Characteristics of High-Pressure Injection Pump Operated with Renewable Fuel for Diesel Engines

Abstract

1. Introduction

2. Materials and Methods

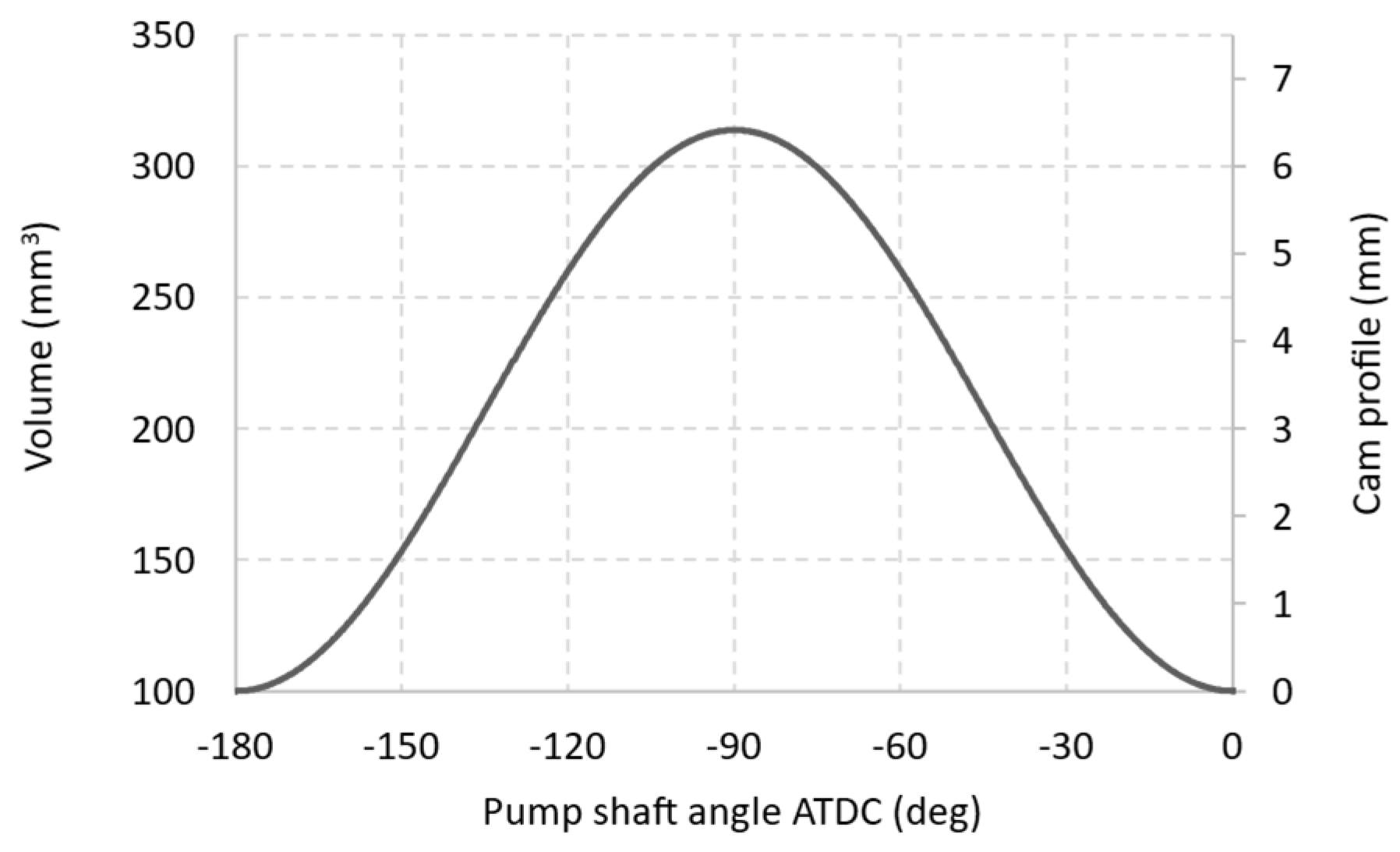

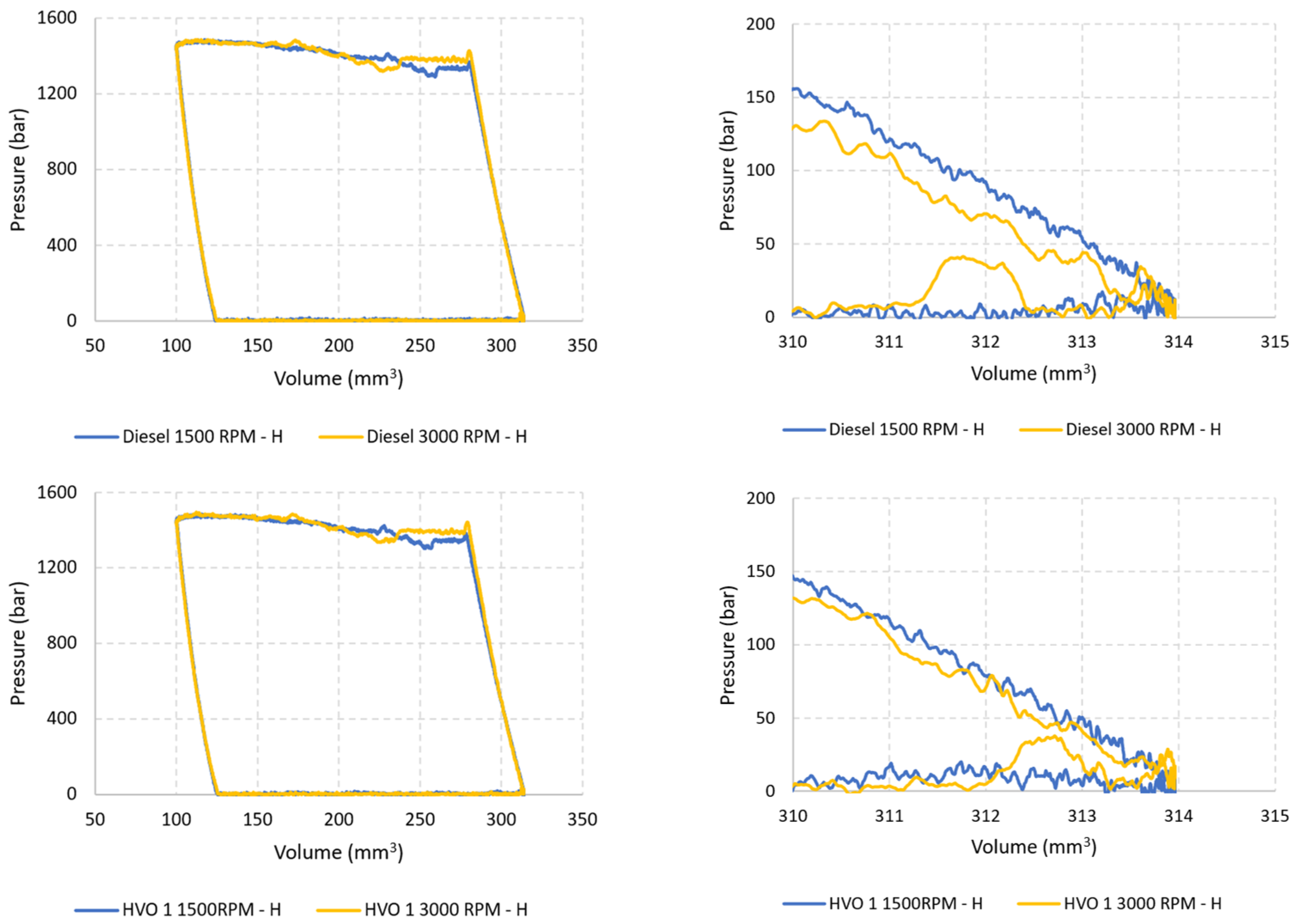

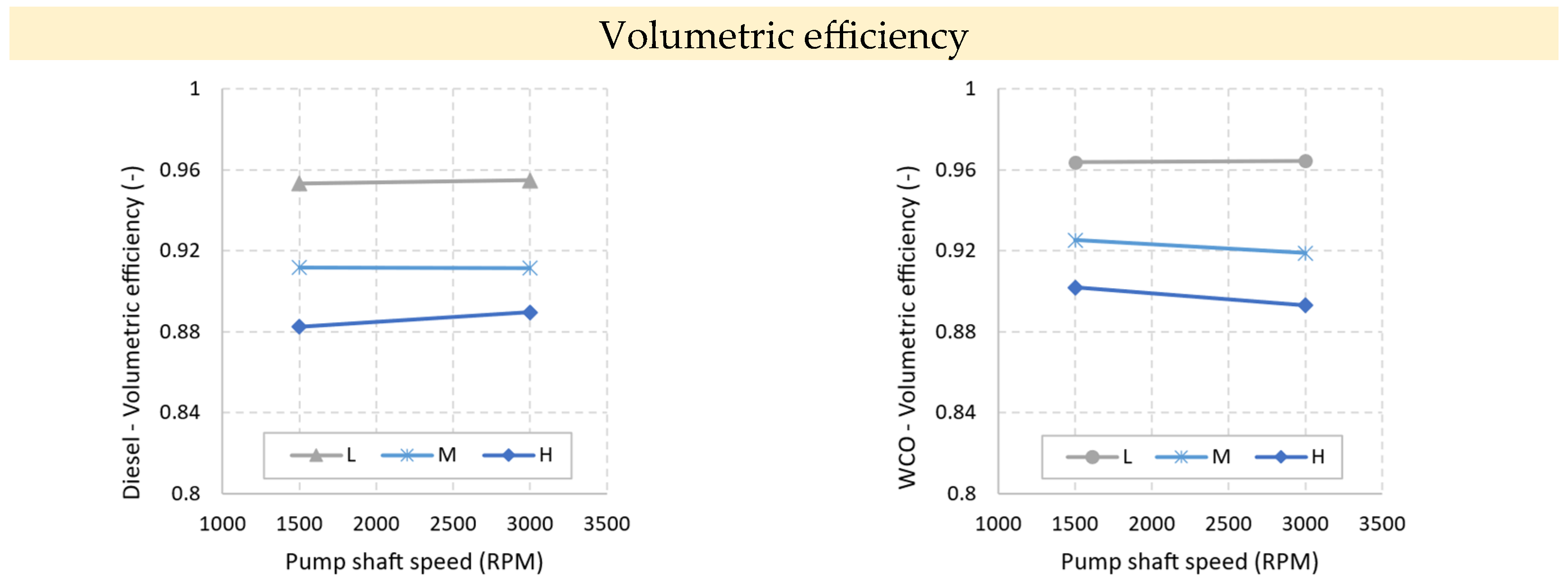

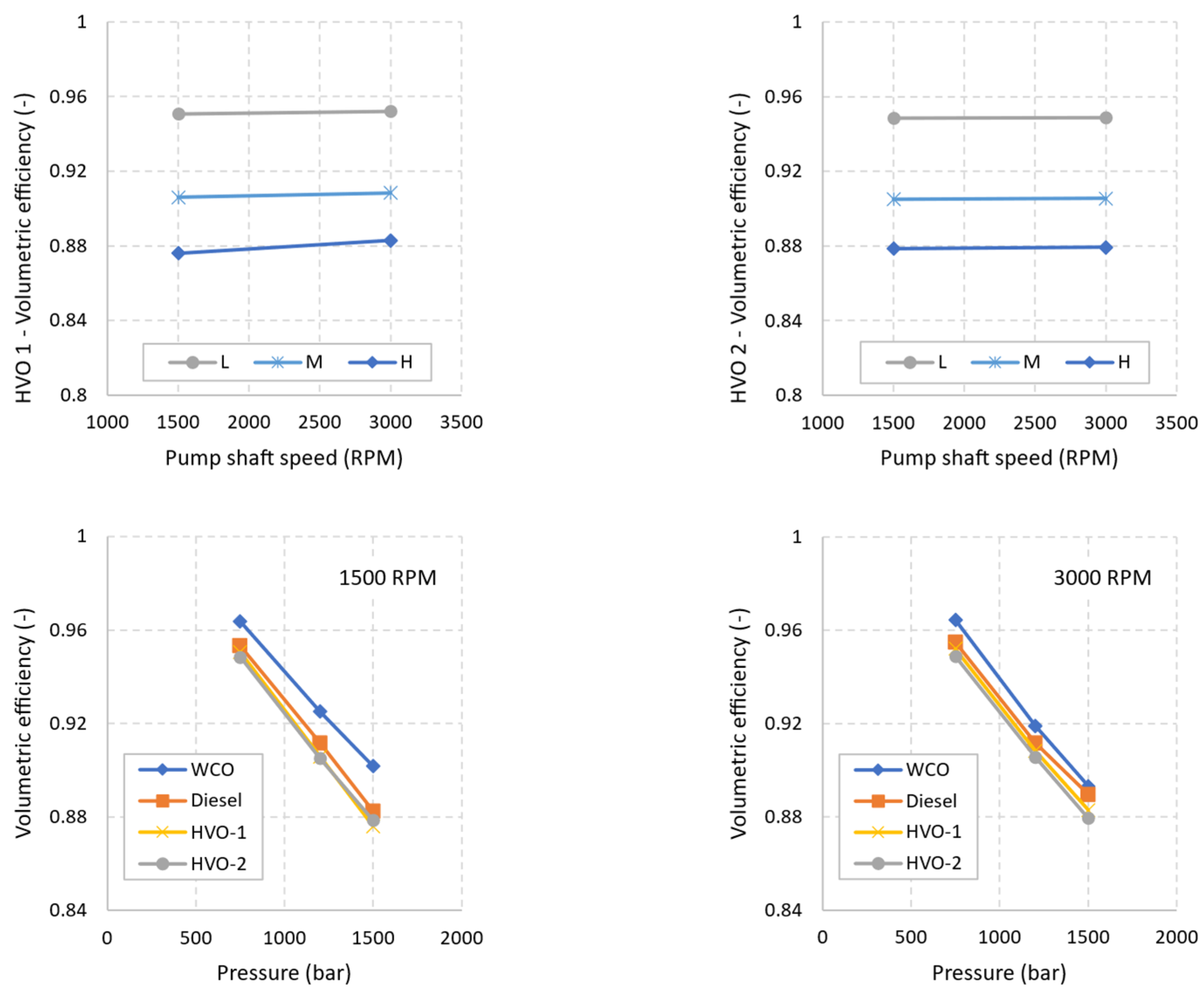

2.1. Pump Operation Cycle and Volumetric Efficiency

- -

- from the acquired measurements, at least 64 averages are calculated (according to [20], the minimum value for averaging a sample of measurements is 30);

- -

- , the average of the mean values , is calculated;

- -

- the deviations from the mean value, , are determined;

- -

- the standard deviation is calculated, where N = 64 indicates the number of partial acquisitions.

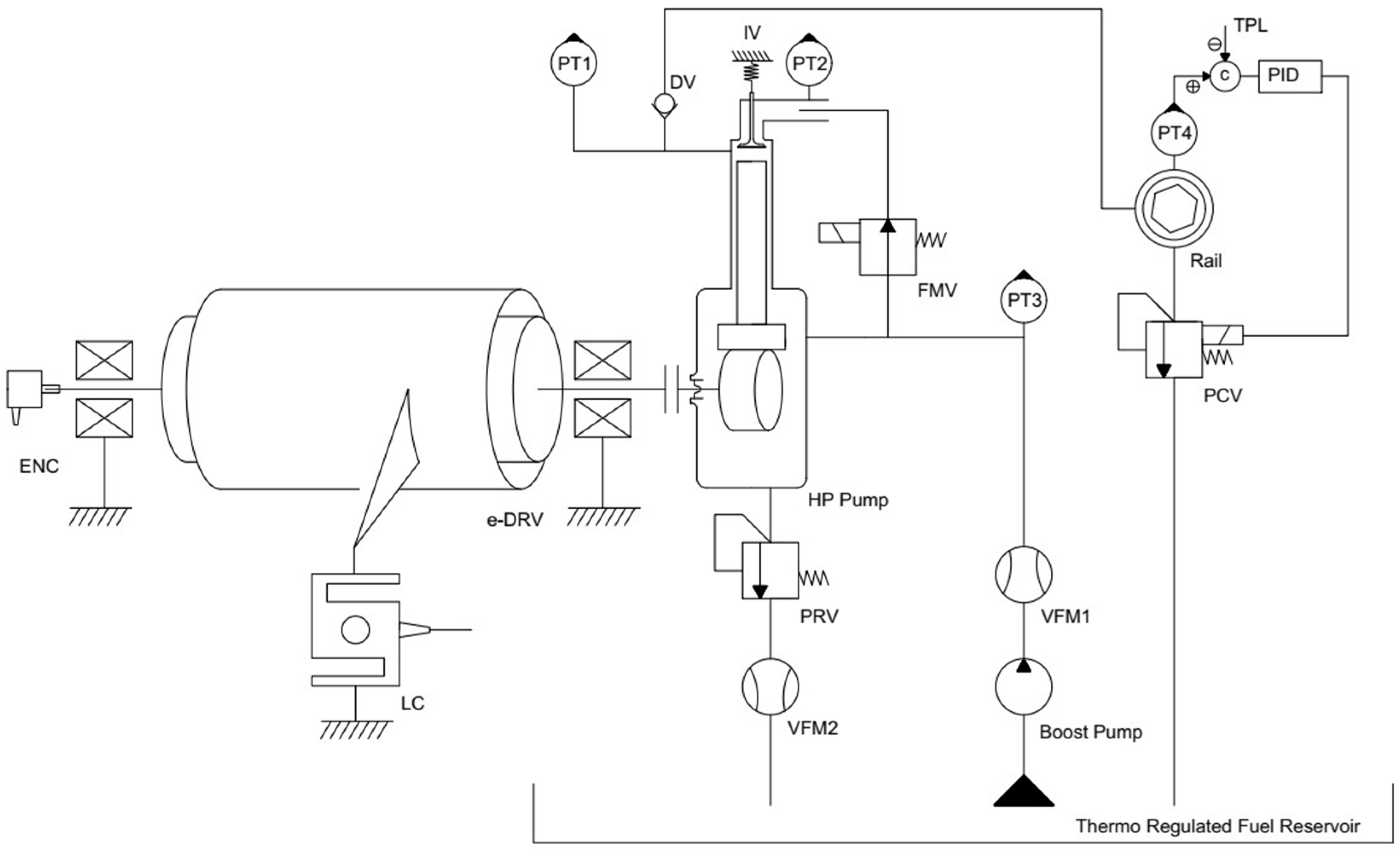

2.2. Experimental Setup

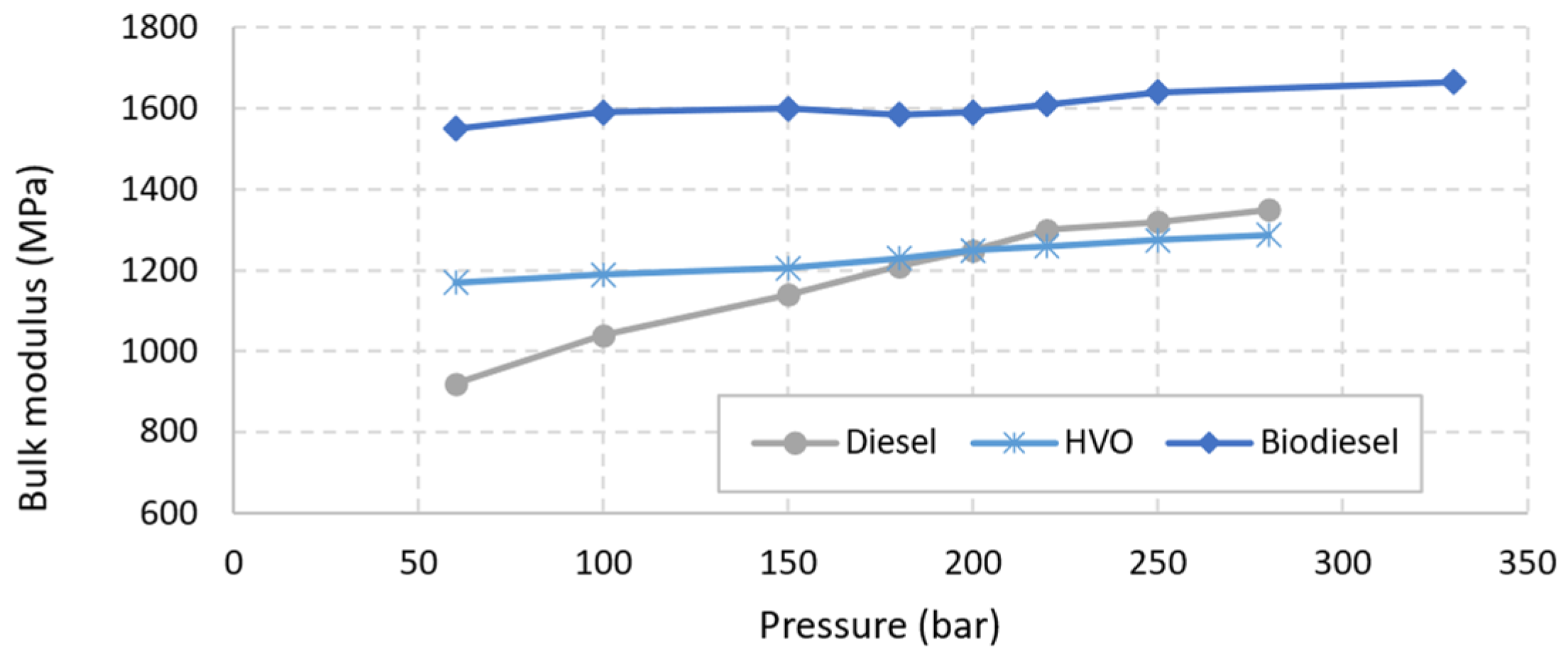

2.3. Tested Fluids

2.4. Test Cases

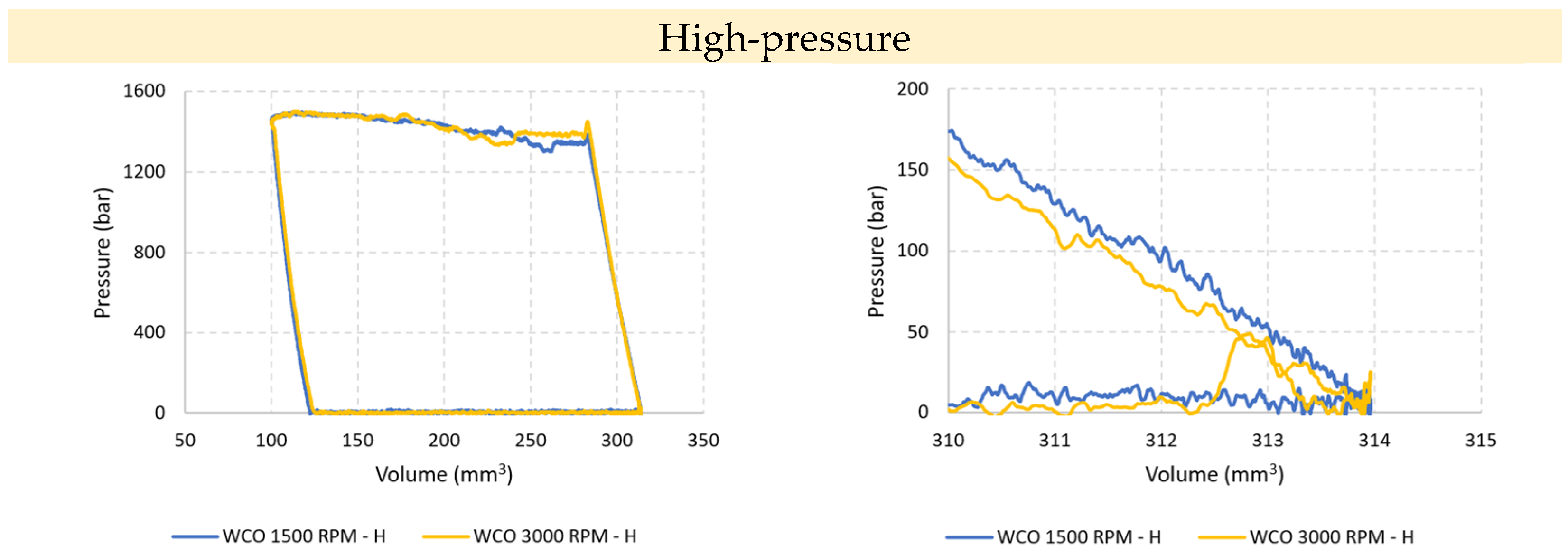

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hua, Y. Research progress of higher alcohols as alternative fuels for compression ignition engines. Fuel 2024, 357, 129749. [Google Scholar] [CrossRef]

- Yadav, J.; Deppenkemper, K.; Pischinger, S. Impact of renewable fuels on heavy-duty engine performance and emissions. Energy Rep. 2023, 9, 1977–1989. [Google Scholar] [CrossRef]

- Betgeri, V.; Bhardwaj, O.P.; Pischinger, S. Investigation of the drop-in capabilities of a renewable 1-Octanol based E-fuel for heavy-duty engine applications. Energy 2023, 282, 128811. [Google Scholar] [CrossRef]

- Khan, M.Z.A.; Khan, H.A.; Ravi, S.S.; Turner, J.W.; Aziz, M. Potential of clean liquid fuels in decarbonizing transportation—An overlooked net- zero pathway? Renew. Sustain. Energy Rev. 2023, 183, 113483. [Google Scholar] [CrossRef]

- Chiatti, G.; Chiavola, O.; Recco, E.; Palmieri, F. Soot Particles Experimental Characterization during Cold Start of a Micro Car Engine. Energy Procedia 2016, 101, 662–669. [Google Scholar] [CrossRef]

- Samanta, S.; Sahoo, R.R. Waste Cooking (Palm) Oil as an Economical Source of Biodiesel Production for Alternative Green Fuel and Efficient Lubricant. Bioenergy Res. 2021, 14, 163–174. [Google Scholar] [CrossRef]

- Amran, N.A.; Bello, U.; Hazwan Ruslan, M.S. The role of antioxidants in improving biodiesel’s oxidative stability, poor cold flow properties, and the effects of the duo on engine performance: A review. Heliyon 2022, 8, e09846. [Google Scholar] [CrossRef] [PubMed]

- Jablonický, J.; Feriancová, P.; Tulík, J.; Hujo, L.; Tkáč, Z.; Kuchar, P.; Tomić, M.; Kaszkowiak, J. Assessment of technical and ecological parameters of a diesel engine in the application of new samples of biofuels. J. Mar. Sci. Eng. 2022, 10, 1. [Google Scholar] [CrossRef]

- Pochi, D.; Fanigliulo, R.; Grilli, R.; Fornaciari, L.; Bisaglia, C.; Cutini, M.; Brambilla, M.; Sagliano, A.; Capuzzi, L.; Palmieri, F.; et al. Design and Assessment of a Test Rig for Hydrodynamic Tests on Hydraulic Fluids. In Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2020; Volume 67, pp. 419–429. [Google Scholar]

- Sonthalia, A.; Kumar, N. Hydroprocessed vegetable oil as a fuel for transportation sector: A review. J. Energy Inst. 2019, 92, 1–17. [Google Scholar] [CrossRef]

- Da Costa, R.B.R.; Coronado, C.J.R.; Hernández, J.J.; Malaquias, A.C.T.; Flores, L.F.V.; de Carvalho, J.A. Experimental assessment of power generation using a compression ignition engine fueled by farnesane—A renewable diesel from sugarcane. Energy 2021, 233, 121187. [Google Scholar] [CrossRef]

- Chiavola, O.; Palmieri, F. On a Modified VCO Nozzle Layout for Diesel Common Rail Injectors under Actual Needle Displacement. Energy Procedia 2017, 126, 1027–1034. [Google Scholar] [CrossRef]

- Jin, T.; Wang, C.; Moro, A.; Roell, A.; Wu, X.; Luo, F. The influence of needle eccentric motion on injection and spray characteristics of a two-layered eight-hole diesel injector. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 09544070231179779. [Google Scholar] [CrossRef]

- Stroia, B. A Compact and Efficient Modular High Pressure Diesel Common Rail Pump Platform for Future Diesel Engine Applications. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2023. [Google Scholar]

- Cavallo, D.M.; Chiavola, O.; Frattini, E.; Palmieri, F. On the Modeling of Single-Piston CR Pump. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2022. [Google Scholar]

- Cavallo, M.; Frattini, E.; Palmieri, F. Fuel Influence on Single-Piston Common Rail Pump Performance. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Trzaska, J.; Hernández, J.J.; Boehman, A.L. The effect of 1-octanol blending on the multi-stage autoignition of conventional diesel and HVO fuels. Fuel 2023, 354, 129386. [Google Scholar] [CrossRef]

- Preuß, J.; Munch, K.; Denbratt, I. Performance and emissions of renewable blends with OME3-5 and HVO in heavy duty and light duty compression ignition engines. Fuel 2021, 303, 121275. [Google Scholar] [CrossRef]

- Chiavola, O.; Frattini, E.; Lancione, S.; Palmieri, F. Operation Cycle of Diesel CR Injection Pump via Pressure Measurement in Piston Working Chamber. Energies 2021, 14, 5385. [Google Scholar] [CrossRef]

- Hughes, I.; Hase, T. Measurements and Their Uncertainties: A Practical Guide to Modern Error Analysis; OUP: Oxford, UK, 2010. [Google Scholar]

- Manring, N.D. Measuring pump efficiency: Uncertainty considerations. J. Energy Resour. Technol. Trans. ASME 2005, 127, 280–284. [Google Scholar] [CrossRef]

- Bosch, R. Automotive Handbook, 10th ed.; Wiley: Hoboken, NJ, USA, 2019; p. 1750. [Google Scholar]

- Payri, R.; Salvador, F.J.; Gimeno, J.; Bracho, G. The effect of temperature and pressure on thermodynamic properties of diesel and biodiesel fuels. Fuel 2011, 90, 1172–1180. [Google Scholar] [CrossRef]

- Lapuerta, M.; Agudelo, J.R.; Prorok, M.; Boehman, A.L. Bulk modulus of compressibility of diesel/biodiesel/HVO blends. Energy Fuels 2012, 26, 1336–1343. [Google Scholar] [CrossRef]

- Kim, T.; Boehman, A.L. Experimental Measurement of the Isothermal Bulk Modulus of Compressibility and Speed of Sound of Conventional and Alternative Jet Fuels. Energy Fuels 2021, 35, 13813–13829. [Google Scholar] [CrossRef]

| Pump Specification | |

|---|---|

| Pump model | Robert Bosch GmBH (D), model CP4.1 |

| Layout | Single plunger, 2 strokes per shaft revolution |

| Nominal max pressure | 1800 bar |

| Typical speed range | 750–4200 rpm |

| Nominal pump displacement | 427.4 mm3/rev |

| Nominal flow rate range | 38–215 dm3 per hour |

| Dead volume | 100 mm3 |

| Piston diameter | 6.48 mm |

| Piston stroke | 6.48 mm |

| Flow Rate Measurement | |||

| Denomination | Sensor | Range (L/min) | Acquisition |

| VFM1 | VSE Volumentechnik, Neuenrade (D), model VSI 0.1 | 0.01–10 | National Instruments, Austin (TX, USA), model PXIe 6341 |

| VFM2 | |||

| Pressure Measurement | |||

| Denomination | Sensor | Range (bar) | Conditioning |

| PT1 | Kistler, Winterthur (CH), model 4067 | 0–3000 | Kistler, Winterthur (CH), model 4618 |

| PT2 | Kistler, Winterthur (CH), model 4005 | 0–5 | Kistler, Winterthur (CH), model 4618 |

| PT3 | AEP Transducers, Modena, (IT), model TP16 | 0–20 | National Instruments, Austin (TX, USA), model 4330 PXIe |

| PT4 | Kistler, Winterthur (CH), model 4067 | 0–2000 | Kistler, Winterthur (CH), model 4618 |

| Injection pump drive system | |||

| Component | Description | ||

| Electric drive | Asynchronous motor and frequency converter | ||

| Encoder | Quadrature encoder | 1800 pp/rev | |

| DAQ System | |||

| Component | Description and specification | ||

| DAQ chassis | National Instruments, Austin (TX, USA), model PXIe 1088 | ||

| Strain/bridge module | National Instruments, Austin (TX, USA), model PXIe 4330, 8 channel, 24 bit, Strain/bridge input module | ||

| IO module | National Instruments, Austin (TX, USA), model PXIe 6341, multi-channel Analog–Digital Input, Counter-500 kS/s | ||

| Specifications at 40 °C | ||||

|---|---|---|---|---|

| Fluid ID | Commercial Name | Viscosity | Density | Regulation Compliance |

| (mm2/s) | (kg/m3) | |||

| Diesel | “Diesel+” by ENI | 2.0 | 820 | EN 590 |

| WCO | “WCO” by DP Lubrificanti | 4.1 | 843 | EN 14214 |

| HVO 1 | “MY Ren. Diesel” by NESTE | 3.0 | 780 | EN 15490 |

| HVO 2 | “HVOLUTION” by ENI | 3.1 | 770 | EN 15490 |

| Pump Speed | |||

| 3000 RPM | 1500 RPM | ||

| Rail Pressure | |||

| Low Pressure (L) | Medium Pressure (M) | High Pressure (H) | |

| 750 bar | 1200 bar | 1500 bar | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiavola, O.; Palmieri, F.; Verdoliva, F. Characteristics of High-Pressure Injection Pump Operated with Renewable Fuel for Diesel Engines. Energies 2024, 17, 1656. https://doi.org/10.3390/en17071656

Chiavola O, Palmieri F, Verdoliva F. Characteristics of High-Pressure Injection Pump Operated with Renewable Fuel for Diesel Engines. Energies. 2024; 17(7):1656. https://doi.org/10.3390/en17071656

Chicago/Turabian StyleChiavola, Ornella, Fulvio Palmieri, and Francesco Verdoliva. 2024. "Characteristics of High-Pressure Injection Pump Operated with Renewable Fuel for Diesel Engines" Energies 17, no. 7: 1656. https://doi.org/10.3390/en17071656

APA StyleChiavola, O., Palmieri, F., & Verdoliva, F. (2024). Characteristics of High-Pressure Injection Pump Operated with Renewable Fuel for Diesel Engines. Energies, 17(7), 1656. https://doi.org/10.3390/en17071656