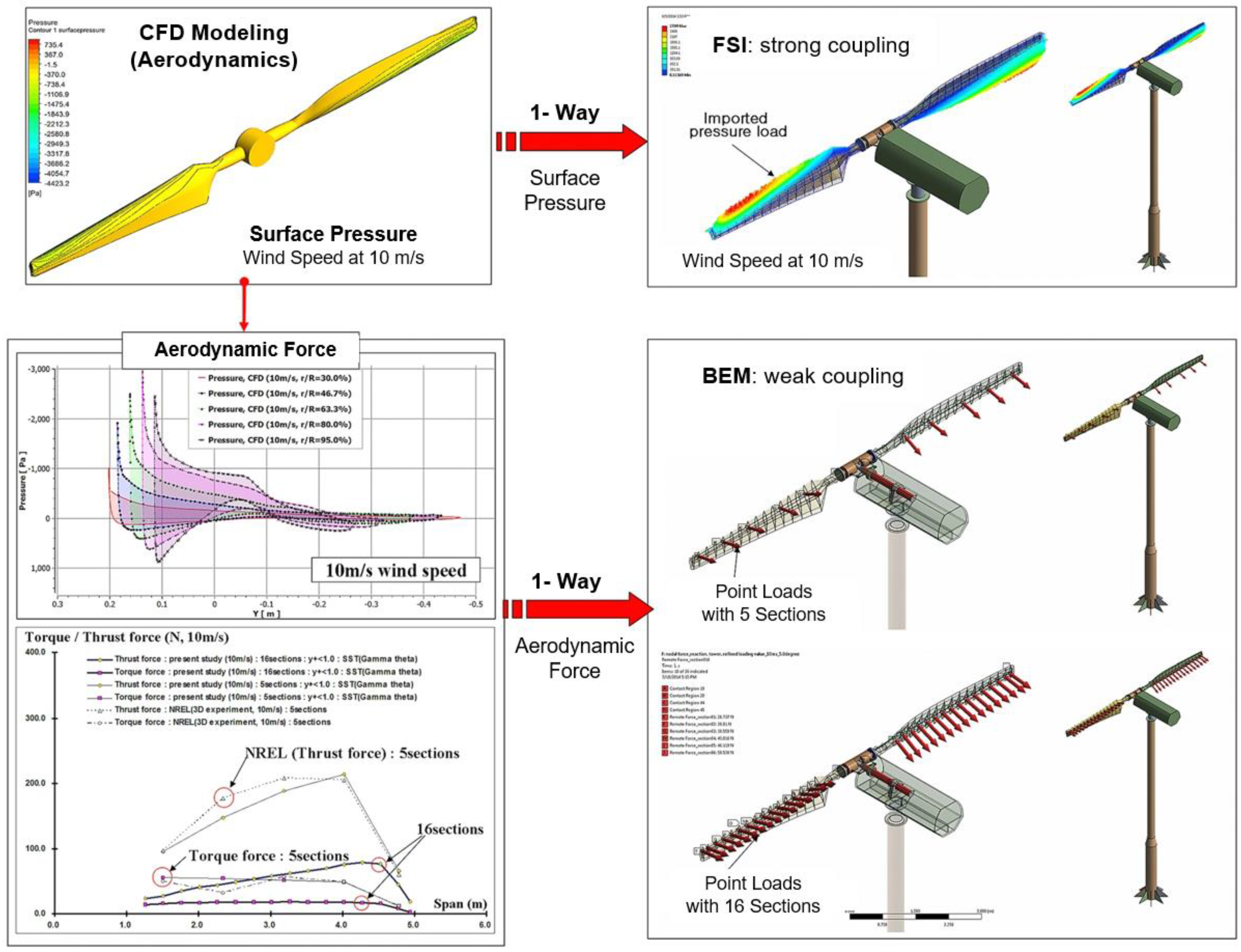

Previous CFD studies have focused on the aerodynamics of the concerned blades modified with different tips [

23], and verification and validation of this approach were carried out against the experimental measurement of the baseline wind turbine model by NREL [

26]. In this study, as part of the FSI simulation, a CFD analysis is performed in the same manner as the previous one, i.e., the aerodynamics of these wind turbines at different wind speeds are solved in ANSYS CFX. The results from the aerodynamics analysis (pressure) are then transferred to the structural solver to complete the FEA-based structural analysis by evaluating the directional displacement, total deformation, stress distribution, and strain distribution.

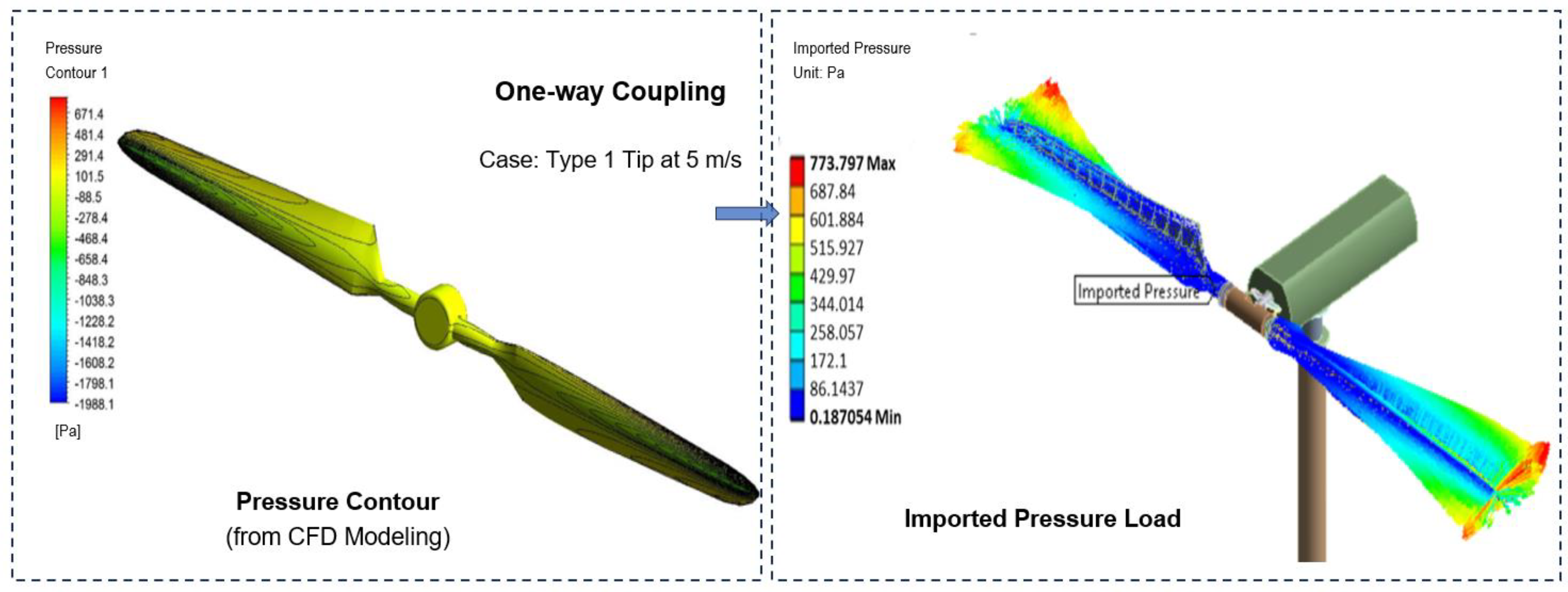

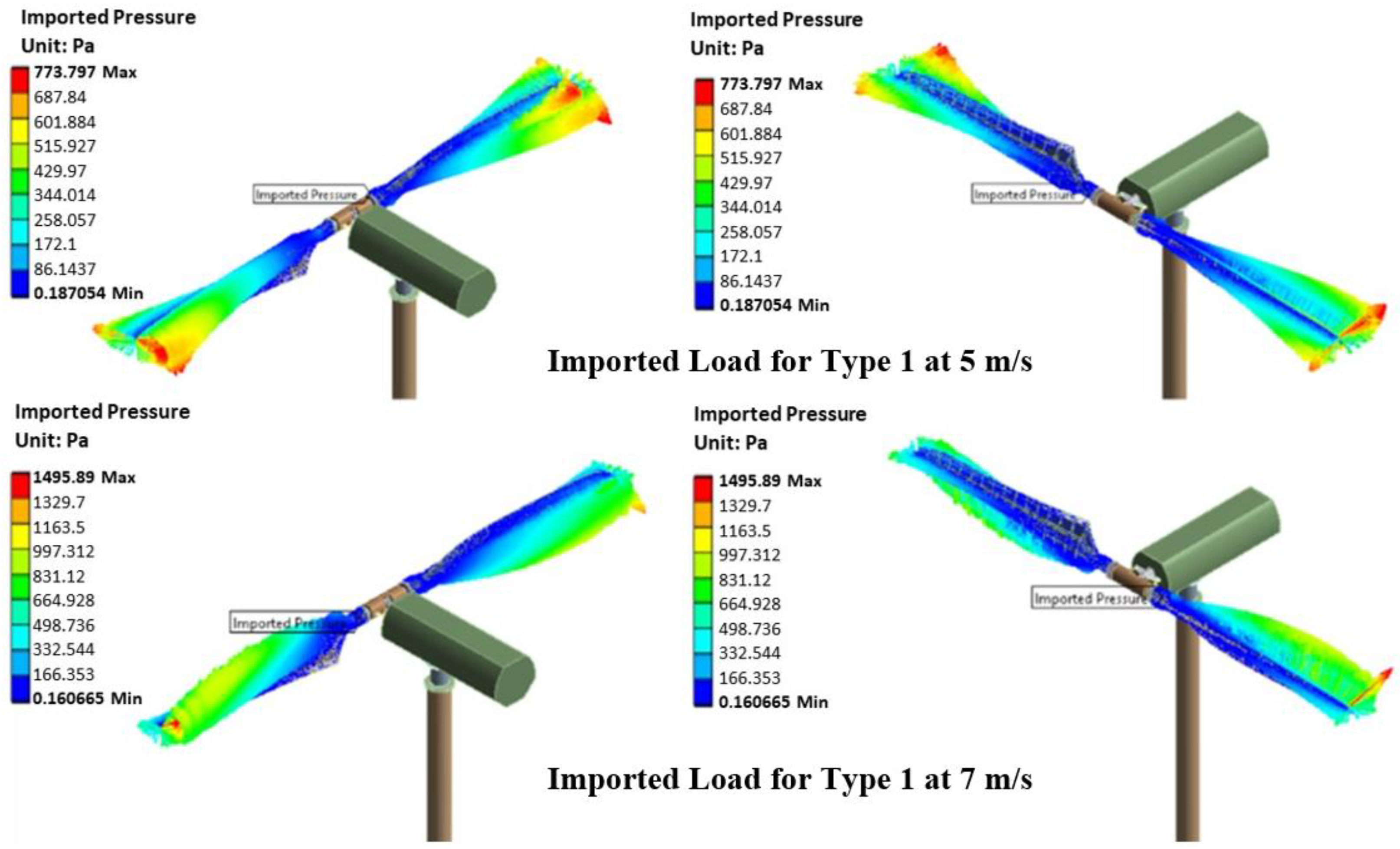

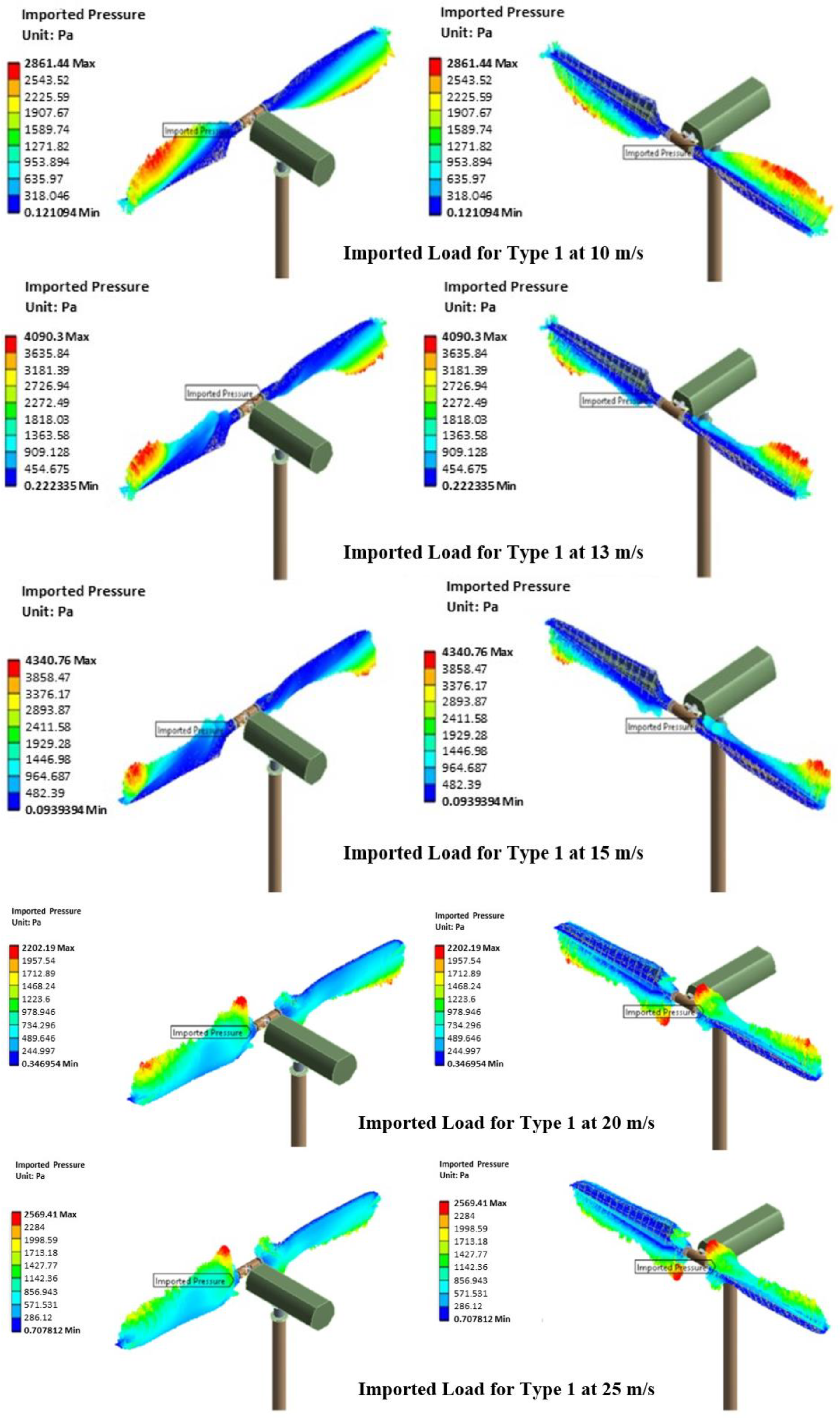

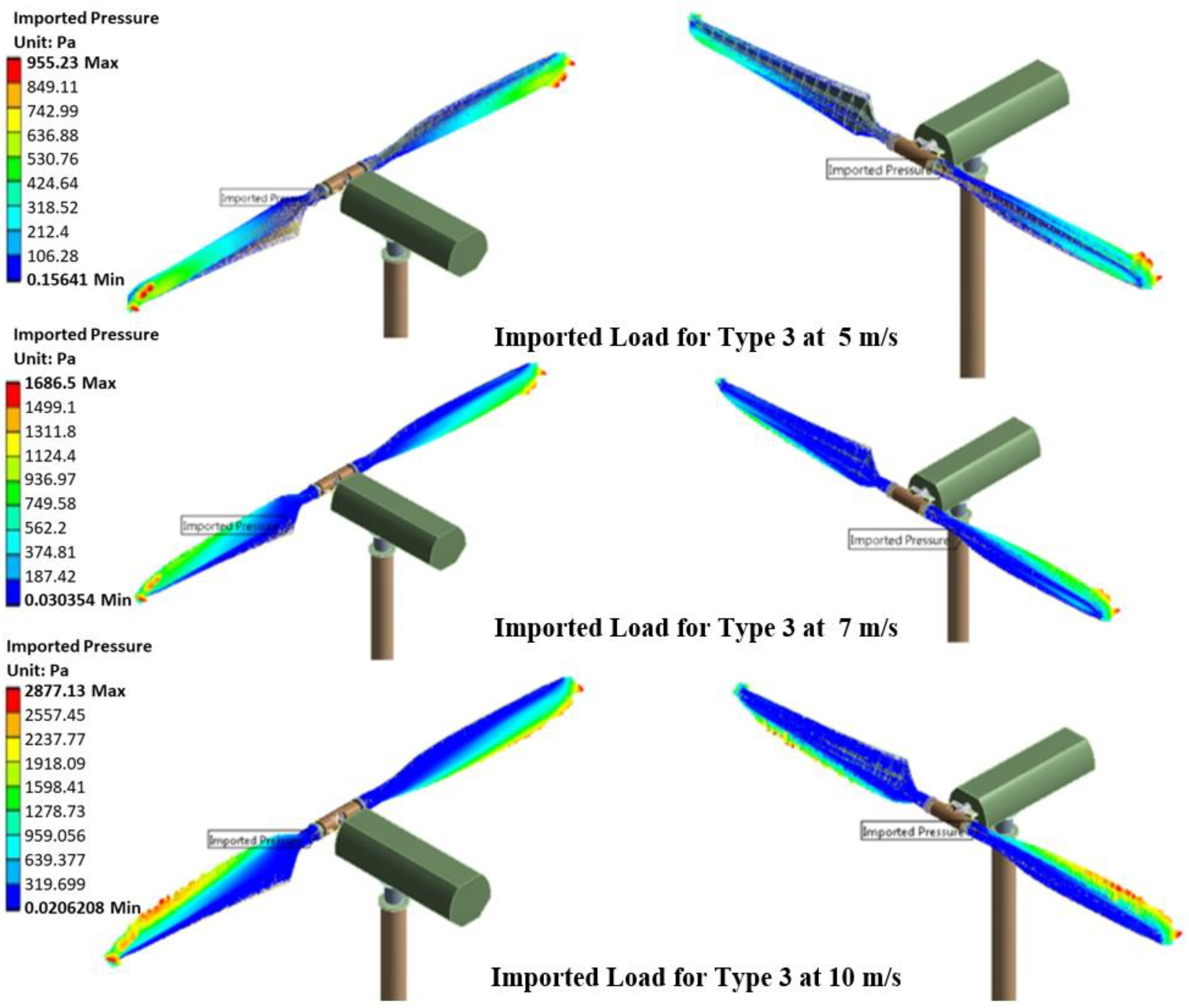

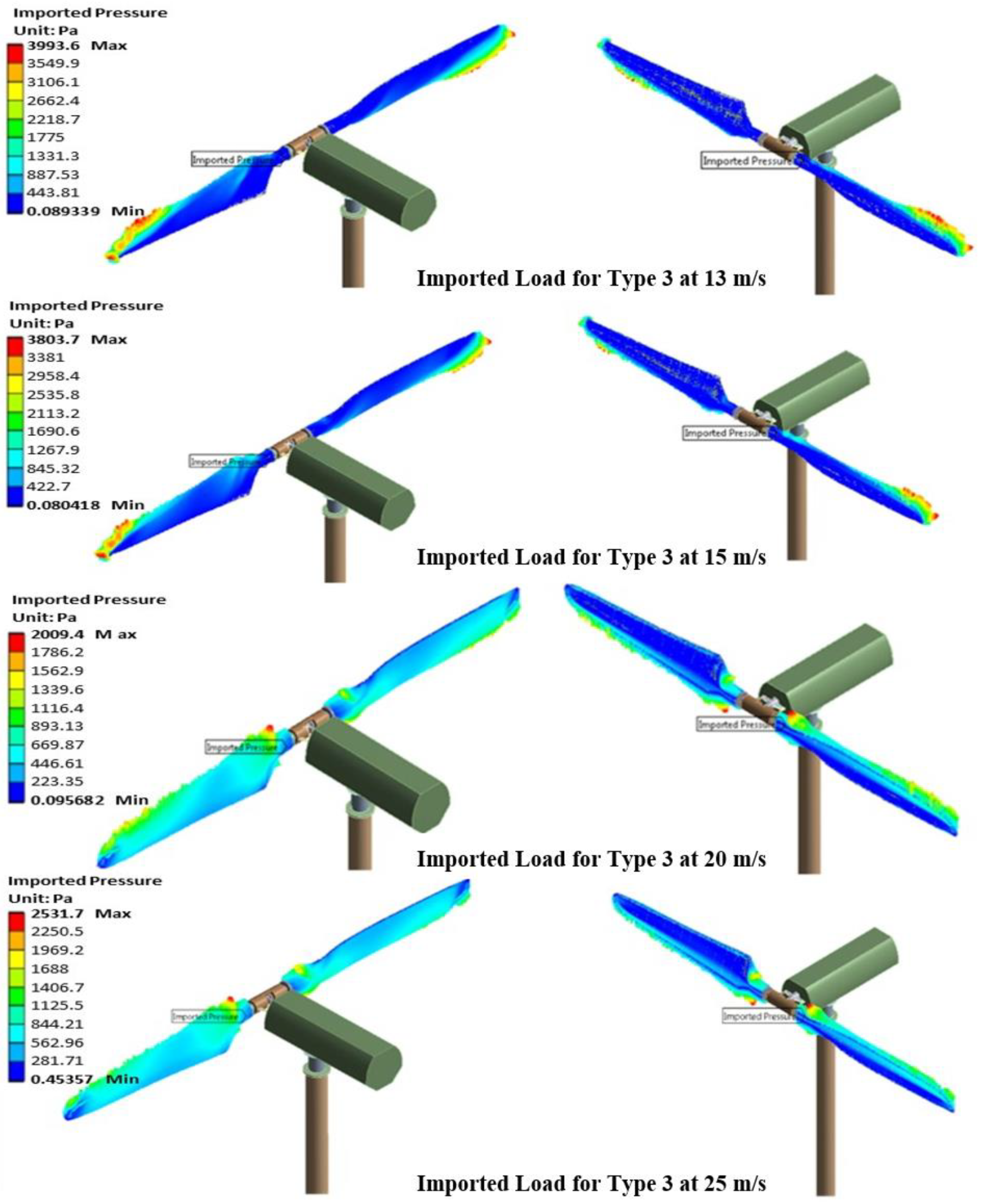

3.1. Pressure Loads Imported from CFD Analysis

As described in the previous section, the pressure loads obtained from the fluid solver are transferred to the structural solver through mapping. Through the mapping, the scale value from the fluid solver (pressure) is imported to the structural solver as normal stress loads (dubbed as Imported Pressure) on the body surface. These loads on structures can be represented in a manner of vector plots as illustrated below (

Figure 12).

These imported loads (pressure) are presented in the following isometric views for each type of blade tip at different wind speeds, i.e., 5 m/s, 7 m/s, 10 m/s, 13 m/s, 15 m/s, 20 m/s, and 25 m/s.

For the blade modified with a Type 1 tip shape as shown in

Figure 13, at low wind speeds of 5 m/s and 7 m/s, the maximum pressures for each case are 773.80 Pa and 1495.89 Pa, respectively. A drastic color variation is observed at its leading edge near the tip, which indicates the occurrence of a strong suction pressure. On the other hand, minimum pressures for both speeds are found near the hub and indicated by the blue color on the plot. Pressure magnitude is relatively increased over the span on the back side of the blades, i.e., the “suction side”. The pressure distribution on the surface is significantly affected by the wind speed as shown in the cases of medium- and high-wind speeds. Although the pressure distribution at 10 m/s seems to follow a similar pattern for the cases at lower wind speeds, the suction areas at the leading edge near the tip for speeds 13 m/s and 15 m/s are significantly decreased. It is also shown that at these speeds, unstable pressure distribution starts to present in the hub region. This observation is believed to be due to the occurrence of complex flow separation at these speeds. Moreover, the flow over the blades at higher wind speeds is fully separated across the span of the blade. Therefore, the suction pressure is not only placed at the leading edge near the tip and does not necessarily represent the maximum magnitude of the pressure. Suction effects at these speeds appear stronger on the leading edge near the hub.

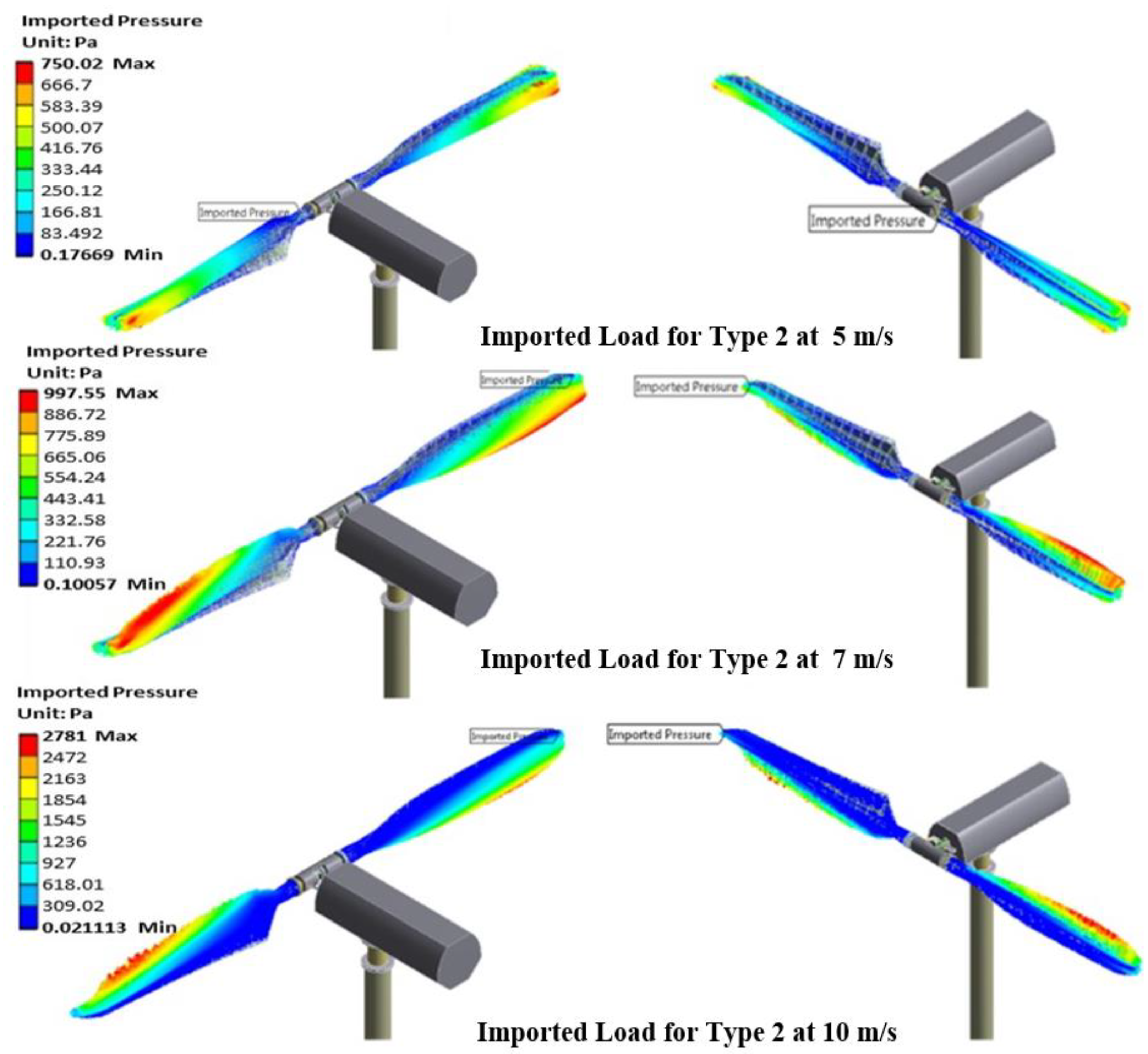

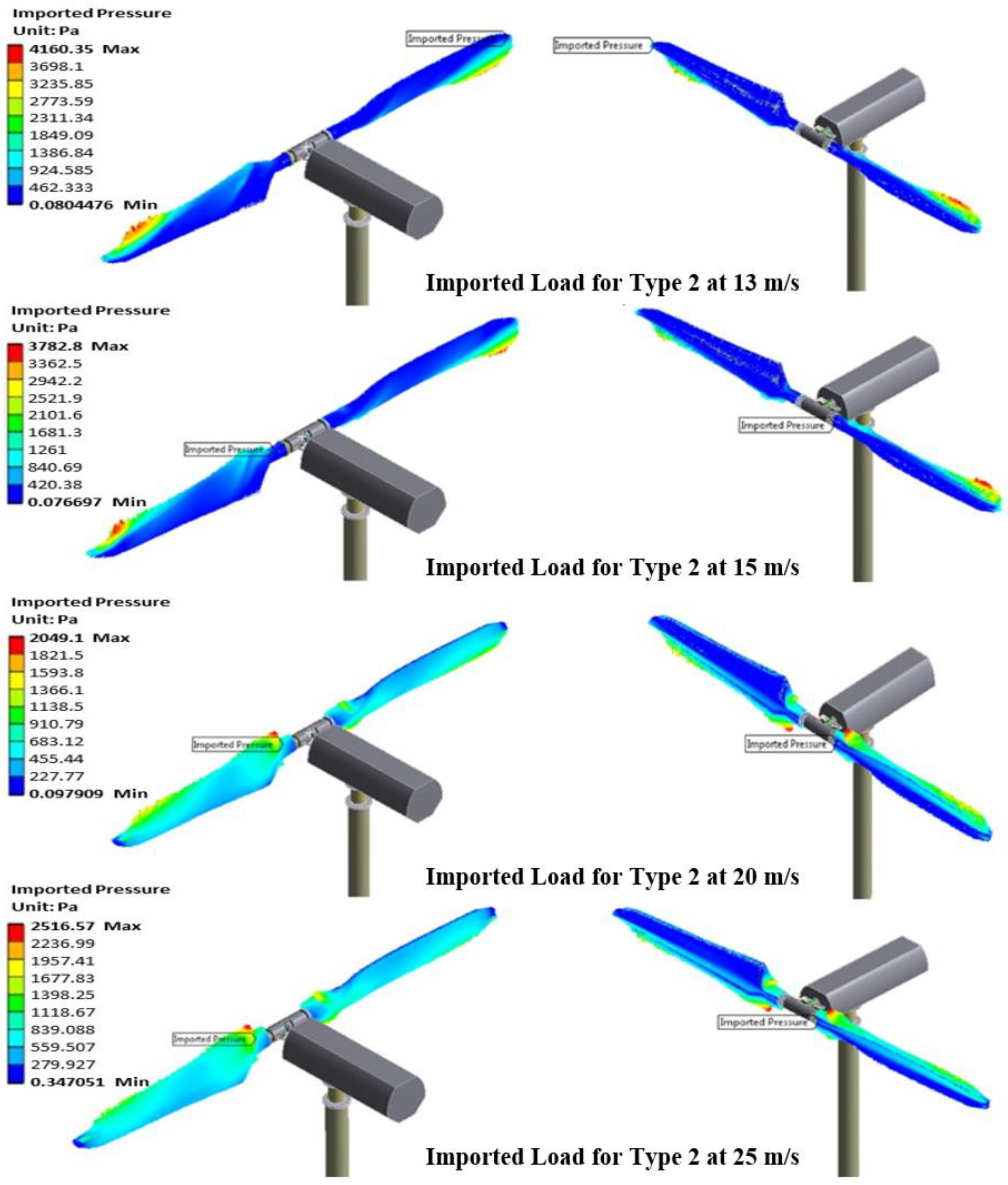

The pressure distributions after being imported to the structural solver for blades with a Type 2 tip are presented for all wind speeds in

Figure 14. The effects of varying wind speeds and stall phenomenon are straightforward. In the pre-stall region (5 m/s and 7 m/s), the maximum pressure magnitude was seen to occur at the tip of the blade. In the dynamic stall region (10 m/s, 13 m/s, and 15 m/s), the suction effect was stronger at the leading edge near to the tip. The suction is more concentrated at the hub’s leading-edge location for the last two wind speeds that fall into the deep stall region (20 m/s and 25 m/s).

The pressure distributions on the blade with a Type 3 tip for all wind speeds are presented in

Figure 15. The maximum pressure magnitude for the Type 3 blade was higher compared with the two other blades at 5 m/s, 7 m/s, and 10 m/s. The maximum pressure magnitude increased with the increase in the wind speed for those cases. The effect of flow separation started to show at the wind speed of 13 m/s. The influence of flow separation was remarkable on the maximum pressure magnitude in that it decreased from 3993 Pa at a 13 m/s wind speed to 3802 Pa at 15 m/s. In the deep stall region, the maximum pressure magnitude was seen to increase from 2009 Pa at 20 m/s to 2531 Pa at 25 m/s.

In short, at low wind speeds, the pressure distribution on the blade’s surface is found to be larger at the tip of the back side of the blades. The velocity at the tip is normally larger than the region near the hub; therefore, the pressure magnitude in that region increases due to the velocity difference between the suction side and the pressure side.

At medium wind speeds, the blade lays in three complex stall regions—the transition region, the dynamic stall region, and the deep stall region. This phenomenon results in a decrease in the suction area near the tip as the wind speed increases. The pressure reaches its maximum value in this wind speed region. As the wind speed continues to increase, a suction area occurs near the hub and the pressure magnitudes decrease compared to those of the medium wind speeds.

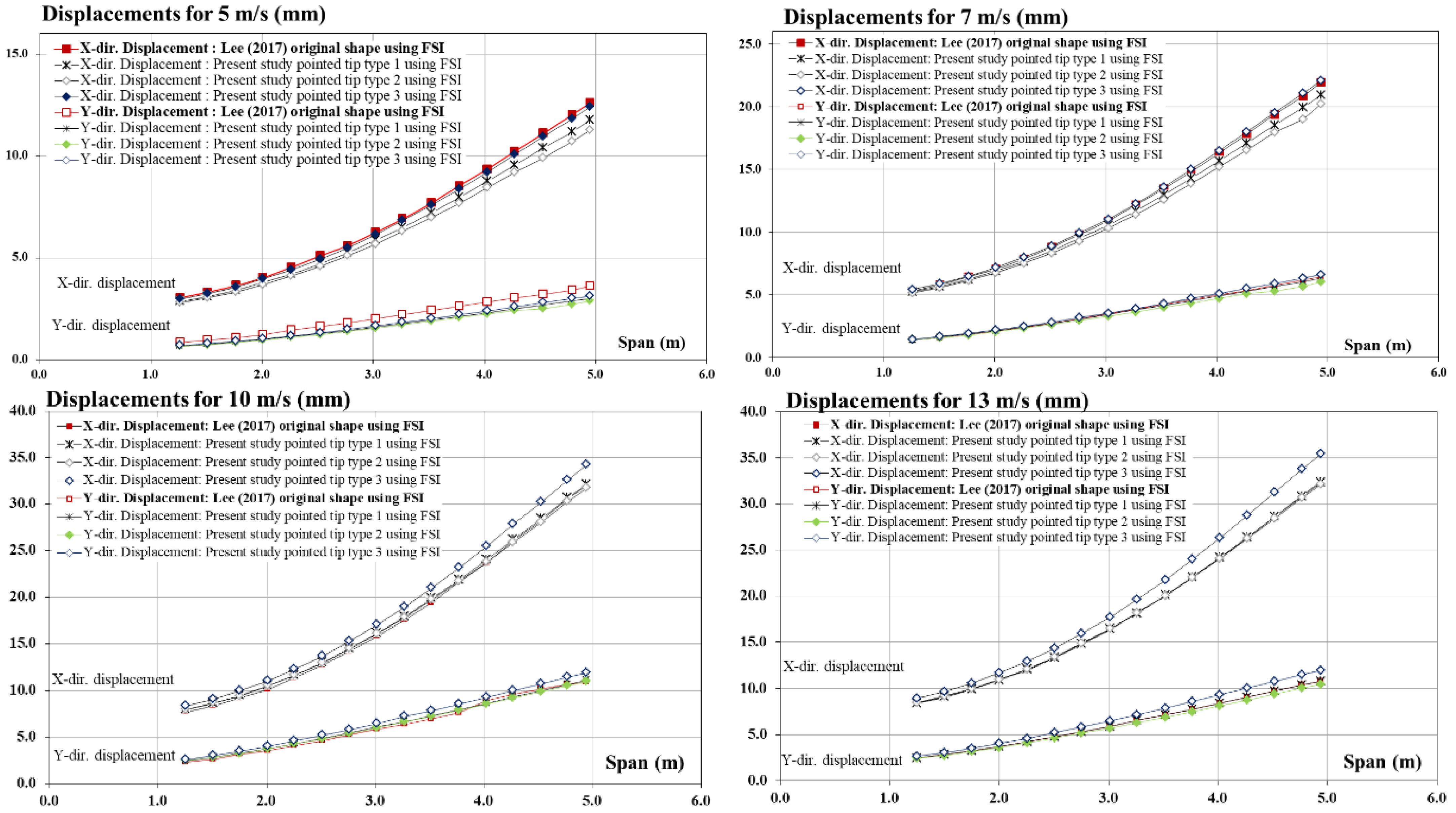

3.2. Directional Displacement

The pressure distribution on the turbine blades results in structural deformations of the whole wind turbine. In this section, the directional displacements of blades with a Type 1 tip in the X-axis (flow’s direction) and Y-axis (direction of the blade rotation) are extracted at 16 sections over the whole span and compared with the experimental measurements, the BEM (for both 5 and 16 sections), and the FSI results of blades with the NREL original shape. X- and Y-direction displacements are plotted in the same graph for each wind speed case. For all speed values, the deformation in the downstream direction (X-axis) is found to be larger than the one along the Y-axis.

Figure 16 presents the displacements along the blade span at wind speeds of 5 m/s and 7 m/s. In both cases, the deformation from NREL measuring is the largest. Smaller displacements for a Type 1 blade are found compared to the FSI results using the original shape. The results were close to the results of the BEM analysis with 16 sections. The BEM results using five sections, however, show a significantly larger deviation from the experimental results. At low wind speeds (5 m/s and 7 m/s), the Type 1 blade resulted in less deformation than the blade of its original shape for both experimental measurements and FSI analysis. In the relevant CFD analysis [

26], the thrust force of a Type 1 blade was found to be slightly less than that of the original blade. It indicates that the structural deformation along the X-axis is expected to be smaller. The structural results are, therefore, in good agreement with the previous CFD simulations, and the thrust effect of the pointed-tip shape can be found in the structural displacements over the span.

These X- and Y-displacements increase with the wind speed, as seen in

Figure 17. At a wind speed of 10 m/s, the X-displacement reached 33 mm at the tip for the pointed shape (Type 1) which is 13 mm more than the displacement found at 7 m/s. It can be seen that the X-displacements for this case are the same as those from the original shape using the FSI method. The experimental measurements provided the largest displacement, although the difference between the FSI results and experimental measurements was not large. It is worth noting that the effect of the fluid on the tower was not considered, which resulted in smaller displacement values for all FSI cases compared to the experimental results. The main objective was to compare the structural performances of the three pointed blades with the performances of the original NREL wind turbine blade using FSI method. The torque generated by the wind turbine with a pointed tip was found to be larger than the blade with the original tip shape at 10 m/s; therefore, the Y-axis displacements at this speed were slightly larger than the original shape.

At wind speeds of 13 m/s and 15 m/s, the thrust forces on a blade Type 1 and the original shape calculated in CFD analyses were found to be lower than the experimental measurements. Significant differences are also observed in the directional displacements, accordingly, as seen in

Figure 17. Furthermore, the CFD analysis results show no effects on the structural displacements between the tipped blade and the original blade at wind speeds of 10 m/s and 13 m/s. At a wind speed of 15 m/s, the shape effect is observed in the X-displacement values along the span. The pointed-tip X-displacements, in this case, were similar to the ones of the original NREL shape using FSI near the hub. Starting from approximately 60% of the span, the displacement of the tipped blade was slightly less than that of the original shape. For the medium wind speeds, the maximum X-directional displacements are observed to be in the range of 30–34 mm; meanwhile, the maximum value for Y-directional displacements remained between 9 mm and 11 mm.

At high speeds of 20 m/s and 25 m/s, the thrust value increased, which generated larger displacements in both X- and Y-directions. The displacements of blades with pointed tips were found to be less than those of the original shape. The results show that the X- and Y-displacements of the last section were increased by 29% from 20 m/s to 25 m/s, as seen in

Figure 17.

The previous study has clearly shown that the deformation of the blades is dominated by the displacements along the X-axis. The blade modified with a Type 1 tip generates smaller displacements than the blade with the original shape in all wind speeds concerned in this study except 10 and 13 m/s. The blade with a Type 1 tip was observed to be subjected to lower thrust than the blade with the original shape and the shape effect was negligible at wind speeds of 10 m/s to 15 m/s due to the unstable flow observed within this region [

26]. The shape effects demonstrated in the structural displacements were found to be similar to the original shape for wind speeds of 10 m/s and 13 m/s, and negligible for the wind speed of 15 m/s.

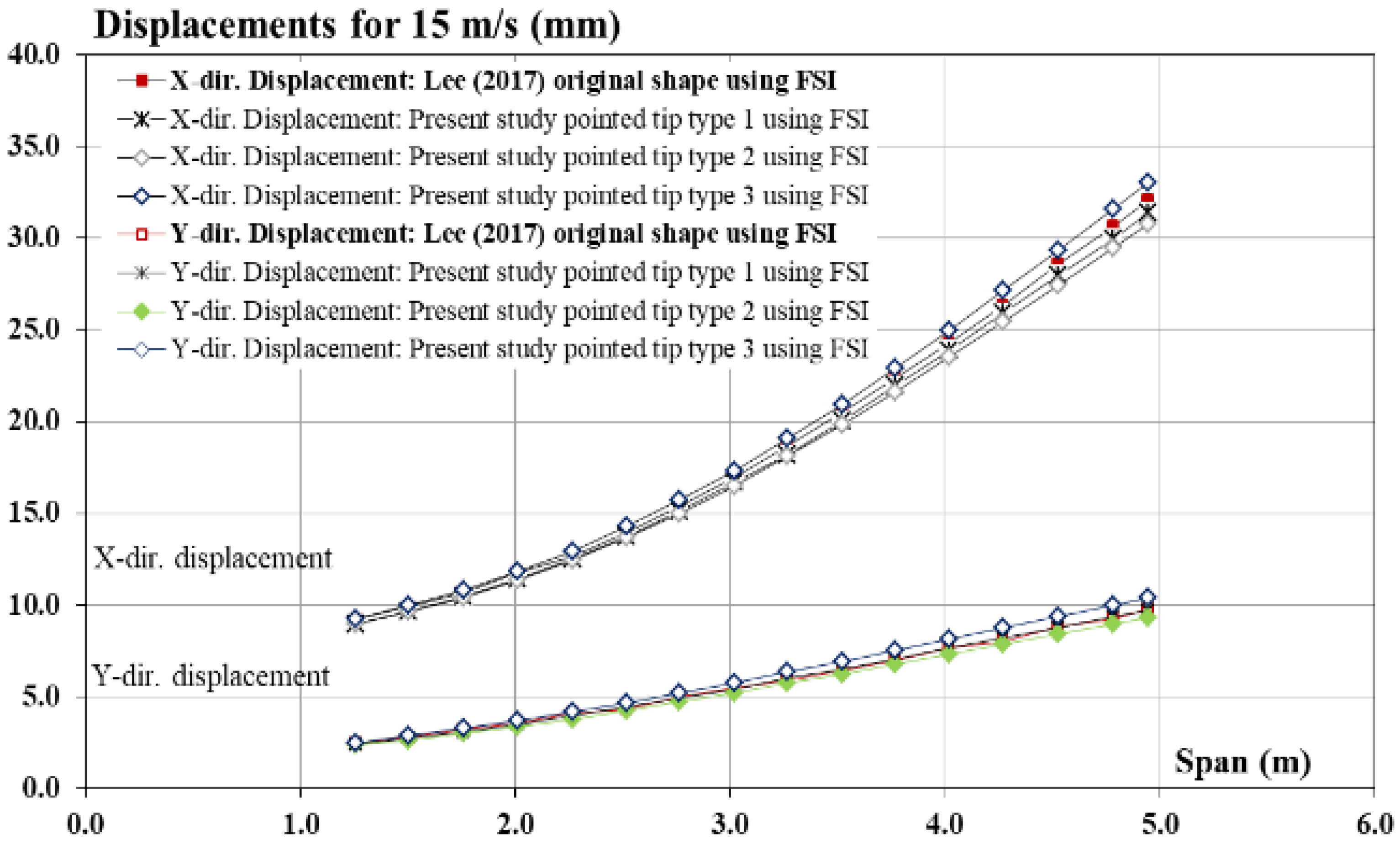

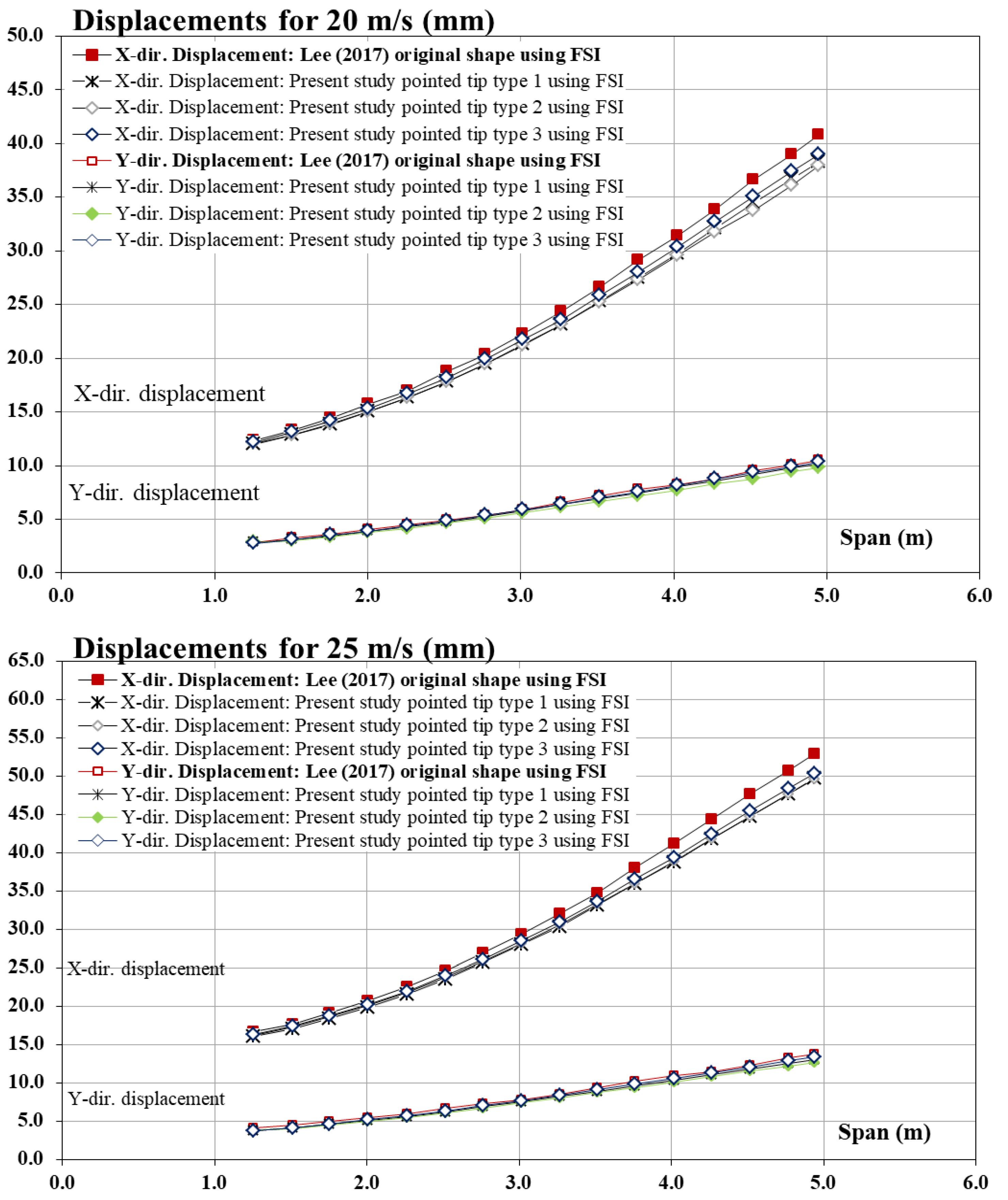

In this study, the directional displacements of blades with three different pointed-tip shapes are compared with those from the FSI analysis using the blade with the original shape, as seen in

Figure 18. At low wind speeds (i.e., at 5 m/s and 7 m/s), the results of the blade with pointed tip Type 3 show a small deviation from those of the original shape. At a wind speed of 5 m/s, the blade of the original shape is found to undergo the largest X- and Y-displacements. For the blade with pointed tip Type 3, maximum displacements in the X- and Y-axes decreased by 1.58% and 15.32%, respectively, from the results of the original shape. At the wind speed of 7 m/s, an increase from the results of the original shape is observed in the maximum X- and Y-displacements of blade Type 3 by 0.67% and 2.6477%, respectively. The other two blade shapes (Type 1 and Type 2) generated smaller X-displacement compared with the original shape. For the Y-displacement, the blade with a Type 2 tip is found to be subjected to the smallest displacement within all the concerned blades.

At wind speeds of 10 m/s and 13 m/s, the shape effect is found to be insignificant for blades with the Type 1- and Type 2-pointed tips Type 1Type 2 in terms of X-axis and Y-axis displacements. However, the blade with the leading-edge-tapered tip (Type 3) is subjected to increased deformations along the X- and Y-axes by 7.01% and 9.27%, respectively. For those wind speeds, the CFD analysis results in higher torque and thrust values for blade Type 3, which explains the increase in the Y- and X-displacements, respectively.

At a wind speed of 15 m/s, a decrease in the difference between the thrust and torque forces of the blade Type 3 and the original shape is observed compared with the results from lower wind speeds. As shown in

Figure 19, the X-displacement deviation of Type 3 from the original shape decreases to 3%. The Y-displacements are still larger than the original shape, although the deviation decreased to 6.9%. The blade Type 2 undergoes the smallest displacements at this wind speed.

For high wind speeds (20 m/s and 25 m/s), the flow around the turbine gets separated from the back side of the blades due to the increase in the angle of attack that represents the angle between the airflow and the chord line of the airfoil. The change in the shape at the tip did not capture the effect of the pointed geometry; therefore, the thrust force (that is responsible for the X-displacements) of the original shape was the highest. This resulted in higher values of displacements along the X-axis compared to the other three cases. The change in torque was insignificant at these high wind speeds; therefore, Y-displacements of the three pointed tip cases were very close to those of the NREL shape. But, Type 2′s displacements remained the lowest. From 20 to 25 m/s, the deformation increased. The highest X- and Y-displacements were captured at 25 m/s and for all four shapes, an increase of more than 24% occurred as seen in

Figure 20.

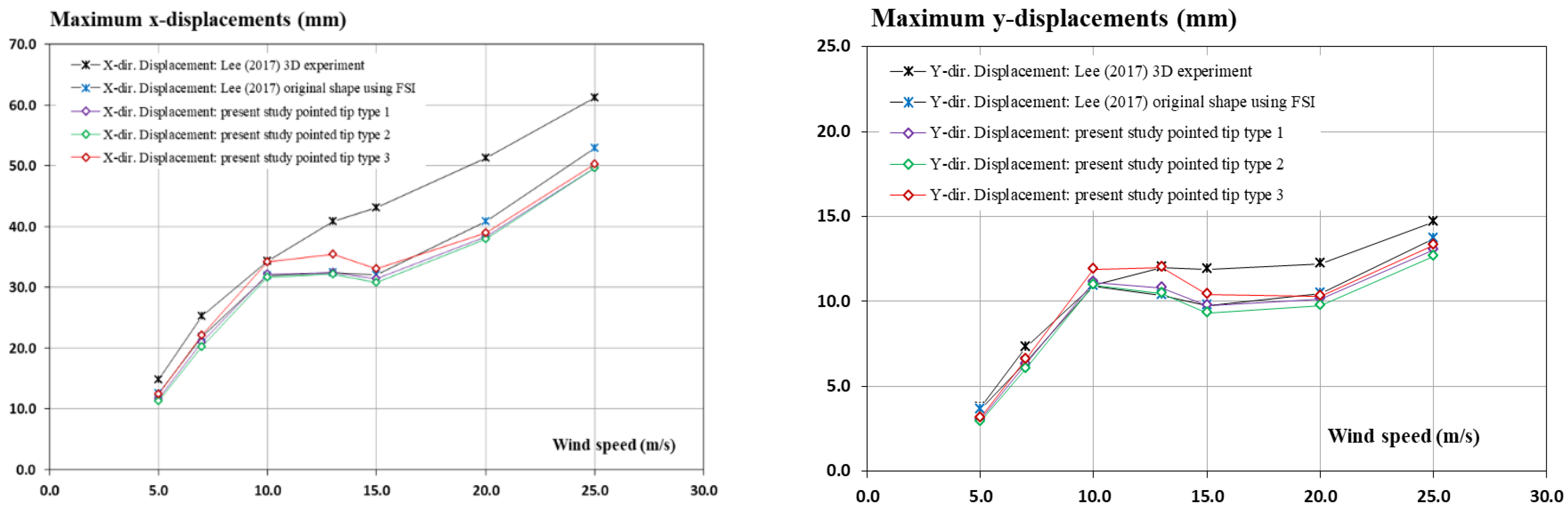

Figure 21 shows the comparison of maximum X- and Y-axes displacement for different blades. It is found that the experimental measurements overall undergo the largest maximum displacements along the X-axis, and these values increase with the wind speed. It can be concluded that the FSI method underestimated the displacements caused by the flow due to the complex three-dimensional effects of the air on the surface of the blades. The influence of modified tip shapes on the aerodynamic forces on the structures of the wind turbine is considerable, specifically on the blades. This shape effect results in a small reduction in the maximum X-axis displacements on the pointed-tip blades at low wind speeds. The blade with a Type 3 tip, however, undergoes a slightly higher deformation along the X-axis than the original shape using the FSI method. From wind speeds of 10 m/s to 15 m/s, the FSI simulations indicate that the Type 3 blade showed maximum displacements that exceeded the ones of the original NREL shape. Small variations from the original case are observed from the results with the other pointed tips (Type 1 and Type 2). At higher wind speeds, the maximum displacements of NREL blades are found to be larger than the results analyzed in our present study.

The maximum Y-axis displacements of different blades are also compared with the results of the original NREL blade. At low wind speeds, the blades with pointed tips undergo less displacement than the experimental measurements. At the mid-range speed (10–13 m/s), however, the pointed-tip effect augmented the displacements on blade Type 3 more than the experimental measurements. The maximum Y-axis displacement decreases again for the blade Type 3 at 15 m/s, while remaining larger than the blade with the original shape in FSI simulations. At higher speeds, the shape effect of the tip modification is relatively insignificant, as the change in the maximum displacements is found to be like each other with the original shape undergoing the largest displacement. Even though the Y-axis displacements are considerably smaller than those in the X-axis, one of the pointed-tip shapes resulted in larger deformations than the original shape along the Y-axis in the mid-range of wind speeds. The increase could cause further deformations in the structures and eventually reduce the stability of the wind turbine.

3.3. Total Deformation

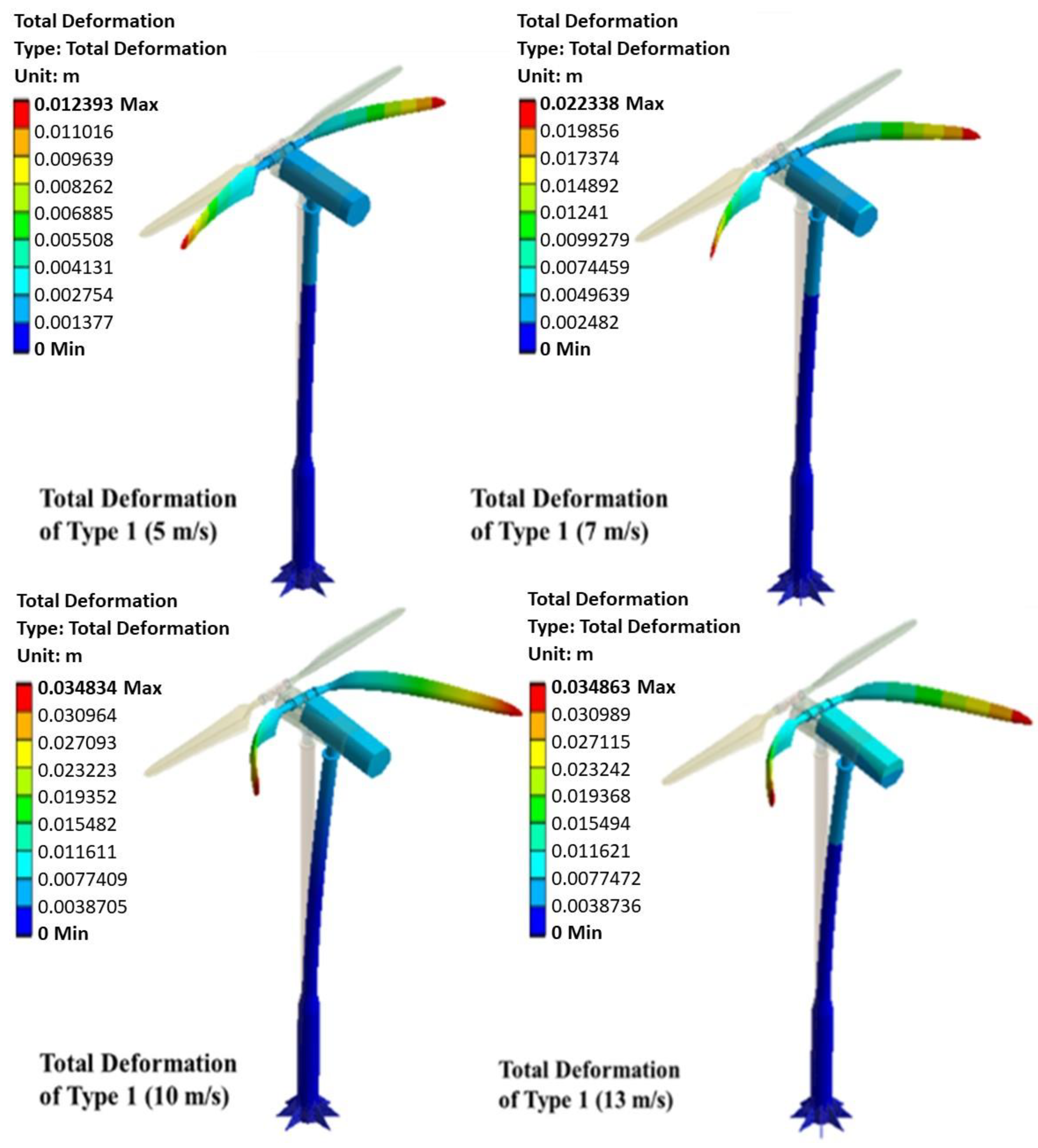

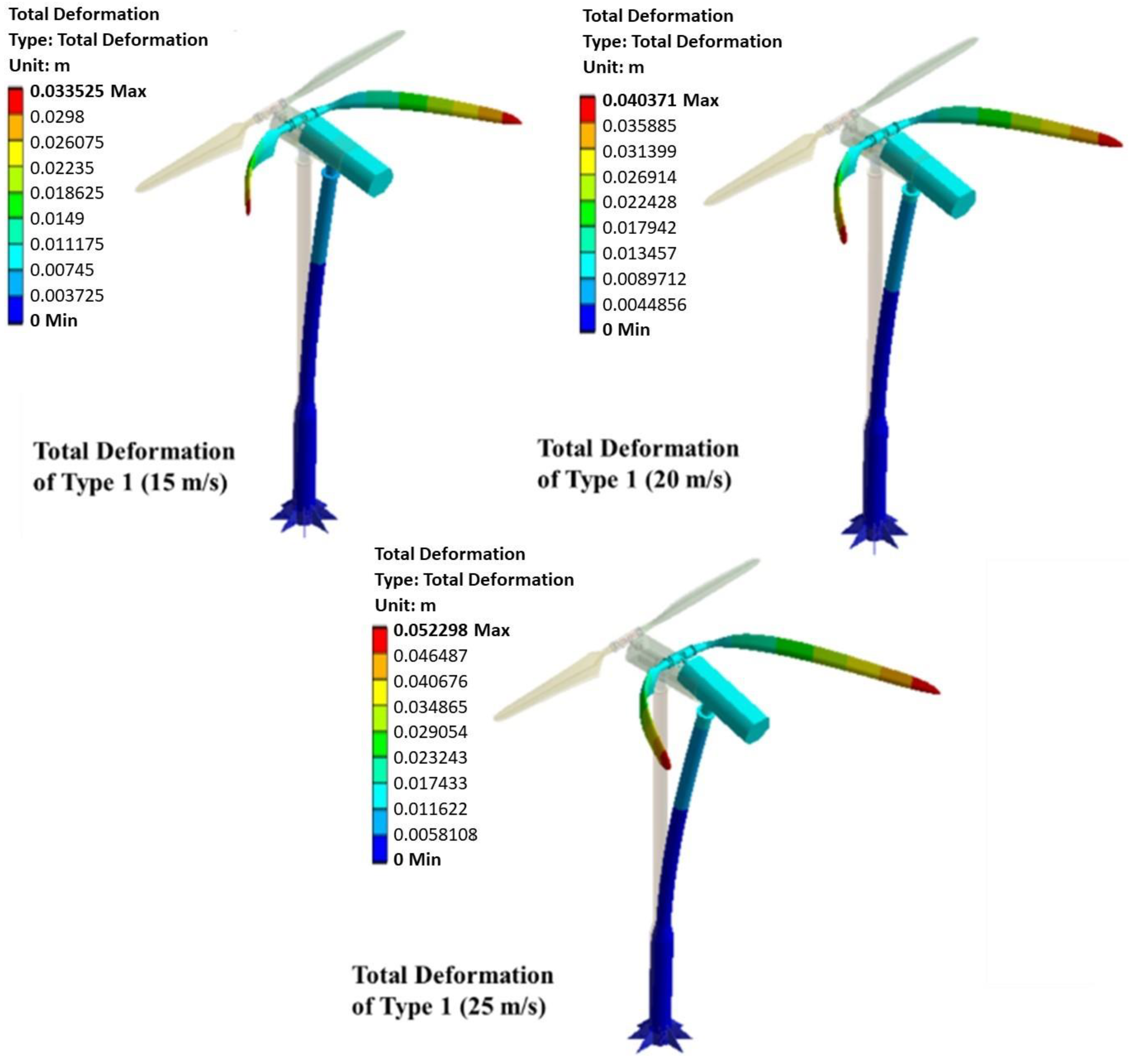

The aerodynamic loads that wind turbines encounter from the wind can be represented as thrust (in the X-axis direction) and torque (in the Y-axis direction), with the latter driving the rotor for power generation. These loads also result in the deformation of the wind turbine blades. For horizontal axis wind turbines, like the turbines considered in this study for instance, the maximum total deformation of the blade normally occurs at the tip. In the structural analysis of this study, the bottom of the tower is specified as a fixed support. Therefore, the minimum deformations occurred at the tower structure for all wind speeds.

Figure 22 below shows the increase in the total deformation of blade Type 1 with the change in the wind speed. The deformation of the turbine and the shape of its original model are represented to investigate the load effect on the structure. The deformation is magnified 130 times to facilitate the observation of this effect. The color distribution indicates the deformation values distributed along the whole wind turbine structure and the maximum deflection is observed at the tip of the blades for all wind speeds. It can also be seen that the effect of the blades’ surface pressure distribution on the tower is negligible at low wind speeds, but increases gradually with the wind speed. Furthermore, the same change pattern of structural deformation along the blades is observed for all concerned blade shapes.

The intensity of aerodynamic loads depends on the wind speeds; therefore, the blade deformation over the span for all concerned speed cases is compared for each type of blade separately in

Figure 23. At wind speeds of 5 m/s and 7 m/s, the airflow (wind) striking the blades forms a small angle of attack with reference to the chord line of the airfoil of turbine blades. This small angle of attack results in attachment of the flow on the upper and lower surface of the airfoil. In this region, the ratio of the aerodynamic forces as lift-to-drag (also indicating the efficiency of the turbines) increases with the angle of attack. Both the thrust and torque, generated from the lift and drag forces, increased with the wind speed in this region. Therefore, the total deformation increases drastically from 5 m/s to 7 m/s for all three blades. The maximum values at wind speeds of 7 m/s for the pointed tips Type 1, Type 2, and Type 3 increased to 80.4%, 81.5%, and 80.2% compared with 5 m/s, respectively. For medium wind speeds (at 10 m/s, 13 m/s, and 15 m/s), the ratio of lift-to-drag is found to reach its local optimum value and then begins to decrease again. In this speed region, flow separation is observed to occur at certain blade locations. The torque force for all blades reaches its maximum value at 10 m/s. On the other hand, the thrust force increases gradually from 10 m/s to 15 m/s, although the deformations observed at the three wind speeds are similar. According to the relevant CFD results [

26], the thrust force distribution along the span for 10 m/s, 13 m/s, and 15 m/s were shown to be close to each other towards the tip. Therefore, the overlapping of deformation results is found at those wind speeds. At high wind speeds (20 m/s and 25 m/s), the flow gets separated from the suction side of the blade. Therefore, the torque force decreased compared with lower-speed cases. The thrust force though continues to increase, and the relevant maximum total deformation is found at a wind speed of 25 m/s. The largest deformation overall is found on the blade Type 3 at a value of 52.06 mm.

3.5. Stress Distribution

Stress analysis is an important approach in the structural design practice as the failure of most structural components is usually due to stress. A material is determined to start failing when its Von Mises stress is larger than the yield stress of the material, which is known as the Von Mises Yield Criterion. FEA-stress analysis allows the prediction of the areas where the maximum stress value occurs. In this study, polyethylene is used as the material of the blades, and its tensile yield strength is 25 MPa.

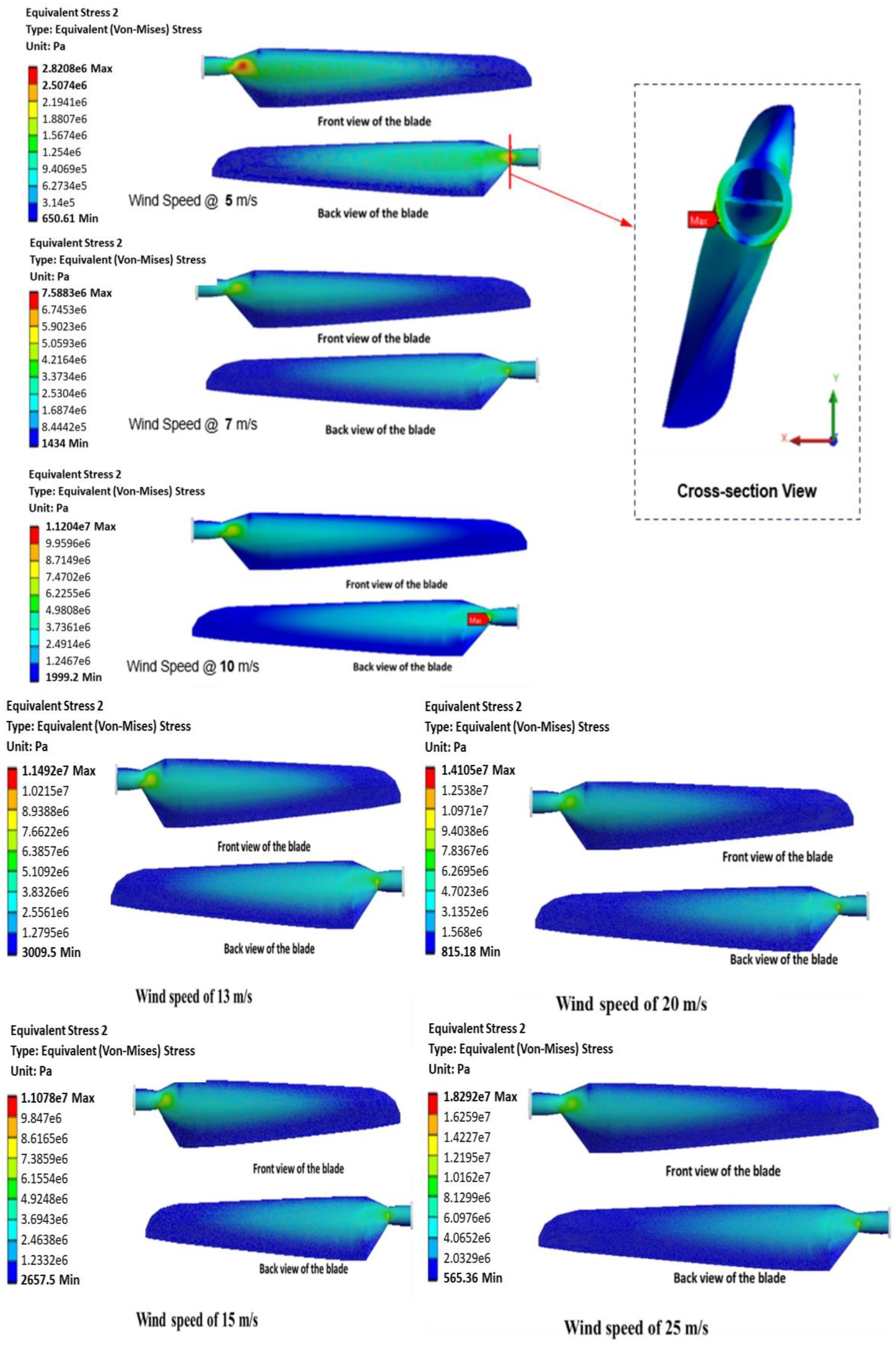

As shown in

Figure 25, the stress distribution of blade Type 3 is represented for all wind speeds. It includes a front view of the blade which faces the wind, and a back view of the blade. For wind speed of 5 m/s, in particular, an internal view to visualize the stress distribution inside the blade is also plotted for illustration. The maximum stress was detected at the back of the blades on the transition between the root and the airfoil section of the blade. The wind speed of 5 m/s is the lowest considered in this analysis; therefore, the maximum equivalent stress value is considerably small compared with the material yield strength. The maximum stress value is 2.82 MPa which is about one-eighth of the yield strength of polyethylene. With the increase in wind speed, the maximum equivalent stress value increases, while its distribution along the blade remains similar. The stress becomes more concentrated in the back of the transition section of the blade.

From 5 m/s to 7 m/s, the maximum stress increases by 169%, which is due to the change in both thrust and torque forces that occurred between those two speeds. At the wind speed of 10 m/s, the maximum stress is found to be larger than the one at 7 m/s with an increase of 47%. After 10 m/s, the torque force experiences a small decrease, while the thrust force continues to increase. This effect results in a minor change in the maximum equivalent stress which is a 2% increase from 10 m/s to 13 m/s. For this blade with a Type 3 tip, the torque decreased after 13 m/s with a bigger slope. Therefore, a small decrease in the maximum stress value occurred at 15 m/s. At high wind speeds, the maximum stress reached 14.1 MPa and 18.3 MPa at wind speeds of 20 m/s and 25 m/s, respectively, and is almost three-fifths and four-fifths the yield strength, respectively. Blade Type 3 results in larger maximum stress values overall, but even at the highest speed, the equivalent stress remains smaller than its yield limit. The stress–strain for all the wind speeds is considered to remain linear, and the strain generated will not cause a break or a failure of the material.

The CFD results [

26] showed that blade Type 3 generates the largest torque for all wind speeds and thrust is relatively larger compared to Type 1 and Type 2. The reaction of the blades to those loading forces shows that the largest stress values occurred with Type 3.

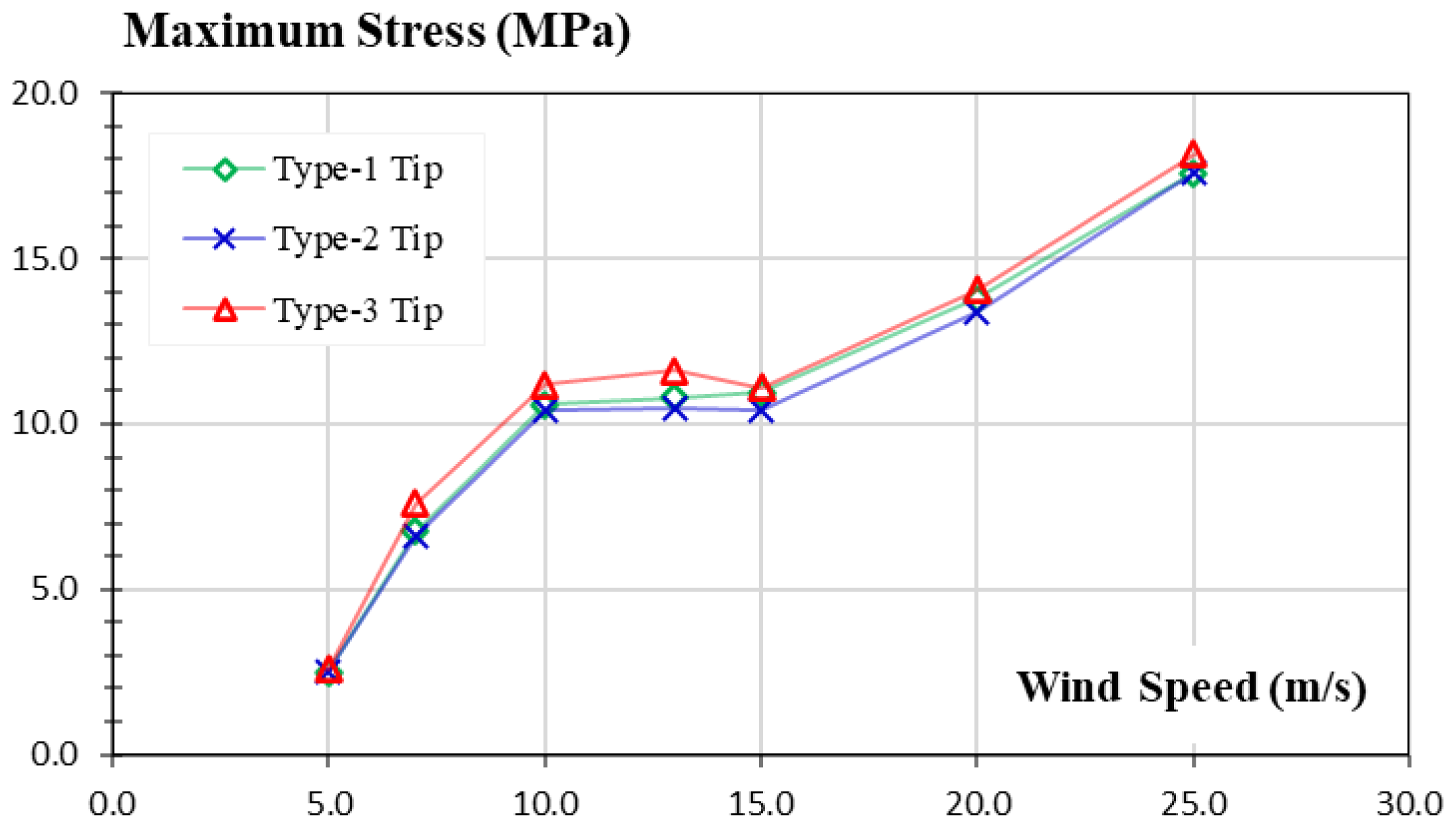

Figure 26 shows a comparison of the maximum stress values among blades with all three tip shapes at each of the seven considered wind speeds. It can be seen from the plot that the blade Type 2 experiences the lowest stress. At low speeds (5 m/s and 7 m/s), the difference of stress between the three types of blades is negligible. From a wind speed of 10 m/s to 13 m/s, the change in the maximum stress for each blade is also insignificant for the three blades. An increase in the maximum stress from the value captured at 10 m/s occurred, and at 13 m/s relevant increase reached 1.4%, 1.04%, and 2.5% for blades Type 1, Type 2 and Type 3, respectively. From 13 m/s to 15 m/s, the maximum stress decreases slightly. After 15 m/s, the stress starts to increase again to reach the maximum value of 17.655 MPa, 17.686 MPa, and 18.2972 MPa for Type 1, Type 2, and Type 3, respectively. These maximum stress values found at the highest wind speed is still less than the yield stress of the material for all three shapes.

3.6. Strain Distribution

Strain is the amount of deformation experienced by the body that results from an applied force (stress). It is calculated as the ratio of the deformed dimension to its original value. In this study, a static-structural analysis is performed, in other words, the variations of the loads and the structure’s response with respect to time are assumed to be insignificant in the analysis. The objective of this study is to predict the structural behavior of the wind turbine blades due to the geometry change with modified tips.

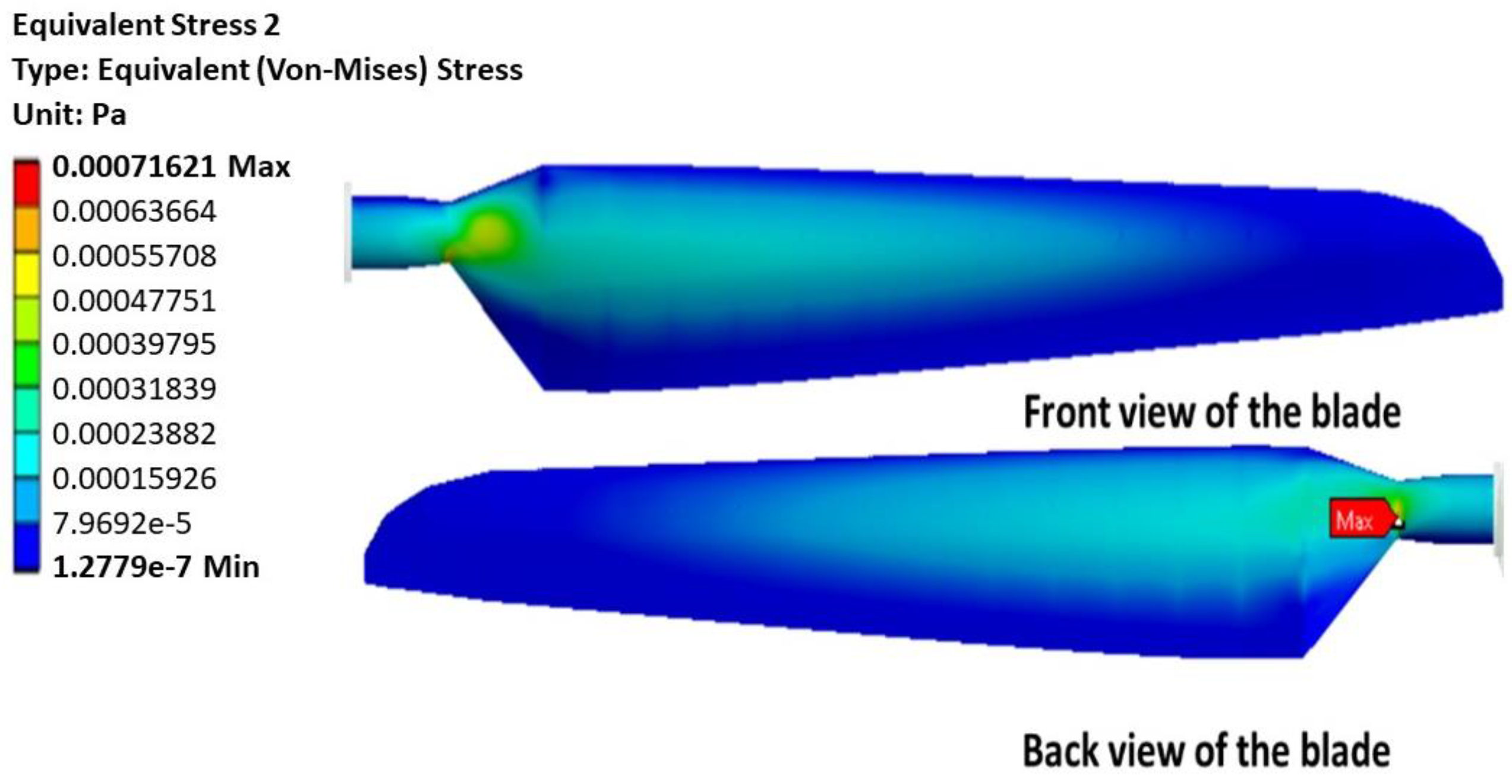

The results from the CFD analysis show the efficiency of the pointed tips in terms of aerodynamics, while the displacements resulting from structural analysis show that blades modified with pointed tips experience larger deformations compared with the original blade. Like stress, the equivalent strain is a scalar value that represents the complex 3-D strains in a structure with a single scalar value. The maximum strain is found on the root of the back side of the blades. An example of the strain distribution is shown in

Figure 27 to illustrate the strain distribution along the blade with a Type 3 tip at a wind speed of 10 m/s. The front and back sides of the concerned blade present almost the same distributions. Both the leading and trailing edges exhibit smaller values while the middle area of the blade demonstrates a relatively larger strain value since the deformation is dominated by loading in the flap-wise direction. Among the three types of blades, it can be concluded that at low wind speeds (e.g., 5 m/s and 7 m/s), the tip effect is not relevant. The equivalent strain, therefore, is almost the same for the pointed-tip cases. At medium wind speeds (e.g., from 10 m/s to 15 m/s), the blade Type 3 (as predicted in the deformation values) experiences the highest value of the strain. At a wind speed of 10 m/s, the increase in the maximum equivalent strain value of blade Type 3 from those of blades Type 1 and Type 2 reached 11% and 8%, respectively. At 13 m/s, the strain values of blade Type 1 and Type 2 are close, while the value of blade Type 3 is about 9% higher. The deviation of strains between different blades decreases at 15 m/s and the value of blade Type 3 is about 4% and 7% higher than those of Type 1 and Type 2, respectively. At high wind speeds (e.g., 20 m/s and 25 m/s), blade Type 3 experiences larger deformations than the other two shapes, and the percentages of the increase are 2% and 3% for 20 m/s and 25 m/s, respectively. Two conclusions can then be made in this case; the first will be to neglect the effect of the tip on the structure of the blades since the strains were very small and focus on the increase in the torque force that was brought by the change in the tip shape. The second one will be to study the wind turbine’s structural response in extreme wind cases, and extract the strains and deformations generated to analyze the impact of the tip on higher wind speeds than the one used in this study.

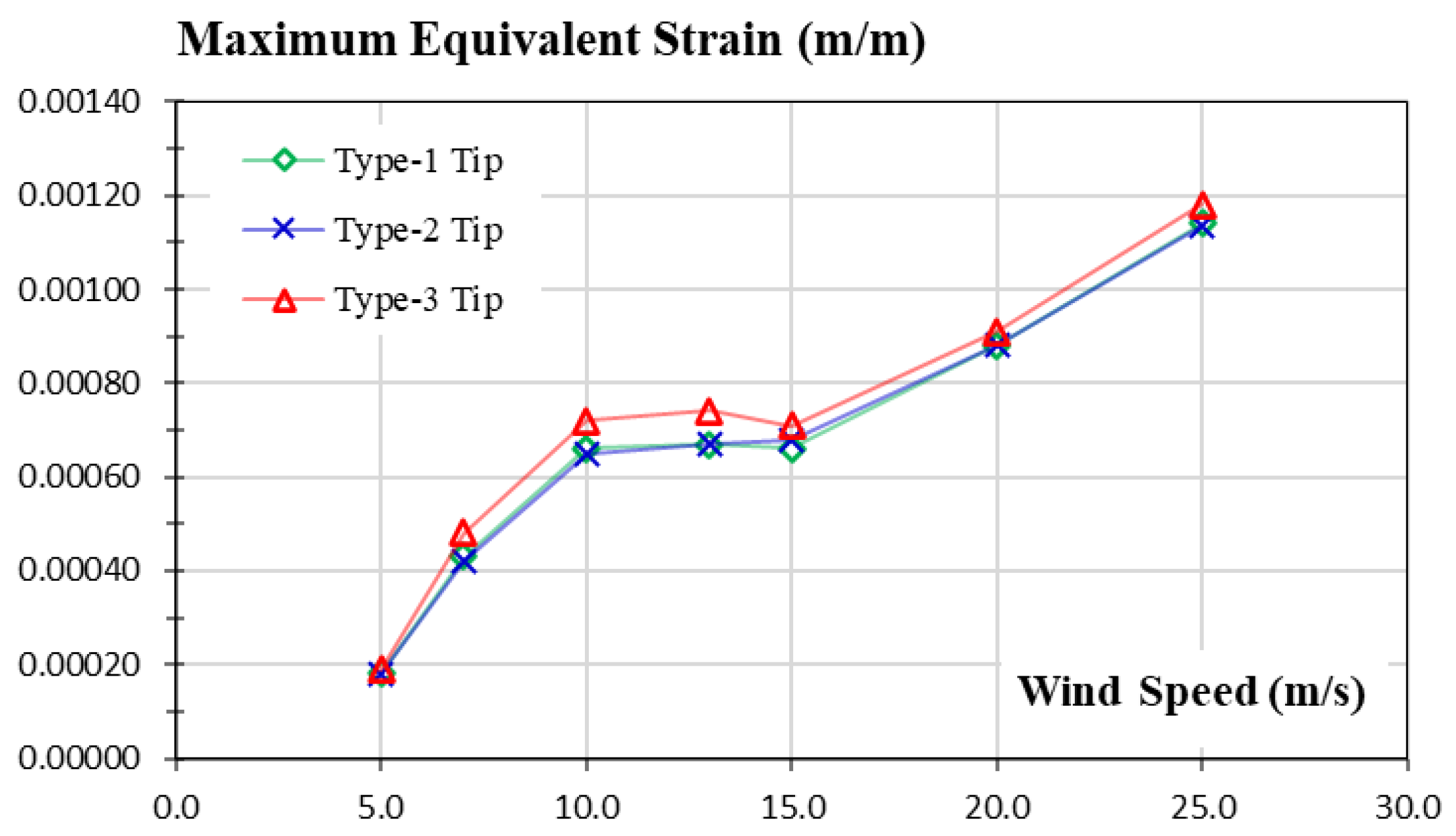

Figure 28 shows the maximum equivalent strain that occurs on the three blades at each wind speed considered in this study. Larger maximum strain values are found for blade Type 3 compared with the other two blades. For all blade types, the strain values start to increase with the incremental wind speeds in the low-speed region but become stable after a wind speed of 10 m/s. A slight decrease occurred in the maximum value of strain at 15 m/s for blade Type 3. For other blades, the strain value remains between 0.06% and 0.08% in the medium-speed range. After a wind speed of 15 m/s, the strain increases linearly with the wind speed for all blades. It is worth noting that strains observed on the blade modified with a pointed tip from its leading edge (Type 3) are larger than those of the other two blades for all concerned wind speeds, while strains of the blade with a pointed tip from the trailing edge (Type 2) are found to be the smallest at all wind speeds except for 15 m/s.