Heat Transfer Mechanism Study of an Embedded Heat Pipe for New Energy Consumption System Enhancement

Abstract

1. Introduction

2. Numerical Modeling and Validation

2.1. Physical Model and Meshing

2.2. Materials and Methods

- (1)

- Continuity Equation

- (2)

- Momentum Equation

- (3)

- Energy Equation

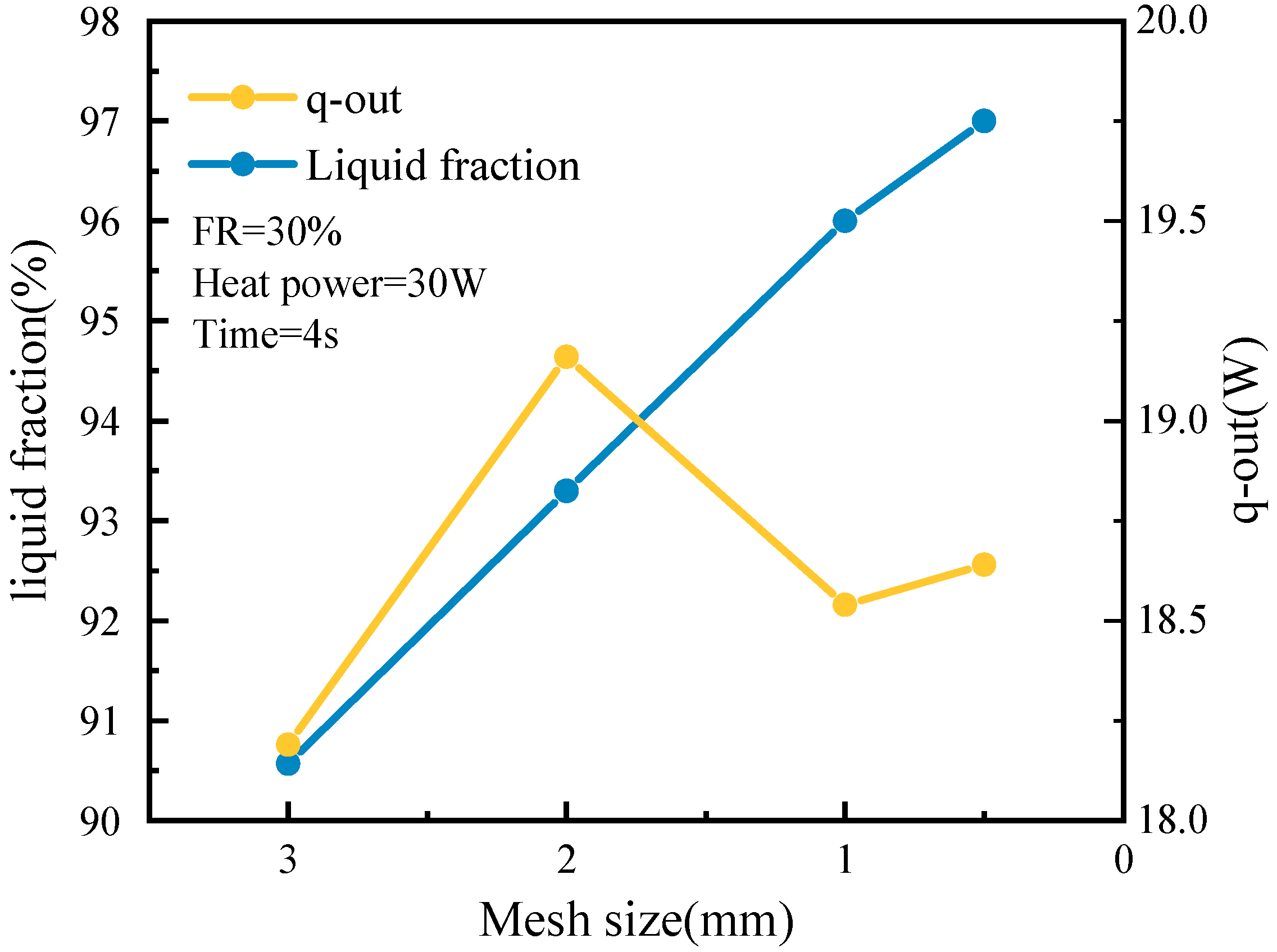

2.3. Grid Independence and Experimental Verification

3. Results and Discussion

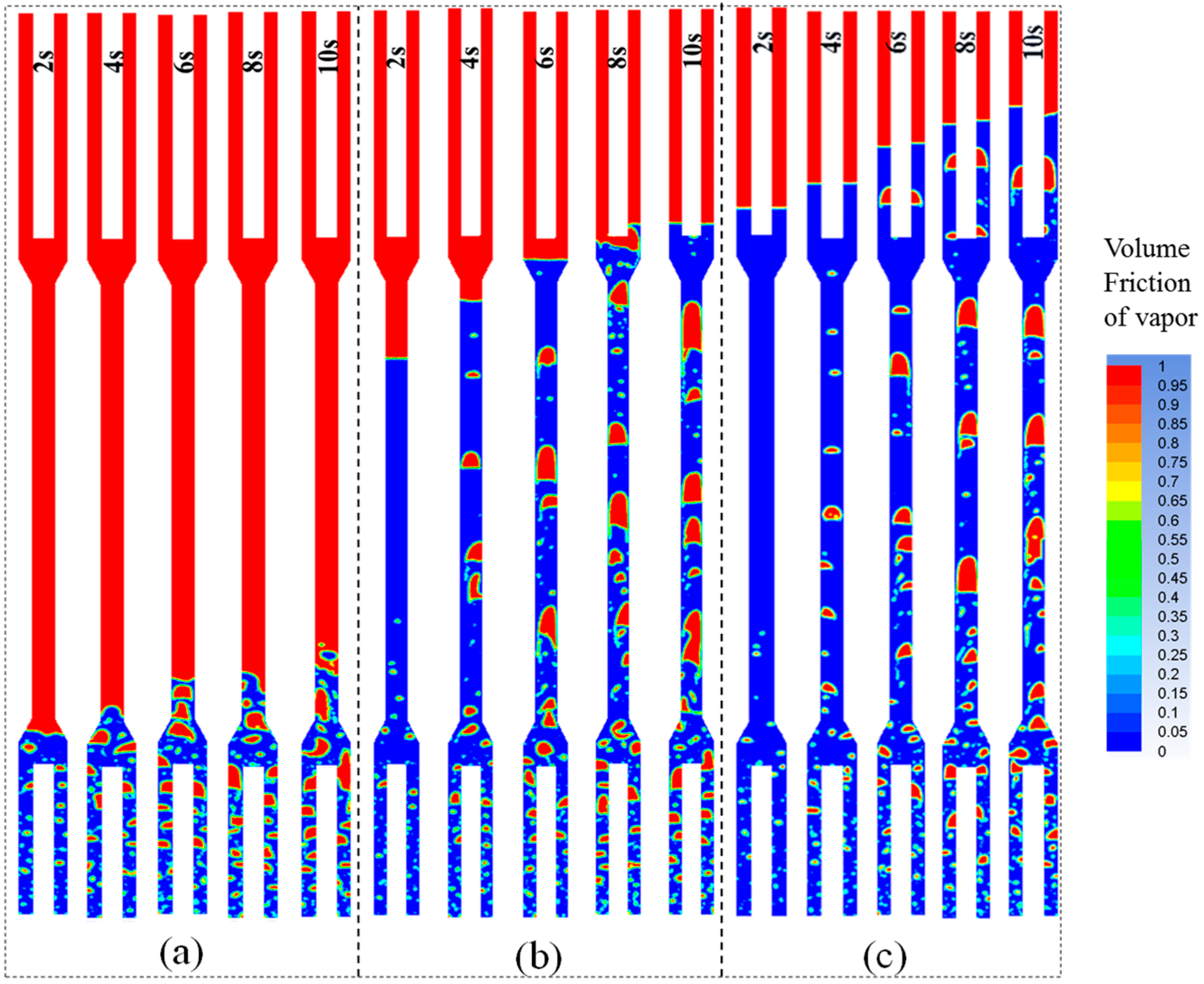

3.1. Flow State Evolution Inside the Heat Pipe

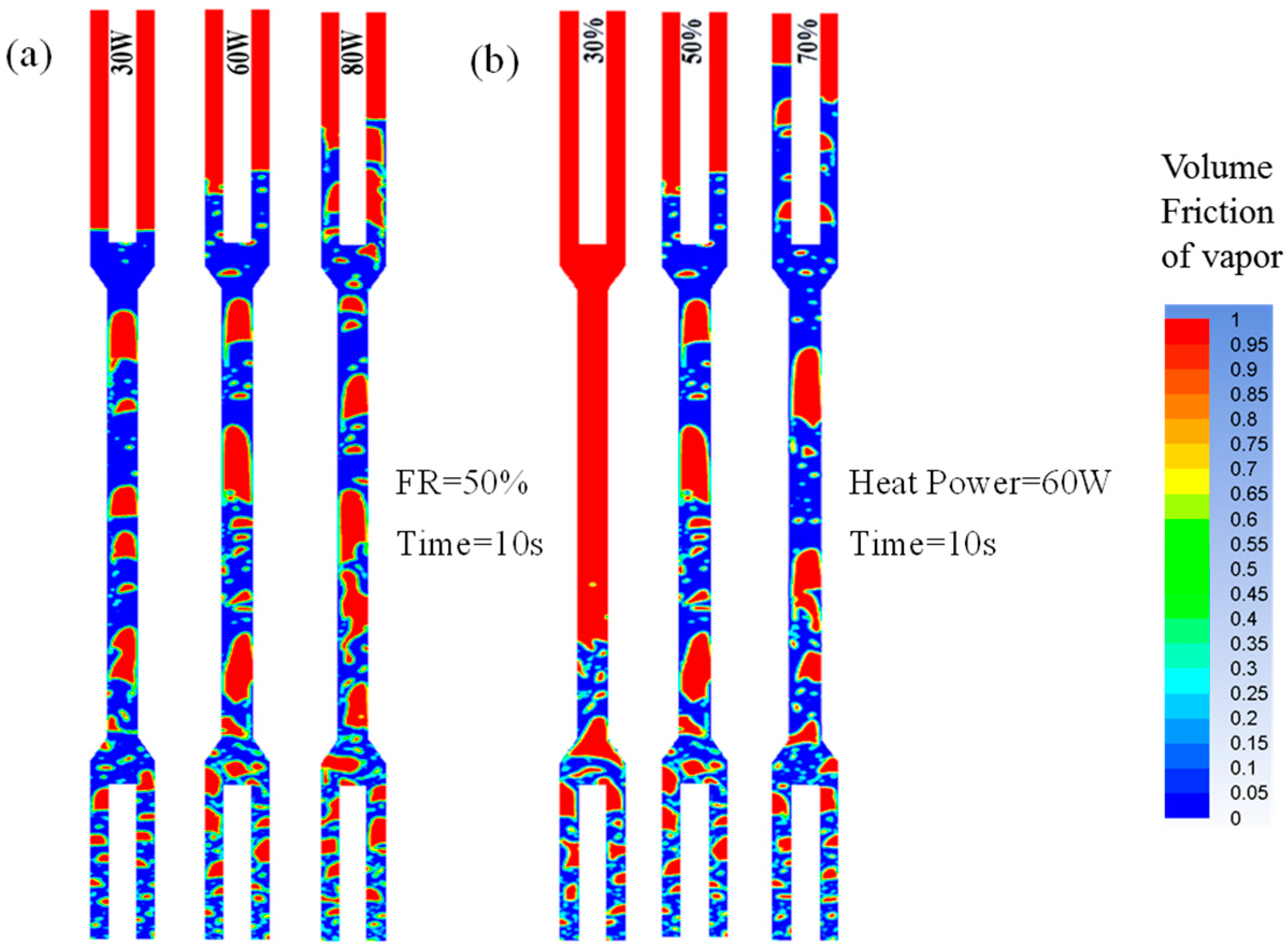

3.2. Comparative Analysis of Two-Phase Flow Patterns in Heat Pipe Under Different Working Conditions

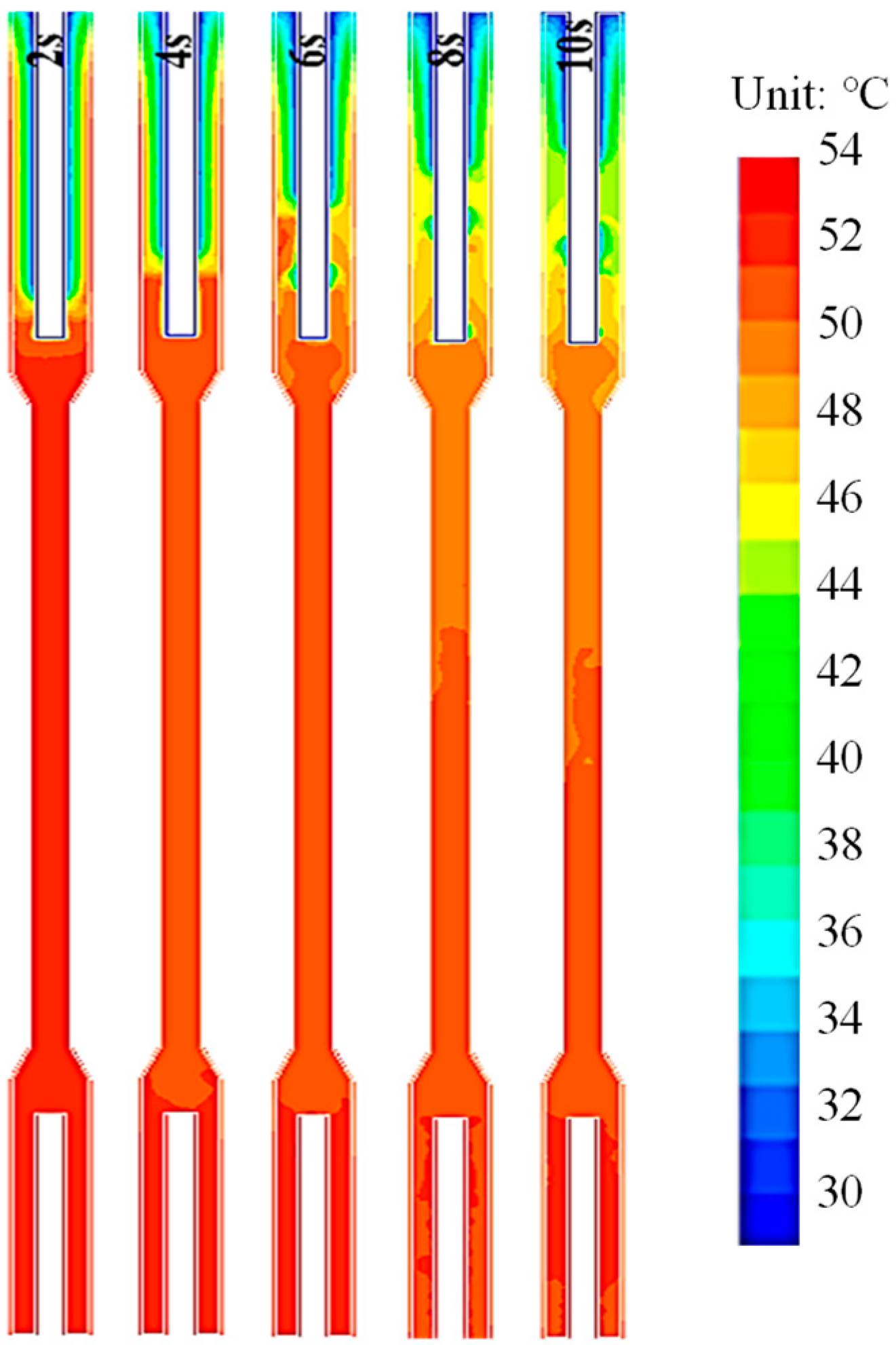

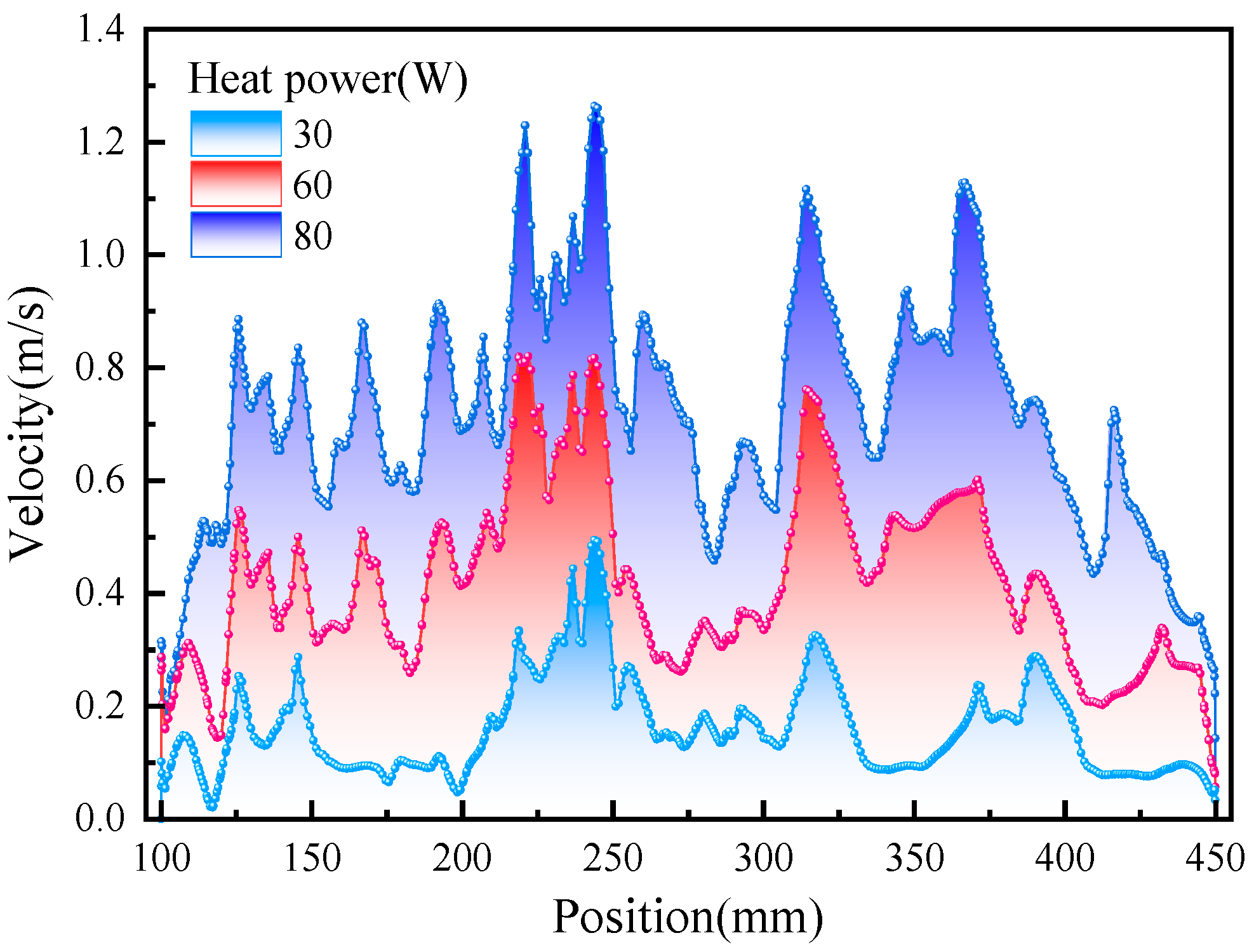

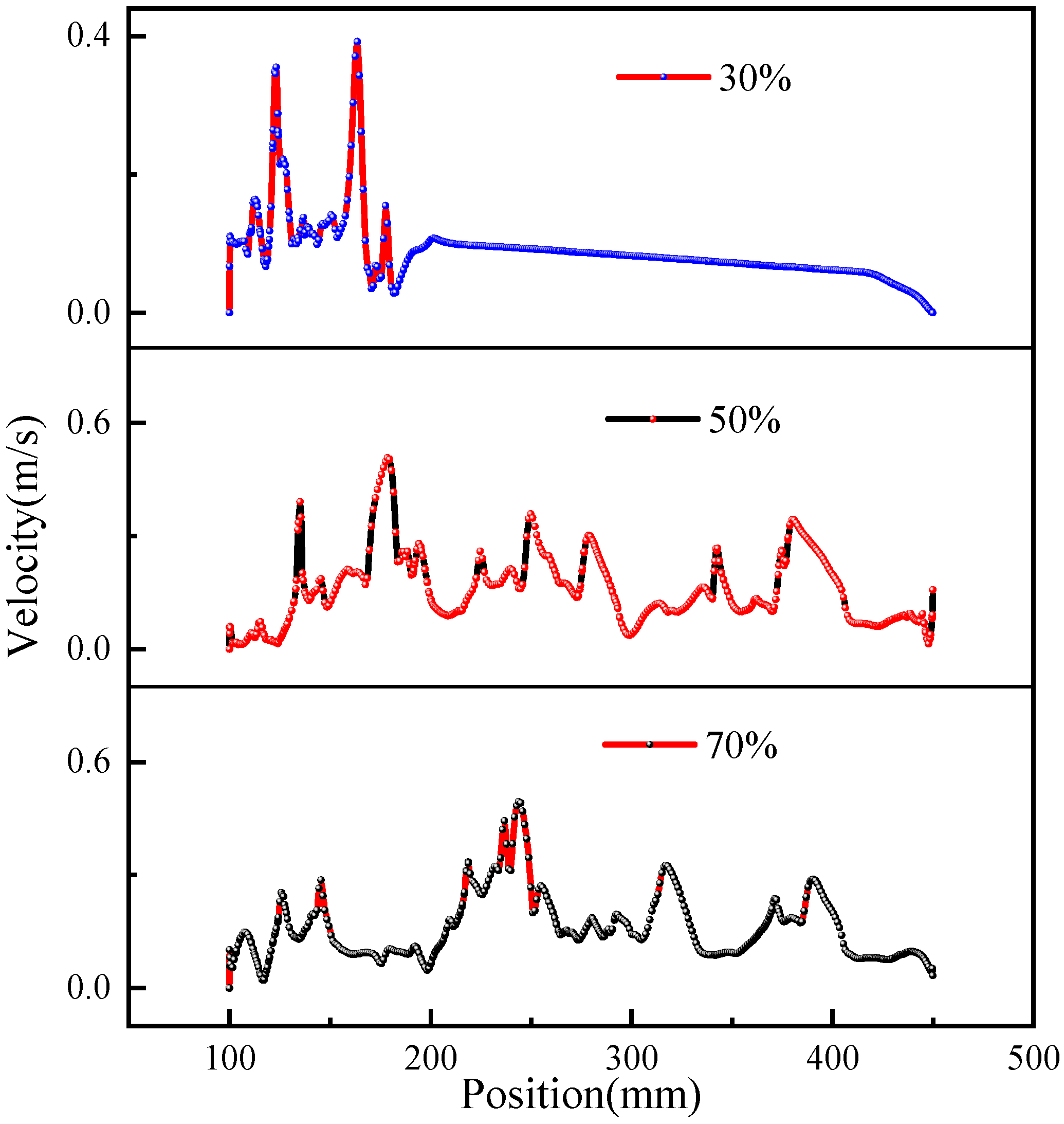

3.3. Temperature and Velocity Distribution Inside the Heat Pipe

4. Conclusions

- (1)

- As the heating power increases, large bubbles and slugs are more likely to form inside the heat pipe. When the heating power reaches a certain level, the bottom of the adiabatic section can no longer maintain the shape of the slug, causing the slug to break and merge, eventually forming a local annular flow.

- (2)

- Under low FRs, the liquid level is relatively low, and bubbles are likely to burst through the liquid surface after formation, preventing the formation of stable slugs. As the FR increases, the likelihood of slug flow and annular flow inside the heat pipe increases, and the liquid level rises.

- (3)

- The FR affects the velocity field distribution within the heat pipe, with the location of the maximum velocity varying under different FRs. At FRs of 30%, 50%, and 70%, the maximum axial velocities are 0.39 m/s, 0.51 m/s, and 0.48 m/s, respectively. Therefore, choosing the appropriate heating power and liquid filling rate can optimize the heat transfer characteristics of the heat pipe.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamic |

| FR | Filling ratio |

| NHT | Numerical Heat Transfer |

| UDF | User Defined Function |

| VOF | Volume of Fluid |

References

- Geng, L.; Xiao, T.; Jiang, J.P.; Luo, K.F.; Yan, Y.B.; Liu, C.H. Wide temperature range phase change cold energy storage by using esterification between polyethylene glycol and lauric acid. Chem. Eng. J. 2024, 496, 154005. [Google Scholar] [CrossRef]

- Filina, O.A.; Martyushev, N.V.; Malozyomov, B.V.; Tynchenko, V.S.; Kukartsev, V.A.; Bashmur, K.A.; Pavlov, P.P.; Panfilova, T.A. Increasing the Efficiency of Diagnostics in the Brush-Commutator Assembly of a Direct Current Electric Motor. Energies 2024, 17, 17. [Google Scholar] [CrossRef]

- Wu, Q.; Yu, B.; Zhou, F.; Wu, J.; Xu, L. Numerical Simulation of Evaporation Section of Ultra-long Gravity Heat Pipe in Geothermal Energy Extraction System. Chem. Eng. Mach. 2022, 49, 642–647. [Google Scholar]

- Huang, W.; Cao, W.; Li, T.; Jiang, F. Numerical study and economic analysis of gravity heat pipe hot dry rock geothermal system. CIESC J. 2021, 72, 1302–1313. [Google Scholar]

- Zhao, J.; Wang, Z.; Dai, C.; Liu, C.; Rao, Z. Research on heat transfer performance of amphiphilic nanofluid solar gravity heat pipe. CIESC J. 2020, 71, 5461–5469. [Google Scholar]

- Peng, D.; Guo, Y.; Lu, Y.; Wu, Y. Experimental Study on Heat Transfer Characteristics of Naphthalene Gravity Heat Pipe in Molten Salt. Acta Energiae Solaris Sin. 2021, 42, 317–322. [Google Scholar]

- Ramos-Alvarado, B.; Li, P.; Liu, H.; Hernandez-Guerrero, A. CFD study of liquid-cooled heat sinks with microchannel flow field configurations for electronics, fuel cells, and concentrated solar cells. Appl. Therm. Eng. 2011, 31, 2494–2507. [Google Scholar] [CrossRef]

- Sundaram, A.S.; Bhaskaran, A. Thermal Modeling of Thermosyphon Integrated Heat Sink for CPU Cooling. J. Electron. Cool. Therm. Control. 2011, 1, 15–21. [Google Scholar] [CrossRef]

- Srikanth, R.; Nair, R.S.; Balaji, C. Thermosyphon assisted melting of pcm inside a rectangular enclosure: A synergistic numerical approach. J. Phys. Conf. Ser. 2016, 745, 032130. [Google Scholar] [CrossRef]

- Zhang, H.; Xie, G.; Zhan, H.; Bi, S. Progress of research on visualization of internal procedure of two-phase closed thermosyphon and its heat transfer enhancement. Chem. Ind. Eng. Prog. 2017, 36, 791–801. [Google Scholar]

- Han, C.; Zou, L. Study on the heat transfer characteristics of a moderate-temperature heat pipe heat exchanger. Int. J. Heat Mass. Transf. 2015, 91, 302–310. [Google Scholar] [CrossRef]

- Yue, C.; Zhang, Q.; Zhai, Z.; Ling, L. Numerical investigation on thermal characteristics and flow distribution of a parallel micro-channel separate heat pipe in data center. Int. J. Refrig. 2019, 98, 150–160. [Google Scholar] [CrossRef]

- Li, Y.; Qi, F.; Guo, H.; Guo, Z.; Xu, G.; Liu, J. Numerical investigation of thermal runaway propagation in a li-ion battery module using the heat pipe cooling system. Numer. Heat Transf. Part A Appl. 2019, 75, 183–199. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, K.; Wang, C.; Tang, S.; Zhang, D.; Tian, W.; Su, G.H.; Qiu, S. Numerical analysis of segmented thermoelectric generators applied in the heat pipe cooled nuclear reactor. Appl. Therm. Eng. 2022, 204, 117949. [Google Scholar] [CrossRef]

- Li, C.; Guan, Y.; Wang, X.; Li, G.; Zhou, C.; Xun, Y. Experimental and numerical studies on heat transfer characteristics of vertical deep-buried u-bend pipe to supply heat in buildings with geothermal energy. Energy 2018, 142, 689–701. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Chen, W.; Zhou, S.; Zhai, P. Experimental and numerical investigation for hot water boiler with inorganic heat pipes. Int. J. Heat Mass. Transf. 2017, 114, 743–747. [Google Scholar] [CrossRef]

- Zheng, S.L.; Qiu, Z.N.; He, C.W.; Wang, X.L.; Wang, X.P.; Wang, Z.Y.; Zhao, X.D.; Shittu, S. Research on heat transfer mechanism and performance of a novel adaptive enclosure structure based on micro-channel heat pipe. Energy 2022, 254, 124237. [Google Scholar] [CrossRef]

- Ochi, A.; Saidi, A. Impact of governance quality, population and economic growth on greenhouse gas emissions: An analysis based on a panel VAR model. J. Environ. Manag. 2024, 370, 122613. [Google Scholar] [CrossRef]

- Faraji, H.; Teggar, M.; Arshad, A.; Arici, M.; Berra, E.; Choukairy, K. Lattice Boltzmann simulation of natural convection heat transfer phenomenon for thermal management of multiple electronic components. Therm. Sci. Eng. Prog. 2023, 45, 102216. [Google Scholar] [CrossRef]

- Zhan, H.; Li, C.; Wang, L.; Wu, Z.; Zhang, H. Simulation of the thermosyphon ebullition and condensation based on VOF model. Energy Metall. Ind. 2016, 35, 30–36. [Google Scholar]

- Shen, C.; Yu, P.; Zhang, D.; Lv, H.; Yang, J.; Yang, X. Numerical Simulation of Heat and Mass Transfer in a Parallel Flow Heat Exchanger. J. Eng. Thermophys. 2018, 38, 1309–1312. [Google Scholar]

- Chen, J.; Yang, S.; Liao, S.; Cao, X. Experimental investigation of effective parameters on geyser periodicity in a vertical heated system. Exp. Therm. Fluid Sci. 2015, 68, 163–176. [Google Scholar] [CrossRef]

- Alizadehdakhel, A.; Rahimi, M.; Alsairafi, A.A. CF-Dmodeling of flow and heat transfer in a thermosyphon. Int. Commun. Heat Mass. Transf. 2009, 37, 312–318. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, W. Numerical Study on Optimization of Gravity Heat Pipe Geometry. J. Tianjin Chengjian Univ. 2019, 25, 317–320. [Google Scholar]

- Fertahi, S.E.-D.; Bouhal, T.; Agrouaz, Y.; Kousksou, T.; El Rhafiki, T.; Zeraouli, Y. Performance optimization of a two-phase closed thermosyphon through CFD numerical simulations. Appl. Therm. Eng. 2018, 128, 551–563. [Google Scholar] [CrossRef]

- Buczyński, R.; Weber, R.; Szlęk, A. Innovative design solutions for small-scale domestic boilers: Combustion improvements using a cfd-based mathematical model. J. Energy Inst. 2015, 88, 53–63. [Google Scholar] [CrossRef]

- Zhao, J.; Dai, Y.; Wang, Z.; Liu, Y.; Xu, W.; Mao, Y.; Wang, C. Study on the thermal performance of thermal energy storage and heating module based on a novel embedded heat pipe. J. Energy Storage 2022, 52, 104743. [Google Scholar] [CrossRef]

- Geng, L.; Cui, J.P.; Zhang, C.L.; Yan, Y.B.; Zhao, J.T.; Liu, C.H. Chemistry in phase change energy storage: Properties regulation on organic phase change materials by covalent bond modification. Chem. Eng. J. 2024, 495, 153359. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R.; Nagaj, R.; Zuromskaite-Nagaj, B.; Grebski, W.W. The Influence of the Global Energy Crisis on Energy Efficiency: A Comprehensive Analysis. Energies 2024, 17, 947. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Zhu, J.; Wang, M.X.; Gao, Q.L. Experimental study on heat transfer and storage of a heating system coupled with solar flat heat pipe and phase change material unit. J. Energy Storage 2023, 73, 108971. [Google Scholar] [CrossRef]

- Silaev, V.I.; Klyuev, R.V.; Eremeev, D.V.; Martynova, T.A.; Danilchenko, Y.V. Analysis of the carbon footprint created by mining enterprises. Min. Informational Anal. Bull. 2023, 11, 265–277. [Google Scholar]

- Geng, L.; Wang, J.P.; Yang, X.L.; Jiang, J.P.; Li, R.; Yan, Y.B.; Zhao, J.T.; Liu, C.H. Synergistic enhancement of phase change materials through three-dimensional porous layered covalent triazine framework/expanded graphite composites for solar energy storage and beyond. Chem. Eng. J. 2024, 487, 150749. [Google Scholar] [CrossRef]

- Geng, L.; Huang, W.B.; Jiang, J.P.; Zhang, C.L.; Cui, J.P.; Yan, Y.B.; Liu, C.H. Cold energy storage enhancement and phase transition temperature regulation. J. Energy Storage 2024, 97, 112903. [Google Scholar] [CrossRef]

- Ge, M.; Zheng, G.A. Fluid-Solid Mixing Transfer Mechanism and Flow Patterns of the Double-Layered Impeller Stirring Tank by the CFD-DEM Method. Energies 2024, 17, 1513. [Google Scholar] [CrossRef]

- Su, Z.; Li, Z.; Wang, K.; Kuang, Y.; Wang, H.; Yang, J. Investigation of improved VOF method in CFD simulation of sodium heat pipes using a multi-zone modeling method. Int. Commun. Heat Mass. Transf. 2024, 157, 107669. [Google Scholar] [CrossRef]

- Brackbill, J.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Fadhl, B.; Wrobel, L.C.; Jouhara, H. Numerical modelling of the temperature distribution in a two-phase closed thermosyphon. Appl. Therm. Eng. 2013, 60, 122–131. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Yu, H.; Zhang, Y.; Zhang, S.; Shi, Z.; Xie, J.; Zhang, S.; Liu, C. Heat Transfer Mechanism Study of an Embedded Heat Pipe for New Energy Consumption System Enhancement. Energies 2024, 17, 6162. https://doi.org/10.3390/en17236162

Cheng Y, Yu H, Zhang Y, Zhang S, Shi Z, Xie J, Zhang S, Liu C. Heat Transfer Mechanism Study of an Embedded Heat Pipe for New Energy Consumption System Enhancement. Energies. 2024; 17(23):6162. https://doi.org/10.3390/en17236162

Chicago/Turabian StyleCheng, Yuanlin, Hu Yu, Yi Zhang, Shu Zhang, Zhipeng Shi, Jinlin Xie, Silu Zhang, and Changhui Liu. 2024. "Heat Transfer Mechanism Study of an Embedded Heat Pipe for New Energy Consumption System Enhancement" Energies 17, no. 23: 6162. https://doi.org/10.3390/en17236162

APA StyleCheng, Y., Yu, H., Zhang, Y., Zhang, S., Shi, Z., Xie, J., Zhang, S., & Liu, C. (2024). Heat Transfer Mechanism Study of an Embedded Heat Pipe for New Energy Consumption System Enhancement. Energies, 17(23), 6162. https://doi.org/10.3390/en17236162