A Novel Data-Driven Approach for Predicting the Performance Degradation of a Gas Turbine

Abstract

1. Introduction

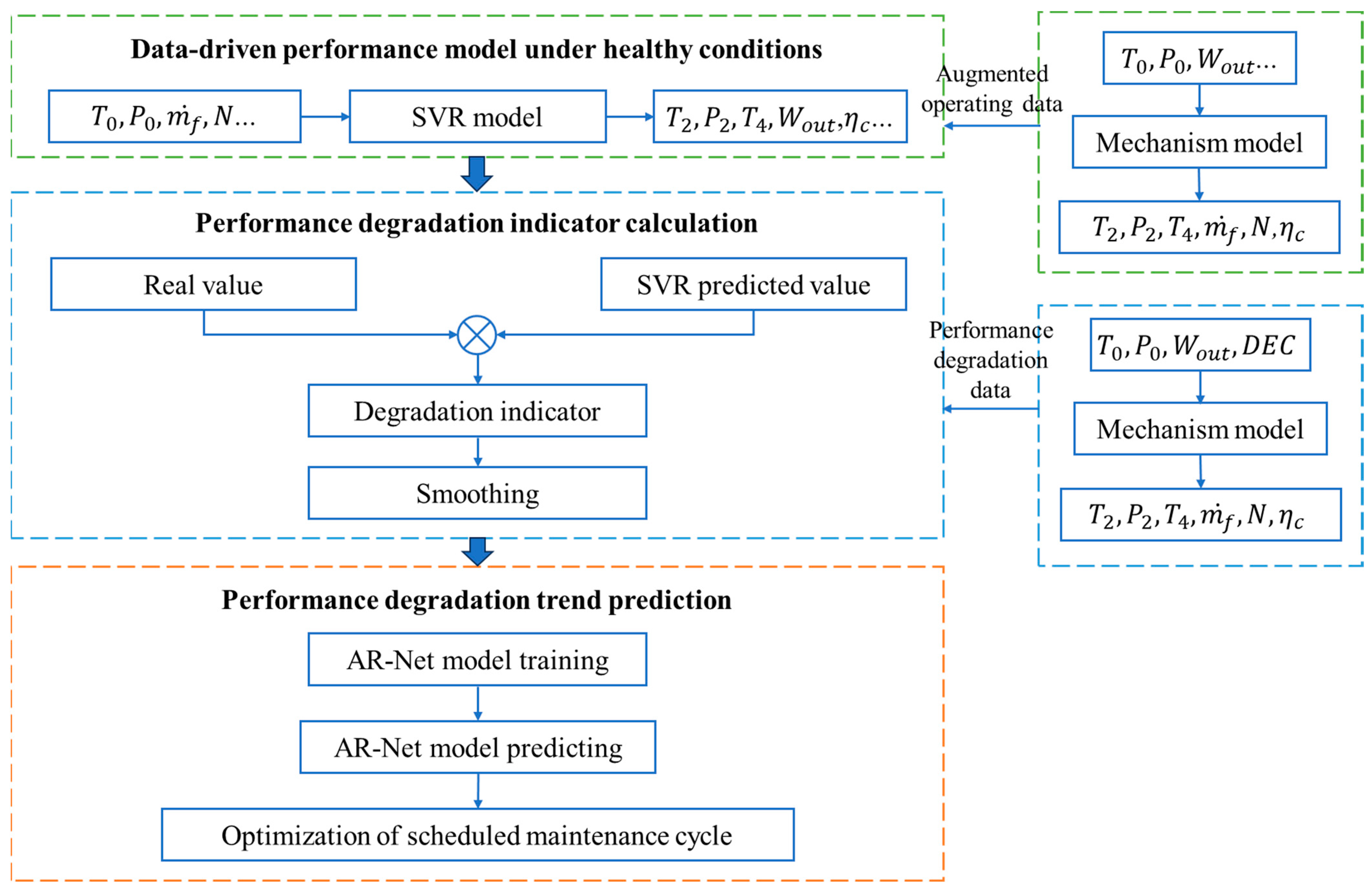

2. Methodology

2.1. Gas Turbine Structure and Mechanism Model

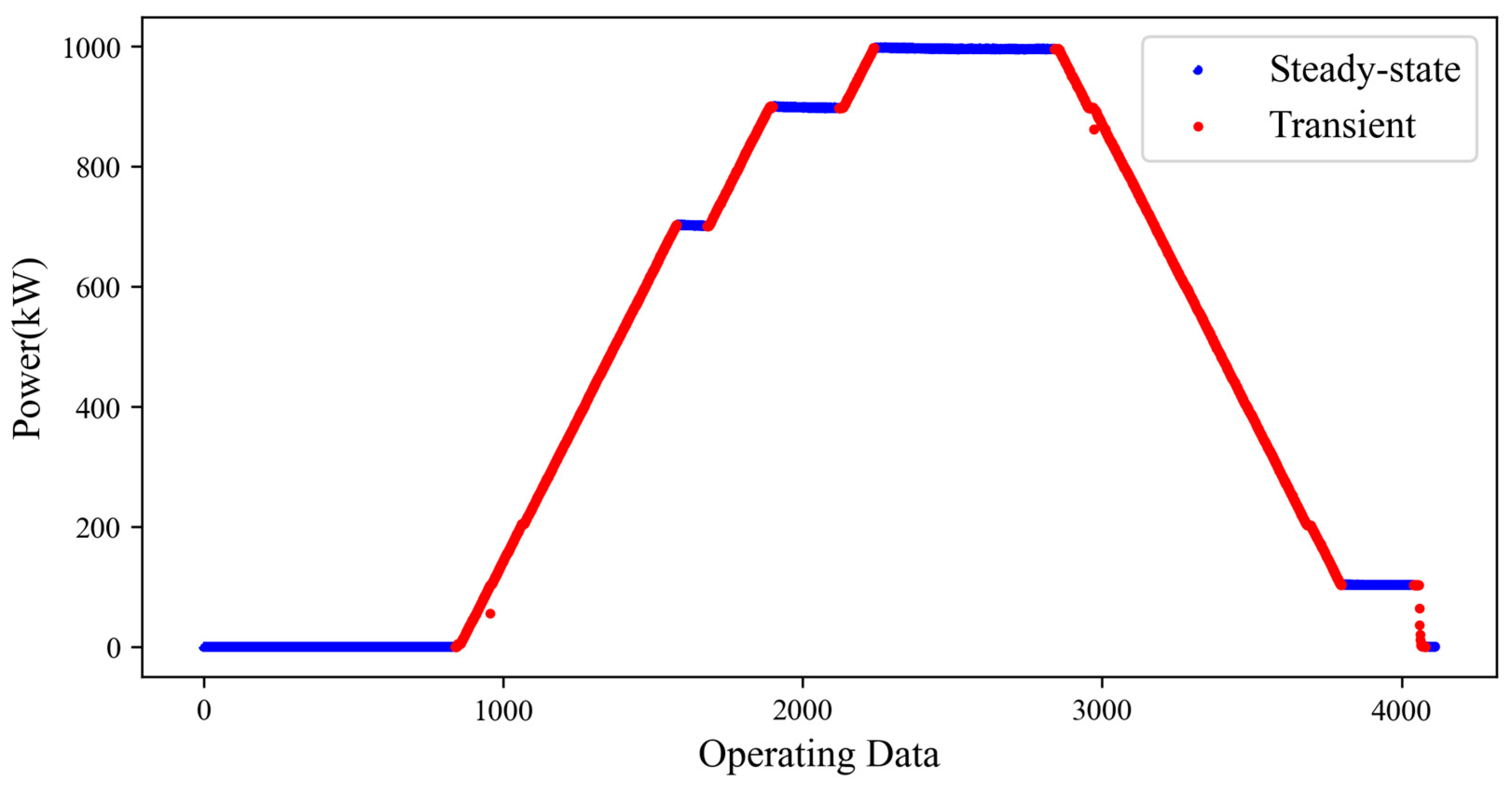

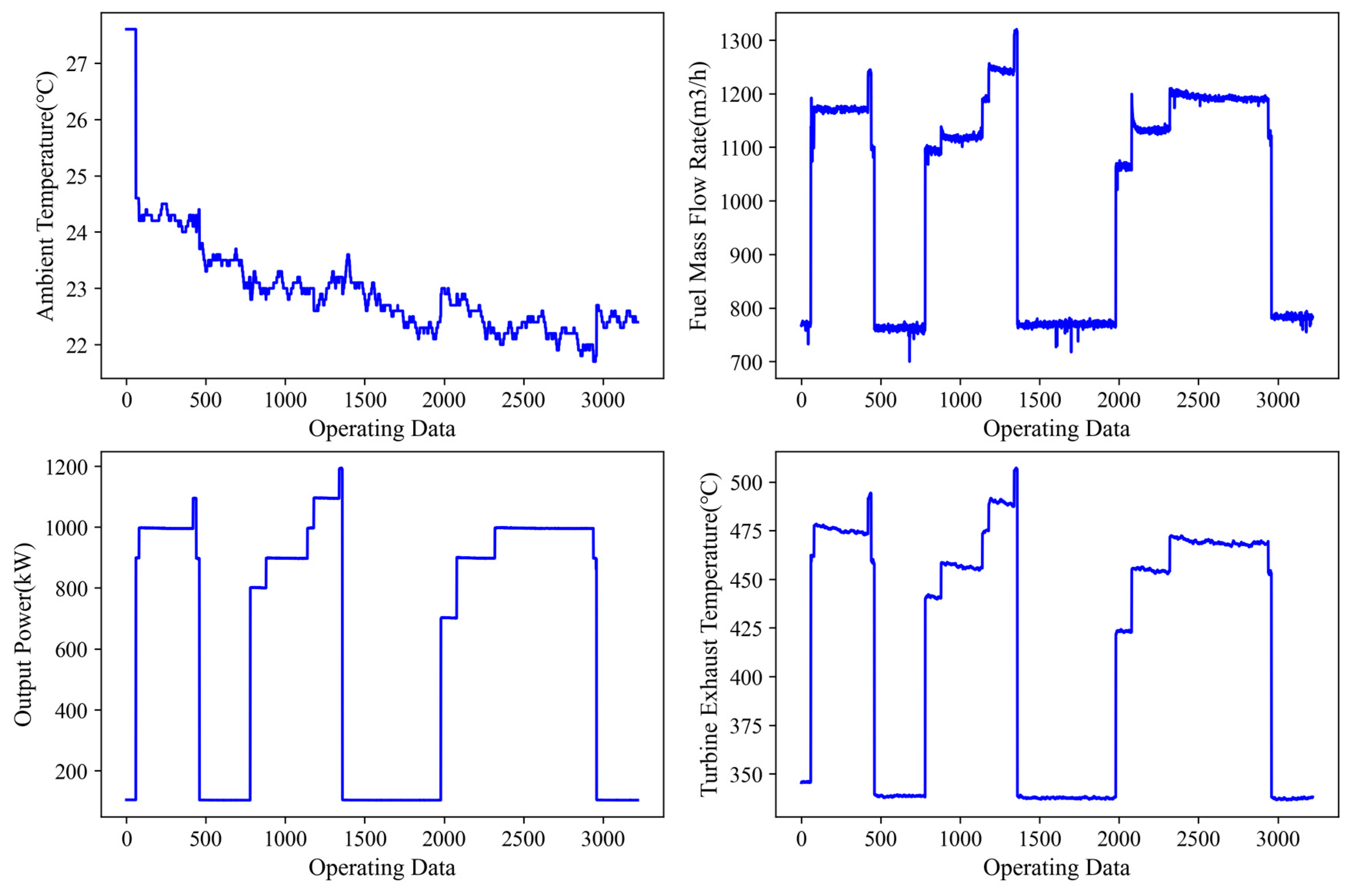

2.2. Data Preprocessing

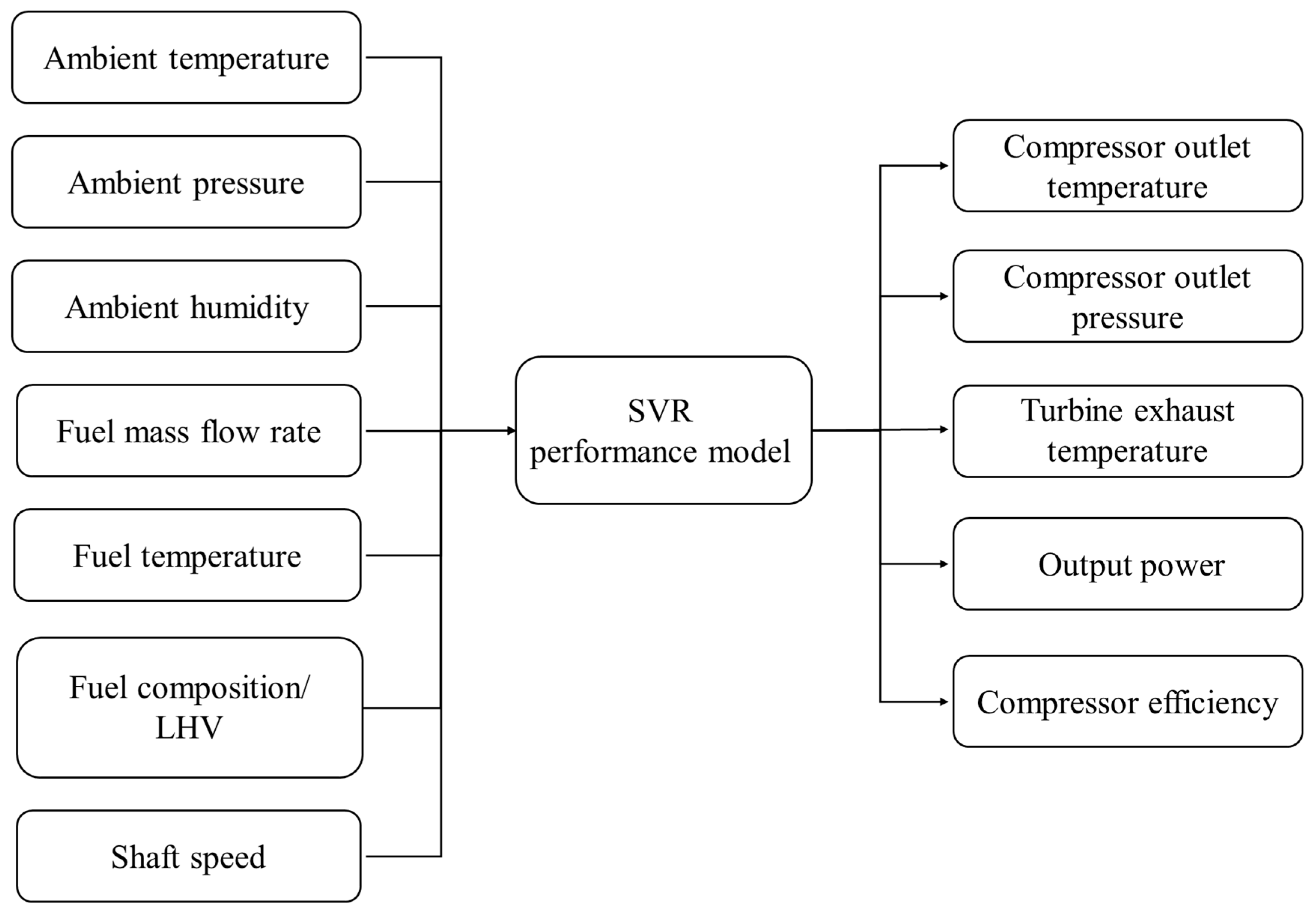

2.3. Gas Turbine Performance Model Based on Support Vector Regression

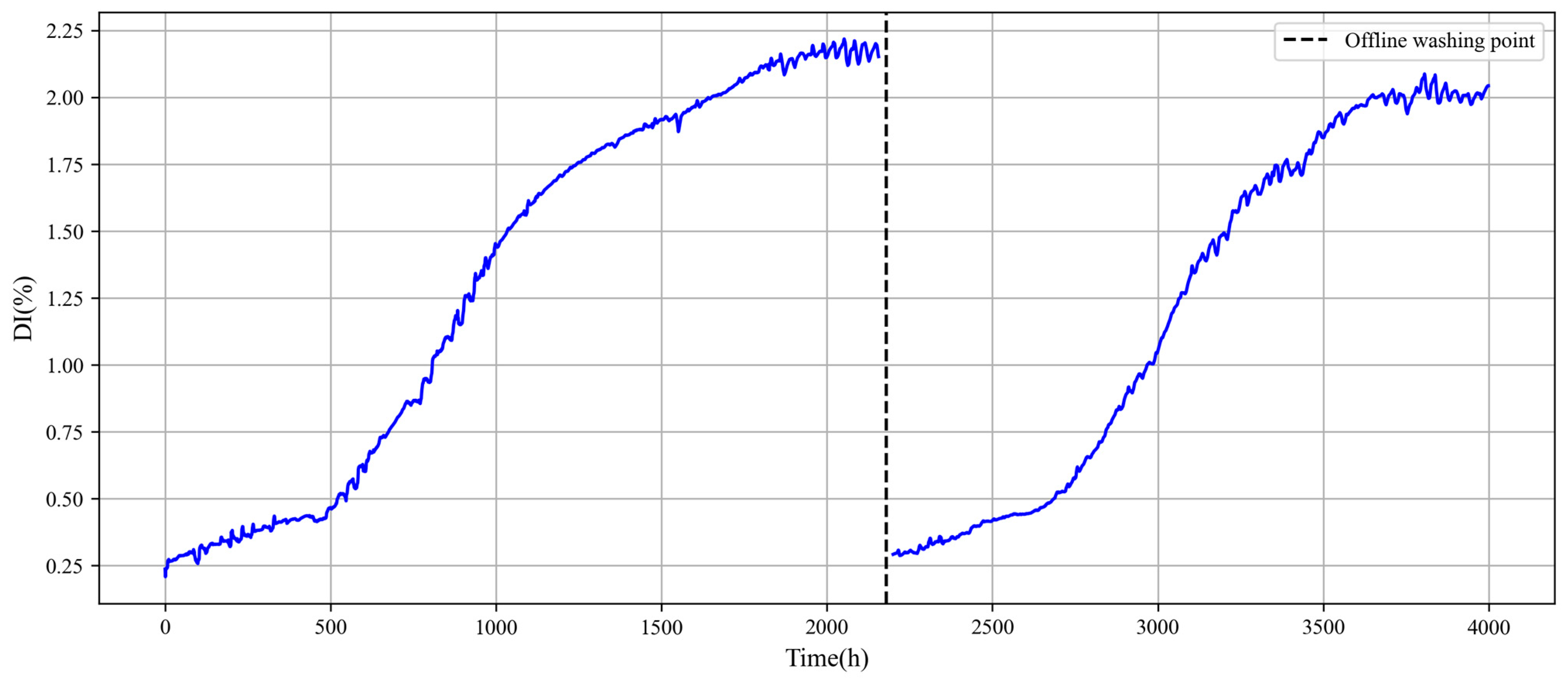

2.4. Smoothing of the Degradation Indicator Based on the Piecewise Linear Model

2.5. Performance Degradation Prediction Model Based on an Autoregressive Neural Network

3. Results and Discussions

3.1. Performance Model Training

3.2. Performance Degradation Indicator Calculation

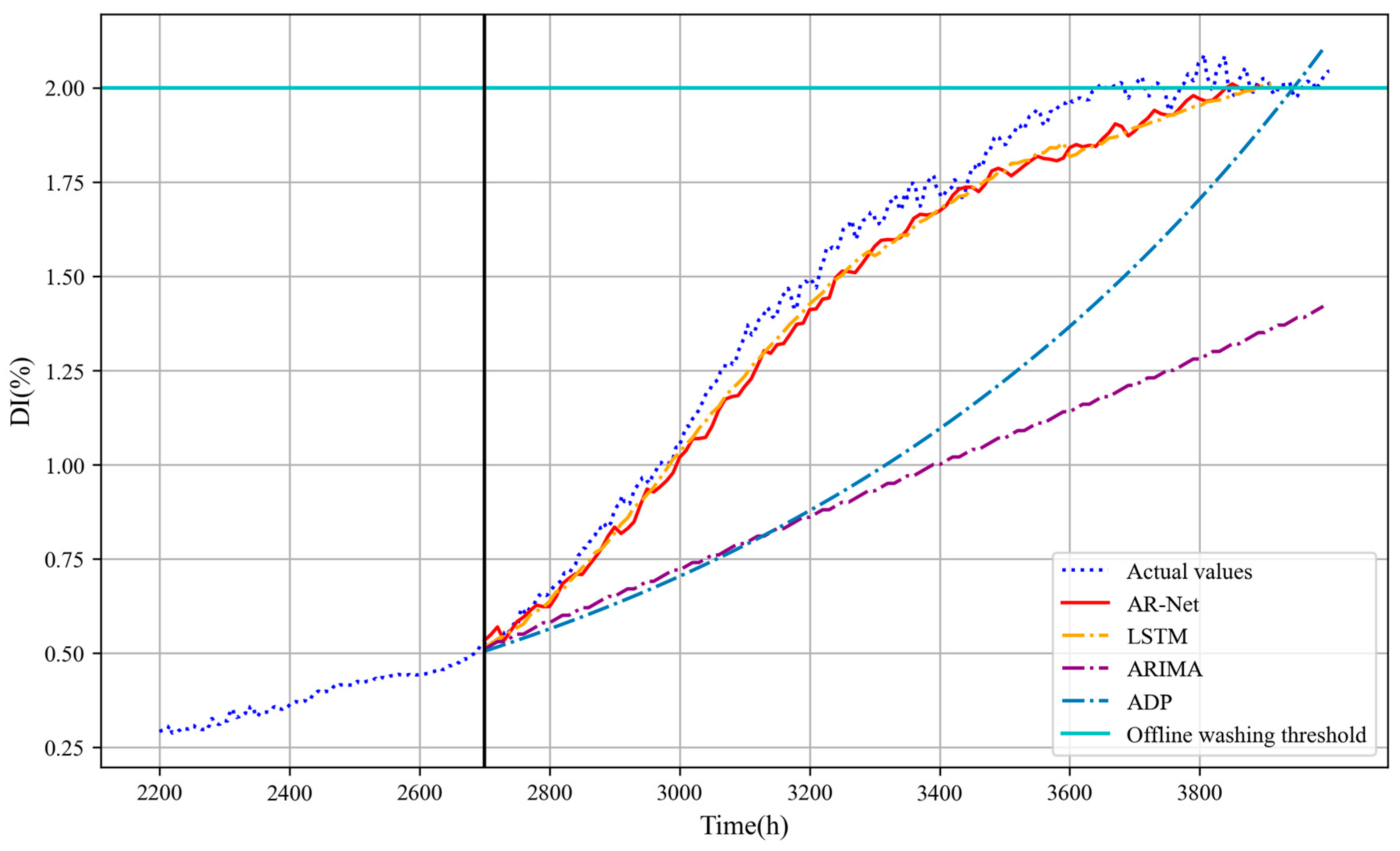

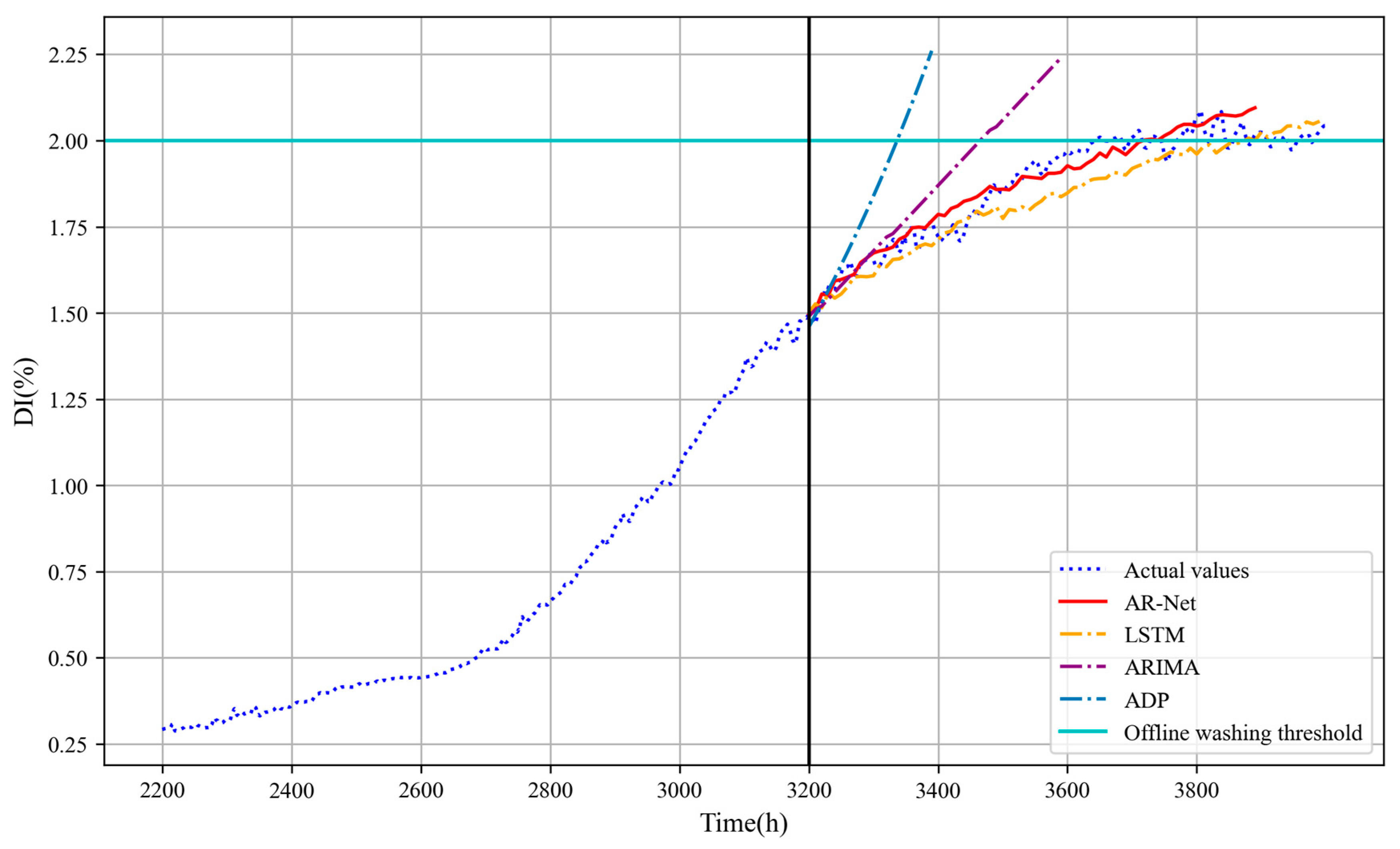

3.3. Prediction Model Validation and Comparison

4. Conclusions

- The predicted values of the SVR performance model and measured parameters can be used to calculate . After smoothing with a piecewise linear model, the influence of environmental conditions and control factors is eliminated to some extent.

- The prediction model based on AR-Net can accurately predict the performance degradation of gas turbines over time and demonstrates the superiority of the proposed method compared to other models.

- In practical engineering applications, various degradation indicators, such as residual power output and residual exhaust temperature, can be used to comprehensively assess the performance degradation trend of a gas turbine and its components. This allows for better scheduling of turbine maintenance, thus optimizing operational costs and major overhaul time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Latin symbols | |

| ADP | adaptive degradation prediction |

| ARIMA | autoregressive integrated moving average |

| AR-Net | autoregressive neural network |

| DEC | compressor efficiency degradation |

| DI | degradation indicator |

| LSTM | long short-term memory |

| fuel mass flow rate | |

| N | shaft speed |

| P | pressure |

| SVR | support vector regression |

| T | temperature |

| output power | |

| Greek symbols | |

| compressor polytropic efficiency | |

| compression ratio | |

| temperature ratio | |

| Subscripts | |

| 0 | ambient |

| 2 | compressor outlet |

| 4 | turbine outlet |

| deg | degraded parameters |

| svr | output parameters of the SVR model |

References

- Hanachi, H.; Liu, J.; Ding, P.; Kim, I.Y.; Mechefske, C.K. Predictive compressor wash optimization for economic operation of gas turbine. J. Eng. Gas Turbines Power. 2018, 140, 121006. [Google Scholar] [CrossRef]

- Kurz, R.; Brun, K. Degradation of gas turbine performance in natural gas service. J. Nat. Gas Sci. Eng. 2009, 1, 95–102. [Google Scholar] [CrossRef]

- Tahan, M.; Tsoutsanis, E.; Muhammad, M.; Karim, Z.A. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: A review. Appl. Energy 2017, 198, 122–144. [Google Scholar] [CrossRef]

- Schneider, E.; Demircioglu Bussjaeger, S.; Franco, S.; Therkorn, D. Analysis of compressor on-line washing to optimize gas turbine power plant performance. J. Eng. Gas Turbines Power. 2010, 132, 062001. [Google Scholar] [CrossRef]

- Kurz, R.; Brun, K. Gas Turbine Tutorial-Maintenance and Operating Practices Effects on Degradation and Life. In Proceedings of the 36th Turbomachinery Symposium; Texas A&M University, Turbomachinery Laboratories: College Station, TX, USA, 2007; pp. 173–186. [Google Scholar]

- Hanachi, H.; Mechefske, C.; Liu, J.; Banerjee, A.; Chen, Y. Performance-based gas turbine health monitoring, diagnostics, and prognostics: A survey. IEEE Trans. Reliab. 2018, 67, 1340–1363. [Google Scholar] [CrossRef]

- Hanachi, H.; Liu, J.; Banerjee, A.; Chen, Y.; Koul, A. A Physics-Based Performance Indicator for Gas Turbine Engines Under Variable Operating Conditions. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Blinstrub, J.; Li, Y.G.; Newby, M.; Zhou, Q.; Stigant, G.; Pilidis, P.; Hönen, H. Application of Gas Path Analysis to Compressor Diagnosis of an Industrial Gas Turbine Using Field Data. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Lu, F.; Ju, H.; Huang, J. An improved extended Kalman filter with inequality constraints for gas turbine engine health monitoring. Aerosp. Sci. Technol. 2016, 58, 36–47. [Google Scholar] [CrossRef]

- Lu, F.; Gao, T.; Huang, J.; Qiu, X. Nonlinear Kalman filters for aircraft engine gas path health estimation with measurement uncertainty. Aerosp. Sci. Technol. 2018, 76, 126–140. [Google Scholar] [CrossRef]

- Rahmoune, M.B.; Hafaifa, A.; Kouzou, A.; Chen, X.; Chaibet, A. Gas turbine monitoring using neural network dynamic nonlinear autoregressive with external exogenous input modelling. Math. Comput. Simul. 2021, 179, 23–47. [Google Scholar] [CrossRef]

- Alam, M.M.; Bodruzzaman, M.; Zein-Sabatto, M.S. Online prognostics of aircraft turbine engine component’s remaining useful life (RUL). In Proceedings of the IEEE SOUTHEASTCON 2014, Lexington, KY, USA, 13–16 March 2014; pp. 1–6. [Google Scholar]

- Sun, L.; Liu, T.; Xie, Y.; Zhang, D.; Xia, X. Real-time power prediction approach for turbine using deep learning techniques. Energy 2021, 233, 121130. [Google Scholar] [CrossRef]

- Liu, Z.; Karimi, I.A. Gas turbine performance prediction via machine learning. Energy 2020, 192, 116627. [Google Scholar] [CrossRef]

- Palmé, T.; Liard, F.; Cameron, D. Hybrid Modeling of Heavy Duty Gas Turbines for On-Line Performance Monitoring. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Li, Y.G.; Nilkitsaranont, P. Gas turbine performance prognostic for condition-based maintenance. Appl. Energy 2009, 86, 2152–2161. [Google Scholar] [CrossRef]

- Zhou, D.; Yu, Z.; Zhang, H.; Weng, S. A novel grey prognostic model based on Markov process and grey incidence analysis for energy conversion equipment degradation. Energy 2016, 109, 420–429. [Google Scholar] [CrossRef]

- Wang, W.; Li, S.; Wang, J.; Cui, B. Prediction on gas path performance degradation of gas turbine based on time series model. J. Eng. Therm. Energy Power 2016, 31, 50–55. [Google Scholar]

- Zagorowska, M.; Schulze Spüntrup, F.; Ditlefsen, A.-M.; Imsland, L.; Lunde, E.; Thornhill, N.F. Adaptive detection and prediction of performance degradation in off-shore turbomachinery. Appl. Energy 2020, 268, 114934. [Google Scholar] [CrossRef]

- Chen, J.; Tang, X.; Lu, J.; Zhang, H. A Compressor Off-Line Washing Schedule Optimization Method with a LSTM Deep Learning Model Predicting the Fouling Trend. J. Eng. Gas Turbines Power 2022, 144, 081005. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, C.; Tian, X.; Huang, H.; Deng, G.; Guan, Y.; Jiang, D. A hybrid model of LSTM neural networks with a thermodynamic model for condition-based maintenance of compressor fouling. Meas. Sci. Technol. 2021, 32, 124007. [Google Scholar] [CrossRef]

- Triebe, O.; Laptev, N.P.; Rajagopal, R. AR-Net: A simple Auto-Regressive Neural Network for time-series. arXiv 2019, arXiv:1911.12436. [Google Scholar]

- Zhou, Z. Deep Learning Based Air Quality Prediction with Time Series Sensor Data; Arizona State University: Tempe, AZ, USA, 2023. [Google Scholar]

- Xiao, Z.; Huang, X.; Liu, J.; Li, C.; Tai, Y. A novel method based on time series ensemble model for hourly photovoltaic power prediction. Energy 2023, 276, 127542. [Google Scholar] [CrossRef]

- Shehzad, M.K.; Rose, L.; Azam, M.F.; Assaad, M. Real-Time Massive MIMO Channel Prediction: A Combination of Deep Learning and NeuralProphet. In Proceedings of the GLOBECOM 2022-2022 IEEE Global Communications Conference, Rio de Janeiro, Brazil, 4–8 December 2022; pp. 1423–1428. [Google Scholar]

- Wang, Z.; Gu, J.; Han, X.; Zhu, J.; Huang, Y. Reference Value Determination Based on Data Driven under Full Operating Conditions of Gas Turbine. Process Autom. Instrum. 2019, 40, 5–8+13. [Google Scholar]

- Awad, M.; Khanna, R.; Awad, M.; Khanna, R. Support vector regression. In Efficient Learning Machines: Theories, Concepts, and Applications for Engineers and System Designers; Springer: Singapore, 2015; pp. 67–80. [Google Scholar]

- Gao, F.; Kou, P.; Gao, L.; Guan, X. Boosting regression methods based on a geometric conversion approach: Using SVMs base learners. Neurocomputing 2013, 113, 67–87. [Google Scholar] [CrossRef]

- Taylor, S.J.; Letham, B. Forecasting at scale. Am. Stat. 2018, 72, 37–45. [Google Scholar] [CrossRef]

- Zhang, F.; Cheng, L.; Wu, M.; Xu, X.; Wang, P.; Liu, Z. Performance analysis of two-stage thermoelectric generator model based on Latin hypercube sampling. Energy Convers. Manag. 2020, 221, 113159. [Google Scholar] [CrossRef]

- Najjar, Y.S.; Alalul, O.F.; Abu-Shamleh, A. Degradation analysis of a heavy-duty gas turbine engine under full and part load conditions. Int. J. Energy Res. 2020, 44, 4529–4542. [Google Scholar] [CrossRef]

- Wang, T. 15—The gas and steam turbines and combined cycle in IGCC systems. In Integrated Gasification Combined Cycle (IGCC) Technologies; Wang, T., Stiegel, G., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 497–640. [Google Scholar]

| Parameter | Value |

|---|---|

| Power generation/MW | 2 |

| Power generation efficiency/% | 25.7 |

| Pressure ratio | 7.5 |

| Exhaust flow rate/(Kg/s) | 10.1 |

| Turbine inlet temperature/K | 1223 |

| Exhaust temperature/K | 803 |

| Variables | Search Space |

|---|---|

| (°C) | [−10, 50] |

| (bar) | [0.98285, 1.04365] |

| (kW) | [200, 2000] |

| Performance Parameters | RMSE | MAPE |

|---|---|---|

| 0.39 | 0.06% | |

| 0.04 | 0.53% | |

| 0.33 | 0.05% | |

| 0.58 | 0.04% | |

| 0.003 | 0.39% |

| Model | Setting |

|---|---|

| AR-Net | Input steps: 500 Output steps: 300 First hidden layer size: 64 Second hidden layer size: 32 |

| LSTM | Input steps: 500 Output steps: 300 First hidden layer size: 64 Second hidden layer size: 32 |

| ARIMA | AR order: 500 Integrated order: 3 MA order: 500 |

| ADP | The number of data points fitted: 500 |

| AR-Net | LSTM | ARIMA | ADP | |||||

|---|---|---|---|---|---|---|---|---|

| Time (h) | RMSE | MAPE | RMSE | MAPE | RMSE | MAPE | RMSE | MAPE |

| 500 | 0.08 | 5.10 | 0.08 | 4.80 | 0.58 | 33.42 | 0.47 | 29.24 |

| 1000 | 0.06 | 2.51 | 0.09 | 4.49 | 0.33 | 14.37 | 1.00 | 46.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, S.; Zhang, X.; Luo, M. A Novel Data-Driven Approach for Predicting the Performance Degradation of a Gas Turbine. Energies 2024, 17, 781. https://doi.org/10.3390/en17040781

Dai S, Zhang X, Luo M. A Novel Data-Driven Approach for Predicting the Performance Degradation of a Gas Turbine. Energies. 2024; 17(4):781. https://doi.org/10.3390/en17040781

Chicago/Turabian StyleDai, Shun, Xiaoyi Zhang, and Mingyu Luo. 2024. "A Novel Data-Driven Approach for Predicting the Performance Degradation of a Gas Turbine" Energies 17, no. 4: 781. https://doi.org/10.3390/en17040781

APA StyleDai, S., Zhang, X., & Luo, M. (2024). A Novel Data-Driven Approach for Predicting the Performance Degradation of a Gas Turbine. Energies, 17(4), 781. https://doi.org/10.3390/en17040781