Simulating Water Invasion Dynamics in Fractured Gas Reservoirs

Abstract

1. Introduction

2. Experimental Objective

3. Experimental Setup and Procedure

3.1. Experimental Setup

3.2. Experiment Conditions

3.2.1. Experimental Temperature and Pressure

3.2.2. Experimental Fluids

3.2.3. Experimental Cores

3.3. Experimental Scheme Design

3.4. Experimental Procedure

- (1)

- Create artificial fractures in a core sample according to the fracture permeability and penetration in one experimental scheme.

- (2)

- Install the artificially fractured core into the core holder and apply a confining pressure up to 85 MPa.

- (3)

- Saturate the core model with gas, ensuring that the gas saturation is complete once the reservoir pressure is balanced at 75 MPa.

- (4)

- Fill the high-pressure resistance intermediate container with the simulated formation water and pressurize it to 75 MPa.

- (5)

- Connect the water in the intermediate container with the gas-saturated core model.

- (6)

- Utilize the constant temperature chamber to heat both the core holder and the intermediate container and maintain it at a constant temperature of 142 °C.

- (7)

- Gradually reduce the internal pressure at intervals of 2 Mpa; record the average gas and water production rates, as well as the pressure at water breakthrough for each 2 MPa pressure drop. Terminate the experiment when the internal pressure reaches 5 MPa.

4. Experiment Result Analysis

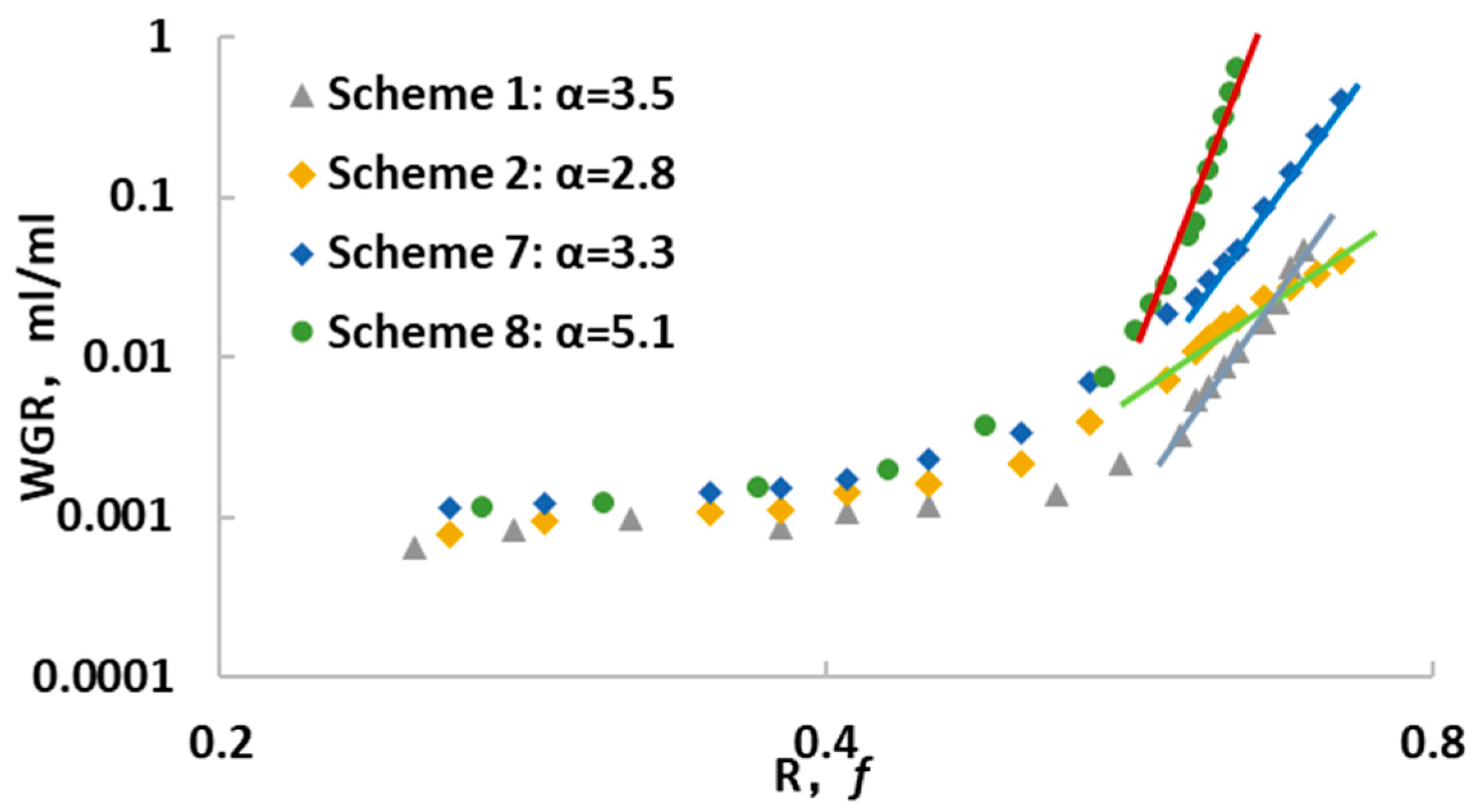

4.1. Analysis of Water Production Types

4.2. Analysis of Effects of Experimental Parameters on Water Invasion Indicators

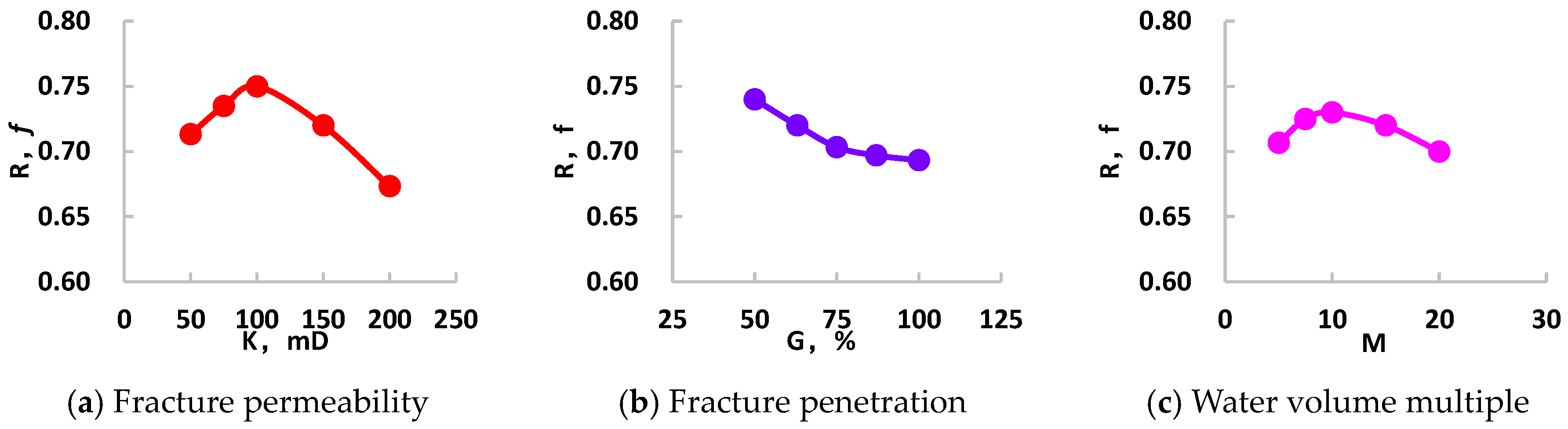

4.2.1. Recovery Factor

4.2.2. Average Water–Gas Ratio

4.2.3. Pressure at Water Breakthrough

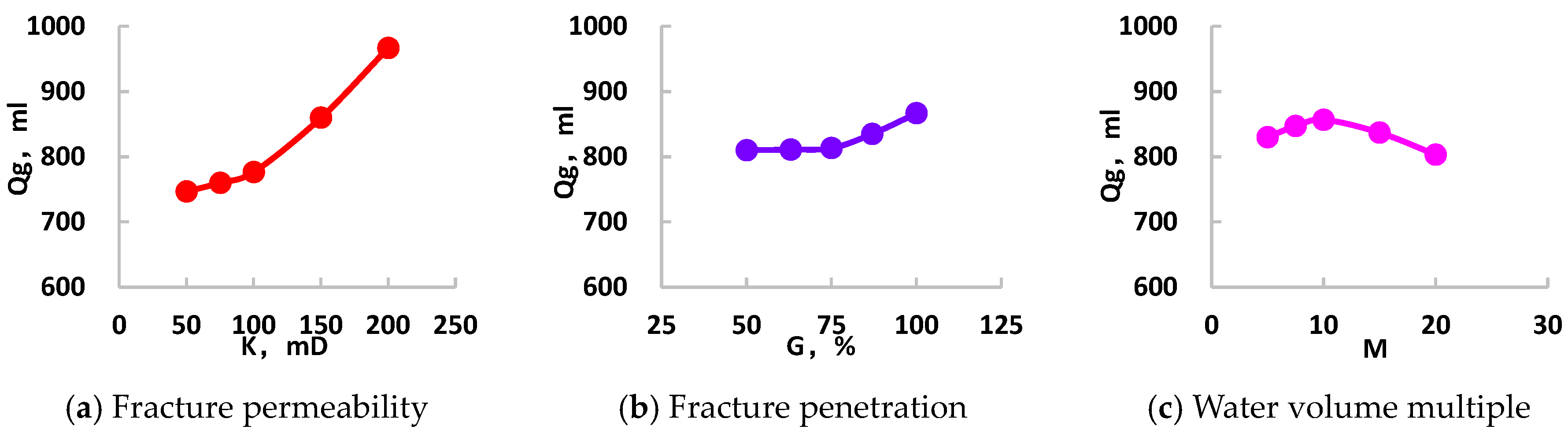

4.2.4. Average Gas Production

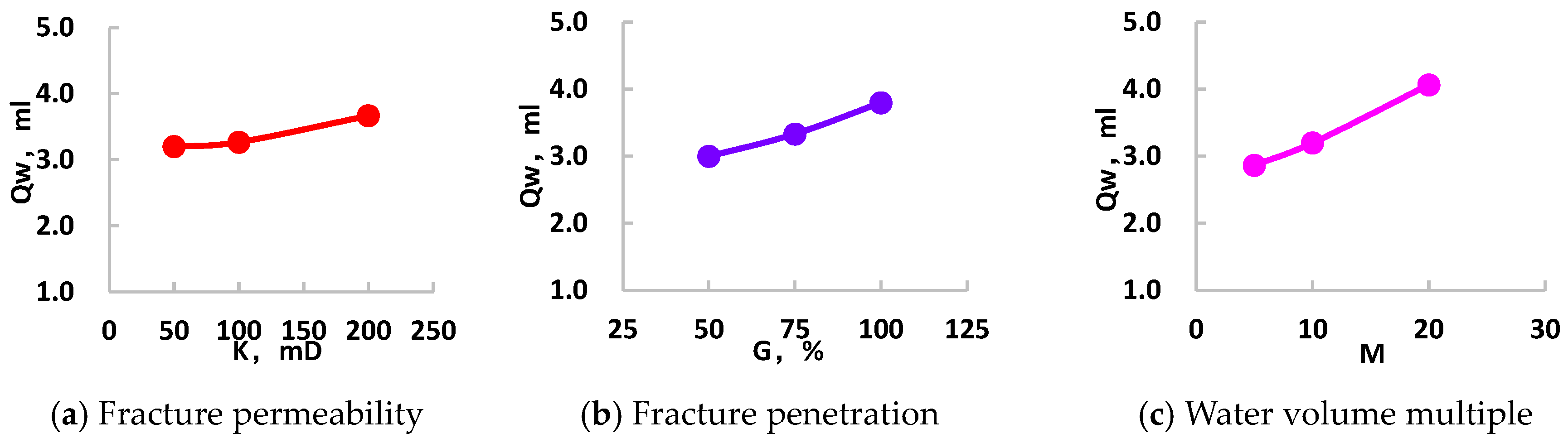

4.2.5. Average Water Production

5. Conclusions

- (1)

- By optimizing the experimental sequence and utilizing the orthogonal test method, it is possible to carry out more effective and comprehensive experimental research with a smaller number of core samples.

- (2)

- The core size was sufficient to obtain the diagnostic curve pattern of water production. The greater the fracture permeability, the fracture penetration, and the water volume multiple, the larger the slope of diagnostic curves and the more severe the water invasion and water channeling.

- (3)

- The experimental results showed that the effects of the experimental parameters on the recovery factor and average water production can be ranked as water volume multiple > fracture penetration > fracture permeability, with the influence of the water volume multiple being slightly greater than that of the other two parameters. For the average water–gas ratio, the fracture penetration exhibited a stronger sensitivity and more significant influence; in the case of the water breakthrough time and average gas production, the fracture permeability had a stronger sensitivity and greater influence.

- (4)

- For fracture-pore-type gas reservoirs, if there are through-fractures between the gas well and the edge and bottom water during the development process, the edge and bottom water will rapidly advance into the wellbore along the fractures. The advancing speed of the fracture water invasion front is closely related to the reservoir permeability and edge and bottom water. There was a positive correlation between the size of the water body, that is, the higher the reservoir permeability and the larger the water body, the faster the front advance speed, which will lead to a significant decrease in gas well production and final recovery volume.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, B.; Zheng, R.; Liu, H.; Lei, W.; Chen, R. Characteristics of Carbonate Reservoir in Callovian-Oxfordian of Samandepe Gasfield, Turkmenistan. Acta. Geol. Sin. 2010, 84, 117–126. [Google Scholar]

- Cheng, Y.; Mu, L.; Zhu, E.; Zhang, P.; Guo, C.; Leng, Y.; Wei, Z.; Chen, Y.; Xing, Y.; Cheng, M.; et al. Water producing mechanisms of carbonate reservoirs gas wells: A case study of the Right Bank Field of Amu Darya, Turkmenistan. Pet. Explor. Dev. 2017, 44, 89–96. [Google Scholar] [CrossRef]

- Song, H.; Cheng, H.; Yuan, F.; Cheng, L.; Yue, P. Prediction and Application of Drilling-Induced Fracture Occurrences under Different Stress Regimes. Processes 2024, 12, 1874. [Google Scholar] [CrossRef]

- Sun, Z. Production characteristics and the optimization of development schemes of fractured gas reservoir with edge or bottom water. Pet. Explor. Dev. 2002, 29, 69–71. [Google Scholar] [CrossRef]

- Hu, Y.; Li, X.; Wan, Y.; Jiao, C.; Xu, X.; Guo, C.; Jing, W. The experimental study of water invasion mechanism in fracture and the influence on the development of gas reservoir. Nat. Gas. Geo. 2016, 5, 910–917. [Google Scholar] [CrossRef]

- Tang, J.R. Gas Reservoir Engineering Technology; Petroleum Industry Press: Beijing, China, 2011. [Google Scholar]

- Qiang, L.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The Carrying Behavior of Water-Based Fracturing Fluid in Shale Reservoir Fractures and Molecular Dynamics of Sand-Carrying Mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Han, Y. A Numerical Investigation on Kick Control with the Displacement Kill Method during a Well Test in a Deep-Water Gas Reservoir: A Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Zhang, L.; He, W. Single well water invasion model for fractured bottom water gas reservoirs. Nat. Gas. Ind. 1994, 14, 48–50. [Google Scholar]

- Tao, L.; Yong, F. Numerical simulation study on water coning of large-fractured gas well with finite volume method. J. Southwest Pet. Univ. Sci. Technol. Ed. 2001, 23, 19–22. [Google Scholar] [CrossRef]

- Xu, X.; Wan, Y.; Chen, Y.; Hu, Y.; Mei, Q.; Jiao, C.-Y. Physical simulation of water invasion and water control for the fractured water-bearing gas reservoirs. Nat. Gas. Geosic. 2019, 30, 1508–1518. [Google Scholar] [CrossRef]

- Hu, Y.; Le, P.; Guo, C.; Chen, P.; Xiao, Y.; Qu, S.; Wang, X. Experimental Study on Water Invasion in Full-Diameter Cores from Fractured Carbonate Reservoirs. Xinjiang Pet Geo. 2023, 4, 479–484. [Google Scholar]

- Zhang, X.; Zhang, L.; Li, Y.; Zhou, Q. A new method for water invasion performance prediction in the early stage of fractured and water-carrying gas reservoir development. J. Southwest Pet. Univ. Sci. Technol. Ed. 2007, 29, 82–85. [Google Scholar] [CrossRef]

- Peng, X.; Du, Z. Percolation model and numeral simulation of bottom water gas reservoirs with big fractures. Nat. Gas. Ind. 2004, 24, 116–119. [Google Scholar] [CrossRef]

- Wang, X.; Tian, J.; Zhu, G.; Liang, B. A 3D numerical simulation of gas-water biphase for fractured gas reservoirs with low permeability. China Offshore Oil Gas 2010, 22, 168–171. [Google Scholar] [CrossRef]

- Persoff, P.; Pruess, K. Two-phase flow visualization and relative permeability measurement in natural rough-walled rock fractures. Water Resour. 1995, 31, 1175–1186. [Google Scholar] [CrossRef]

- Zhou, K.; Li, N.; Zhang, Q.; Tang, X. Experimental research on gas-water two phase flow and confined gas for mation mechanism. Nat. Gas. Ind. 2002, 22, 122–125. [Google Scholar]

- Fan, H.; Zhong, B.; Li, X.; Liu, Y.; Yang, H.; Feng, X.; Zhang, Y. Studies on water invasion mechanism of fractured-watered gas reservoir. Nat. Gas. Geo. 2012, 23, 1179–1184. [Google Scholar]

- Hu, Y.; Li, X.; Wan, Y.; Lu, J.; Zhu, H.; Zhang, Y.; Zhu, Q.; Yang, M.; Niu, L. Physical simulation on gas percolation in tight sandstone. Pet. Explor. Dev. 2013, 40, 580–584. [Google Scholar] [CrossRef]

- Fang, F.; Li, X.; Gao, S.; Xue, H.; Zhu, X.; Liu, H.; An, W.; Li, C. Visual simulation experimental study on water invasion rulesof gas reservoir with edge and bottom water. Nat. Gas. Geo. 2016, 27, 2246–2252. [Google Scholar] [CrossRef]

- Wang, L.; Yang, S.; Peng, X.; Deng, H.; Li, L.; Meng, Z.; Kun, Q.; Wang, Q. Visual experiments on the occurrence characteristics of multi-type reservoir water in fracture-cavity carbonate gas reservoir. Acta. Pet. Sin. 2018, 39, 686–696. [Google Scholar] [CrossRef]

- Shen, W.; Li, X.; Liu, X.; Lu, J.; Jiao, C. Physical simulation of water influx mechanism in fractured gas reservoirs. J. Cent. South Univ. Sci. Technol. 2014, 45, 3283–3287. [Google Scholar]

- He, G. Experimental study on EOR of gas reservoir with different penetrating level. Pet. Ind. Tech. 2016, 23, 79. [Google Scholar]

- Li, C. Recovering technology of fractured and watered gas reservoirs. Nat. Gas. Ind. 2003, 23, 123–126. [Google Scholar] [CrossRef]

| Component | Molar Percentage (%) | Component | Molar Percentage (%) |

|---|---|---|---|

| O2 + Ar | 0.0000 | iC4H10 | 0.1670 |

| He | 0.0092 | nC4H10 | 0.2111 |

| H2 | 0.0985 | iC5H12 | 0.0920 |

| N2 | 0.5265 | nC5H12 | 0.0776 |

| CO2 | 4.1874 | C6H14 | 0.1313 |

| H2S | 0.0218 | C7H16 | 0.1115 |

| CH4 | 89.6571 | C8H18 | 0.0653 |

| C2H6 | 3.7082 | C9H20 | 0.0279 |

| C3H8 | 0.9044 | C10H22 | 0.0032 |

| relative density = 0.6399 | compression factor = 0.9970 | ||

| hydrogen sulfide = 313 g/m3 | carbon dioxide = 82,271 mg/m3 | ||

| molecular weight = 18.58 g/mol | |||

| Density | pH Value | HCO3− (mg/L) | Cl− (mg/L) | SO42− (mg/L) | Ca2+ (mg/L) |

|---|---|---|---|---|---|

| 1.055 | 6.1 | 433.1 | 44,792.1 | 751.5 | 5010 |

| Mg2+ (mg/L) | K+/Na+(mg/L) | Total Anion (mg/L) | Total Cation (mg/L) | Surin Classification | Total Mineralization (mg/L) |

| 608 | 22,854.4 | 45,976.7 | 28,662.3 | chloride calcium type | 74,639.0 |

| Scheme No. | Fracture Permeability (mD) | Fracture Penetration (%) | Water Volume Multiple |

|---|---|---|---|

| 1 | 50 | 100 | 5 |

| 2 | 50 | 75 | 10 |

| 3 | 50 | 50 | 30 |

| 4 | 100 | 75 | 30 |

| 5 | 100 | 50 | 5 |

| 6 | 100 | 100 | 10 |

| 7 | 200 | 50 | 10 |

| 8 | 200 | 100 | 30 |

| 9 | 200 | 75 | 5 |

| Scheme No. | Parameter Value | Experimental Results | ||||||

|---|---|---|---|---|---|---|---|---|

| Fracture Permeability (mD) | Fracture Penetration (%) | Water Volume Multiple | Recovery Factor f | Average Water–Gas Ratio (mL/mL) | Pressure at Water Breakthrough (MPa) | Average Gas Production (mL) | Average Water Production (mL) | |

| 1 | 50 | 100 | 5 | 0.69 | 0.0035 | 40 | 790 | 2.8 |

| 2 | 50 | 75 | 10 | 0.72 | 0.0040 | 42 | 750 | 3 |

| 3 | 50 | 50 | 20 | 0.73 | 0.0054 | 46 | 700 | 3.8 |

| 4 | 100 | 75 | 20 | 0.73 | 0.0049 | 50 | 740 | 3.6 |

| 5 | 100 | 50 | 5 | 0.77 | 0.0032 | 40 | 750 | 2.4 |

| 6 | 100 | 100 | 10 | 0.75 | 0.0045 | 49 | 840 | 3.8 |

| 7 | 200 | 50 | 10 | 0.72 | 0.0029 | 48 | 980 | 2.8 |

| 8 | 200 | 100 | 20 | 0.64 | 0.0049 | 52 | 970 | 4.8 |

| 9 | 200 | 75 | 5 | 0.66 | 0.0036 | 46 | 950 | 3.4 |

| Evaluation Indicator | Parameter | Fracture Permeability K, mD | Fracture Penetration G, % | Water Volume Multiple M | |||

|---|---|---|---|---|---|---|---|

| Value | Result | Value | Result | Value | Result | ||

| Recovery Factor R, f | Mean value 1 | 50 | 0.713 | 50 | 0.740 | 5 | 0.707 |

| Mean value 2 | 75 | 0.735 | 63 | 0.721 | 7.5 | 0.725 | |

| Mean value 3 | 100 | 0.750 | 75 | 0.703 | 10 | 0.730 | |

| Mean value 4 | 150 | 0.721 | 87 | 0.697 | 15 | 0.720 | |

| Mean value 5 | 200 | 0.673 | 100 | 0.693 | 20 | 0.700 | |

| Range | 0.077 | 0.047 | 0.030 | ||||

| Average Water–Gas Ratio WGR, mL/mL | Mean value 1 | 50 | 0.0043 | 50 | 0.0038 | 5 | 0.0034 |

| Mean value 2 | 100 | 0.0042 | 75 | 0.0041 | 10 | 0.0038 | |

| Mean value 3 | 200 | 0.0038 | 100 | 0.0043 | 20 | 0.0051 | |

| Range | 0.0005 | 0.0005 | 0.0017 | ||||

| Pressure at Water Breakthrough P, MPa | Mean value 1 | 50 | 42.7 | 50 | 44.7 | 5 | 42.0 |

| Mean value 2 | 100 | 46.3 | 75 | 46.0 | 10 | 46.3 | |

| Mean value 3 | 200 | 48.7 | 100 | 47.0 | 20 | 49.3 | |

| Range | 6.0 | 2.3 | 7.3 | ||||

| Average Gas Production Qg, mL | Mean value 1 | 50 | 747 | 50 | 810 | 5 | 830 |

| Mean value 2 | 75 | 760 | 63 | 811 | 7.5 | 847 | |

| Mean value 3 | 100 | 777 | 75 | 813 | 10 | 857 | |

| Mean value 4 | 150 | 860 | 87 | 835 | 15 | 837 | |

| Mean value 5 | 200 | 967 | 100 | 867 | 20 | 803 | |

| Range | 220 | 57 | 54 | ||||

| Average Water Production Qw, mL | Mean value 1 | 50 | 3.20 | 50 | 3.00 | 5 | 2.87 |

| Mean value 2 | 100 | 3.27 | 75 | 3.33 | 10 | 3.20 | |

| Mean value 3 | 200 | 3.67 | 100 | 3.80 | 20 | 4.07 | |

| Range | 0.47 | 0.80 | 1.20 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhang, E.; Yue, P.; Zhao, H.; Xie, Z.; Liu, W. Simulating Water Invasion Dynamics in Fractured Gas Reservoirs. Energies 2024, 17, 6055. https://doi.org/10.3390/en17236055

Li Y, Zhang E, Yue P, Zhao H, Xie Z, Liu W. Simulating Water Invasion Dynamics in Fractured Gas Reservoirs. Energies. 2024; 17(23):6055. https://doi.org/10.3390/en17236055

Chicago/Turabian StyleLi, Yueyang, Enli Zhang, Ping Yue, Han Zhao, Zhiwei Xie, and Wei Liu. 2024. "Simulating Water Invasion Dynamics in Fractured Gas Reservoirs" Energies 17, no. 23: 6055. https://doi.org/10.3390/en17236055

APA StyleLi, Y., Zhang, E., Yue, P., Zhao, H., Xie, Z., & Liu, W. (2024). Simulating Water Invasion Dynamics in Fractured Gas Reservoirs. Energies, 17(23), 6055. https://doi.org/10.3390/en17236055