Forecasting End-of-Life Wind Turbine Material Flows in Australia under Various Wind Energy Deployment Scenarios

Abstract

1. Introduction

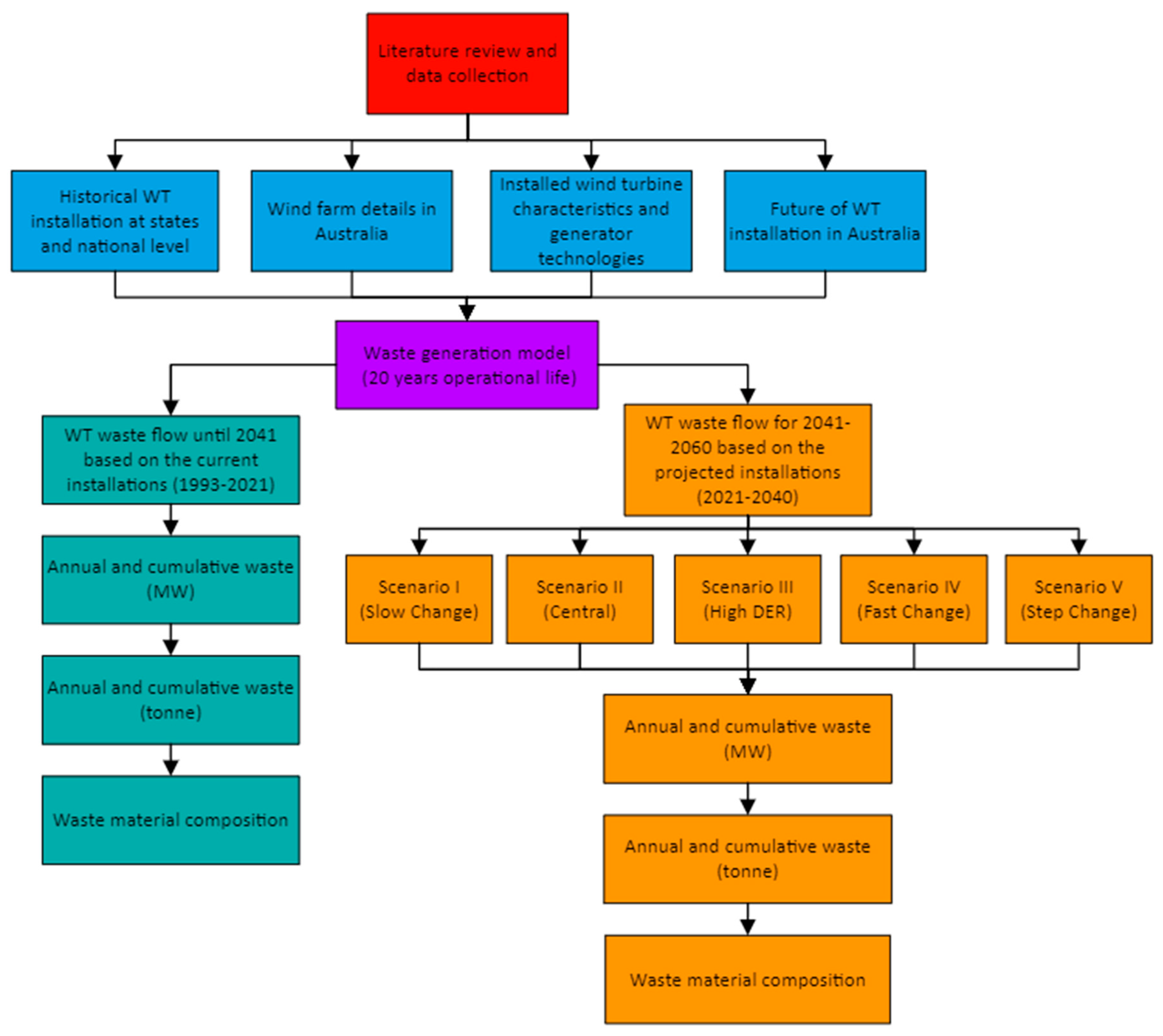

2. Materials and Methods

2.1. Wind Turbine Generator Technology

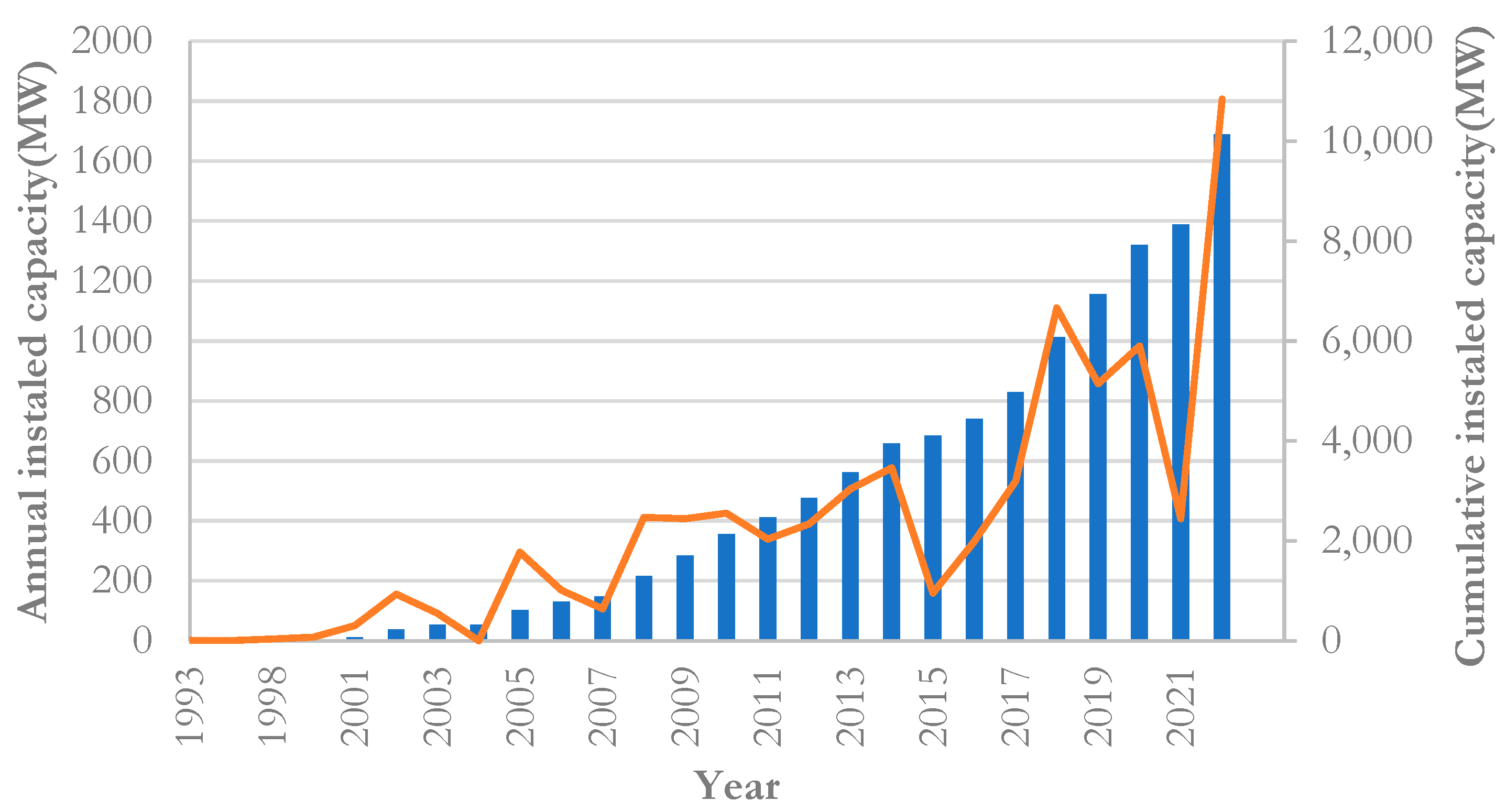

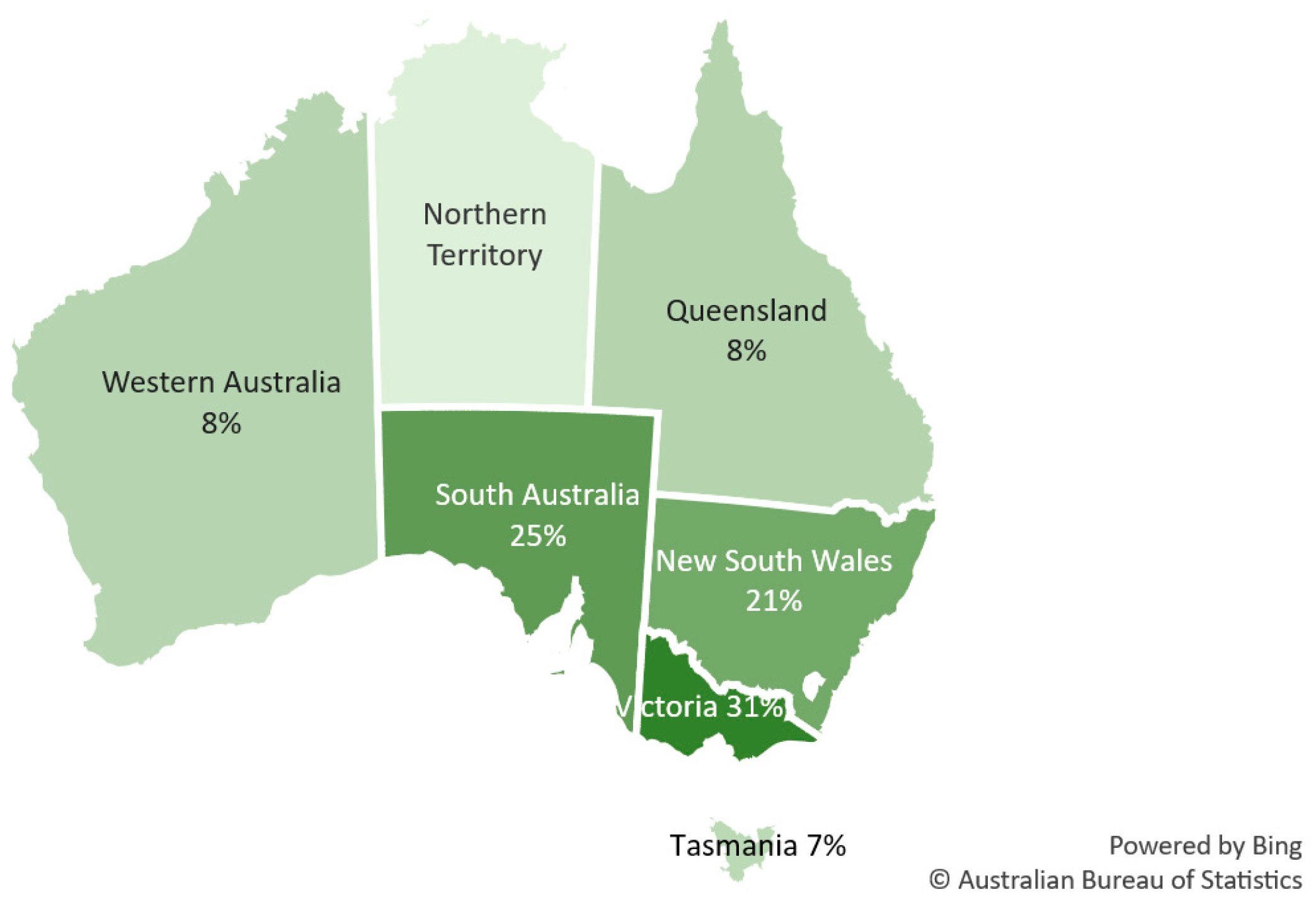

2.2. Wind Energy Development in Australia

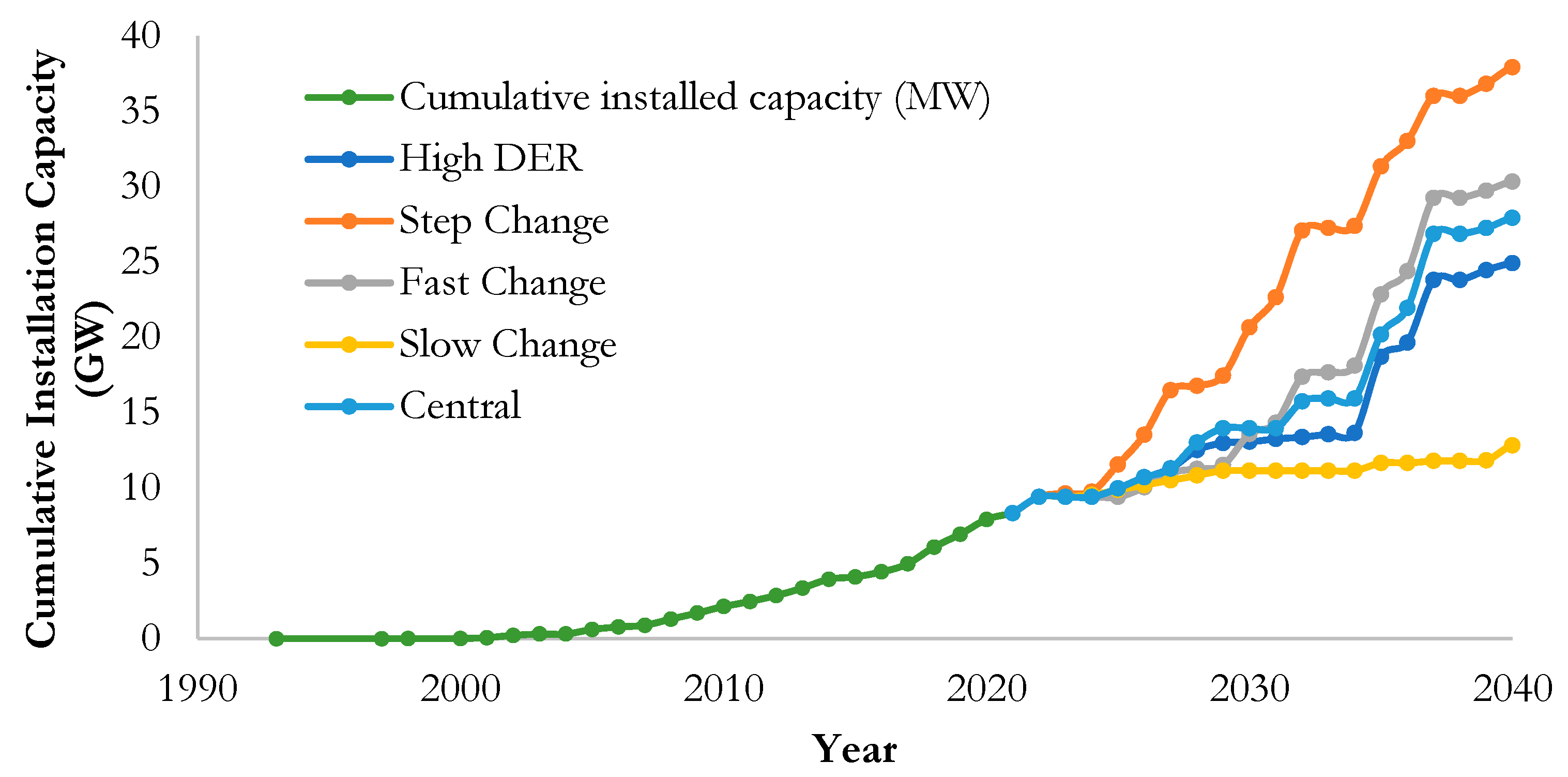

2.3. Wind Energy Forecast up to 2041

2.4. Wind Turbine Lifetime

2.5. Material Flow Analysis

- Initially, the generator technology (different types of DD and GB generators) of each installed wind turbine in Australia was identified based on Section 2.2.

- Total wind energy capacity in Australia until 2041 was categorized according to the available WT generator technologies.

- The authors assumed that these turbines will be discarded after 20 years (discussed in Section 2.4), resulting in the annual and cumulative waste of Australian WTs in terms of MW until 2060.

- Finally, a new formulation was developed to calculate the EoL wind turbine weight until 2060 according to Equation (1) and a technical report published by Carrara et al. [37] which provided essential information regarding the material composition of wind turbines. Hence, the total weight of the waste () is calculated from the following:

3. Results

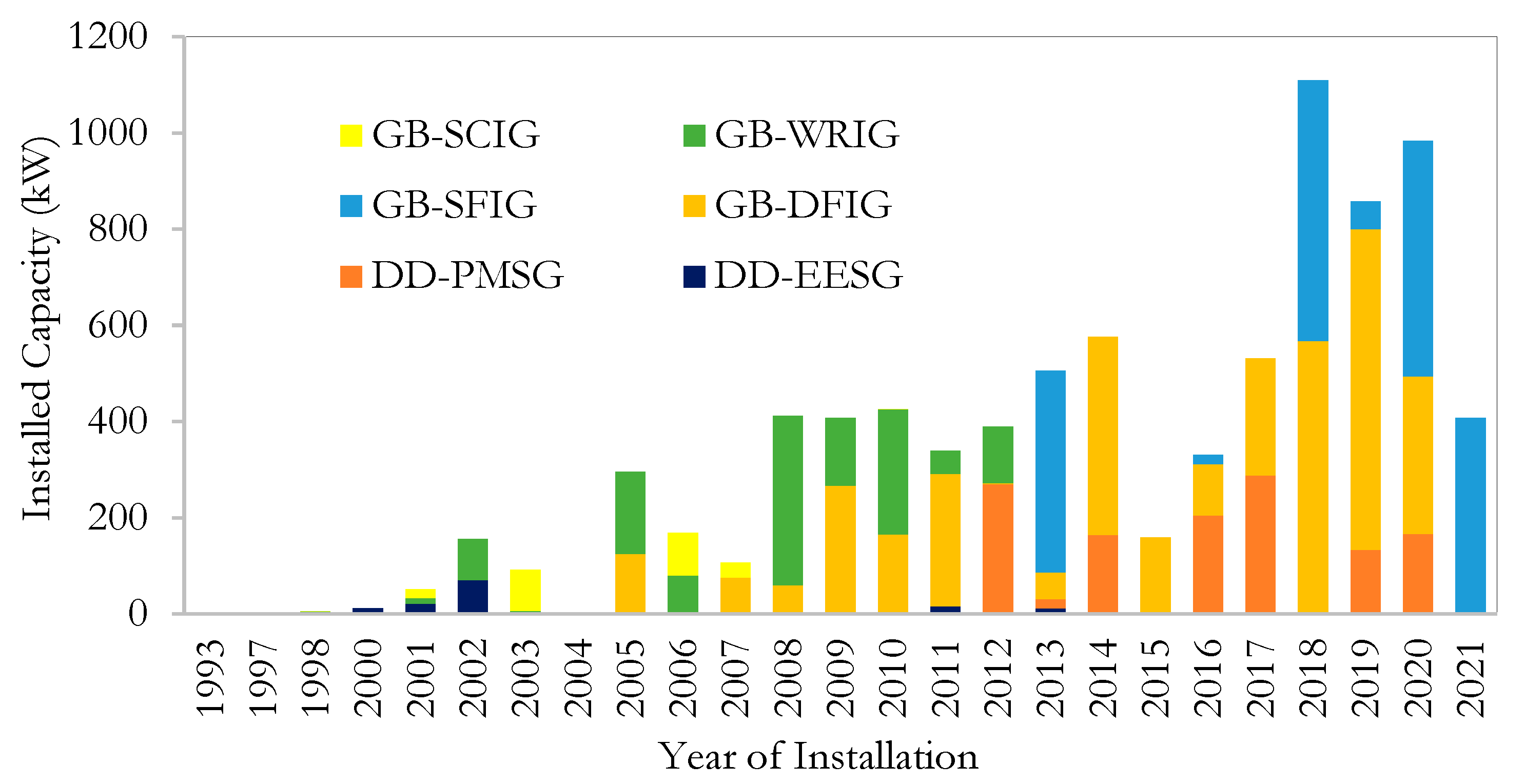

3.1. WT Deployment Outlook in Australia until 2022

3.2. Wind Energy Projection in Australia from 2022 to 2041

3.3. WT Classification

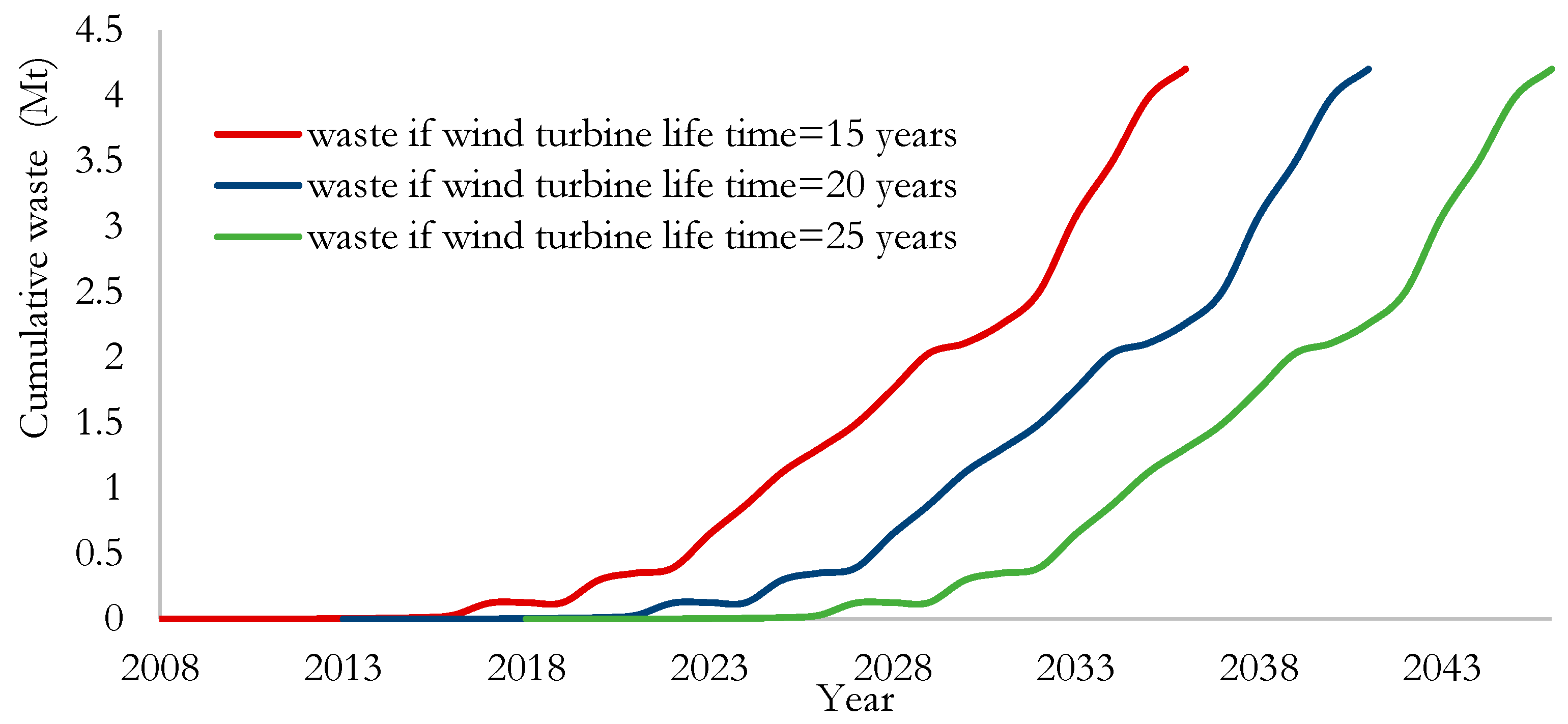

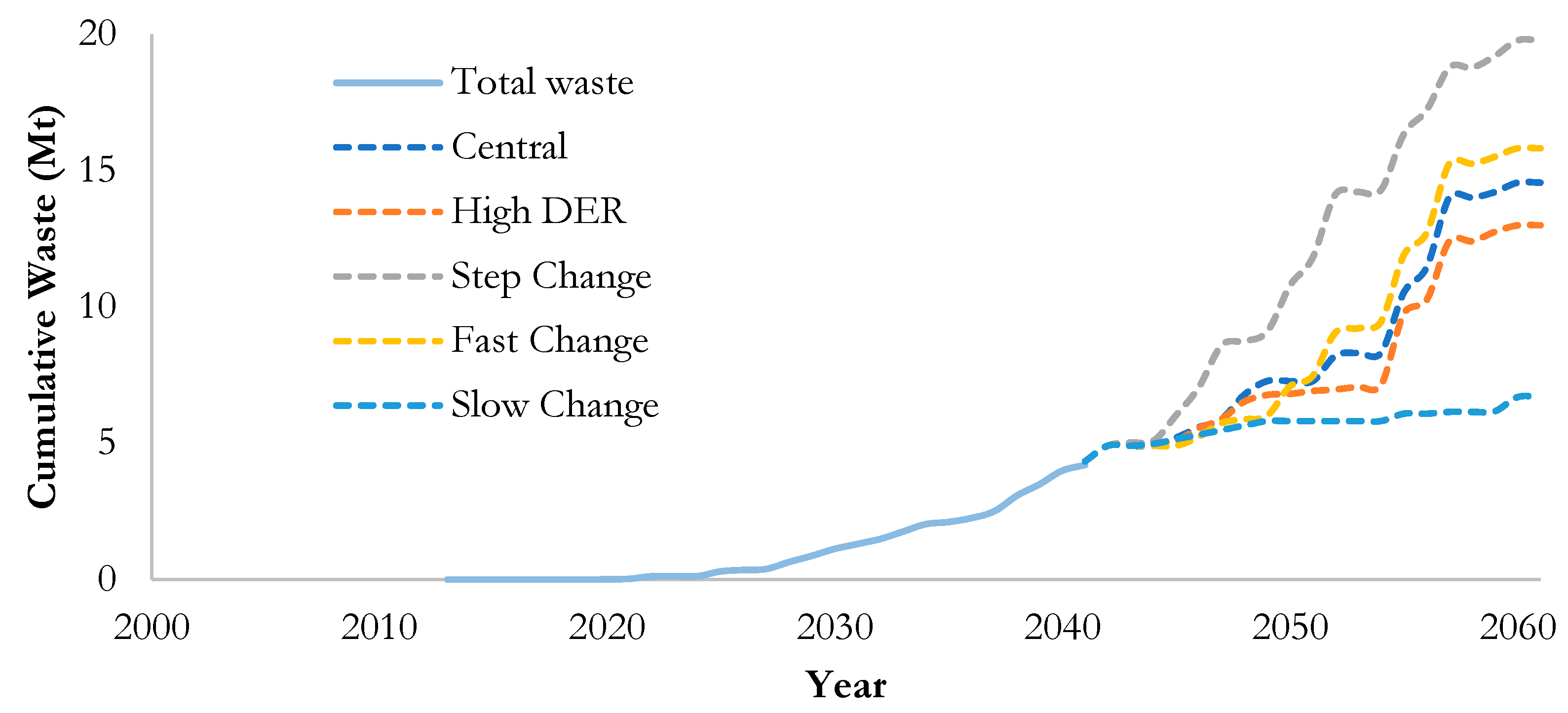

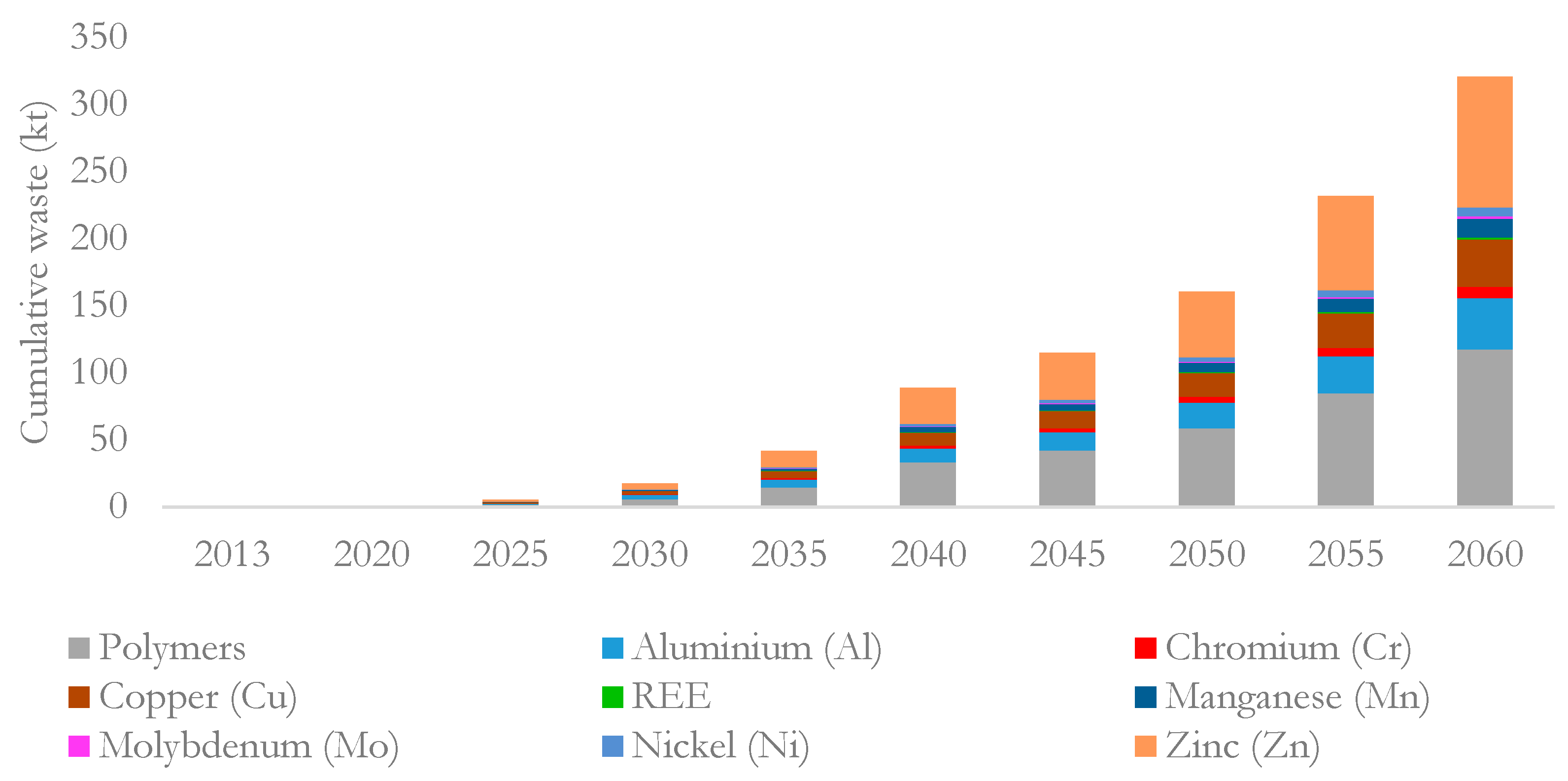

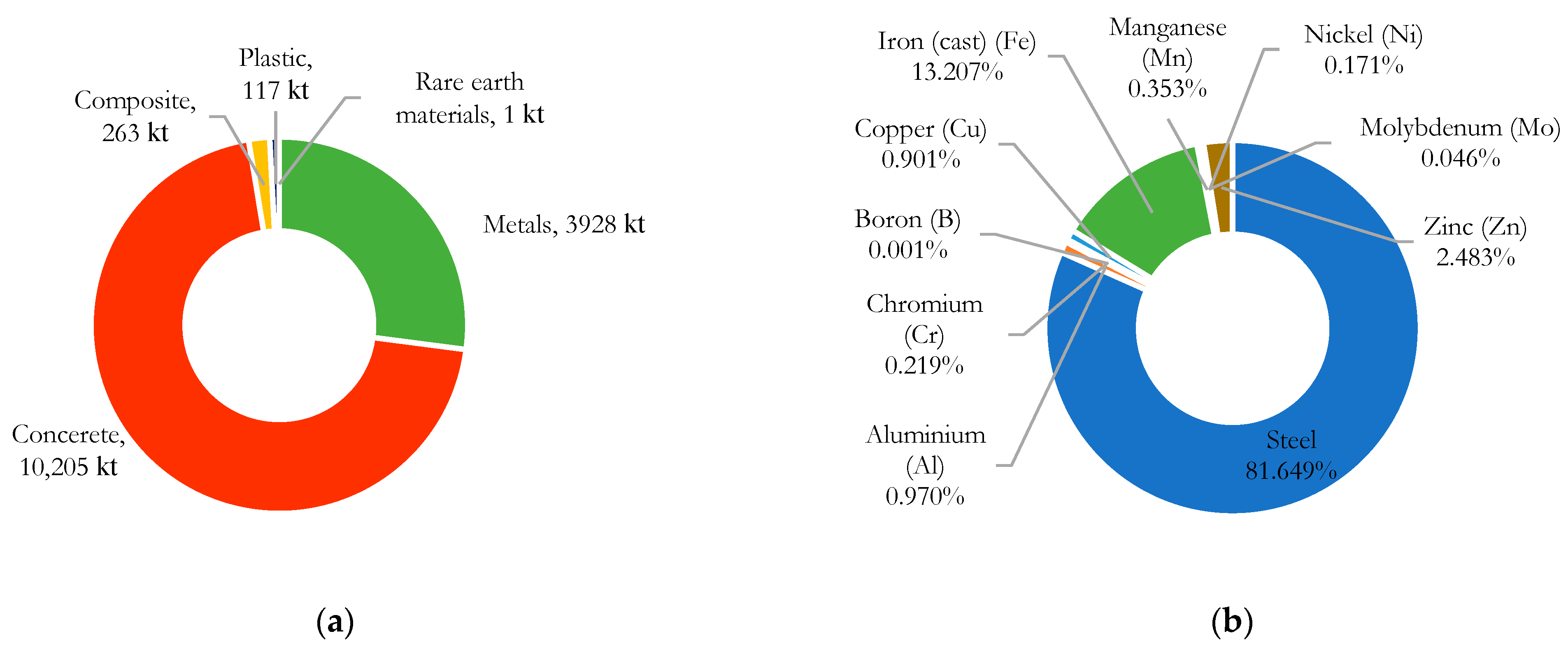

3.4. WT Waste Projection from 2013 to 2060

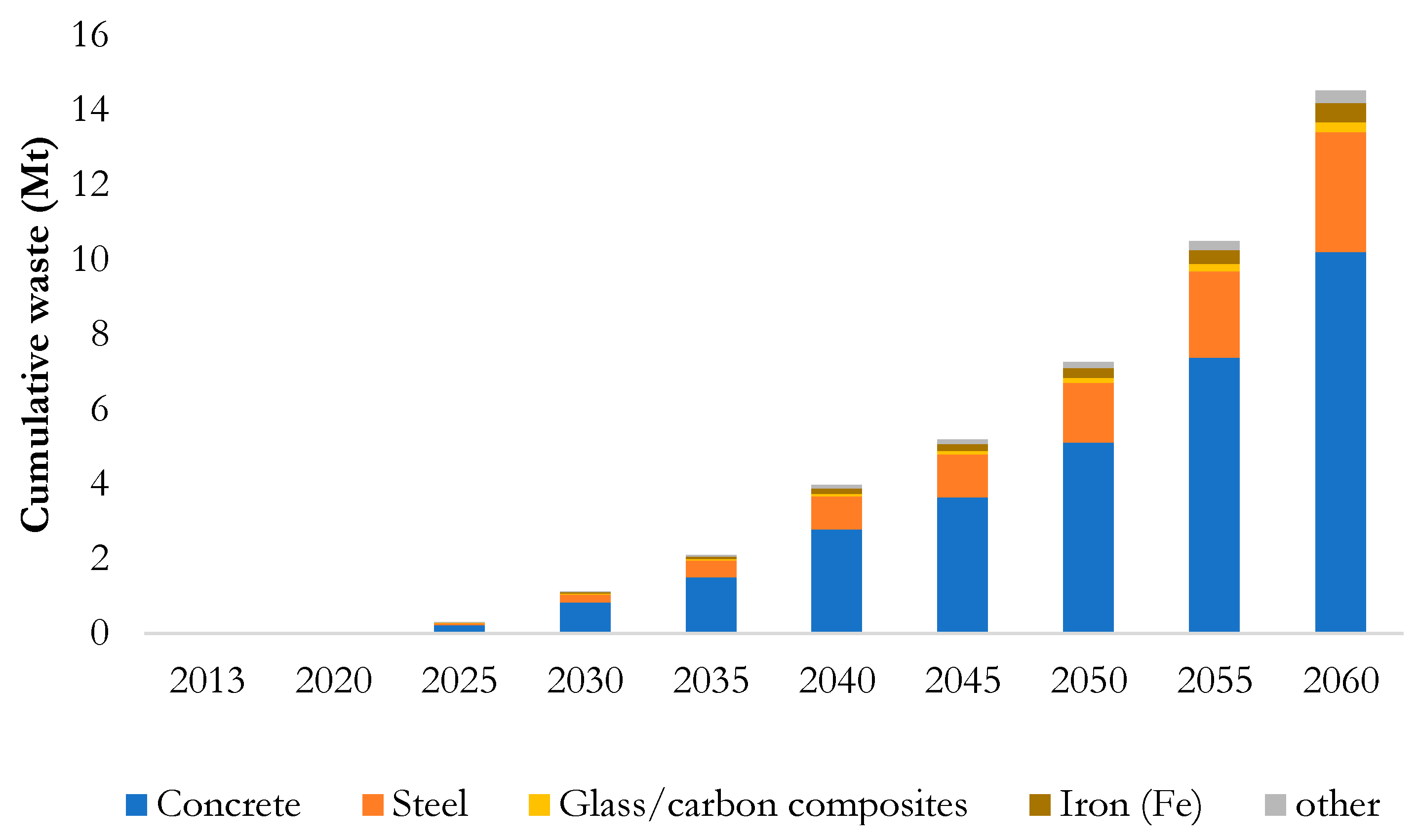

3.5. WT Material Waste Streams and Economic Value

3.6. Repowering

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AEMO | Australian Energy Market Operator |

| DD | Direct drive |

| DER | Distributed energy resource |

| DFIG | Double-fed induction generator |

| EESG | Electrically excited synchronous generator |

| EoL | End of Life |

| GB | Gearbox |

| GIS | Geographical Information System |

| GW | Gigawatts |

| HTS | High-temperature superconductor |

| IRENA | International Renewable Energy Agency |

| kt | Kilo tonnes |

| MFA | Material flow analysis |

| Mt | Million tonnes |

| PMSG | Permanent magnet synchronous generator |

| REEs | Rare earth elements |

| SCIG | Squirrel cage induction generator |

| VRE | Variable renewable energy |

| WPSs | Waste processing systems |

| WRIG | Wound rotor induction generator |

| WT | Wind turbine |

References

- Psomopoulos, C.S.; Kalkanis, K.; Kaminaris, S.; Ioannidis, G.C.; Pachos, P. A review of the potential for the recovery of wind turbine blade waste materials. Recycling 2019, 4, 7. [Google Scholar] [CrossRef]

- The Wind Power. Wind Farms Databases. Available online: https://www.thewindpower.net/store_windfarms_view_all_en.php (accessed on 17 May 2021).

- IRENA. Future of Wind: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects (A Global Energy Transformation Paper); International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Khalid, M.Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of wind turbine blades through modern recycling technologies: A road to zero waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Council, C.E. Wind. Available online: https://www.cleanenergycouncil.org.au/resources/technologies/wind (accessed on 1 February 2023).

- Hao, S.; Kuah, A.T.H.; Rudd, C.D.; Wong, K.H.; Lai, N.Y.G.; Mao, J.; Liu, X. A circular economy approach to green energy: Wind turbine, waste, and material recovery. Sci. Total Environ. 2020, 702, 135054. [Google Scholar] [CrossRef]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.M.; Van Gerven, T.; Jones, P.T.; et al. REE Recovery from End-of-Life NdFeB Permanent Magnet Scrap: A Critical Review. J. Sustain. Metall. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Giorgini, L.; Benelli, T.; Brancolini, G.; Mazzocchetti, L. Recycling of carbon fiber reinforced composite waste to close their life cycle in a cradle-to-cradle approach. Curr. Opin. Green Sustain. Chem. 2020, 26, 100368. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Dorigato, A. Recycling of thermosetting composites for wind blade application. Adv. Ind. Eng. Polym. Res. 2021, 4, 116–132. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef] [PubMed]

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fibre reinforced polymers and related waste generated by the wind power sector until 2050. Resour. Conserv. Recycl. 2019, 141, 30–39. [Google Scholar] [CrossRef]

- Ratner, S.; Gomonov, K.; Revinova, S.; Lazanyuk, I. Eco-design of energy production systems: The problem of renewable energy capacity recycling. Appl. Sci. 2020, 10, 4339. [Google Scholar] [CrossRef]

- Jensen, J.P. Evaluating the environmental impacts of recycling wind turbines. Wind Energy 2019, 22, 316–326. [Google Scholar] [CrossRef]

- Topham, E.; McMillan, D.; Bradley, S.; Hart, E. Recycling offshore wind farms at decommissioning stage. Energy Policy 2019, 129, 698–709. [Google Scholar] [CrossRef]

- Adedipe, T.; Shafiee, M. An economic assessment framework for decommissioning of offshore wind farms using a cost breakdown structure. Int. J. Life Cycle Assess. 2021, 26, 344–370. [Google Scholar] [CrossRef]

- Andersen, N.; Eriksson, O.; Hillman, K.; Wallhagen, M. Wind turbines’ end-of-life: Quantification and characterisation of future waste materials on a national level. Energies 2016, 9, 999. [Google Scholar] [CrossRef]

- Tazi, N.; Kim, J.; Bouzidi, Y.; Chatelet, E.; Liu, G. Waste and material flow analysis in the end-of-life wind energy system. Resour. Conserv. Recycl. 2019, 145, 199–207. [Google Scholar] [CrossRef]

- Tota-Maharaj, K.; McMahon, A. Resource and waste quantification scenarios for wind turbine decommissioning in the United Kingdom. Waste Dispos. Sustain. Energy 2020, 3, 117–144. [Google Scholar] [CrossRef]

- Lichtenegger, G.; Rentizelas, A.A.; Trivyza, N.; Siegl, S. Offshore and onshore wind turbine blade waste material forecast at a regional level in Europe until 2050. Waste Manag. 2020, 106, 120–131. [Google Scholar] [CrossRef]

- Chen, Y.; Cai, G.; Zheng, L.; Zhang, Y.; Qi, X.; Ke, S.; Gao, L.; Bai, R.; Liu, G. Modeling waste generation and end-of-life management of wind power development in Guangdong, China until 2050. Resour. Conserv. Recycl. 2021, 169, 105533. [Google Scholar] [CrossRef]

- Heng, H.; Meng, F.; McKechnie, J. Wind turbine blade wastes and the environmental impacts in Canada. Waste Manag. 2021, 133, 59–70. [Google Scholar] [CrossRef]

- Cooperman, A.; Eberle, A.; Lantz, E. Wind turbine blade material in the United States: Quantities, costs, and end-of-life options. Resour. Conserv. Recycl. 2021, 168, 105439. [Google Scholar] [CrossRef]

- Delaney, E.L.; McKinley, J.M.; Megarry, W.; Graham, C.; Leahy, P.G.; Bank, L.C.; Gentry, R. An integrated geospatial approach for repurposing wind turbine blades. Resour. Conserv. Recycl. 2021, 170, 105601. [Google Scholar] [CrossRef]

- Tremeac, B.; Meunier, F. Life cycle analysis of 4.5 MW and 250 W wind turbines. Renew. Sustain. Energy Rev. 2009, 13, 2104–2110. [Google Scholar] [CrossRef]

- Vorrath, S. World’s First “Fully Recyclable” Wind Turbine Blades Roll Off Production Line. Available online: https://reneweconomy.com.au/worlds-first-fully-recyclable-wind-turbine-blades-roll-off-production-line/ (accessed on 1 March 2023).

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Mechanical and thermal study of 3D printing composite filaments from wind turbine waste. Polym. Compos. 2021, 45, 2305–2316. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Tahir, M.; Fayazbakhsh, K.; Lessard, L. Tensile properties and interfacial shear strength of recycled fibers from wind turbine waste. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105786. [Google Scholar] [CrossRef]

- Arias, F.; Bank, L. Assessment of Present/Future Decommissioned Wind Blade Fiber-Reinforced Composite Material in the United States. 2016. Available online: https://www.researchgate.net/profile/Lawrence-Bank/publication/338430512_Assessment_of_PresentFuture_Decommissioned_Wind_Blade_Fiber-Reinforced_Composite_Material_in_the_United_States/links/5e148256299bf10bc396e246/Assessment-of-Present-Future-Decommissioned-Wind-Blade-Fiber-Reinforced-Composite-Material-in-the-United-States.pdf (accessed on 1 February 2023).

- Gennitsaris, S.; Sagani, A.; Sofianopoulou, S.; Dedoussis, V. Integrated LCA and DEA approach for circular economy-driven performance evaluation of wind turbine end-of-life treatment options. Appl. Energy 2023, 339, 120951. [Google Scholar] [CrossRef]

- Diez-Cañamero, B.; Mendoza, J.M.F. Circular economy performance and carbon footprint of wind turbine blade waste management alternatives. Waste Manag. 2023, 164, 94–105. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Marquez, D.; Florin, N.; Hall, W.; Majewski, P.; Wang, H.; Stewart, R.A. State-of-the-art review of product stewardship strategies for large composite wind turbine blades. Resour. Conserv. Recycl. Adv. 2022, 15, 200109. [Google Scholar] [CrossRef]

- Australian Government. Electricity Generation. Available online: https://www.energy.gov.au/data/electricity-generation#:~:text=Renewables%20contributed%2032%25%20of%20total,and%20households%20in%202021%2D22 (accessed on 1 February 2023).

- Clean-Energy-Council. Best Practice Guidelines for Implementation of Wind Energy Projects in Australia; Australian Government: Melbourne, Australia, 2018. [Google Scholar]

- Mahmoudi, S.; Huda, N.; Behnia, M. Photovoltaic waste assessment: Forecasting and screening of emerging waste in Australia. Resour. Conserv. Recycl. 2019, 146, 192–205. [Google Scholar] [CrossRef]

- Salim, H.K.; Stewart, R.A.; Sahin, O.; Dudley, M. Systems approach to end-of-life management of residential photovoltaic panels and battery energy storage system in Australia. Renew. Sustain. Energy Rev. 2020, 134, 110176. [Google Scholar] [CrossRef]

- Carrara, S.; Alves Dias, P.; Plazzotta, B.; Pavel, C. Raw Materials Demand for Wind and Solar PV Technologies in the Transition towards a Decarbonised Energy System; Publication Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Australian Energy Market Operator (AEMO). 2020 Integrated System Plan; Australian Energy Market Operator: Melbourne, Australia, 2020. [Google Scholar]

- Vestas. Life Cycle Assessment of Electricity Produced from Onshore Sited Wind Power Plants Based on Vestas V82-1.65 MW Turbines; Vestas: Aarhus, Denmark, 2006; pp. 1–77. [Google Scholar]

- Daily Metal Prices. Available online: https://www.dailymetalprice.com/ (accessed on 1 June 2022).

- Luengo, M.M.; Kolios, A. Failure mode identification and end of life scenarios of offshore wind turbines: A review. Energies 2015, 8, 8339–8354. [Google Scholar] [CrossRef]

- Kasner, R. The environmental efficiency of materials used in the lifecycle of a wind farm. Sustain. Mater. Technol. 2022, 34, e00512. [Google Scholar] [CrossRef]

- Beauson, J.; Laurent, A.; Rudolph, D.P.; Pagh Jensen, J. The complex end-of-life of wind turbine blades: A review of the European context. Renew. Sustain. Energy Rev. 2022, 155, 111847. [Google Scholar] [CrossRef]

- Tomaras, J. Waste Management and Recycling; Parliament of Australia: Canberra, Australia, 2020. Available online: https://www.aph.gov.au/About_Parliament/Parliamentary_Departments/Parliamentary_Library/pubs/rp/BudgetReview202021/WasteManagementRecycling (accessed on 30 November 2023).

- Australian Government. National Waste Policy Action Plan. Department of Climate Change, Energy, the Environment and Water, Australia; 2019. Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/national-waste-policy-action-plan#daff-page-main (accessed on 30 November 2023).

- Tam, V.W.Y. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- Pickin, J.; Randell, P.; Trinh, J.; Grant, B. National Waste Report 2018; Department of the Environment and Energy; Blue Environment Pty Ltd.: Docklands, Australia, 2018. [Google Scholar]

- ACT Government. Steel Recycling. Transport Canberra and City Services, Australia; 2018. Available online: https://www.cityservices.act.gov.au/recyclopaedia (accessed on 30 November 2023).

- Australian Alumimium Council. Scrap Aluminium Recycling in Australia. 2021. Available online: https://aluminium.org.au/wp-content/uploads/2021/07/210708-AAC-Recycling-Summary-Approved.pdf (accessed on 30 November 2023).

- van Beers, D.; Kapur, A.; Graedel, T.E. Copper and zinc recycling in Australia: Potential quantities and policy options. J. Clean. Prod. 2007, 15, 862–877. [Google Scholar] [CrossRef]

- DAWE. National Plastics Plan 2021; DAWE: Canberra, Australia, 2021. [Google Scholar]

- Locock, K. The Recycled Plastics Market: Global Analysis and Trends; CSIRO: Canberra, Australia, 2017. [Google Scholar]

- Garrett, P.; Ronde, K. Life Cycle Assessment of Electricity Production from a V90-2.0 MW Gridstreamer Wind Plant; Vestas Wind Systems: Randers, Denmark, 2011. [Google Scholar]

- Gentry, R.; Bank, L.; Chen, J.F.; Arias, F.; Al-Haddad, T. Adaptive reuse of FRP composite wind turbine blades for civil infrastructure construction. In Proceedings of the 9th International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, CICE 2018, Paris, France, 17–19 July 2018; pp. 692–698. [Google Scholar]

- Gentry, T.R.; Al-Haddad, T.; Bank, L.C.; Arias, F.R.; Nagle, A.; Leahy, P. Structural Analysis of a Roof Extracted from a Wind Turbine Blade. J. Archit. Eng. 2020, 26, 04020040. [Google Scholar] [CrossRef]

- Goodman, J.H. Architectonic reuse of wind turbine blades. In Proceedings of the 39th ASES National Solar Conference 2010, SOLAR 2010, Phoenix, AZ, USA, 17–22 May 2010; pp. 1324–1333. [Google Scholar]

- Alshannaq, A.; Scott, D.; Bank, L.; Bermek, M.; Gentry, R. Structural re-use of de-commissioned wind turbine blades in civil engineering applications. In Proceedings of the Proceedings of the American Society for Composites—34th Technical Conference, ASC 2019, Atlanta, GA, USA, 23–25 September 2019. [Google Scholar]

- André, A.; Kullberg, J.; Nygren, D.; Mattsson, C.; Nedev, G.; Haghani, R. Re-use of wind turbine blade for construction and infrastructure applications. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 41st Risø International Symposium on Materials Science: “Materials and Design for Next Generation Wind Turbine Blades”, Roskilde, Denmark, 7–10 September 2020; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Cheng, G.; Yang, S.; Wang, X.; Guo, Z.; Cai, M. Study on the Recycling of Waste Wind Turbine Blades. J. Eng. Res. 2023, 11, 13–17. [Google Scholar] [CrossRef]

- Mamanpush, S.H.; Li, H.; Englund, K.; Tabatabaei, A.T. Recycled wind turbine blades as a feedstock for second generation composites. Waste Manag. 2018, 76, 708–714. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Rieder, K.-A.; Tian, Y.; Chen, C. Concrete with discrete slender elements from mechanically recycled wind turbine blades. Resour. Conserv. Recycl. 2018, 128, 11–21. [Google Scholar] [CrossRef]

- Oliveira, P.S.; Antunes, M.L.P.; da Cruz, N.C.; Rangel, E.C.; de Azevedo, A.R.G.; Durrant, S.F. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction. J. Clean. Prod. 2020, 274, 122948. [Google Scholar] [CrossRef]

- Clean Energy Council. Winding Up Decommissioning, Recycling and Resource Recovery of Australian Wind Turbines; Clean Energy Council’s Wind Recycling Working Group: Perth, Australia, 2023; Available online: https://assets.cleanenergycouncil.org.au/documents/Wind-turbine-recycling-report-2023.pdf (accessed on 1 February 2023).

- VDZ. Decarbonisation Pathways for the Australian Cement and Concrete Sector; Cement Industry Federation: Forrest, Australia, 2022. [Google Scholar]

- Palle Paul Mejame, M.; King, D.; Banhalmi-zakar, Z.; He, Y. Circular economy: A sustainable management strategy for rare earth elements consumption in Australia. Curr. Res. Environ. Sustain. 2022, 4, 100157. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N. Reshaping WEEE management in Australia: An investigation on the untapped WEEE products. J. Clean. Prod. 2020, 250, 119496. [Google Scholar] [CrossRef]

| Author/Year | Journal | Geographical Area | Research Focus |

|---|---|---|---|

| Andersen et al., 2016 [17] | Energies | Sweden | Wind turbine waste estimation until 2034 by MFA |

| Liu and Barlow, 2017 [11] | Waste Management | Worldwide | Wind turbine blade waste estimation until 2050 |

| Tazi et al., 2019 [18] | Resources, Conservation & Recycling | French | Waste estimation of installed wind turbines until 2020 considering maintenance activities and waste |

| Lefeuvre, A., 2019 [12] | Resources, Conservation and Recycling | Worldwide | Wind turbine blade waste estimation until 2050 |

| Tota-Maharaj and McMahon, 2020 [19] | Waste Disposal & Sustainable Energy | UK | Wind turbine waste estimation until 2039 by MFA |

| Lichtenegger et al., 2020 [20] | Waste Management | Europe | Wind turbine blade waste estimation until 2050 based on the regional growth rate |

| Chen et al., 2021 [21] | Resources, Conservation and Recycling | China | Wind turbine waste estimation until 2050 |

| Heng et al., 2021 [22] | Waste Management | Canada | Wind turbine blade waste estimation until 2050 |

| Cooperman et al., 2021 [23] | Resources, Conservation & Recycling | USA | Wind turbine blade waste estimation until 2050 |

| Delaney et al., 2021 [24] | Resources, Conservation & Recycling | Ireland | Wind turbine blade waste estimation until 2040 coupled with an integrated Geographical Information System (GIS) model |

| Name | Area | Power (MW) | Number of Turbines | Hub Height (m) | Turbine Manufacturer | Commissioning Year | Wind Turbine Model | Wind Turbine Power (kW) | Blade Diameter (m) | Wind Turbine Technology |

|---|---|---|---|---|---|---|---|---|---|---|

| Ten Mile Lagoon | Western Australia | 2.025 | 9 | - | Vestas | 1993 | Vestas V27/225 | 225 | 27 | GB-WRIG |

| Denham | Western Australia | 0.46 | 2 | - | Enercon | 1997 | Enercon | 230 | - | DD-EESG |

| Thursday Island | Queensland | 0.45 | 2 | - | - | 1997 | - | 225 | - | |

| Denham | Western Australia | 0.23 | 1 | - | Enercon | 1998 | Enercon | 230 | - | DD-EESG |

| Huxley Hill | Tasmania | 0.75 | 3 | - | Nordex | 1998 | Nordex N29/250 | 250 | 29 | GB-SCIG |

| Crookwell | New South Wales | 4.8 | 8 | 45 | Vestas | 1998 | Vestas V44/600 | 600 | 44 | GB-WRIG |

| Windy Hill | Queensland | 12 | 20 | 46 | Enercon | 2000 | Enercon E44/600 | 600 | 44 | DD-EESG |

| Portland Wind Farm | Victoria | 18.2 | 14 | 50 | Bonus | 2001 | Bonus B62/1300 | 1300 | 62 | GB-SCIG |

| Albany | Western Australia | 21.6 | 12 | 65 | Enercon | 2001 | Enercon E66/1800 | 1800 | 66 | DD-EESG |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alavi, Z.; Khalilpour, K.; Florin, N. Forecasting End-of-Life Wind Turbine Material Flows in Australia under Various Wind Energy Deployment Scenarios. Energies 2024, 17, 914. https://doi.org/10.3390/en17040914

Alavi Z, Khalilpour K, Florin N. Forecasting End-of-Life Wind Turbine Material Flows in Australia under Various Wind Energy Deployment Scenarios. Energies. 2024; 17(4):914. https://doi.org/10.3390/en17040914

Chicago/Turabian StyleAlavi, Zahraossadat, Kaveh Khalilpour, and Nick Florin. 2024. "Forecasting End-of-Life Wind Turbine Material Flows in Australia under Various Wind Energy Deployment Scenarios" Energies 17, no. 4: 914. https://doi.org/10.3390/en17040914

APA StyleAlavi, Z., Khalilpour, K., & Florin, N. (2024). Forecasting End-of-Life Wind Turbine Material Flows in Australia under Various Wind Energy Deployment Scenarios. Energies, 17(4), 914. https://doi.org/10.3390/en17040914