Influence of Plastic Strain on Heat Capacity of L485ME Pipe Steel Grade

Abstract

1. Introduction

2. Materials and Methods

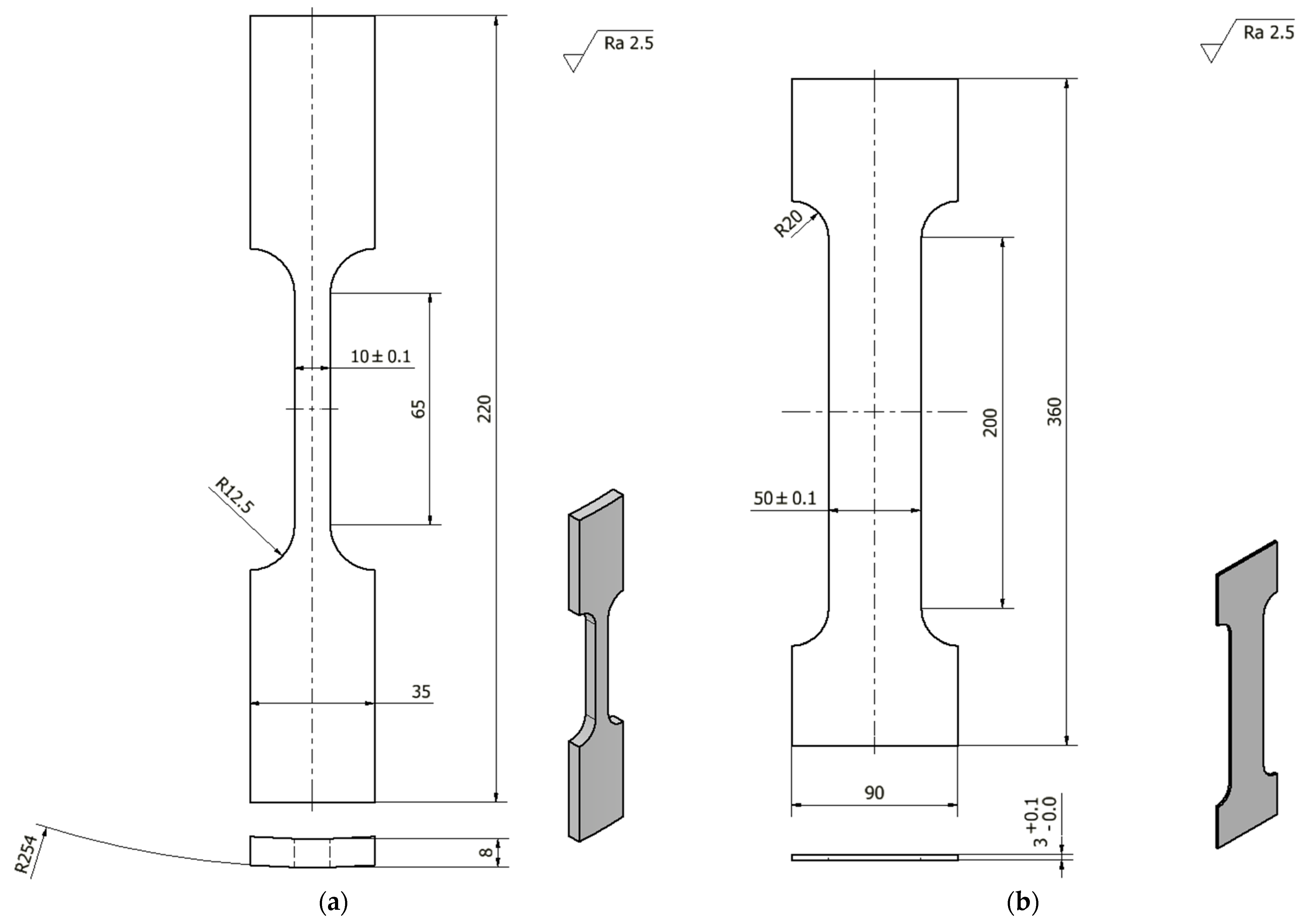

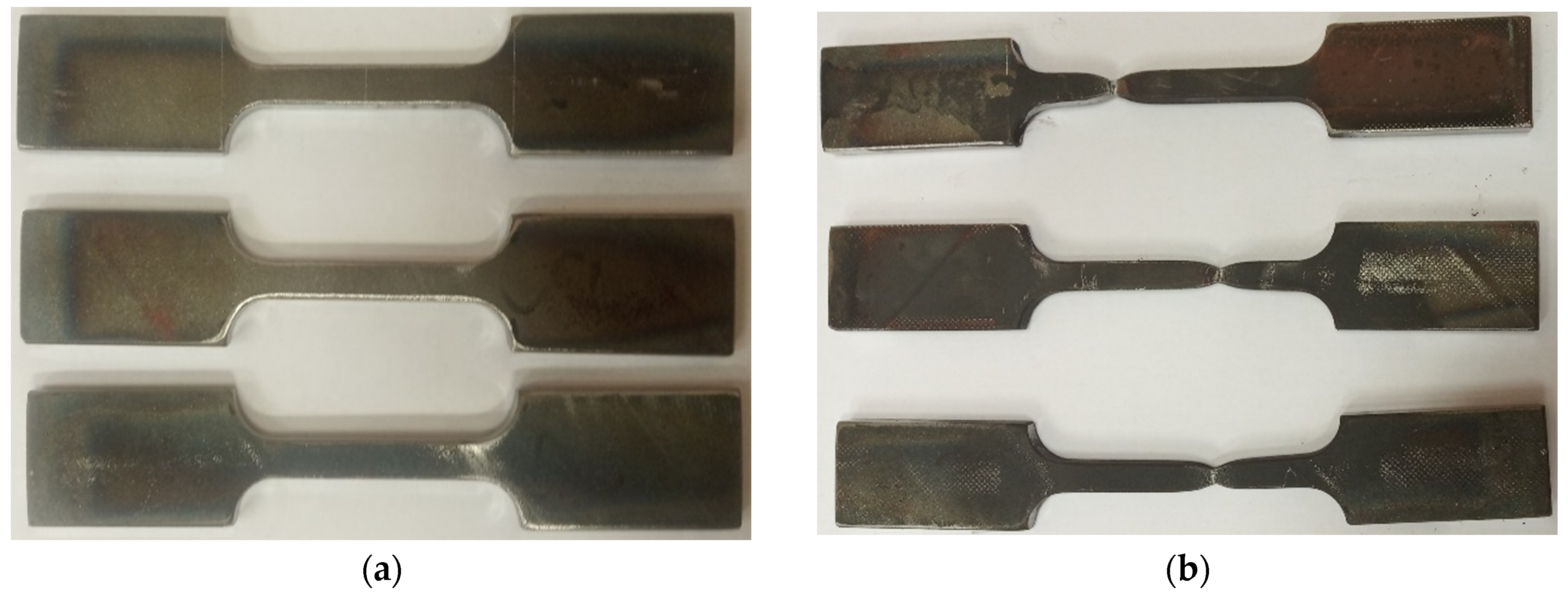

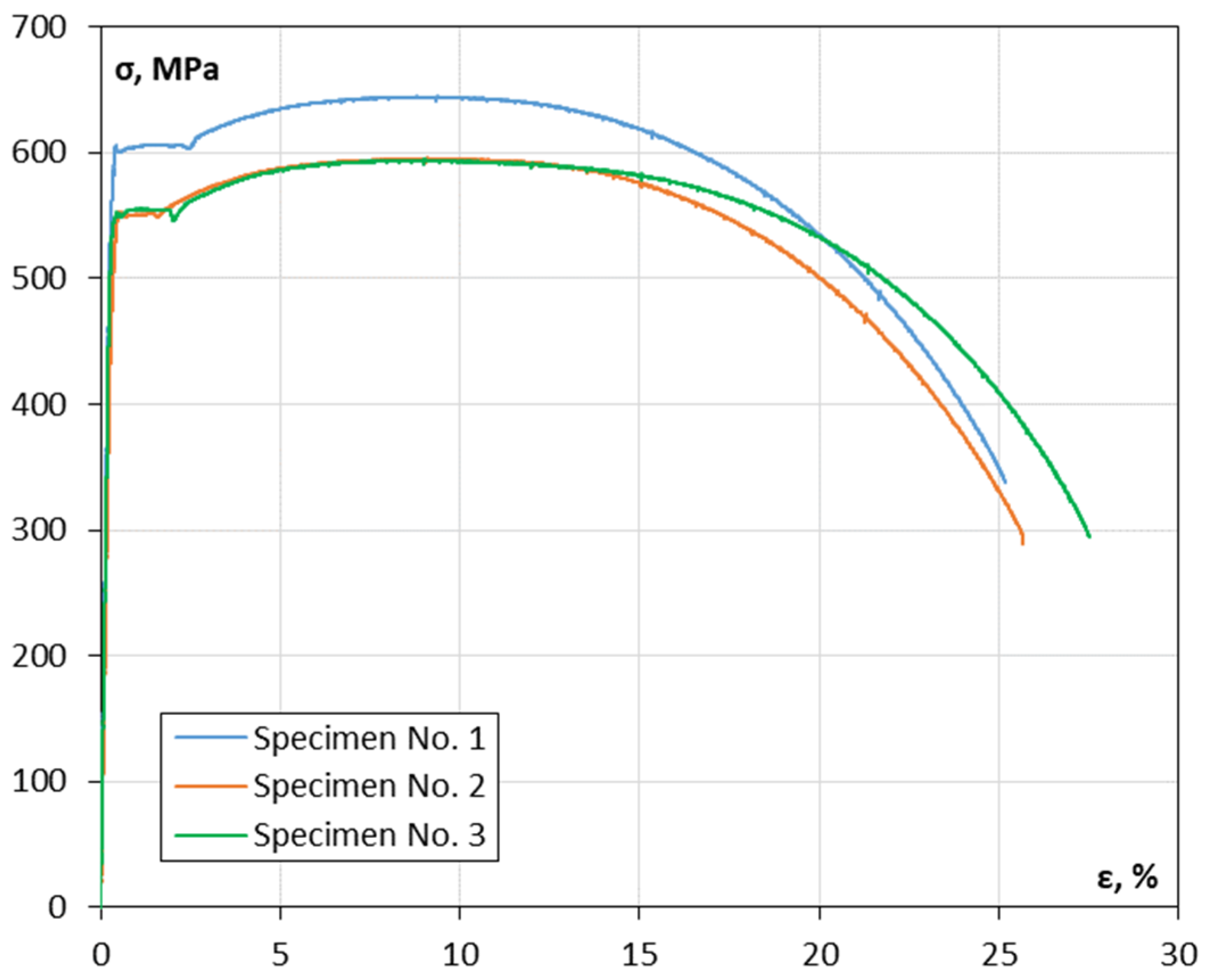

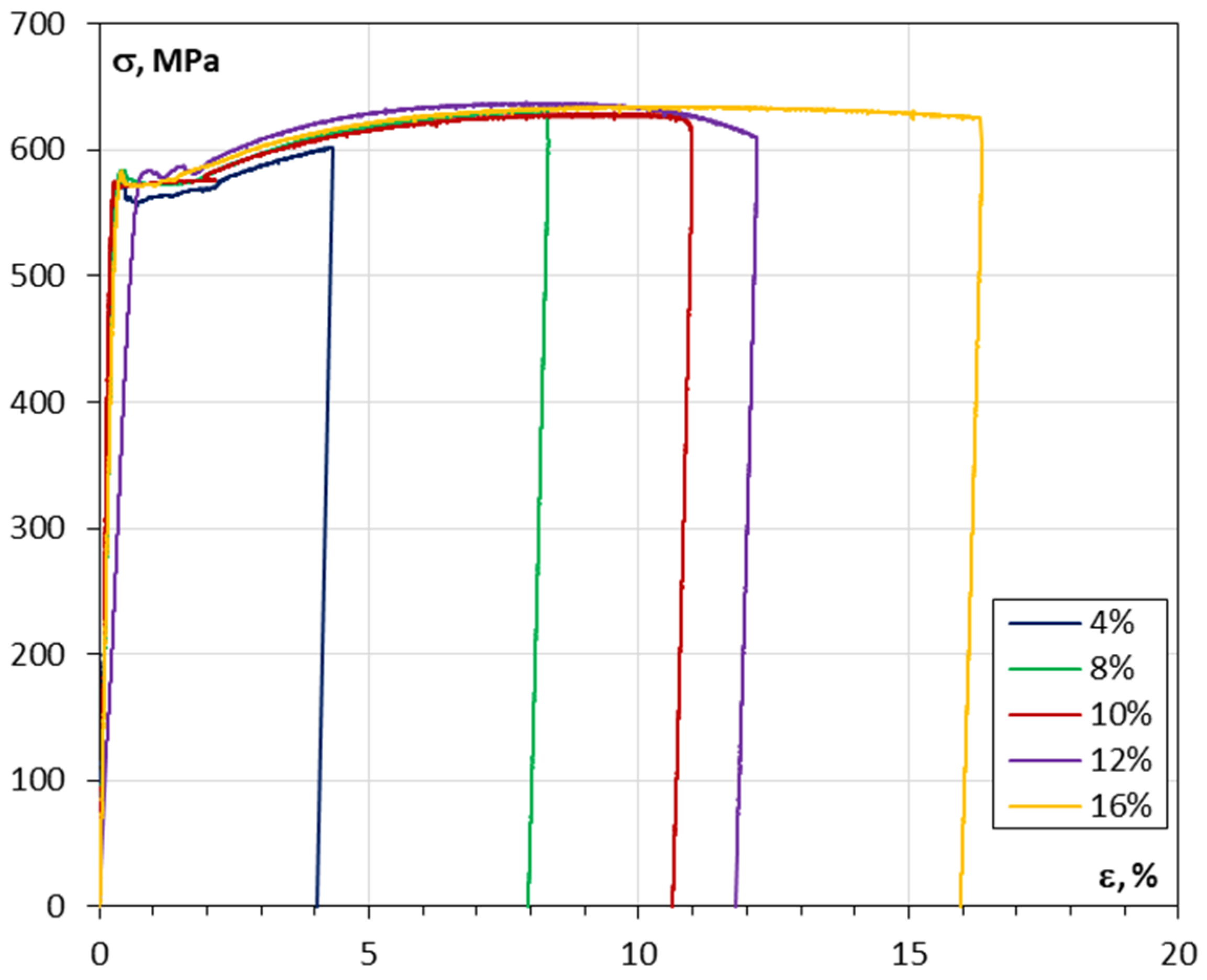

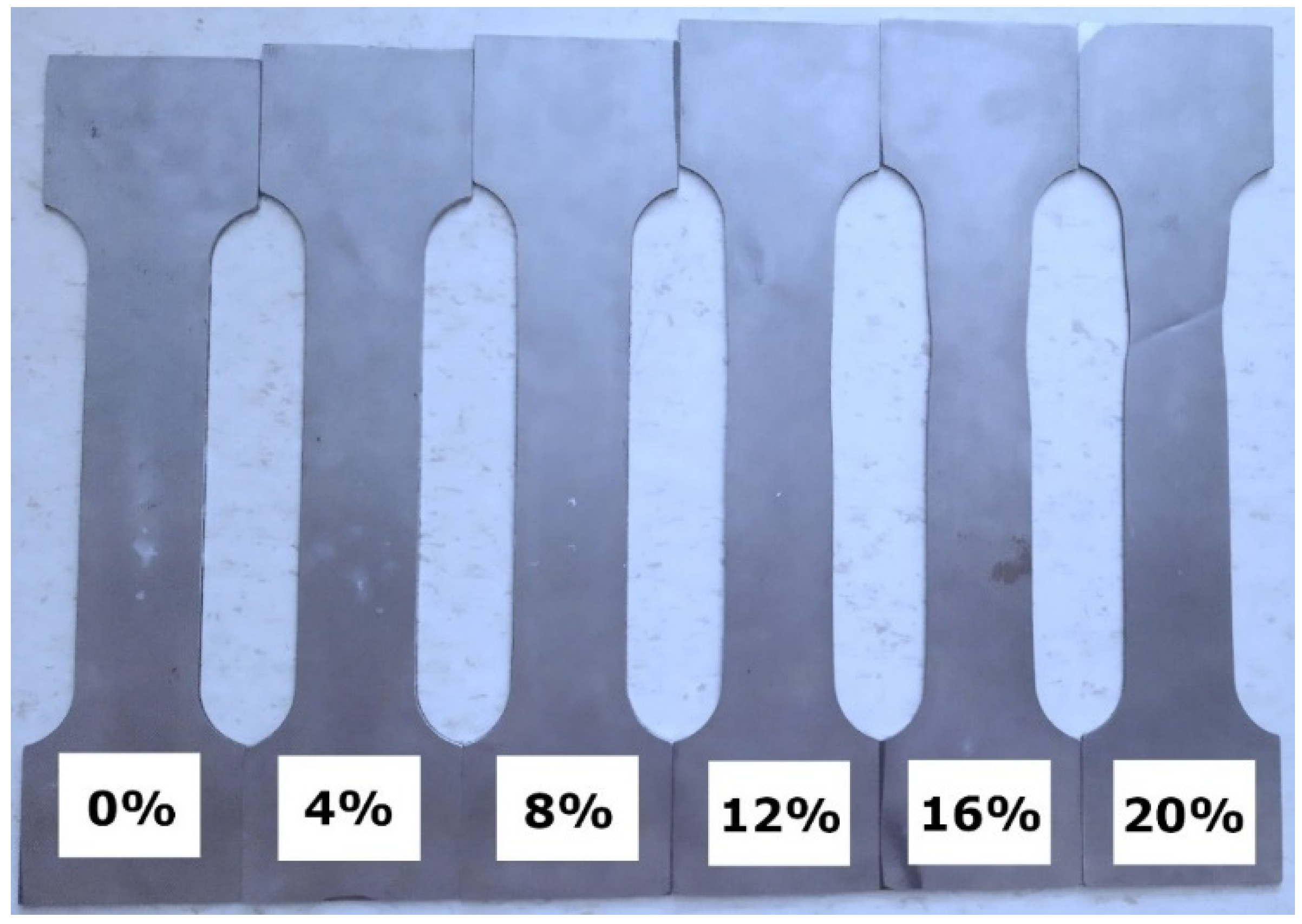

2.1. Mechanical Tests of Thermo-Mechanically Rolled Tubes

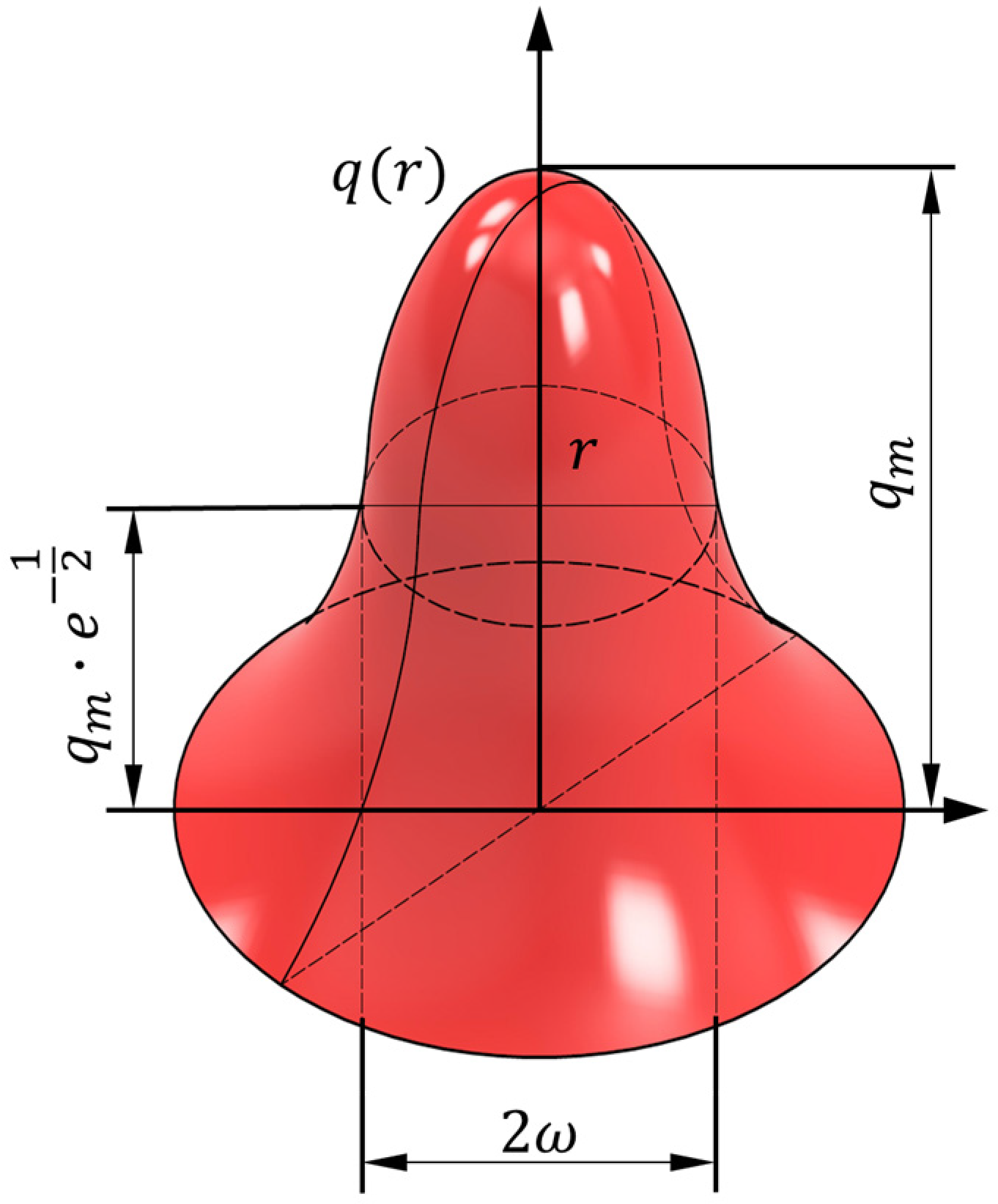

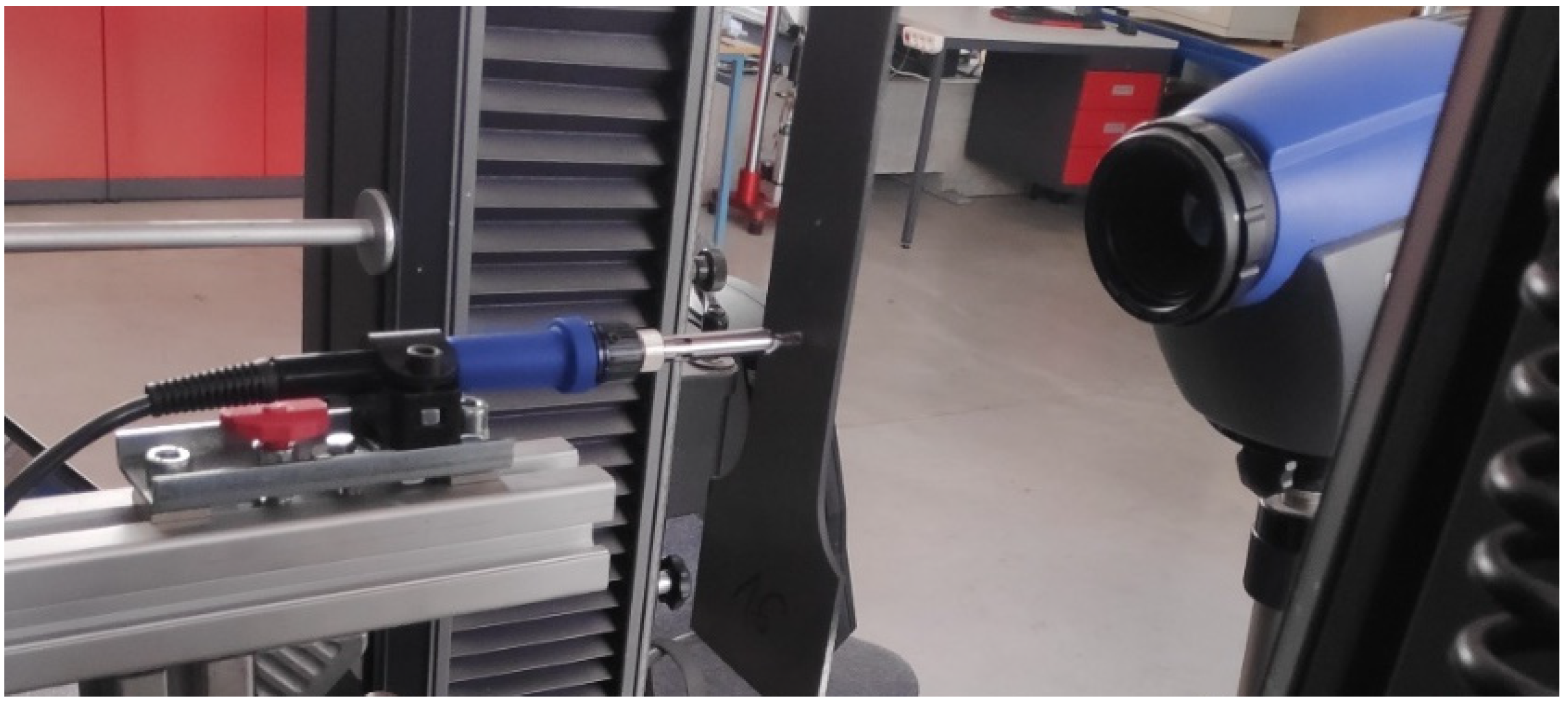

2.2. Heat Source Description

- q(r)

- is the heat flux capacity at radius r, W;

- qm

- is the maximum value of heat flux capacity at the center of the heat source, W;

- ω

- is the concentration coefficient, the distance at which the heat flux capacity decreases by factor e−1/2, m.

- t

- is the time, s;

- α

- is the thermal diffusivity coefficient, m2/s:

- λ

- is the thermal conductivity coefficient of the material, W/(m·K);

- l

- is the specimen thickness, m;

- cp

- is the specific heat capacity, J/(kg·K);

- ρ

- is the density of steel, kg/m3.

3. Results

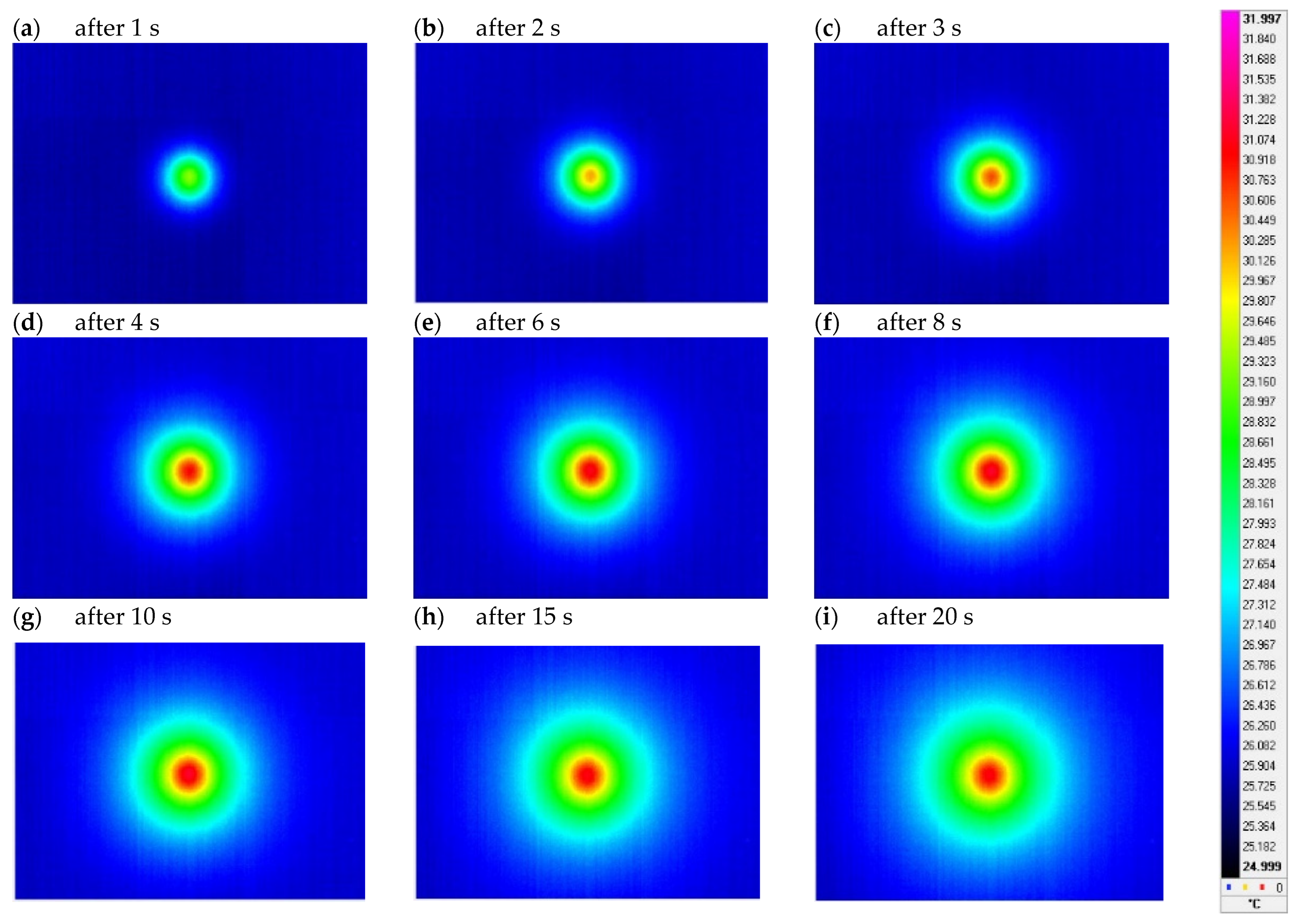

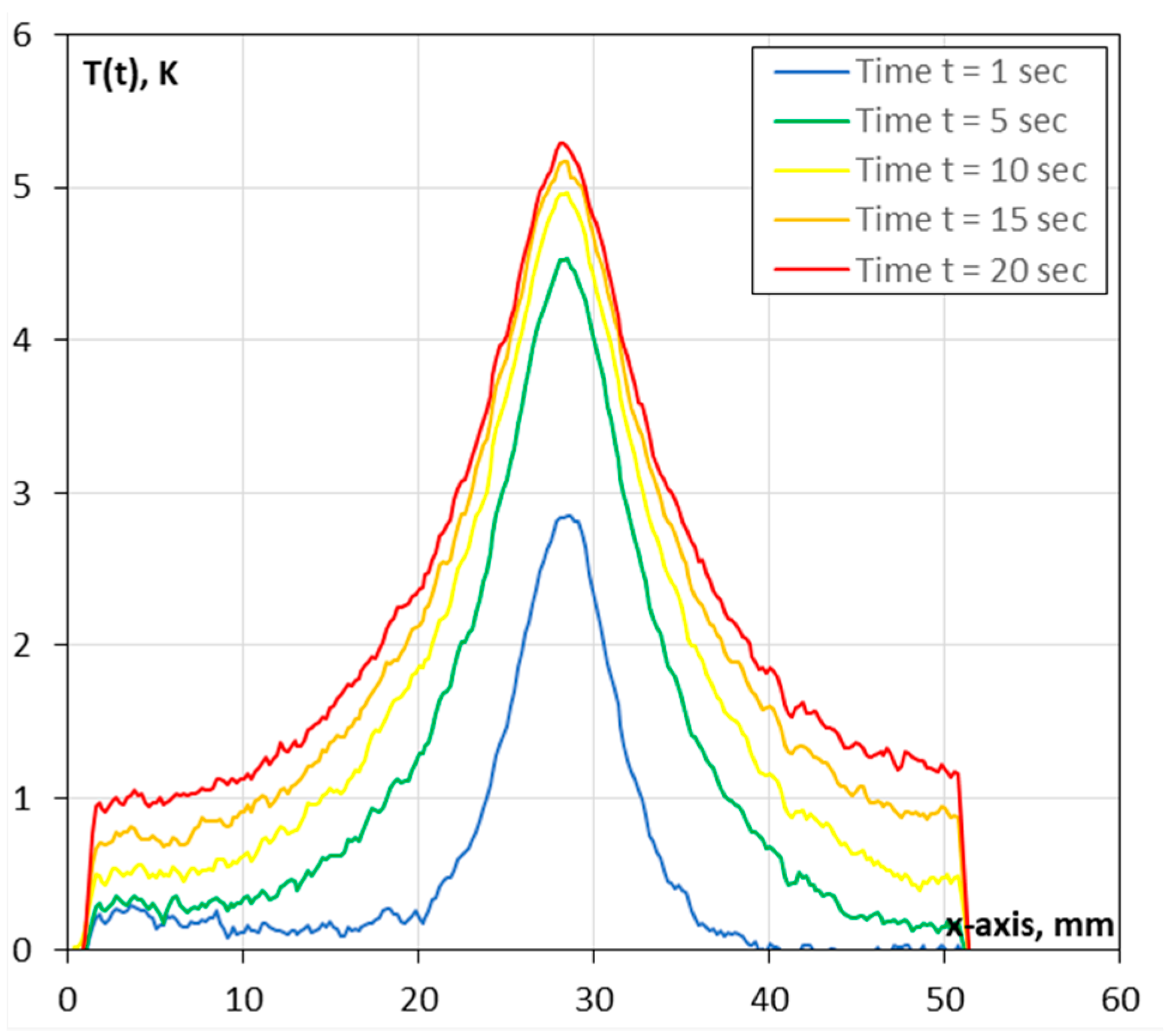

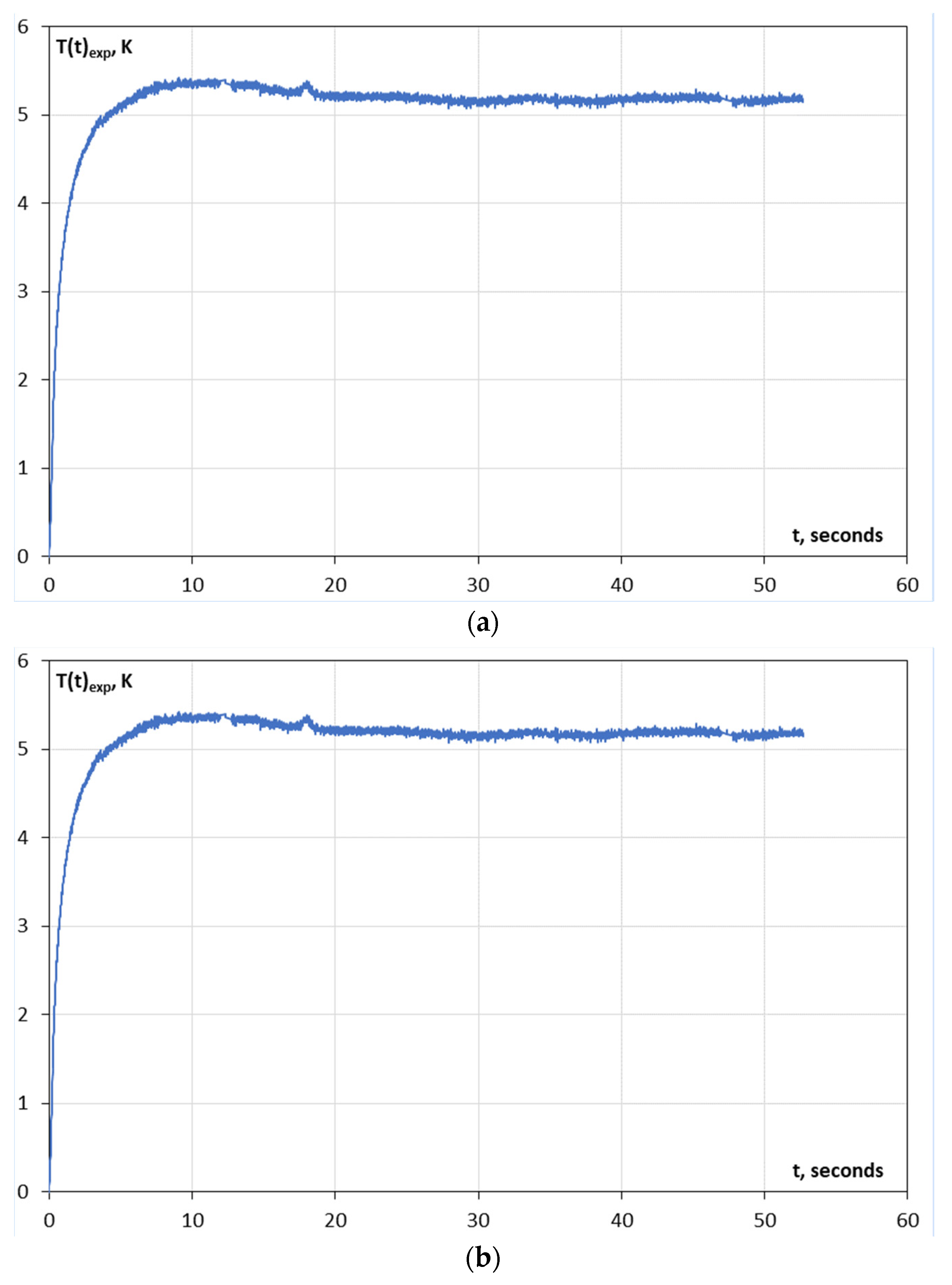

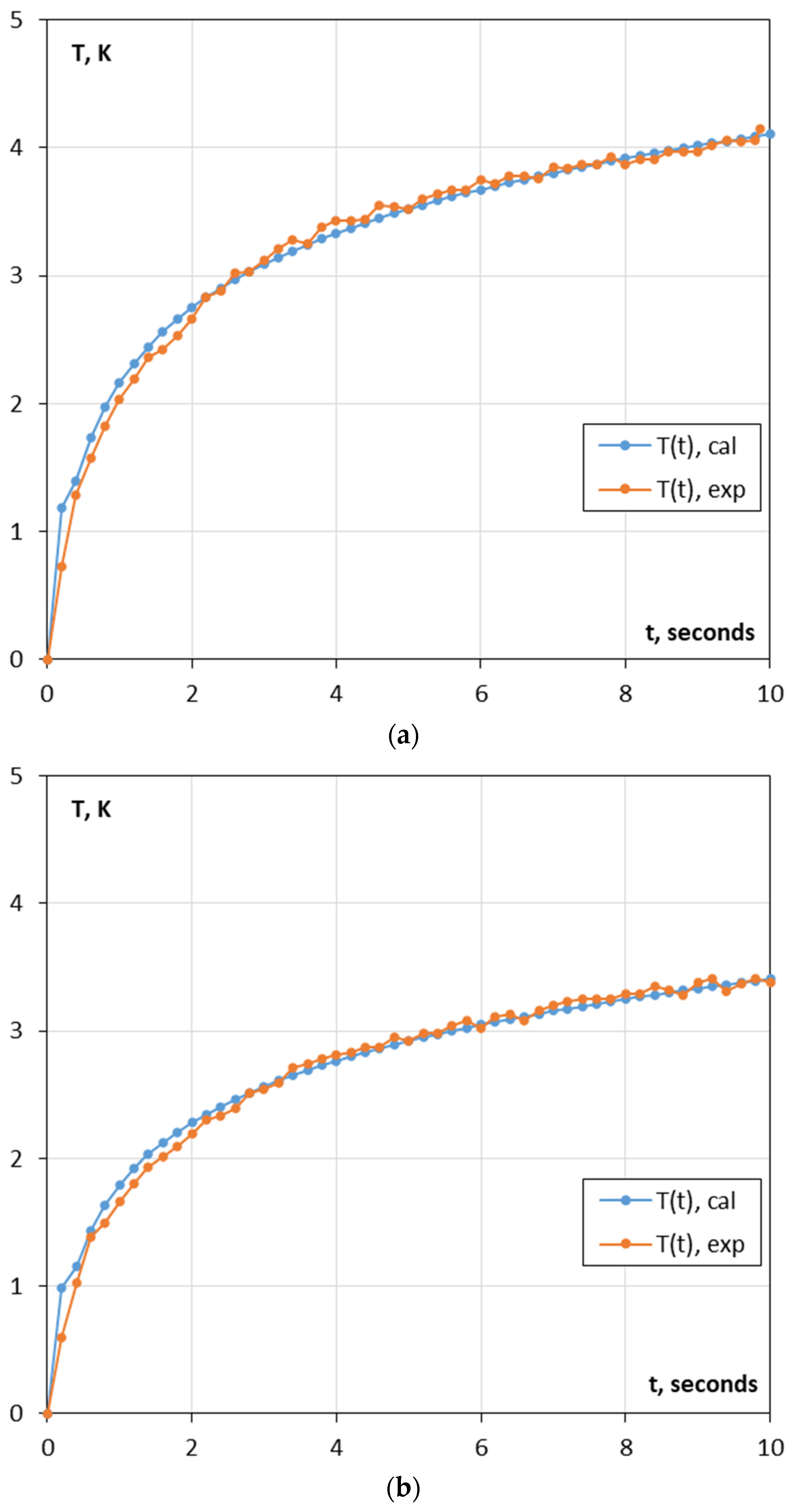

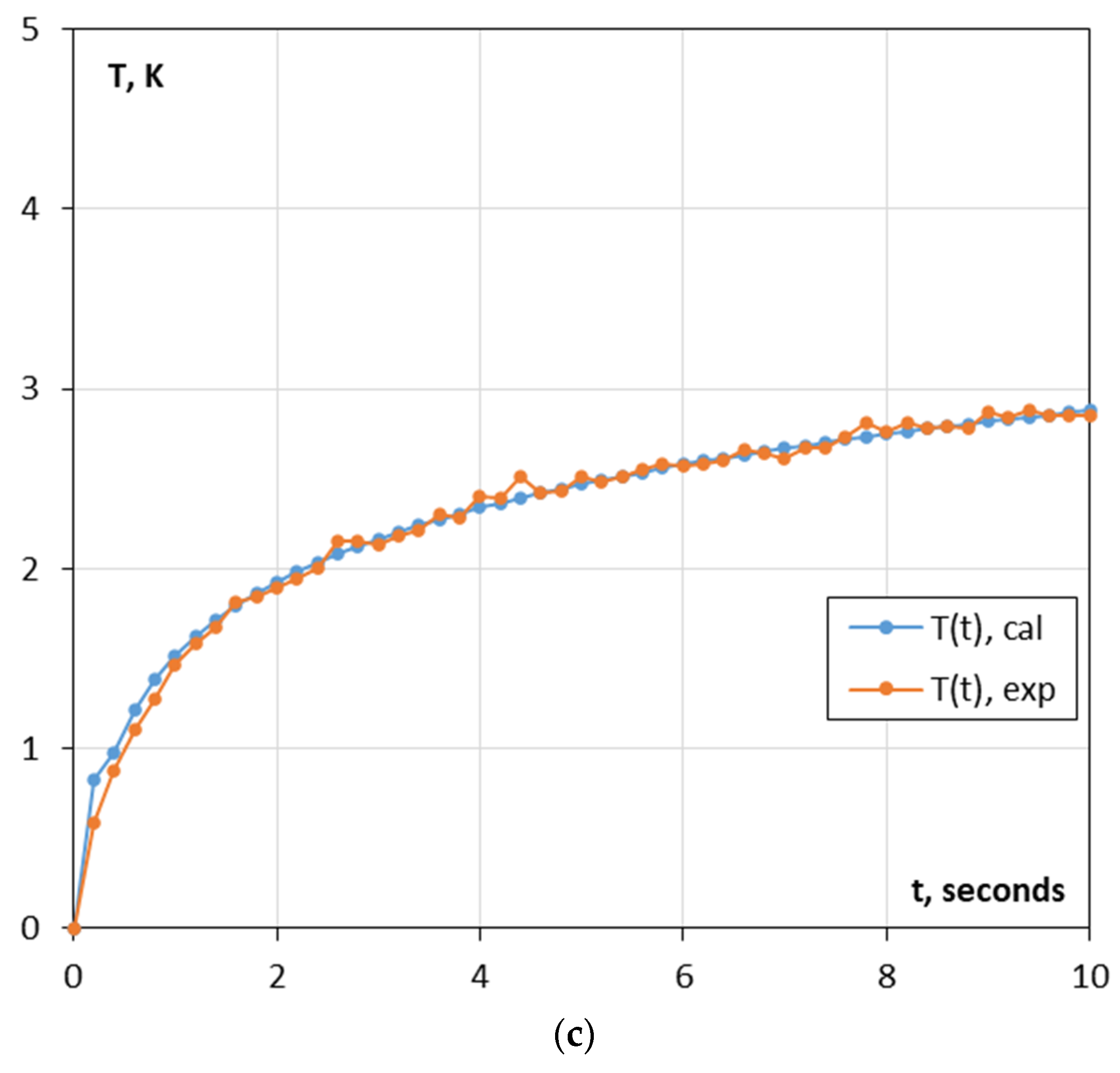

3.1. Thermo-Graphical Identification of Heat Flux Parameters

- −

- sheet thickness: l = 4.04 mm;

- −

- thermal conductivity coefficient of steel: λ = 42.2 W/(m·K);

- −

- specific heat capacity: cp = 461 J/(kg·K);

- −

- steel density: ρ = 7830 kg/m3.

- −

- resolution: 320 × 256 pixels;

- −

- pixel size: 25 μm;

- −

- spectral range: 3.6 ÷ 5.0 μm;

- −

- sensitivity: below 20 mK (8 mK achievable);

- −

- recording frequency for full resolution with digital image transfer up to 140 Hz (up to 25 kHz in 64 × 8 pixel resolution);

- −

- programmable integration time in the range from 10 μs to 10 ms.

- −

- heat flux capacity q = 0.87 W,

- −

- concentration coefficient ω = 7.74 × 10−4 m.

| Q, W | ω, m | |

|---|---|---|

| Point 1 | 0.86 | 7.74 × 10−4 |

| Point 2 | 0.88 | 7.74 × 10−4 |

3.2. Thermophysical Parameters of L485ME Steel Grade

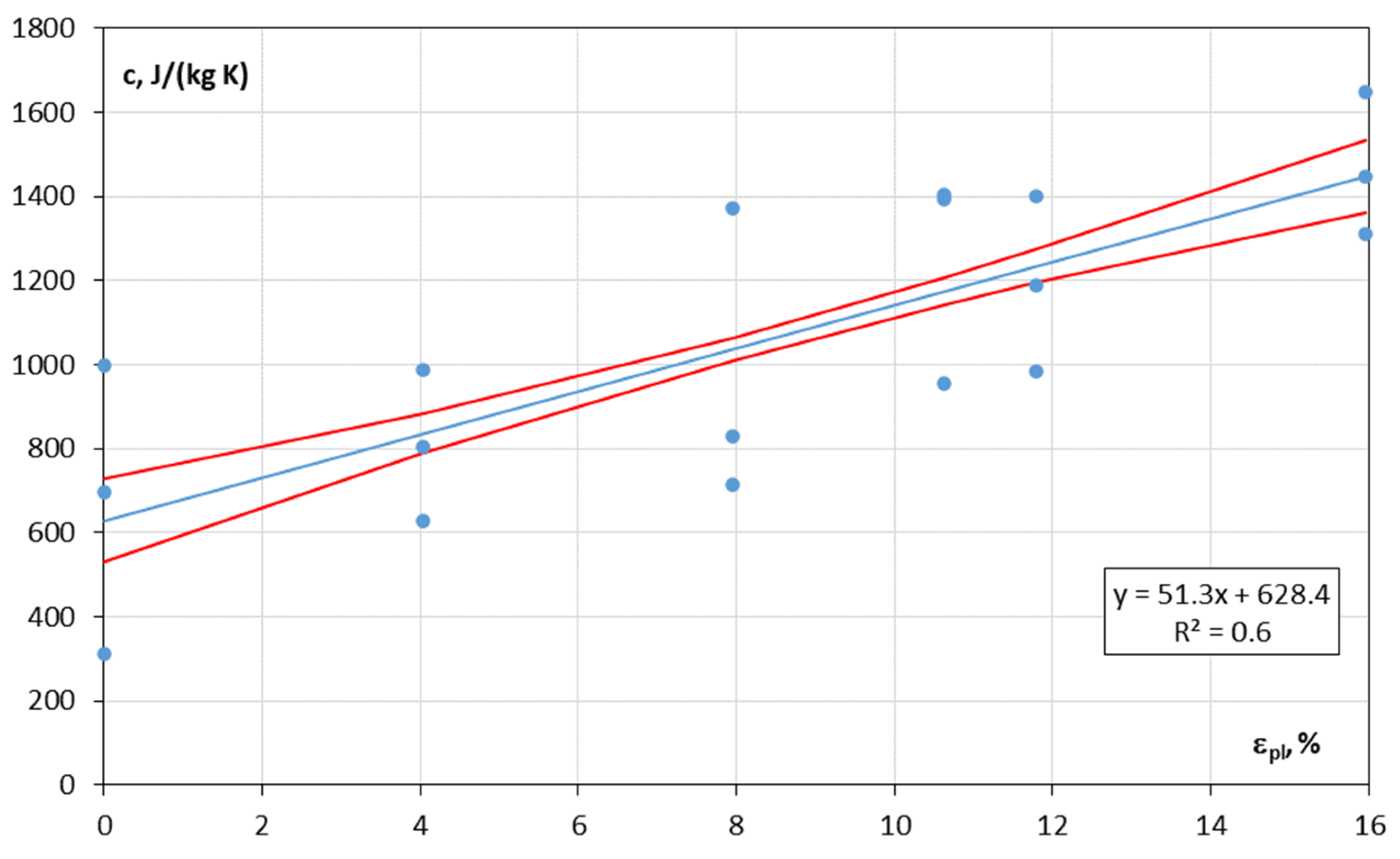

4. Heat Capacity as a Function of Strain for Thermo-Mechanically Rolled Steel

5. Conclusions

- ▪

- At the initial stages of sample plastic deformation, the heat capacity of thermo-mechanically rolled pipe steel remains almost independent of strain and later, with increasing elongation during tensile tests, the value of cp begins to rise. In the case of the studied pipe steel, the occurrence of sample narrowing in the perpendicular direction during the tensile test limits the plastic strain maximum values of εpl ≤ 16% for a reliable, in terms of accuracy, heat capacity determination.

- ▪

- Until the appearance of the sample necking during the tensile test, deformation of the steel sample is relatively homogenous. After reaching a local constriction of the sample, the heat capacity evaluation was disturbed due to unreliable determination of the local strain. The constrains in assessment of an influence of the heat capacity on the plastic deformation of steel after necking is primarily due to difficulties in measurement with the use of an extensometer. In the conducted tests, an extensometer indicates the average strain of the specimen over the gauge length. The appearance of necking locally causes the plastic strain to be greater than the one measured with an extensometer.

- ▪

- The presented methodology using infrared thermography is appropriate for determination of the specific heat capacity of metals. Regarding the fitting equations and rules obtained in the present paper, it can be mentioned that the obtained relationship is valid for the investigated steel grade. However, the general relations between plastic strain and specific heat capacity and trends can be valid at least for thermo-mechanically rolled steels such as L555ME or L450ME. The advantage of the proposed methodology is its applicability to the other metallic materials.

- ▪

- By implementing the proposed methodology, engineers can enhance their ability to detect and evaluate deformations in critical infrastructure components, thereby facilitating proactive maintenance strategies and ensuring the integrity and reliability of industrial structures. Moreover, a linear regression equation derived from our experimental results provides a practical tool for engineers to predict specific heat capacity changes corresponding to varying levels of plastic elongation in L485ME steel grade. Of course, this requires a much wider research program. At this stage, only the existence of a statistically significant correlation, which could become the basis for such a method, has been introduced.

- ▪

- Further investigations using other methods of the heat capacity evaluation of deformed steel are expected. Perhaps the use of field methods for measuring specimen strain would make it possible to determine local values of plastic strain and consider their larger values for the measurement.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Code Availability

Al Declaration

References

- Botvina, L.R.; Levin, V.P.; Tyutin, M.R.; Zharkova, N.A. Heat Capacity of Deformed Steels. Dokl. Phys. 2010, 55, 494–497. [Google Scholar] [CrossRef]

- Zhelnin, M.; Iziumova, A.; Vshivkov, A.; Plekhov, O. Experimental study of an effect of plastic deformation on thermal properties of stainless steel. Quant. InfraRed Thermogr. J. 2018, 16, 74–86. [Google Scholar] [CrossRef]

- Tao, N.; Li, L.X.; Sun, J.G. Simultaneous measurement of thermal conductivity and heat capacity by flash thermal imaging methods. Rev. Sci. Instrum. 2017, 88, 064903. [Google Scholar] [CrossRef] [PubMed]

- Ślęzak, T.; Zmywaczyk, J.; Koniorczyk, P.; Śnieżek, L. DSC Investigations of the Phase Transition in the High Strength Steel S960QL. Adv. Mater. Res. 2015, 1126, 148–154. [Google Scholar] [CrossRef]

- Moyseychik, E.A.; Vavilov, V.P.; Kuimova, M.V. Infrared thermographic assessment of heat release phenomena in steel parts subjected to quasi-static deformation. Measurement 2021, 185, 110117. [Google Scholar] [CrossRef]

- Haneef, T.; Lahiri, B.B.; Bagavathiappan, S.; Mukhopadhyay, C.K.; Philip, J.; Rao, B.P.C.; Jayakumar, T. Study of the tensile behavior of AISI type 316 stainless steel using acoustic emission and infrared thermography techniques. J. Mater. Res. Technol. 2015, 4, 241–253. [Google Scholar] [CrossRef]

- Risitano, G.; Santonocito, D. Experimental and numerical assessment of the end of the thermoelastic effect during static traction test. Procedia Struct. Integr. 2020, 28, 1449–1457. [Google Scholar] [CrossRef]

- Huang, L.; Peng, L.; Mi, X.; Zhao, G.; Huang, G.; Xie, H.; Zhang, W. Effect of Cold Working on the Properties and Microstructure of Cu-3.5 wt% Ti Alloy. Materials 2022, 15, 8042. [Google Scholar] [CrossRef] [PubMed]

- Bhowmick, S.; Shenoy, V.B. Effect of deformation on the thermal conductivity of solids. J Chem Phys. 2006, 125, 164513. [Google Scholar] [CrossRef] [PubMed]

- Kourov, N.I.; Korolev, A.V.; Pushin, V.G. Effect of plastic deformation by torsion on the heat capacity of the Ni50.5Ti49.5 alloy. Phys. Solid State 2012, 54, 883–885. [Google Scholar] [CrossRef]

- Lipski, A. Change of Specimen Temperature during the Monotonic Tensile Test and Correlation between the Yield Strength and Thermoelasto-Plastic Limit Stress on the Example of Aluminum Alloys. Materials 2021, 14, 13. [Google Scholar] [CrossRef] [PubMed]

- Lipski, A. Accelerated Determination of Fatigue Limit and S-N Curve by Means of Thermographic Method for X5CrNi18-10 Steel. Acta Mech. Autom. 2016, 10, 22–27. [Google Scholar] [CrossRef]

- Skibicki, D.; Lipski, A.; Pejkowski, Ł. Evaluation of plastic strain work and multiaxial fatigue life in CuZn37 alloy by means of thermography method and energy-based approaches of Ellyin and Garud. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2541–2556. [Google Scholar] [CrossRef]

- Lee, H.W.; Basaran, C.; Egner, H.; Lipski, A.; Piotrowski, M.; Mroziński, S.; Noushad Bin Jamal, M.; Rao, C.L. Modeling ultrasonic vibration fatigue with unified mechanics theory. Int. J. Solids Struct. 2022, 236–237, 111313. [Google Scholar] [CrossRef]

- EN-ISO 3183:2019; Petroleum and Natural Gas Industries—Steel Pipe for Pipeline Transportation System. Technical Committee: ISO/TC 67/SC 2; BSI Standards Limited: London, UK, 2019.

- API Spec 5L, 46th ed.; American Petroleum Institute: Washington, DC, USA, 2018.

- Witek, M. Possibilities of using X80, X100, X120 high strength steels for onshore gas transmission pipelines. J. Nat. Gas Sci. Eng. 2015, 27, 374–384. [Google Scholar] [CrossRef]

- ASTM A370-23; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2013.

- PN-EN-ISO 6892-1:2019E; Metallic Materials—Tensile Testing—Part 1: Method of Tests at Room Temperatures. Technical Committee: ISO/TC 164/SC 1. BSI Standards Limited: London, UK, 2019.

- Zhelnin, M.; Iziumova, A.; Plekhov, O. Determining the thermal constant of metals by infrared thermography. AIP Conf. Proc. 2016, 1785, 040095. [Google Scholar] [CrossRef]

- Eagar, T.W.; Tsai, N.S. Temperature fields produced by traveling distributed heat sources. Weld. Res. Suppl. 1983, 62, 346–355. [Google Scholar]

- Zaiontz, C. Real Statistics Using Excel. 2023. Available online: www.real-statistics.com (accessed on 1 February 2024).

- Abdelghani, M.; Tewfik, G.; Witek, M.; Djahida, D. Factors of Stress Concentration around Spherical Cavity Embedded in Cylinder Subjected to Internal Pressure. Materials 2021, 14, 3057. [Google Scholar] [CrossRef] [PubMed]

| Specimen No. 1 | Specimen No. 2 | Specimen No. 3 | |

|---|---|---|---|

| Specimen section width, mm | 10.20 | 10.26 | 10.29 |

| Specimen section thickness, mm | 8.60 | 8.60 | 8.60 |

| Upper yield point ReH, MPa | 606.1 | 552.6 | 552.0 |

| Lower yield point ReL, MPa | 603.2 | 549.0 | 545.3 |

| Ultimate tensile strength Rm, MPa | 644.9 | 595.7 | 594.3 |

| Specimen Designation | Obtained Plastic Deformation | Specimen Section Initial Width | Specimen Section Initial Thickness |

|---|---|---|---|

| εpl, % | mm | mm | |

| Strain 4% | 4.04% | 50.26 | 3.02 |

| Strain 8% | 7.95% | 50.21 | 3.03 |

| Strain 10% | 10.63% | 50.16 | 3.02 |

| Strain 12% | 11.80% | 50.22 | 3.04 |

| Strain 16% | 15.96% | 50.19 | 3.04 |

| Plastic Strain | Sample Thickness | Density | Thermal Conductivity Coefficient | Thermal Diffusivity Coefficient | Specific Heat Capacity | |||

|---|---|---|---|---|---|---|---|---|

| εpl | l, mm | ρ, kg/m3 | λ, W/(m·K) | α × 10−6, m2/s | cp, J/(kg·K) | |||

| 0% | 3.04 | 8 066 | 47.1 | 59.5 | 18.7 | 12.7 | 312.6 | 668.4 |

| 54.5 | 9.7 | 695.1 | ||||||

| 77.0 | 9.6 | 997.5 | ||||||

| 4.04% | 3.00 | 7 943 | 60.7 | 72.9 | 9.5 | 11.9 | 804.0 | 806.3 |

| 83.6 | 16.8 | 627.7 | ||||||

| 74.3 | 9.5 | 987.3 | ||||||

| 7.95% | 2.99 | 7 823 | 113.7 | 76.2 | 10.6 | 9.9 | 1370.5 | 971.2 |

| 54.5 | 9.8 | 713.7 | ||||||

| 60.6 | 9.3 | 829.3 | ||||||

| 10.63% | 2.96 | 7 668 | 68.5 | 89.1 | 9.3 | 9.3 | 956.4 | 1251.2 |

| 99.1 | 9.3 | 1392.6 | ||||||

| 99.5 | 9.2 | 1404.5 | ||||||

| 11.80% | 2.92 | 7 635 | 68.2 | 82.5 | 9.1 | 9.1 | 983.3 | 1190.4 |

| 82.2 | 9.1 | 1188.7 | ||||||

| 97.2 | 9.1 | 1399.1 | ||||||

| 15.96% | 2.89 | 7 607 | 62.6 | 83.7 | 5.0 | 7.7 | 1648.2 | 1467.5 |

| 89.7 | 9.0 | 1308.7 | ||||||

| 98.9 | 9.0 | 1445.6 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lipski, A.; Witek, M.; Abdelghani, M.; Swacha, P. Influence of Plastic Strain on Heat Capacity of L485ME Pipe Steel Grade. Energies 2024, 17, 1554. https://doi.org/10.3390/en17071554

Lipski A, Witek M, Abdelghani M, Swacha P. Influence of Plastic Strain on Heat Capacity of L485ME Pipe Steel Grade. Energies. 2024; 17(7):1554. https://doi.org/10.3390/en17071554

Chicago/Turabian StyleLipski, Adam, Maciej Witek, Mechri Abdelghani, and Piotr Swacha. 2024. "Influence of Plastic Strain on Heat Capacity of L485ME Pipe Steel Grade" Energies 17, no. 7: 1554. https://doi.org/10.3390/en17071554

APA StyleLipski, A., Witek, M., Abdelghani, M., & Swacha, P. (2024). Influence of Plastic Strain on Heat Capacity of L485ME Pipe Steel Grade. Energies, 17(7), 1554. https://doi.org/10.3390/en17071554