Abstract

The transportation sector is experiencing a profound shift, driven by the urgent need to reduce greenhouse gas (GHG) emissions from internal combustion engine vehicles (ICEVs). As electric vehicle (EV) adoption accelerates, the sustainability of the materials used in their production, particularly in electric motors, is becoming a critical focus. This paper examines the sustainability of both traditional and emerging materials used in EV traction motors, with an emphasis on permanent magnet synchronous motors (PMSMs), which remain the dominant technology in the industry. Key challenges include the environmental and supply-chain concerns associated with rare earth elements (REEs) used in permanent magnets, as well as the sustainability of copper windings. Automakers are exploring alternatives such as REE-free permanent magnets, soft magnetic composites (SMCs) for reduced losses in the core, and carbon nanotube (CNT) windings for superior electrical, thermal, and mechanical properties. The topic of materials for EV traction motors is discussed in the literature; however, the focus on environmental, social, and economic sustainability is often lacking. This paper fills the gap by connecting the technological aspects with sustainability considerations, offering insights into the future configuration of EV motors.

1. Introduction

The transportation sector is undergoing a significant transformation. Increasing environmental concerns about greenhouse gas (GHG) emissions and pollutants produced by conventional internal combustion engine vehicles (ICEVs) have led to a gradual decline in the sales of ICEVs. This shift is closely tied to the global effort to reduce reliance on fossil fuels and achieve net-zero greenhouse gas emissions by 2050, as outlined in the 2015 Paris 21st Conference of Parties (COP21) agreement on climate change mitigation. According to the International Energy Agency (IEA), 14 million electric vehicles (EVs), including battery electric vehicles (BEVs) and plug-in hybrid vehicles (PHEVs), were sold worldwide in 2023, corresponding to nearly 20% of the total marker [1].

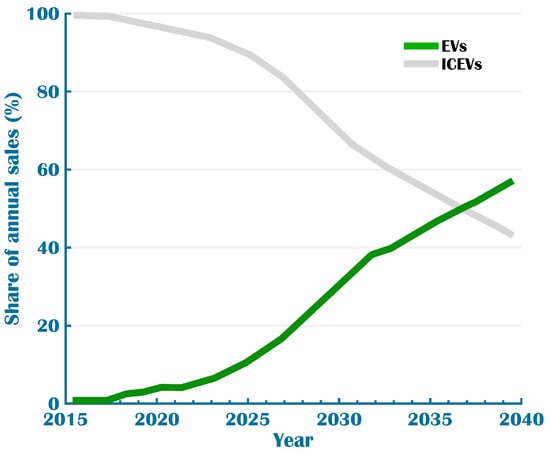

It is well-recognized that EVs have several advantages in terms of maintenance services [2], and with the increasing battery lifetime and deployment of charging infrastructures, significant growth is projected in the production and sales of EVs in the coming years, as illustrated in Figure 1. In 2019, 7.2 million electric cars were sold globally. Based on current projections, annual electric vehicle sales are expected to reach 9 million units by 2025 and nearly 26 million by 2030. Additionally, it is anticipated that global annual sales of electric cars will surpass those of internal combustion engine vehicles before 2040 [3].

Figure 1.

Forecasting global electric car sales over the next 20 years. Reproduced from BloombergNEF’s Electric Vehicle Outlook 2019 [4].

In 2022, the IEA reported 34 billion tonnes of emissions from fuel combustion [5], 24% of which (approximately 8 billion tonnes) are due to the transport sector [6]. Moreover, it is recognized that private cars and vans are responsible for around 10% of global emissions [7]. Emissions from transportation are also increasing faster than those from any other sector, making it critical to implement effective measures to address this rising trend.

The electrification of transport systems is a crucial step in reducing global emissions, with electric vehicles set to play a pivotal role in decarbonization and lowering air pollution levels. Many researchers use the Life Cycle Assessment (LCA) to compare the environmental impact of EVs with that of traditional ICEVs [8,9].

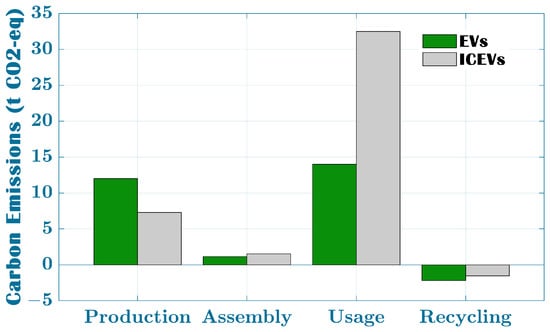

As pointed out in [10], three legs for the sustainability of EVs are highlighted: (i) fabrication stage, (ii) lifetime usage, and (iii) disposal and end-of-life (EoL) recycling process. The literature reports contradictory results in terms of GHG emissions between EVs and conventional ICEVs [11], however, as illustrated in Figure 2, it is recognized that EVs have higher emissions in the production stage and lower emissions in the usage phase [12,13]. The former is mainly due to the high energy consumption and GHG emissions associated with preparing the battery pack [12,14]. The reduction in battery pack costs, currently driven by lithium-ion (Li-ion) technology, along with improvements in capacity, represents the key technological challenge for the widespread adoption of EVs. The latter is strictly affected by the type of fuel used in the generation of electric energy.

Figure 2.

Comparative life-cycle emissions for EVs and ICEVs. Reproduced from [13].

The sustainability of electrification of the transport sector must concern not only the economic, technical, and environmental perspectives but also the political and social sphere [15,16,17].

While most public and scientific attention on EV advancements is currently centered on battery technology, the electric traction motor is the true core of the energy conversion process. Extensive research explores the current challenges and emerging trends in electric motor development, and how these factors influence the electrification of the transportation sector [18,19,20,21]. Research typically focuses on the sustainability challenges and emerging materials associated with permanent magnet synchronous motors (PMSMs), as they are the preferred choice for EV manufacturers [18,22]. However, an electric motor consists of many components, each of which is crucial to the development of next-generation EV motors and is a key focus of ongoing research. With these considerations in mind, this research addresses the question: “What will the future configuration of EV motors look like”? This paper examines both traditional and emerging materials to chart a potential path for the evolution of EV motors, with a particular focus on the materials used for:

- Permanent magnets (PMs),

- Ferromagnetic core,

- Windings.

It is worth mentioning that the topic of materials for EV traction motors is widely discussed in the literature [22,23,24,25]. However, the focus on environmental, social, and economic sustainability is often lacking. This paper fills the gap by connecting the technological aspects with sustainability considerations.

The paper is organized as follows. A general overview of the EV market and EV traction motors is given in Section 2. Section 3 discusses the traditional materials for EV traction motors, while emerging materials for permanent magnets, ferromagnetic cores, and windings are analyzed in Section 4. In conclusion, Section 5 wraps up the paper by highlighting the main findings and suggesting directions for future research and investigation.

2. Current Status of EV Traction Motors

In this section, a summary of the current status of EV traction motor topologies is given. Different topologies of traction motors have been investigated and performances compared [26,27,28,29]. Generally, three classes of EV traction motors are currently considered: (i) PMSMs, (ii) switched reluctance motors (SRMs), and (iii) induction motors (IMs), each characterized by pros and cons [29,30,31,32]. As pointed out in [33], the following characteristics are required for an EV traction motor:

- High torque density,

- High overload capability,

- Low torque ripple,

- Large flux-weakening capability,

- High efficiency to reduce the losses,

A list of motor types for some BEVs, including the production year, is given in Table 1. Most EVs, approximately 90% of the total, are equipped with a PMSM, as is confirmed by the market trend [34].

PM-free traction motors, such as the IM and the synchronous reluctance motor (SynRM), are not widely adopted within the current EV industry due to technical limitations; however, they continue to attract significant interest [35,36]. IM, as an alternative to PMSM, offers the key advantage of allowing the excitation field to be switched off, eliminating iron losses when the motor is not in operation.

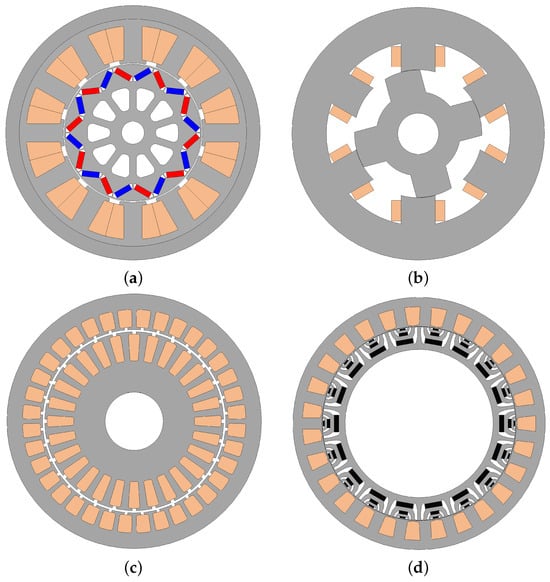

SynRMs exhibit reduced torque density and power factor if compared to interior permanent magnet (IPM) motors. However, the performance of SynRM can be increased by inserting PMs [18,37]. In literature, this machine is called permanent magnet-assisted SynRM (PMaSynRM). Looking at Table 1, it can be noticed that Tesla EVs are equipped with such kind of traction motors. Schematic representations of the cross-sections of PMSM, SRM, IM, and PMaSynRM are shown in Figure 3. Another PM-free motor is the externally excited synchronous motor (EESM), installed in Renault Zoe and BMW ix3 vehicles [38,39], characterized by a higher value of power density if compared to IMs. Recently, a rotating transformer with a wireless power transmission system has been proposed to improve the transmission of energy to the rotor [40].

Figure 3.

Schematics of electric motors. (a) PMSM. (b) SRM. (c) IM. (d) PMaSynRM.

Table 1.

List of BEVs, including production year and motor type [39,41,42,43].

Table 1.

List of BEVs, including production year and motor type [39,41,42,43].

| EV Model | Motor Type | Year | Power [kW] |

|---|---|---|---|

| Audi Q6 e-tron | IM (front) + PMSM (rear) | 2024 | 285 |

| BMW i5 Touring | EESM | 2024 | 250 |

| Chevrolet Equinox EV | PMSM | 2024 | 159–215 |

| Hyundai Ioniq 5 | PMSM | 2021 | 125 |

| Honda e:NP2 | PMSM | 2024 | 150 |

| Jaguar I-Pace | PMSM | 2018 | 294 |

| Kia EV6 | PMSM | 2021 | 239 |

| Land Rover | SMR | 2013 | 70 |

| Mercedes-Benz EQE | PMSM | 2021 | 215–505 |

| Renault ZOE | EESM | 2021 | 100 |

| Tesla Model 3 | IM (front) + IPM-SynRM (rear) | 2020 | 366 |

| Tesla Model Y | IM (front) + IPM-SynRM (rear) | 2020 | 247 |

| Volvo EX90 | PMSM | 2024 | 279–380 |

| Xiaomi SU7 | PMSM | 2024 | 220–495 |

It is crucial to conduct an LCA of electric motors to accurately quantify the potential environmental impacts associated with EV traction motors. This assessment spans the entire lifecycle, from the extraction of raw materials such as copper and iron to the motor’s end-of-life disposal, while also evaluating recycling potential and sustainability opportunities [44,45].

3. Traditional Materials for EV Traction Motors

3.1. Permanent Magnets

The majority of EV traction motors, as pointed out in Section 2, are based on the PMSM configuration. In this section, the materials currently used for PMs are analyzed, recalling that the ideal characteristics of a PM suited for EV traction motors are [22]:

- High value of the maximum energy product [J/], representing the maximum energy stored per unit volume,

- High value of enables the magnet to resist demagnetization in the presence of external magnetic fields,

- High value of . The higher the material , the stronger the forces of magnetic attraction and repulsion that generate the driving torque,

- A low coercivity and remanence temperature coefficient.

The per-unit-volume losses due to the eddy currents can be expressed as:

where is a material constant, is the maximum value of the magnetic induction, f is the frequency, s is a characteristic dimension of the component, and the electric resistivity.

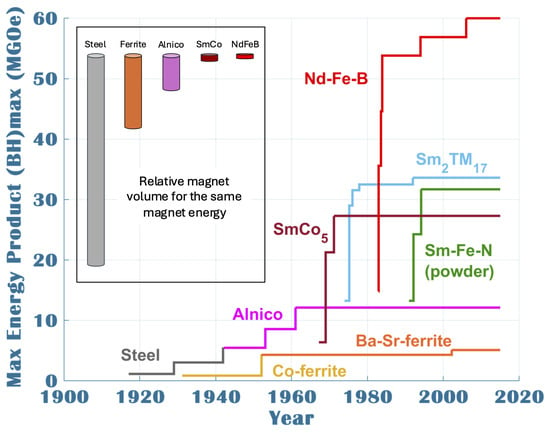

As illustrated in Figure 4, a major milestone in the development of magnets occurred around the 1940s with the invention of AlNiCo permanent magnets. AlNiCo refers to a family of iron-based alloys that incorporate aluminum (Al), nickel (Ni), and cobalt (Co). AlNiCo and ferrite magnets, however, are characterized by low values of . The true revolution in the magnet industry began in the 1970s with the development of rare earth element (REE)-based PMs. According to the International Union of Applied and Pure Chemistry, REEs are 17 elements in the periodic table corresponding to the 15 lanthanides plus the elements yttrium (Y) and scandium (Sc). REEs are generally subdivided into two main subgroups: light REEs (LREEs) and heavy REEs (HREEs) [46]. The revolution started with samarium-cobalt (SmCo) magnets, followed by neodymium-iron-boron (NdFeB) in the early 1980s, and samarium-iron-nitride (SmFeN) [21]. These advancements significantly enhanced magnetic performance, driving innovation and enabling modern applications.

Figure 4.

Timeline of materials for PMs and their maximum energy product [47].

The superiority of REE-based PMs becomes evident when considering the value of , justifying the use of REEs for the realization of PMs for electric traction motors. Table 2 provides a detailed overview of the key properties of traditional PM materials, highlighting their performance characteristics.

Table 2.

Properties of traditional PM materials [29].

AlNiCo magnets have one of the highest Curie temperatures among permanent magnets, but their cost is relatively high due to the inclusion of cobalt. On the other hand, ferrite magnets are more affordable and distinguished by their high electrical resistivity, which minimizes eddy current losses as stated by Equation (1). SmCo magnets offer excellent thermal stability but are among the most expensive available. Nd-based magnets provide a cost-effective solution compared to other REE-containing magnets, offering high efficiency and magnetic density in a compact form, making them an ideal choice for applications requiring powerful performance at a relatively low cost.

The Issue of Rare Earth Elements

Challenges related to REEs are widely discussed in research and remain a key concern for the EV industry [31,48]. Among all REEs, samarium (Sm), terbium (Tb), neodymium (Nd), and dysprosium (Dy) are currently used to manufacture high-performance PMs [36]. Sm and Nd are categorized as LREEs, while Tb and Dy are HREEs. More than 50% of the REEs global market is driven by PMs and catalysts, where the former is expected to increase in the next years due to the electrification campaign [49,50]. The REE content in SmCo magnets is approximately 22 to 40%, while for NdFeB magnets, 22 to 31% of Nd, 0.07 to 13% of promethium (Pr), and 0.77 to 4.2% of Dy are used [46]. In particular, Dy is added to NdFeB magnets to enhance their thermal stability, preventing demagnetization at higher temperatures [51]. It is worth mentioning that hybrid electric vehicles (HEVs) are one of the largest consumers of REEs [52]. Major REE content in HEVs is due to nickel-metal-hydride (NiMH) batteries and the hybrid transmission (motor and generator) [53].

The issue of using REEs extends beyond environmental sustainability, encompassing geopolitical concerns as well. A framework for assessing the environmental impact of a product is outlined in the Environmental Priority Strategies (EPS) system, which measures environmental burden in terms of environmental load units (ELU). One ELU corresponds to the environmental damage cost of one Euro. According to [54], Dy has the highest impact, with a score of 1500 ELU/kg, while Nd registers a lower score of 202 ELU/kg.

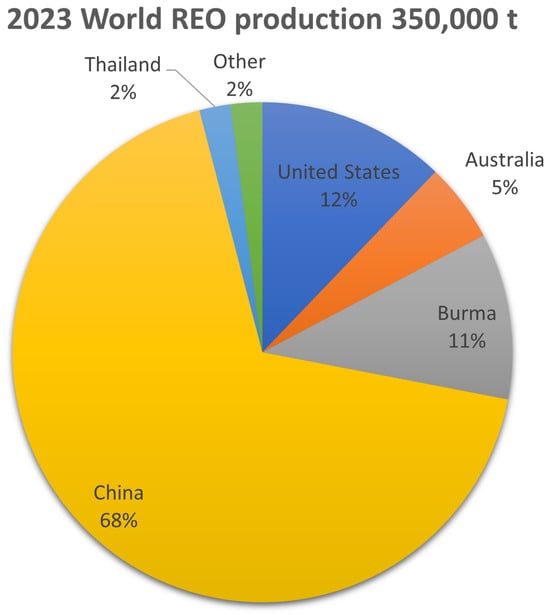

As shown in Figure 5, which depicts global rare-earth oxide (REO) production in 2023, China emerges as the dominant producer of REOs [55].

Figure 5.

Distribution of global rare earth mine production in 2023. Data adapted from [55].

The dominance of China in the REE market (also known as the Chinese era) began around the early 1990s, following the decline of the Mountain Pass mine in California, largely due to environmental concerns and the inability to compete with the lower prices of REEs exported from China [56]. The risks of relying on a single dominant supplier became a major focus of research, especially after the 2011 REE crisis, which led to a sharp spike in prices [57,58].

Beyond the economic impact of price volatility, there are significant social and environmental concerns related to REE mining. It is widely acknowledged that mining activities must be closely regulated to ensure worker safety and health [59,60,61,62]. These issues are particularly pressing for the European Union (EU), where the automotive industry is a major economic pillar. According to the European Commission, the EU relies on China for more than 90% of its REE supply [63], raising important questions about the future of its well-established automotive sector and its long-term supply chain security. In this scenario, the recycling technologies for REE-based PM are of great interest, as discussed in what follows.

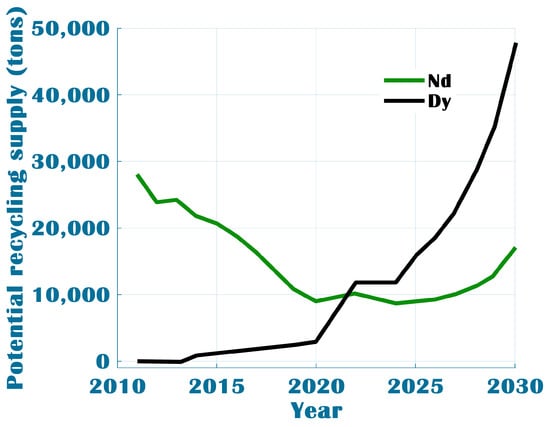

The demand for REEs is projected to rise significantly in the coming years due to the ongoing electrification of the transportation and energy sectors. Although lanthanum (La) and cerium (Ce) are the most abundant REEs produced, the majority of demand is concentrated on Nd and Dy [64,65]. This imbalance may result in a supply shortage of Nd and Dy, prompting increased focus on the potential for recycling and recovering these critical elements from EoL products. In 2018, less than 1% of rare earth elements were recycled [65]. However, projections, as illustrated in Figure 6, suggest that recycled REEs will become a significant resource by 2030, playing a much larger role in meeting global demand [66]. A comprehensive review of the challenges surrounding REE recycling is provided in [67], where various methodologies for recycling REE magnets are explored. Notably, for magnets used in hybrid and electric vehicles, direct reuse is a potential option. However, the primary limitation is that these components have long service lifespans, meaning they are not yet available in large quantities as scrap for recycling. Generally, the approaches for REE recycling include [67]:

Figure 6.

Potential recycling supply ratio for Nd and Dy. Data adapted from [66].

- Hydrometallurgical methods,

- Pyrometallurgical methods,

- Gas-phase extraction.

The description of these methods is out of the scope of the paper; the interested reader can find detailed information in [67,68,69]. A hydrogen-free mechanical-based recycling technique is recently proposed in [70].

3.2. Ferromagnetic Core

In an EV traction motor, the ferromagnetic core serves the crucial function of confining and guiding magnetic flux. The material selected for this core must possess the following characteristics:

- High relative magnetic permeability , essential for effectively guiding magnetic flux and minimizing its dispersion,

- Low eddy current and hysteresis losses to increase overall efficiency,

- High magnetic saturation value ,

- Low coercivity value ,

- Thermal stability.

The materials that best lend themselves to the creation of the ferromagnetic core are those belonging to the family of soft ferromagnetic materials. Silicon (Si) (or electrical) steel, discovered in 1900, accounts for the major share of the global market because of its high values of and . Electrical steel contains from 1% to 6% of Si, but the most common for the creation of the core of electric motors has 3.25% of Si content. The two most common types of electrical steel are grain-oriented and non-grain-oriented (NGO). NGO electrical steel is characterized by crystalline grains that are distributed randomly, without a preferential direction. This gives isotropic, i.e., uniform magnetic properties in all directions. It has higher core losses than grain-oriented electrical steel, making it very lossy when operating at high frequencies. However, it is easier to produce and cheaper (the approximate cost is about 950–1000 USD/ton). Currently, the NGO Si-iron (SiFe) is the preferred material for the realization of the ferromagnetic core of EV traction motors [24,71]. A summary of the properties of Si steel is given in Table 3.

Table 3.

Properties of Si steel [72].

3.3. Windings

Since the early development of electric motors, copper (Cu) has been the predominant material for windings, thanks to its outstanding electrical conductivity, allowing the reduction of Joule losses, and strong mechanical properties. In contrast, aluminum (Al) has been used to a lesser extent, primarily in budget-friendly applications where minimizing the motor’s weight is a priority. The key properties of Cu and Al are summarized in Table 4.

Table 4.

Aluminum and copper properties.

Al-based windings generally result in decreased torque performance [73]. However, in high-frequency, high-speed EV traction motors, the impact on overall machine efficiency is relatively minor since AC losses result in being lower than in copper winding [74,75,76].

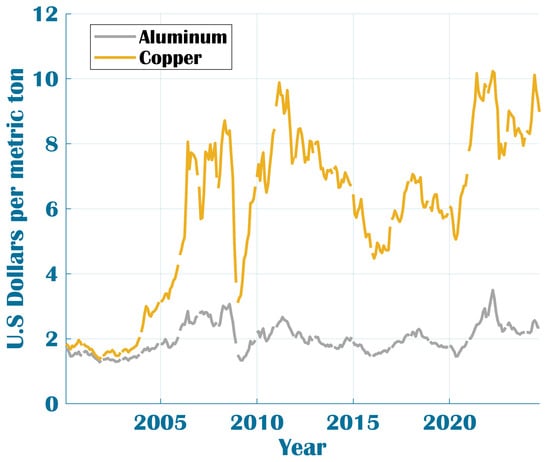

Given the increasing electrification of the transport sector, extensive studies have been conducted to project the future global demand for copper [77]. Since 2000, copper has undergone large price increases, especially compared to aluminum. As can be seen from Figure 7, aluminum costs approximately four times less than copper per kilogram.

Figure 7.

Global price of aluminum and copper from 2000 to today. Data adapted from [78].

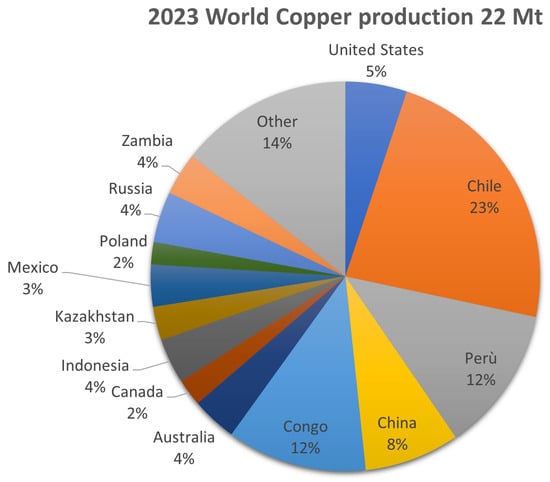

The worldwide copper mine production in 2023 is illustrated in Figure 8. Alongside REEs, copper is identified as a high-risk material that could become a bottleneck in the transition to green technologies [79,80,81].

Figure 8.

Distribution of global copper mine production in 2023. Data adapted from [82].

According to [54], copper ranks just behind REEs in environmental load in EV traction motors, scoring 131 ELU/kg. This high score is largely due to the environmental impact of copper mining, including the release of heavy metals and its limited availability [83].

The concept of sustainability is crucial for copper mining, particularly in GHG emissions associated with copper production [84]. To align with global efforts to reduce GHG emissions, recent years have seen a growing focus on the production of “green” copper, i.e., copper manufactured with a significantly lower environmental impact [85,86], e.g., as is the case of Chile mining companies using solar energy in their plants [87]. This initiative involves adopting cleaner energy sources and improving mining efficiency to minimize the ecological footprint of copper extraction and processing.

4. Emerging Materials for EV Traction Motors

4.1. Permanent Magnets

Given the challenges associated with the use of REEs for PMs, the current trend is shifting toward designing and manufacturing electric motors that utilize a reduced content of REEs or non-REE PMs. However, this transition is complex, as it necessitates sacrificing the exceptional magnetic properties afforded by SmCo and NdFeB. The need to substitute REEs for PMs is driven not only by global market dynamics, which are largely influenced by China, but also by significant environmental and toxicity concerns, as highlighted in Section 3.1. According to [35], NdFeB magnets, despite comprising less than 5% of an electric motor’s total mass, account for approximately 25% of the motor’s total GHG emissions. This underscores the substantial environmental impact of REEs in electrification technologies.

It is important to note that motor weight is a critical factor in the EV industry, making it particularly challenging to replace NdFeB magnets, which are characterized by very high . A detailed description of emerging materials for PMs is provided in [22,88], where three main candidates are highlighted. The first one is the SmFeN, in particular, . This is a REE-based magnet; however, currently, Sm is less critical than Nd and Dy due to the lower demand [89]. SmFeN is characterized by high kJ/, making it comparable to NdFeB magnets. Together with SmFeN, two non-REE magnets are identified: and the mineral tetrataenite L10 FeNi [88,90]. For FeN, the theoretical value of is about 1034 kJ/; however, currently, it was demonstrated the possibility of producing FeN compounds with kJ/ [22,91].

The potential of Mn-based compounds for EV traction motors has been explored [88,92]. A key advantage of this REE-free magnet is its estimated low cost of approximately 11 USD/kg [93], along with its higher values of and compared to ferrite magnets. The theoretical value of is approximately 135 kJ/ for the anisotropic low-temperature phase MnBi [94]. A significant drawback, which may pose challenges in the design of next-generation EV traction motors based on MnBi magnets, is the need to increase the motor size to match the performance of NdFeB-based motors [92].

A summary of the properties of emerging materials for PMs is listed in Table 5.

Table 5.

Properties of emerging PM materials [94,95,96].

It is important to note that ferrite magnets can be used as a substitute for REE-based magnets [97,98]. Although they possess weaker magnetic properties than REE magnets, ferrite magnets remain highly appealing due to their lower cost, particularly for applications such as PMaSynRM [99].

4.2. Ferromagnetic Core

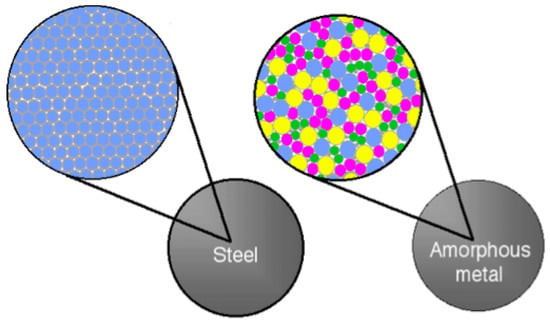

To reduce iron losses and enhance the efficiency of EV traction motors, thereby lowering energy consumption, alternative materials to electric steel are being actively explored. This topic is covered by many research papers [23,71]. Amorphous and nanocrystalline alloys, discovered at the end of 1960 and 1980, respectively, have recently attracted the attention of the realization of high-efficiency electric motors [100,101,102]. Amorphous materials, whose structure compared to that of steel is shown in Figure 9, are metals with a non-crystalline anisotropy. Amorphous metals such as Silicon-Iron-Boron (SiFeB) have higher resistivity if compared to SiFe alloys; however, there are still challenges in constructing complex geometries with these materials due to their low stiffness and elastic modulus [23,25]. The coercivity value of amorphous alloys, as listed in Table 6 for the case of the 0.0025 mm Amorphous METGLAS® 2605HB1M Alloy, can be around 2 A/m.

Figure 9.

Structure of steel and amorphous metal [103].

In contrast to amorphous metals, nanocrystalline alloys exhibit a crystalline composition. Nanocrystalline alloys, such as the FINEMET® FeCuNbSiB, are characterized by a microstructure with small grains. FeCuNbSiB alloy has superior properties to cobalt-based amorphous alloy; however, the major drawback of FeCuNbSiB is its mechanical brittleness, which may limit its applicability to EV traction motors, even if some attempts have been recently made [104,105,106]. Moreover, nanocrystalline alloys are much more expensive than amorphous and SiFe alloys [101]. It is worth mentioning that the potential substitution of Nd with molybdenum (Mo) is analyzed in [107], bringing no notable differences.

Soft magnetic composites (SMCs) have attracted the attention of the research community since the 1990s due to their unique properties with several potential technological applications [108]. These materials are generally made up of iron powder on a micrometer scale. The particles are also coated with a thin electrical insulation layer. The advantage of handling powders is related to the possibility of generating complex 3-D geometries with advanced additive manufacturing techniques [109]. As listed in Table 6, the relative permeability of such materials is very low due to the presence of air gaps within the structure; however, their electrical resistivity is very high, thus suitable to reduce the losses. Generally, if compared to electrical steel, SMC materials have:

- Significantly lower relative magnetic permeability due to the presence of spaces of air in the compound,

- Higher hysteresis losses due to the mechanical stress that forms during the compaction process,

- Lower mechanical resistance, which makes the core more sensitive to permanent damage,

- Lower magnetic saturation flux density.

Table 6.

Properties amorphous, nanocrystalline and SMC material [72,110,111,112,113,114].

Table 6.

Properties amorphous, nanocrystalline and SMC material [72,110,111,112,113,114].

| Parameter | Amorphous METGLAS® 2605HB1M | Nanocrystalline FINEMET® FeCuNbSiB | SMC |

|---|---|---|---|

| Density [kg/] | 7300 | 7180 | 7300 |

| [T] | 1.63 | 1.45 | 1.53 |

| – | 950 | ||

| Electrical resistivity [m] | 1.3 | 1.2–1.5 | 280 |

| Coercive force [A/m] | 2.12 | <10 | 200 |

Due to the substantial differences in properties between non-grain-oriented Si steel and SMCs, directly substituting a silicon steel core with an SMC core often leads to performance degradation, with only marginal improvements. However, recent research efforts have focused on enhancing material properties, optimizing production techniques, and exploring innovative core geometries to exploit the potential of SMCs [115].

Alongside SMCs, dual-phase materials developed by General Electric are also gaining attention [24,25,116]. A SynRM utilizing a dual-phase core material has been proposed, demonstrating competitive performance compared to Dy-free IPMs [117]. Dual-phase materials enable the variation of magnetic properties, such as permeability, across different regions through tailored manufacturing techniques [118].

4.3. Windings

The rising global demand for copper, its relatively high cost, and the push for improved performance have driven the search for innovative alternative materials. Among the most promising candidates at the forefront of scientific research are carbon nanotubes (CNTs), which have the potential to improve motor efficiency while maintaining cost-effectiveness significantly [119,120,121]. CNTs gained worldwide attention following Iijima’s publication in 1991 [122]. CNTs have shown tremendous potential and, in recent years, have been considered as a possible replacement for copper in electric motor windings due to their exceptional mechanical, thermal, and electrical properties [123,124]. Structurally, CNTs are cylindrical formations with diameters on the micrometer scale, composed of carbon atoms arranged in a planar hexagonal lattice.

CNTs can be synthesized through five main processes: (i) arc discharge, (ii) laser ablation, (iii) electrolysis, (iv) sonochemical/hydrothermal, and (v) chemical vapor deposition (CVD) [125]. Where the latter is recognized as the most popular method for the production of CNTs. CNTs can be categorized into single-walled, double-walled, and multi-walled nanotubes.

As shown in Table 7, CNTs have a density approximately 6 times lower than that of copper, which could significantly reduce the weight of an electric motor if used in place of copper windings. Additionally, CNTs exhibit lower electrical resistivity than copper, potentially leading to a significant reduction in Joule losses and thus improving overall motor efficiency. It is worth noting that copper composite CNT, such as Cu-CNT, has recently garnered attention for its potential to enhance significantly the properties of the compound [126].

Table 7.

Properties of CNT [127].

Despite their excellent thermal, electrical, and mechanical properties, CNTs have yet to be widely adopted in commercial electric motors and remain confined to research laboratories. The exceptional properties mentioned above are only observed in high-quality CNTs, which, at present, can only be produced in limited quantities and at a significant cost [128]. The synthesis of CNTs from bio-feedstocks and bio-derived compounds is discussed in [125]. The possibility of using biomaterials as precursors of CNTs is of great interest for the definition of a smart way to produce nanomaterials sustainably. The impact of CNTs on human health and the environment is the subject of study in many research papers [129,130,131,132], and the role of LCA is of central importance [133,134].

High-temperature superconductors (HTS) operating at higher temperatures than low-temperature superconductors, are very attractive for the construction of windings for future EV traction motors due to their negligible electrical resistivity. In literature, several research papers discuss the applicability of HTS for EVs [135,136,137]. Despite the significant advancements in HTS electric motors, challenges related to commercial viability persist. The design of HTS windings and cooling systems remains intricate, and the initial production and operational costs of HTS motor drives continue to be high.

5. Conclusions

This paper discusses the sustainability of traditional and emerging materials for the active parts of EV traction motors. As outlined in the previous sections, the PMSM based on NdFeB magnets, NGO SiFe iron core, and copper windings is the most common choice for EV traction motors. However, automakers are actively exploring alternative solutions to address environmental, economic, and political challenges. One of the main challenges remains how to create high-efficiency EV traction motors with REE-free permanent magnets. Together with REE-based magnets, the focus is also on the sustainability issues of copper-based windings. Even if copper itself can indeed be 100% recycled, several questions are posed concerning the relationship between global demand and recycling capabilities in the future.

Significant progress in electrical machines can only be achieved by embracing entirely new, breakthrough technologies. It is difficult to answer the question posed at the beginning of the article, on what the future configuration of EV motors looks like; indeed, as highlighted previously, the transition from traditional to novel materials is affected by many actors. From the previous analyses, it can be stated that the PMSM with an NGO SiFe core and copper windings will be the reference configuration for the electrification of the worldwide car park. The possibility of realizing optimized PMaSynRM without REEs is of great interest. Further research is needed before novel material solutions for permanent magnets, cores, and windings can be industrialized for use in EV traction motors.

Author Contributions

Conceptualization, F.L., R.T. and N.B.; formal analysis, F.L.; investigation, F.L.; writing—original draft preparation, F.L.; writing—review and editing, F.L., R.T. and N.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no funding.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| GHG | Greenhouse gas |

| ICEV | Internal combustion engine vehicle |

| IEA | International energy agency |

| EV | Electric vehicle |

| BEV | Battery electric vehicle |

| PHEV | Plug-in hybrid electric vehicle |

| LCA | Life cycle assessment |

| EoF | End of fife |

| PMSM | Permanent magnet synchronous motor |

| PM | Permanent magnet |

| SRM | Switched reluctance motor |

| IM | Induction motor |

| IPM | Interior permanent magnet |

| SynRM | Synchronous reluctance motor |

| PMaSynRM | Permanent magnet assisted synchronous reluctance motor |

| EESM | Externally excited synchronous motor |

| REE | Rare-earth element |

| LREE | Light rare-earth element |

| HREE | Heavy rare-earth element |

| HEV | Hybrid electric vehicles |

| EPS | Environmental priority strategies |

| ELU | Environmental load units |

| EU | European union |

| REO | Rare-earth oxide |

| NGO | Non-grain-oriented |

| SMC | Soft magnetic composite |

| CNT | Carbon nanotubes |

| HTS | High temperature superconductors |

References

- Trends in Electric Cars. Available online: https://www.iea.org/reports/global-ev-outlook-2024/trends-in-electric-cars (accessed on 4 September 2024).

- Tan, K.M.; Yong, J.Y.; Ramachandaramurthy, V.K.; Mansor, M.; Teh, J.; Guerrero, J.M. Factors influencing global transportation electrification: Comparative analysis of electric and internal combustion engine vehicles. Renew. Sustain. Energy Rev. 2023, 184, 113582. [Google Scholar] [CrossRef]

- Parajuly, K.; Ternald, D.; Kuehr, R. The Future of Electric Vehicles and Material Resources: A Foresight Brief; United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- Bloomberg New Energy Finance. Electric Vehicle Outlook 2019; Bloomberg New Energy Finance: New York, NY, USA, 2019. [Google Scholar]

- Climate Pledges Explorer. Available online: https://www.iea.org/data-and-statistics/?country=WORLD&fuel=CO2%20emissions&indicator=TotCO22 (accessed on 4 September 2024).

- Global CO2 Emissions from Transport by Sub-Sector in the Net Zero Scenario, 2000–2030. Available online: https://www.iea.org/data-and-statistics/charts/global-co2-emissions-from-transport-by-sub-sector-in-the-net-zero-scenario-2000-2030-2 (accessed on 24 September 2024).

- Cars and Vans. Available online: https://www.iea.org/energy-system/transport/cars-and-vans (accessed on 24 September 2024).

- Van Vliet, O.; Brouwer, A.S.; Kuramochi, T.; van Den Broek, M.; Faaij, A. Energy use, cost and CO2 emissions of electric cars. J. Power Sources 2011, 196, 2298–2310. [Google Scholar] [CrossRef]

- Faria, R.; Marques, P.; Moura, P.; Freire, F.; Delgado, J.; De Almeida, A.T. Impact of the electricity mix and use profile in the life-cycle assessment of electric vehicles. Renew. Sustain. Energy Rev. 2013, 24, 271–287. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A review on electric vehicles: Technologies and challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Farzaneh, F.; Jung, S. Lifecycle carbon footprint comparison between internal combustion engine versus electric transit vehicle: A case study in the US. J. Clean. Prod. 2023, 390, 136111. [Google Scholar] [CrossRef]

- Gao, Z.; Xie, H.; Yang, X.; Zhang, L.; Yu, H.; Wang, W.; Liu, Y.; Xu, Y.; Ma, B.; Liu, X.; et al. Electric vehicle lifecycle carbon emission reduction: A review. Carbon Neutraliz. 2023, 2, 528–550. [Google Scholar] [CrossRef]

- Deng, C.; Qian, Y.; Song, X.; Xie, M.; Duan, H.; Shen, P.; Qiao, Q. Are electric vehicles really the optimal option for the transportation sector in China to approach pollution reduction and carbon neutrality goals? J. Environ. Manag. 2024, 356, 120648. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J.; Arsenault, R.; Bae, C.; Ahn, S.; Lee, J. Cradle-to-gate emissions from a commercial electric vehicle Li-ion battery: A comparative analysis. Environ. Sci. Technol. 2016, 50, 7715–7722. [Google Scholar] [CrossRef]

- Omahne, V.; Knez, M.; Obrecht, M. Social aspects of electric vehicles research—Trends and relations to sustainable development goals. World Electr. Veh. J. 2021, 12, 15. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Ghadimi, P.; Raugei, M.; Wu, Y.; Heidrich, O. Challenges and recent developments in supply and value chains of electric vehicle batteries: A sustainability perspective. Resour. Conserv. Recycl. 2022, 180, 106144. [Google Scholar] [CrossRef]

- Niri, A.J.; Poelzer, G.A.; Zhang, S.E.; Rosenkranz, J.; Pettersson, M.; Ghorbani, Y. Sustainability challenges throughout the electric vehicle battery value chain. Renew. Sustain. Energy Rev. 2024, 191, 114176. [Google Scholar] [CrossRef]

- Wang, Z.; Ching, T.W.; Huang, S.; Wang, H.; Xu, T. Challenges Faced by Electric Vehicle Motors and Their Solutions. IEEE Access 2021, 9, 5228–5249. [Google Scholar] [CrossRef]

- Lee, C.H.; Hua, W.; Long, T.; Jiang, C.; Iyer, L.V. A critical review of emerging technologies for electric and hybrid vehicles. IEEE Open J. Veh. Technol. 2021, 2, 471–485. [Google Scholar] [CrossRef]

- Zhang, X.; Gerada, D.; Xu, Z.; Zhang, F.; Gerada, C. A review of carbon emissions from electrical machine materials. Electronics 2024, 13, 1714. [Google Scholar] [CrossRef]

- Podmiljšak, B.; Saje, B.; Jenuš, P.; Tomše, T.; Kobe, S.; Žužek, K.; Šturm, S. The Future of Permanent-Magnet-Based Electric Motors: How Will Rare Earths Affect Electrification? Materials 2024, 17, 848. [Google Scholar] [CrossRef]

- Rom, C.L.; Smaha, R.W.; O’Donnell, S.; Dugu, S.; Bauers, S.R. Emerging magnetic materials for electric vehicle drive motors. MRS Bull. 2024, 49, 738–750. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft magnetic material status and trends in electric machines. IEEE Trans. Ind. Electron. 2016, 64, 2405–2414. [Google Scholar] [CrossRef]

- Ramesh, P.; Lenin, N. High power density electrical machines for electric vehicles—Comprehensive review based on material technology. IEEE Trans. Magn. 2019, 55, 0900121. [Google Scholar] [CrossRef]

- O’Donnell, D.; Bartos, S.; Tjong, J.; Kar, N.C. Utilization of innovative materials toward permanent magnet synchronous e-motors for traction application: A review. In Proceedings of the 2020 2nd International Conference on Smart Power & Internet Energy Systems (SPIES), Bangkok, Thailand, 15–18 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 380–385. [Google Scholar]

- Hashemnia, N.; Asaei, B. Comparative study of using different electric motors in the electric vehicles. In Proceedings of the 2008 18th International Conference on Electrical Machines, Vilamoura, Portugal, 6–9 September 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1–5. [Google Scholar]

- Pellegrino, G.; Vagati, A.; Boazzo, B.; Guglielmi, P. Comparison of induction and PM synchronous motor drives for EV application including design examples. IEEE Trans. Ind. Appl. 2012, 48, 2322–2332. [Google Scholar] [CrossRef]

- Huynh, T.A.; Hsieh, M.F. Performance analysis of permanent magnet motors for electric vehicles (EV) traction considering driving cycles. Energies 2018, 11, 1385. [Google Scholar] [CrossRef]

- Thangavel, S.; Mohanraj, D.; Girijaprasanna, T.; Raju, S.; Dhanamjayulu, C.; Muyeen, S. A comprehensive review on electric vehicle: Battery management system, charging station, traction motors. IEEE Access 2023, 11, 20994–21019. [Google Scholar] [CrossRef]

- Yang, Z.; Shang, F.; Brown, I.P.; Krishnamurthy, M. Comparative study of interior permanent magnet, induction, and switched reluctance motor drives for EV and HEV applications. IEEE Trans. Transp. Electrif. 2015, 1, 245–254. [Google Scholar] [CrossRef]

- Jahns, T. Getting rare-earth magnets out of EV traction machines: A review of the many approaches being pursued to minimize or eliminate rare-earth magnets from future EV drivetrains. IEEE Electrif. Mag. 2017, 5, 6–18. [Google Scholar] [CrossRef]

- El Hadraoui, H.; Zegrari, M.; Chebak, A.; Laayati, O.; Guennouni, N. A multi-criteria analysis and trends of electric motors for electric vehicles. World Electr. Veh. J. 2022, 13, 65. [Google Scholar] [CrossRef]

- Bianchi, N.; Bolognani, S.; Carraro, E.; Castiello, M.; Fornasiero, E. Electric vehicle traction based on synchronous reluctance motors. IEEE Trans. Ind. Appl. 2016, 52, 4762–4769. [Google Scholar] [CrossRef]

- Adamas Intelligence. EV Motor Materials Monthly Report. 2022. Available online: https://www.adamasintel.com/wp-content/uploads/2024/07/Adamas-Intelligence-EV-Motor-Materials-Monthly-Sample-June-2022.pdf (accessed on 2 October 2024).

- Widmer, J.D.; Martin, R.; Kimiabeigi, M. Electric vehicle traction motors without rare earth magnets. Sustain. Mater. Technol. 2015, 3, 7–13. [Google Scholar] [CrossRef]

- Riba, J.R.; López-Torres, C.; Romeral, L.; Garcia, A. Rare-earth-free propulsion motors for electric vehicles: A technology review. Renew. Sustain. Energy Rev. 2016, 57, 367–379. [Google Scholar] [CrossRef]

- Wang, Y.; Bianchi, N.; Qu, R. Comparative study of non-rare-earth and rare-earth PM motors for EV applications. Energies 2022, 15, 2711. [Google Scholar] [CrossRef]

- Estenlund, S.; Alaküla, M.; Reinap, A. PM-less machine topologies for EV traction: A literature review. In Proceedings of the 2016 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Toulouse, France, 2–4 November 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Traction Motors in Electric Vehicles: A Snapshot of Technologies and Performance. Available online: https://www.hv.se/globalassets/dokument/iv/e-drive-2---report.pdf (accessed on 25 September 2024).

- Müller, S.; Maier, D.; Parspour, N. Inductive electrically excited synchronous machine for electrical vehicles—Design, optimization and measurement. Energies 2023, 16, 1657. [Google Scholar] [CrossRef]

- Sporty Performance: Powerful Drives. Available online: https://www.audi-mediacenter.com/en/the-audi-q6-e-tron-electric-mobility-on-a-new-level-15929/sporty-performance-powerful-drives-15932 (accessed on 30 September 2024).

- Xiaomi SU 7 MAX. Available online: https://www.evhub.cc/portfolio/items/xiaomi-su-7-max (accessed on 30 September 2024).

- Chevrolet Equinox EV. Available online: https://greencarscompare.com/cars/chevrolet-equinox-ev-awd/ (accessed on 30 September 2024).

- Hernandez, M.; Messagie, M.; Hegazy, O.; Marengo, L.; Winter, O.; Van Mierlo, J. Environmental impact of traction electric motors for electric vehicles applications. Int. J. Life Cycle Assess. 2017, 22, 54–65. [Google Scholar] [CrossRef]

- de Souza, D.F.; da Silva, P.P.F.; Sauer, I.L.; de Almeida, A.T.; Tatizawa, H. Life Cycle Assessment of Electric Motors-A Systematic Literature Review. J. Clean. Prod. 2024, 456, 142366. [Google Scholar] [CrossRef]

- Ormerod, J.; Karati, A.; Baghel, A.P.S.; Prodius, D.; Nlebedim, I.C. Sourcing, Refining and Recycling of Rare-Earth Magnets. Sustainability 2023, 15, 14901. [Google Scholar] [CrossRef]

- Permanent Magnets History in the Aspect of Magnet Energy. Available online: https://www.magnetnrg.com/pm-hisory.html (accessed on 26 September 2024).

- Pavel, C.C.; Thiel, C.; Degreif, S.; Blagoeva, D.; Buchert, M.; Schüler, D.; Tzimas, E. Role of substitution in mitigating the supply pressure of rare earths in electric road transport applications. Sustain. Mater. Technol. 2017, 12, 62–72. [Google Scholar] [CrossRef]

- Papagianni, S.; Moschovi, A.M.; Sakkas, K.M.; Chalaris, M.; Yakoumis, I. Preprocessing and leaching methods for extraction of REE from permanent magnets: A scoping review. AppliedChem 2022, 2, 14. [Google Scholar] [CrossRef]

- Torta, G.; Ciacci, L.; Vassura, I.; Passarini, F. Exploring mass and economic potentials of rare earth elements recycling from electric vehicles at end-of-life. Miner. Econ. 2024, 37, 573–587. [Google Scholar] [CrossRef]

- Vaimann, T.; Kallaste, A.; Kilk, A.; Belahcen, A. Magnetic properties of reduced Dy NdFeB permanent magnets and their usage in electrical machines. In Proceedings of the 2013 Africon, Pointe aux Piments, Mauritius, 9–12 September 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1–5. [Google Scholar]

- Alonso, E.; Wallington, T.; Sherman, A.; Everson, M.; Field, F.; Roth, R.; Kirchain, R. An assessment of the rare earth element content of conventional and electric vehicles. SAE Int. J. Mater. Manuf. 2012, 5, 473–477. [Google Scholar] [CrossRef]

- Yano, J.; Muroi, T.; Sakai, S.I. Rare earth element recovery potentials from end-of-life hybrid electric vehicle components in 2010–2030. J. Mater. Cycles Waste Manag. 2016, 18, 655–664. [Google Scholar] [CrossRef]

- Steen, B.; Rydberg, T. Eps Weighting Factors-Version 2020d; IVL Svenska Miljöinstitutet: Stockholm, Sweden, 2020; Volume D, pp. 2018–2020. [Google Scholar]

- Rare Earths Statistics and Information. Available online: https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-rare-earths.pdf (accessed on 26 September 2024).

- Stegen, K.S. Heavy rare earths, permanent magnets, and renewable energies: An imminent crisis. Energy Policy 2015, 79, 1–8. [Google Scholar] [CrossRef]

- Looney, R. Recent Developments on the Rare Earth Front: Evidence of a new technocratic mercantilism emerging in China? World Econ. J. 2011, 12, 47–78. [Google Scholar]

- Chen, Y.; Zheng, B. What happens after the rare earth crisis: A systematic literature review. Sustainability 2019, 11, 1288. [Google Scholar] [CrossRef]

- Ali, S.H. Social and environmental impact of the rare earth industries. Resources 2014, 3, 123–134. [Google Scholar] [CrossRef]

- Bailey, G.; Mancheri, N.; Van Acker, K. Sustainability of permanent rare earth magnet motors in (H) EV industry. J. Sustain. Metall. 2017, 3, 611–626. [Google Scholar] [CrossRef]

- Jouini, M.; Royer-Lavallée, A.; Pabst, T.; Chung, E.; Kim, R.; Cheong, Y.W.; Neculita, C.M. Sustainable production of rare earth elements from mine waste and geoethics. Minerals 2022, 12, 809. [Google Scholar] [CrossRef]

- Agusdinata, D.B.; Liu, W. Global sustainability of electric vehicles minerals: A critical review of news media. Extr. Ind. Soc. 2023, 13, 101231. [Google Scholar] [CrossRef]

- Charalampides, G.; Vatalis, K.I.; Apostoplos, B.; Ploutarch-Nikolas, B. Rare earth elements: Industrial applications and economic dependency of Europe. Procedia Econ. Financ. 2015, 24, 126–135. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Z.; Chen, C. Global potential of rare earth resources and rare earth demand from clean technologies. Minerals 2017, 7, 203. [Google Scholar] [CrossRef]

- Jowitt, S.M.; Werner, T.T.; Weng, Z.; Mudd, G.M. Recycling of the rare earth elements. Curr. Opin. Green Sustain. Chem. 2018, 13, 1–7. [Google Scholar] [CrossRef]

- Rademaker, J.H.; Kleijn, R.; Yang, Y. Recycling as a strategy against rare earth element criticality: A systemic evaluation of the potential yield of NdFeB magnet recycling. Environ. Sci. Technol. 2013, 47, 10129–10136. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.M.; Van Gerven, T.; Jones, P.T.; et al. REE recovery from end-of-life NdFeB permanent magnet scrap: A critical review. J. Sustain. Metall. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Kumari, A.; Sahu, S.K. A comprehensive review on recycling of critical raw materials from spent neodymium iron boron (NdFeB) magnet. Sep. Purif. Technol. 2023, 317, 123527. [Google Scholar] [CrossRef]

- Pošković, E.; Ferraris, L.; Franchini, F.; Caneschi, A. Rare Earth Magnets Recycling: Study of a Safer and Cost-Effective Technique. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, eaao0195. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Yang, K.; Zhang, H.; Jiang, F.; Tang, L. A study on a novel multistage-AFPM with modular stator core made of different materials of silicon steel and SMC. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–4. [Google Scholar]

- Mukundan, S.; Dhulipati, H.; Chauvin, L.; Silva Guruwatta Vidanalage, B.D.; Edrisy, A.; Tjong, J.; Kar, N.C. Comparative Performance Analysis of Copper and Aluminum Wound Fractional—Slot PMSMs for High—Speed Traction Application. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Pastura, M.; Barater, D.; Nuzzo, S.; Franceschini, G. Investigation of resistivity impact on ac losses in hairpin conductors. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Notari, R.; Pastura, M.; Nuzzo, S.; Barater, D.; Franceschini, G.; Gerada, C. AC losses reduction in Hairpin Windings produced via Additive Manufacturing. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1144–1149. [Google Scholar]

- Petrelli, G.; Nuzzo, S.; Zou, T.; Cutuli, G.; Barater, D.; Gerada, C. On Comparing Aluminum and Copper in Wound Field Synchronous Motors for Traction Applications. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–7. [Google Scholar]

- Elshkaki, A.; Graedel, T.E.; Ciacci, L.; Reck, B.K. Copper demand, supply, and associated energy use to 2050. Glob. Environ. Chang. 2016, 39, 305–315. [Google Scholar] [CrossRef]

- FRED. Federal Reserve Economic Data (FRED)t. Available online: https://fred.stlouisfed.org/ (accessed on 2 October 2024).

- Valero, A.; Valero, A.; Calvo, G.; Ortego, A. Material bottlenecks in the future development of green technologies. Renew. Sustain. Energy Rev. 2018, 93, 178–200. [Google Scholar] [CrossRef]

- Huang, C.L.; Xu, M.; Cui, S.; Li, Z.; Fang, H.; Wang, P. Copper-induced ripple effects by the expanding electric vehicle fleet: A crisis or an opportunity. Resour. Conserv. Recycl. 2020, 161, 104861. [Google Scholar] [CrossRef]

- Born, K.; Ciftci, M.M. The limitations of end-of-life copper recycling and its implications for the circular economy of metals. Resour. Conserv. Recycl. 2024, 200, 107318. [Google Scholar] [CrossRef]

- Copper Statistics and Information. Available online: https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-copper.pdf (accessed on 30 September 2024).

- Acquaviva, A.; Diana, M.; Raghuraman, B.; Petersson, L.; Nategh, S. Sustainability aspects of electrical machines for e-mobility applications part ii: Aluminium hairpin vs. copper hairpin. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Northey, S.; Haque, N.; Mudd, G. Using sustainability reporting to assess the environmental footprint of copper mining. J. Clean. Prod. 2013, 40, 118–128. [Google Scholar] [CrossRef]

- Guzmán, J.I.; Faúndez, P.; Jara, J.J.; Retamal, C. On the source of metals and the environmental sustainability of battery electric vehicles versus internal combustion engine vehicles: The lithium production case study. J. Clean. Prod. 2022, 376, 133588. [Google Scholar] [CrossRef]

- Onifade, M.; Zvarivadza, T.; Adebisi, J.A.; Said, K.O.; Dayo-Olupona, O.; Lawal, A.I.; Khandelwal, M. Advancing toward sustainability: The emergence of green mining technologies and practices. Green Smart Min. Eng. 2024, 1, 157–174. [Google Scholar] [CrossRef]

- Tiwari, N.K.; Pal, V.C. A Comprehensive review of the utilization of solar energy in the copper mining process. In Proceedings of the 2022 IEEE Silchar Subsection Conference (SILCON), Silchar, India, 4–6 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Kramer, M.; McCallum, R.; Anderson, I.; Constantinides, S. Prospects for non-rare earth permanent magnets for traction motors and generators. Jom 2012, 64, 752–763. [Google Scholar] [CrossRef]

- Goodenough, K.M.; Wall, F.; Merriman, D. The rare earth elements: Demand, global resources, and challenges for resourcing future generations. Nat. Resour. Res. 2018, 27, 201–216. [Google Scholar] [CrossRef]

- Mandal, S.; Debata, M.; Sengupta, P.; Basu, S. L10 FeNi: A promising material for next generation permanent magnets. Crit. Rev. Solid State Mater. Sci. 2023, 48, 703–725. [Google Scholar] [CrossRef]

- Wang, J.P. Environment-friendly bulk Fe16N2 permanent magnet: Review and prospective. J. Magn. Magn. Mater. 2020, 497, 165962. [Google Scholar] [CrossRef]

- Brody, R.; Ohodnicki, P.; Ghosh, M.; Macias, C.; Sherman, A.; Talaat, A.; Cui, J.; Grainger, B. Trade study for rare-earth-free interior permanent magnet synchronous machine using MnBi permanent magnets. IEEE Trans. Ind. Appl. 2024, 60, 6010–6022. [Google Scholar] [CrossRef]

- Cui, J. Cost Effective 6.5% Silicon Steel Laminate for Electric Machines. 2020. Available online: https://www.osti.gov/biblio/1749947 (accessed on 2 October 2024).

- Jiang, X.; Roosendaal, T.; Lu, X.; Palasyuk, O.; Dennis, K.W.; Dahl, M.; Choi, J.P.; Polikarpov, E.; Marinescu, M.; Cui, J. Mechanical and electrical properties of low temperature phase MnBi. J. Appl. Phys. 2016, 119, 033903. [Google Scholar] [CrossRef]

- Rani, P.; Kashyap, M.K.; Singla, R.; Thakur, J.; Reshak, A.H. Magnetism and magnetocrystalline anisotropy of tetragonally distorted L10-FeNi: N alloy. J. Alloys Compd. 2020, 835, 155325. [Google Scholar] [CrossRef]

- Ye, L.; Wang, F.; Liu, Y.; Zhou, H.; Liu, L.; Ding, Y.; Sun, Y.; Yan, A. New structural features and pinning-evolved coercivity mechanism: A potential route for developing high coercivities in anisotropic Sm-Fe-N material. J. Mater. Res. Technol. 2024, 30, 451–460. [Google Scholar] [CrossRef]

- Galioto, S.J.; Reddy, P.B.; El-Refaie, A.M.; Alexander, J.P. Effect of magnet types on performance of high-speed spoke interior-permanent-magnet machines designed for traction applications. IEEE Trans. Ind. Appl. 2014, 51, 2148–2160. [Google Scholar] [CrossRef]

- Matsuhashi, D.; Matsuo, K.; Okitsu, T.; Ashikaga, T.; Mizuno, T. Comparison study of various motors for EVs and the potentiality of a ferrite magnet motor. IEEJ J. Ind. Appl. 2015, 4, 174–179. [Google Scholar] [CrossRef][Green Version]

- Obata, M.; Morimoto, S.; Sanada, M.; Inoue, Y. Characteristic of PMASynRM with ferrite magnets for EV/HEV applications. In Proceedings of the 2012 15th International Conference on Electrical Machines and Systems (ICEMS), Sapporo, Japan, 21–24 October 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–6. [Google Scholar]

- Silveyra, J.M.; Xu, P.; Keylin, V.; DeGeorge, V.; Leary, A.; McHenry, M.E. Amorphous and nanocomposite materials for energy-efficient electric motors. J. Electron. Mater. 2016, 45, 219–225. [Google Scholar] [CrossRef]

- Kauder, T.; Hameyer, K. Performance factor comparison of nanocrystalline, amorphous, and crystalline soft magnetic materials for medium-frequency applications. IEEE Trans. Magn. 2017, 53, 8401504. [Google Scholar] [CrossRef]

- Theisen, E.A. Recent advances and remaining challenges in manufacturing of amorphous and nanocrystalline alloys. IEEE Trans. Magn. 2022, 58, 2001207. [Google Scholar] [CrossRef]

- Amorphous Metal. Available online: https://education.mrsec.wisc.edu/amorphous-metal/ (accessed on 7 October 2024).

- Nishiyama, N.; Tanimoto, K.; Makino, A. Outstanding efficiency in energy conversion for electric motors constructed by nanocrystalline soft magnetic alloy “NANOMET®” cores. AIP Adv. 2016, 6, 055925. [Google Scholar] [CrossRef]

- Nonaka, T.; Zeze, S.; Makino, S.; Ohto, M. Research on motor with nanocrystalline soft magnetic alloy stator cores. J. Eng. 2019, 2019, 4158–4162. [Google Scholar]

- Enomoto, Y.; Deguchi, K.; Imagawa, T. Development of an Ultimate-high-efficiency Motor by utilizing High-Bs Nanocrystalline Alloy. IEEJ J. Ind. Appl. 2020, 9, 102–108. [Google Scholar] [CrossRef]

- Butvin, P.; Butvinová, B.; Silveyra, J.M.; Chromčíková, M.; Janičkovič, D.; Sitek, J.; Švec, P.; Vlasák, G. Effects of substitution of Mo for Nb on less-common properties of Finemet alloys. J. Magn. Magn. Mater. 2010, 322, 3035–3040. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Lamichhane, T.N.; Sethuraman, L.; Dalagan, A.; Wang, H.; Keller, J.; Paranthaman, M.P. Additive manufacturing of soft magnets for electrical machines—A review. Mater. Today Phys. 2020, 15, 100255. [Google Scholar] [CrossRef]

- Yoshizawa, Y.a.; Oguma, S.; Yamauchi, K. New Fe-based soft magnetic alloys composed of ultrafine grain structure. J. Appl. Phys. 1988, 64, 6044–6046. [Google Scholar] [CrossRef]

- Taccetti, J.M.; Johnson, J.B.; Rose, C.R. Characterization and modeling of amorphous metallic cores. In Proceedings of the 2015 IEEE Pulsed Power Conference (PPC), Austin, TX, USA, 31 May–4 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–4. [Google Scholar]

- Enomoto, Y.; Kimura, M.; Marukawa, Y.; Sano, H. Distributed Winding IPM Motor with an Amorphous Metal Stator Core. IEEJ J. Ind. Appl. 2022, 11, 730–736. [Google Scholar]

- Metglas Amorphous Metal Transformer Core. Available online: https://metglas.com/wp-content/uploads/2020/05/DT-Core-TechBulletin-21-May-2020-Final.pdf (accessed on 7 October 2024).

- FINEMET Nanocrystalline Soft Magnetic Material. Available online: https://www.hilltech.com/pdf/hl-fm10-cFinemetIntro.pdf (accessed on 7 October 2024).

- Guo, Y.; Ba, X.; Liu, L.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. A review of electric motors with soft magnetic composite cores for electric drives. Energies 2023, 16, 2053. [Google Scholar] [CrossRef]

- Huang, S.; Zou, M.; Zhang, W.; Rallabandi, V.; Dial, L.; Buresh, S.; Zierer, J.; Jassal, A.; Johnson, F. Development of dual phase soft magnetic laminate for advanced electric machines. AIP Adv. 2023, 13, 025021. [Google Scholar] [CrossRef]

- Reddy, P.B.; El-Refaie, A.M.; Galioto, S.; Alexander, J.P. Design of Synchronous Reluctance Motor Utilizing Dual-Phase Material for Traction Applications. IEEE Trans. Ind. Appl. 2017, 53, 1948–1957. [Google Scholar] [CrossRef]

- Ismagilov, F.; Vavilov, V.; Pronin, E.; Yushkova, O.; Zherebtsov, A. Investigation of technologies for manufacturing dual-phase magnetic steels for elements of electric machines: A review. J. Magn. Magn. Mater. 2023, 588, 171320. [Google Scholar] [CrossRef]

- Rallabandi, V.; Taran, N.; Ionel, D.M.; Eastham, J.F. On the feasibility of carbon nanotube windings for electrical machines—Case study for a coreless axial flux motor. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–7. [Google Scholar]

- Zhang, S.; Nguyen, N.; Leonhardt, B.; Jolowsky, C.; Hao, A.; Park, J.G.; Liang, R. Carbon-nanotube-based electrical conductors: Fabrication, optimization, and applications. Adv. Electron. Mater. 2019, 5, 1800811. [Google Scholar] [CrossRef]

- Sivasubramaniyam, V.; Ramasamy, S.; Venkatraman, M.; Gatto, G.; Kumar, A. Carbon nanotubes as an alternative to copper wires in electrical machines: A review. Energies 2023, 16, 3665. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- De Volder, M.F.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef]

- Pyrhönen, J.; Montonen, J.; Lindh, P.; Vauterin, J.; Otto, M. Replacing copper with new carbon nanomaterials in electrical machine windings. Int. Rev. Electr. Eng. 2015, 10. [Google Scholar] [CrossRef][Green Version]

- Janas, D. From bio to nano: A review of sustainable methods of synthesis of carbon nanotubes. Sustainability 2020, 12, 4115. [Google Scholar] [CrossRef]

- Robert, F.; Prince, A.A.; Fredo, A.J. Investigation of using CNT and Cu/CNT wires for replacing Cu for power electronics and electrical applications. ECS J. Solid State Sci. Technol. 2022, 11, 023011. [Google Scholar] [CrossRef]

- Chiricozzi, E.; Angeloni, L.; Natali, M.; Passeri, D. The nanomaterials and the new generation of electric motors. In Proceedings of the 7th International Conference on Magnetism and Metallurgy, Rome, Italy, 13–15 June 2016. [Google Scholar]

- Pyrhönen, J.; Otto, M.; Ayguzina, V.; Petrov, I.; Vauterin, J.; Ismagilov, F.; Vavilov, V.Y. Applicability of carbon nanotube materials in present-day and future electrical machines. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; IEEE: Piscataway, NJ, USA, 2020; Volume 1, pp. 2379–2384. [Google Scholar]

- Healy, M.L.; Dahlben, L.J.; Isaacs, J.A. Environmental assessment of single-walled carbon nanotube processes. J. Ind. Ecol. 2008, 12, 376–393. [Google Scholar] [CrossRef]

- Plata, D.L.; Hart, A.J.; Reddy, C.M.; Gschwend, P.M. Early evaluation of potential environmental impacts of carbon nanotube synthesis by chemical vapor deposition. Environ. Sci. Technol. 2009, 43, 8367–8373. [Google Scholar] [CrossRef] [PubMed]

- Petersen, E.J.; Zhang, L.; Mattison, N.T.; O’Carroll, D.M.; Whelton, A.J.; Uddin, N.; Nguyen, T.; Huang, Q.; Henry, T.B.; Holbrook, R.D.; et al. Potential release pathways, environmental fate, and ecological risks of carbon nanotubes. Environ. Sci. Technol. 2011, 45, 9837–9856. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Goerzen, D.; Jena, P.V.; Zeng, E.; Pasquali, M.; Meidl, R.A.; Heller, D.A. Human and environmental safety of carbon nanotubes across their life cycle. Nat. Rev. Mater. 2024, 9, 63–81. [Google Scholar] [CrossRef]

- Upadhyayula, V.K.; Meyer, D.E.; Curran, M.A.; Gonzalez, M.A. Life cycle assessment as a tool to enhance the environmental performance of carbon nanotube products: A review. J. Clean. Prod. 2012, 26, 37–47. [Google Scholar] [CrossRef]

- Gavankar, S.; Suh, S.; Keller, A.A. The role of scale and technology maturity in life cycle assessment of emerging technologies: A case study on carbon nanotubes. J. Ind. Ecol. 2015, 19, 51–60. [Google Scholar] [CrossRef]

- Sekiguchi, D.; Nakamura, T.; Misawa, S.; Kitano, H.; Matsuo, T.; Amemiya, N.; Ito, Y.; Yoshikawa, M.; Terazawa, T.; Osamura, K.; et al. Trial test of fully HTS induction/synchronous machine for next generation electric vehicle. IEEE Trans. Appl. Supercond. 2011, 22, 5200904. [Google Scholar] [CrossRef]

- Nakamura, T.; Itoh, Y.; Yoshikawa, M.; Nishimura, T.; Ogasa, T.; Amemiya, N.; Ohashi, Y.; Fukui, S.; Furuse, M. Tremendous enhancement of torque density in HTS induction/synchronous machine for transportation equipments. IEEE Trans. Appl. Supercond. 2014, 25, 5202304. [Google Scholar] [CrossRef]

- Cha, J.; Yoon, J.; Koo, J.; Bong, U.; Sim, K.; Hahn, S. Loss Reduction and Operating Time Extension Using Segmented HTS Field Coil Bobbin for High-Speed Operation of EV Traction Motor. IEEE Trans. Appl. Supercond. 2024, 34, 5201705. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).