Study on the Influence of the Application of Phase Change Material on Residential Energy Consumption in Cold Regions of China

Abstract

1. Introduction

1.1. Impact of Climate Change on Building Energy Consumption Demands

1.2. Applications of PCM in Construction

1.3. Other Applications of PCM

1.4. Applicability of PCM under Different Climate Conditions

1.5. Literature Gap and Research Object

- Currently, the majority of quantitative research focuses on the application of PCMs in tropical regions for construction purposes. According to ASHRAE Standard 169-2013, regions classified within the numerical range of 6 to 8 can be categorized as cold regions [49]. Table 1 illustrates that some studies have examined the use of PCMs in cold regions, such as Moscow in Russia, Billing in the USA, Kiruna in Sweden and Ottawa and Yellowknife in Canada. However, the effectiveness of PCM in severe cold and cold regions of China still has research potential and significance.

- In the past, cold regions of China were considered not to consume a significant amount of cooling energy. However, due to the impact of climate change, buildings in this region now face new challenges in terms of cooling energy demand. Limited research has addressed the application of PCMs in this climatic zone and its efficacy in reducing cooling energy consumption.

- In China, there are significant differences in outdoor weather conditions among different climatic zones. However, limited comparative research has been conducted on the efficacy of PCMs in reducing cooling energy consumption in residential buildings during summer across various climatic zones. It is necessary to further explore the applicability of PCMs under different climatic conditions in China from the perspective of energy-saving effects.

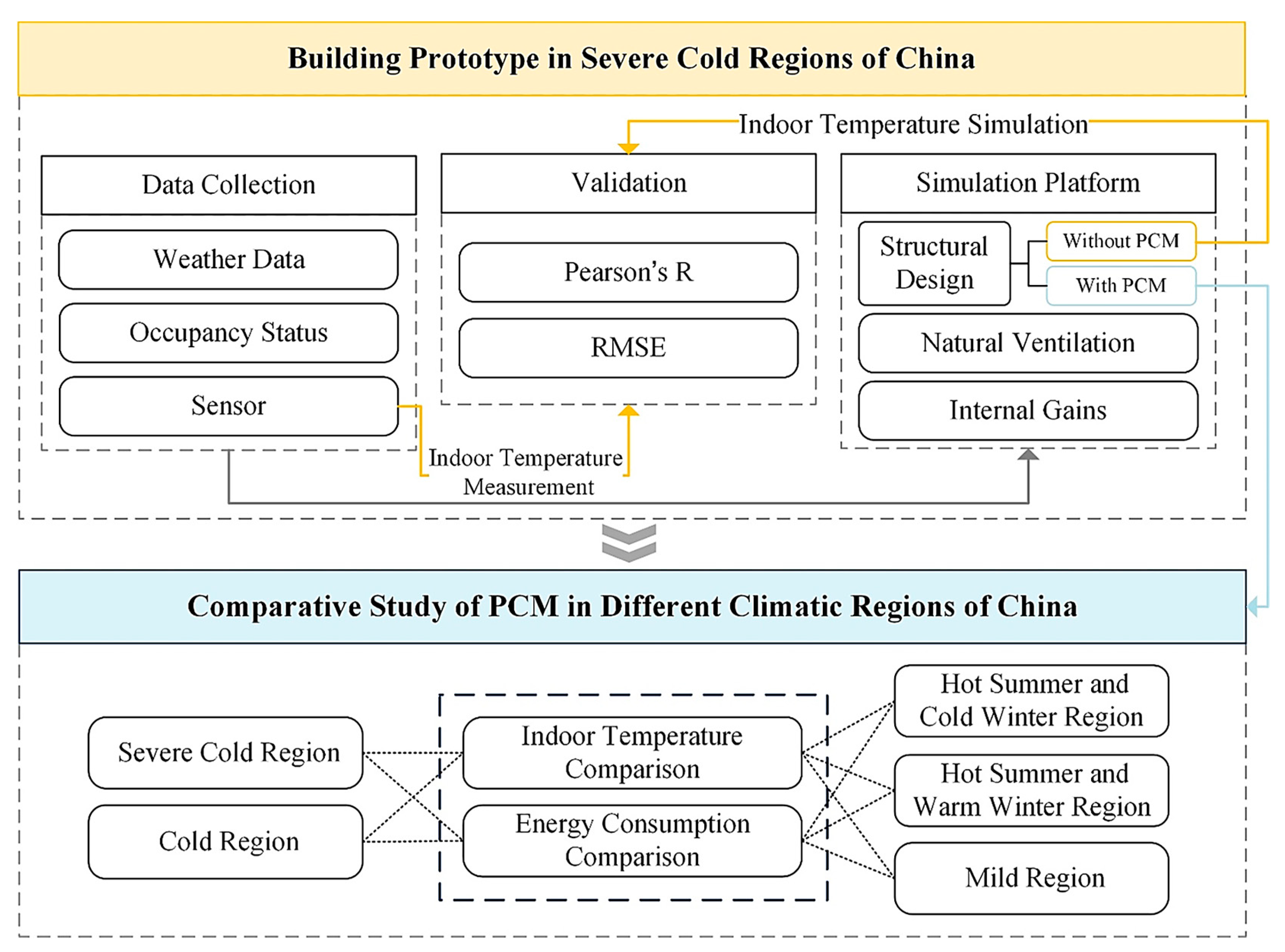

2. Methodology

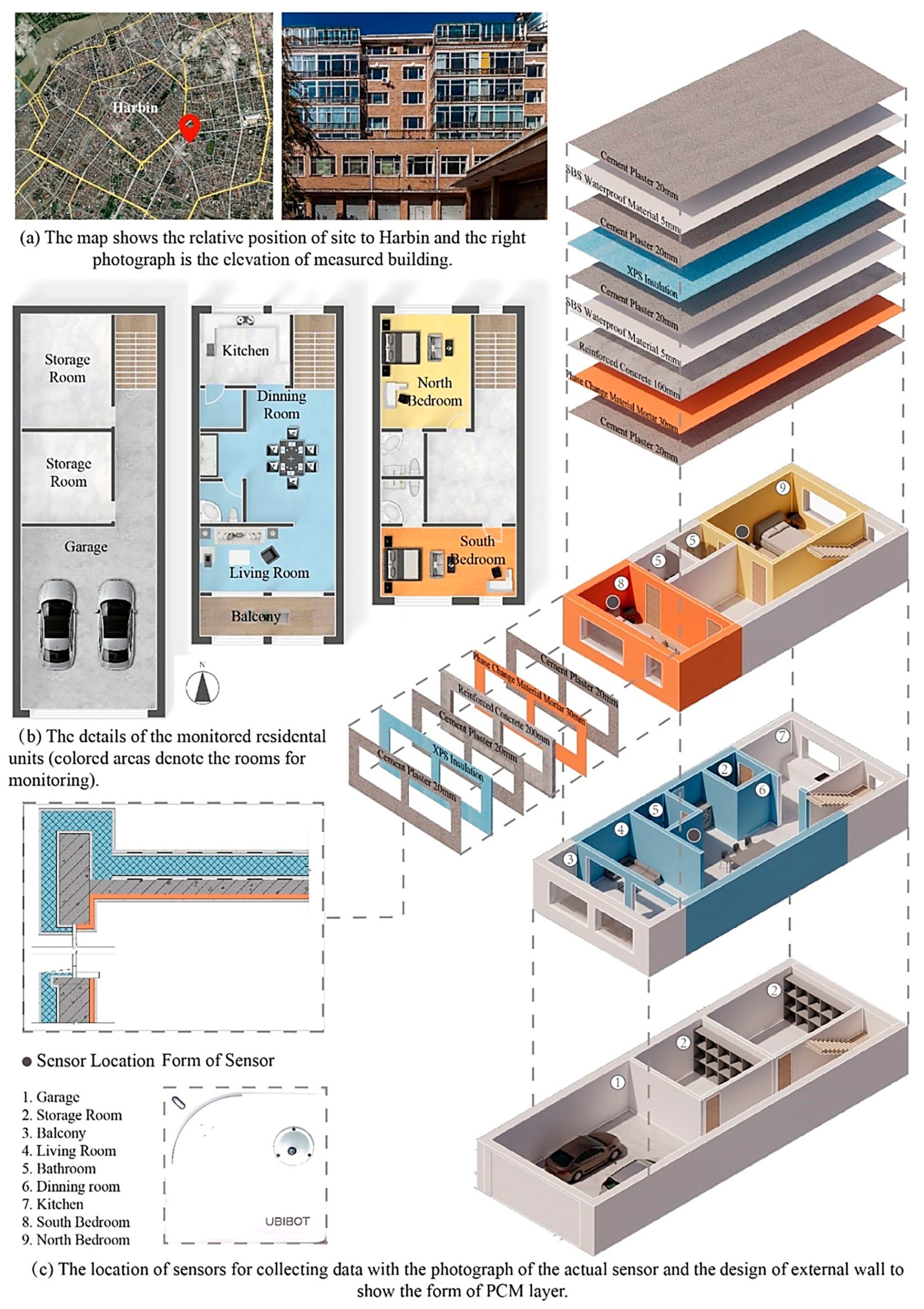

2.1. Building Description

2.2. Climate Zones and Representative Cities

2.3. Simulation and Validation

3. Results

3.1. Measurement and Validation

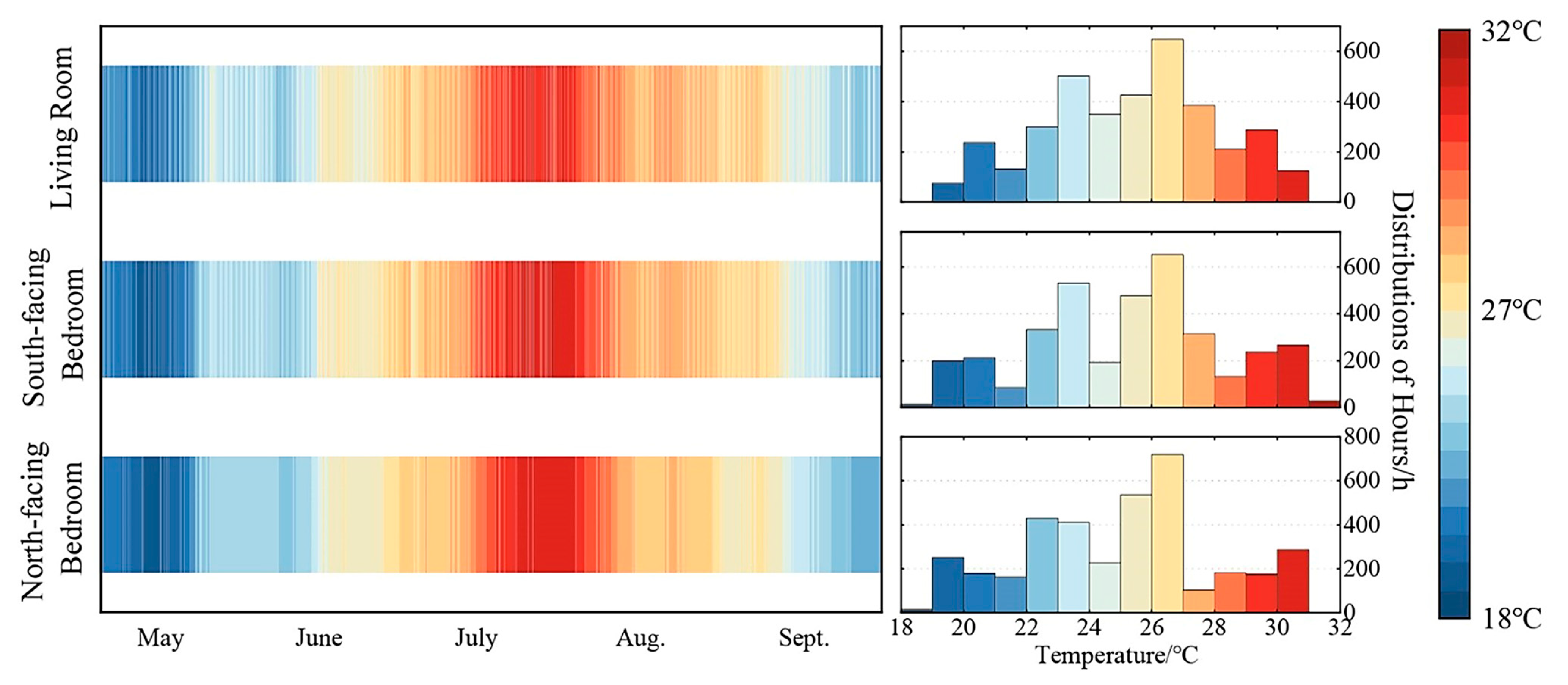

3.1.1. Indoor Temperature Measurement Results in the Severe Cold Region

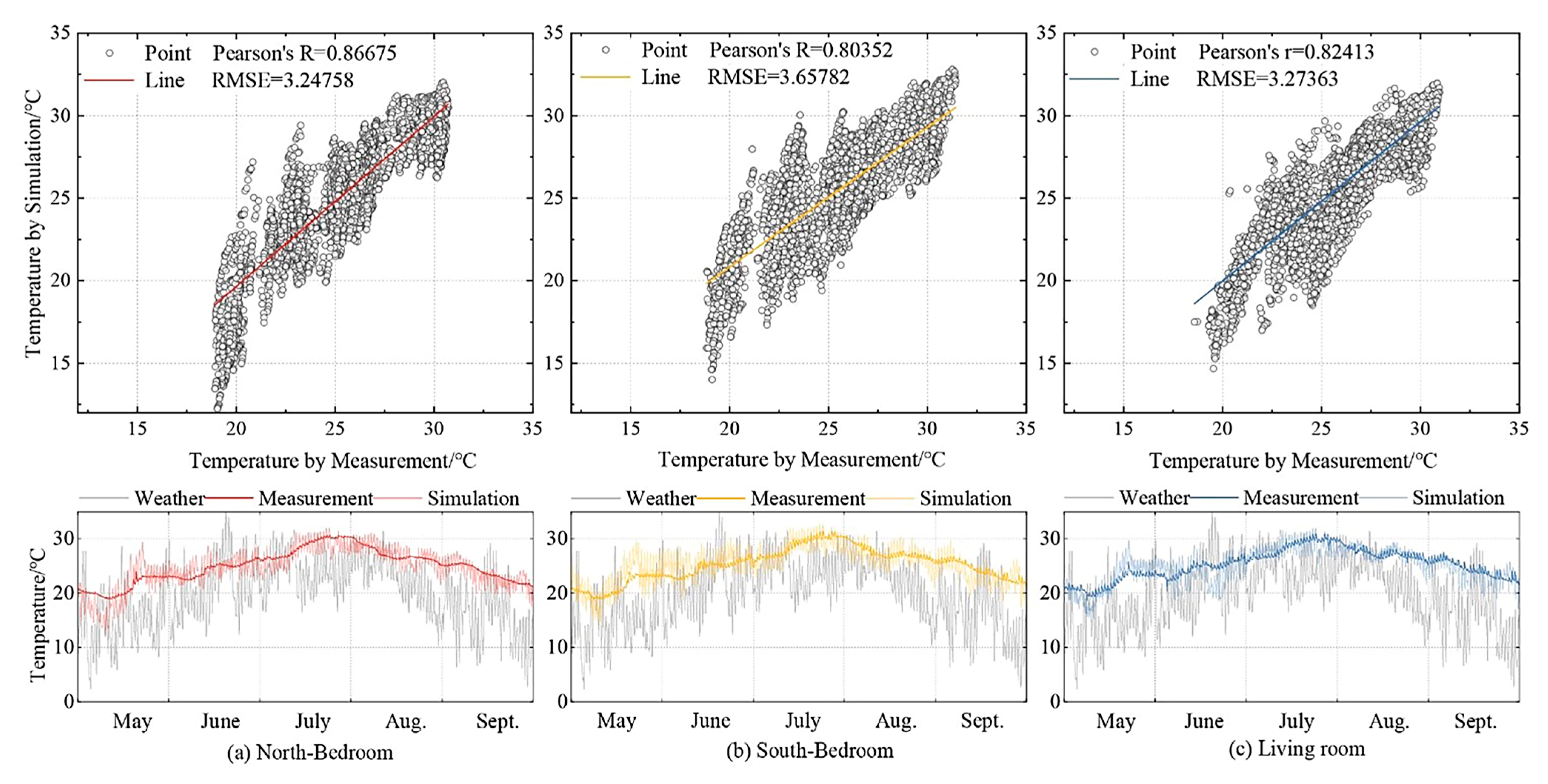

3.1.2. Validation Results

3.2. Simulation Results

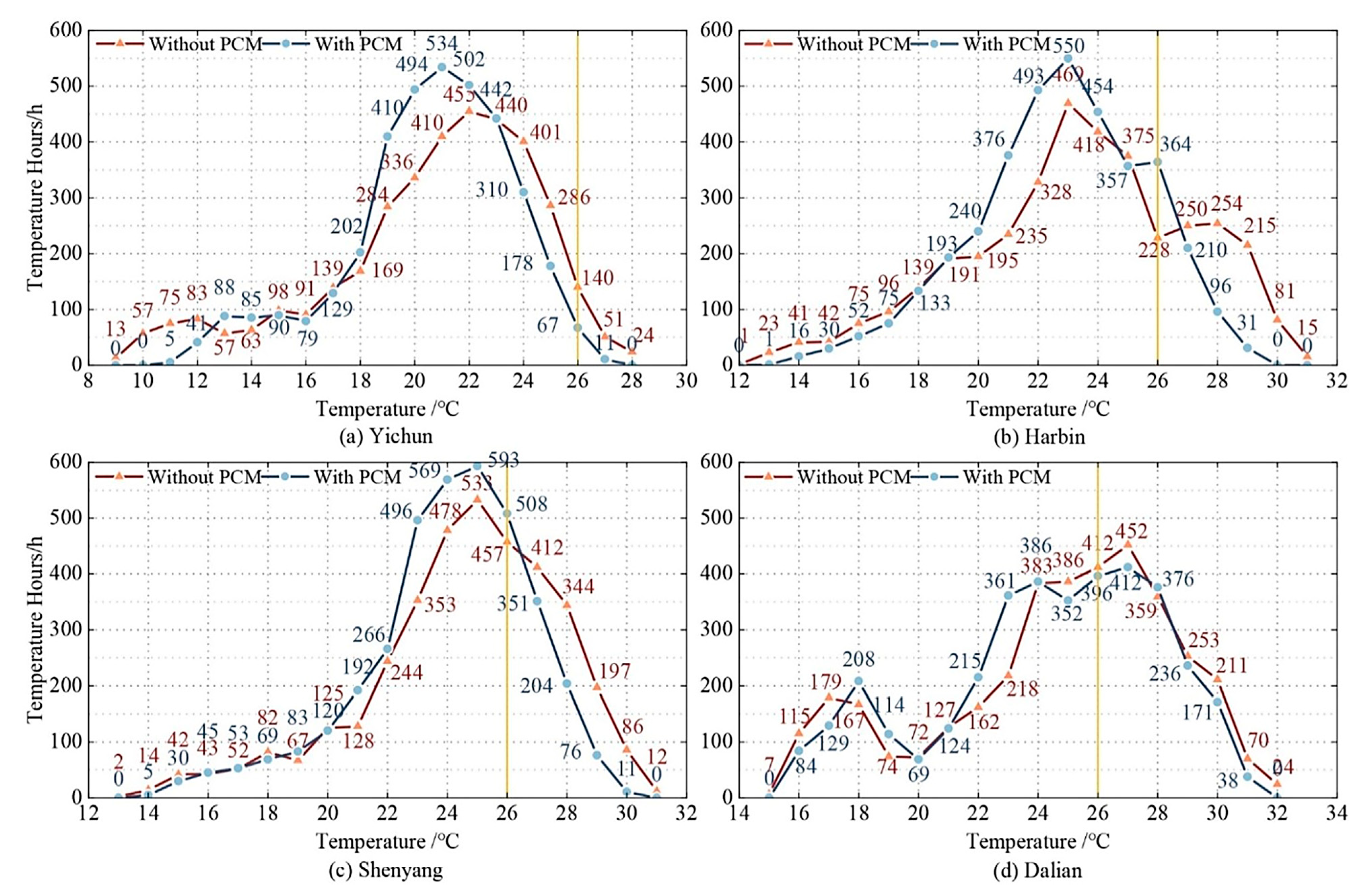

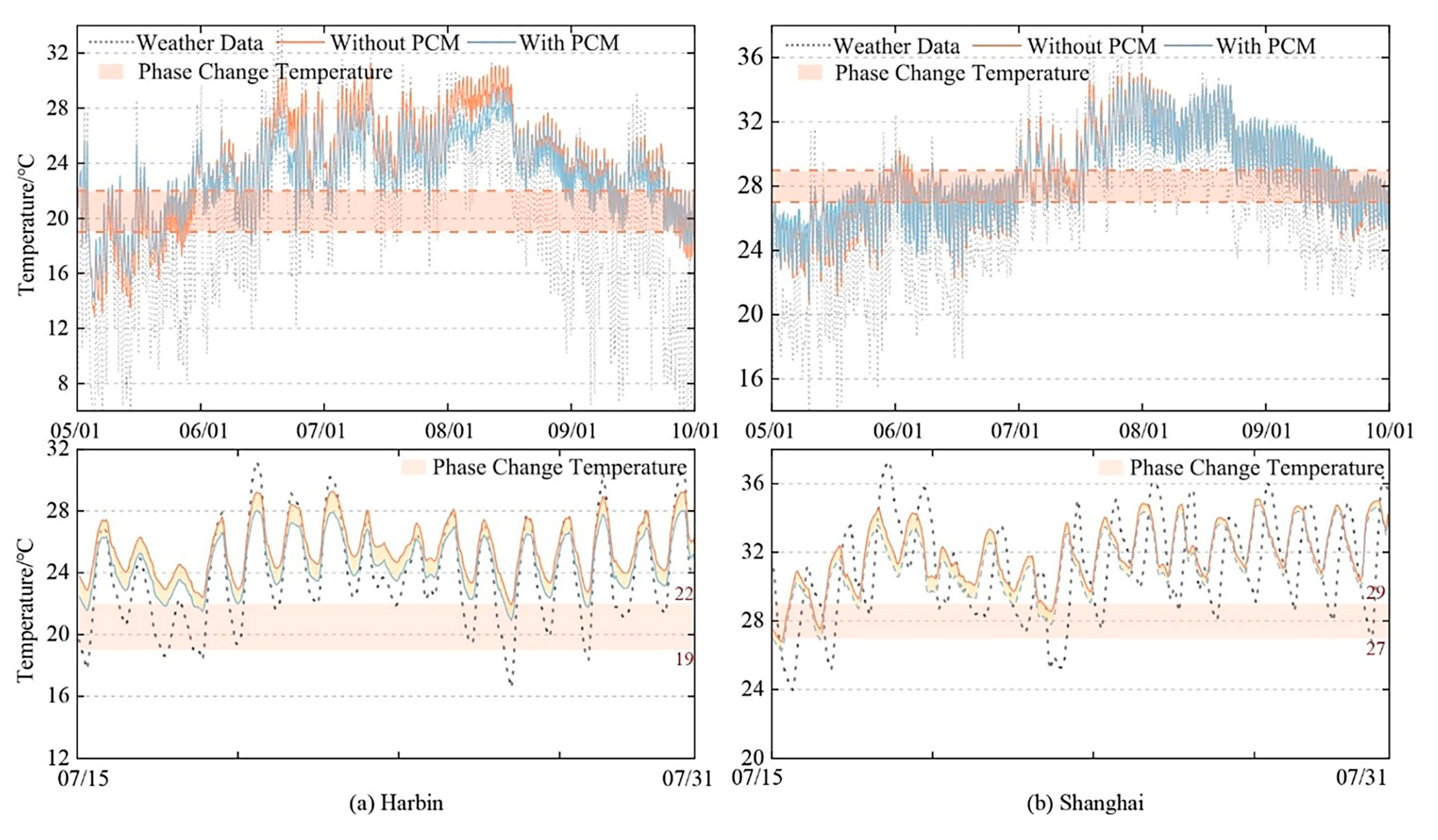

3.2.1. Effect of PCM on Indoor Temperature

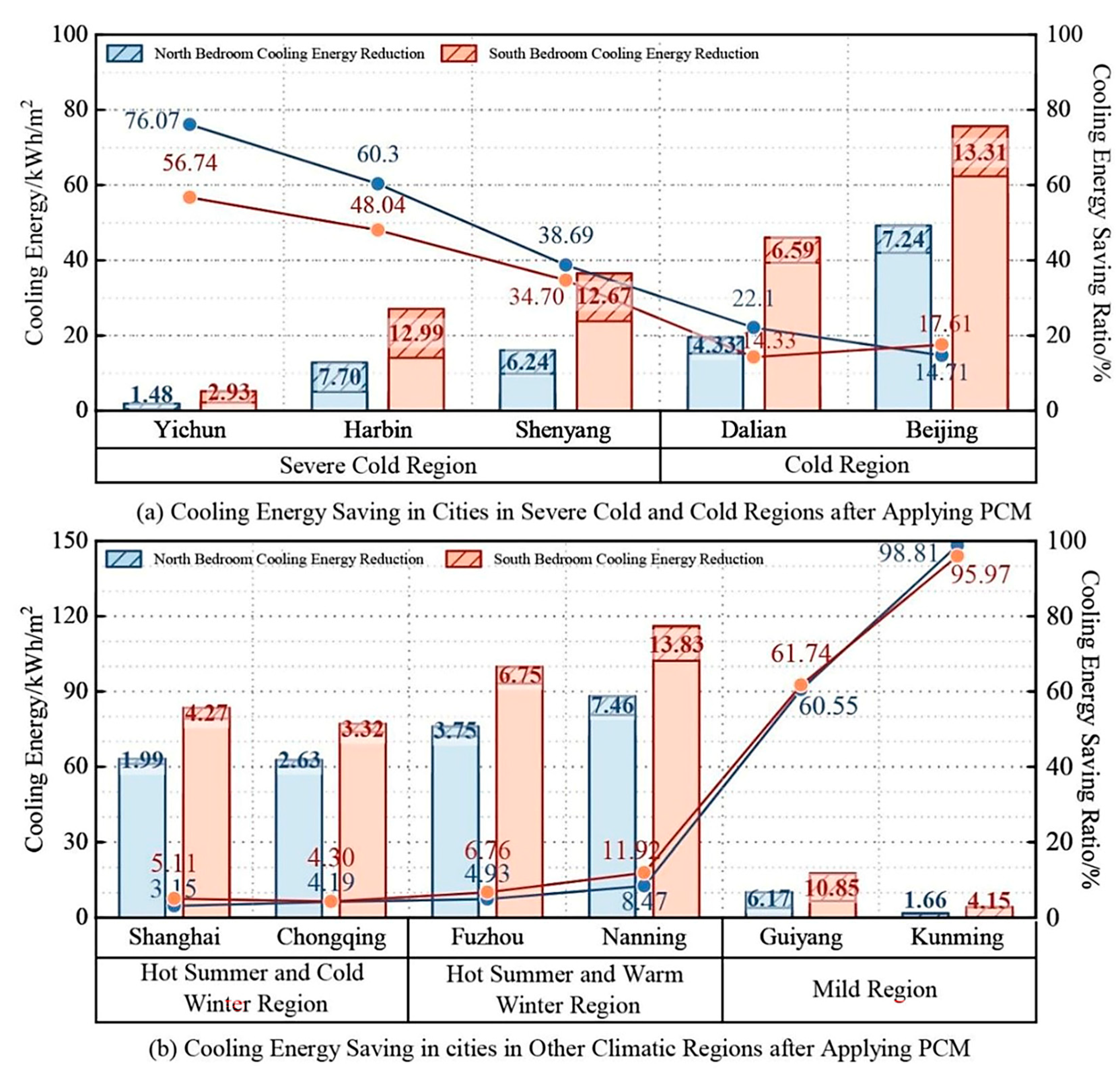

3.2.2. Effect of PCM on Cooling Energy Consumption

4. Discussion

4.1. Energy Saving Potential of PCM in the Severe Cold Region

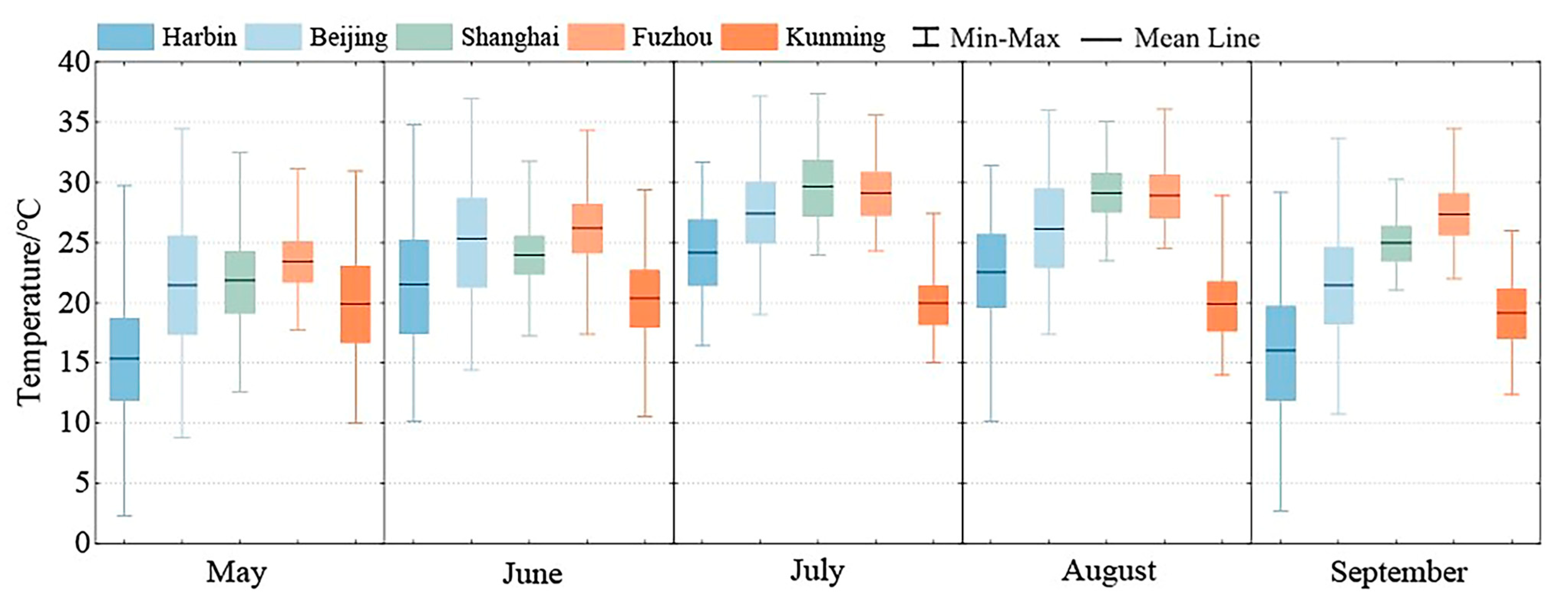

4.2. Effects of Climate Differences on the Applicability of PCM

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| City | Month | Period | Nature Ventilation | Infiltration |

|---|---|---|---|---|

| Yichun (IA) | 1 June−30 June | 7:00−9:00; 17:00−20:00 | 3 h−1 | 0.4 h−1 |

| 1 July−31 August | 0:00−24:00 | |||

| 1 September−31 May (next year) | 7:00−8:00; 17:00−18:00 | |||

| Harbin (IB) | 1 May−30 June | 7:00−9:00; 17:00−20:00 | 3 h−1 | 0.4 h−1 |

| 1 July−31 August | 0:00−24:00 | |||

| 1 September−30 September | 8:00−20:00 | |||

| 1 October−30 April | 7:00−8:00; 17:00−18:00 | |||

| Shenyang (IC) | 1 May−31 May | 7:00−9:00; 17:00−20:00 | 3 h−1 | 0.4 h−1 |

| 1 June−31 August | 0:00−24:00 | |||

| 1 September−30 September | 8:00−21:00 | |||

| 1 October−30 April | 7:00−8:00; 17:00−19:00 | |||

| Dalian (IIA) | 1 April−14 May | 7:00−9:00; 17:00−20:00 | 6 h−1 | 0.4 h−1 |

| 15 May−15 September | 0:00−24:00 | |||

| 16 September−30 September | 8:00−21:00 | |||

| 1 October−31 March | 7:00−8:00; 17:00−19:00 | |||

| Beijing (IIB) | 16 March−15 May | 7:00−9:00; 17:00−20:00 | 6 h−1 | 0.4 h−1 |

| 16 May−1 October | 0:00−24:00 | |||

| 2 October−15 March | 7:00−8:00; 17:00−19:00 | |||

| Shanghai (IIIA) | 1 May−30 June | 0:00−7:00; 17:00−20:00 | 6 h−1 | 0.4 h−1 |

| 1 July−30 September | 0:00−24:00 | |||

| 1 October−30 November | 0:00−7:00; 17:00−20:00 | |||

| 1 December−30 April (next year) | 7:00−11:00; 17:00−20:00 | |||

| Chongqing (IIIB) | 1 May−14 June | 0:00−7:00; 17:00−20:00 | 6 h−1 | 0.4 h−1 |

| 15 July−15 October | 0:00−24:00 | |||

| 16 October−30 November | 0:00−7:00; 17:00−20:00 | |||

| 1 December−30 April (next year) | 7:00−11:00; 17:00−20:00 | |||

| Fuzhou (IVA) | 1 May−31 May | 0:00−7:00; 17:00−20:00 | 6 h−1 | 0.4 h−1 |

| 1 June−31 October | 0:00−24:00 | |||

| 1 November−30 November | 0:00−7:00; 17:00−20:00 | |||

| 1 December−30 April (next year) | 7:00−11:00; 17:00−20:00 | |||

| Nanning (IVA) | 1 May−31 May | 0:00−7:00; 17:00−21:00 | 6 h−1 | 0.4 h−1 |

| 1 June−31 October | 0:00−24:00 | |||

| 1 November−30 November | 0:00−7:00; 17:00−21:00 | |||

| 1 December−30 April (next year) | 7:00−11:00; 17:00−21:00 | |||

| Guiyang (VA) | 1 May−30 June | 7:00−10:00; 17:00−20:00 | 3 h−1 | 0.4 h−1 |

| 1 July−31 August | 0:00−24:00 | |||

| 1 September−30 September | 7:00−10:00; 17:00−20:00 | |||

| 1 October−30 April | 7:00−9:00; 17:00−19:00 | |||

| Kunming (VB) | 1 May−30 June | 7:00−10:00; 17:00−20:00 | 3 h−1 | 0.4 h−1 |

| 1 July−31 August | 0:00−24:00 | |||

| 1 September−30 September | 7:00−10:00; 17:00−20:00 | |||

| 1 October−30 April | 7:00−9:00; 17:00−19:00 |

| Construction | Layer | λ (W/m K) | ρ (kg/m3) | Cp (J/kg K) |

|---|---|---|---|---|

| External wall | Cement Plaster | 0.93 | 1800 | 1050 |

| XPS | 0.03 | 35 | 1380 | |

| Render | 0.93 | 1800 | 1050 | |

| Reinforced concrete | 1.74 | 2500 | 920 | |

| Cement Plaster | 0.93 | 1800 | 1050 | |

| Roof | Cement Plaster | 0.93 | 1800 | 1050 |

| SBS waterproof material | 0.17 | 600 | 1470 | |

| Render | 0.93 | 1800 | 1050 | |

| XPS | 0.03 | 35 | 1380 | |

| Render | 0.93 | 1800 | 1050 | |

| SBS waterproof material | 0.17 | 600 | 1470 | |

| Reinforced concrete | 0.74 | 2500 | 920 | |

| Cement Plaster | 0.93 | 1800 | 1050 | |

| Ground floor | Timber flooring | 0.14 | 650 | 1200 |

| Cement Plaster | 0.93 | 1800 | 1050 | |

| SBS waterproof material | 0.17 | 600 | 1470 | |

| Reinforced concrete | 1.74 | 2500 | 920 | |

| Render | 0.93 | 1800 | 1050 | |

| XPS | 0.03 | 35 | 1380 | |

| Cast concrete | 1.13 | 2000 | 1000 |

| City | U-Values for Envelope Components (W/m2⋅K) | ||

|---|---|---|---|

| External Walls | Roof | Ground | |

| Yichun (IA) | 0.35 | 0.15 | 0.23 |

| Harbin (IB) | 0.35 | 0.20 | 0.23 |

| Shenyang (IC) | 0.40 | 0.20 | 0.27 |

| Dalian (IIA) | 0.45 | 0.25 | 0.32 |

| Beijing (IIB) | 0.45 | 0.30 | 0.32 |

| Shanghai (IIIA) | 1.00 | 0.40 | 0.48 |

| Chongqing (IIIB) | 1.20 | 0.40 | 0.48 |

| Fuzhou (IVA) | 1.50 | 0.40 | 1.30 |

| Nanning (IVA) | 1.50 | 0.40 | 1.30 |

| Guiyang (VA) | 1.00 | 0.40 | 0.70 |

| Kunming (VB) | 1.80 | 1.00 | 1.30 |

| Type | Room Type | Value/W | Time |

|---|---|---|---|

| People | Bedrooms (facing north) | 1 × 75 | 6: 00−8: 00; 22: 00−23: 00 |

| 0.7 × 75 | 23: 00−6: 00 | ||

| Bedrooms (facing south) | 2 × 75 | 6: 00−8: 00; 22: 00−23: 00 | |

| 1.4 × 75 | 23: 00−6: 00 | ||

| Livingroom | 2 × 75 | 9:00−22:00 | |

| Electric Equipment | Bedrooms | 60 | 8:00−23:00 |

| 7.8 | 23:00−8:00 | ||

| Livingroom | 83.6 | 8:00−23:00 | |

| 10.8 | 23:00−8:00 | ||

| Lighting | Bedrooms | 75 | 17:00−23:00 |

| Livingroom | 110 | 17:00−23:00 |

References

- Wang, H.; Chen, Q. Impact of climate change heating and cooling energy use in buildings in the United States. Energy Build. 2014, 82, 428–436. [Google Scholar] [CrossRef]

- Zhai, Z.J.; Helman, J.M. Implications of climate changes to building energy and design. Sustain. Cities Soc. 2019, 44, 511–519. [Google Scholar] [CrossRef]

- The Paris Agreement. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 30 January 2024).

- Kalbasi, R.; Samali, B.; Afrand, M. Taking benefits of using PCMs in buildings to meet energy efficiency criteria in net zero by 2050. Chemosphere 2023, 311, 137100. [Google Scholar] [CrossRef] [PubMed]

- Jensen, S.Ø.; Marszal-Pomianowska, A.; Lollini, R.; Pasut, W.; Knotzer, A.; Engelmann, P.; Stafford, A.; Reynders, G. IEA EBC Annex 67 Energy Flexible Buildings. Energy Build. 2017, 155, 25–34. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Cabeza, L.F.; Serrano, S.; Barreneche, C.; Petrichenko, K. Heating and cooling energy trends and drivers in buildings. Renew. Sustain. Energy Rev. 2015, 41, 85–98. [Google Scholar] [CrossRef]

- Khawaja, S.A.; Memon, S.A. Novel indicators to evaluate PCM performance under different ventilation strategies by considering the impact of climate change. J. Build. Eng. 2023, 74, 106848. [Google Scholar] [CrossRef]

- Chakraborty, D.; Alam, A.; Chaudhuri, S.; Başağaoğlu, H.; Sulbaran, T.; Langar, S. Scenario-based prediction of climate change impacts on building cooling energy consumption with explainable artificial intelligence. Appl. Energy 2021, 291, 116807. [Google Scholar] [CrossRef]

- Van Ruijven, B.J.; De Cian, E.; Wing, I.S. Amplification of future energy demand growth due to climate change. Nat. Commun. 2019, 10, 2762. [Google Scholar] [CrossRef]

- Deng, Z.; Javanroodi, K.; Nik, V.M.; Chen, Y. Using urban building energy modeling to quantify the energy performance of residential buildings under climate change. Build. Simul. 2023, 16, 1629–1643. [Google Scholar] [CrossRef]

- Xiong, J.; Guo, S.; Wu, Y.; Yan, D.; Xiao, C.; Lu, X. Predicting the response of heating and cooling demands of residential buildings with various thermal performances in China to climate change. Energy 2023, 269, 126789. [Google Scholar] [CrossRef]

- Bo, R.; Chang, W.S.; Yu, Y.; Xu, Y.; Guo, H. Overheating of residential buildings in the severe cold and cold regions of China: The gap between building policy and performance. Build. Environ. 2022, 225, 109601. [Google Scholar] [CrossRef]

- Wang, R.; Lu, S.; Feng, W.; Xu, B. Tradeoff between heating energy demand in winter and indoor overheating risk in summer constrained by building standards. Build. Simul. 2021, 14, 987–1003. [Google Scholar] [CrossRef]

- Bo, R.; Shao, Y.; Xu, Y.; Yu, Y.; Guo, H.; Chang, W.S. Research on the Relationship between Thermal Insulation Thickness and Summer Overheating Risk: A Case Study in Severe Cold and Cold Regions of China. Buildings 2022, 12, 1032. [Google Scholar] [CrossRef]

- Del Grosso, A.E.; Basso, P. Adaptive building skin structures. Smart Mater. Struct. 2010, 19, 124011. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Noelson, J.C.V.; Saadi, I.; Kenfack, H.; Andrianaharinjaka, A.Z.F.; Ngoumdoum, D.F.; Sela, J.B.; Reiter, S. Application of phase change materials, thermal insulation, and external shading for thermal comfort improvement and cooling energy demand reduction in an office building under different coastal tropical climates. Sol. Energy 2020, 207, 458–470. [Google Scholar] [CrossRef]

- Chen, X.N.; Xu, B.; Fei, Y.; Gan, W.T.; Pei, G. Parameter optimization of phase change material and the combination of phase change material and cool paint according to corresponding energy consumption characteristics under various climates. Energy 2023, 277, 127625. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, L.; Wang, P.; Liu, Z.; Su, X.; Liao, H.; Jiang, X. Potential evaluation of energy flexibility and energy-saving of PCM-integrated office building walls. J. Build. Eng. 2023, 79, 107857. [Google Scholar] [CrossRef]

- Memon, S.A.; Cui, H.Z.; Zhang, H.; Xing, F. Utilization of macro encapsulated phase change materials for the development of thermal energy storage and structural lightweight aggregate concrete. Appl. Energy 2015, 139, 43–55. [Google Scholar] [CrossRef]

- Royon, L.; Karim, L.; Bontemps, A. Thermal energy storage and release of a new component with PCM for integration in floors for thermal management of buildings. Energy Build. 2013, 63, 29–35. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.; Liu, C.; Wu, G. Numerical analysis on thermal performance of roof contained PCM of a single residential building. Energy Convers. Manag. 2015, 100, 147–156. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, Z.; Wu, W.; Zhang, H.; Ren, Y.; Yang, Q. Preparation of a novel diatomite-based PCM gypsum board for temperature-humidity control of buildings. Build. Environ. 2022, 226, 109732. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Soares, N.; Ferreira, V. Experimental testing and numerical modelling of masonry wall solution with PCM incorporation: A passive construction solution. Energy Build. 2012, 49, 235–245. [Google Scholar] [CrossRef]

- Cui, H.; Tang, W.; Qin, Q.; Xing, F.; Liao, W.; Wen, H. Development of structural-functional integrated energy storage concrete with innovative macro-encapsulated PCM by hollow steel ball. Appl. Energy 2017, 185, 107–118. [Google Scholar] [CrossRef]

- Yu, B.; Li, S.; Zhu, H.; Jiang, Q.; Wang, D.; Chen, Y. A composite phase change material for improving the freeze-thaw resistance performance of cement mortars. Constr. Build. Mater. 2023, 387, 131657. [Google Scholar] [CrossRef]

- Hu, J.Y.; Yu, X. Adaptive building roof by coupling thermochromic material and phase change material: Energy performance under different climate conditions. Constr. Build. Mater. 2020, 262, 120481. [Google Scholar] [CrossRef]

- Kishore, R.A.; Bianchi, M.V.; Booten, C.; Vidal, J.; Jackson, R. Optimizing PCM-integrated walls for potential energy savings in US Buildings. Energy Build. 2020, 226, 110355. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Y.; Wu, L.; Shi, M. Thermal response of brick wall filled with phase change materials (PCM) under fluctuating outdoor temperatures. Energy Build. 2011, 43, 3514–3520. [Google Scholar] [CrossRef]

- Zhou, D.; Eames, P. Phase Change Material Wallboard (PCMW) melting temperature optimisation for passive indoor temperature control. Renew. Energy 2019, 139, 507–514. [Google Scholar] [CrossRef]

- Godoy-Vaca, L.; Vallejo-Coral, E.C.; Martínez-Gómez, J.; Orozco, M.; Villacreses, G. Predicted medium vote thermal comfort analysis applying energy simulations with phase change materials for very hot-humid climates in social housing in Ecuador. Sustainability 2021, 13, 1257. [Google Scholar] [CrossRef]

- Kuznik, F.; Virgone, J.; Johannes, K. In-situ study of thermal comfort enhancement in a renovated building equipped with phase change material wallboard. Renew. Energy 2011, 36, 1458–1462. [Google Scholar] [CrossRef]

- Beemkumar, N.; Yuvarajan, D.; Arulprakasajothi, M.; Elangovan, K.; Arunkumar, T. Control of room temperature fluctuations in the building by incorporating PCM in the roof. J. Therm. Anal. Calorim. 2021, 143, 3039–3046. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Masi, R.F.; Mastellone, M.; Vanoli, G.P. Phase Change Materials for Reducing Cooling Energy Demand and Improving Indoor Comfort: A Step-by-Step Retrofit of a Mediterranean Educational Building. Energies 2019, 12, 3661. [Google Scholar] [CrossRef]

- Terhan, M.; Ilgar, G. Investigation of used PCM-integrated into building exterior walls for energy savings and optimization of PCM melting temperatures. Constr. Build. Mater. 2023, 369, 130601. [Google Scholar] [CrossRef]

- Hammid, A.T.; Jebur, Y.M.; Lafta, H.A.; Parwata, I.W.; Patra, I.; Arenas, L.A.B. The arrangement of phase change materials inside a building wall and its energy performance. Sustain. Energy Technol. Assess. 2023, 57, 103158. [Google Scholar] [CrossRef]

- Salihi, M.; El Fiti, M.; Harmen, Y.; Chhiti, Y.; Chebak, A.; Alaoui, F.E.M.H.; Achak, M.; Bentiss, F.; Jama, C. Evaluation of global energy performance of building walls integrating PCM: Numerical study in semi-arid climate in Morocco. Case Stud. Constr. Mater. 2022, 16, e00979. [Google Scholar] [CrossRef]

- Nicolalde, J.F.; Cabrera, M.; Martínez-Gómez, J.; Salazar, R.B.; Reyes, E. Selection of a phase change material for energy storage by multi-criteria decision method regarding the thermal comfort in a vehicle. J. Energy Storage 2022, 51, 104437. [Google Scholar] [CrossRef]

- Santosh, C.; Ramesh, R.; Selvaraj, M. A comprehensive review on current advances of thermal energy storage and its applications. Alex. Eng. J. 2022, 61, 5455–5463. [Google Scholar]

- Deepak, S.R.; Jian, W.; Imran, A.; Yulong, D.; Alkaabi, A.K. Melting performance enhancement in a thermal energy storage unit using active vortex generation by electric field. J. Energy Storage 2023, 67, 107593. [Google Scholar]

- Prieto, C.; Cabeza, L.F. Thermal energy storage (TES) with phase change materials (PCM) in solar power plants (CSP). Concept and plant performance. Appl. Energy 2019, 254, 113646. [Google Scholar] [CrossRef]

- Nghana, B.; Tariku, F. Phase change material’s (PCM) impacts on the energy performance and thermal comfort of buildings in a mild climate. Build. Environ. 2016, 99, 221–238. [Google Scholar] [CrossRef]

- Hasan, A.; Al-Sallal, K.A.; Alnoman, H.; Rashid, Y.; Abdelbaqi, S. Effect of Phase Change Materials (PCMs) Integrated into a Concrete Block on Heat Gain Prevention in a Hot Climate. Sustainability 2016, 8, 1009. [Google Scholar] [CrossRef]

- Yu, J.; Dong, Y.; Zhao, Y.; Yu, Y.; Chen, Y.; Guo, H. Using phase change materials to alleviate overheating phenomenon of residential buildings in severe cold and cold regions of China. Case Stud. Therm. Eng. 2023, 49, 103207. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Yang, L.; Liu, T.; Zhang, C.; Dong, H. Climatic and seasonal suitability of phase change materials coupled with night ventilation for office buildings in Western China. Renew. Energy 2020, 147, 356–373. [Google Scholar] [CrossRef]

- Soares, N.; Gaspar, A.R.; Santos, P.; Costa, J.J. Multi-dimensional optimization of the incorporation of PCM-drywalls in lightweight steel-framed residential buildings in different climates. Energy Build. 2014, 70, 411–421. [Google Scholar] [CrossRef]

- Li, W.; Jing, M.; Li, R.; Gao, J.; Zhu, J.; Li, R. Study of the optimal placement of phase change materials in existing buildings for cooling load reduction- Take the Central Plain of China as an example. Renew. Energy 2023, 209, 71–84. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Sheng, Z.; Wu, W.; Wang, Y.; Dumoulin, J. Study on thermal storage effectiveness of a novel PCM concrete applied in buildings located at four cities. Renew. Energy 2023, 218, 119262. [Google Scholar] [CrossRef]

- Dehkordi, B.S.; Afrand, M. Energy-saving owing to using PCM into buildings: Considering of hot and cold climate region. Sustain. Energy Technol. Assess. 2022, 52, 102112. [Google Scholar]

- ASHRAE Standard 169-2013; Weather Data for Building Design Standards. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2013.

- Kim, Y.U.; Yang, S.; Yun, B.Y.; Kim, S. Evaluation of energy consumption in apartment buildings with biochar and phase-change material aggregate-applied artificial stone finishing materials. Int. J. Energy Res. 2022, 46, 12772–12786. [Google Scholar] [CrossRef]

- Calene, B.; Cynthia, A.C. Economics and lifecycle carbon assessment of coconut oil as an alternative to paraffin phase change materials in North America. Energy Build. 2023, 294, 113268. [Google Scholar]

- GB 50176-2016; Code for Thermal Design of Civil Building. Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD): Beijing, China, 2016.

- The Chartered Institution of Building Services Engineers. Design Methodology for the Assessment of Overheating Risk in Homes; The Chartered Institution of Building Services Engineers: London, UK, 2017. [Google Scholar]

- Qureshi, W.A.; Nair, N.-K.C.; Farid, M.M. Impact of energy storage in buildings on electricity demand side management. Energy Convers. Manag. 2011, 52, 2110–2120. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, C.; Hu, C.X. Thermal Performance and Energy Conservation Effect of Grain Bin Walls Incorporating PCM in Different Ecological Areas of China. Processes 2022, 10, 2360. [Google Scholar] [CrossRef]

- Na, Z.; Fuli, L.; Pengpeng, L.; Pingfang, H.; Mengdu, W. Energy Sav. potential of a novel phase change material wallboard in typical climate regions of China. Energy Build. 2016, 128, 360–369. [Google Scholar]

- Xuming, M.; Ran, L.; Hongzhi, C.; Shazim Ali, M.; Feng, X.; Yiu, L. Energy and economic analysis of building integrated with PCM in different cities of China. Appl. Energy 2016, 175, 324–336. [Google Scholar]

| Country | City | ASHRAE Climate | Conclusions | Ref. |

|---|---|---|---|---|

| USA | Phoenix | 3B | In cities with extreme and longer winters, integrating PCM was effective for the heating season. | [27] |

| Las Vegas | 4B | |||

| Baltimore | 4A | |||

| Denver | 5B | |||

| Billings | 6B | |||

| Spain | Sevilla | 3A | PCMs were suitable for Mediterranean climates, increasing energy efficiency by up to 62% in the Csb-Coimbra climate. | [45] |

| Portugal | Coimbra | 3A | ||

| Italy | Milan | 4A | ||

| France | Paris | 4A | ||

| Romania | Bucharest | 4A | ||

| Poland | Warsaw | 5B | ||

| Sweden | Kiruna | 7 | ||

| India | New Delhi | 1B | The cooling energy decrease was concentrated in cold climate regions, such as in the Incheon, Chicago, and Moscow. | [50] |

| China | Hongkong | 2A | ||

| Australia | Brisbane | 2A | ||

| South Africa | Johannesburg | 3C | ||

| Spain | Madrid | 3C | ||

| Korea | Incheon | 4A | ||

| USA | Chicago | 5A | ||

| Russia | Moscow | 6A | ||

| Canada | Ottawa | 6A | PCM would minimize lifetime carbon emissions beyond coconut oil in both Houston and Yellowknife. | [51] |

| Yellowknife | 8 | |||

| USA | Houston | 2A |

| Climate Region | Sub-Region | Main Indicators | Representative City | Precise Location | U-Value (W/m2·K) | |

|---|---|---|---|---|---|---|

| Temperature/°C | HDD and CDD | |||||

| Severe cold region | 1A | tmin·m ≤ −10 °C | 6000 ≤ HDD18 | Yichun | 128.84 E 47.71 N | Roof: ≤0.15 Wall: ≤0.35 |

| 1B | 5000 ≤ HDD18 < 6000 | Harbin | 126.58 E 45.93 N | Roof: ≤0.20 Wall: ≤0.35 | ||

| 1C | 3800 ≤ HDD18 < 5000 | Shenyang | 123.51 E 41.73 N | Roof: ≤0.20 Wall: ≤0.40 | ||

| Cold region | 2A | −10 °C < tmin·m ≤ 0 °C | 2000 ≤ HDD18 < 3800 CDD26 ≤ 90 | Dalian | 121.66 E 438.91 N | Roof: ≤0.25 Wall: ≤0.45 |

| 2B | 2000 ≤ HDD18 < 3800 CDD26 > 90 | Beijing | 116.58 E 40.08 N | Roof: ≤0.30 Wall: ≤0.45 | ||

| Hot summer and cold winter region | 3A | 0 °C < tmin·m ≤ 10 °C 25 °C < tmax·m ≤ 30 °C | 1200 ≤ HDD18 < 2000 | Shanghai | 121.44 E 31.39 N | Roof: ≤0.40 Wall: ≤1.00 |

| 3B | 700 ≤ HDD18 < 1200 | Chongqing | 106.46 E 29.58 N | Roof: ≤0.40 Wall: ≤1.20 | ||

| Hot summer and warm winter region | 4A | 10 °C < tmin·m 25 °C < tmax·m ≤ 29 °C | 500 ≤ HDD18 < 700 | Fuzhou | 119.29 E 26.08 N | Roof: ≤0.40 Wall: ≤1.50 |

| 4B | HDD18 < 500 | Nanning | 108.55 E 22.78 N | Roof: ≤0.40 Wall: ≤1.50 | ||

| Mild region | 5A | 0 °C < tmin·m ≤ 13 °C 18 °C < tmax·m ≤ 25 °C | CDD26 < 10 700 ≤ HDD18 < 2000 | Guiyang | 106.73 E 26.59 N | Roof: ≤0.40 Wall: ≤1.00 |

| 5B | CDD26 < 10 HDD18 < 700 | Kunming | 102.74 E 24.99 N | Roof: ≤1.00 Wall: ≤1.80 | ||

| Climate Region | Sub-Region | City | Peaking Melting Temperature (°C) | Phase Change Temperature Range (°C) | Enthalpy (kJ/kg) |

|---|---|---|---|---|---|

| Severe Cold | IA | Yichun | 22 | 19–22 | 170 |

| IB | Harbin | 24 | 21–25 | 180 | |

| IC | Shenyang | 25 | 23–26 | 180 | |

| Cold | IIA | Dalian | 25 | 23–26 | 180 |

| IIB | Beijing | 25 | 23–26 | 180 | |

| Hot Summer and Cold Winter | IIIA | Shanghai | 28 | 27–29 | 250 |

| IIIB | Chongqing | 28 | 27–29 | 250 | |

| Hot Summer and Warm Winter | IVA | Fuzhou | 28 | 27–29 | 250 |

| IVB | Nanning | 28 | 27–29 | 250 | |

| Mild | VA | Guiyang | 25 | 23–26 | 180 |

| VB | Kunming | 24 | 21–25 | 180 |

| Room | May | June | July | Aug. | Sept. | |

|---|---|---|---|---|---|---|

| Tmax | North Bedroom | 23.92 °C | 26.61 °C | 30.71 °C | 30.32 °C | 25.67 °C |

| South Bedroom | 23.91 °C | 27.26 °C | 31.42 °C | 30.54 °C | 26.77 °C | |

| Living Room | 25.81 °C | 27.32 °C | 30.95 °C | 30.02 °C | 27.47 °C | |

| Tmean | North Bedroom | 21.06 °C | 24.37 °C | 28.56 °C | 27.16 °C | 23.60 °C |

| South Bedroom | 21.26 °C | 24.60 °C | 28.78 °C | 27.47 °C | 24.16 °C | |

| Living Room | 21.85 °C | 24.60 °C | 28.47 °C | 27.38 °C | 24.35 °C | |

| Tmin | North Bedroom | 18.92 °C | 22.36 °C | 25.86 °C | 25.02 °C | 21.14 °C |

| South Bedroom | 18.83 °C | 22.39 °C | 24.82 °C | 25.46 °C | 21.40 °C | |

| Living Room | 18.57 °C | 20.33 °C | 25.44 °C | 25.30 °C | 21.50 °C |

| Climate Region | Sub-Region | City | Cooling Energy (kWh/m2) | Cooling Energy Reduction | ||

|---|---|---|---|---|---|---|

| Without PCM | With PCM | Value (kWh/m2) | Ratio (%) | |||

| Severe Cold | IA | Yichun | 1.95 | 0.47 | 1.48 | 76.07 |

| IB | Harbin | 12.77 | 5.07 | 7.70 | 60.30 | |

| IC | Shenyang | 16.13 | 9.89 | 6.24 | 38.69 | |

| Cold | IIA | Dalian | 19.61 | 15.28 | 4.33 | 22.10 |

| IIB | Beijing | 49.23 | 41.99 | 7.24 | 14.71 | |

| Climate Region | Sub-Region | City | Cooling Energy (kWh/m2) | Cooling Energy Reduction | ||

|---|---|---|---|---|---|---|

| Without PCM | With PCM | Value (kWh/m2) | Ratio (%) | |||

| Severe Cold | IA | Yichun | 5.17 | 2.24 | 2.93 | 56.74 |

| IB | Harbin | 27.04 | 14.05 | 12.99 | 48.04 | |

| IC | Shenyang | 36.50 | 23.83 | 12.67 | 34.70 | |

| Cold | IIA | Dalian | 45.99 | 39.40 | 6.59 | 14.33 |

| IIB | Beijing | 75.62 | 62.31 | 13.31 | 17.61 | |

| Climate Region | Sub-Region | City | Cooling Energy (kWh/m2) | Cooling Energy Reduction | ||

|---|---|---|---|---|---|---|

| Without PCM | With PCM | Value (kWh/m2) | Ratio (%) | |||

| Hot Summer and Cold Winter | IIIA | Shanghai | 63.13 | 61.14 | 1.99 | 3.15 |

| IIIB | Chongqing | 62.73 | 60.10 | 2.63 | 4.19 | |

| Hot Summer and Warm Winter | IVA | Fuzhou | 75.99 | 72.24 | 3.75 | 4.93 |

| IVB | Nanning | 88.11 | 80.65 | 7.46 | 8.47 | |

| Mild | VA | Guiyang | 10.19 | 4.02 | 6.17 | 60.55 |

| VB | Kunming | 1.68 | 0.02 | 1.66 | 98.81 | |

| Climate Region | Sub-Region | City | Cooling Energy (kWh/m2) | Cooling Energy Reduction | ||

|---|---|---|---|---|---|---|

| Without PCM | With PCM | Value (kWh/m2) | Ratio (%) | |||

| Hot Summer and Cold Winter | IIIA | Shanghai | 83.47 | 79.20 | 4.27 | 5.11 |

| IIIB | Chongqing | 77.14 | 73.82 | 3.32 | 4.30 | |

| Hot Summer and Warm Winter | IVA | Fuzhou | 99.88 | 93.13 | 6.75 | 6.76 |

| IVB | Nanning | 116.05 | 102.22 | 13.83 | 11.92 | |

| Mild | VA | Guiyang | 17.57 | 6.72 | 10.85 | 61.74 |

| VB | Kunming | 4.32 | 0.17 | 4.15 | 95.97 | |

| City | Climate Region | Sub-Region | Conclusions | Ref. |

|---|---|---|---|---|

| Yichun | Severe cold | IA | PCM saved cooling energy in south-facing bedrooms in these four cities by 25.67%, 15.36%, 14.61%, and 15.34%, respectively. | [43] |

| Harbin | IB | |||

| Shenyang | IC | |||

| Dalian | Cold | IIA | ||

| Urumqi | Severe cold | IC | The PCM strategy was the best choice for the transition season in cities in severe cold zone. | [44] |

| Altay | IB | |||

| Turpan | Cold | IIB | ||

| Xi’an | IIB | |||

| Chongqing | Hot summer and cold winter | IIIB | ||

| Chengdu | IIIA | |||

| Nanning | Hot summer and warm winter | IVB | ||

| Hechi | IVA | |||

| Guiyang | Mild | VA | ||

| Kunming | VA | |||

| Harbin | Severe cold | IB | In these three cities, the percentages of energy saving were 17.5%, 14.8%, and 12.5%, respectively. | [55] |

| Zhengzhou | Cold | IIB | ||

| Guangzhou | Hot summer and warm winter | IVB | ||

| Harbin | Severe cold | IB | Energy saving rates of using PCM novel wallboards were 11.9% in Harbin, 6.6% in Beijing, 4.1% in Wuhan, 3.8% in Guangzhou, and 12.3% in Kunming. | [56] |

| Beijing | Cold | IIB | ||

| Wuhan | Hot summer and cold winter | IIIA | ||

| Guangzhou | Hot summer and warm winter | IVB | ||

| Kunming | Mild | VA | ||

| Shenyang | Severe cold | IC | Energy saving potential of Shenyang was found to be the best. Zhengzhou and Changsha followed Shenyang. | [57] |

| Zhengzhou | Cold | IIB | ||

| Changsha | Hot summer and cold winter | IIIA | ||

| Kunming | Mild | VA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Shao, Y.; Zhao, B.; Chen, Y.; Yu, J.; Guo, H. Study on the Influence of the Application of Phase Change Material on Residential Energy Consumption in Cold Regions of China. Energies 2024, 17, 1527. https://doi.org/10.3390/en17071527

Wang C, Shao Y, Zhao B, Chen Y, Yu J, Guo H. Study on the Influence of the Application of Phase Change Material on Residential Energy Consumption in Cold Regions of China. Energies. 2024; 17(7):1527. https://doi.org/10.3390/en17071527

Chicago/Turabian StyleWang, Chen, Yu Shao, Bolun Zhao, Yang Chen, Jiahui Yu, and Haibo Guo. 2024. "Study on the Influence of the Application of Phase Change Material on Residential Energy Consumption in Cold Regions of China" Energies 17, no. 7: 1527. https://doi.org/10.3390/en17071527

APA StyleWang, C., Shao, Y., Zhao, B., Chen, Y., Yu, J., & Guo, H. (2024). Study on the Influence of the Application of Phase Change Material on Residential Energy Consumption in Cold Regions of China. Energies, 17(7), 1527. https://doi.org/10.3390/en17071527