Arcese, G., & Falcone, D. (2024). Exploring the Environmental Benefits of an Open-Loop Circular Economy Strategy for Automotive Batteries in Industrial Applications. Energies, 17(7), 1720. https://doi.org/10.3390/en17071720