Research on the Multiscale Microscopic Pore Structure of a Coalbed Methane Reservoir

Abstract

1. Introduction

2. Experimental Methods

2.1. Principle of Low Pressure Nitrogen Adsorption

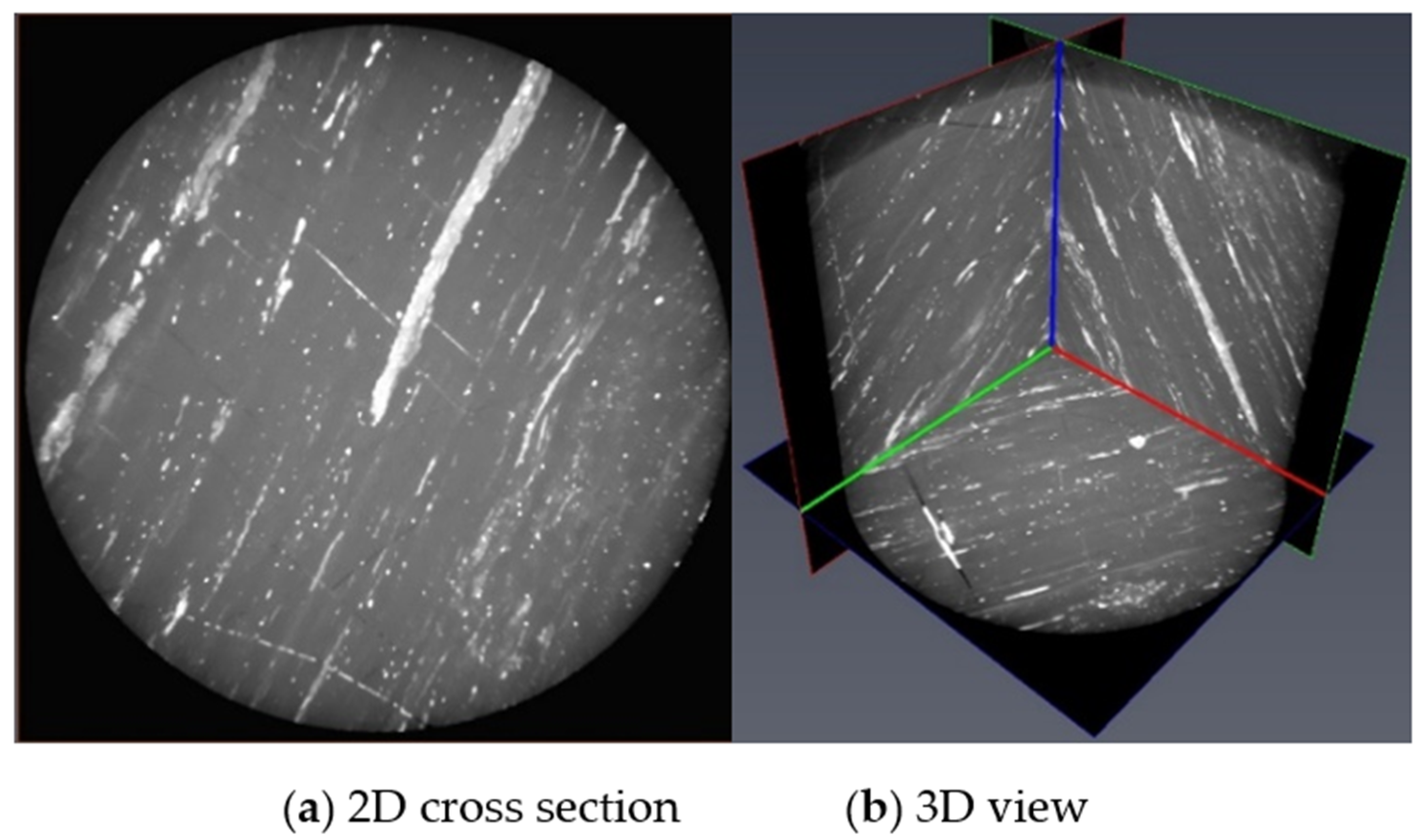

2.2. XCT Experiment

2.3. SEM-MAPs and SEM Experiments

3. Pore Development at a Single Scale

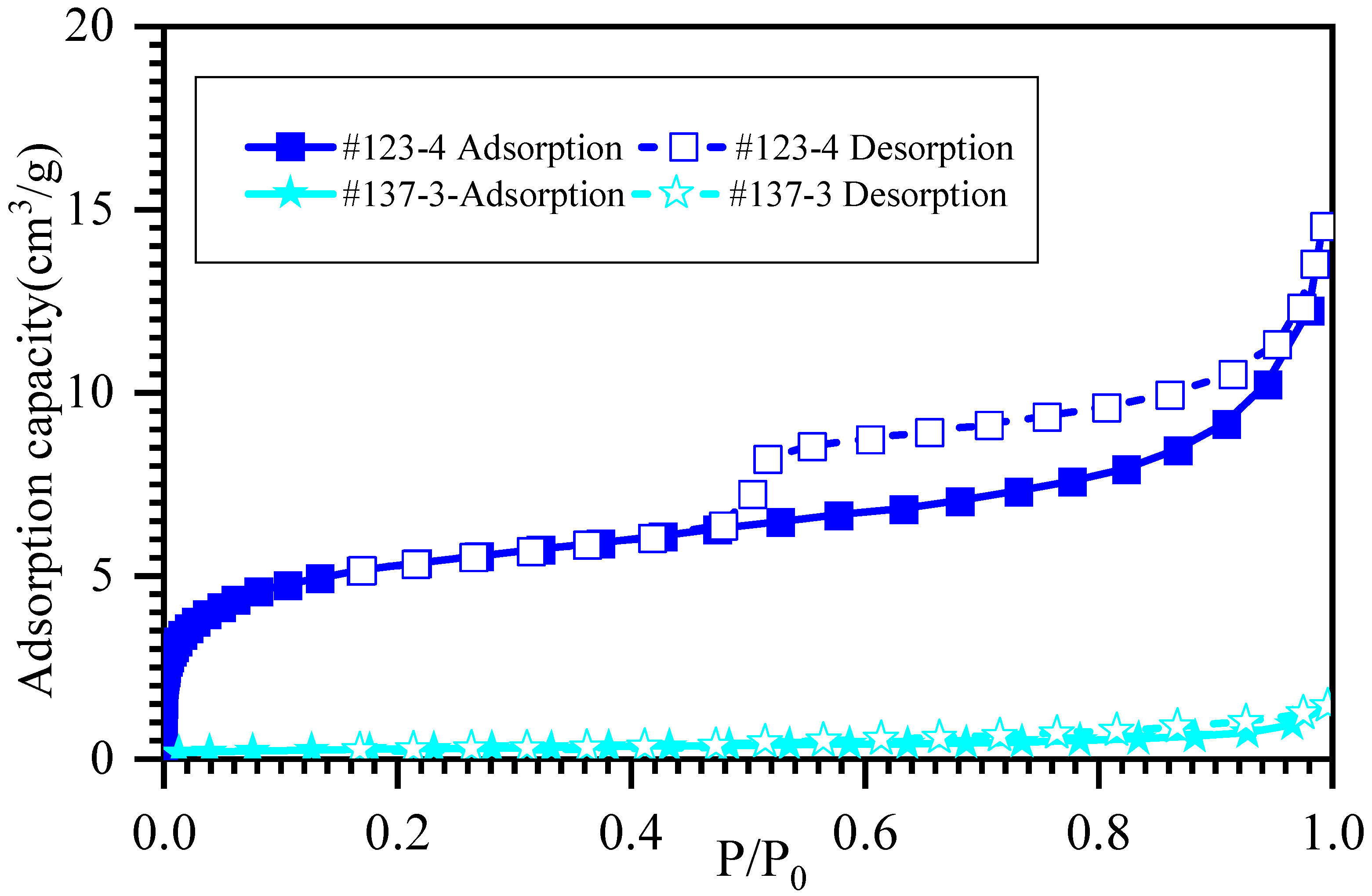

3.1. Low-Pressure Nitrogen Adsorption Experiment

3.1.1. Low-Pressure Nitrogen Adsorption–Desorption Curve Analysis

3.1.2. Distribution Characteristics of Coal Rock Adsorption Pore Structure

3.2. XCT Petrographic Analysis

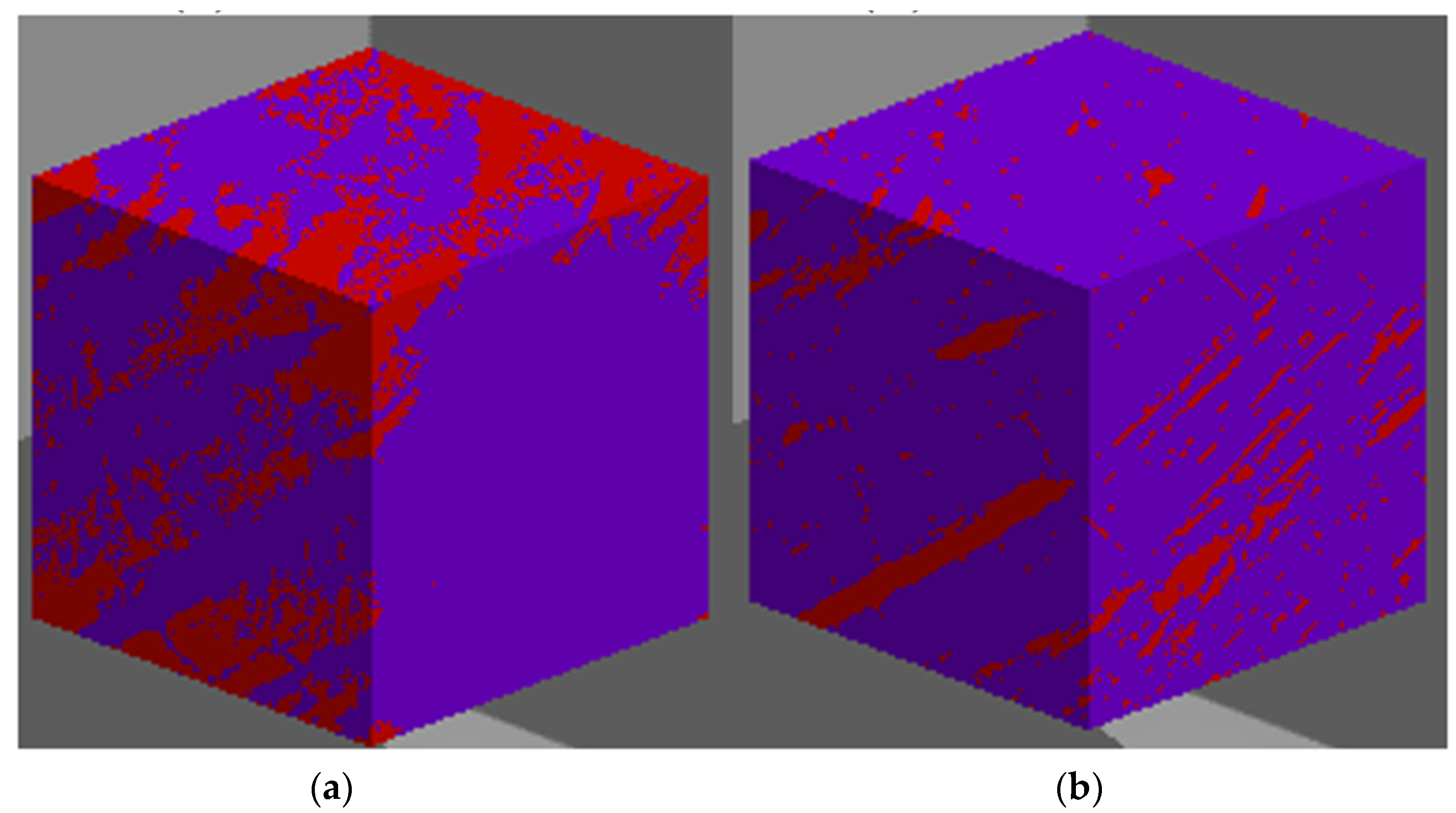

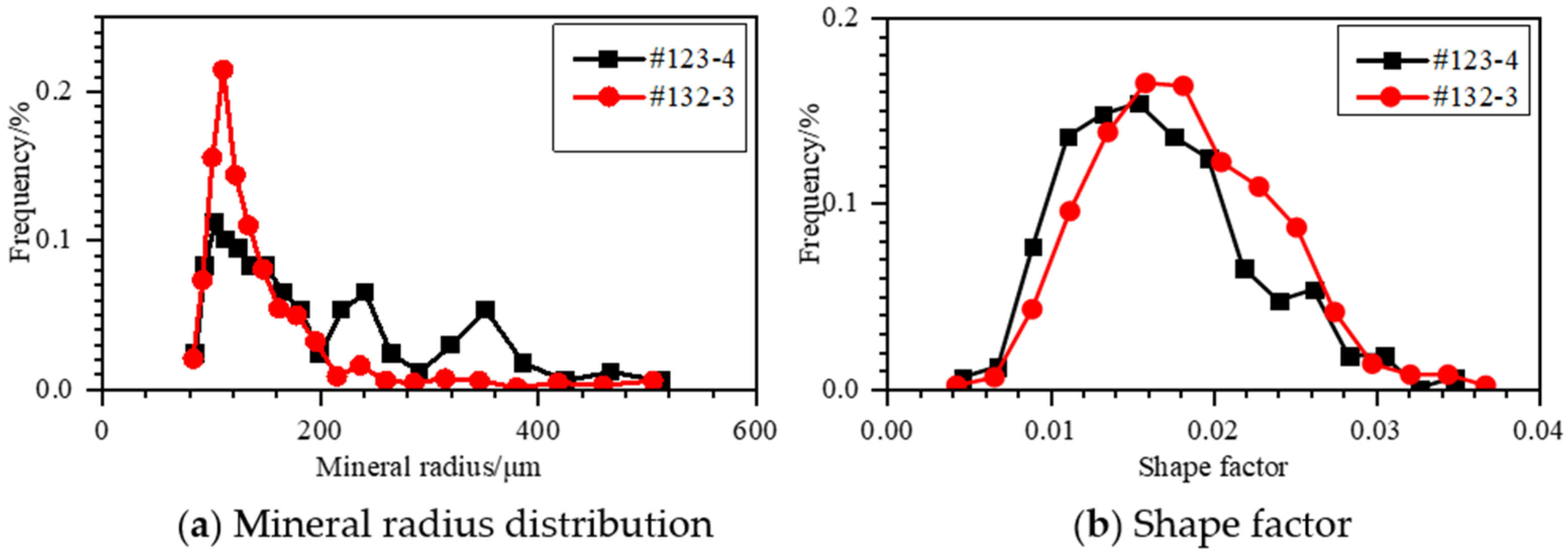

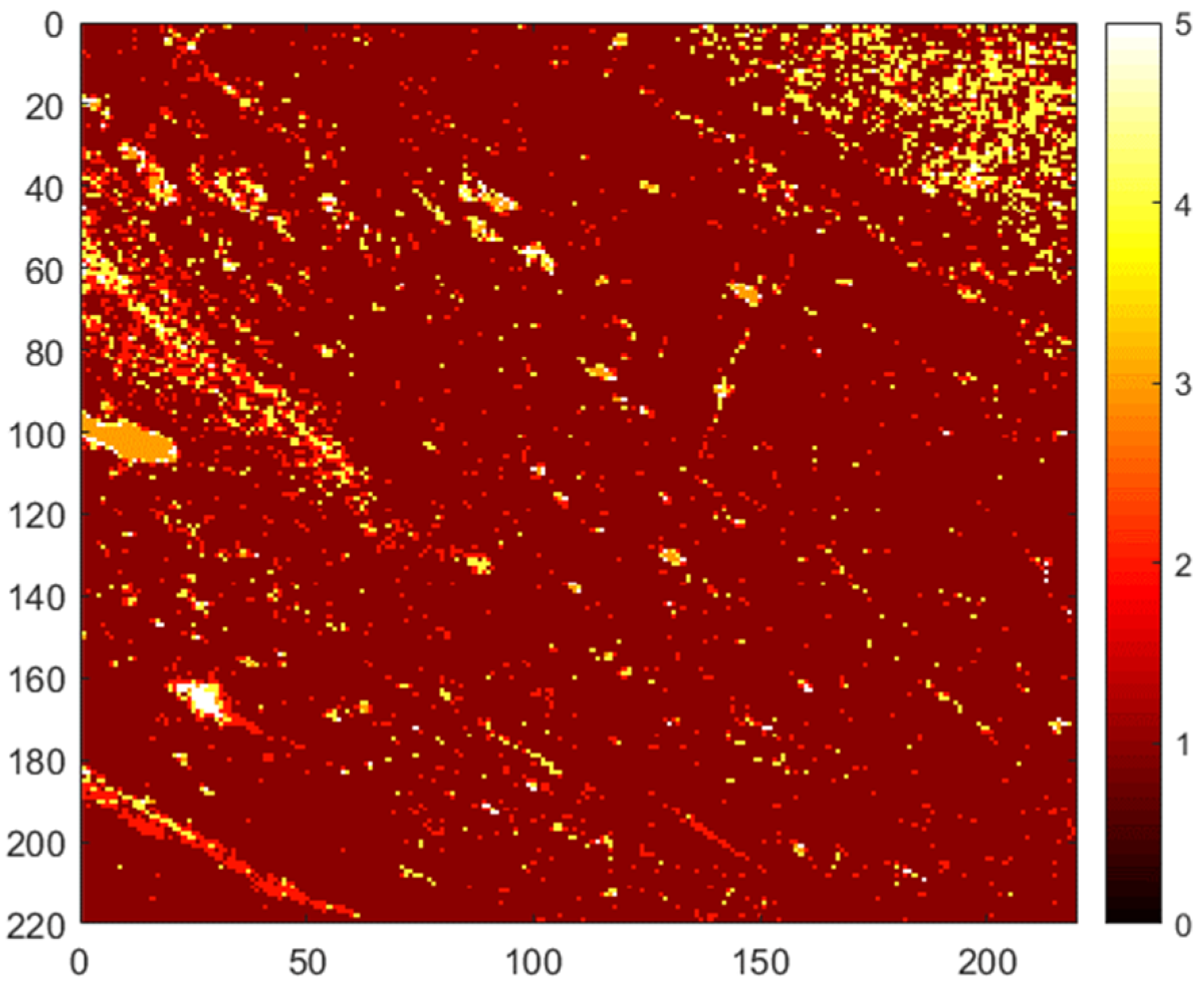

3.3. Pore Structure Analysis Based on SEM-MAPs

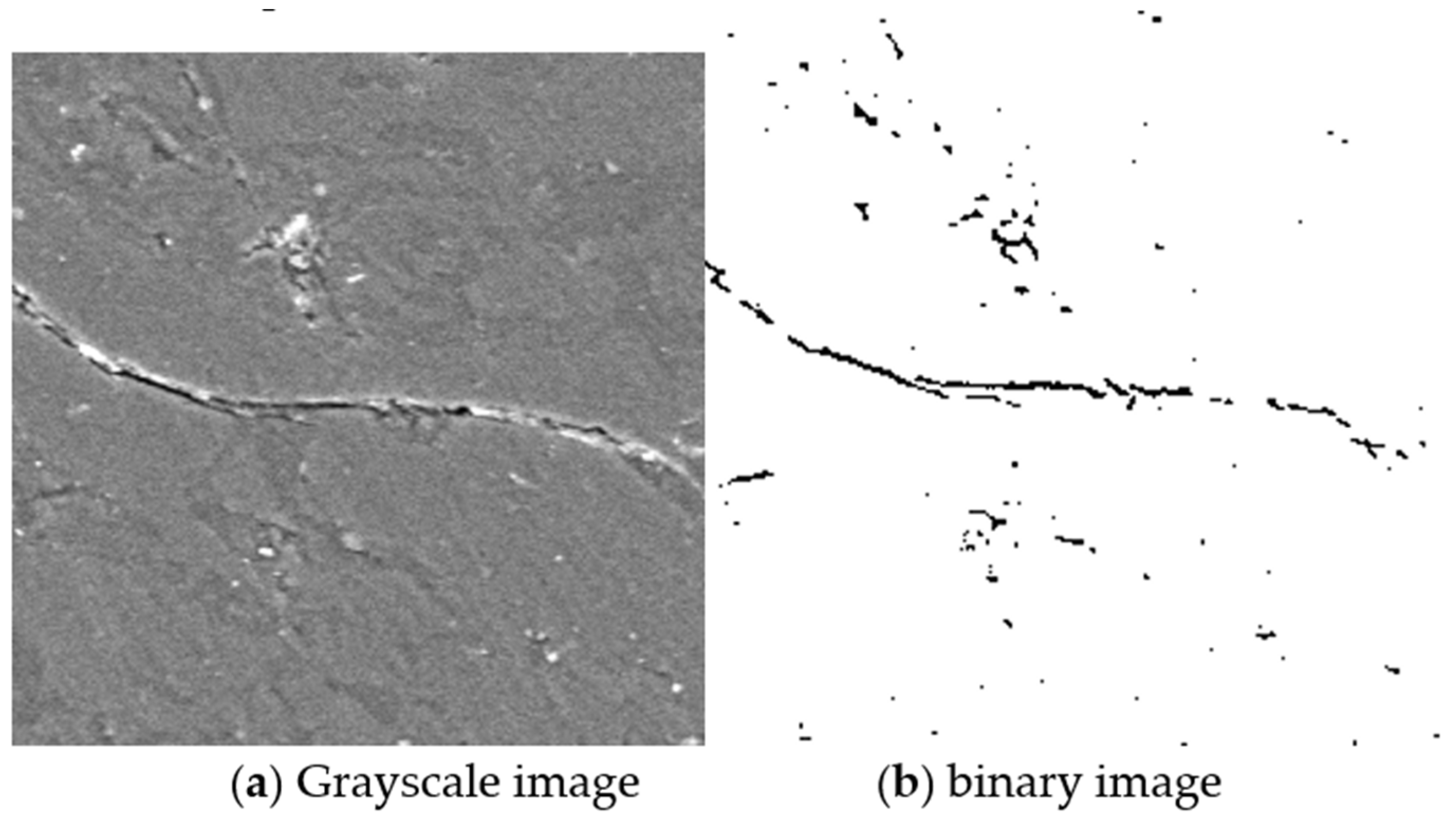

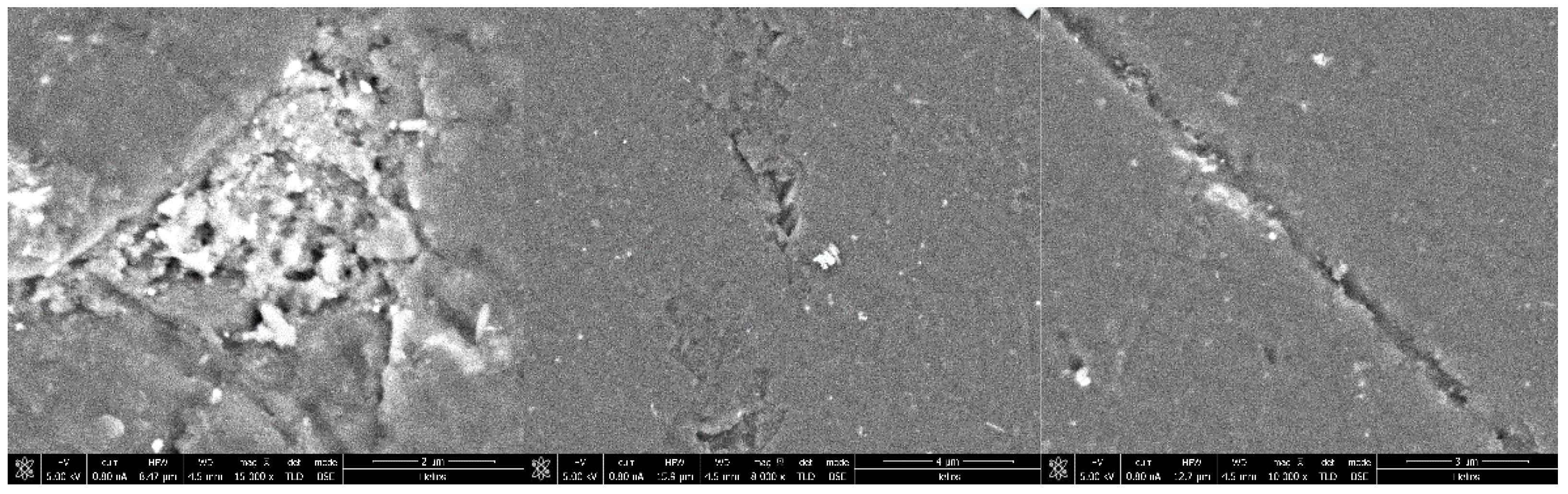

3.3.1. Micro-Fractures

3.3.2. Organic Matter Pores

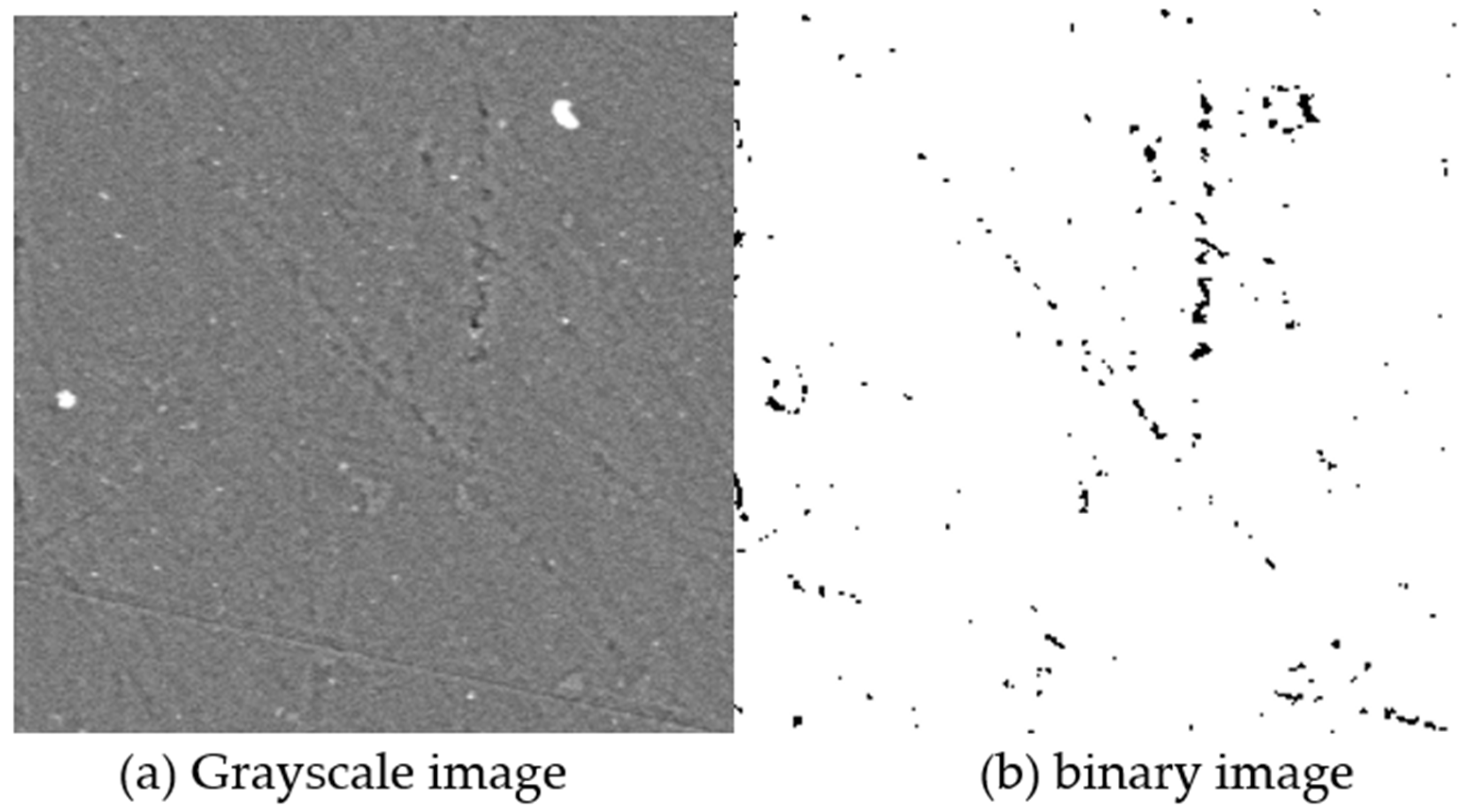

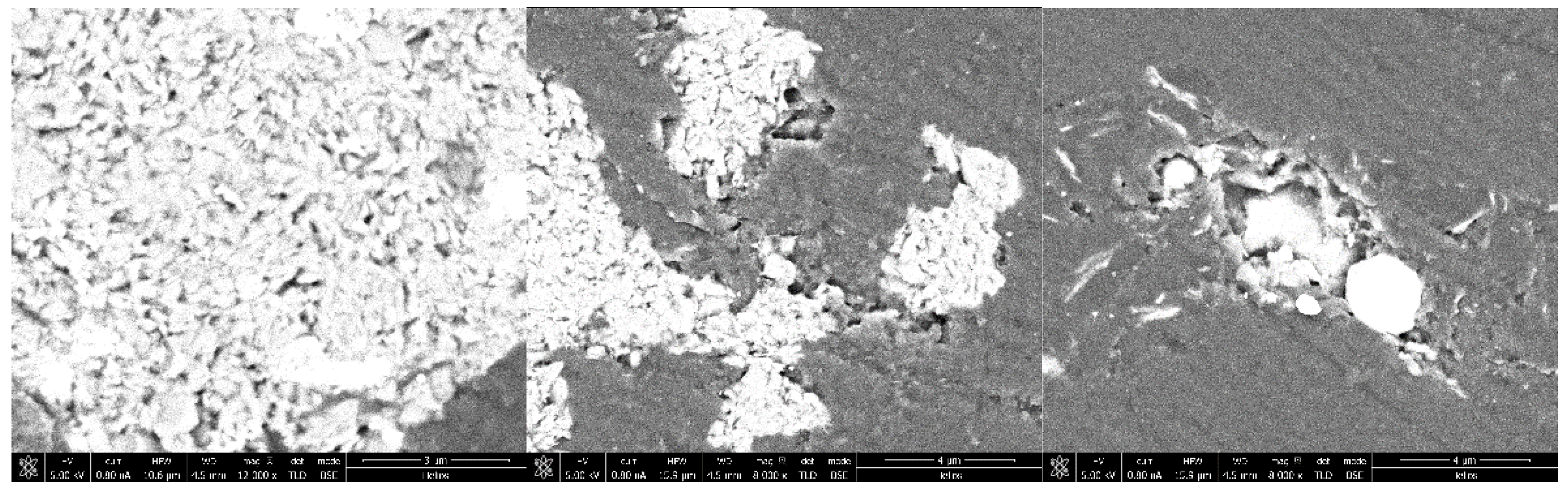

3.3.3. Inorganic Pores

3.4. SEM-Based Pore Structure Analysis

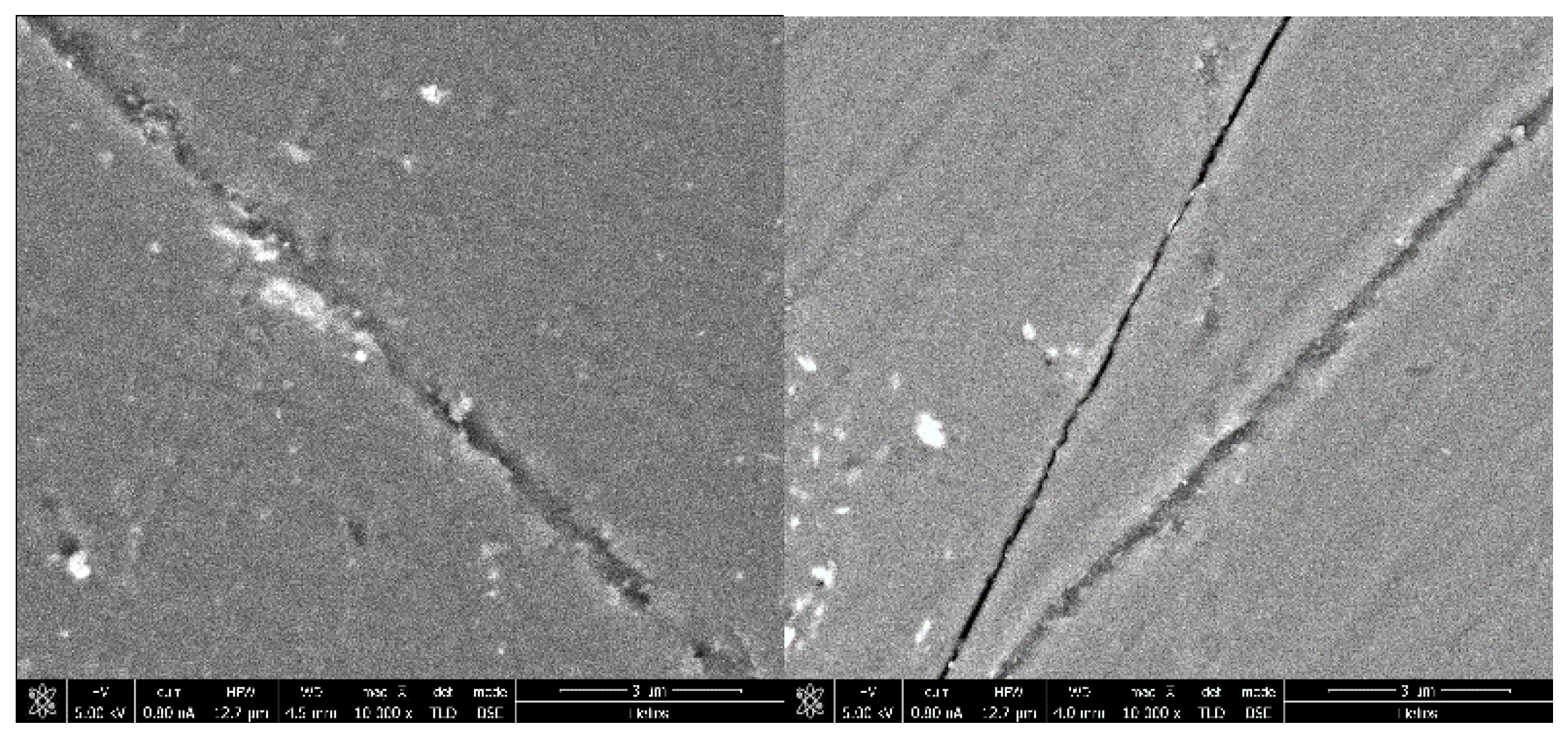

3.4.1. Micro-Fractures

3.4.2. Organic Matter Pores

3.4.3. Inorganic Pores

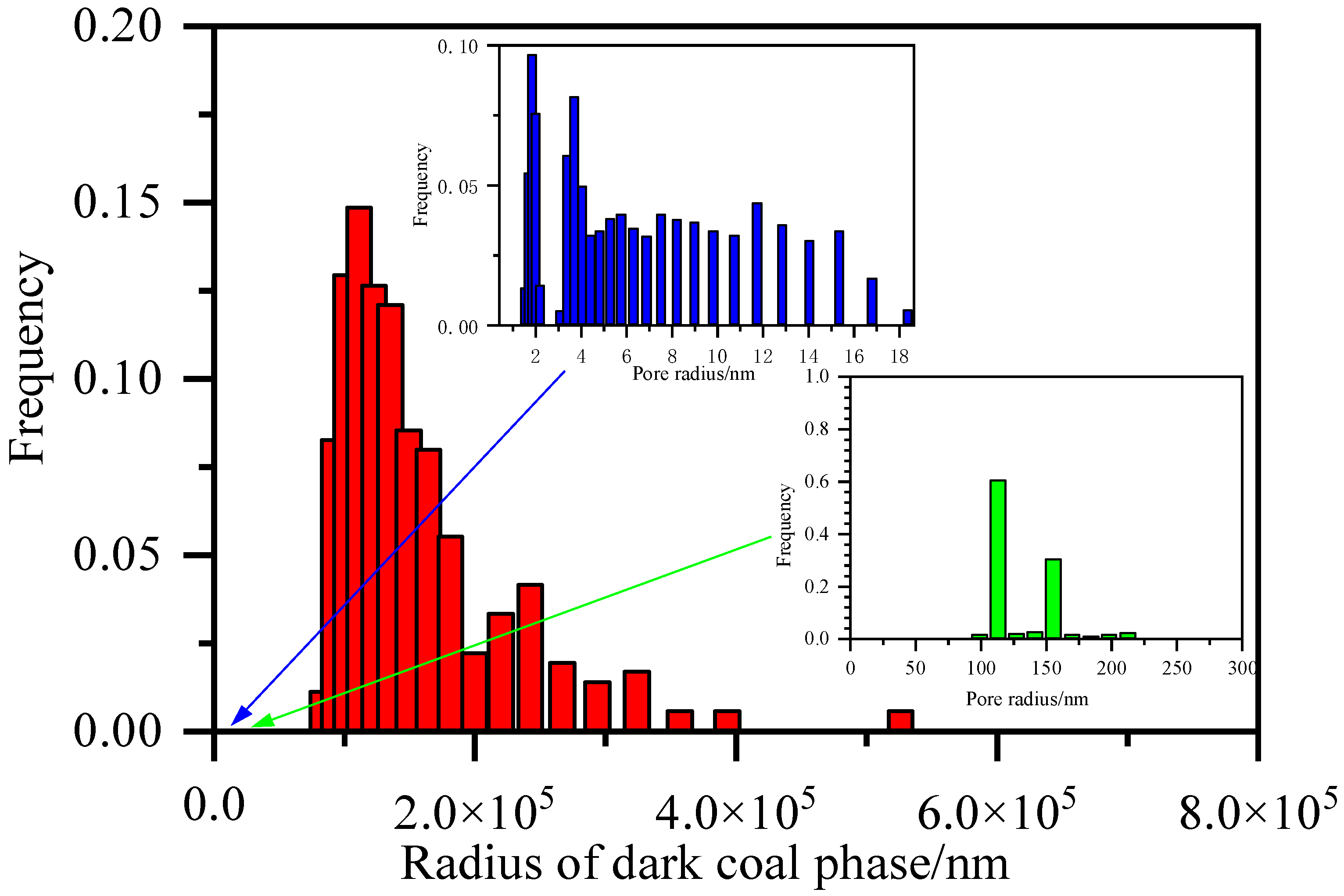

4. Multi-Scale Pore Structure Characteristics

Comparison of Low Pressure Nitrogen Adsorption Experiments

5. Conclusions

- (1)

- A single experimental method cannot accurately and comprehensively reveal the microstructure of coal and rock reservoirs. Through the combined use of low-pressure nitrogen adsorption experiments, XCT imaging technology, and scanning electron microscopy experiments, the pore size distribution and pore shape of coal and rock samples can be simultaneously realized. Qualitative, quantitative, and visual single-scale and multi-scale representations of topological structures provide technical support for understanding the pore structure of coal and rock.

- (2)

- Based on XCT images, SEM-MAP images, and SEM images, combined with image feature extraction and classification algorithms, establish the relationship between coal and rock sample graphics from the nanoscale to the micron scale. The microscopic pore structure properties of coal rock samples are determined by the structural characteristics of various types of pores and their proportions. Inorganic pores mostly exist between minerals and are abundantly developed; they are composed of individual mineral pores and bright and dark coal. Mineral pores account for a relatively small proportion in coal and rock samples; organic pores are developed in the bright coal phase and dark coal phase, with good connectivity. The development of organic pores and inorganic pores is balanced. The entire rock sample pore structure is composed of bright coal, as determined by the pore structure.

- (3)

- The pore structure of the experimental coal and rock samples shows multi-scale characteristics with complex pore types, including inorganic pores, organic pores, and fractures. Among them, the mineral particles are mainly quartz, mostly distributed at the interface of lithofacies and parallel to it, with sizes ranging from nanoscale to millimeter scale; pores are mainly organic pores, and inorganic pores are developed in a small amount of minerals, with sizes concentrated at 2 nm~50 μm; cracks show typical multi-scale characteristics, mostly appearing at the interface of lithofacies and parallel to the interface, with sizes ranging from nanoscale to micron and millimeter scales.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yao, Y.; Liu, D.; Tang, D.Z.; Tang, S.-H.; Huang, W. Preservation and deliverability characteristics of coalbed methane, North China. Pet. Explor. Dev. 2007, 34, 664–668. [Google Scholar]

- Liu, S.Q.; Sang, S.X.; Liu, H.H.; Zhu, Q.-P. Growth characteristics and genetic types of pores and fractures in a high-rank coal reservoir of the southern Qinshui basin. Ore Geol. Rev. 2015, 64, 140–151. [Google Scholar] [CrossRef]

- Sun, J.; Cheng, A.; Liu, K.; Yan, X.; Zhang, L.; Zhao, X. Current situation and development trend of coalbed methane development and utilization technology in coal mine area. J. China Coal Soc. 2020, 45, 258–267. [Google Scholar]

- Liu, S.; Xue, H.; Zhao, M. Pore Structure and Fractal Characteristics of Coal Measure Shale in the Wuxiang Block in the Qinshui Basin. Processes 2023, 11, 3362. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; Huang, S.; Ma, F.; Sun, Q.; Li, F.; Pan, S.; Tian, W. Resource types, formation, distribution and prospects of coal-measure gas. Pet. Explor. Dev. 2019, 46, 451–462. [Google Scholar] [CrossRef]

- Hu, Q.; Jia, H.; Zhang, C.; Fan, B.; Mao, C.; Zhang, Q. Stable-production period prediction method and application in high-rank coalbed methane wells: A case study of Fanzhuang-Zhengzhuang Block in southern Qinshui Basin. Coal Geol. Explor. 2022, 50, 137–144. [Google Scholar] [CrossRef]

- Liu, H.; Sang, S.; Xue, J.; Lan, T.; Xu, H.; Ren, B.; Li, S. Evolution and geochemical characteristics of gas phase fluid and its response to inter-well interference during multi-well drainage of coalbed methane. J. Pet. Sci. Eng. 2018, 162, 491–501. [Google Scholar] [CrossRef]

- Zhang, Z.; Ren, J.; Zhao, Y.; Wang, M.; Yang, J.; Zhang, C. Geological Characteristics of Low-Yield and Low-Efficiency CBM Wells and Practical Measures for Production Increase in the Qinshui Basin. ACS Omega 2023, 8, 47530–47539. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Wu, C.; Huo, Z.; Zhao, Q. Productivity characteristics and controlling factors of coal-bed methane vertical well in a coal block of Qinshui Basin. Energy Explor. Exploit. 2023, 01445987231219766. [Google Scholar] [CrossRef]

- Ye, J.; Hou, S.; Zhang, S. Progress of coalbed methane exploration and development in China during the 13th Five-Year Plan period and the next exploration direction. Coal Geol. Explor. 2022, 50, 15–22. [Google Scholar] [CrossRef]

- Keshavarz, A.; Sakurovs, R.; Grigore, M.; Sayyafzadeh, M. Effect of maceral composition and coal rank on gas diffusion in Australian coals. Int. J. Coal Geol. 2017, 173, 65–75. [Google Scholar] [CrossRef]

- Meng, Q.; Zhao, Y.; Hu, Y.; Feng, Z.; Yu, Y. Experimental study on pore structure and pore shape of coking coal. J. China Coal Soc. 2011, 36, 487–490. [Google Scholar]

- Meng, Z.; Zhang, K.; Shen, Z. Difference analysis of methane diffusion properties between tectonic coal and primary coal. Coal Geol. Explor. 2022, 50, 102–109. [Google Scholar]

- Li, H.Y.; Ogawa, Y.; Shimada, S. Mechanism of methane flow through sheared coals and its role on methane recovery. Fuel 2003, 82, 1271–1279. [Google Scholar] [CrossRef]

- Yang, C.L.; Meng, Y.Y.; Li, X.C.; Nie, B.; Zhu, F. Effects of Nanoscale Pore Structure Characteristics on Coalbed Methane Diffusion. J. Nanosci. Nanotechnol. 2017, 17, 6347–6355. [Google Scholar]

- Zhao, Y.Q.; Wang, S.; Cheng, G.; He, L. Study on coal and gangue recognition method based on the combination of X-ray transmission and diffraction principle. Energy Sources Part A-Recovery Util. Environ. Eff. 2022, 44, 9716–9728. [Google Scholar] [CrossRef]

- Cheng, J.; Xia, X.; Wang, L. Determining Nuclear Magnetic Resonance Surface Relaxivity of Shales. Energy Fuels 2023, 37, 4986–4995. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Xu, H.; Yang, Z. Advanced characterization of physical properties of coals with different coal structures by nuclear magnetic resonance and X-ray computed tomography. Comput. Geosci. 2012, 48, 220–227. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M.; Cai, Y.D.; Li, J.Q. Advanced characterization of pores and fractures in coals by nuclear magnetic resonance and X-ray computed tomography. Sci. China Earth Sci. 2010, 53, 854–862. [Google Scholar] [CrossRef]

- Jiang, W.; Song, X.; Zhong, L. Research on the pore properties of different coal body structure coals and the effects on gas outburst based on the low-temperature nitrogen adsorption method. J. China Coal Soc. 2011, 36, 609–614. [Google Scholar]

- Chen, P.; Tang, X. The research on the adsorption of nitrogen in low temperature and micro-pore properties in coal. J. China Coal Soc. 2001, 26, 552–556. [Google Scholar]

- Yu, Y.; Hu, Y.; Liang, W.; Meng, Q.; Feng, Z. Study on pore characteristics of lean coal at different temperature by CT technology. Chinese J. Geophys. 2012, 55, 637–644. (In Chinese) [Google Scholar]

- Yao, Y.; Liu, D.; Che, Y.; Tang, D.; Tang, S.; Huang, W. Non-destructive characterization of coal samples from China using microfocus X-ray computed tomography. Int. J. Coal Geol. 2009, 80, 113–123. [Google Scholar] [CrossRef]

- Ji, L.; Lin, M.; Cao, G.; Jiang, W. A multiscale reconstructing method for shale based on SEM image and experiment data. J. Pet. Sci. Eng. 2019, 179, 586–599. [Google Scholar] [CrossRef]

- Kelly, S.; El-Sobky, H.; Torres-Verdín, C.; Balhoff, M.T. Assessing the utility of FIB-SEM images for shale digital rock physics. Adv. Water Resour. 2016, 95, 302–316. [Google Scholar] [CrossRef]

- Keller, L.M.; Schuetz, P.; Erni, R.; Rossell, M.D.; Lucas, F.; Gasser, P.; Holzer, L. Characterization of multi-scale microstructural fea-tures in Opalinus Clay. Microporous Mesoporous Mater. 2013, 170, 83–94. [Google Scholar] [CrossRef]

- Li, Z.Q.; Peng, J.S.; Li, L.; Qi, L.; Wai, Y. Novel Dynamic Multiscale Model of Apparent Diffusion Permeability of Methane through Low-Permeability Coal Seams. Energy Fuels 2021, 35, 7844–7857. [Google Scholar] [CrossRef]

- Sun, H.; Zhou, L.; Fan, D.Y.; Zhang, L.; Yang, Y.; Zhang, K.; Yao, J. Permeability prediction of considering organic matter distribution based on deep learning. Phys. Fluids 2023, 35, 032014. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Yang, Y.S.; Li, R.; Li, J.; Yang, J.; Liu, K. Microstructure-based multi-scale evaluation of fluid flow in an anthracite coal sample with partially-percolating voxels. Model. Simul. Mater. Sci. Eng. 2019, 27, 065003. [Google Scholar] [CrossRef]

- Li, X.; Gao, Z.; Fang, S.; Ren, C.; Yang, K.; Wang, F. Fractal Characterization of Nanopore Structure in Shale, Tight Sandstone and Mudstone from the Ordos Basin of China Using Nitrogen Adsorption. Energies 2019, 12, 583. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, Q.; Yan, C.; Chen, H.; He, Y. A New Adsorption Equation for Nano-Porous Shale Rocks and Its Application in Pore Size Distribution Analysis. Energies 2022, 15, 3199. [Google Scholar] [CrossRef]

- Giffin, S.; Littke, R.; Klaver, J.; Urai, J.L. Application of BIB-SEM technology to characterize macropore morphology in coal. Int. J. Coal Geol. 2013, 114, 85–95. [Google Scholar] [CrossRef]

- Song, W.; Liu, L.; Sun, H.; Zhang, K.; Yang, Y.; Yao, J. Pore structure characterization and flow ability of shale oil reservoir based on digital cores. Reserv. Eval. Dev. 2021, 11, 497–505. [Google Scholar]

- Zhao, J.; Chen, H.; Zhang, J.; Zhang, W.; Chen, G. Quantitative characterization of organic and inorganic pores in shale based on FIB-SEM. Front. Earth Sci. 2022, 10, 994312. [Google Scholar] [CrossRef]

- Saif, T.; Lin, Q.; Butcher, A.R.; Bijeljic, B.; Blunt, M.J. Multi-scale multi-dimensional microstructure imaging of oil shale pyrolysis using X-ray micro-tomography, automated ultra-high resolution SEM, MAPS Mineralogy and FIB-SEM. Appl. Energy 2017, 202, 628–647. [Google Scholar] [CrossRef]

- Chen, Q.; Tian, Y.; Li, P.; Yan, C.; Pang, Y.; Zheng, L.; Deng, H.; Zhou, W.; Meng, X. Study on Shale Adsorption Equation Based on Monolayer Adsorption, Multilayer Adsorption, and Capillary Condensation. J. Chem. 2017, 2017, 1496463. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Liu, L.; Zhou, L.; Imani, G.; Liu, Z.; Wu, H.; Sun, H.; Fang, H. Research on the Multiscale Microscopic Pore Structure of a Coalbed Methane Reservoir. Energies 2024, 17, 1081. https://doi.org/10.3390/en17051081

Lu X, Liu L, Zhou L, Imani G, Liu Z, Wu H, Sun H, Fang H. Research on the Multiscale Microscopic Pore Structure of a Coalbed Methane Reservoir. Energies. 2024; 17(5):1081. https://doi.org/10.3390/en17051081

Chicago/Turabian StyleLu, Xiuqin, Lei Liu, Liang Zhou, Gloire Imani, Zhong Liu, Haoyu Wu, Hai Sun, and Huili Fang. 2024. "Research on the Multiscale Microscopic Pore Structure of a Coalbed Methane Reservoir" Energies 17, no. 5: 1081. https://doi.org/10.3390/en17051081

APA StyleLu, X., Liu, L., Zhou, L., Imani, G., Liu, Z., Wu, H., Sun, H., & Fang, H. (2024). Research on the Multiscale Microscopic Pore Structure of a Coalbed Methane Reservoir. Energies, 17(5), 1081. https://doi.org/10.3390/en17051081