Modern SCADA for CSP Systems Based on OPC UA, Wi-Fi Mesh Networks, and Open-Source Software

Abstract

1. Introduction

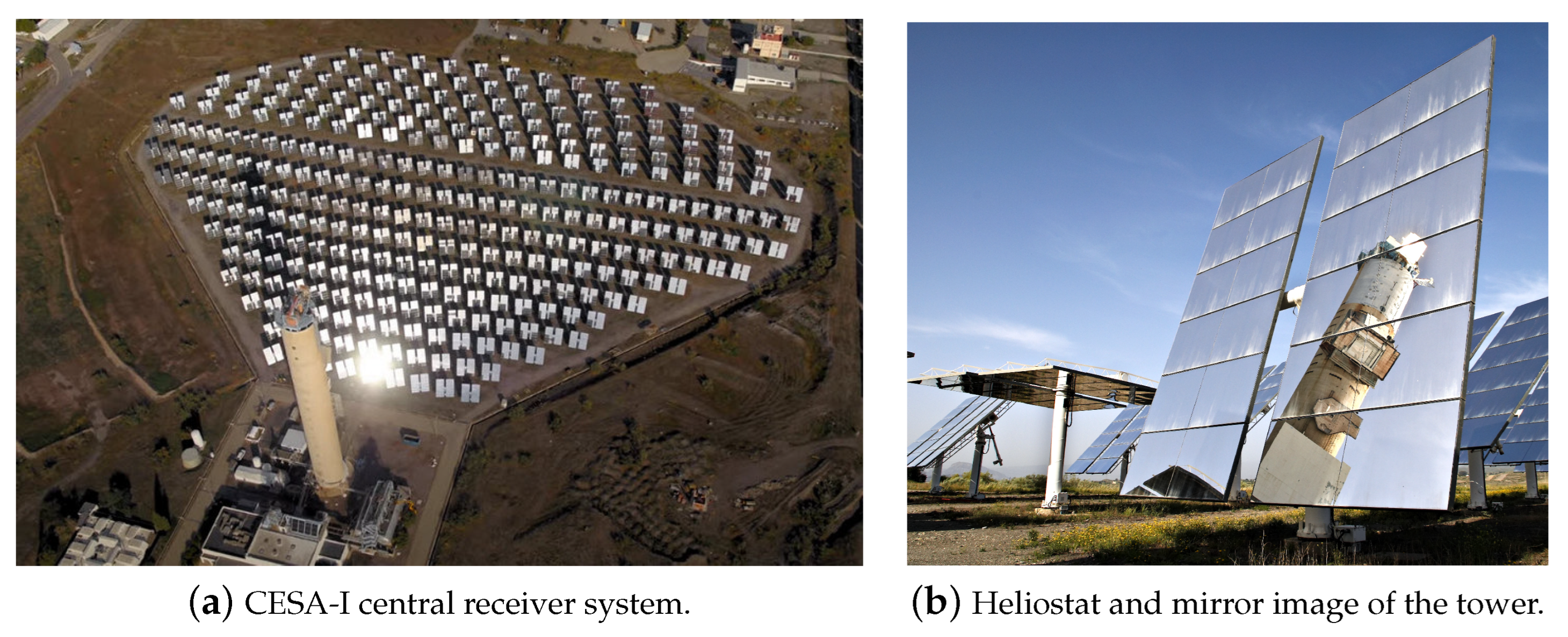

1.1. Concentrated Solar Power

1.2. Plataforma Solar de Almería

1.3. Smart Heliostat

1.4. Supervisory Control and Data Acquisition System in Energy Sector

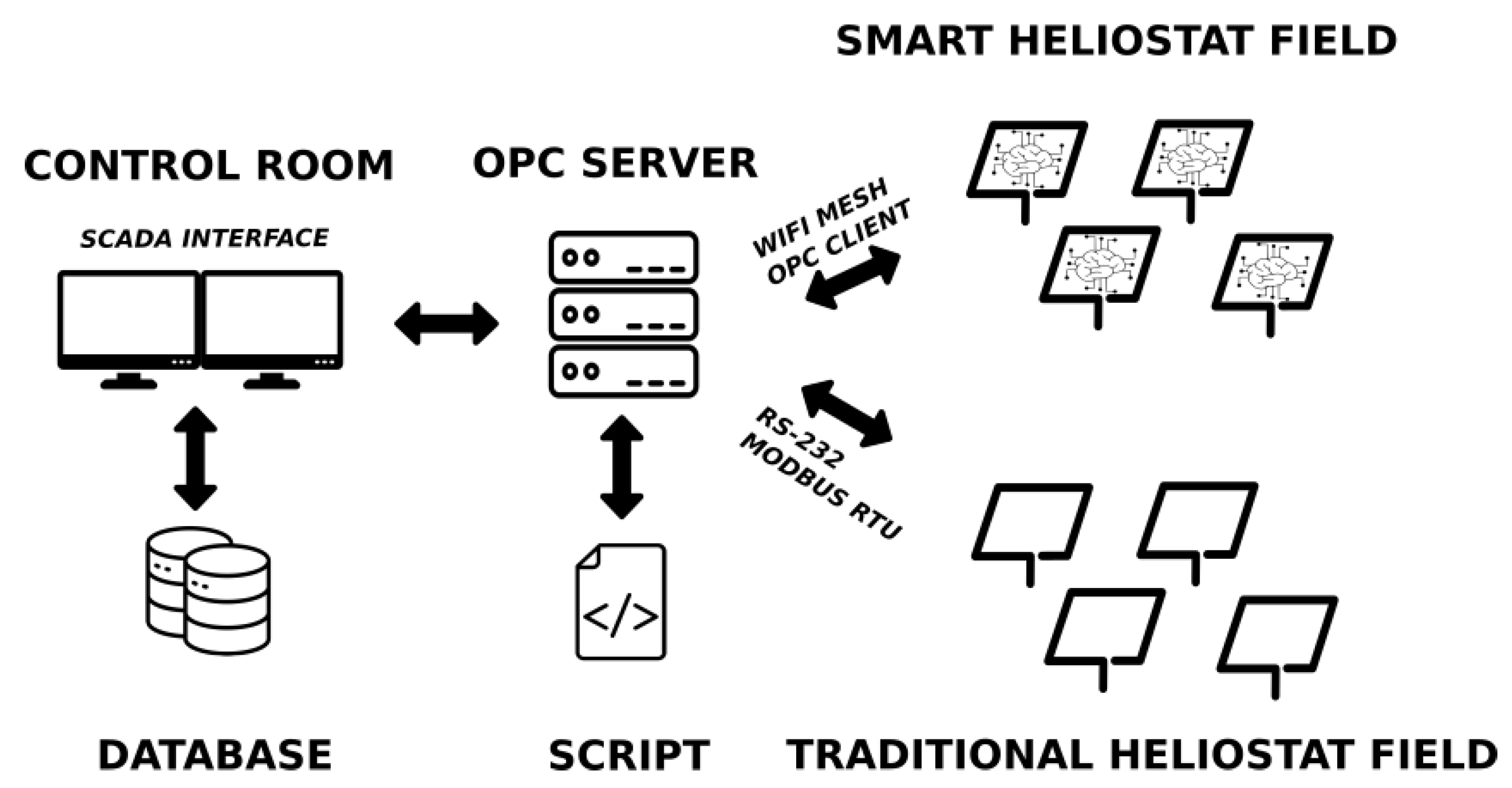

2. Materials and Methods

2.1. OPC Server

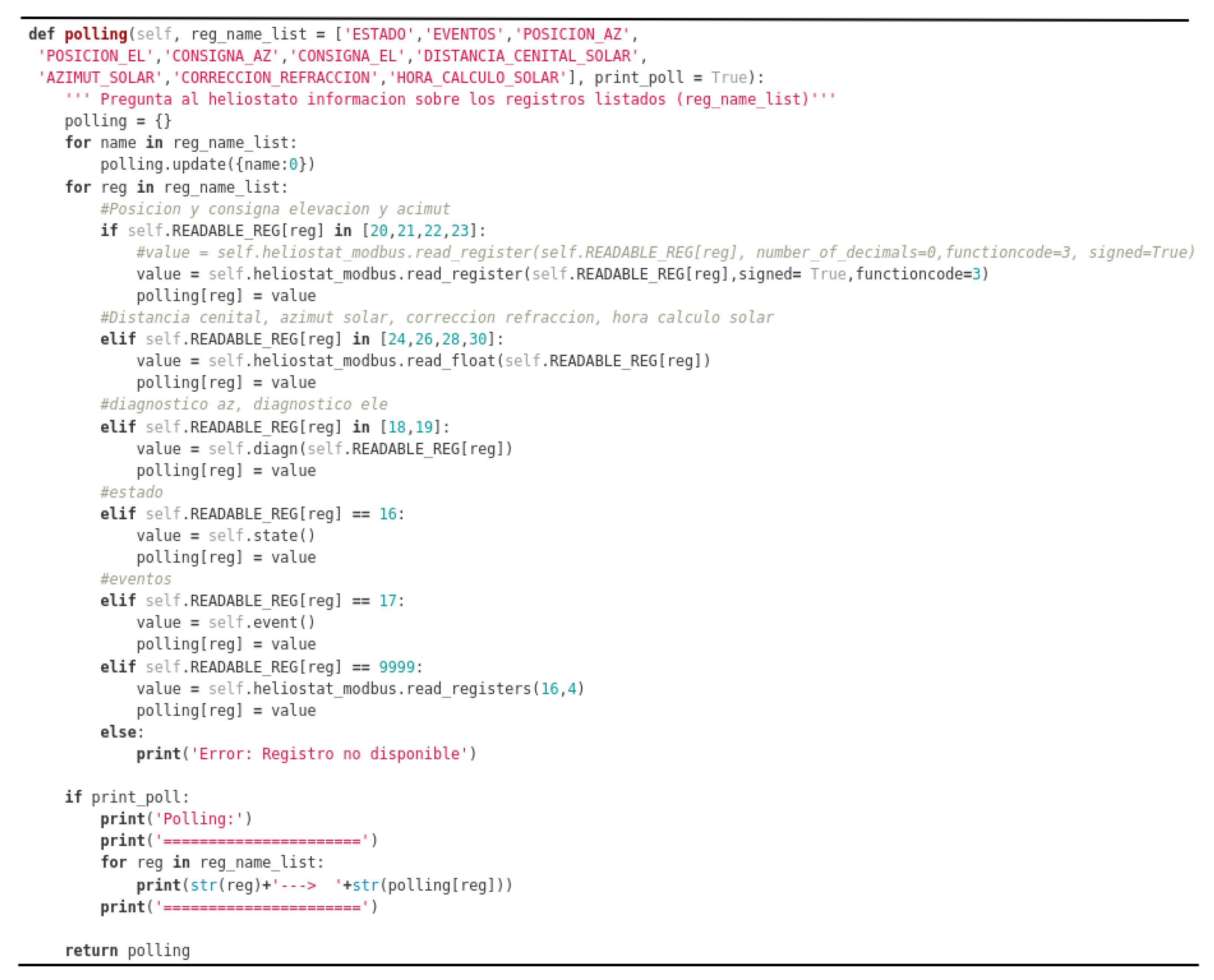

2.2. Gateway Modbus-OPC

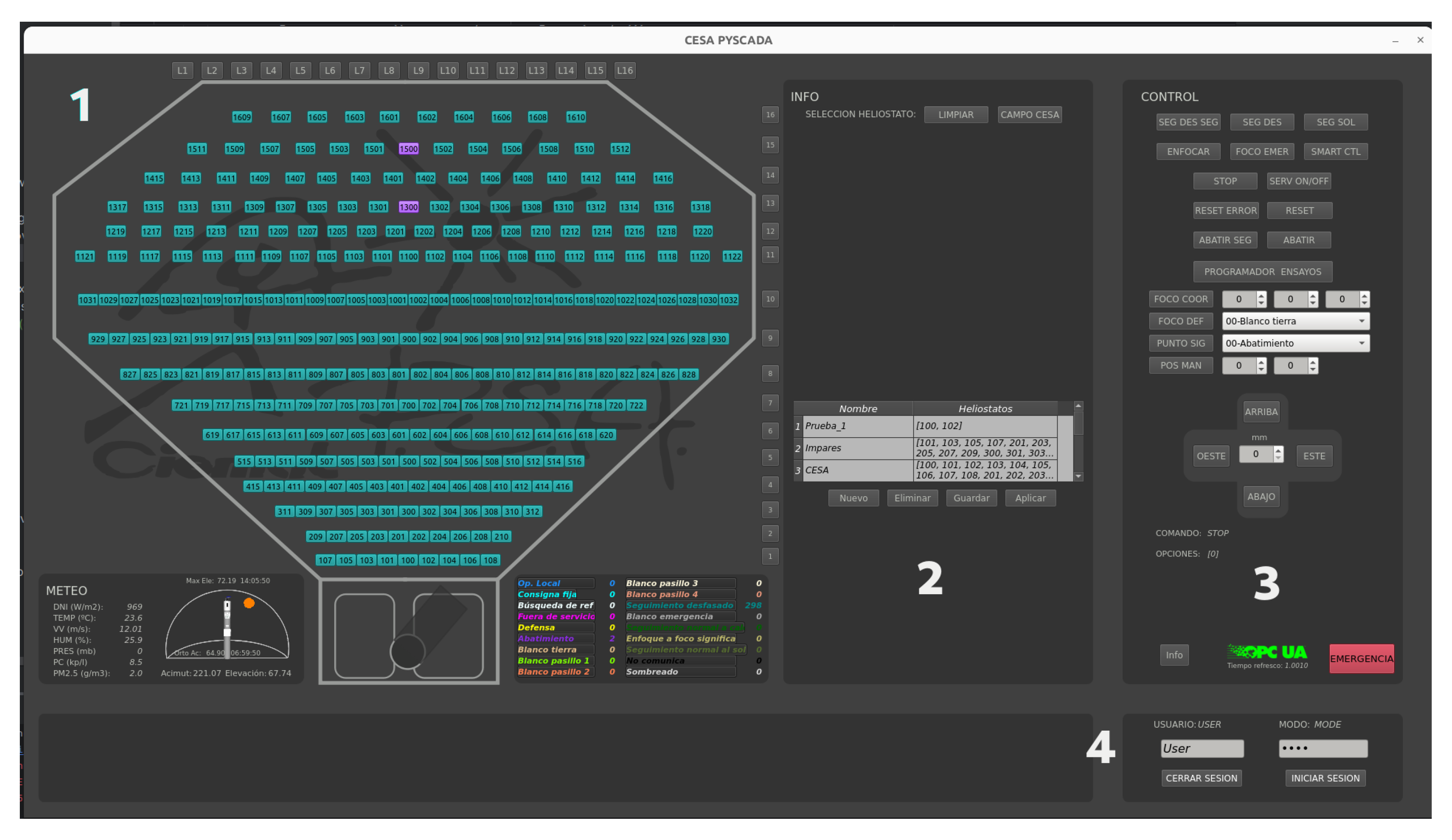

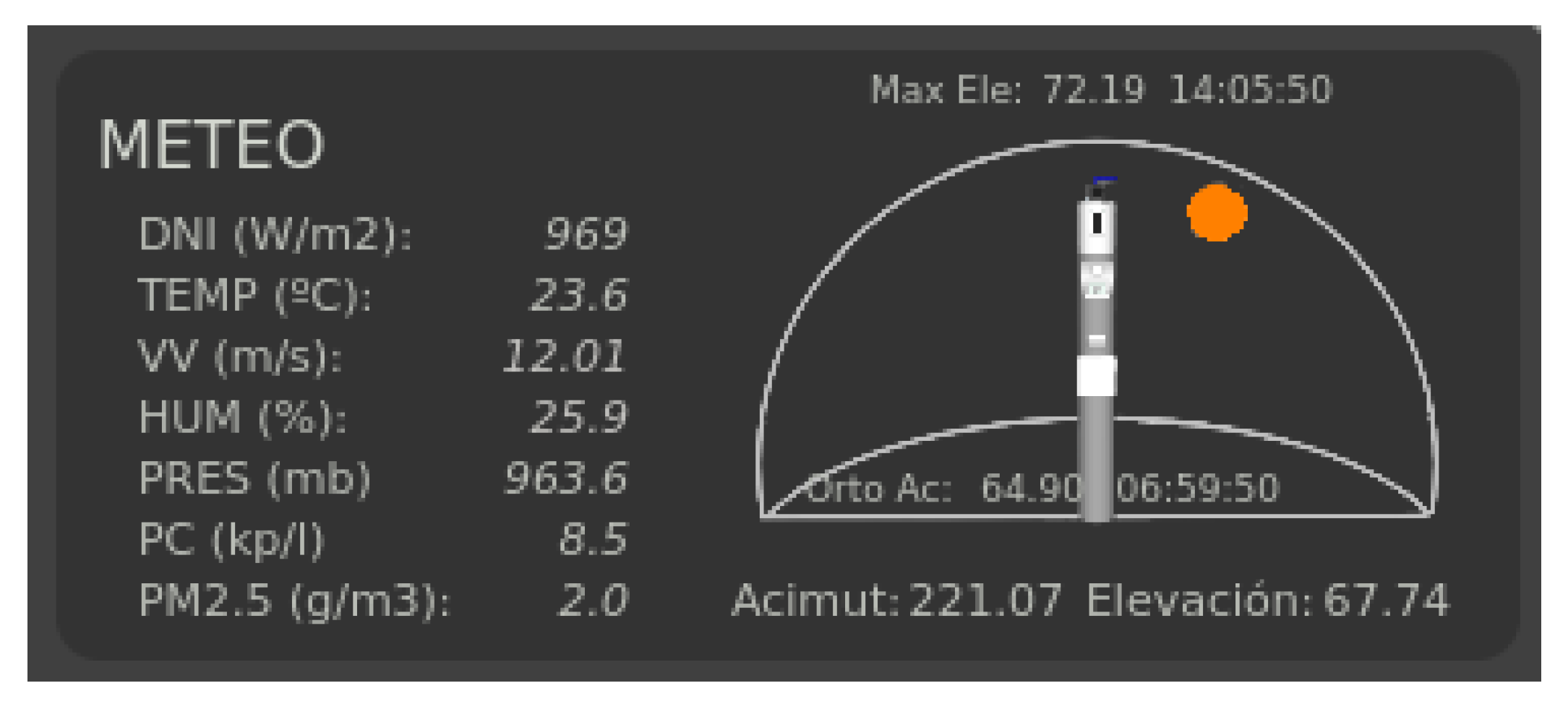

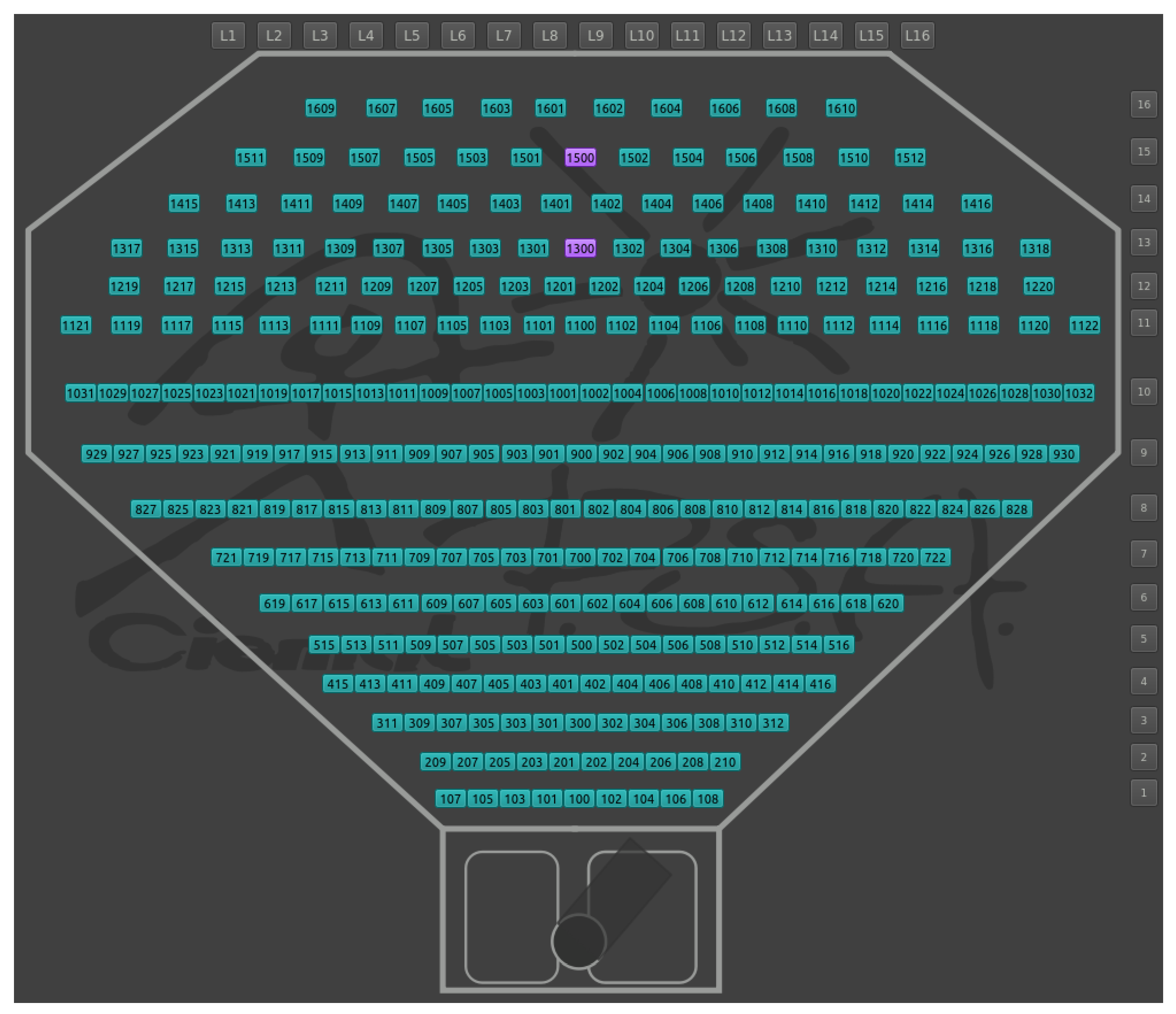

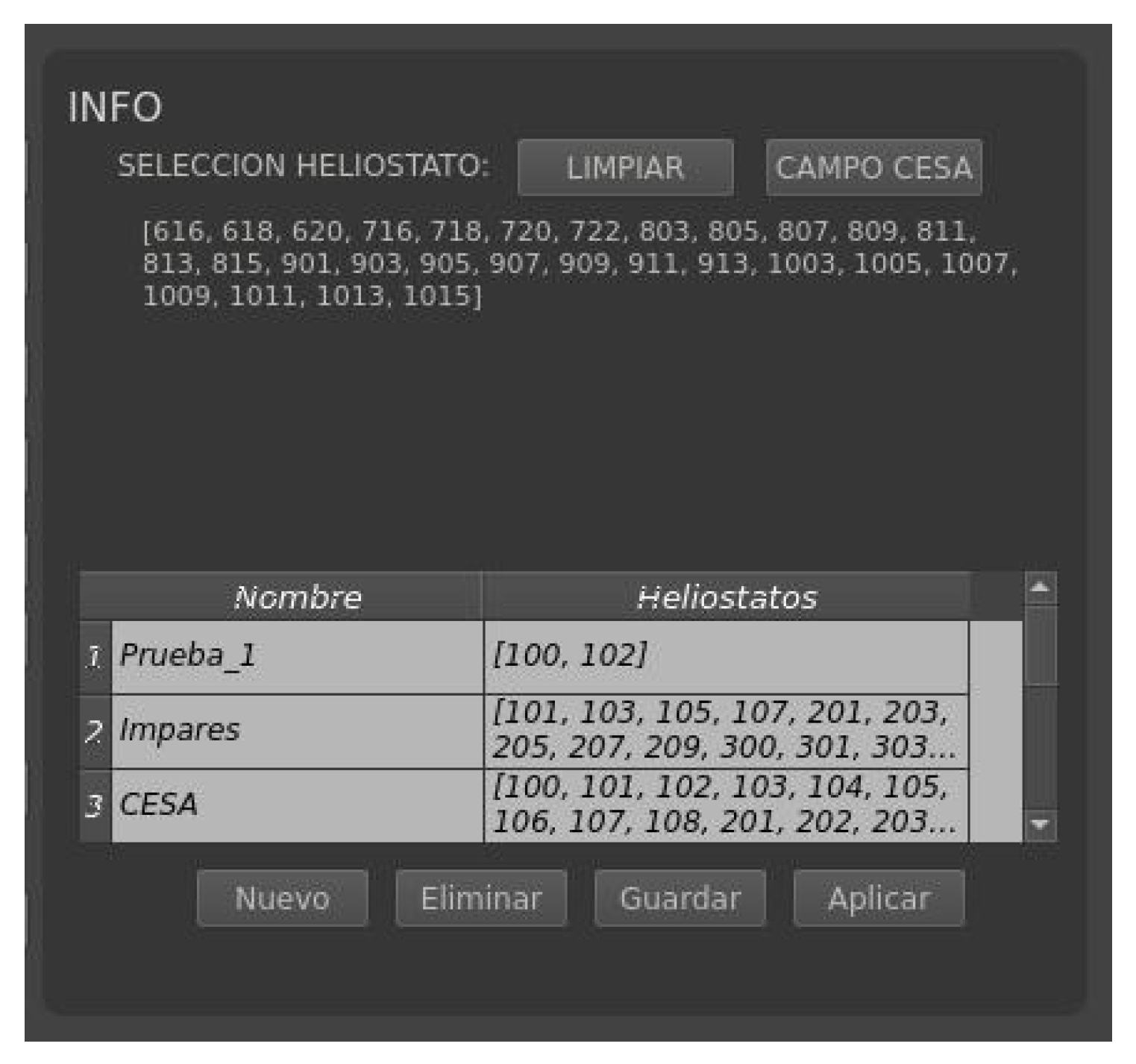

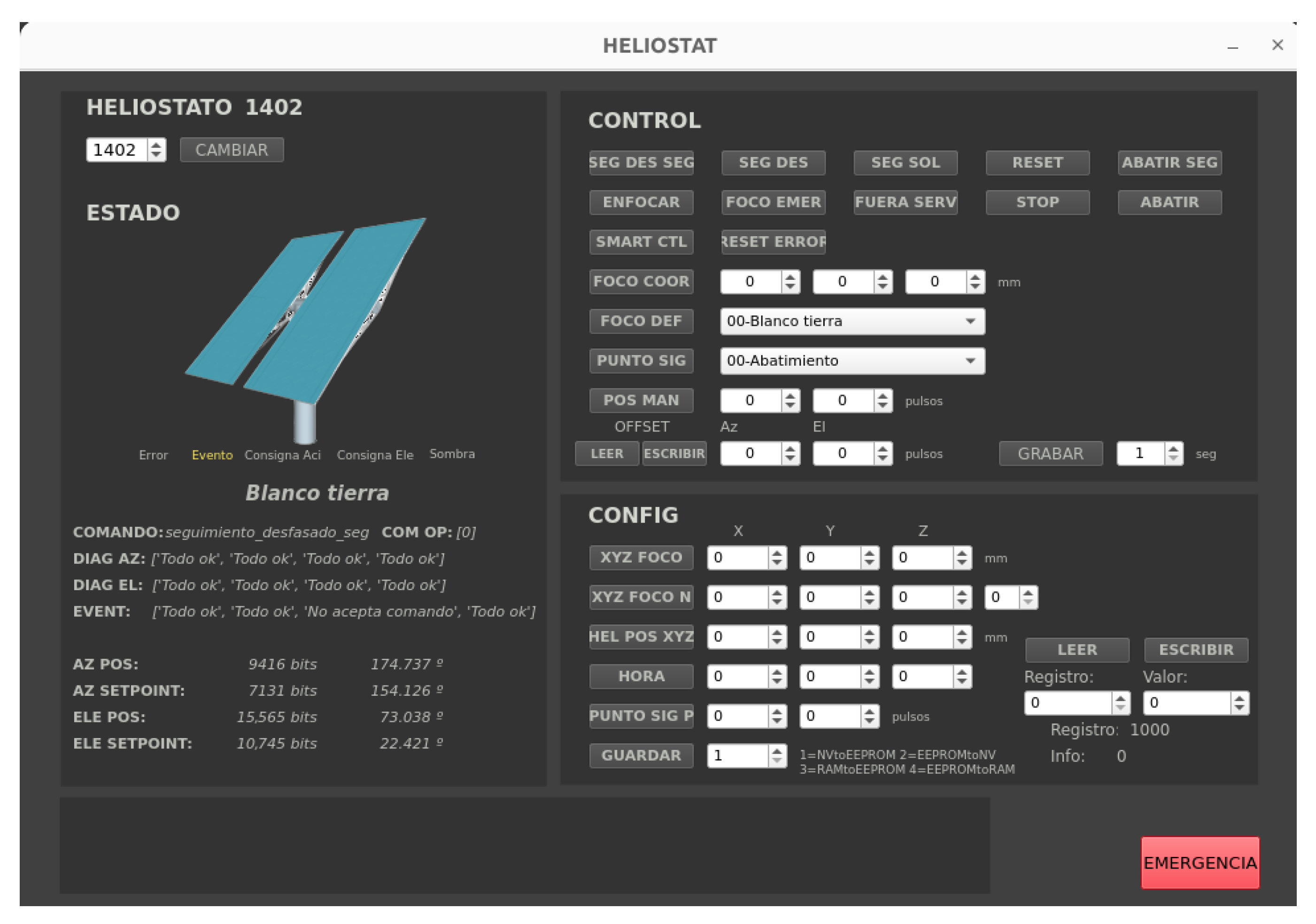

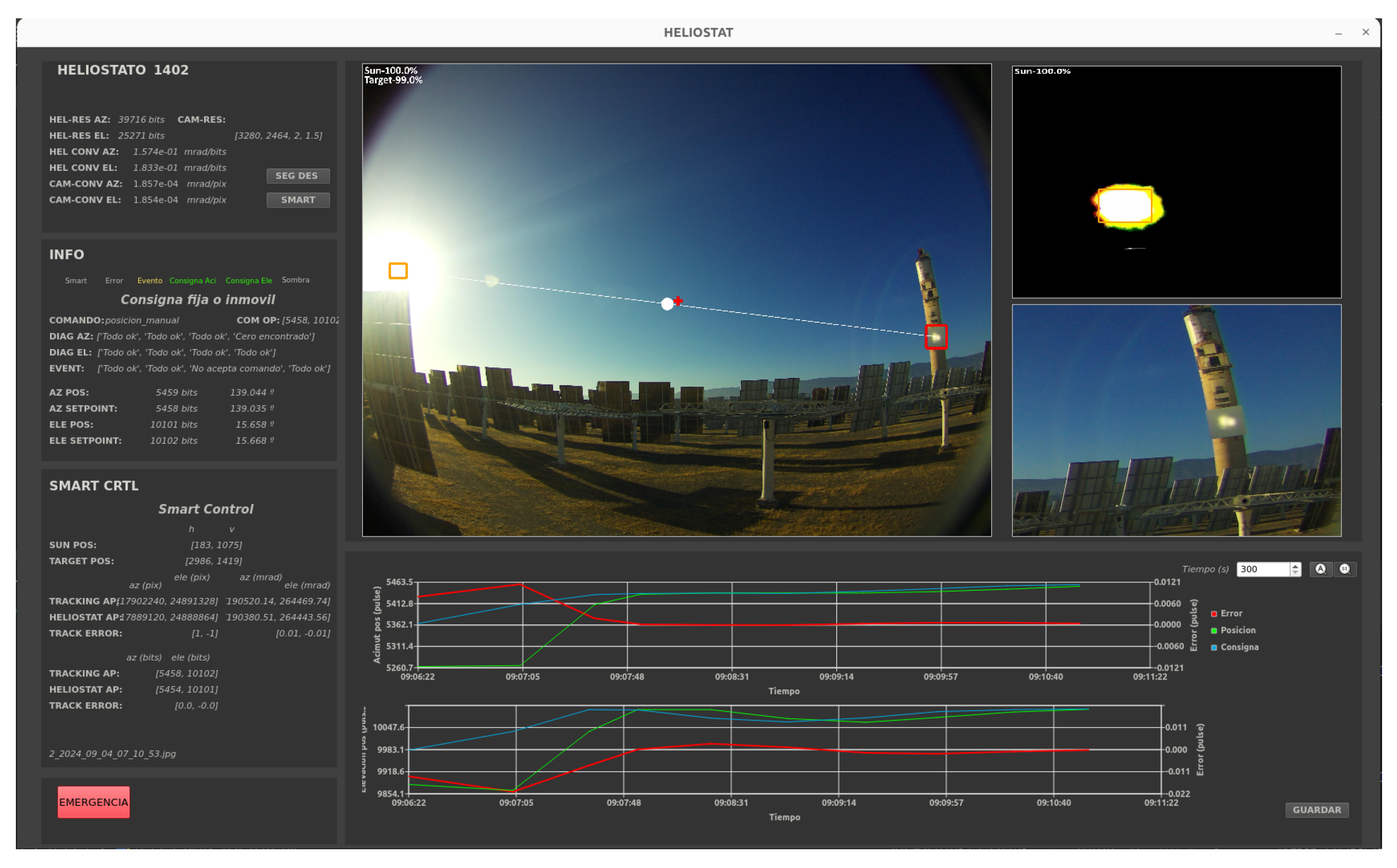

2.3. SCADA Interface

- Operación local: Heliostat operating under local control only.

- Consigna fija: Heliostat positioned at a fixed setpoint for both azimuth and elevation.

- Búsqueda referencia: Heliostat searching for the ‘zero reference’ in both azimuth and elevation.

- Fuera de servicio: Heliostat that is out of service and not operational.

- Defensa: Heliostat in a defensive position to protect against high winds.

- Abatimiento: Heliostat in its rest or stow position.

- Blanco tierra, pasillo 1, pasillo 2, pasillo 3, pasillo 4: Consecutive safety corridor points used to guide the heliostat toward the receiver.

- Seguimiento desfasado: Heliostat is tracking, but aimed at a standby position near the receiver, not directly at it.

- Blanco emergencia: A designated target point used in emergency situations.

- Seguimiento normal a caldera: Heliostat tracking a specific point at the top of the tower, different from the main receiver.

- Enfoque a foco significativo: Tracking toward a user-defined significant target.

- Seguimiento normal al sol: Heliostat tracking the sun with its aim vector parallel to the solar vector.

- No comunica: Communication with the heliostat has been lost.

- Sombreado: The heliostat is shaded by the tower.

3. Results

3.1. Wi-Fi Mesh Communication Test

3.2. Gateway and Modbus-OPC Library Test

3.3. OPC Server Test

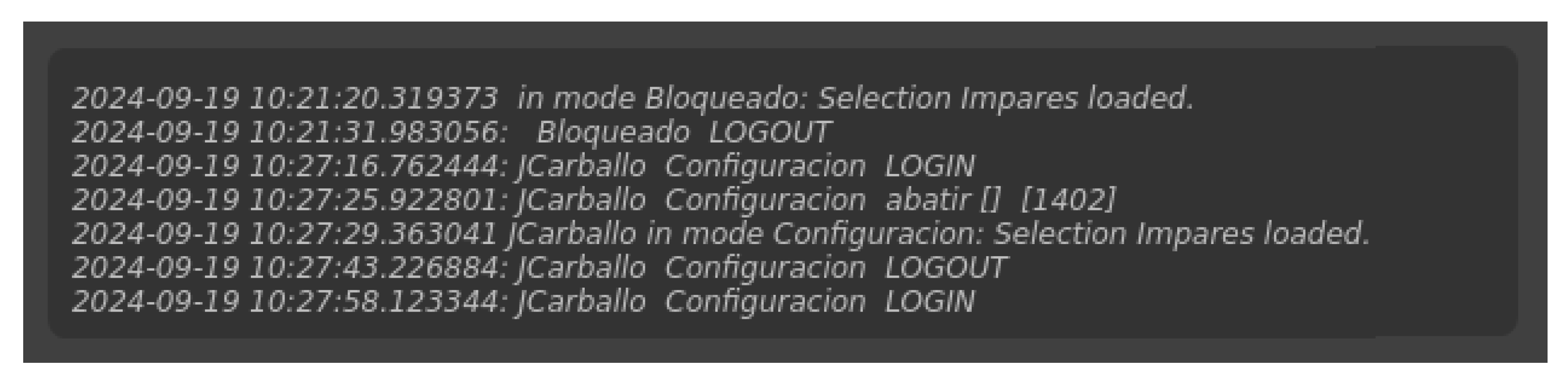

3.4. Usability

3.5. Stability

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | artificial intelligence |

| CSP | concentrated solar power |

| CST | concentrated solar technology |

| DNI | direct normal irradiance |

| HelIoT | smart heliostat |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| LCOE | levelized cost of energy |

| LED | light-emitting diode |

| OPC | open platform communications |

| PSA | Plataforma Solar de Almería |

| PV | photovoltaics |

| SCADA | Supervisory Control and Data Acquisition |

| UA | Unified Architecture |

References

- International Renewable Energy Agency (IRENA). Renewable Power Generation Costs in 2022. 2023. Available online: https://www.irena.org/Publications/2023/Aug/Renewable-power-generation-costs-in-2022 (accessed on 12 July 2024).

- Kiasari, M.; Ghaffari, M.; Aly, H.H. A Comprehensive Review of the Current Status of Smart Grid Technologies for Renewable Energies Integration and Future Trends: The Role of Machine Learning and Energy Storage Systems. Energies 2024, 17, 4128. [Google Scholar] [CrossRef]

- Grigoras, G.; Gârbea, R.; Neagu, B.-C. Toward Smart SCADA Systems in the Hydropower Plants through Integrating Data Mining-Based Knowledge Discovery Modules. Appl. Sci. 2024, 14, 8228. [Google Scholar] [CrossRef]

- Castillo-Navarro, J.; Kristjanpoller, F.; Mena, R.; Godoy, D.R.; Viveros, P. A Methodological Framework for Managing the Alarms in Wind Turbine Control and Data Acquisition Systems for Failure Analysis. Machines 2024, 12, 597. [Google Scholar] [CrossRef]

- Bonilla, J.; Blanco Galvez, J.; Zarza, E.; Alarcón-Padilla, D.-C. Feasibility and Practical Limits of Full Decarbonization of the Electricity Market with Renewable Energy: Application to the Spanish Power Sector. Energy 2021, 239, 122437. [Google Scholar] [CrossRef]

- Carballo, J.A.; Bonilla, J.; Berenguel, M.; Fernández-Reche, J.; García, G. New approach for solar tracking systems based on computer vision, low cost hardware and deep learning. Renew. Energy 2019, 133, 1158–1166. [Google Scholar] [CrossRef]

- Carballo, J.A.; Bonilla, J.; Fernández-Reche, J.; Nouri, B.; Avila-Marin, A.; Fabel, Y.; Alarcón-Padilla, D.-C. Cloud Detection and Tracking Based on Object Detection with Convolutional Neural Networks. Algorithms 2023, 16, 487. [Google Scholar] [CrossRef]

- Biswal, A.; Bansal, H.O. SCADA and Its Applications to Renewable Energy Systems Integration. In Proceedings of the 2014 9th International Conference on Industrial and Information Systems (ICIIS), Gwalior, India, 15–17 December 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, G.; Xie, J.; Wang, S. Application of Artificial Intelligence in Power System Monitoring and Fault Diagnosis. Energies 2023, 16, 5477. [Google Scholar] [CrossRef]

- de Azambuja, A.J.G.; Plesker, C.; Schützer, K.; Anderl, R.; Schleich, B.; Almeida, V.R. Artificial Intelligence-Based Cyber Security in the Context of Industry 4.0—A Survey. Electronics 2023, 12, 1920. [Google Scholar] [CrossRef]

- Nankya, M.; Chataut, R.; Akl, R. Securing Industrial Control Systems: Components, Cyber Threats, and Machine Learning-Driven Defense Strategies. Sensors 2023, 23, 8840. [Google Scholar] [CrossRef] [PubMed]

- Wali, A.; Alshehry, F. A Survey of Security Challenges in Cloud-Based SCADA Systems. Computers 2024, 13, 97. [Google Scholar] [CrossRef]

- Khalid, W.; Jamil, M.; Khan, A.A.; Awais, Q. Open-Source Internet of Things-Based Supervisory Control and Data Acquisition System for Photovoltaic Monitoring and Control Using HTTP and TCP/IP Protocols. Energies 2024, 17, 4083. [Google Scholar] [CrossRef]

- OPC Foundation. OPC Unified Architecture. Available online: https://opcfoundation.org (accessed on 5 September 2024).

- Van Rossum, G.; Drake, F.L. Python 3 Reference Manual; CreateSpace: Scotts Valley, CA, USA, 2009; ISBN 1441412697. [Google Scholar]

- FreeOpcUa Contributors. Opcua-Asyncio: Asynchronous Python Client and Server for OPC UA. Available online: https://github.com/FreeOpcUa/opcua-asyncio (accessed on 5 September 2024).

- Carballo, J.A.; Bonilla, J.; Cruz, N.C.; Fernández-Reche, J.; Álvarez, J.D.; Avila-Marin, A.; Berenguel, M. Reinforcement Learning for Heliostat Aiming: Improving the Performance of Solar Tower Plants. Appl. Energy 2025, 377, 124574. [Google Scholar] [CrossRef]

| Node/Variable | Description |

|---|---|

| Command_node | A child node of the heliostat node used for sending commands to the heliostat’s local control system. |

| Command | Writable variable that holds the current command to be executed (e.g., sun tracking, stop, cleaning). |

| Command_op | Writable variable containing additional operational parameters for the command. |

| Diag | Diagnostic variable covering aspects of the system’s diagnostics, such as failure states and local control conditions. |

| Event | Logs event information related to the heliostat (e.g., setpoint achievements, reference point detections). |

| HEl_IoT_id | Represents the unique identifier of the heliostat device. |

| Smart_node | A child node of the heliostat node for advanced operations within the heliostat system. |

| State | Writable variable storing the current state of the smart node; used to trigger smart operations. |

| HelIoT | Writable variable storing complex data related to the heliostat operations, formatted as a JSON-like string. |

| State | Holds the operational state information of the heliostat (e.g., sun tracking, stop). |

| pos_az and pos_el | Store the actual azimuth and elevation positions of the heliostat. |

| setpoint_az and setpoint_el | Indicate the setpoint positions for the azimuth and elevation axes. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carballo, J.A.; Bonilla, J.; Fernández-Reche, J.; Avila-Marin, A.L.; Díaz, B. Modern SCADA for CSP Systems Based on OPC UA, Wi-Fi Mesh Networks, and Open-Source Software. Energies 2024, 17, 6284. https://doi.org/10.3390/en17246284

Carballo JA, Bonilla J, Fernández-Reche J, Avila-Marin AL, Díaz B. Modern SCADA for CSP Systems Based on OPC UA, Wi-Fi Mesh Networks, and Open-Source Software. Energies. 2024; 17(24):6284. https://doi.org/10.3390/en17246284

Chicago/Turabian StyleCarballo, Jose Antonio, Javier Bonilla, Jesús Fernández-Reche, Antonio Luis Avila-Marin, and Blas Díaz. 2024. "Modern SCADA for CSP Systems Based on OPC UA, Wi-Fi Mesh Networks, and Open-Source Software" Energies 17, no. 24: 6284. https://doi.org/10.3390/en17246284

APA StyleCarballo, J. A., Bonilla, J., Fernández-Reche, J., Avila-Marin, A. L., & Díaz, B. (2024). Modern SCADA for CSP Systems Based on OPC UA, Wi-Fi Mesh Networks, and Open-Source Software. Energies, 17(24), 6284. https://doi.org/10.3390/en17246284