Alternative Analyzers for the Measurement of Gaseous Compounds During Type-Approval of Heavy-Duty Vehicles

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

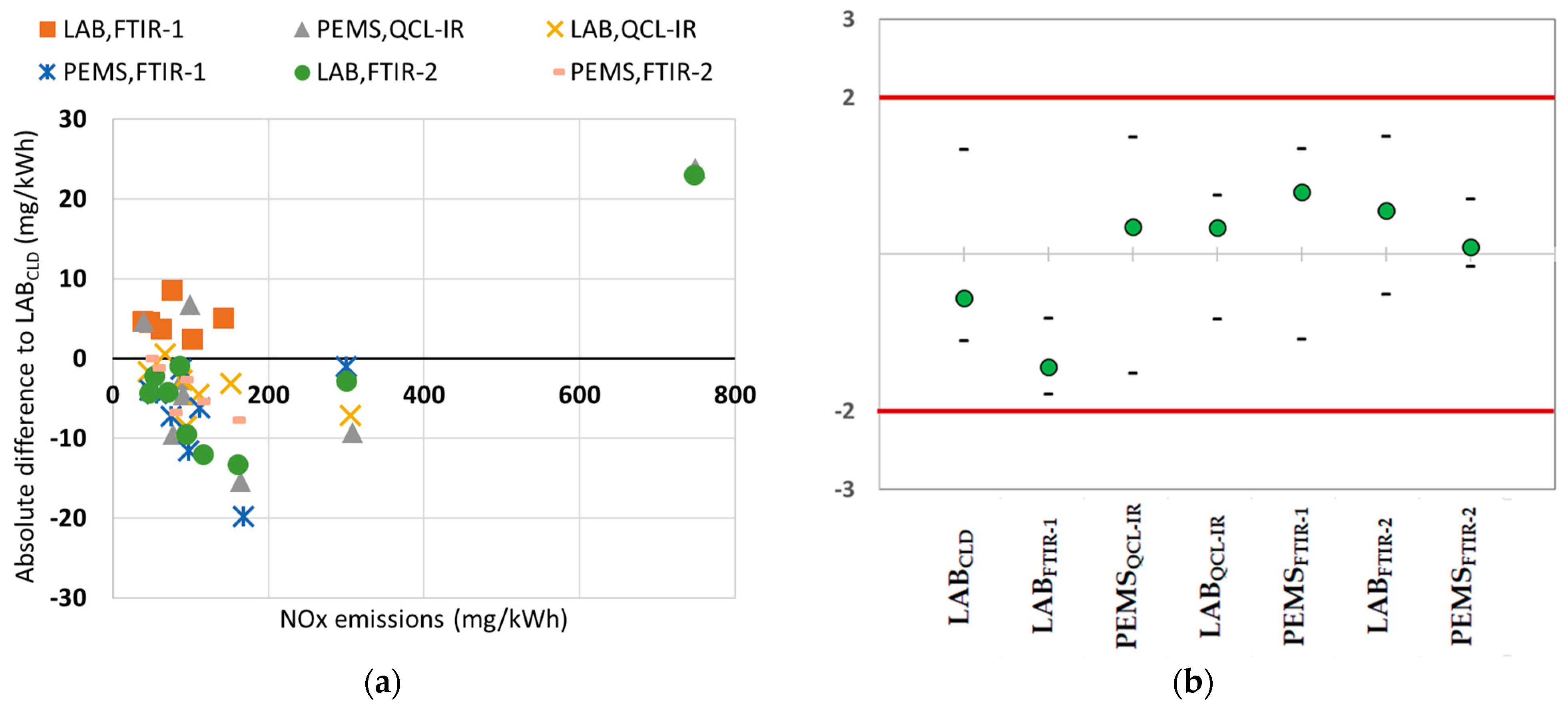

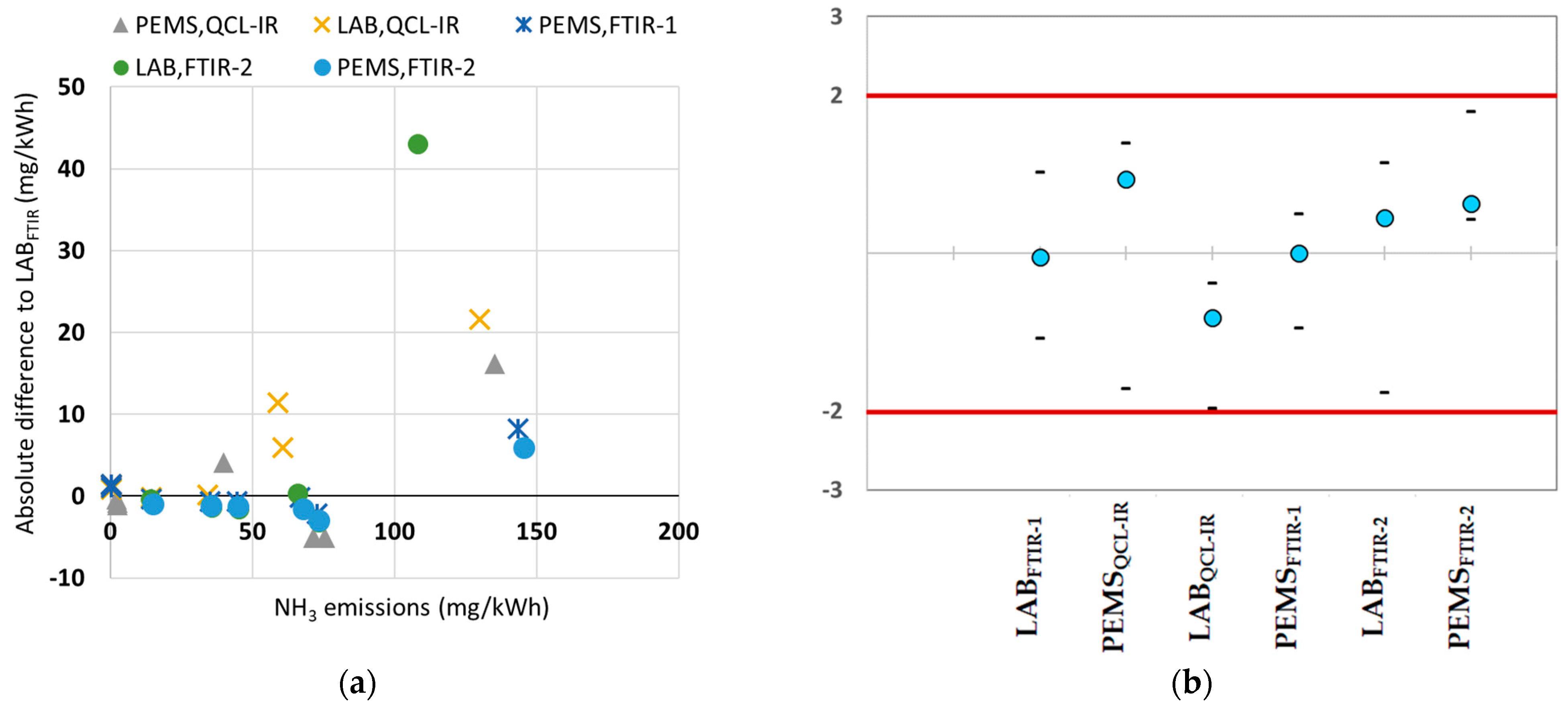

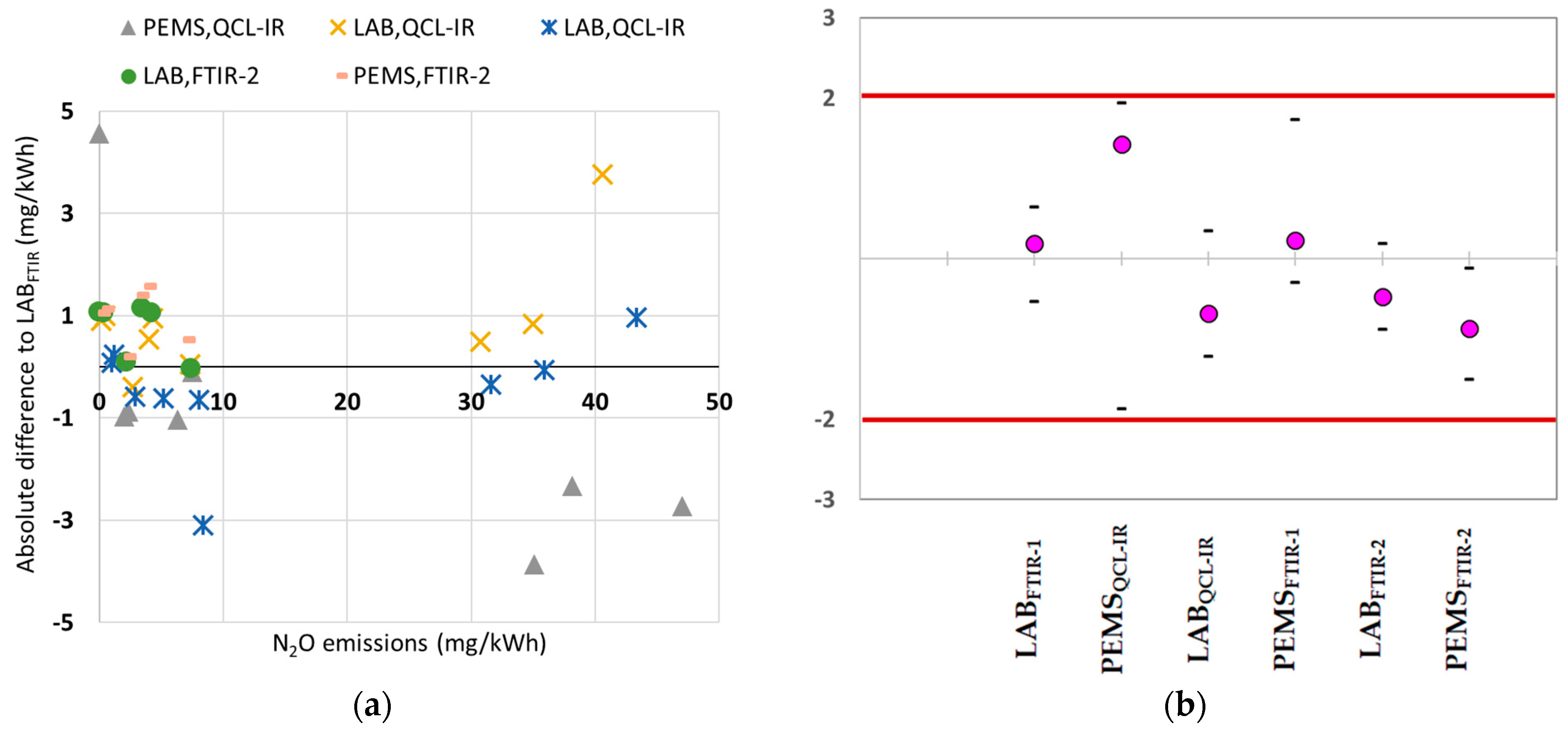

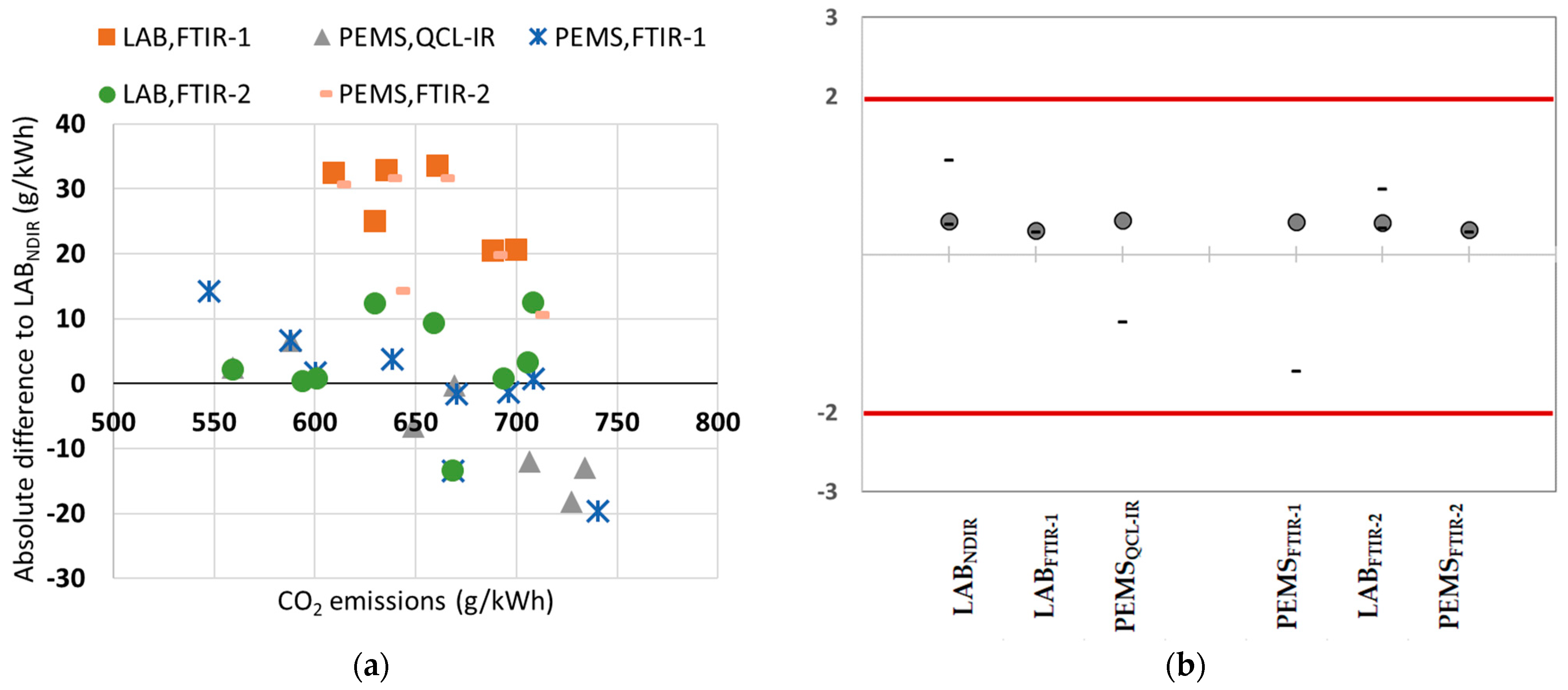

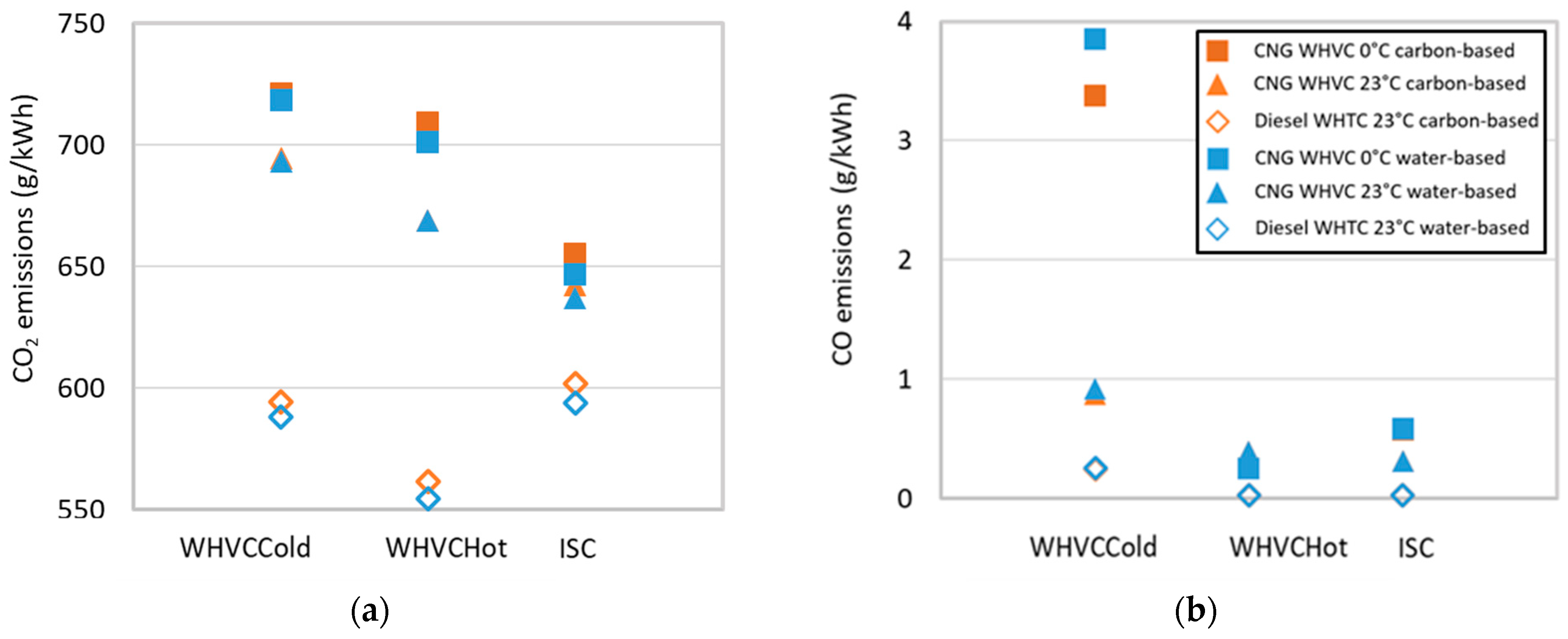

3.1. Measurement of Gaseous Pollutants and CO2

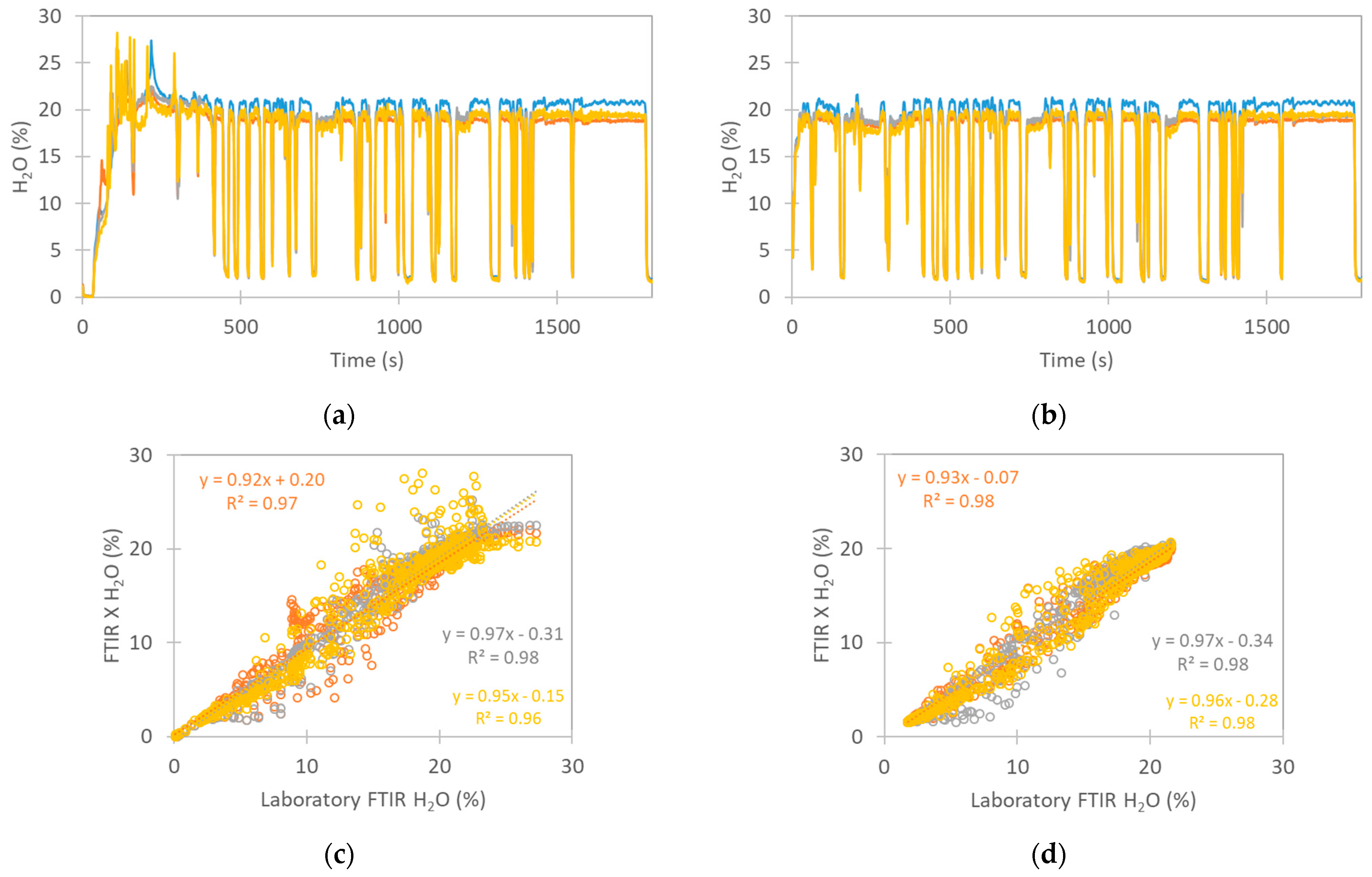

3.2. H2O Measurement and Dry-to-Wet Correction

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EU. Council Directive 70/220/EEC of 20 March 1970 on the Approximation of the Laws of the Member States Relating to Measures to be Taken against Air Pollution by Gases from Positive-Ignition Engines of Motor Vehicles. Off. J. Eur. Union 1970, 76, 1–22. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A31970L0220 (accessed on 10 October 2024).

- EU. Council Directive 74/290/EEC of 28 May 1974 Adapting to Technical Progress Council Directive No 70/220/EEC on the Approximation of the Laws of the Member States Relating to Measures to be Taken against Air Pollution by Gases from Positive-Ignition Engines of Motor Vehicles. Off. J. Eur. Union 1974, 159, 61–69. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX%3A31974L0290 (accessed on 10 October 2024).

- EU. Council Directive 88/77/EEC of 3 December 1987 on the Approximation of the Laws of the Member States Relating to the Measures to be Taken against the Emission of Gaseous Pollutants from Diesel Engines for Use in Vehicles. Off. J. Eur. Union 1988, 36, 33–61. [Google Scholar]

- EU. Directive 96/1/EC of the European Parliament and of the Council of 22 January 1996 Amending Directive 88/77/EEC on the Approximation of the Laws of the Member States Relating to the Measures to be Taken against the Emission of Gaseous and Particulate Pollutants from Diesel Engines for Use in Vehicles. Off. J. Eur. Union 1996, 40, 1–9. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A31996L0001 (accessed on 10 October 2024).

- EU. Directive 2005/55/EC of the European Parliament and of the Council of 28 September 2005 on the Approximation of the Laws of the Member States Relating to the Measures to be Taken against the Emission of Gaseous and Particulate Pollutants from Compression-Ignition Engines for Use in Vehicles, and the Emission of Gaseous Pollutants from Positive-Ignition Engines Fuelled with Natural Gas or Liquefied Petroleum Gas for Use in Vehicles (Text with EEA Relevance). Off. J. Eur. Union 2005, 275, 1–163. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32005L0055 (accessed on 10 October 2024).

- EU. Commission Directive 2008/74/EC of 18 July 2008 Amending, as Regards the Type Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and Access to Vehicle Repair and Maintenance Information, Directive 2005/55/EC of the European Parliament and of the Council and Directive 2005/78/EC (Text with EEA Relevance). Off. J. Eur. Union 2008, 192, 51–59. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX%3A32008L0074 (accessed on 10 October 2024).

- EU. Commission Regulation (EU) No 582/2011 of 25 May 2011 Implementing and Amending Regulation (EC) No 595/2009 of the European Parliament and of the Council with Respect to Emissions from Heavy Duty Vehicles (Euro VI) and Amending Annexes I and III to Directive 2007/46/EC of the European Parliament and of the Council Text with EEA Relevance. Off. J. Eur. Union 2011, 167, 1–168. Available online: https://eur-lex.europa.eu/eli/reg/2011/582/oj (accessed on 10 October 2024).

- Balogun, F.; Wang-Alho, H.; Sirviö, K.; Mikulski, M. FTIR Analysis for Determining Stability of Methanol–HVO Blends for Non-Road Engine Application. Energies 2024, 17, 3921. [Google Scholar] [CrossRef]

- Su, S.; Hou, P.; Wang, X.; Lyu, L.; Ge, Y.; Lyu, T.; Lai, Y.; Luo, W.; Wang, Y. Evaluating the Measurement Uncertainty of On-Road NOx Using a Portable Emission Measurement System (PEMS) Based on Real Testing Data in China. Atmosphere 2023, 14, 702. [Google Scholar] [CrossRef]

- Miao, G.; Wang, X.; Xuan, G.; Liu, J.; Ma, W.; Zhang, L. Emission Characteristics of Nitrous Oxide (N2O) from Conventional Gasoline and Hybrid Vehicles. Atmosphere 2024, 15, 1142. [Google Scholar] [CrossRef]

- Cao, T.; Durbin, T.D.; Cocker, D.R.; Wanker, R.; Schimpl, T.; Pointner, V.; Oberguggenberger, K.; Johnson, K.C. A Comprehensive Evaluation of a Gaseous Portable Emissions Measurement System with a Mobile Reference Laboratory. Emiss. Control Sci. Technol. 2016, 2, 173–180. [Google Scholar] [CrossRef]

- Wang, G.; Qian, C.; Yang, G.L.; Nan, L.G.; Yu, H.G. Verification of PEMS measurement accuracy based on light vehicle emission test system. E3S Web Conf. 2021, 268, 11. [Google Scholar] [CrossRef]

- Broekaert, S.; Grigoratos, T.; Savvidis, D.; Fontaras, G. Assessment of waste heat recovery for heavy-duty vehicles during on-road operation. Appl. Therm. Eng. 2021, 191, 116891. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Zardini, A.A.; Clairotte, M. Exhaust Gas Condensation during Engine Cold Start and Application of the Dry-Wet Correction Factor. Appl. Sci. 2019, 9, 2263. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W. Alcohols as Biofuel for a Diesel Engine with Blend Mode—A Review. Energies 2024, 17, 4516. [Google Scholar] [CrossRef]

- Gandiglio, M.; Marocco, P. Mapping Hydrogen Initiatives in Italy: An Overview of Funding and Projects. Energies 2024, 17, 2614. [Google Scholar] [CrossRef]

- Muhssen, H.S.; Zöldy, M.; Bereczky, Á. A Comprehensive Review on the Hydrogen–Natural Gas–Diesel Tri-Fuel Engine Exhaust Emissions. Energies 2024, 17, 3862. [Google Scholar] [CrossRef]

- Baldinelli, A.; Francesconi, M.; Antonelli, M. Hydrogen, E-Fuels, Biofuels: What Is the Most Viable Alternative to Diesel for Heavy-Duty Internal Combustion Engine Vehicles? Energies 2024, 17, 4728. [Google Scholar] [CrossRef]

- Zhu, H.; Ma, T.; Toumasatos, Z.; Cao, S.; Karavalakis, G.; Johnson, K.C.; Durbin, T. On-road NOx and NH3 emissions measurements from in-use heavy-duty diesel and natural gas trucks in the South Coast air Basin of California. Atmos. Environ. 2024, 316, 120179. [Google Scholar] [CrossRef]

- Vojtíšek-Lom, M.; Beránek, V.; Klír, V.; Jindra, P.; Pechout, M.; Voříšek, T. On-road and laboratory emissions of NO, NO2, NH3, N2O and CH4 from late-model EU light utility vehicles: Comparison of diesel and CNG. Sci. Total Environ. 2018, 616–617, 774–784. [Google Scholar] [CrossRef]

- Onishi, Y.; Hamauchi, S.; Shibuya, K.; McWilliams-Ward, K.; Akita, M.; Tsurumi, K. Development of On-Board NH3 and N2O Analyzer Utilizing Mid-Infrared Laser Absorption Spectroscopy; SAE Technical Paper 2021-01-0610; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Shibuya, K.; Podzorov, A.; Matsuhama, M.; Nishimura, K.; Magari, M. High sensitivity and low interference gas analyzer with feature extraction from mid-infrared laser absorption-modulated signal. Meas. Sci. Technol. 2021, 32, 035201. [Google Scholar] [CrossRef]

- Ferrarese, C.; Franzetti, J.; Selleri, T.; Suarez-Bertoa, R. VOC emissions from Euro 6 vehicles. Environ. Sci. Eur. 2024, 36, 27. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Selleri, T.; Gioria, R.; Melas, A.D.; Ferrarese, C.; Franzetti, J.; Arlitt, B.; Nagura, N.; Hanada, T.; Giechaskiel, B. Real-Time Measurements of Formaldehyde Emissions from Modern Vehicles. Energies 2022, 15, 7680. [Google Scholar] [CrossRef]

- Selleri, T.; Gioria, R.; Melas, A.D.; Giechaskiel, B.; Forloni, F.; Mendoza Villafuerte, P.; Demuynck, J.; Bosteels, D.; Wilkes, T.; Simons, O.; et al. Measuring Emissions from a Demonstrator Heavy-Duty Diesel Vehicle under Real-World Conditions—Moving Forward to Euro VII. Catalysts 2022, 12, 184. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Jakobsson, T.; Karlsson, H.L.; Khan, M.Y.; Kronlund, L.; Otsuki, Y.; Bredenbeck, J.; Handler-Matejka, S. Assessment of On-Board and Laboratory Gas Measurement Systems for Future Heavy-Duty Emissions Regulations. Int. J. Environ. Res. Public Health 2022, 19, 6199. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Franzetti, J.; Valverde, V.; Clairotte, M.; Suarez-Bertoa, R. Measurement of Light-Duty Vehicle Exhaust Emissions with Light Absorption Spectrometers. Technologies 2024, 12, 32. [Google Scholar] [CrossRef]

- Gioria, R.; Selleri, T.; Giechaskiel, B.; Franzetti, J.; Ferrarese, C.; Melas, A.; Forloni, F.; Suarez-Bertoa, R.; Perujo, A. Regulated and unregulated emissions from Euro VI Diesel and CNG heavy-duty vehicles. Transp. Res. Part D Transp. Environ. 2024, 134, 104349. [Google Scholar] [CrossRef]

- ISO 17043:2010; Conformity Assessment—General Requirements for Proficiency Testing. ISO: Geneva, Switzerland, 2010.

- Thiruvengadam, A.; Besch, M.; Carder, D.; Oshinuga, A.; Pasek, R.; Hogo, H.; Gautam, M. Unregulated greenhouse gas and ammonia emissions from current technology heavy-duty vehicles. J. Air Waste Manag. Assoc. 2016, 66, 1045–1060. [Google Scholar] [CrossRef]

- Valverde, V.; Kondo, Y.; Otsuki, Y.; Krenz, T.; Melas, A.; Suarez-Bertoa, R.; Giechaskiel, B. Measurement of Gaseous Exhaust Emissions of Light-Duty Vehicles in Preparation for Euro 7: A Comparison of Portable and Laboratory Instrumentation. Energies 2023, 16, 2561. [Google Scholar] [CrossRef]

- Ferri, D.; Elsener, M.; Kröcher, O. Methane oxidation over a honeycomb Pd-only three-way catalyst under static and periodic operation. Appl. Catal. B Environ. 2018, 220, 67–77. [Google Scholar] [CrossRef]

- Xin, Q. Diesel Engine System Design; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Mera, Z.; Fonseca, N.; López, J.M.; Casanova, J. Analysis of the high instantaneous NOx emissions from Euro 6 diesel passenger cars under real driving conditions. Appl. Energy 2019, 242, 1074–1089. [Google Scholar] [CrossRef]

- Zhu, H.; McCaffery, C.; Yang, J.; Li, C.; Karavalakis, G.; Johnson, K.C.; Durbin, T.D. Characterizing emission rates of regulated and unregulated pollutants from two ultra-low NOx CNG heavy-duty vehicles. Fuel 2020, 277, 118192. [Google Scholar] [CrossRef]

- Agency for Toxic Substances and Disease Registry. Toxicological Profile for Ammonia; US Department of Health and Human Services: Atlanta, GA, USA, 2004.

- Finlayson-Pitts, B.J.; Pitts, J.N. Chemistry of the Upper and Lower Atmosphere; Elsevier: New York, NY, USA, 1999. [Google Scholar]

- Suarez-Bertoa, R.; Zardini, A.A.; Lilova, V.; Meyer, D.; Nakatani, S.; Hibel, F.; Ewers, J.; Clairotte, M.; Hill, L.; Astorga, C. Intercomparison of real-time tailpipe ammonia measurements from vehicles tested over the new world-harmonized light-duty vehicle test cycle (WLTC). Environ. Sci. Pollut. Res. 2015, 22, 7450–7460. [Google Scholar] [CrossRef] [PubMed]

- Suarez-Bertoa, R.; Lähde, T.; Pavlovic, J.; Valverde, V.; Clairotte, M.; Giechaskiel, B. Laboratory and On-Road Evaluation of a GPF-Equipped Gasoline Vehicle. Catalysts 2019, 9, 678. [Google Scholar] [CrossRef]

- Whittington, B.I.; Jiang, C.J.; Trimm, D.L. Vehicle exhaust catalysis: I. The relative importance of catalytic oxidation, steam reforming and water-gas shift reactions. Catal. Today 1995, 26, 41–45. [Google Scholar] [CrossRef]

- Bradow, R.L.; Stump, F.D. Unregulated Emissions from Three-Way Catalyst Cars; SAE Technical Paper No. 770369; SAE International: Warrendale, PA, USA, 1977. [Google Scholar]

- Guan, B.; Zhan, R.; Lin, H.; Huang, Z. Review of state of the art technologies of selective catalytic reduction of NOx from diesel engine exhaust. Appl. Therm. Eng. 2014, 66, 395–414. [Google Scholar] [CrossRef]

- Brinklow, G.; Herreros, J.M.; Zeraati Rezaei, S.; Doustdar, O.; Tsolakis, A.; Kolpin, A.; Millington, P. Non-Carbon Greenhouse Gas Emissions for Hybrid Electric Vehicles: Three-Way Catalyst Nitrous Oxide and Ammonia Trade-Off. Int. J. Environ. Sci. Technol. 2023, 20, 12521–12532. [Google Scholar] [CrossRef]

- Colombo, M.; Nova, I.; Tronconi, E. Detailed kinetic modeling of the NH3–NO/NO2 SCR reactions over a commercial Cu-zeolite catalyst for Diesel exhausts after treatment. Catal. Today 2012, 197, 243–255. [Google Scholar] [CrossRef]

- EC. Regulation (EU) 2024/1257 of the European Parliament and of the Council of 24 April 2024 on Type-Approval of Motor Vehicles and Engines and of Systems, Components and Separate Technical Units Intended for Such Vehicles, with Respect to Their Emissions and Battery Durability (Euro 7), Amending Regulation (EU) 2018/858 of the European Parliament and of the Council and Repealing Regulations (EC) No 715/2007 and (EC) No 595/2009 of the European Parliament and of the Council, Commission Regulation (EU) No 582/2011, Commission Regulation (EU) 2017/1151, Commission Regulation (EU) 2017/2400 and Commission Implementing Regulation (EU) 2022/1362, OJ L, 2024/1257. 5 August 2024. Available online: https://eur-lex.europa.eu/eli/reg/2024/1257/oj (accessed on 10 October 2024).

- Ravishankara, A.R.; Daniel, J.S.; Portmann, R.W. Nitrous oxide (N2O): The dominant ozone-depleting substance emitted in the 21st century. Science 2009, 326, 123–125. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Gioria, R.; Selleri, T.; Lilova, V.; Melas, A.; Onishi, Y.; Franzetti, J.; Forloni, F.; Perujo, A. NH3 and N2O Real World Emissions Measurement from a CNG Heavy Duty Vehicle Using On-Board Measurement Systems. Appl. Sci. 2021, 11, 10055. [Google Scholar] [CrossRef]

- Ayala, A.; Gebel, M.; Okamoto, R.; Rieger, P.; Kado, N.Y.; Cotter, C.; Verma, N. Oxidation Catalyst Effect on CNG Transit Bus Emissions; SAE Technical Paper 2003-01-1900; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Zeng, P.; Lyu, X.; Guo, H.; Cheng, H.; Wang, Z.; Liu, X.; Zhang, W. Spatial variation of sources and photochemistry of formaldehyde in Wuhan, Central China. Atmos. Environ. 2019, 214, 116826. [Google Scholar] [CrossRef]

- Karavalakis, G.; Durbin, T.; Russell, R. CRC Project No. AVFL—17b: Biodiesel and Renewable Diesel Characterization and Testing in Modern LD Diesel Passenger Cars and Trucks; Coordinating Research Council, Inc.: Alpharetta, GA, USA, 2014. [Google Scholar]

- Wei, L.; Yao, C.; Wang, Q.; Pan, W.; Han, G. Combustion and emission characteristics of a turbocharged diesel engine using high premixed ratio of methanol and diesel fuel. Fuel 2015, 140, 156–163. [Google Scholar] [CrossRef]

- Geng, P.; Zhang, H.; Yang, S.; Yao, C. Comparative study on measurements of formaldehyde emission of methanol/gasoline fueled SI engine. Fuel 2015, 148, 9–15. [Google Scholar] [CrossRef]

- UNECE. Global Technical Regulation No. 15 (Worldwide Harmonized Light Vehicles Test Procedure). Available online: https://unece.org/transport/standards/transport/vehicle-regulations-wp29/global-technical-regulations-gtrs (accessed on 10 October 2024).

- Baan, R.; Grosse, Y.; Straif, K.; Lauby-Secretan, B.; El Ghissassi, F.; Bouvard, V.; Benbrahim-Tallaa, L.; Guha, N.; Freeman, C.; Galichet, L.; et al. A review of human carcinogens—Part F: Chemical agents and related occupations. Lancet Oncol. 2009, 10, 1143–1144. [Google Scholar] [CrossRef]

- Available online: https://www.ecfr.gov/current/title-40/chapter-I/subchapter-U/part-1066/subpart-G/section-1066.635 (accessed on 10 October 2024).

- Wallner, T. Correlation between speciated hydrocarbon emissions and flame ionization detector response for gasoline/alcohol blends. J. Eng. Gas Turbines Power 2011, 133, 82801. [Google Scholar] [CrossRef]

- EU. Regulation (EU) 2024/1610 of the European Parliament and of the Council of 14 May 2024 Amending Regulation (EU) 2019/1242 as Regards Strengthening the CO2 Emission Performance Standards for New Heavy-Duty Vehicles and Integrating Reporting Obligations, Amending Regulation (EU) 2018/858 and Repealing Regulation (EU) 2018/956. OJ L, 2024/1610. 6 June 2024. Available online: https://eur-lex.europa.eu/eli/reg/2024/1610/oj (accessed on 10 October 2024).

- Available online: https://www.federalregister.gov/documents/2024/04/22/2024-06809/greenhouse-gas-emissions-standards-for-heavy-duty-vehicles-phase-3 (accessed on 10 October 2024).

| Instrument | NOx | CH4 | CO | NH3 | N2O | HCHO | CO2 | H2O |

|---|---|---|---|---|---|---|---|---|

| LABCLD | X | - | - | - | - | - | - | - |

| LABNDIR | - | - | X | - | - | - | X | - |

| LABFID | - | X | - | - | - | - | - | - |

| LABFTIR-1 | X | X | X | X | X | X | X | X |

| LABFTIR-2 | X | X | X | X | X | X | X | X |

| LABQCL-IR | X | - | - | X | X | * | - | - |

| PEMSFTIR-1 | X | X | X | X | X | X | X | X |

| PEMSFTIR-2 | X | X | X | X | X | X | X | X |

| PEMSQCL-IR | X | X | X | X | X | X | X | - |

| 3 | CNG HD Vehicle | Diesel HD Engine |

|---|---|---|

| Vehicle category | N3 | - |

| Emission standard | Euro VI Step E | Euro VI Step E |

| Fuel type | CNG | Diesel |

| Length (mm) | 9765 | - |

| Vehicle mass in running order (kg) | 15,525 | - |

| Vehicle technically permissible max laden mass (kg) | 26,000 | - |

| Axle layout | 3 axis-6 wheels-8 tires | - |

| Working principle | Spark ignition | Compression ignition |

| Engine configuration | 6 cylinders in line | 6 cylinders in line |

| Engine size (cm3) | 8710 | 12,800 |

| Maximum power | 251 kW @ 2000 rpm | 405 kW @ 1700 rpm |

| Gearbox | Automatic | - |

| After-treatment configuration | TWC | DOC + DPF + SCR/ASC |

| Instrument Code | Commercial Name | Sampling Rate (L/min) | Spectral Resolution (cm−1) | Optical Path (m) | Acquisition Frequency (Hz) |

|---|---|---|---|---|---|

| LABFTIR-1 | AVL SESAM 1 | 6.5 | 0.5 | 2 | 1 |

| LABFTIR-2 | IAG Versa06 LP 2 | 8 | 0.5 | 5.11 | 5 |

| LABQCL-IR | HORIBA MEXA-ONE-XL-NX 1 | 8 | <0.01 | 12.4 | 10 |

| PEMSFTIR-1 | AVL MOVE FT | 5.5 | 0.5 | 5 | 1 |

| PEMSFTIR-2 | IAG OPS 2 | 8 | 0.5 | 5.11 | 5 |

| PEMSQCL-IR | VERIDRIVE 3 | 3.3 | <0.01 | 5 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suarez-Bertoa, R.; Gioria, R.; Ferrarese, C.; Finocchiaro, L.; Giechaskiel, B. Alternative Analyzers for the Measurement of Gaseous Compounds During Type-Approval of Heavy-Duty Vehicles. Energies 2024, 17, 5676. https://doi.org/10.3390/en17225676

Suarez-Bertoa R, Gioria R, Ferrarese C, Finocchiaro L, Giechaskiel B. Alternative Analyzers for the Measurement of Gaseous Compounds During Type-Approval of Heavy-Duty Vehicles. Energies. 2024; 17(22):5676. https://doi.org/10.3390/en17225676

Chicago/Turabian StyleSuarez-Bertoa, Ricardo, Roberto Gioria, Christian Ferrarese, Lorenzo Finocchiaro, and Barouch Giechaskiel. 2024. "Alternative Analyzers for the Measurement of Gaseous Compounds During Type-Approval of Heavy-Duty Vehicles" Energies 17, no. 22: 5676. https://doi.org/10.3390/en17225676

APA StyleSuarez-Bertoa, R., Gioria, R., Ferrarese, C., Finocchiaro, L., & Giechaskiel, B. (2024). Alternative Analyzers for the Measurement of Gaseous Compounds During Type-Approval of Heavy-Duty Vehicles. Energies, 17(22), 5676. https://doi.org/10.3390/en17225676