Dedicated HVAC Technology in the Renovation of Historic Buildings on the Example of the Marshal Pilsudski Manor in Sulejówek

Abstract

1. Introduction

2. Materials and Methods

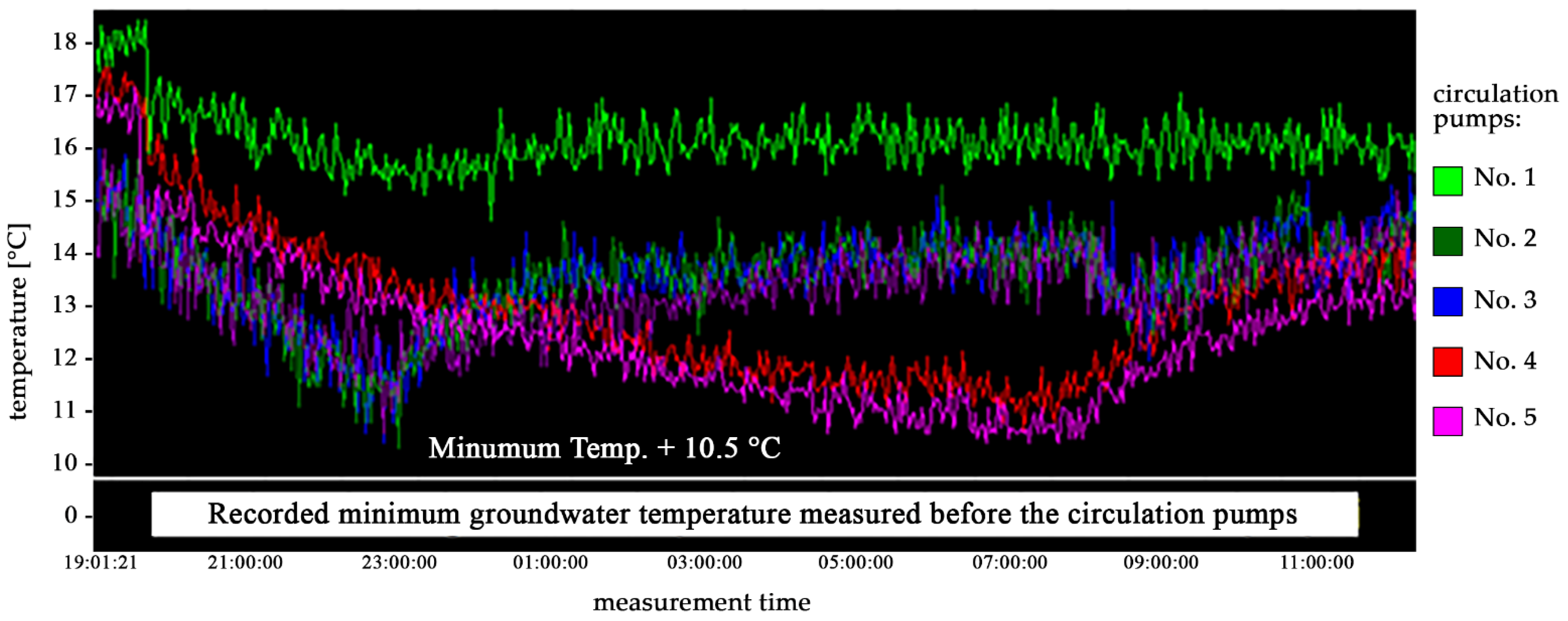

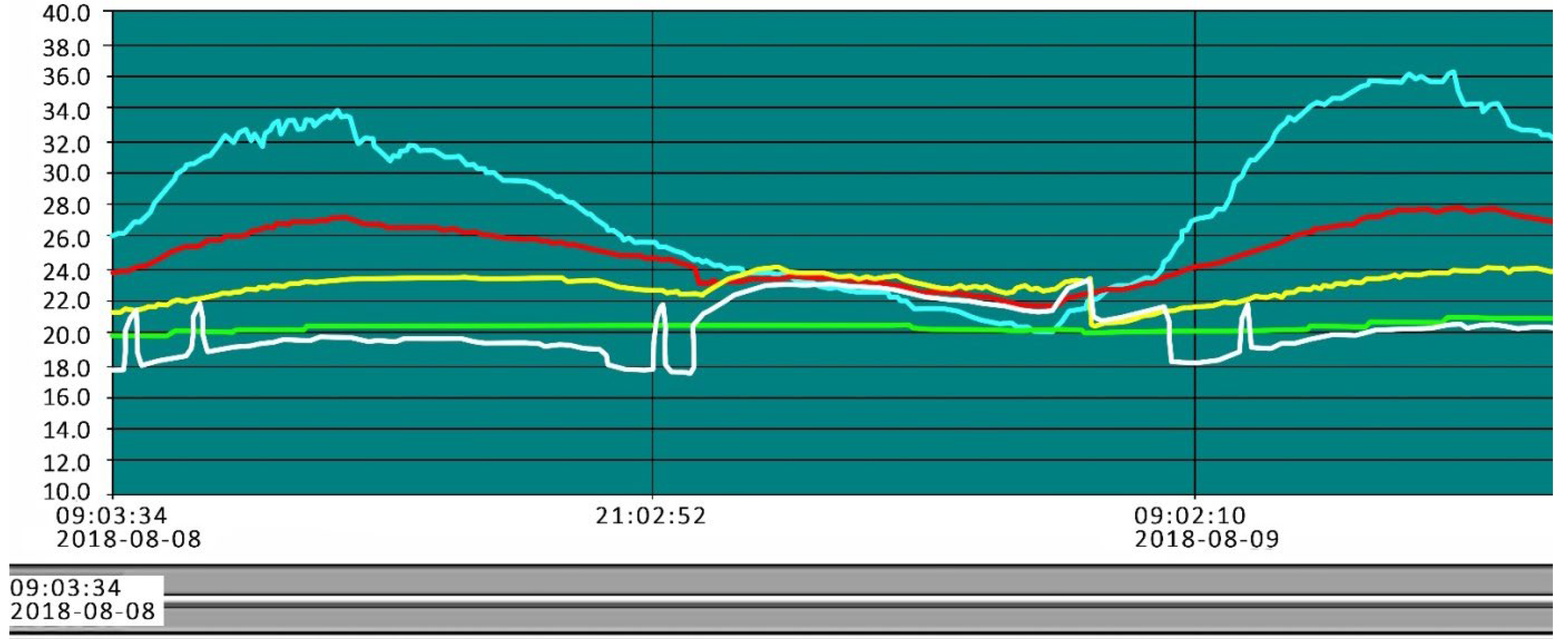

2.1. FCH Technology for Recovery of Groundwater Energy

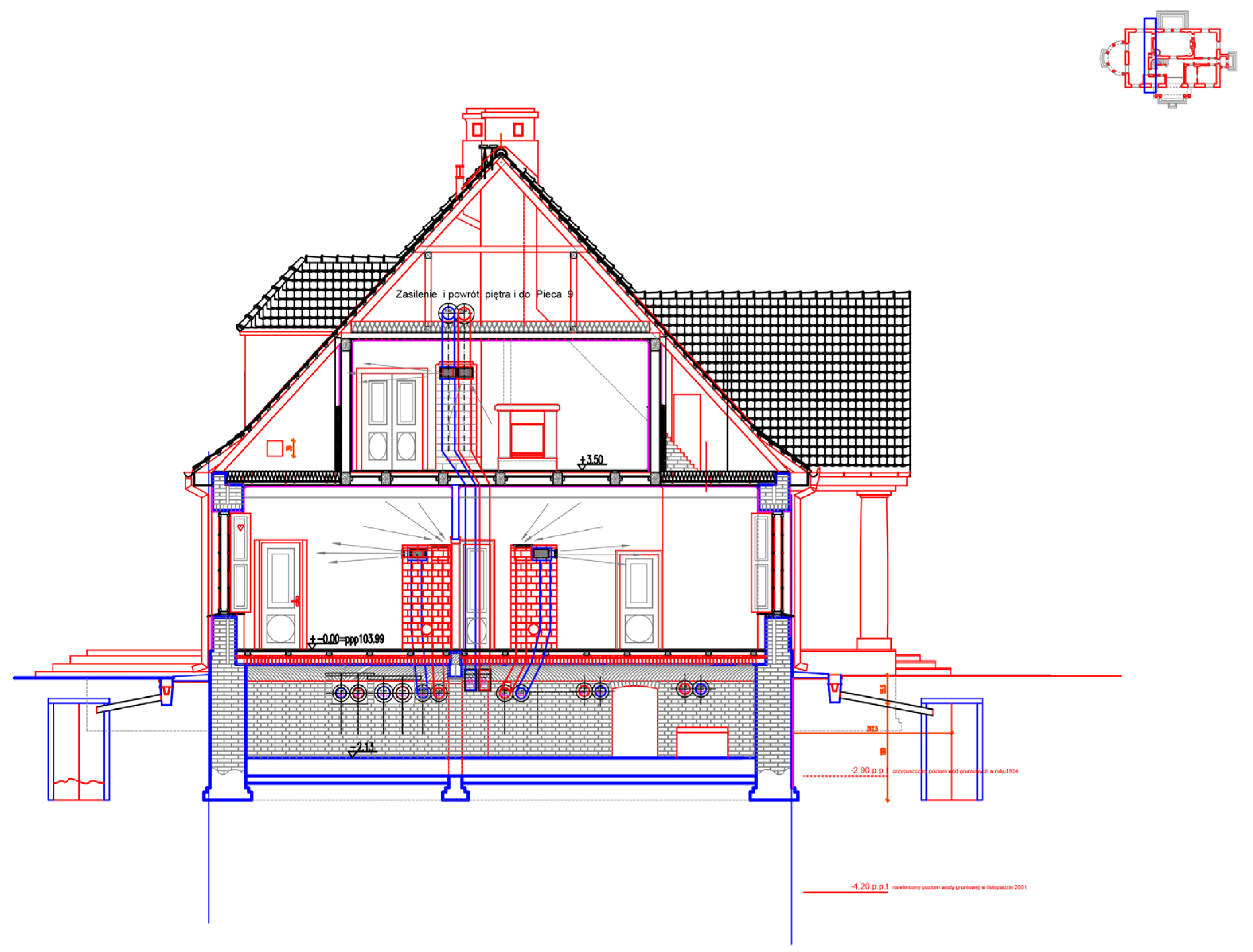

2.2. FCH HVAC Technology Project

3. Results

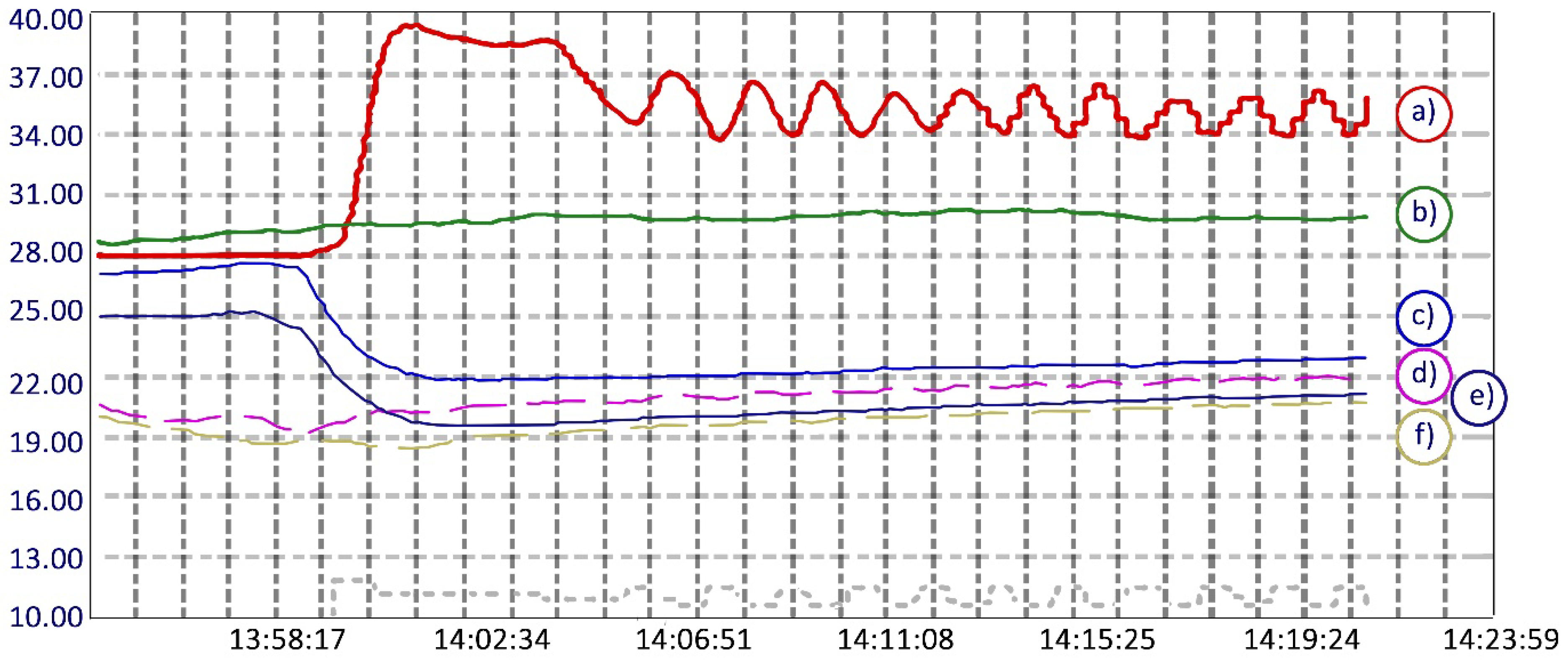

3.1. Expected Results of the FCH HVAC Technology

- V is the volumetric air flow rate m3/s.

- ρ is the air density = 1.2 kg/m3.

- Cp is the specific heat of air = 1.005 kJ/kg·K.

- ∆T is the difference in the air temperature upstream and downstream of the heater (39.80–23.5 °C).

3.2. Financial Aspect of the Use of FCH HVAC

3.3. The Impact of FCH HVAC Technology on Reducing CO2 Emissions

- 1.

- Electricity is at least 50% necessary for the operation of the fans.

- 2.

- Cooling energy that is generated in condensers or AWL in 50%.

- 3.

- Heat energy in the range of 50% to 70%.

- Facility no. 1 (Figure 10): the total cost for the control panel is PLN 218,055.7.

- Facility no. 2 (Figure 11): the total cost for the head office is PLN 179,697.3.

- Facility no. 3 (Figure 12): the total cost for the head office is PLN 77,911.4.

- Lower facility operating costs:

- Lower CO2 emissions:

- Lower heating costs:

- Lower cooling costs:

- Lower fan operating costs:

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tagliapietra, S.; Zachmann, G.; Edenhofer, O.; Glachant, J.-M.; Linares, P.; Loeschel, A. The European Union Energy Transition: Key Priorities for the next Five Years. Energy Policy 2019, 132, 950–954. [Google Scholar] [CrossRef]

- Lowe, R. Policy and Strategy Challenges for Climate Change and Building Stocks. Build. Res. Inf. 2009, 37, 206–212. [Google Scholar] [CrossRef]

- European Union. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC Text with EEA Relevance; European Union: Brussels, Belgium, 2012; Volume 315. [Google Scholar]

- Skiba, M.; Bazan-Krzywoszańska, A.; Mrówczyńska, M.; Łączak, A. Economic Conditions for the Development of Energy Efficient Civil Engineering Using RES in the Policy of Cohesion of the European Union (2014–2020). Case Study: The Town of Zielona Gora. Energy Build. 2016, 118, 170–180. [Google Scholar] [CrossRef]

- Egging, R. Drivers, Trends, and Uncertainty in Long-Term Price Projections for Energy Management in Public Buildings. Energy Policy 2013, 62, 617–624. [Google Scholar] [CrossRef]

- Zhu, K.; Victoria, M.; Andresen, G.B.; Greiner, M. Impact of Climatic, Technical and Economic Uncertainties on the Optimal Design of a Coupled Fossil-Free Electricity, Heating and Cooling System in Europe. Appl. Energy 2020, 262, 114500. [Google Scholar] [CrossRef]

- Ferdyn-Grygierek, J.; Grygierek, K. HVAC Control Methods for Drastically Improved Hygrothermal Museum Microclimates in Warm Season. Build. Environ. 2019, 149, 90–99. [Google Scholar] [CrossRef]

- Wrana, J.; Struzik, W.; Gleń, P. Natural Energy Stored in Groundwater Deposits as a New Way of Obtaining Green Energy for Urban Planners, Architects and Environmentalists. Energies 2022, 15, 4716. [Google Scholar] [CrossRef]

- Wrana, J.; Struzik, W.; Kwiatkowski, B.; Gleń, P. Release of Energy from Groundwater/with Reduction in CO2 Emissions of More Than 50% from HVAC in the Extension and Revitalization of the Former Palace of the Sobieski Family in Lublin. Energies 2022, 15, 6627. [Google Scholar] [CrossRef]

- Hou, F.; Ma, J.; Kwok, H.H.L.; Cheng, J.C.P. Prediction and Optimization of Thermal Comfort, IAQ and Energy Consumption of Typical Air-Conditioned Rooms Based on a Hybrid Prediction Model. Build. Environ. 2022, 225, 109576. [Google Scholar] [CrossRef]

- Wrana, J.; Struzik, W. Research for Achieving High Quality Air in Architecture and Urban Planning on the Example of the Educational and Sports Center in Józefów near Warsaw, Poland. In Current Perspectives and New Directions in Mechanics, Modelling and Design of Structural Systems; CRC Press: Boca Raton, FL, USA, 2022; ISBN 978-1-00-334845-0. [Google Scholar]

- Cramton, P.; Kerr, S. Tradeable Carbon Permit Auctions: How and Why to Auction Not Grandfather. Energy Policy 2002, 30, 333–345. [Google Scholar] [CrossRef]

- Jaan, S. ReFuelEU Aviation Initiative: Sustainable Aviation Fuels and the Fit for 55 Package; European Parliamentary Research Service: Brussels, Belgium, 2022. [Google Scholar]

- Parker, L. Carbon Tax and Greenhouse Gas Control: Options and Considerations for Congress; Library of Congress: Washington, DC, USA, 2009. [Google Scholar]

- Thisted, E.V.; Thisted, R.V. The Diffusion of Carbon Taxes and Emission Trading Schemes: The Emerging Norm of Carbon Pricing. Environ. Politics 2020, 29, 804–824. [Google Scholar] [CrossRef]

- PBL Trends in Global CO2 and Total Greenhouse Gas Emissions; 2020 Report. Available online: https://www.pbl.nl/en/publications/trends-in-global-co2-and-total-greenhouse-gas-emissions-2020-report (accessed on 21 June 2022).

- Rutz, D.; Ball, I.; Di Costanzo, B.; Janssen, R.; Tretter, H.; Knaus, K.; Drexlmeier, S.; Baumann, C.; Puente, F.; Šegon, V.; et al. An Urgent Call for the Phase-out of Fossil Space Heating Systems and for the Support of Renewables in the Heating Sector; ETA-Florence Renewable Energies: Florence, Italy, 2020; pp. 930–932. [Google Scholar]

- Bao, Y.; Bing, S.; Fu, X.; Anbang, L.; Kehua, L.; Shen, L.; Rui, Y.; Qiuzhuang, L.; Ao, L.; Yuanyang, L.; et al. Energy-Oriented Control Retrofit for Existing HVAC System Adopting Data-Driven MPC—Methodology, Implementation and Field Test. Energy Build. 2023, 295, 113286. [Google Scholar] [CrossRef]

- Coma, J.; Maldonado, J.M.; de Gracia, A.; Gimbernat, T.; Botargues, T.; Cabeza, L.F. Comparative Analysis of Energy Demand and CO2 Emissions on Different Typologies of Residential Buildings in Europe. Energies 2019, 12, 2436. [Google Scholar] [CrossRef]

- Pachano, J.E.; Fernández-Vigil Iglesias, M.; Saiz, J.C.; Fernández Bandera, C. Two-Stage Multi-Step Energy Model Calibration of the Cooling Systems of a Large-Space Commercial Building. Appl. Therm. Eng. 2023, 230, 120638. [Google Scholar] [CrossRef]

- Abualigah, L.; Zitar, R.A.; Almotairi, K.H.; Hussein, A.M.; Abd Elaziz, M.; Nikoo, M.R.; Gandomi, A.H. Wind, Solar, and Photovoltaic Renewable Energy Systems with and without Energy Storage Optimization: A Survey of Advanced Machine Learning and Deep Learning Techniques. Energies 2022, 15, 578. [Google Scholar] [CrossRef]

- Mitali, J.; Dhinakaran, S.; Mohamad, A.A. Energy Storage Systems: A Review. Energy Storage Sav. 2022, 1, 166–216. [Google Scholar] [CrossRef]

- Stemmle, R.; Blum, P.; Schüppler, S.; Fleuchaus, P.; Limoges, M.; Bayer, P.; Menberg, K. Environmental Impacts of Aquifer Thermal Energy Storage (ATES). Renew. Sustain. Energy Rev. 2021, 151, 111560. [Google Scholar] [CrossRef]

- Salat, S. Energy Loads, CO2 Emissions and Building Stocks: Morphologies, Typologies, Energy Systems and Behaviour. Build. Res. Inf. 2009, 37, 598–609. [Google Scholar] [CrossRef]

- Rodrigues, E.; Fernandes, M.S.; Carvalho, D. Future Weather Generator for Building Performance Research: An Open-Source Morphing Tool and an Application. Build. Environ. 2023, 233, 110104. [Google Scholar] [CrossRef]

- Shook, P.; Choi, J.-K.; Kissock, K. Analyzing the Multiscale Impacts of Implementing Energy-Efficient HVAC Improvements Through Energy Audits and Economic Input–Output Analysis. J. Energy Resour. Technol. 2022, 145, 1–20. [Google Scholar] [CrossRef]

- Skoczkowski, T.; Bielecki, S. Efektywność energetyczna—Polityczno-formalne uwarunkowania rozwoju w Polsce i Unii Europejskiej. Polityka Energetyczna / Energy Policy J. 2016, 19, 5–20. [Google Scholar]

- Maroufmashat, A.; Fowler, M. Transition of Future Energy System Infrastructure; through Power-to-Gas Pathways. Energies 2017, 10, 1089. [Google Scholar] [CrossRef]

- Zhang, X.; Chan, S.H.; Ho, H.K.; Tan, S.-C.; Li, M.; Li, G.; Li, J.; Feng, Z. Towards a Smart Energy Network: The Roles of Fuel/Electrolysis Cells and Technological Perspectives. Int. J. Hydrogen Energy 2015, 40, 6866–6919. [Google Scholar] [CrossRef]

- Zerefos, S.C.; Tessas, C.A.; Kotsiopoulos, A.M.; Founda, D.; Kokkini, A. The Role of Building Form in Energy Consumption: The Case of a Prismatic Building in Athens. Energy Build. 2012, 48, 97–102. [Google Scholar] [CrossRef]

- Dolšak, J. Determinants of Energy Efficient Retrofits in Residential Sector: A Comprehensive Analysis. Energy Build. 2023, 282, 112801. [Google Scholar] [CrossRef]

- Filippín, C.; Ricard, F.; Flores Larsen, S. Evaluation of Heating Energy Consumption Patterns in the Residential Building Sector Using Stepwise Selection and Multivariate Analysis. Energy Build. 2013, 66, 571–581. [Google Scholar] [CrossRef]

- Qin, H.; Yu, Z.; Li, T.; Liu, X.; Li, L. Energy-Efficient Heating Control for Nearly Zero Energy Residential Buildings with Deep Reinforcement Learning. Energy 2023, 264, 126209. [Google Scholar] [CrossRef]

- Aksoezen, M.; Daniel, M.; Hassler, U.; Kohler, N. Building Age as an Indicator for Energy Consumption. Energy Build. 2015, 87, 74–86. [Google Scholar] [CrossRef]

- Rey-Hernández, J.M.; San José-Alonso, J.F.; Velasco-Gómez, E.; Yousif, C.; Rey-Martínez, F.J. Performance Analysis of a Hybrid Ventilation System in a near Zero Energy Building. Build. Environ. 2020, 185, 107265. [Google Scholar] [CrossRef]

- Struzik, W. Air handling unit with the system forcing the air circulation in the rooms ventilation and air conditioning in various climate conditions . 2015. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.415163?lng=pl (accessed on 15 November 2024).

- Struzik, W. Arrangement of Devices for Obtaining Hot Water from the Underground Water Installation for the Air Conditioning and Ventilation Equipment. 2015. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.425437?lng=pl (accessed on 15 November 2024).

- Struzik, W. System of Devices for Acquiring Hot Water from the Underground Water System Intended for the Air Conditioning and Ventilation Equipment. 2013. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.406309?lng=pl (accessed on 15 November 2024).

- Struzik, W. System Equipment to Obtain Ice Water from the Ground Water System for Air Conditioning, Refrigeration. 2012. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.398322?lng=pl (accessed on 15 November 2024).

- Lande, E.J.; Ritter, S.; Karlsrud, K.; Nordal, S. Understanding Effects from Overburden Drilling of Piles—A Rational Approach to Reduce the Impacts on the Surroundings. Can. Geotech. J. 2024, 61, 2206–2222. [Google Scholar] [CrossRef]

- Asadimehr, S. Examining Drilling Problems and Practical Solutions Regarding Them. Eurasian J. Chem. Med. Pet. Res. 2024, 3, 552–562. [Google Scholar]

- Capuano, L.E., Jr. 5—Geothermal Well Drilling. In Geothermal Power Generation, 2nd ed.; DiPippo, R., Gutiérrez-Negrín, L.C.A., Chiasson, A., Eds.; Woodhead Publishing Series in Energy; Elsevier: Amsterdam, The Netherlands, 2024; pp. 125–158. ISBN 978-0-443-24750-7. [Google Scholar]

- Ghanitoos, H.; Goharimanesh, M.; Akbari, A. Prediction of Drill Penetration Rate in Drilling Oil Wells Using Mathematical and Neurofuzzy Modeling Methods. Energy Rep. 2024, 11, 145–152. [Google Scholar] [CrossRef]

- Al-Waked, R.; Nasif, M.S.; Groenhout, N.; Partridge, L. Energy Performance and CO2 Emissions of HVAC Systems in Commercial Buildings. Buildings 2017, 7, 84. [Google Scholar] [CrossRef]

- Verma, V.; Meena, C.S.; Thangavel, S.; Kumar, A.; Choudhary, T.; Dwivedi, G. Ground and Solar Assisted Heat Pump Systems for Space Heating and Cooling Applications in the Northern Region of India—A Study on Energy and CO2 Saving Potential. Sustain. Energy Technol. Assess. 2023, 59, 103405. [Google Scholar] [CrossRef]

- Obiuto, N.C.; Ebirim, W.; Ninduwezuor-Ehiobu, N.; Ani, E.C.; Olu-lawal, K.A.; Ugwuanyi, E.D. Integrating Sustainability Into HVAC Project Management: Challenges and Opportunities. Eng. Sci. Technol. J. 2024, 5, 873–887. [Google Scholar] [CrossRef]

- Ebirim, W.; Olu-lawal, K.A.; Ninduwezuor-Ehiobu, N.; Montero, D.J.P.; Usman, F.O.; Ani, E.C. Leveraging Project Management Tools for Energy Efficiency in HVAC Operations: A Path to Climate Resilience. Eng. Sci. Technol. J. 2024, 5, 653–661. [Google Scholar] [CrossRef]

- Karimi, H.; Adibhesami, M.A.; Bazazzadeh, H.; Movafagh, S. Green Buildings: Human-Centered and Energy Efficiency Optimization Strategies. Energies 2023, 16, 3681. [Google Scholar] [CrossRef]

- Ebirim, W.; Usman, F.O.; Montero, D.J.P.; Ninduwezuor-Ehiobu, N.; Ani, E.C.; Olu-lawal, K.A. Assessing the Impact of Climate Change on HVAC System Design and Project Management. Int. J. Appl. Res. Soc. Sci. 2024, 6, 173–184. [Google Scholar] [CrossRef]

- Yildiz, O.F.; Yilmaz, M.; Celik, A. Reduction of Energy Consumption and CO2 Emissions of HVAC System in Airport Terminal Buildings. Build. Environ. 2022, 208, 108632. [Google Scholar] [CrossRef]

- Farouk, N.; El-Rahman, M.A.; Sharifpur, M.; Guo, W. Assessment of CO2 Emissions Associated with HVAC System in Buildings Equipped with Phase Change Materials. J. Build. Eng. 2022, 51, 104236. [Google Scholar] [CrossRef]

- Pylsy, P.; Lylykangas, K.; Kurnitski, J. Buildings’ Energy Efficiency Measures Effect on CO2 Emissions in Combined Heating, Cooling and Electricity Production. Renew. Sustain. Energy Rev. 2020, 134, 110299. [Google Scholar] [CrossRef]

- Khadra, A.; Akander, J.; Myhren, J.A. Greenhouse Gas Payback Time of Different HVAC Systems in the Renovation of Nordic District-Heated Multifamily Buildings Considering Future Energy Production Scenarios. Buildings 2024, 14, 413. [Google Scholar] [CrossRef]

| Parameter | Traditional Ground Water Heat Pump a | FCH Installations b |

|---|---|---|

| Installation power | 3.3 MW | 3.0 MW |

| Number of boreholes | 825 set | 285 set |

| Depth of boreholes | 100 m | 20 m |

| Cost of drilling | EUR 1,968,085 | EUR 147,606 |

| Electric energy consumption | 855 kWh | 0 kWh |

| Electricity consumption distribution | 100 kWh | 100 kWh |

| Total electric energy consumption | 955 kWh | 100 kWh |

| Cost of pumps | EUR 404,255 | EUR 21,276 |

| Coefficient of performance | 3.85 | 20 |

| Investment cost c | EUR 2,372,340 | EUR 425,532 |

| Operation cost | 20 EUR/m2/year | 3.0 EUR/m2/year |

| Carbon footprint d | 100% | 20% |

| Object | Cubic Capacity [m2] | FCH [EUR] * | Traditional [EUR] |

|---|---|---|---|

| Marshal Piłsudski Museum | 500 | 6.1 | 15.2 |

| Palace in Radzyń Podlaski | 1800 | 6.7 | 16.9 |

| Palace in Lublin | 5585 | 6.5 | 16.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gleń, P.; Wrana, J.; Struzik, W.; Jaromin-Gleń, K. Dedicated HVAC Technology in the Renovation of Historic Buildings on the Example of the Marshal Pilsudski Manor in Sulejówek. Energies 2024, 17, 5946. https://doi.org/10.3390/en17235946

Gleń P, Wrana J, Struzik W, Jaromin-Gleń K. Dedicated HVAC Technology in the Renovation of Historic Buildings on the Example of the Marshal Pilsudski Manor in Sulejówek. Energies. 2024; 17(23):5946. https://doi.org/10.3390/en17235946

Chicago/Turabian StyleGleń, Piotr, Jan Wrana, Wojciech Struzik, and Katarzyna Jaromin-Gleń. 2024. "Dedicated HVAC Technology in the Renovation of Historic Buildings on the Example of the Marshal Pilsudski Manor in Sulejówek" Energies 17, no. 23: 5946. https://doi.org/10.3390/en17235946

APA StyleGleń, P., Wrana, J., Struzik, W., & Jaromin-Gleń, K. (2024). Dedicated HVAC Technology in the Renovation of Historic Buildings on the Example of the Marshal Pilsudski Manor in Sulejówek. Energies, 17(23), 5946. https://doi.org/10.3390/en17235946