Abstract

Currently, the production of sludge in China is on the rise annually, and the co-combustion of sludge with biomass for power and heat generation represents a viable method for the bulk treatment of sludge. In this study, we examined the combustion characteristics of municipal sludge (MS), bagasse (BA), and their blends using thermogravimetric analysis. Orthogonal experiments were conducted to assess the impact of ultrasonic pretreatment on the co-combustion properties of MS and BA. Prior to ultrasonic pretreatment, the combustion of BA was characterized by three distinct stages, while MS exhibited two stages. At a 30% MS ratio, the promotional interaction between BA and MS was most pronounced. Following ultrasonic pretreatment, the combustion of BA was simplified to two stages. With a 10% MS mass ratio, ultrasonic pretreatment enhanced the comprehensive combustion characteristic index, thereby improving the combustion performance of the mixture. The activation energy increased post-pretreatment, particularly when the MS content was 50%. Under the conditions of 45 kHz frequency, 500 W power, 3 h duration, and a 10% MS blending ratio, the mixture displayed reduced mass residue, elevated reaction rates, and superior combustion efficiency. This research aims to introduce a novel approach to the harmless disposal, volume reduction, and resourceful utilization of sludge.

1. Introduction

MS is the by-product resulting from the treatment of domestic sewage or household wastewater at sewage treatment facilities. It consists of a diverse mixture of floatables and sediments. MS is an extremely complex blend containing heavy metal elements, organic contaminants, and nitrogen and phosphorus compounds. If not properly managed, it has the potential to cause both water and air pollution [1,2]. In addition, MS also contains harmful substances, such as microorganisms, parasitic eggs, and pathogenic bacteria, which can affect physical and mental health and food safety [3]. If the sludge is not properly treated, it will seriously harm the natural environment and social environment. Furthermore, by the end of 2021, China’s MS production will be more than 60 million tons [4], and sludge generation will reach 97.72 million tons in 2030 [5]. As such, the safe and efficient treatment of sludge has become an important problem to be solved urgently.

Combustion is a way to treat MS with low pollution and high energy efficiency [6,7,8]. It can not only deal with a large amount of sludge, effectively solving the problem of sludge volume, but also use the heat generated by combustion to achieve multi-level utilization of energy. However, due to the high moisture and ash content and low calorific value of the sludge, it is very difficult to burn sludge alone [9]. To ensure the stability of the sludge combustion treatment process and to obtain more available heat while treating the sludge, it is necessary to add suitable auxiliary solid fuel in the combustion process, such as coal [10,11,12] or biomass [13,14,15], which can effectively dispose of the sludge while also using the heat generated by combustion. Wang et al. [16] conducted a thermogravimetric analysis on the co-combustion of municipal sewage sludge with coal. The sludge was found to enhance the ignition properties, whereas coal contributed to increased reactivity in the high-temperature range and improved the slagging characteristics. Wang et al. [17] examined the co-combustion characteristics of sewage sludge and biomass, demonstrating that the combustion process for sludge, biomass, and their blends can be categorized into three distinct stages: water evaporation, volatile release and combustion, and char combustion. Additionally, their study revealed a synergistic interaction during the combustion of sludge and biomass. Gao et al. [18] investigated the co-combustion characteristics and kinetics of sludge, wood chips, and coal. Through experimental analysis, they determined the optimal blending ratio of wood chips, sludge, and coal for combustion, which yielded the best ignition performance and the highest comprehensive combustion characteristic index (S index).

Sugarcane is mainly planted in tropical and subtropical areas and distributed in more than 100 countries, and China’s sugarcane production ranks third in the world. Sugarcane bagasse is generated during the processing of sugarcane into sugar or ethanol [19]. It is the fraction of biomass composed of the fibrous residue remaining after juice extraction, including crushed stalks and leaves [20]. As BA is a waste material generated during the production of sugar and ethanol, it is readily available at a low cost, and the global production of BA is huge, estimated to be over 700 million tons per year, making it an ideal feedstock for many applications [21]. Also, because of its high volatile content, BA has a high potential to be converted into oxygen-rich fuels. Chen et al. [22] studied the co-combustion characteristic of bagasse and coal by thermogravimetric analysis, finding that compared with the combustion of coal, the co-combustion of bagasse blending with coal had a lower first peak temperature, slightly lower average reaction rate, and higher reaction rate at the first peak.

Pretreatment is commonly employed as a strategy to enhance the combustion properties of biomass [23,24,25]. Pretreatment is used to optimize raw materials by physical, chemical, or microbial means, destroy the connection structure of cellulose–hemicellulose–lignin, remove lignin, and make lignocellulose susceptible to heat. Ultrasonic waves generated by magnetostriction and piezoelectric technology are a kind of mechanical wave with high frequency, short wavelength, good linear propagation, and strong penetration characteristics [26,27]. In the practice of applying ultrasonic pretreatment to biomass macromolecules, it was found that starch, hyaluronic acid, chitosan, and other macromolecules were degraded to varying degrees [28]. Xu et al. [29] studied the influence of ultrasonic pretreatment on the combustion behavior of corn stalks. The activation energy as well as the combustion ignition temperature, could be decreased, which provided better pyrolysis and combustion characteristics.

Therefore, this study delved into the co-combustion characteristics of MS and BA, precisely quantifying the combustion characteristic parameters and kinetic parameters of the mixed samples, and uncovered the interaction mechanism between bagasse and sludge during the combustion process. Building on this foundation, the study innovatively applied ultrasonic technology for the pretreatment of mixed samples, thoroughly investigating the significant impact of different pretreatment conditions on combustion characteristics and kinetic parameters. This research outcome provides a groundbreaking solution for the harmless treatment of harmful substances such as sludge, greatly enhancing the safety levels in both production and daily life and contributing innovative strength to the maintenance of social harmony and stability.

2. Materials and Methods

2.1. Materials

MS and BA were collected from a municipal sewage treatment plant in Guangzhou and a fruit shop near Zhongkai University of Agriculture and Engineering (Baiyun district Zhongluotan town). The raw materials were dried at 105 °C in an air-drying box for 24 h. After being ground and crushed, the sample with a particle size of 178 μm was obtained. The powder samples were sealed and stored in a dryer for subsequent experiments. After drying, the proximate and ultimate analyses of BA and MS were performed according to GB/T 212-2008 [30] and ASTM D5373 [31], respectively, and the results are shown in Table 1. Subsequently, BA and MS were mixed. The corresponding mass ratios of MS were 10%, 30%, and 50%, which were named 90BA10MS, 70BA30MS, and 50BA50MS.

Table 1.

The ultimate and proximate analysis for the BA and MS [26].

2.2. Experimental Facility and Methods

2.2.1. Orthogonal Experimental Design

Orthogonal experimental design is a method of arranging and analyzing multi-factor experiments using orthogonal tables [32]. Its purpose is to replace comprehensive experiments with partial experiments, and by analyzing the results of partial experiments, to understand the situation of comprehensive experiments. This study used an L9(34) orthogonal form, and the results are shown in Table 2. The factors affecting the effect of ultrasonic pretreatment were ultrasonic frequency, ultrasonic power, ultrasonic reaction time, and the mass ratio of MS, represented by A, B, C, and D, respectively. In addition, each factor had three levels: 1, 2, and 3.

Table 2.

The L9(34) orthogonal test.

2.2.2. Experimental Facility

This study used a simultaneous thermal analyzer (METTLER TOLEDO TGA/DSC1) for the thermogravimetry (TG) experiment. The test mass of the sample was set at 5 ± 0.5 mg. The reaction atmosphere was air, with an 80 mL/min flow rate. The heating process was divided into two stages: the drying stage (50–105 °C) and the experimental stage (105–1000 °C), with a heating rate of 40 °C/min.

The ultrasonic pretreatment experiment was performed in a 27 L bath (KQ-500VDV, Kunshan Ultrasonic Instrument Co., Ltd., Shanghai, China). For each treatment, 10 g of the sample was placed in a beaker and immersed in 700 mL of deionized water, stirring constantly. Then, the corresponding frequency, power, and treatment time for orthogonal testing were set. After pretreatment, the sample was air-dried for 48 h and placed in a dry vessel for the TG experiment.

2.3. Data Analysis

To overcome the limitations of using single parameters like initial and burnout temperatures for assessing sample combustion, and to delve into mixture combustion characteristics, this study introduces a comprehensive combustion index (S) for a detailed and overall evaluation of sample combustion behavior. The S can be obtained with Equation (1) [33].

where DTGmax and DTGmean are the maximum and mean weight loss rates during combustion; Ti and Tf are the initial and burnout temperatures, respectively.

For combustion composed of a series of stages, the index S shown in Equation (1) can be rewritten into Equation (2):

where ηi is the mass loss percentage of each step in the total mass loss (%); Si is the index S of each step; S is the index of all steps.

In order to evaluate whether there is interaction between MS and BA and explore the mechanism of interaction, theoretical TG and DTG curves of blends (WT) are calculated with the arithmetically weighted average of a single compound, which is described as Equation (3) [33]:

where αMS and αBA represent the percentage of MS and BA in the blend, and WMS and WBA are the mass loss or mass loss rate of MS and BA in the blend, respectively.

Deviations ΔW between the theoretical (WT) and experimental values (WE) of blends are introduced to further describe the interactions between MS and BA. The calculation formula is shown as Equation (4):

In this paper, the model-free function method was used to analyze the kinetics of combustion. The model-free function method can solve the activation energy without involving the kinetic mechanism function, which can eliminate the influence of the uncertainty of mechanism function on the activation energy solution. The equations of the Coats–Redfern method used in this paper are shown as Equations (5) and (6) [34].

where α is the conversion rate of solid reactants , β is the heating rate, E is the apparent activation energy, A is the apparent prefactor, R is the gas constant, and T is the absolute temperature.

When n ≠ 1, plot and 1/T, and when n = 1, plot and 1/T, a line with a slope of −E/R could be obtained, and then E could be found.

The range analysis method was used to analyze the orthogonal experimental results. The sum of the tests at the m level of the column j factor (i.e., ABCD) is expressed as kjm, i.e., kjm = the average of Kjm/3. The optimal level and combination of column j factors can be determined by the size of the kjm. The range of the j column factor is represented by Rj (Rj = kjmax − kjmin), which reflects the range of experimental indexes when the level of the j column factor fluctuates. The order of the factors can be determined according to the size of Rj. The larger the Rj, the greater the influence of this factor on the experimental index.

3. Results and Discussion

3.1. Co-Combustion Characteristics Before Pretreatment

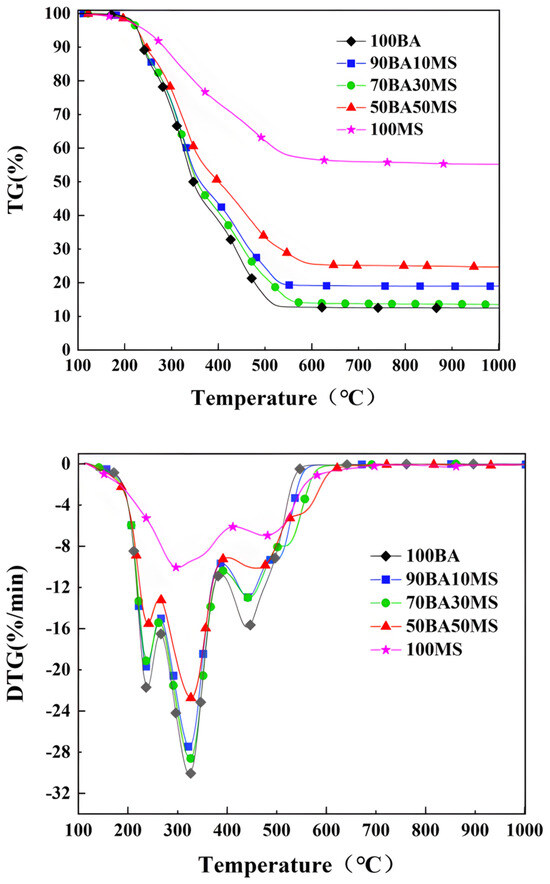

Figure 1 displays the TG and DTG curves for the samples heated at a rate of 40 °C/min, while the corresponding characteristics and parameters are detailed in Table 3. BA’s initial temperature and burnout temperature were 268.8 °C and 568.68 °C, the mass residual rate was 12.47%, and the comprehensive combustion characteristic index (S) was 85.09 × 10−7. It can be seen from Figure 1 that there were three prominent weight loss peaks in the combustion of BA, so the combustion reaction of BA could be divided into three independent stages. The initial stage of combustion occurred within a temperature range of approximately 200–300 °C, predominantly involving the combustion of volatile compounds. This stage contributed to a mass loss of 20.28% of the overall mass loss. The second stage of combustion took place around 300–400 °C. Given that BA is primarily composed of cellulose (approximately 50%), hemicellulose (approximately 30%), and lignin (approximately 15%), along with other trace components, these temperature ranges reflect the thermal degradation profiles of these major constituents [35]. Hence, this stage mainly involved the decomposition of cellulose and hemicellulose. the mass loss accounted for 47.23% of the total mass loss, which accounted for the highest proportion in the three stages. The temperature of the third stage was 400–900 °C, which corresponded to the combustion of lignin and other residues in the sample.

Figure 1.

The TG and DTG curves before pretreatment.

Table 3.

The characteristics parameters before pretreatment.

The initial temperature and burnout temperature of the MS combustion process were 259.3 °C and 647.72 °C, the mass residual rate was 55.10%, and the S was 8.96 × 10−7. Distinct from BA, the combustion of MS was characterized by two distinct stages. The first stage spanned a temperature range of 200–400 °C, during which the volatile components were released and combusted. This phase was marked by the evolution and combustion of volatile gases, including CO2, CO, and a portion of water vapor, driven by heat, leading to a significant loss in the sample’s weight [36]. The second stage of the reaction had a temperature range of 400–900 °C, corresponding to the combustion of fixed carbon and other residues [37]. After BA and MS were mixed, TG and DTG curves of the mixed samples were gradually transferred to the sludge as the proportion of sludge in the mixed samples gradually increased. The characteristic index also decreased from 71.99 × 10−7 to 39.72 × 10−7. Additionally, as depicted in Figure 1, when the MS composition reached 30% of the blend, the combustion curve exhibited a greater similarity to that of the BA sample. This suggested that at this specific ratio, MS and BA may exert a synergistic influence, enhancing the co-combustion process.

3.2. The Interactions Between BA and MS Before Pretreatment

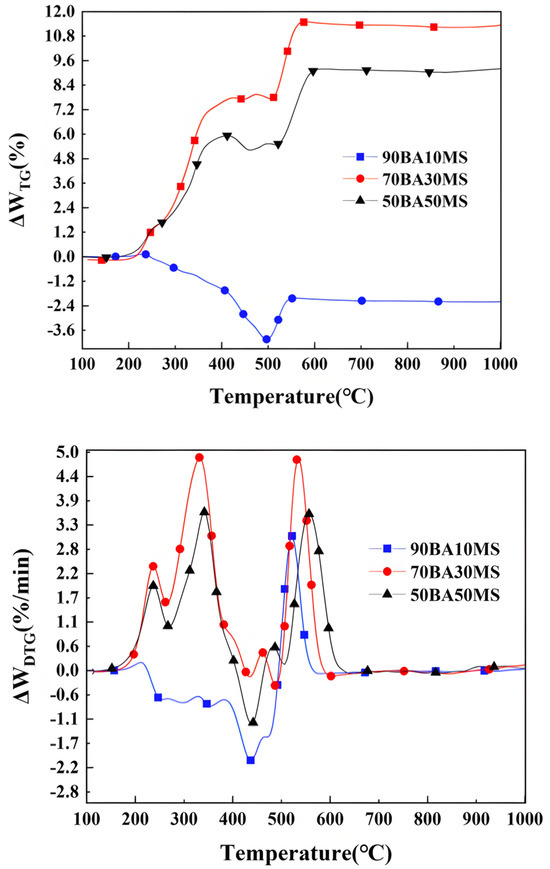

To better observe the synergistic effect between BA and MS, the ΔWTG and ΔWDTG curves of the mixture at a heating rate of 40 °C/min are shown in Figure 2. The data of the TG curve served as a physical metric to assess the extent of completion in the combustion process. A lower residual mass indicates a more thorough combustion reaction. The data of the DTG curve is a physical quantity to measure the intensity of the combustion reaction. The DTG value exists in the form of a negative value, and the greater the weight loss rate, the stronger the reaction. According to Equation (4), when the experimental value falls below the theoretical value, the curve value exceeds zero, signifying a more comprehensive and vigorous combustion of the mixed sample. The blending of BA and MS enhances the combustion reaction. Conversely, if the mixture yields a value less than zero, it suggests an inhibitory effect on the combustion process.

Figure 2.

The ΔWTG and ΔWDTG curves of the mixture.

At mixing ratios of 30% and 50% for MS in the blended sample, the ΔWTG curves lay above the zero line, suggesting that an interaction occurred between BA and MS during the co-combustion process which facilitated the progression of the reaction. It was not difficult to find that when the temperature was below 200 °C, the ΔWTG value was almost close to zero. This was mainly because the ignition temperature of BA and MS was higher than 200 °C, the sample water loss process mainly occurred at this time, and the weight-loss stage and combustion process had not started yet. With the increase in temperature, the ΔWTG value increased continuously, indicating that the interaction of the reaction mainly occurred in the high temperature stage. When the temperature reached 600 °C, the ΔWTG value no longer rose and reached a stable value. Similarly, when the MS ratio was 30% and 50%, the ΔWDTG curves were basically above the zero-point line. There were three peaks on the ΔWDTG curve, corresponding to the temperatures of 220 °C, 330 °C, and 520 °C, respectively, which corresponded to the three stages of the mixed combustion reaction. The second and third stages of the response were more dramatic.

In summary, there was a certain interaction between BA and MS in the process of co-combustion, with the interaction being most pronounced when the MS content was approximately 30%. This was because the MS contained a large number of mineral components, such as calcite, quartz, etc., which could be used as catalysts to promote the combustion reaction [38]. However, upon increasing the sludge ratio to 50%, the high content of inert materials, particularly ash, within the sludge impeded heat conduction and the combustion kinetics, thus diluting the enhancing impact on the combustion process.

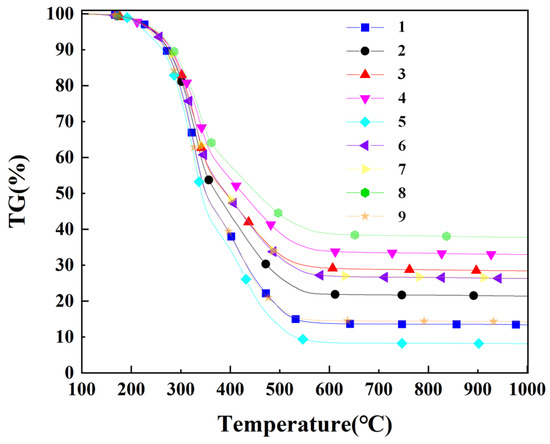

3.3. Co-Combustion Characteristics After Pretreatment

Following ultrasonic pretreatment of the mixed samples, the TG and DTG curves at a heating rate of 40 °C/min are depicted in Figure 3. The associated combustion characteristic parameters are provided in Table 4. After ultrasonic pretreatment, the peak value of the DTG curve presented by the combustion reaction of the mixed sample did not exceed two. That is, the response could be divided into two independent stages. The primary reaction was concentrated in the first reaction stage, so the reaction temperature range could be focused after ultrasonic pretreatment, that is, to promote the mixed combustion reaction. With a 10% concentration of MS, the combustion characteristics were enhanced following ultrasonic pretreatment. This treatment led to a decrease in the mass residual rate, an increase in the maximum weight loss rate, and a more pronounced peak weight loss, surpassing that of 100% BA. Among them, the effect of conditions of 80 kHz, 350 W, and 3 h was the most obvious and the combustion reaction was the most thorough. The mass residual rate was only 8.11%. The maximum weight loss rate was −41.33%, and the index S was 81.61 × 10−7.

Figure 3.

The TG and DTG curves after pretreatment.

Table 4.

The characteristics parameters after pretreatment.

This was mainly related to the characteristics of ultrasonic waves. Ultrasonic waves in the low-frequency stage primarily had a mechanical effect (20–60 kHz), which could form a short bubble. The sonic chemical effect mainly manifested in the high-frequency stage (100–1000 kHz) and stable bubble formation. When the bubble imploded, it ejected violent materials and formed large amounts of energy, which could increase the contact and reaction between the liquid and solid particles [39]. High power could cause a significant cavitation phenomenon and induce a change in biomass structure, significantly impacting ultrasonic treatment results. According to some studies [40,41], soaking a sample in a water bath for 2 h or longer would decrease the biomass’s crystallinity and increase the surface area, thus increasing the likelihood of structural collapse. Furthermore, the lignin–carbohydrate bonding was attenuated, resulting in a decrease in lignin content and an enhancement in cellulose digestibility as the duration of the treatment increased [42]. Therefore, the co-combustion reaction of the sample after ultrasonic pretreatment became more concentrated, faster, and easier.

However, at MS ratios of 30% and 50%, the index S of the samples decreased and the mass residue rate increased after ultrasonic pretreatment. In the case of high sludge content, the formation of cavitation bubbles was weakened, thereby reducing the impact of the ultrasonic waves. Alternatively, when the mixed sample was subjected to ultrasonic pretreatment, the MS was more uniformly dispersed on the surface of the BA and potentially reacted within the BA matrix. At higher sludge concentrations, the combustion performance of the mixed sample decreased.

3.4. Kinetic Analysis Before and After Pretreatment

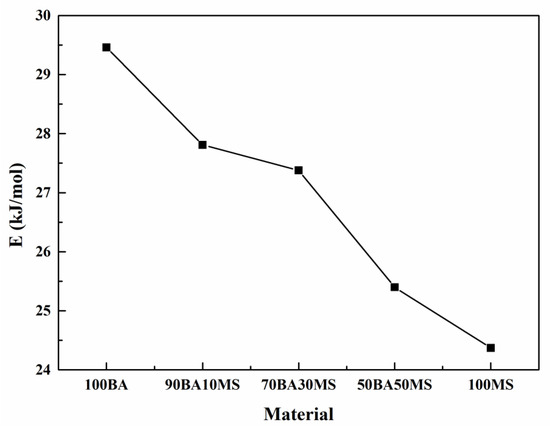

The average activation energy (E) of the sample is shown in Figure 4 and Figure 5, and the correlation coefficients of all samples are greater than 0.99. From Figure 4, it can be seen that the E of BA was 29.46 kJ/mol and the E of MS was 24.37 kJ/mol. The E of BA and MS showed minimal distinction. However, the E of the blended samples exhibited a decline as the proportion of MS increased.

Figure 4.

The activation energy before pretreatment.

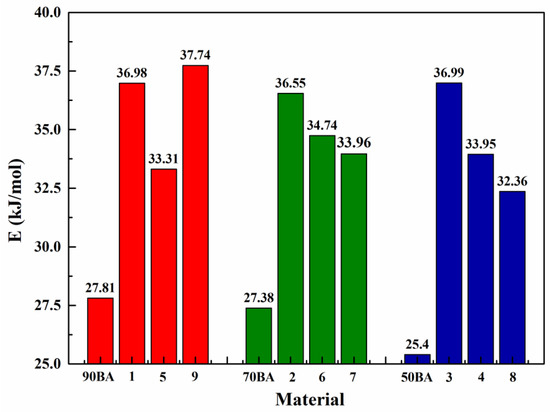

Figure 5.

The activation energy after pretreatment.

As shown in Figure 5, the E after pretreatment was higher than before pretreatment, regardless of the addition ratio. This phenomenon was consistent with research by Zhenyu Wang et al. [43]. This phenomenon could be attributed to the ultrasound-induced disruptions in the bonds between lignin and carbohydrates, as well as damage to certain amorphous carbohydrate linkages. Consequently, the structural regularity of the composite was enhanced [44]. It might also be that the alkali metals in the ash were removed by ultrasonic treatment, which reduced the catalytic effect [28].

After pretreatment, the increase rage of E became large when the MS proportion increased, especially for sample 50BA50MS. The E increased from 25.4 kJ/mol to 36.99 kJ/mol. This might be because after pretreatment, non-combustible substances such as ash and inorganic substances contained in the sludge were more evenly covered on the surface of the sample, hindering the transfer of heat and increasing the difficulty of sample combustion. Under different mixing ratios, samples 5, 7, and 8 had the lowest E values, which were 33.31 kJ/mol, 33.96 kJ/mol, and 32.36 kJ/mol, respectively. According to the experimental conditions of 5, 7, and 8, it can be seen that high frequency and low power could give the sample a relatively low E of mixed samples.

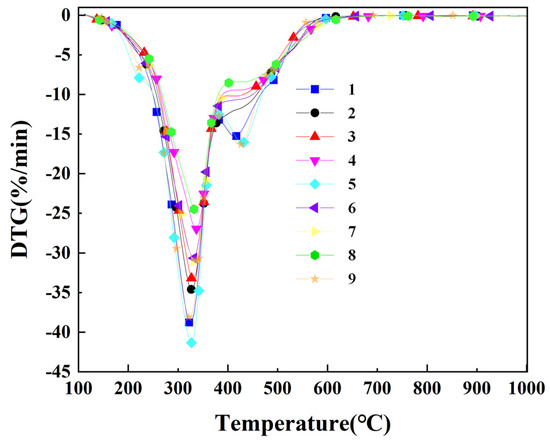

3.5. Orthogonal Analysis

The mass residual rate (Mf), the mass loss rate of the first step (DTG1), and the comprehensive combustion characteristic index (S) were analyzed by the range analysis method, and the results are listed in Table 5.

Table 5.

The orthogonal analysis results for the Mf, DTG1, and S.

Given that the residual mass served as an indicator of the reaction’s completeness, our objective was to minimize the mass residual rate to ensure a more exhaustive combustion process. From Table 5, kA1, kB3, kC3, and kD1 had the minimum values. Hence, under working conditions of 45 kHz, 500 W, 3 h, and 10% MS mixing ratio, the mixed sample burned the most thoroughly. The frequency, power, reaction time, and mixing ratio had R values of 5.09, 3.18, 4.81, and 21.14, respectively. Therefore, the four influencing factors on the mass residual rate in order from weak to strong were as follows: power, reaction time, frequency, and MS mixing ratio. The DTG1 was the maximum rate in this combustion reaction, which is a physical quantity used to measure the intensity of the reaction, so that under the condition 45 kHz, 500 W, 3 h, and 10% MS mixing ratio, the combustion reaction of the mixed sample was the most intense. The order of the influence of four factors from weak to strong was: as follows power, reaction time, frequency, and MS mixing ratio. The S value served as an indicator of the overall combustion capacity. A higher S value corresponded to superior combustion performance of the sample, suggesting a more facile combustion process. It could be seen that the order of the four influencing factors on S from weak to strong was as follows: frequency, power, reaction time, and MS mixing ratio. The best condition was 45 kHz, 500 W, 3 h, and a 10% MS mixing ratio.

It can be seen that the best experimental condition was consistent for these three parameters. High frequencies might cause cavitation bubbles to have insufficient time to expand, compress, and collapse. The cavitation bubbles entered the next stage of expansion before collapsing, resulting in a low cavitation incidence and intensity and a low crack rate of the samples [26]. Higher power levels supplied additional energy, enhancing the thermal impact of the ultrasound. An extended pretreatment reaction time could decrease the sample’s crystallinity and disrupt its structure. Consequently, low frequency, high power, and more reaction time could promote a faster, more thorough, and easier combustion reaction for mixing samples.

4. Conclusions

This study delved into the co-combustion characteristics of MS and BA, accurately quantified the combustion characteristic parameters and kinetic parameters of mixed samples, and revealed the interaction mechanism between bagasse and sludge during the combustion process. On this basis, this study innovatively applied ultrasonic technology for the pretreatment of mixed samples and thoroughly investigated the significant impact of different pretreatment conditions on combustion characteristics and kinetic parameters.

The combustion of BA could be divided into three distinct stages, while MS only exhibited two stages. When MS and BA were mixed and combusted in different proportions, the TG/DTG curves and activation energy of the mixed samples were generally between those of the individual BA and MS samples. It was particularly noteworthy that when the ratio of BA to MS was 7:3, the trend of curve changes in the mixed samples was very similar to that of BA, and the interaction (promotion) between the two was most evident at this ratio. At a spectrometric ratio of 10%, ultrasonic pretreatment significantly enhanced the comprehensive combustion characteristic indicators of the mixed samples, thereby improving their combustion performance. However, as the proportion of sludge increased, the positive impact of ultrasonic pretreatment on combustion performance gradually diminished. After pretreatment, the activation energy increased. Under the optimal conditions of 45 kHz frequency, 500 W power, 3 h of treatment time, and a 10% MS mixing ratio, the mass residue of the mixed samples was reduced, the reaction rate was increased, and the combustion performance was significantly improved.

Future research plans will include mixing lignin, cellulose, and hemicellulose with sludge in different proportions to construct a database for the combustion treatment of sludge-mixed biomass, providing a solid theoretical foundation for the harmless treatment of sludge and other harmful substances.

Author Contributions

Formal analysis, L.Z.; Investigation, Z.X.; Resources, P.L.; Data curation, L.W. and L.C.; Writing—original draft, S.F. and W.L.; Writing—review & editing, S.F., S.C. and Z.X.; Supervision, S.C.; Project administration, P.L. All authors have read and agreed to the published version of the manuscript.

Funding

The National Natural Science Foundation of China (52106285), the Foundation and Applied Foundation Research of Guangdong Province (2023A1515011930), Guangzhou Science and Technology Program Young Doctor Starting Project (SL2023A04J01233), and Guangdong Province key construction discipline research ability improvement project (2022ZDJS024), as well as support from Guangdong Province Key Laboratory of Efficient and Clean Energy Utilization, South China University of Technology (2013A061401005).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China, the Foundation and Applied Foundation Research of Guangdong Province, Guangzhou Science and Technology Program Young Doctor Starting Project, and Guangdong Province key construction discipline research ability improvement project, as well as support from Guangdong Province Key Laboratory of Efficient and Clean Energy Utilization, South China University of Technology.

Conflicts of Interest

Author Luyou Chen was employed by the company Shenzhen Zenergy Co., Ltd. Author Pengfei Lei was employed by the company Guangdong Fennick Energy saving Equipment Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Bin Anwar, T.; Behrose, B.; Ahmed, S. Utilization of textile sludge and public health risk assessment in Bangladesh. Sustain. Environ. Res. 2018, 28, 228–233. [Google Scholar] [CrossRef]

- Zhou, A.; Yu, S.; Deng, S.; Mikulčić, H.; Tan, H.; Wang, X. Enrichment characteristics and environmental risk assessment of heavy metals in municipal sludge pyrolysis biochar. J. Energy Inst. 2023, 111, 101417. [Google Scholar] [CrossRef]

- Jiang, G.; Xu, D.; Hao, B.; Liu, L.; Wang, S.; Wu, Z. Thermochemical methods for the treatment of municipal sludge. J. Clean. Prod. 2021, 311, 127811. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Statistical Yearbook; China Statistics Press: Beijing, China, 2019. [Google Scholar]

- Xu, T.; Wang, C.; Hong, D.; Li, S.; Yue, S. The synergistic effect during co-combustion of municipal sludge and coal: Experimental and ReaxFF molecular dynamic study. Energy 2023, 262, 125553. [Google Scholar] [CrossRef]

- Li, T.; Duan, Y.; Wang, Y.; Zhou, M.; Duan, L. Research progress of ammonia combustion toward low carbon energy. Fuel Process. Technol. 2023, 248, 107821. [Google Scholar] [CrossRef]

- Han, H.; Du, K.; An, X.; Song, Y.; Zhao, Z.; Xu, J.; Jiang, L.; Wang, G.; Wang, Y.; Su, S.; et al. Migration and transformation of trace elements during sewage sludge and coal slime Co-combustion. Chemosphere 2023, 345, 140342. [Google Scholar] [CrossRef]

- Verma, S.; Kumar, M.; Kaur, R.; Kumar, P.; Sillanpää, M.; Štangar, U.L. Comprehensive study of the kinetics of combustion and pyrolysis of petrochemical sludge: Experimentation and application of artificial neural network. J. Anal. Appl. Pyrolysis 2023, 174, 106140. [Google Scholar] [CrossRef]

- Lin, Y.; Liao, Y.; Yu, Z.; Fang, S.; Ma, X. The investigation of co-combustion of sewage sludge and oil shale using thermogravimetric analysis. Thermochim. Acta 2017, 653, 71–78. [Google Scholar] [CrossRef]

- Wei, D.; An, D.; Wang, T.; Zhang, H.; Guo, Y.; Sun, B. Influence of fuel distribution on co-combustion of sludge and coal in a 660 MW tangentially fired boiler. Appl. Therm. Eng. 2023, 227, 120344. [Google Scholar] [CrossRef]

- Wu, W.; Duan, L.; Duan, Y.; Li, L.; Liu, D.; Pallarès, D. Three-dimensional full-loop numerical simulation of coal and sludge co-combustion in a circulating fluidized bed. Fuel 2023, 337, 127235. [Google Scholar] [CrossRef]

- Ji, X.; Yang, Q.; Huang, X.; Wei, D.; Wang, T.; Sun, B. Combustion characteristics and NOx release of sludge combustion with coal in a 660 MW boiler. Appl. Therm. Eng. 2025, 258, 124749. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.I. An investigation of co-combustion municipal sewage sludge with biomass in a 20kW BFB combustor under air-fired and oxygen-enriched condition. Waste Manag. 2017, 70, 114–126. [Google Scholar] [CrossRef] [PubMed]

- Pio, D.; Tarelho, L.; Nunes, T.; Baptista, M.; Matos, M. Co-combustion of residual forest biomass and sludge in a pilot-scale bubbling fluidized bed. J. Clean. Prod. 2020, 249, 119309. [Google Scholar] [CrossRef]

- Iordanidis, A.; Asvesta, A.; Vasileiadou, A. Combustion behaviour of different types of solid wastes and thier blends with lignite. Therm. Sci. 2019, 22, 1077–1088. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, L.; Guo, J.; Wang, B.; Zhang, L.; Xiang, J.; Jin, Y. Thermogravimetric analysis of co-combustion between municipal sewage sludge and coal slime: Combustion characteristics, interaction and kinetics. Thermochim. Acta 2021, 706, 179056. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Yang, W.; Zhao, Q.; Dai, Y. Evaluation of combustion properties and pollutant emission characteristics of blends of sewage sludge and biomass. Sci. Total Environ. 2020, 720, 137365. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, H.; You, C. On the co-combustion characteristics and kinetics of sludge, wood chips, and bituminous coal. Chem. Eng. Res. Des. 2024, 209, 237–247. [Google Scholar] [CrossRef]

- Rawat, S.S.; Sharma, A. Sugarcane bagasse ash—The future composite material: A literature review. Mater. Today Proc. 2023; in press. [Google Scholar]

- Iwuozor, K.O.; Adeniyi, A.G.; Emenike, E.C.; Ojeyemi, T.; Egbemhenghe, A.U.; Okorie, C.J.; Ayoku, B.D.; Saliu, O.D. Prospects and challenges of utilizing sugarcane bagasse as a bio-coagulant precursor for water treatment. Biotechnol. Rep. 2023, 39, e00805. [Google Scholar] [CrossRef]

- Karp, S.G.; Burgos, W.J.M.; Vandenberghe, L.P.S.; Diestra, K.V.; Torres, L.A.Z.; Woiciechowski, A.L.; Letti, L.A.J.; Pereira, G.V.M.; Thomaz-Soccol, V.; Rodrigues, C.; et al. Sugarcane: A Promising Source of Green Carbon in the Circular Bioeconomy. Sugar Tech 2022, 24, 1230–1245. [Google Scholar] [CrossRef]

- Chen, C.; Qin, S.; Chen, F.; Lu, Z.; Cheng, Z. Co-combustion characteristics study of bagasse, coal and their blends by thermogravimetric analysis. J. Energy Inst. 2019, 92, 364–369. [Google Scholar] [CrossRef]

- Beuel, P.; Torres, F.; Rieker, C.; Bursche, J.; Hensel, O. Effects of thermo-biological pretreatments on the combustion properties of wheat straw in a cascaded biorefinery concept. Fuel 2023, 332, 125836. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, G.; Zhu, G.; Zhao, P.; Ma, Z.; Zhang, B. Using microwave pretreatment to improve the high-gradient magnetic-separation desulfurization of pulverized coal before combustion. Fuel 2020, 274, 117826. [Google Scholar] [CrossRef]

- Rinsha, P.; Kavitha, S.; Ravi, Y.K.; Kathiresan, S.; Banu, J.R. Effect of surfactant on microwave pretreatment of sago waste for cost effective biomethane production. Fuel 2025, 381, 133433. [Google Scholar] [CrossRef]

- Fang, S.; Li, C.; Yan, S.; Huang, Z.; Lin, Y.; Zou, H.; Zhang, L. Ultrasonic pretreatment effect on the co-pyrolysis characteristics and products of bagasse and municipal sludge. J. Energy Inst. 2023, 111, 101240. [Google Scholar] [CrossRef]

- Ren, L.; Gong, Y.; Guo, Q.; Yu, G. Enhanced flotation of coal gasification fine slag based on ultrasonic pretreatment pulp and composite collector. Powder Technol. 2023, 424, 118530. [Google Scholar] [CrossRef]

- Fang, S.; Lin, Y.; Lin, Y.; Chen, S.; Shen, X.; Zhong, T.; Ding, L.; Ma, X. Influence of ultrasonic pretreatment on the co-pyrolysis characteristics and kinetic parameters of municipal solid waste and paper mill sludge. Energy 2020, 190, 116310. [Google Scholar] [CrossRef]

- Xu, X.; Tu, R.; Sun, Y.; Wu, Y.; Jiang, E.; Zhen, J. The influence of combined pretreatment with surfactant/ultrasonic and hydrothermal carbonization on fuel properties, pyrolysis and combustion behavior of corn stalk. Bioresour. Technol. 2019, 271, 427–438. [Google Scholar] [CrossRef]

- GB/T 212-2008; Proximate Analysis of Coal. Standardization Administration of China: Beijing, China, 2008.

- D5373−08; StandardTest Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Laboratory Samples of Coal. ASTM International: West Conshohocken, PA, USA, 2008.

- Li, Y. Experimental Design and Data Processing; Chemical Industry Press: Beijing, China, 2017. [Google Scholar]

- Hu, S.; Ma, X.; Lin, Y.; Yu, Z.; Fang, S. Thermogravimetric analysis of the co-combustion of paper mill sludge and municipal solid waste. Energy Convers. Manag. 2015, 99, 112–118. [Google Scholar] [CrossRef]

- Ahmad, M.B.; Embaye, T.M.; Meng, Z.; Wang, F.; Cui, W.; Bukhsh, K.; Deng, S.; Bai, Z.; Ruan, R.; Wang, X. Experimental study on co-combustion of domestic garbage and sewage sludge: Evaluation of synergistic effect and thermo-kinetic behavior. J. Energy Inst. 2024, 114, 101658. [Google Scholar] [CrossRef]

- Hoang, N.V.; Furtado, A.; Donnan, L.; Keeffe, E.C.; Botha, F.C.; Henry, R.J. High-Throughput Profiling of the Fiber and Sugar Composition of Sugarcane Biomass. BioEnergy Res. 2016, 10, 400–416. [Google Scholar] [CrossRef]

- Fang, S.; Yu, Z.; Ma, X.; Lin, Y.; Lin, Y.; Chen, L.; Fan, Y.; Liao, Y. Co-pyrolysis characters between combustible solid waste and paper mill sludge by TG-FTIR and Py-GC/MS. Energy Convers. Manag. 2017, 144, 114–122. [Google Scholar] [CrossRef]

- Ni, Z.; Bi, H.; Jiang, C.; Sun, H.; Zhou, W.; Tian, J.; Lin, Q. Investigation of co-combustion of sewage sludge and coffee industry residue by TG-FTIR and machine learning methods. Fuel 2022, 309, 122082. [Google Scholar] [CrossRef]

- Zhi, Y.; Xu, D.; Jiang, G.; Yang, W.; Chen, Z.; Duan, P.; Zhang, J. A review of hydrothermal carbonization of municipal sludge: Process conditions, physicochemical properties, methods coupling, energy balances and life cycle analyses. Fuel Process. Technol. 2024, 254, 107943. [Google Scholar] [CrossRef]

- Cherpozat, L.; Loranger, E.; Daneault, C. Ultrasonic pretreatment effects on the bio-oil yield of a laboratory-scale slow wood pyrolysis. J. Anal. Appl. Pyrolysis 2017, 126, 31–38. [Google Scholar] [CrossRef]

- Nguyen, T.D.B.; Kang, T.-H.; Lim, Y.-I.; Eom, W.-H.; Kim, S.-J.; Yoo, K.-S. Application of urea-based SNCR to a municipal incinerator: On-site test and CFD simulation. Chem. Eng. J. 2009, 152, 36–43. [Google Scholar] [CrossRef]

- Singh, S.; Bharadwaja, S.T.P.; Yadav, P.K.; Moholkar, V.S.; Goyal, A. Mechanistic Investigation in Ultrasound-Assisted (Alkaline) Delignification of Parthenium hysterophorus Biomass. Ind. Eng. Chem. Res. 2014, 53, 14241–14252. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Azin, M. Pretreatment of sugarcane bagasse by ultrasound energy and dilute acid. Asia-Pac. J. Chem. Eng. 2012, 7, 274–278. [Google Scholar] [CrossRef]

- Wang, Z.; He, Z.; Zhao, Z.; Yi, S.; Mu, J. Influence of ultrasound-assisted extraction on the pyrolysis characteristics and kinetic parameters of eucalyptus. Ultrason. Sonochem. 2017, 37, 47–55. [Google Scholar] [CrossRef]

- Koutsianitis, D.; Mitani, C.; Giagli, K.; Tsalagkas, D.; Halász, K.; Kolonics, O.; Gallis, C.; Csóka, L. Properties of ultrasound extracted bicomponent lignocellulose thin films. Ultrason. Sonochem. 2015, 23, 148–155. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).