Application of Back-to-Back Hybrid Filter to a Hot Strip Mill with Cycloconverters

Abstract

1. Introduction

- High Power and Variable Load Demand: Hot strip mills require substantial power to maintain the high temperatures and forces needed to process metal. This power demand is highly variable, depending on the type, thickness, and desired qualities of the strip being produced, which can create irregular load profiles that complicate PQ management [3].

- Electromagnetic Interference and Harmonics: Equipment in hot strip mills, particularly cycloconverters, can produce significant electromagnetic interference (EMI) and harmonic distortions. These harmonics interfere with sensitive equipment, reduce the efficiency of power distribution, and can cause overheating, requiring specialized filter solutions [1].

- Cycloconverter-Induced PQ Issues: Hot strip mills are driven by cycloconverters with high nominal power, in the megawatt range, to drive synchronous motors [4,5,6,7,8,9]. However, cycloconverters draw distorted currents from the power grid, introducing harmonic, subharmonic, and interharmonic currents into the electrical system [10,11]. This can lead to voltage instability and waveform distortions, negatively impacting both equipment longevity and process control.

- Heat and Harsh Operating Environments: High temperatures and challenging conditions require robust systems that can maintain reliable performance without frequent maintenance. Power filters and control systems must be designed to withstand these extremes while still providing effective harmonic mitigation [12].

- Precision and Stability Requirements: Hot strip mills must maintain precise control over speed, temperature, and thickness to meet stringent quality standards. Power fluctuations and harmonic issues can alter this precision, leading to defects in the final product, increased waste, and higher costs [13].

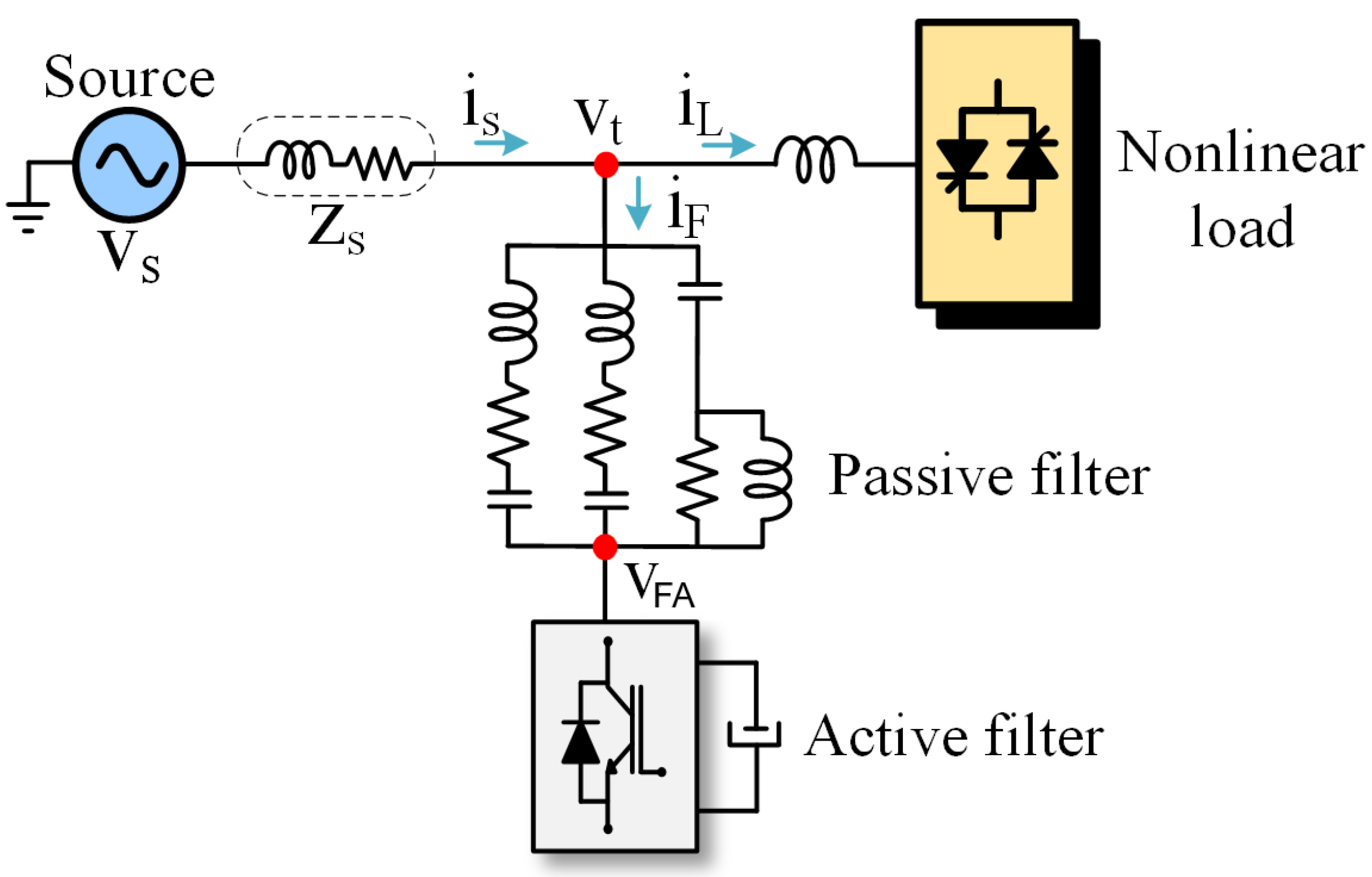

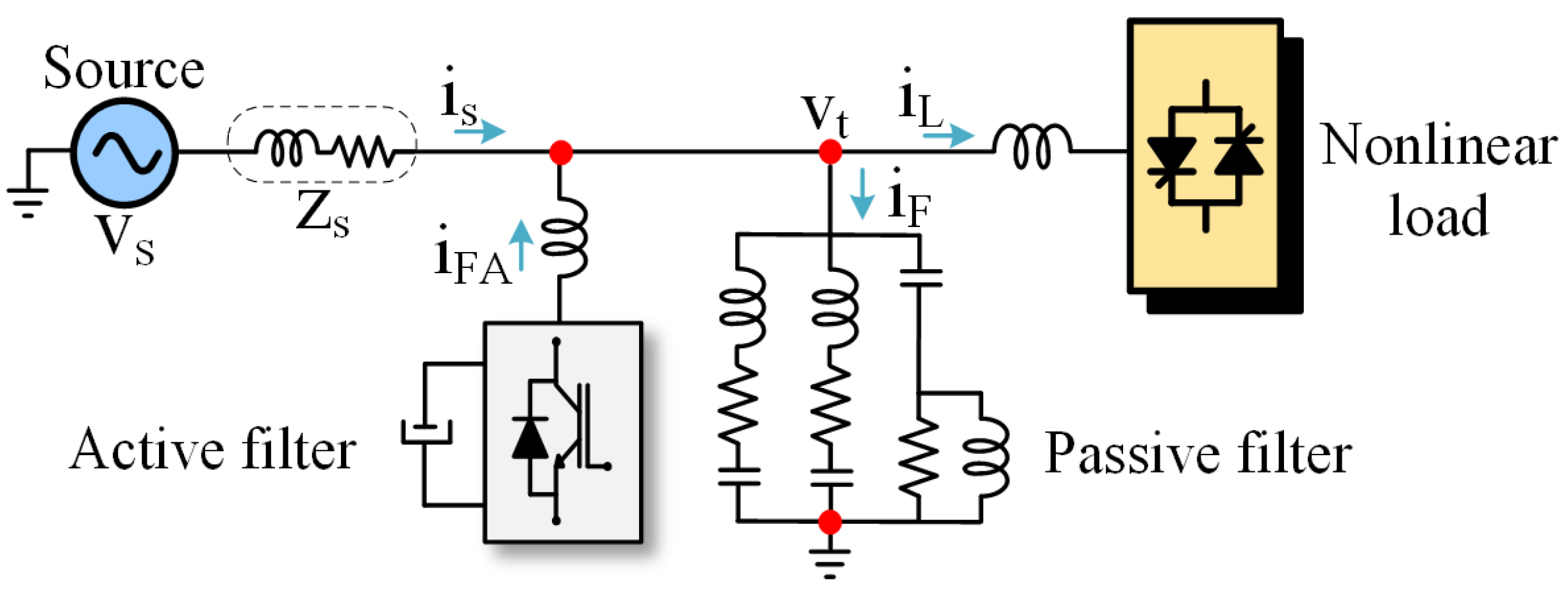

2. Hybrid Filter Topologies

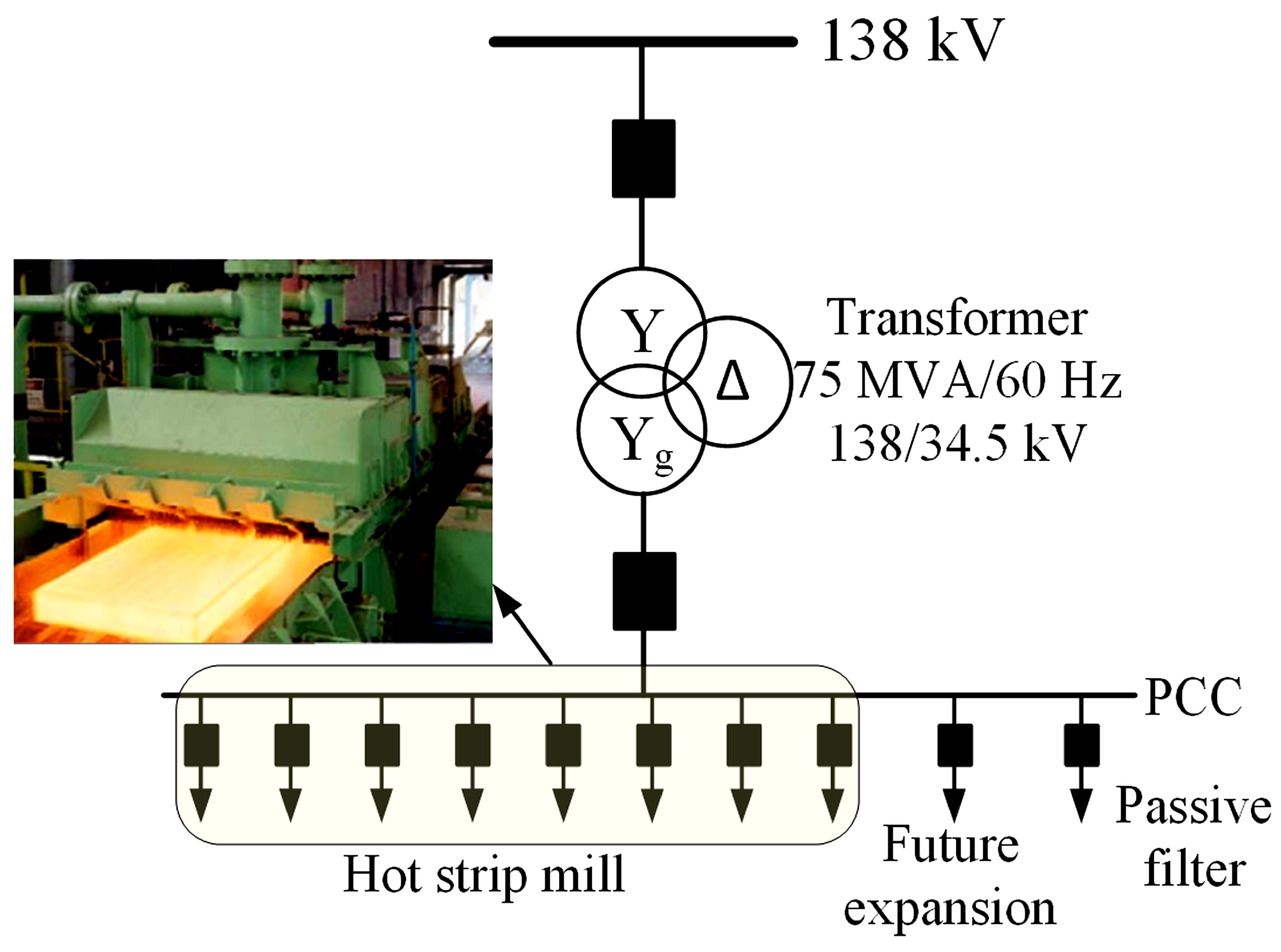

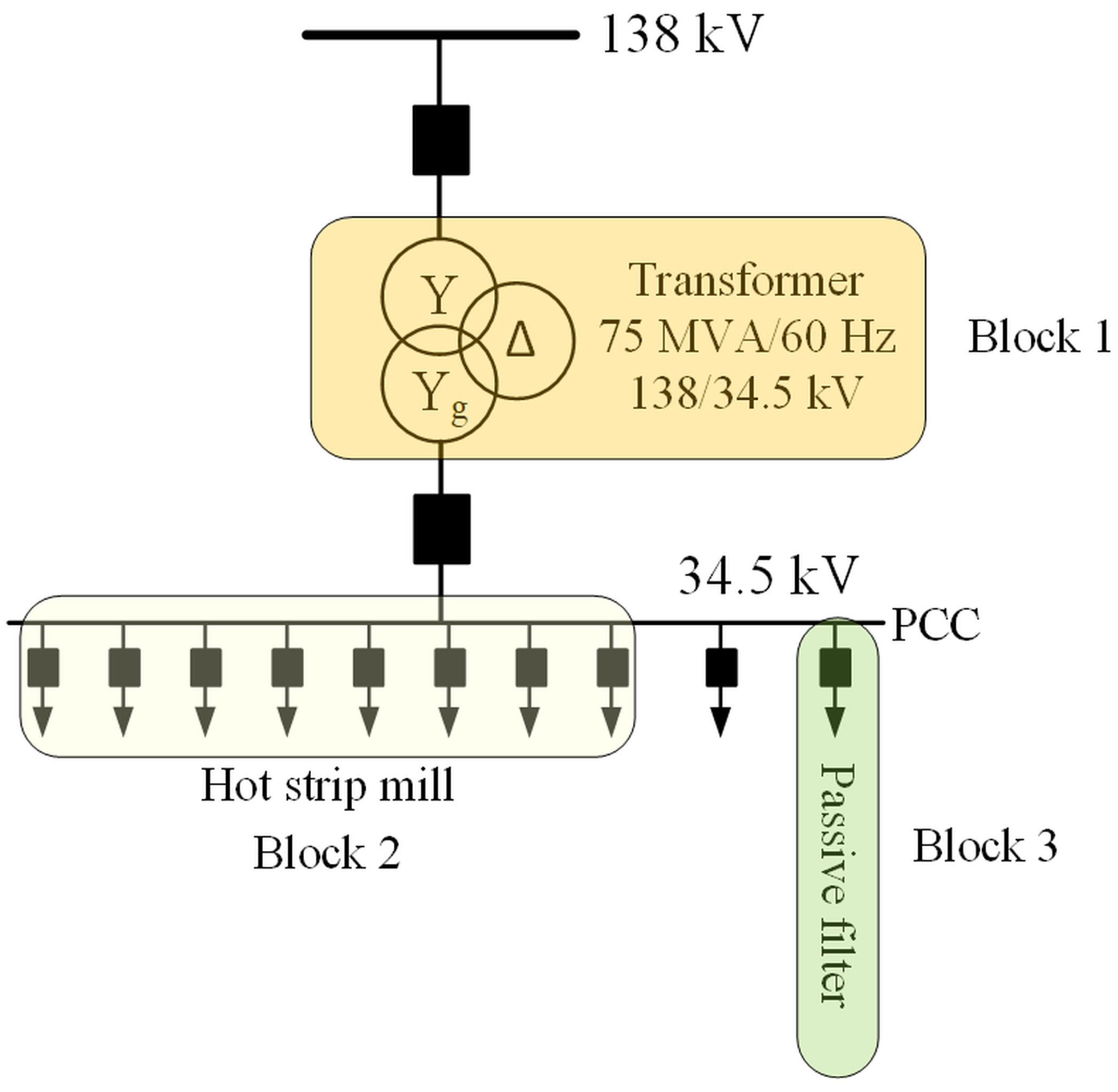

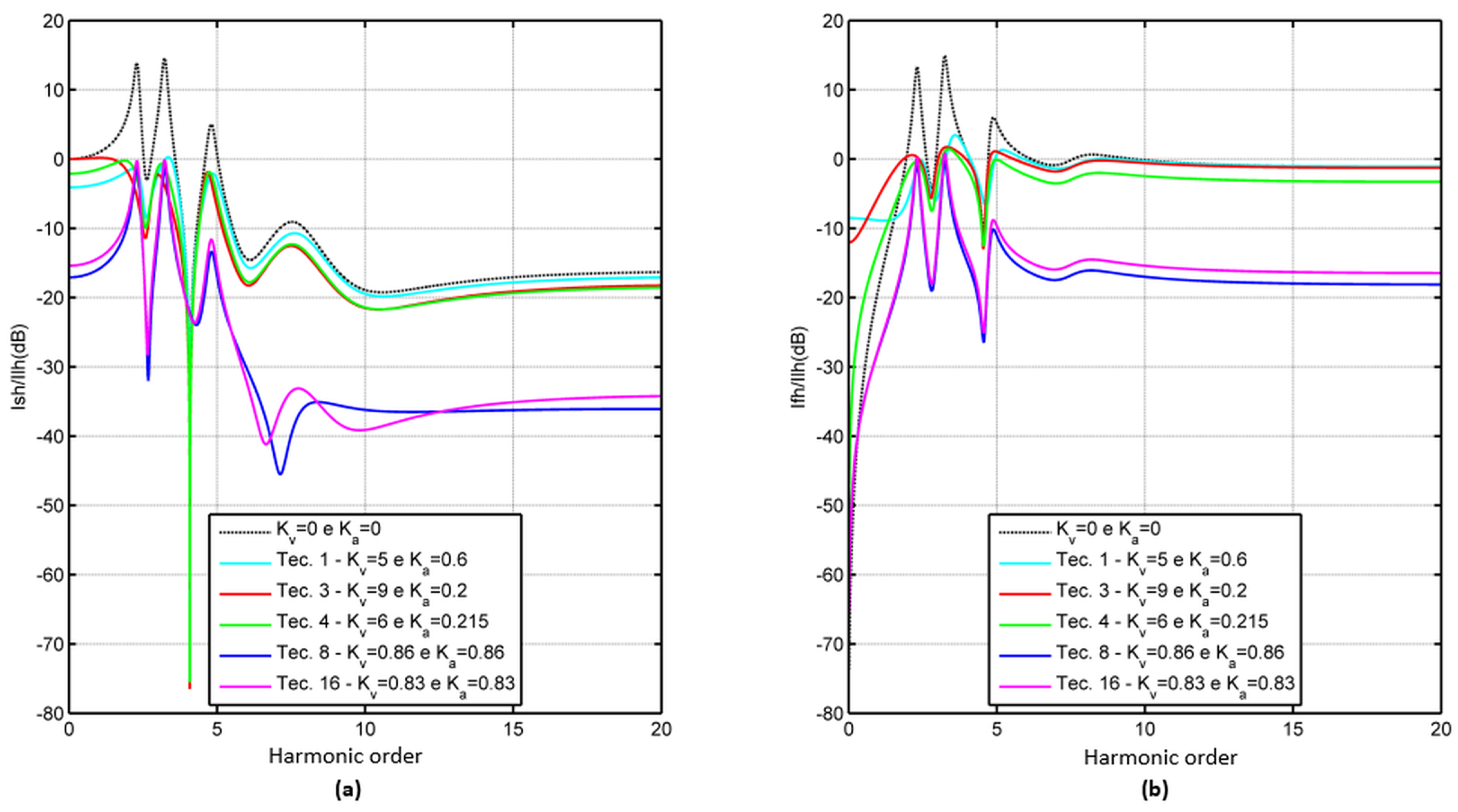

3. Hot Strip Mill Electrical System

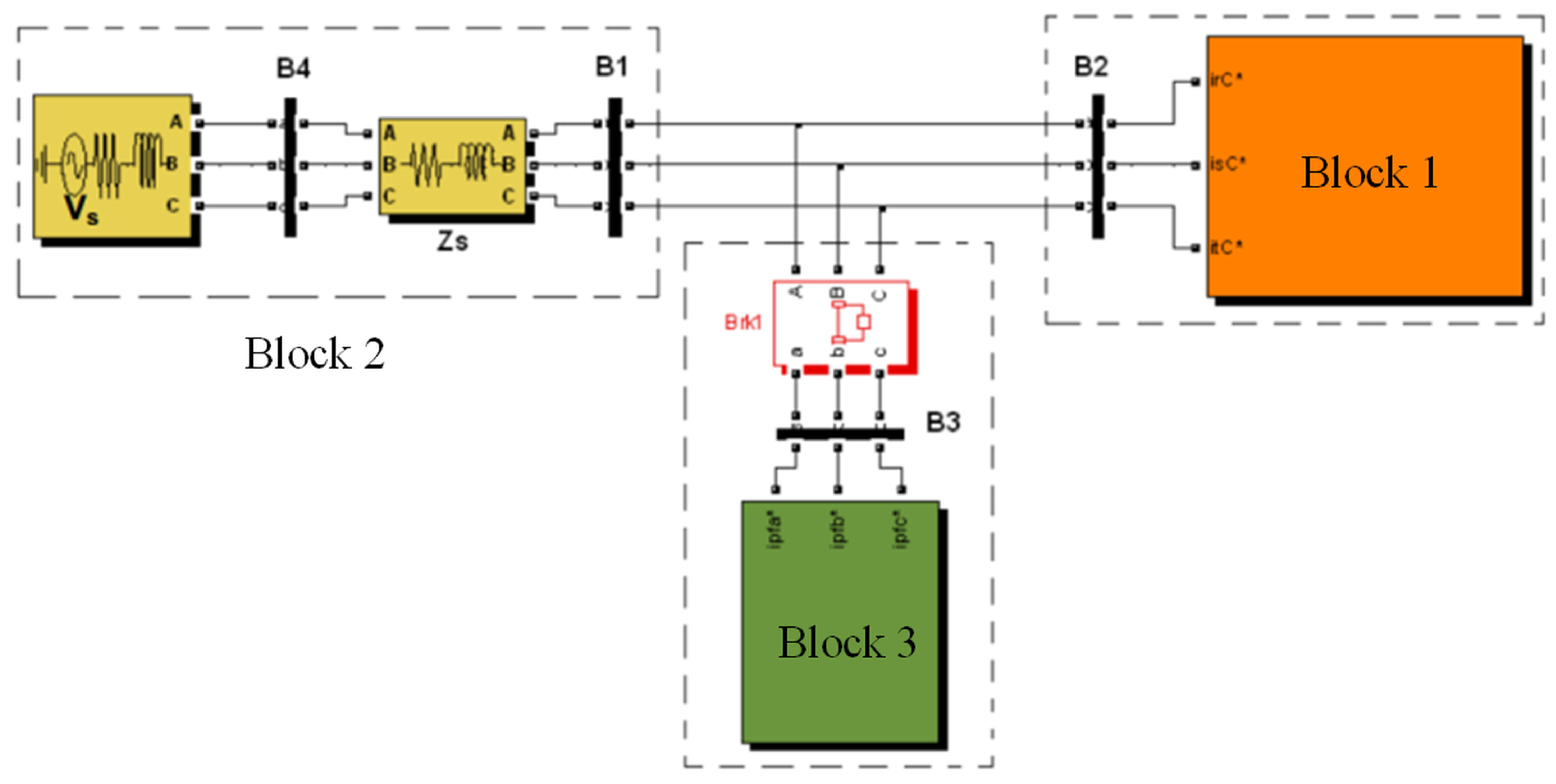

- Block 1 represents a controlled current source representing the set of cycloconverters, injecting the measured currents (50 μs) into the power bus of the electrical system model. This controlled current injection ensures proper system operation.

- Block 2 represents the system transformer, having a nominal power of 75 MVA and a 138/34.5 kV transformation ratio. This transformer is modeled from the secondary side as a voltage source that generates only the 60 Hz positive-sequence component along with its corresponding impedance. Cables connecting the transformer to the rolling mill substation are also modeled as an impedance. This modeling is appropriate due to the short distance between the transformer and the substation, allowing it to be modeled as a short transmission line.

- Block 3 represents the passive filtering system, modeled with specific parameters, including resistors, inductors, and capacitors. These parameters were obtained from technical manuals of the hot strip mill, ensuring accurate modeling of the passive filter system.

4. Proposed Back-to-Back Hybrid Filter

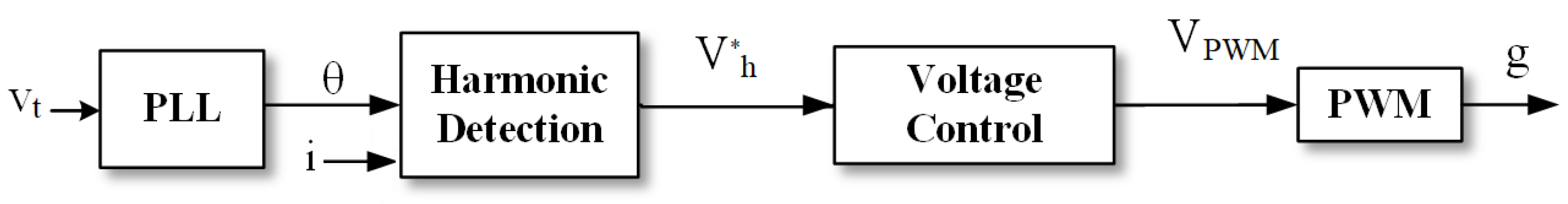

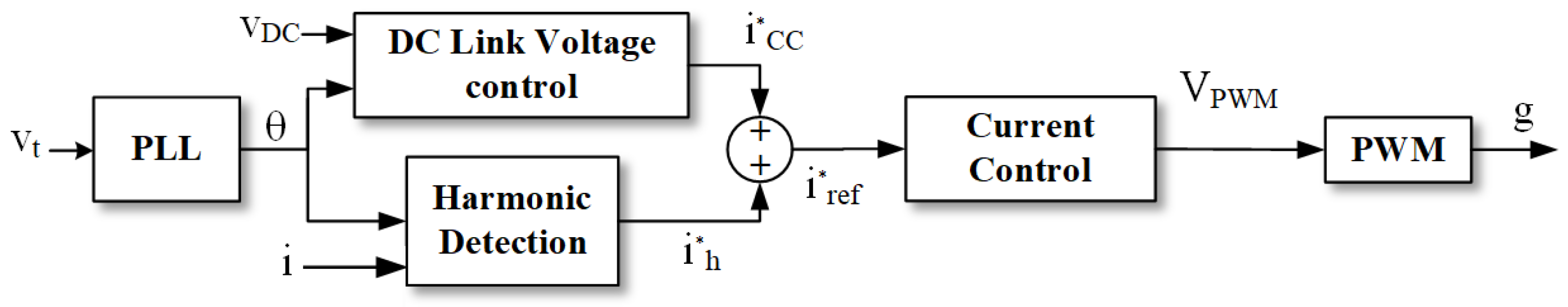

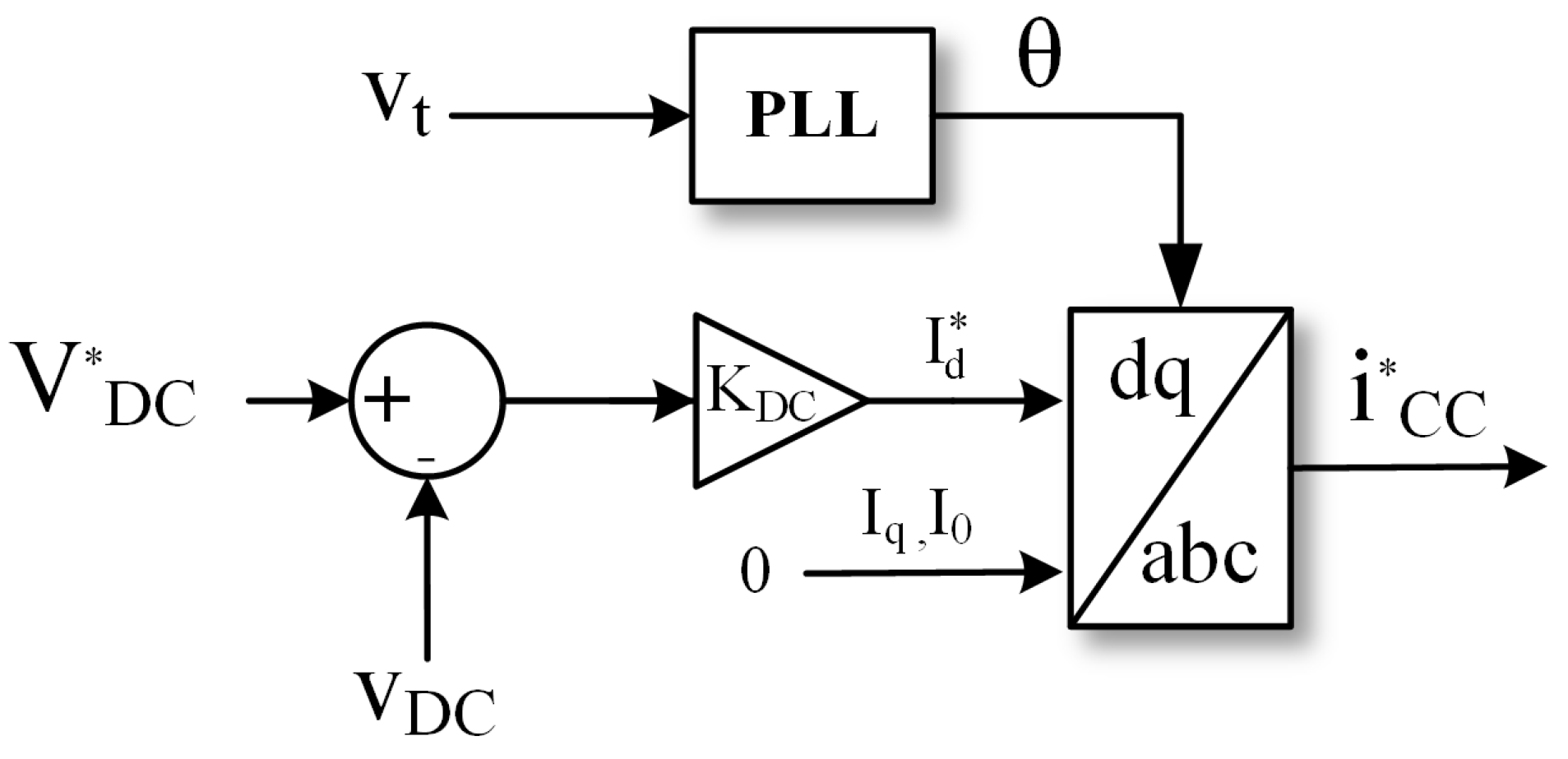

4.1. Back-to-Back Hybrid Filter Control

- —Input voltage vector [].

- i—Input current vector [].

- —Voltage vector for harmonic compensation [].

- —PWM controlled voltage vector [].

- g—Control signals for series hybrid filter.

- —DC link voltage of the inverter;

- —Current vector for DC bus control [];

- —Current vector for harmonic compensation [];

- —Vector for signal summation ( + ).

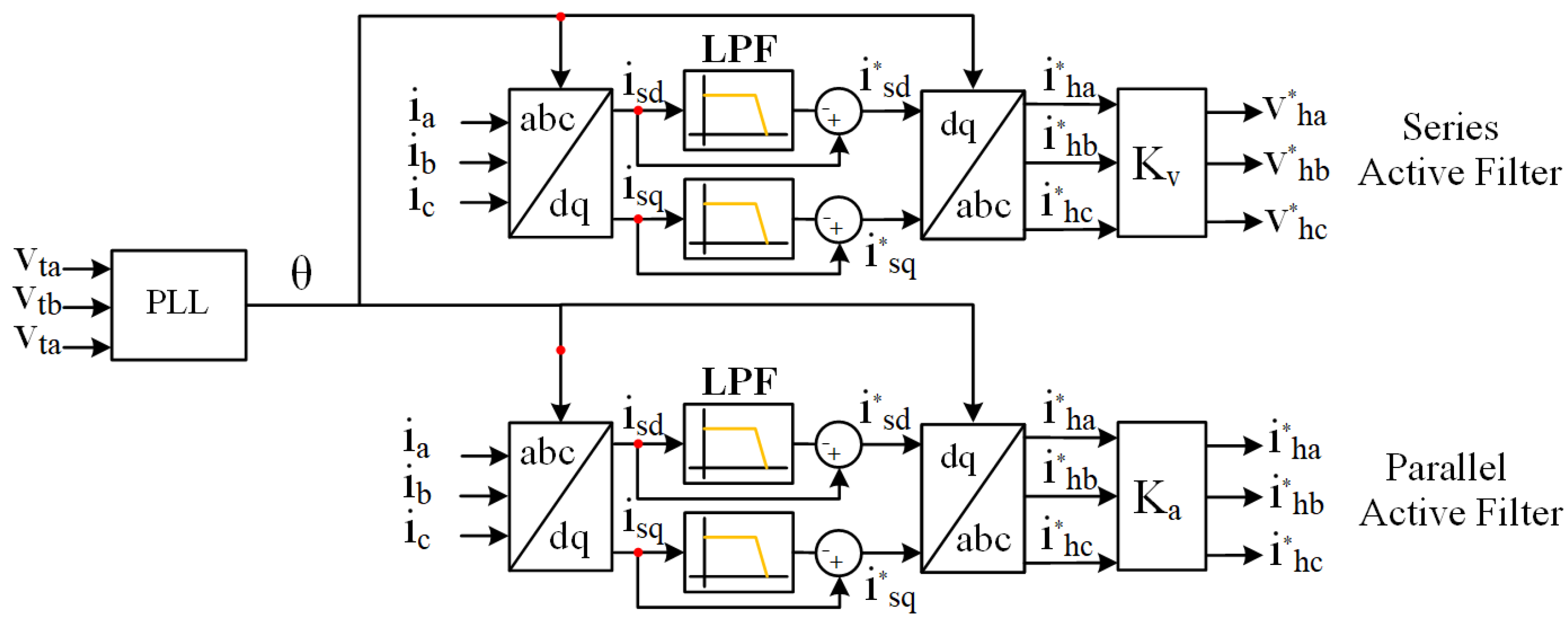

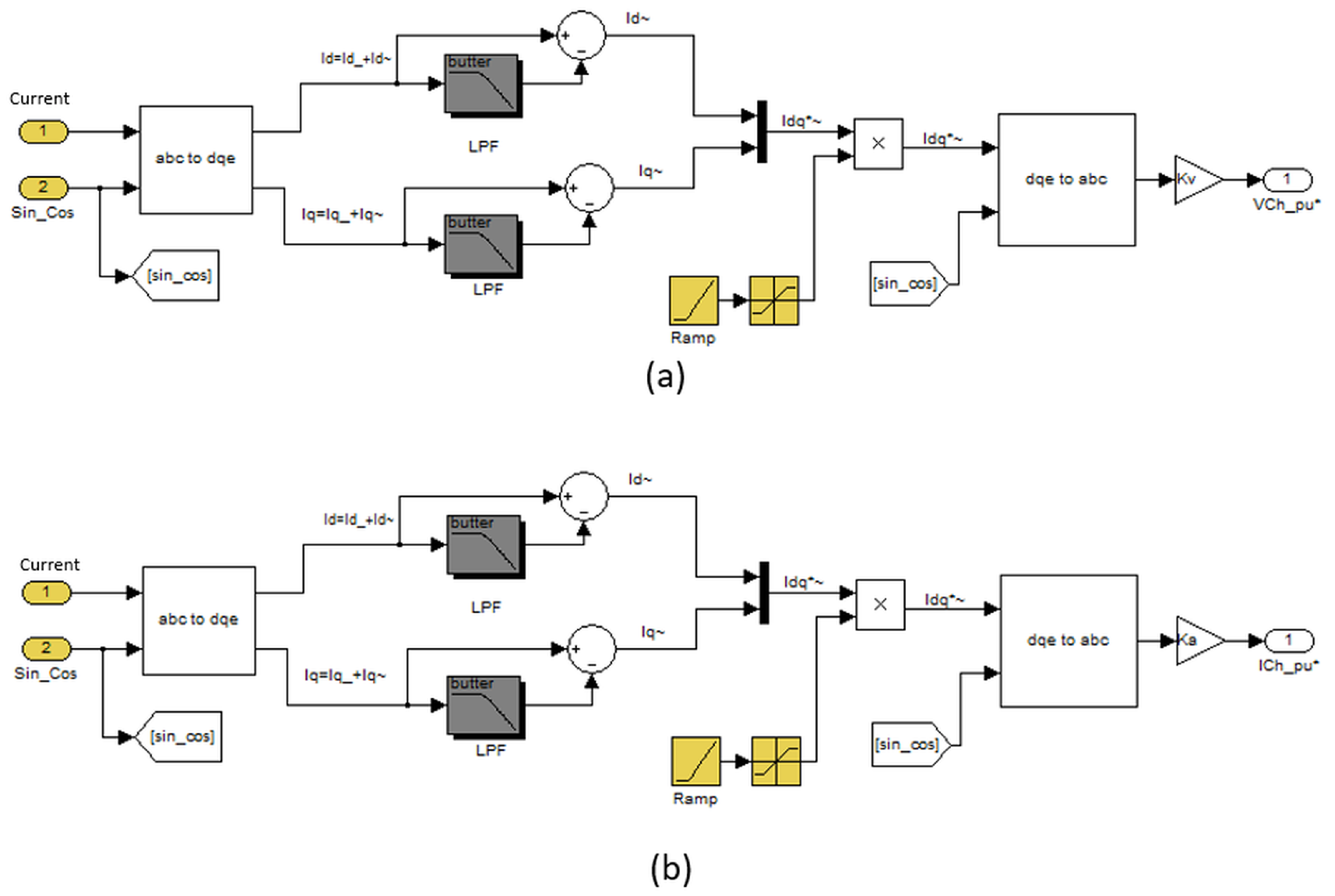

4.2. Harmonic Detection Method

- and are the direct and quadrature currents in the synchronous reference;

- , and are the currents of phases a, b, and c in the time domain.

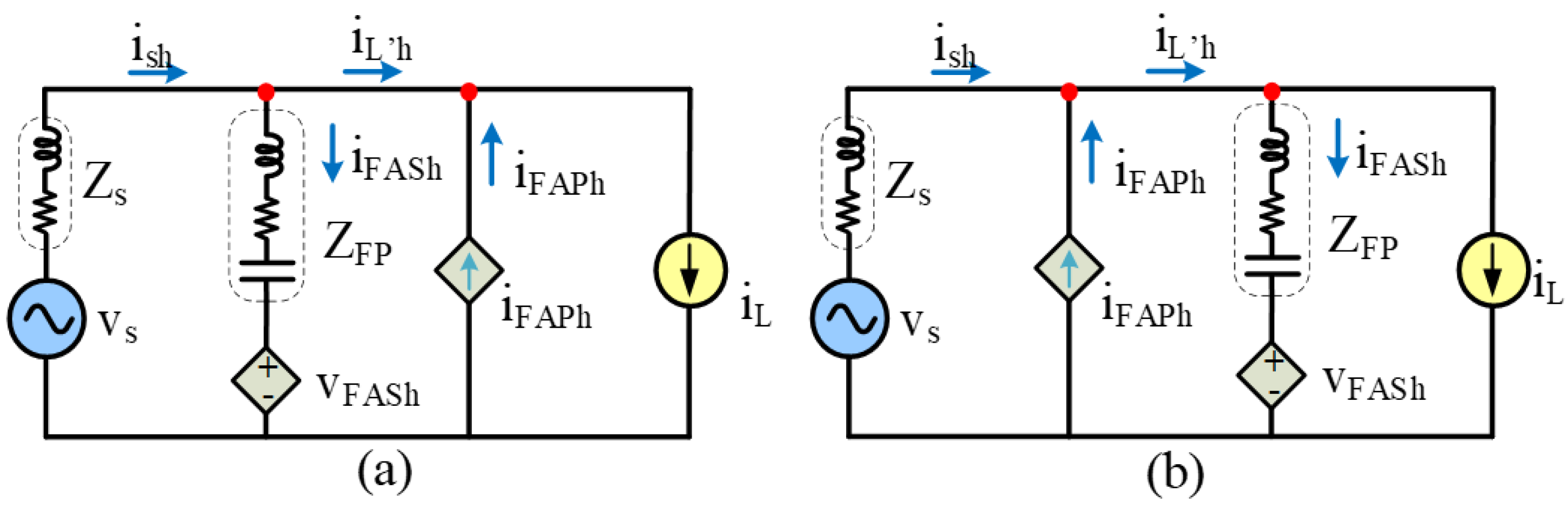

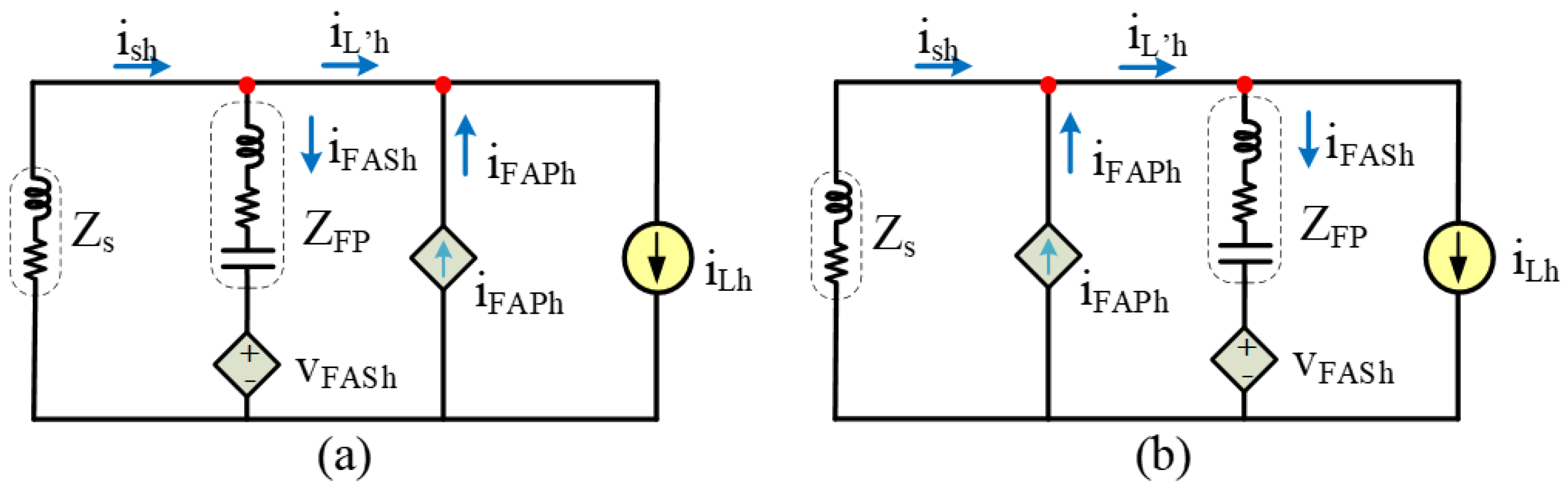

4.3. Harmonic Compensation Principle

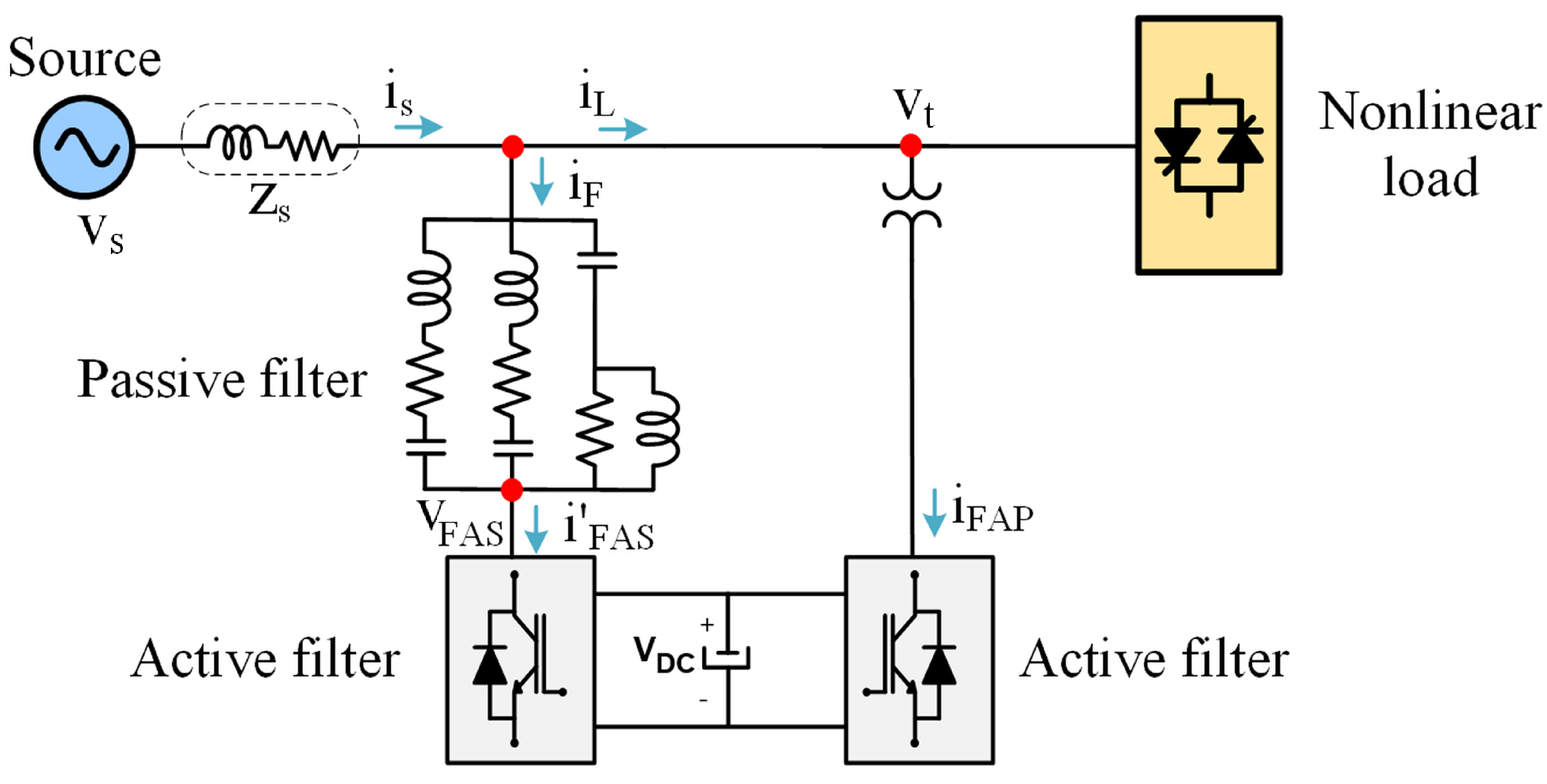

- —Source voltage;

- —Source impedance;

- —Source current;

- —Impedance of the passive filter;

- —Compensation voltage of the series active filter;

- —Current of the series active filter/passive filter;

- —Compensation current of the parallel active filter;

- —Load current.

- —Source current;

- —Intermediate load current;

- —Load current;

- —Passive filter current.

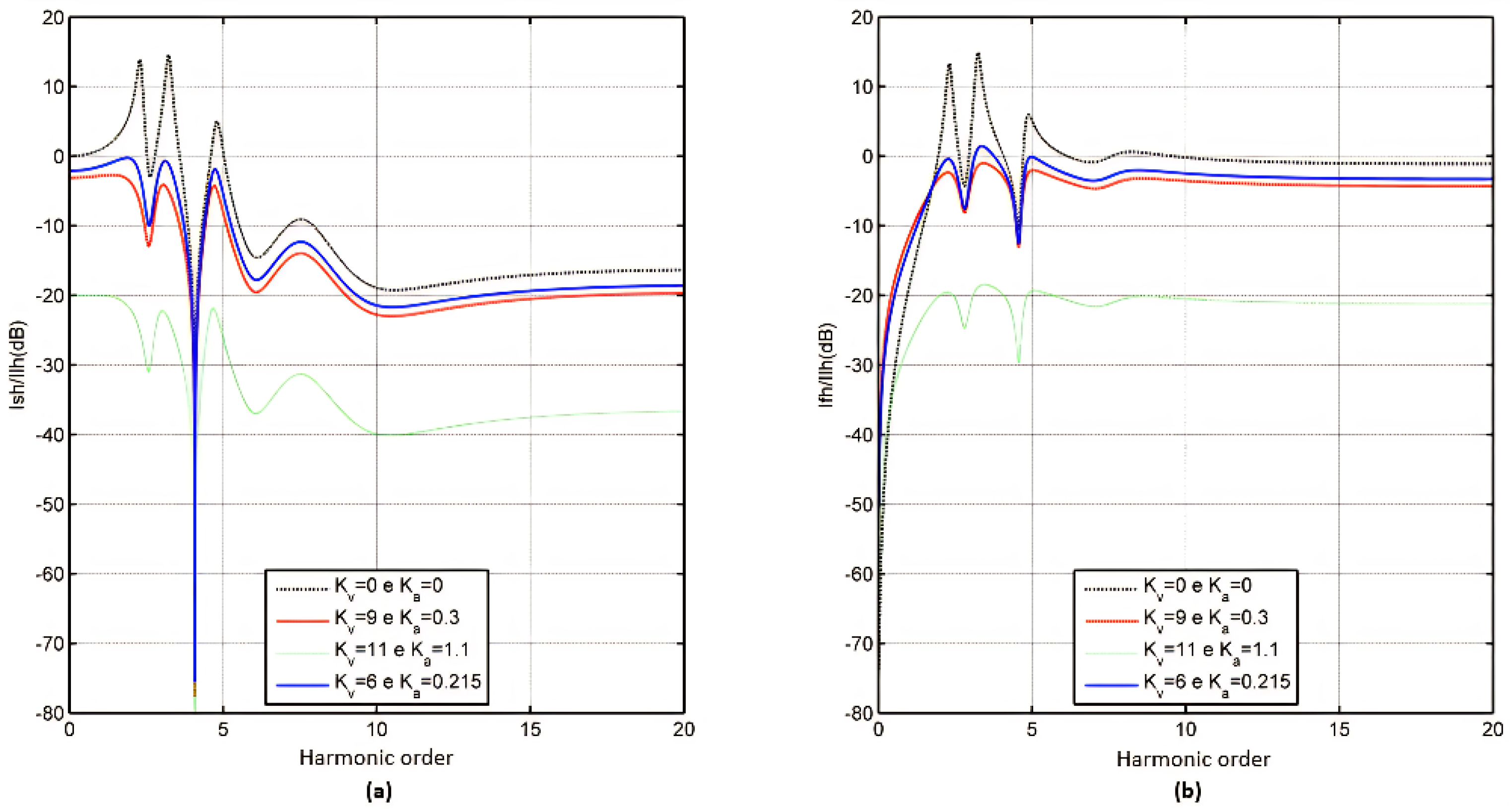

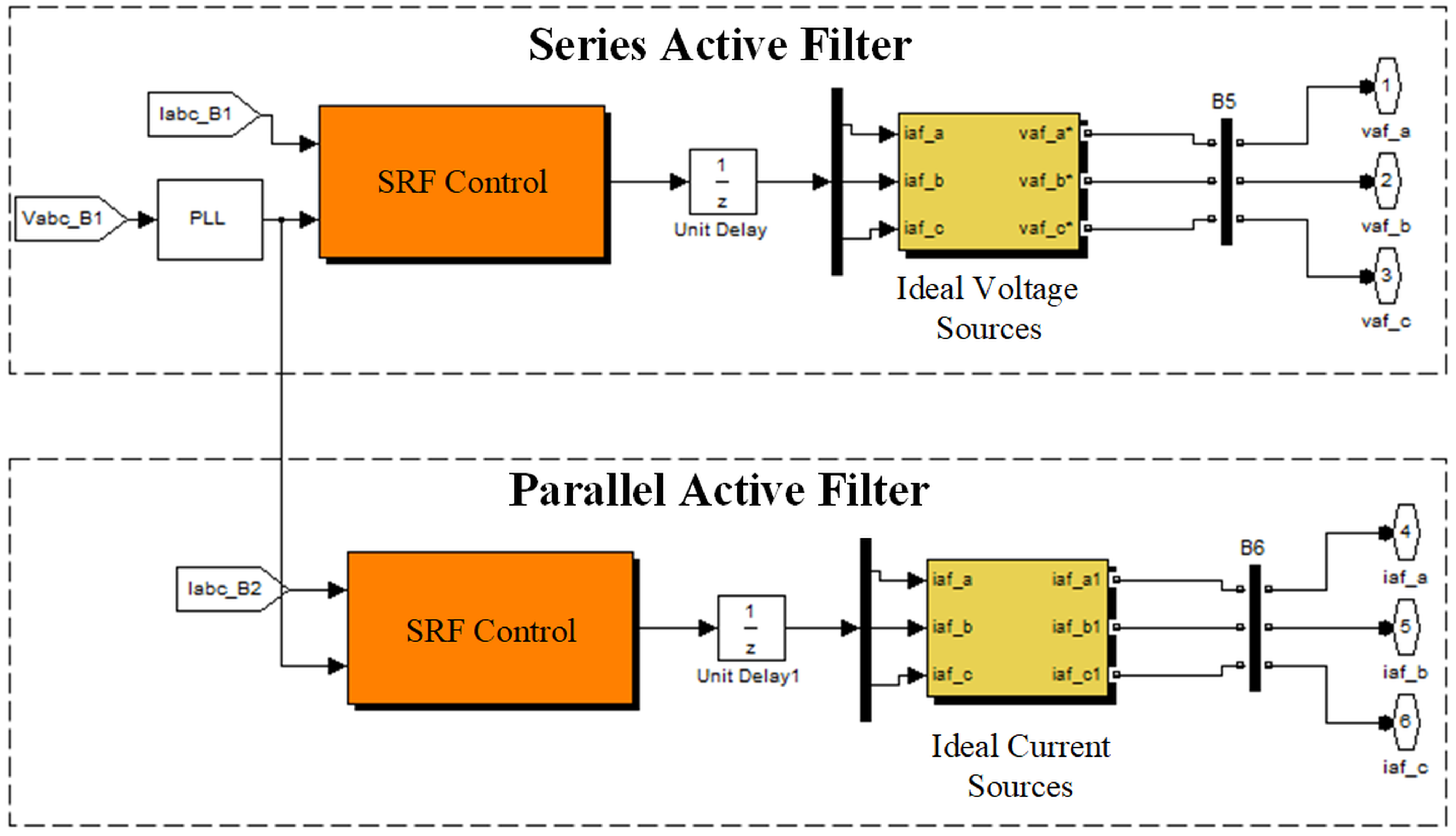

5. Comparison of Harmonic Compensation Techniques

5.1. Technique 4

5.2. Overview of the Techniques Applied to the Back-to-Back Hybrid Filter

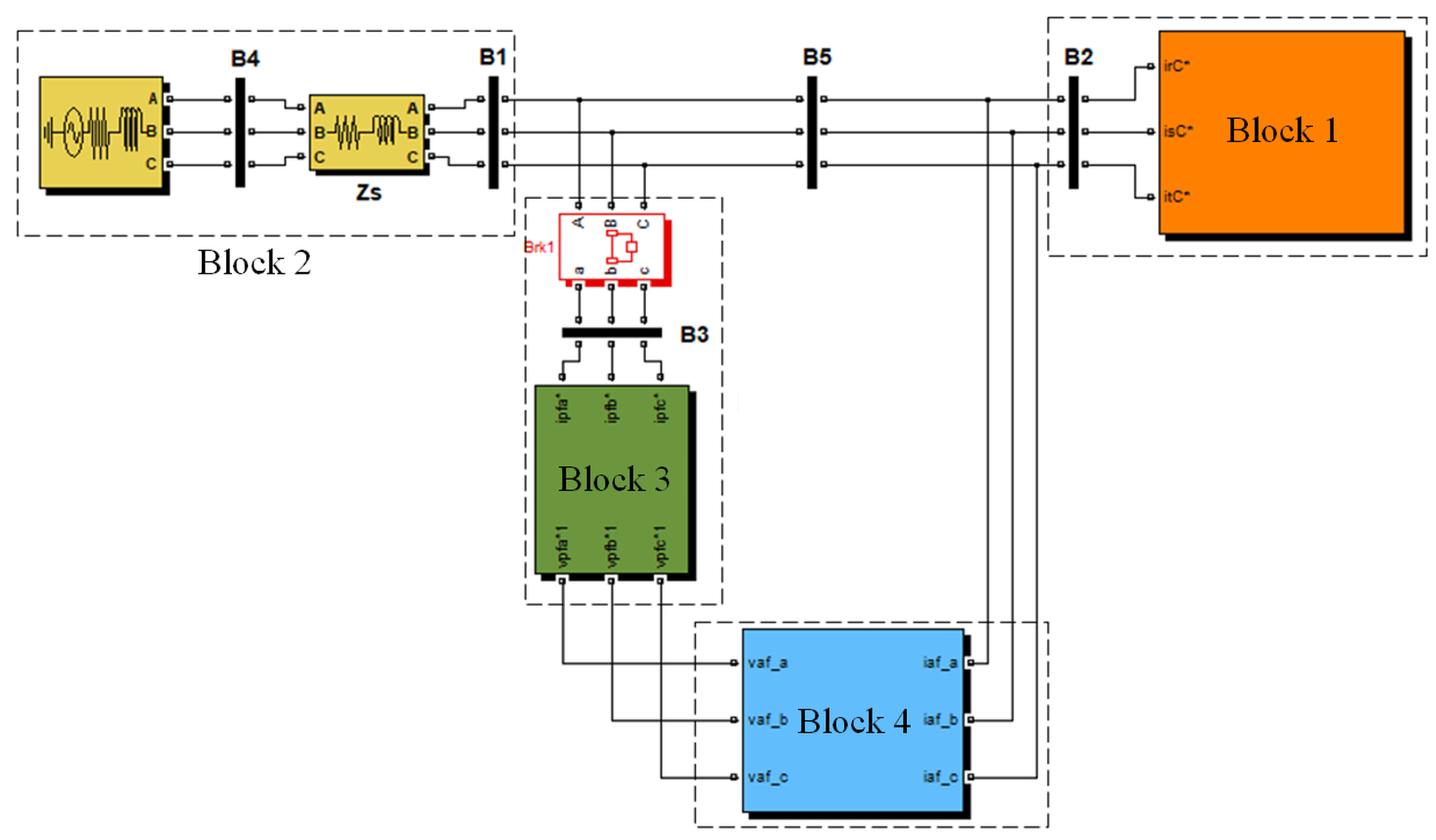

6. Simulation Model of the Back-to-Back Hybrid Filter

- PLL;

- Harmonic detection method using an SRF-type control algorithm;

- Ideal controlled current and voltage sources.

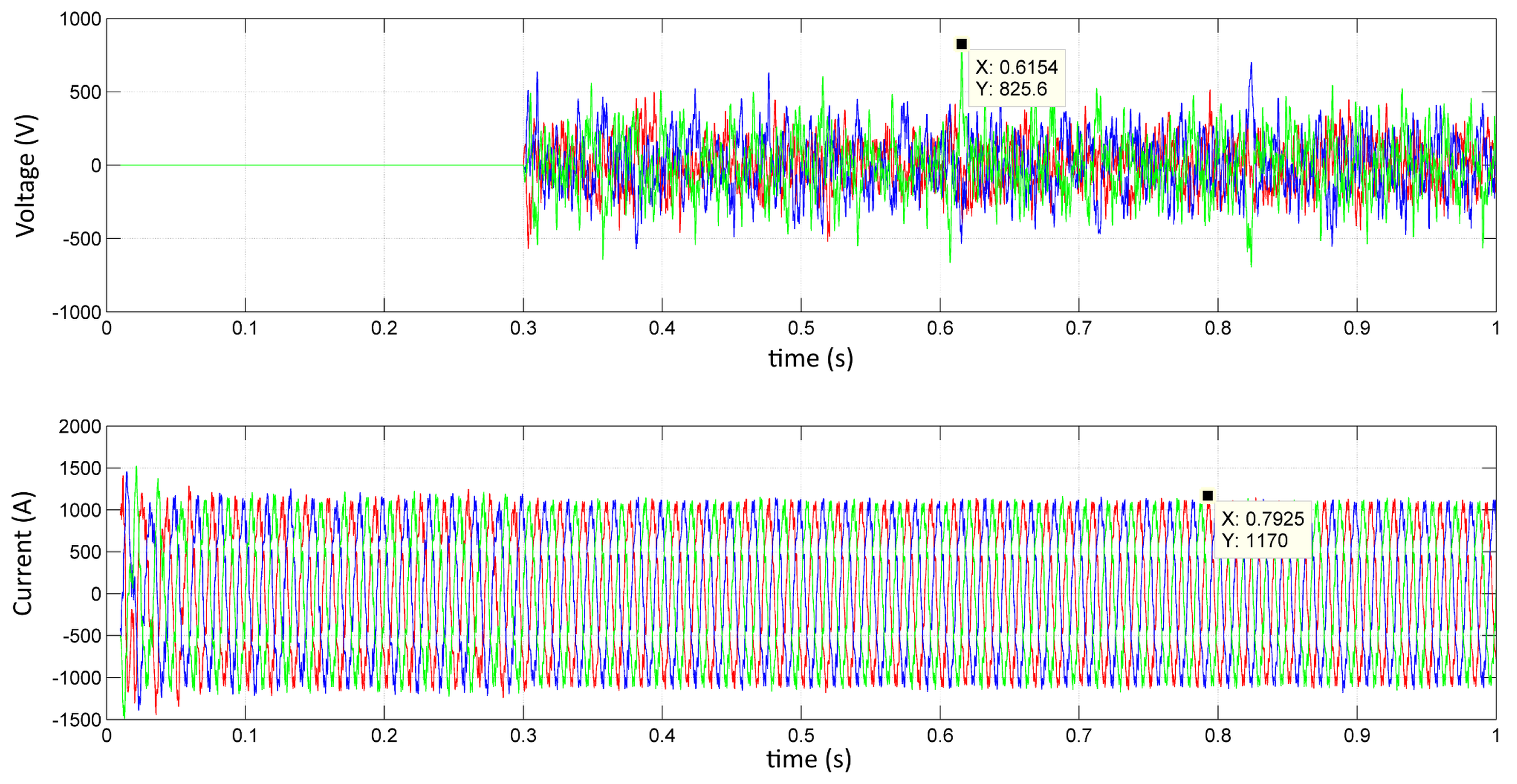

7. Simulation Results of the Back-to-Back Hybrid Filter

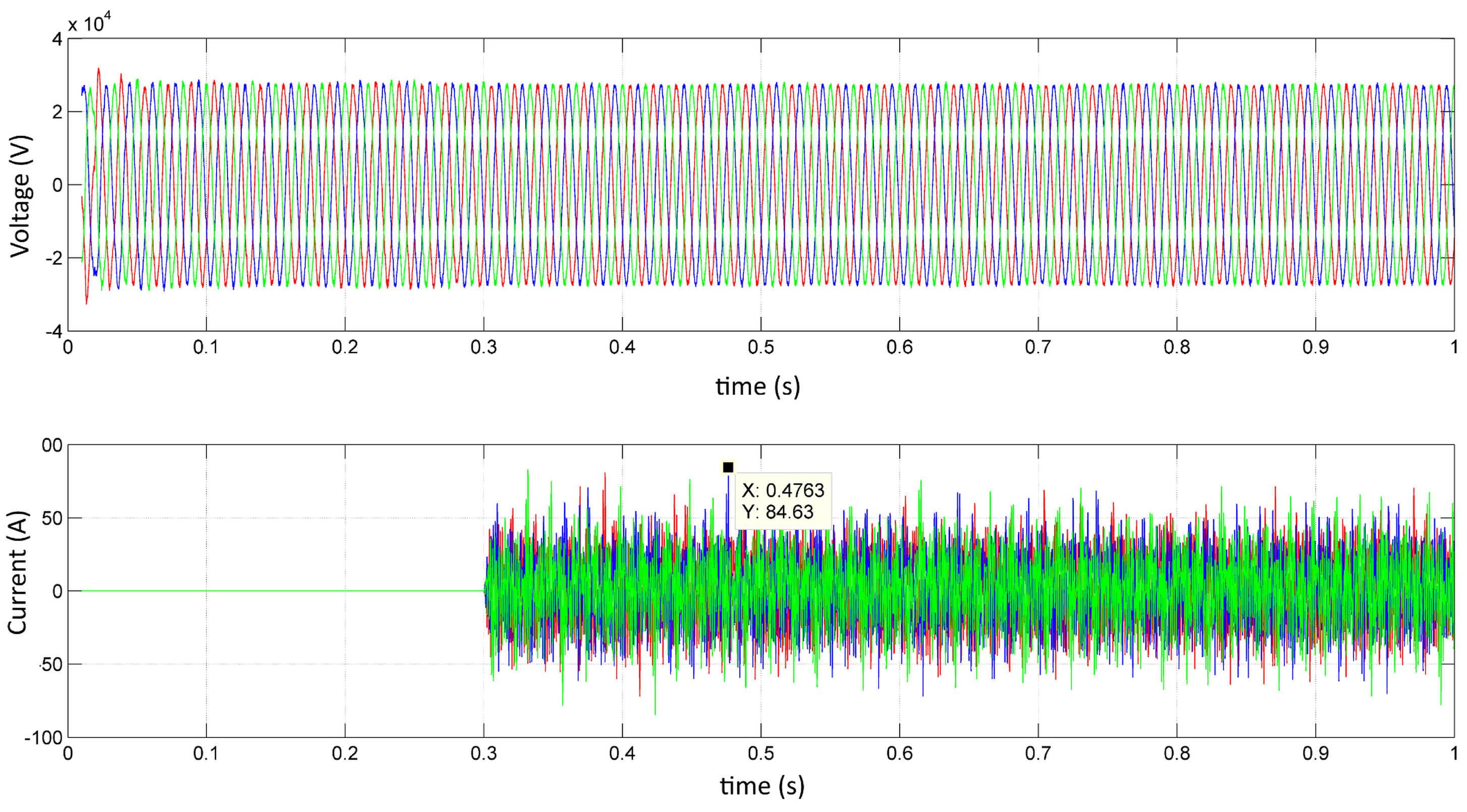

7.1. Simulation Results—Technique 4

- : Nominal active power;

- : Voltage on the DC link;

- : Current in the active filter.

7.2. Overview of Back-to-Back Hybrid Filter Simulation Results

7.3. Performance Analysis of the Back-to-Back Hybrid Filter Against Other Solutions

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, C.; Lee, Y.; Hsu, C.; Ting, D.; Shen, C. Power quality assessment of a hot strip mill with cycloconverter drive systems. In Proceedings of the 2007 IEEE Industry Applications Annual Meeting, New Orleans, LA, USA, 23–27 September 2007; pp. 9–16. [Google Scholar]

- Pittner, J.; Simaan, M.A. Main Drives and Motors. In Tandem Hot Metal Rolling Mill Control: Using Practical Advanced Methods; Springer International Publishing: Cham, Switzerland, 2024; pp. 169–188. [Google Scholar] [CrossRef]

- Orcajo, G.A.; Rodríguez, D.J.; Cano, J.M.; Norniella, J.G.; Ardura, G.P.; Llera, T.R.; Diego Cifrián, R. Dynamic estimation of electrical demand in hot rolling mills. In Proceedings of the 2015 IEEE Industry Applications Society Annual Meeting, Addison, TX, USA, 18–22 October 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Khadkikar, V. Enhancing electric power quality using UPQC: A comprehensive overview. IEEE Trans. Power Electron. 2011, 27, 2284–2297. [Google Scholar] [CrossRef]

- Park, B.; Lee, J.; Yoo, H.; Jang, G. Harmonic mitigation using passive harmonic filters: Case study in a steel mill power system. Energies 2021, 14, 2278. [Google Scholar] [CrossRef]

- Orcajo, G.A.; Rodríguez, J.; Cano, J.M.; Norniella, J.G.; Ardura, P.; Llera, R.; Cifrián, D. Retrofit of a hot rolling mill plant with three-level active front end drives. IEEE Trans. Ind. Appl. 2018, 54, 2964–2974. [Google Scholar] [CrossRef]

- Hulshorst, W.T.; Keet, A.L.; Enslin, J.H. Harmonic Analyses and Mitigation in Large Industrial Steel Plants A Case Study. Electr. Power Qual. Util. Mag. 2006, 2, 1–7. [Google Scholar]

- Orcajo, G.A.A.; Diez, J.R.; Cano, J.M.; Norniella, J.G.; González, J.F.P.; Rojas, C.H.; Ardura, P.; Cifrián, D. Enhancement of power quality in an actual hot rolling mill plant through a STATCOM. IEEE Trans. Ind. Appl. 2020, 56, 3238–3249. [Google Scholar] [CrossRef]

- Karandaev, A.; Kornilov, G.; Khramshin, V.; Khramshin, T. Improving electric power quality within the power supply system of wide-strip hot-rolling mill stand. Procedia Eng. 2015, 129, 2–8. [Google Scholar] [CrossRef][Green Version]

- Liu, Y.; Heydt, G.T.; Chu, R.F. The power quality impact of cycloconverter control strategies. IEEE Trans. Power Deliv. 2005, 20, 1711–1718. [Google Scholar] [CrossRef]

- Aravena, P.; Morán, L.; Dixon, J.; Espinoza, J.; Godoy, O. A new hybrid filter topology for sub and inter-harmonic attenuation in cycloconverter-fed drives applications. In Proceedings of the 2009 IEEE Industry Applications Society Annual Meeting, Houston, TX, USA, 4–8 October 2009; pp. 1–7. [Google Scholar]

- Antunes, H.M.; Pires, I.A.; Silva, S.M. Evaluation of series and parallel hybrid filters applied to hot strip mills with cycloconverters. IEEE Trans. Ind. Appl. 2019, 55, 6643–6651. [Google Scholar] [CrossRef]

- Ardura, P.; Alonso, G.; Cano, J.M.; Norniella, J.G.; Pedrayes, F.; Briz, F.; Cabanas, M.F.; Melero, M.G.; Rojas, C.; Suárez, J.R.G.; et al. Power quality analysis and improvements in a hot rolling mill using a STATCOM. Renew. Energy Power Qual. J. 2014, 1, 582–587. [Google Scholar]

- Hörger, I. Aspects for filter design in case of cycloconverter load. Power Qual. 1997, 97, 10–12. [Google Scholar]

- Basic, D.; Ramsden, V.; Muttik, P. Harmonic and reactive power compensation of high power cycloconverter induction motor drives by using decoupled inverters. In Proceedings of the 1998 International Conference on Power Electronic Drives and Energy Systems for Industrial Growth, Perth, WA, Australia, 1–3 December 1998; Volume 1, pp. 44–49. [Google Scholar]

- Yousif, S.; Wanik, M.; Mohamed, A. Implementation of different passive filter designs for harmonic mitigation. In Proceedings of the PECon 2004. Proceedings. National Power and Energy Conference, Kuala Lumpur, Malaysia, 29–30 November 2004; pp. 229–234. [Google Scholar]

- Zhai, X.; Zhuo, F.; Duan, R.; Lei, W.; Zhang, P.; Wang, Z. Development of a parallel hybrid power filter with respective harmonic compensation method. In Proceedings of the Twenty-First Annual IEEE Applied Power Electronics Conference and Exposition, Dallas, TX, USA, 19–23 March 2006; p. 5. [Google Scholar]

- Singh, B.; Verma, V.; Chandra, A.; Al-Haddad, K. Hybrid filters for power quality improvement. IEE Proc.-Gener. Transm. Distrib. 2005, 152, 365–378. [Google Scholar] [CrossRef]

- Na, H.; Jian, W.; Dianguo, X. A novel shunt hybrid power filter for suppressing harmonics. In Proceedings of the 2006 IEEE International Symposium on Industrial Electronics, Montreal, QC, Canada, 9–13 July 2006; Volume 2, pp. 1155–1160. [Google Scholar]

- Seifossadat, S.G.; Kianinezhad, R.; Ghasemi, A.; Monadi, M. Quality improvement of shunt active power filter, using optimized tuned harmonic passive filters. In Proceedings of the 2008 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 11–13 June 2008; pp. 1388–1393. [Google Scholar]

- Shimamura, T.; Kurosawa, R.; Hirano, M.; Uchino, H. Parallel operation of active and passive filters for variable speed cycloconverter drive systems. In Proceedings of the 15th Annual Conference of IEEE Industrial Electronics Society, Philadelphia, PA, USA, 6–10 November 1989; pp. 186–191. [Google Scholar]

- Ferreira, C.; Simonetti, D.; Sousa, G. Analysis of an Active Filter in Parallel with Cycloconverters and Passive Filters in a System of Metallurgical Lamination. In Proceedings of the Annals of the XVII Brazilian Congress of Automatic, Santos, Brazil, 2007. [Google Scholar]

- Bessadet, I.; Tedjini, H. The performances of hybrid filter in elimination of AC-AC converters harmonics pollution. In Proceedings of the 2018 6th International Renewable and Sustainable Energy Conference (IRSEC), Rabat, Morocco, 5–8 December 2018; pp. 1–6. [Google Scholar]

- Obando, J.A.; Serrano, V. Implementation of a Hybrid ANN-Based Filter for the Reduction of Harmonic Currents. Eur. J. Electr. Eng. Int. De Génie Electr. 2021, 23. [Google Scholar] [CrossRef]

- Basic, D.; Ramsden, V.; Muttik, P. Selective compensation of cycloconverter harmonics and interharmonics by using a hybrid power filter system. In Proceedings of the 2000 IEEE 31st Annual Power Electronics Specialists Conference. Conference Proceedings (Cat. No. 00CH37018), Galway, Ireland, 23–23 June 2000; Volume 3, pp. 1137–1142. [Google Scholar]

- Basic, D.; Ramsden, V.; Muttik, P. Performance of combined power filters in harmonic compensation of high-power cycloconverter drives. In Proceedings of the 1998 Seventh International Conference on Power Electronics and Variable Speed Drives (IEE Conf. Publ. No. 456), London, UK, 21–23 September 1998; pp. 674–679. [Google Scholar]

- Bhattacharya, S.; Cheng, P.T.; Divan, D.M. Hybrid solutions for improving passive filter performance in high power applications. IEEE Trans. Ind. Appl. 1997, 33, 732–747. [Google Scholar] [CrossRef]

- Liu, S.; Liang, Y.; Wang, J.; Liu, Y.; Tu, L.; Xiao, J.; Wang, Y.; Mao, C. A novel control strategy for UPQC applied to large scale industrial enterprises. In Advances in Power and Energy Engineering. In Proceedings of the 8th Asia-Pacific Power and Energy Engineering Conference, Suzhou, China, 15–17 April 2016; CRC Press: Boca Raton, FL, USA, 2016; p. 327. [Google Scholar]

- Krause, R.C.; Antunes, H.M.; Silva, S.M. Study of Back-to-Back Hybrid Filter Applied to a Hot Strip Mill with Cycloconverters. In Proceedings of the 2022 14th Seminar on Power Electronics and Control (SEPOC), Santa Maria, Brazil, 12–15 November 2022; pp. 1–6. [Google Scholar]

- Ferreira, C.G. Análise de um Filtro Ativo em Paralelo a Cicloconversores e Filtro Passivo. Master’s Thesis, Universidade Federal do Espírito Santo, Espírito Santo, Brazil, 2008. [Google Scholar]

- Antunes, H.M.A.; Pires, I.A.; Silva, S.M. Evaluation of Series and Parallel Hybrid Filters Applied to Hot Strip Mills with Cycloconverters. In Proceedings of the 2018 IEEE Industry Applications Society Annual Meeting (IAS), Portland, OR, USA, 23–27 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Acha, E. Power Electronic Control in Electrical Systems; Newnes: London, UK, 2002. [Google Scholar]

- Das, J. Passive filters-potentialities and limitations. IEEE Trans. Ind. Appl. 2004, 40, 232–241. [Google Scholar] [CrossRef]

- Singh, B.; Chandra, A.; Al-Haddad, K. Power Quality: Problems and Mitigation Techniques; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Akagi, H. Active Harmonic Filter. Proc. IEEE 2005, 93, 2128–2138. [Google Scholar] [CrossRef]

- Buła, D.; Zygmanowski, M. Control Strategies Applied to Active Power Filters. Energies 2022, 15, 2408. [Google Scholar] [CrossRef]

- Fuchs, E.F.; Masoum, M.A. Power Quality in Power Systems and Electrical Machines; Academic Press: Cambridge, MA, USA, 2008. [Google Scholar]

- Lin, B.R.; Yang, B.R.; Tsai, H.J. The operation of hybrid active filter for harmonic elimination. In Proceedings of the 4th IEEE International Conference on Power Electronics and Drive Systems. IEEE PEDS 2001-Indonesia. Proceedings (Cat. No. 01TH8594), Denpasar, Indonesia, 25 October 2001; Volume 1, pp. 72–76. [Google Scholar]

- Antunes, H.M.A.; Silva, S.M.; Brandao, D.I.; Machado, A.A.P.; Filho, B.d.J.C. Harmonic compensation using a series hybrid filter in a centralized AC microgrid. J. Control. Autom. Electr. Syst. 2018, 29, 219–229. [Google Scholar] [CrossRef]

- Fujita, H.; Akagi, H. A practical approach to harmonic compensation in power systems-series connection of passive and active filters. IEEE Trans. Ind. Appl. 1991, 27, 1020–1025. [Google Scholar] [CrossRef]

- Chen, Z.; Blaabjerg, F.; Pedersen, J.K. A study of parallel operations of active and passive filters. In Proceedings of the 2002 IEEE 33rd Annual IEEE Power Electronics Specialists Conference. Proceedings (Cat. No. 02CH37289), Cairns, QLD, Australia, 23–27 June 2002; Volume 2, pp. 1021–1026. [Google Scholar]

- Monteiro, L.F.C. Contribuições Para Otimização do Desempenho do Condicionador UPQC (Unified Power Quality Conditioner). PhD Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2008. [Google Scholar]

- Antunes, H.M.A.; Silva, S.M.; Brandao, D.I.; Machado, A.A.P.; de Jesus Cardoso Filho, B. A new multifunctional converter based on a series compensator applied to AC microgrids. Int. J. Electr. Power Energy Syst. 2018, 102, 160–170. [Google Scholar] [CrossRef]

- Rashid, M.H. Power Electronics Handbook; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Miveh, M.R.; Rahmat, M.F.; Ghadimi, A.A.; Mustafa, M.W. Power quality improvement in autonomous microgrids using multi-functional voltage source inverters: A comprehensive review. J. Power Electron. 2015, 15, 1054–1065. [Google Scholar] [CrossRef]

- Asiminoael, L.; Blaabjerg, F.; Hansen, S. Detection is key-Harmonic detection methods for active power filter applications. IEEE Ind. Appl. Mag. 2007, 13, 22–33. [Google Scholar] [CrossRef]

| Technique | Performance | Advantages | Disadvantages | Cost |

|---|---|---|---|---|

| Passive Filters [32,33,34] | Moderate |

|

| Low |

| Active Filters [35,36,37] | High |

|

| High |

| Hybrid Filters [12,18] | High |

|

| Moderate |

| Characteristics | Capacity |

|---|---|

| Power source—34.5 kV | 75 MVA |

| Rolling mils (cycloconverters) | 63 MVA |

| High-pass filter (2.6 HP)—156 Hz | 10 Mvar |

| Band-pass filter (4.08 BP)—244.8 Hz | 10.8 Mvar |

| High-pass filter (6 HP)—360 Hz | 12.5 Mvar |

| High-pass filter (10 HP)—600 Hz | 12.3 Mvar |

| Technique | Series () | Parallel () | Appropriate |

|---|---|---|---|

| 1 | YES | ||

| 2 | NO | ||

| 3 | YES | ||

| 4 | YES | ||

| 5 | NO | ||

| 6 | NO | ||

| 7 | NO | ||

| 8 | YES | ||

| 9 | NO | ||

| 10 | NO | ||

| 11 | NO | ||

| 12 | NO | ||

| 13 | NO | ||

| 14 | NO | ||

| 15 | NO | ||

| 16 | YES |

| Filtering System | Nominal Value (A) | Current (A) |

|---|---|---|

| Passive filter | - | 734.67 |

| High-pass filter —156 Hz (2.6 HP) | 167 | 160.76 |

| Band-pass filter—244.8 Hz (4.08 BP) | 181 | 174.27 |

| High-pass filter—360 Hz (6 HP) | 209 | 203.58 |

| High-pass filter—600 Hz (10 HP) | 206 | 205.91 |

| Filtering System | Nominal (A) | Tec. 1 (A) | Tec. 3 (A) | Tec. 4 (A) | Tec. 8 (A) | Tec. 16 (A) |

|---|---|---|---|---|---|---|

| Passive filter | — | 736.54 | 734.07 | 734.67 | 732.28 | 731.85 |

| High-pass filter—156 Hz | 167 | 160.74 | 160.67 | 160.76 | 160.90 | 160.72 |

| Band-pass filter—244.8 Hz | 181 | 174.97 | 173.98 | 174.27 | 173.58 | 173.63 |

| High-pass filter—360 Hz | 209 | 205.71 | 203.00 | 203.58 | 200.69 | 201.10 |

| High-pass filter—600 Hz | 206 | 210.29 | 205.76 | 205.91 | 198.10 | 198.79 |

| Power active filter series (MVA) | 1.41 | 2.45 | 1.67 | 0.258 | 0.619 | |

| Power parallel active filter (MVA) | 3.38 | 3.38 | 3.57 | 14.30 | 13.80 | |

| Total: () (MVA) | 4.83 | 5.83 | 5.24 | 14.56 | 14.42 | |

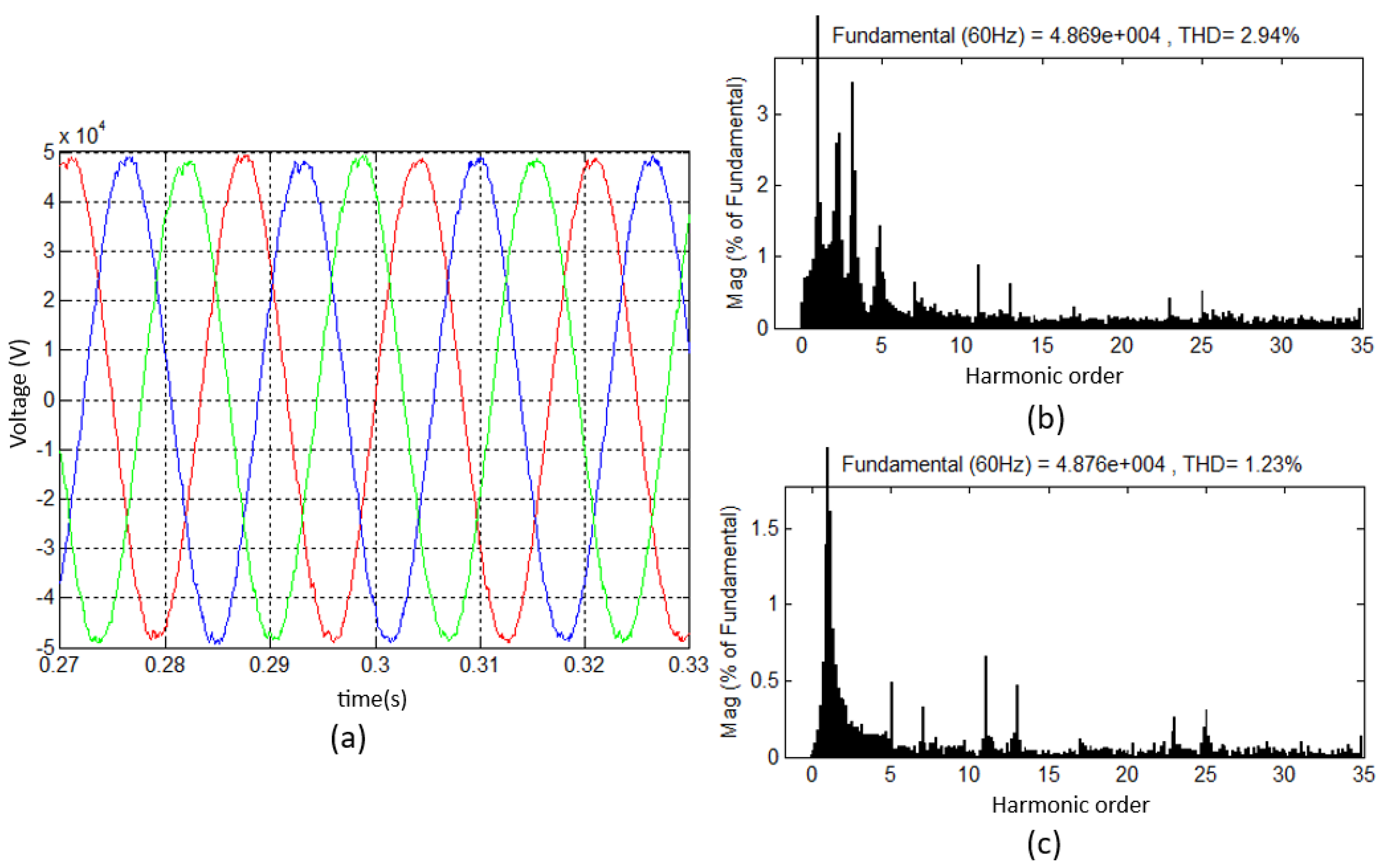

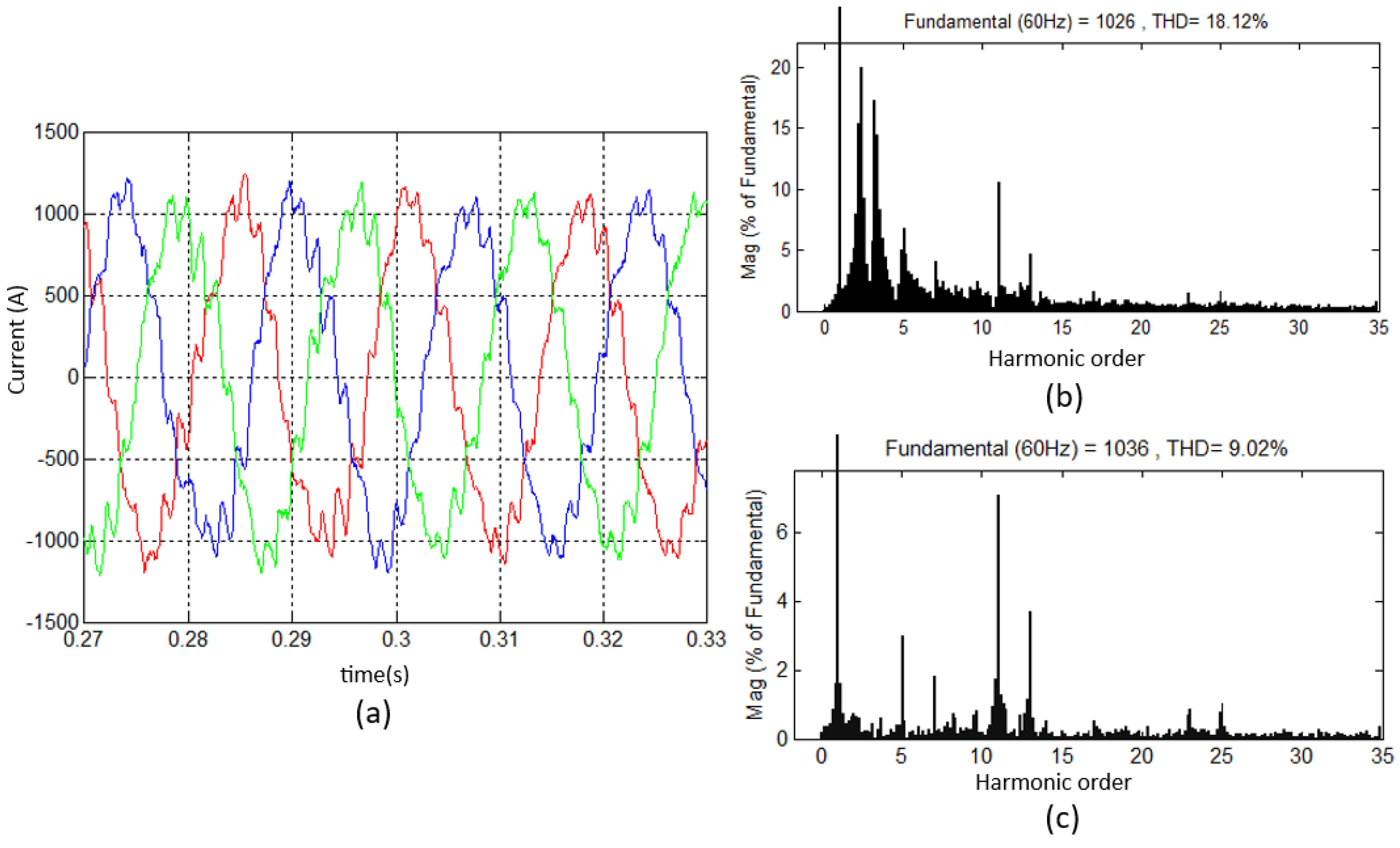

| Topology | PCC Voltage [%] | PCC Current [%] | Passive Filter Current [%] |

|---|---|---|---|

| Passive Filter | 2.94 | 3.01 | 18.12 |

| Tec. 1 | 1.53 | 2.21 | 11.70 |

| Tec. 3 | 1.28 | 1.58 | 9.88 |

| Tec. 4 | 1.23 | 1.78 | 9.02 |

| Tec. 8 | 0.70 | 0.70 | 2.99 |

| Tec. 16 | 0.72 | 0.62 | 2.93 |

| Technique | PCC Voltage Reduction [%] | PCC Current Reduction [%] | Passive Filter Current Reduction [%] |

|---|---|---|---|

| Tec. 1 | 47.96 | 26.58 | 35.42 |

| Tec. 3 | 56.46 | 47.51 | 45.48 |

| Tec. 4 | 58.16 | 40.86 | 50.23 |

| Tec. 8 | 76.19 | 76.08 | 83.49 |

| Tec. 16 | 75.51 | 79.40 | 83.83 |

| Current | Nominal [A] | Back-to-Back [A] | Series [A] | Parallel [A] |

|---|---|---|---|---|

| Passive filter | - | 734.67 | 731.88 | 732.04 |

| High-pass filter—156 Hz | 167 | 160.76 | 159.87 | 160.81 |

| Band-pass filter—244.8 Hz | 181 | 174.27 | 173.27 | 173.56 |

| High-pass filter—360 Hz | 209 | 203.58 | 202.88 | 200.73 |

| High-pass filter—600 Hz | 206 | 205.91 | 209.37 | 198.20 |

| Power active filter series [MVA] | 1.67 | 2.7 | - | |

| Power parallel active filter [MVA] | 3.57 | - | 12.68 | |

| Topology | PCC Voltage [%] | PCC Current [%] | Passive Filter Current [%] |

|---|---|---|---|

| Without hybrid filter | 2.94 | 3.01 | 18.12 |

| Series hybrid filter | 1.39 | 1.68 | 11.86 |

| Parallel hybrid filter | 0.31 | 0.50 | 2.32 |

| Back-to-back hybrid filter | 1.23 | 1.78 | 9.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krause, R.C.K.; Antunes, H.M.A. Application of Back-to-Back Hybrid Filter to a Hot Strip Mill with Cycloconverters. Energies 2024, 17, 6019. https://doi.org/10.3390/en17236019

Krause RCK, Antunes HMA. Application of Back-to-Back Hybrid Filter to a Hot Strip Mill with Cycloconverters. Energies. 2024; 17(23):6019. https://doi.org/10.3390/en17236019

Chicago/Turabian StyleKrause, Rafael Cabral Knaip, and Hélio Marcos André Antunes. 2024. "Application of Back-to-Back Hybrid Filter to a Hot Strip Mill with Cycloconverters" Energies 17, no. 23: 6019. https://doi.org/10.3390/en17236019

APA StyleKrause, R. C. K., & Antunes, H. M. A. (2024). Application of Back-to-Back Hybrid Filter to a Hot Strip Mill with Cycloconverters. Energies, 17(23), 6019. https://doi.org/10.3390/en17236019