Energy Quality of Corn Biomass from Gasoline-Contaminated Soils Remediated with Sorbents

Abstract

1. Introduction

2. Materials and Methods

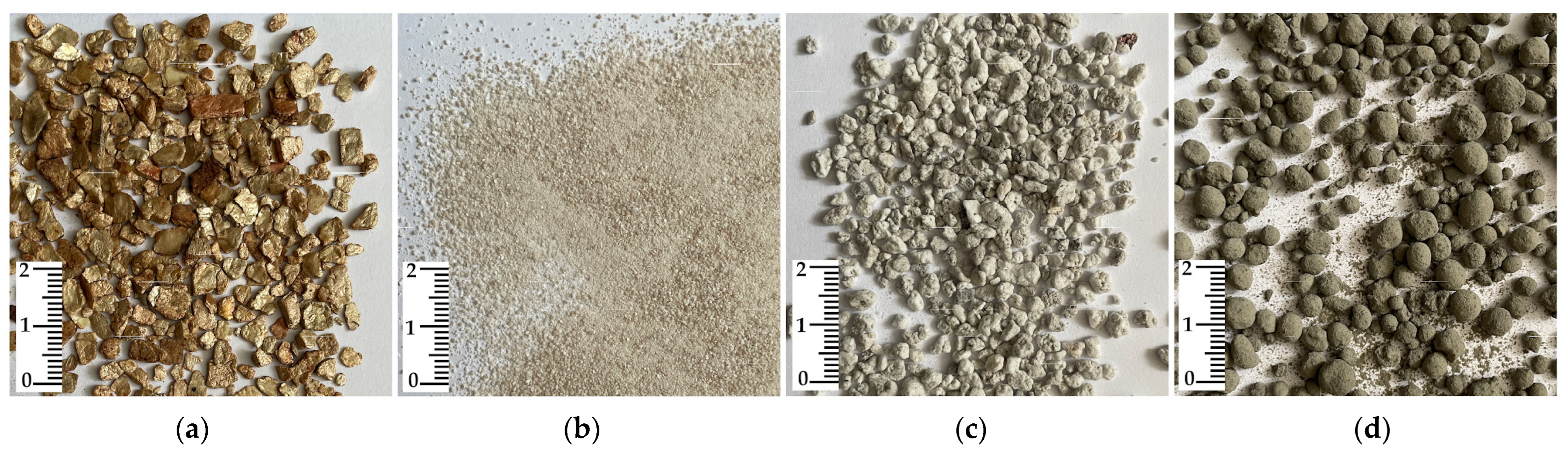

2.1. Research Design

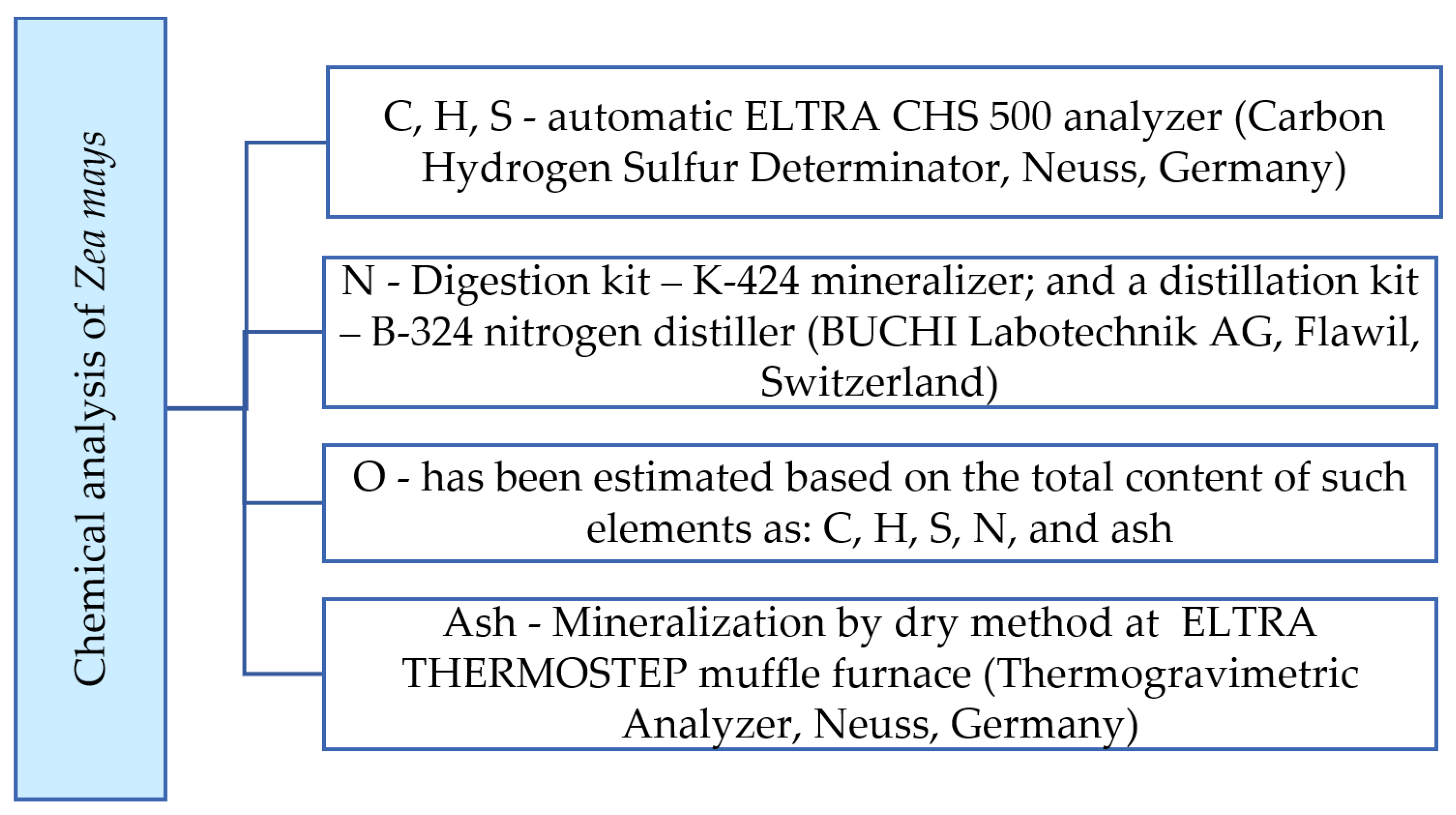

2.2. Laboratory Analyzes

2.3. Statistical Data Processing and Analysis

3. Results

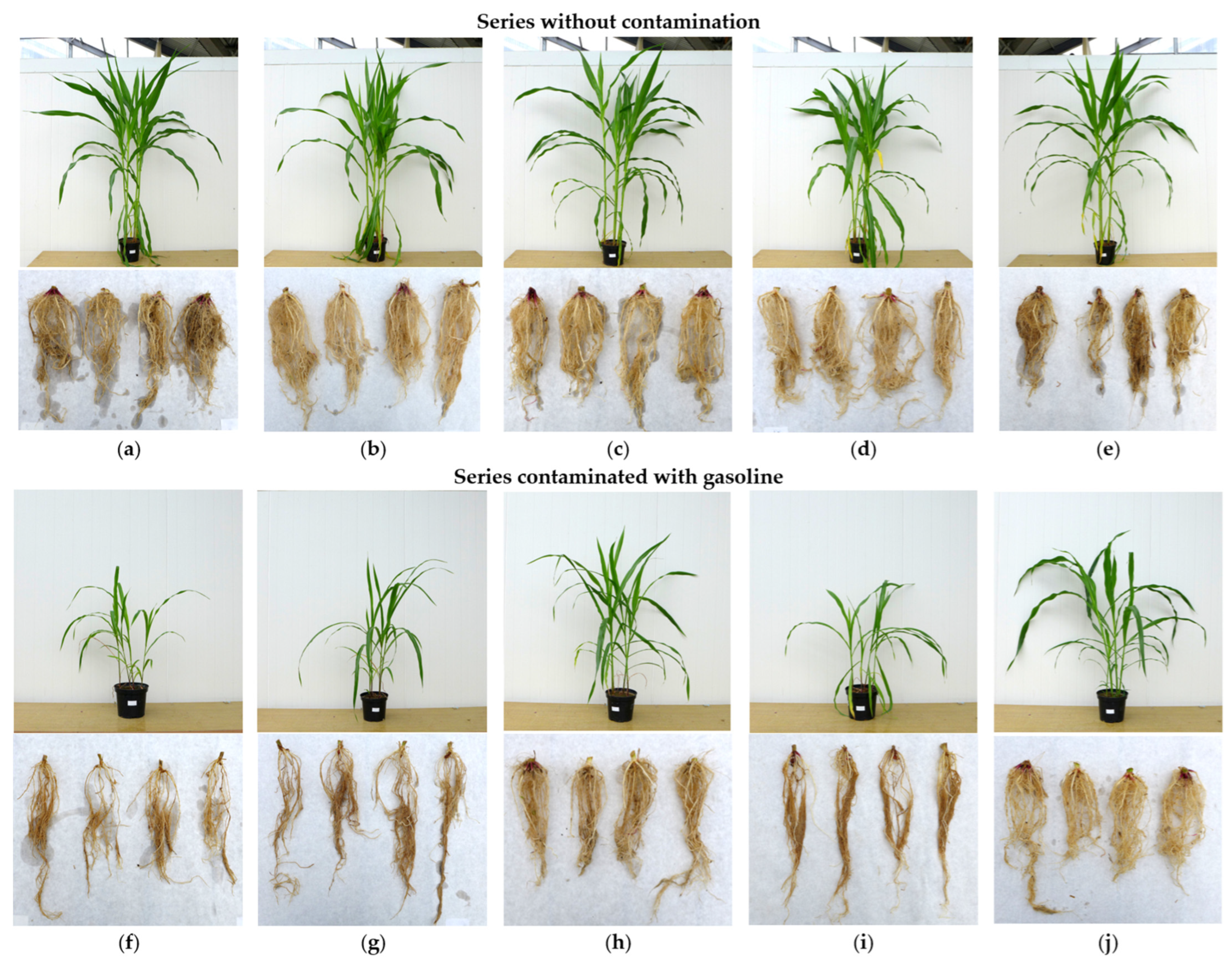

3.1. Zea mays Biomass

3.2. Contents of Ash, Nitrogen, Carbon, Hydrogen, Sulfur and Oxygen in Aboveground Parts of Zea mays

3.3. Energy Value of Aboveground Parts of Zea mays

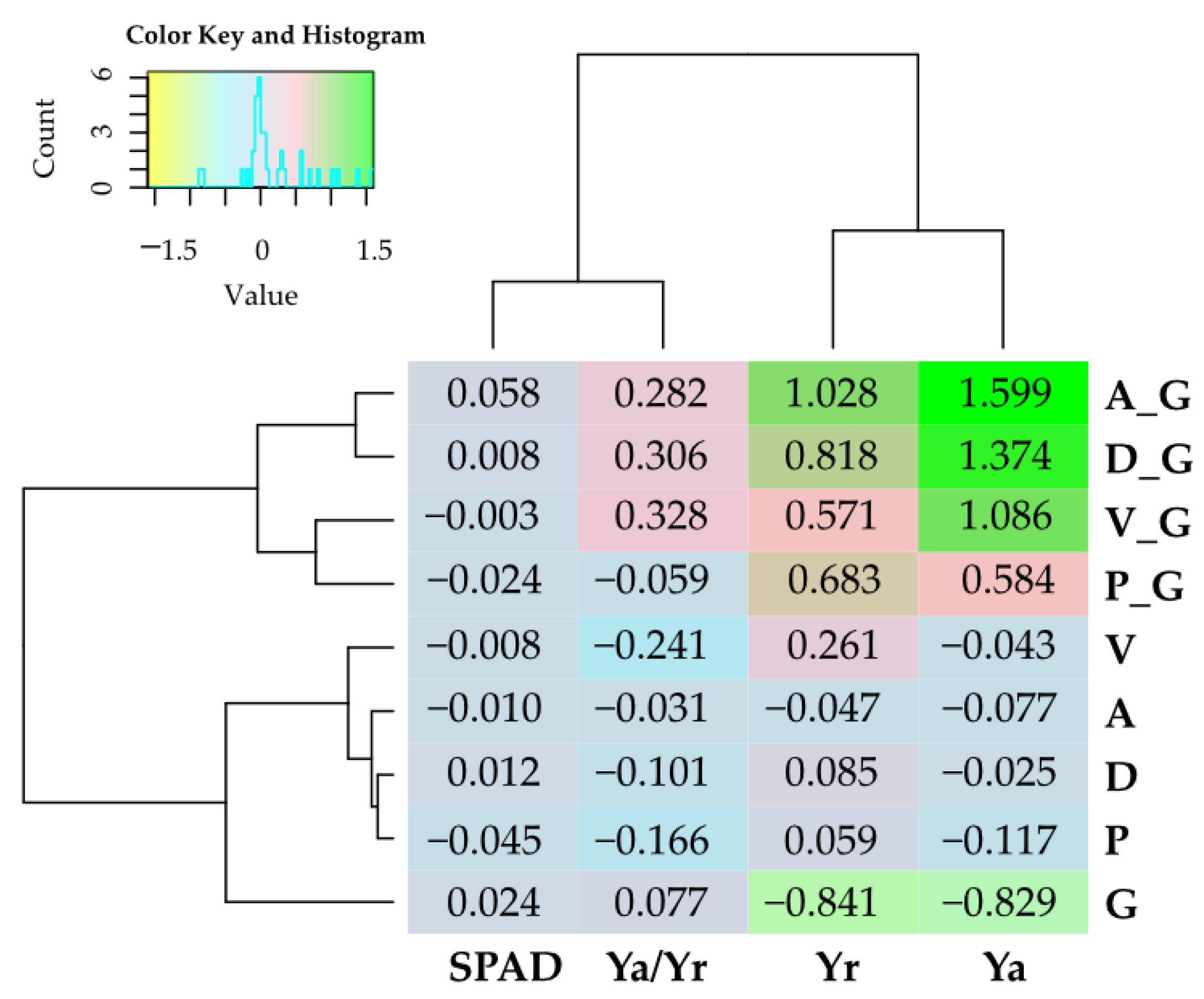

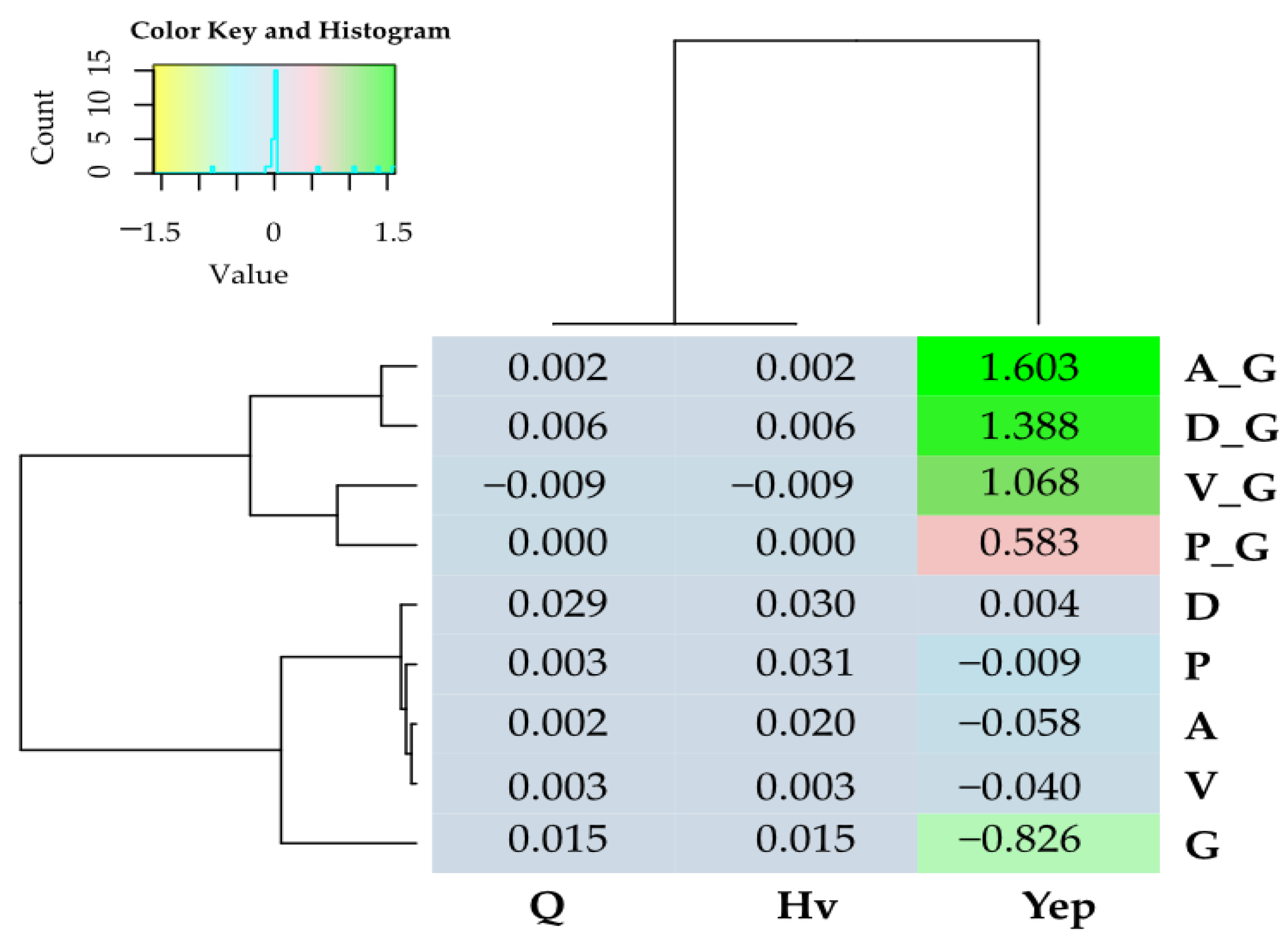

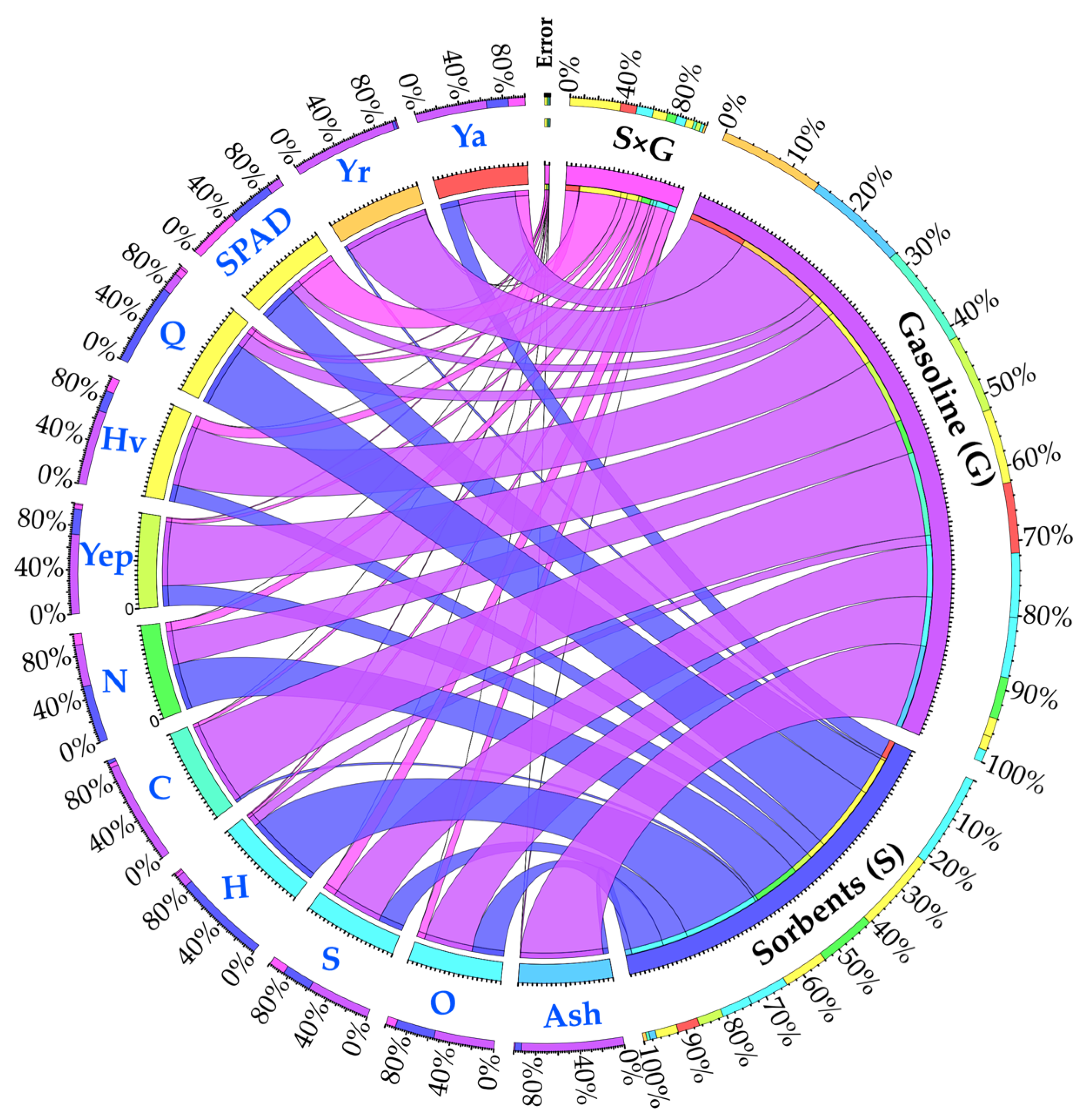

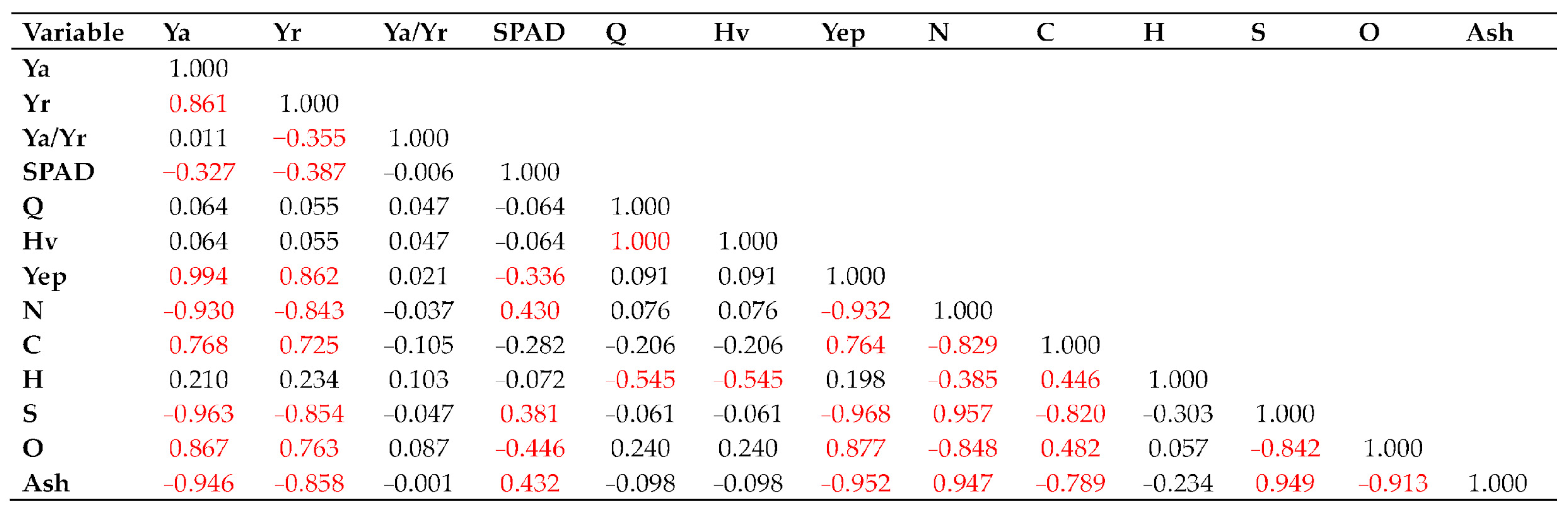

3.4. Interactions Between Zea mays Yield and Its Energy Value

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Jåstad, E.O.; Bolkesjø, T.F.; Trømborg, E.; Rørstad, P.K. The Role of Woody Biomass for Reduction of Fossil GHG Emissions in the Future North European Energy Sector. Appl. Energy 2020, 274, 115360. [Google Scholar] [CrossRef]

- Saez de Bikuña, K.; Garcia, R.; Dias, A.C.; Freire, F. Global Warming Implications from Increased Forest Biomass Utilization for Bioenergy in a Supply-Constrained Context. J. Environ. Manag. 2020, 263, 110292. [Google Scholar] [CrossRef] [PubMed]

- Günal, A.Ç.; Tunca, S.K.; Arslan, P.; Gül, G.; Dinçel, A.S. How Does Sublethal Permethrin Effect Non-Target Aquatic Organisms? Environ. Sci. Pollut. Res. 2021, 28, 52405–52417. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.F.; Rafa, N.; Mofijur, M.; Badruddin, I.A.; Inayat, A.; Ali, M.S.; Farrok, O.; Yunus Khan, T.M. Biohydrogen Production from Biomass Sources: Metabolic Pathways and Economic Analysis. Front. Energy Res. 2021, 9, 753878. [Google Scholar] [CrossRef]

- Anwar, M.N.; Fayyaz, A.; Sohail, N.F.; Khokhar, M.F.; Baqar, M.; Yasar, A.; Rasool, K.; Nazir, A.; Raja, M.U.F.; Rehan, M.; et al. CO2 Utilization: Turning Greenhouse Gas into Fuels and Valuable Products. J. Environ. Manag. 2020, 260, 110059. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, G.; Sharma, A.; Chandra Dash, A. Biomass from Trees for Bioenergy and Biofuels—A Briefing Paper. Mater. Today Proc. 2022, 65, 461–467. [Google Scholar] [CrossRef]

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a Sustainable Bioeconomy: An Overview of World Biomass Production and Utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Gyamfi, B.A.; Ozturk, I.; Bein, M.A.; Bekun, F.V. An Investigation into the Anthropogenic Effect of Biomass Energy Utilization and Economic Sustainability on Environmental Degradation in E7 Economies. Biofuels Bioprod. Biorefining 2021, 15, 840–851. [Google Scholar] [CrossRef]

- Cadillo-Benalcazar, J.J.; Bukkens, S.G.F.; Ripa, M.; Giampietro, M. Why Does the European Union Produce Biofuels? Examining Consistency and Plausibility in Prevailing Narratives with Quantitative Storytelling. Energy Res. Soc. Sci. 2021, 71, 101810. [Google Scholar] [CrossRef]

- Yang, L.; Wang, X.-C.; Dai, M.; Chen, B.; Qiao, Y.; Deng, H.; Zhang, D.; Zhang, Y.; Villas Bôas de Almeida, C.M.; Chiu, A.S.F.; et al. Shifting from Fossil-Based Economy to Bio-Based Economy: Status Quo, Challenges, and Prospects. Energy 2021, 228, 120533. [Google Scholar] [CrossRef]

- Vijay, V.; Chandra, R.; Subbarao, P.M.V. Biomass as a Means of Achieving Rural Energy Self-Sufficiency: A Concept. Built Environ. Proj. Asset Manag. 2022, 12, 382–400. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Janalizadeh, H.; Yousefi, H.; Jahangir, M.H. Biofuel for Energy Self-Sufficiency in Agricultural Sector of Iran. Sustain. Energy Technol. Assess. 2021, 44, 101069. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Lo, S.-L. Predicting Heating Value of Lignocellulosic Biomass Based on Elemental Analysis. Energy 2020, 191, 116501. [Google Scholar] [CrossRef]

- Mao, G.; Huang, N.; Chen, L.; Wang, H. Research on Biomass Energy and Environment from the Past to the Future: A Bibliometric Analysis. Sci. Total Environ. 2018, 635, 1081–1090. [Google Scholar] [CrossRef] [PubMed]

- de Paulo, E.H.; dos Santos, F.D.; Folli, G.S.; Santos, L.P.; Nascimento, M.H.C.; Moro, M.K.; da Cunha, P.H.P.; Castro, E.V.R.; Cunha Neto, A.; Filgueiras, P.R. Determination of Gross Calorific Value in Crude Oil by Variable Selection Methods Applied to 13C NMR Spectroscopy. Fuel 2022, 311, 122527. [Google Scholar] [CrossRef]

- Amaral, L.V.; Santos, N.D.S.A.; Roso, V.R.; de Oliveira Sebastião, R.d.C.; Pujatti, F.J.P. Effects of Gasoline Composition on Engine Performance, Exhaust Gases and Operational Costs. Renew. Sustain. Energy Rev. 2021, 135, 110196. [Google Scholar] [CrossRef]

- Zaharin, M.S.M.; Abdullah, N.R.; Masjuki, H.H.; Ali, O.M.; Najafi, G.; Yusaf, T. Evaluation on Physicochemical Properties of Iso-Butanol Additives in Ethanol-Gasoline Blend on Performance and Emission Characteristics of a Spark-Ignition Engine. Appl. Therm. Eng. 2018, 144, 960–971. [Google Scholar] [CrossRef]

- Stöcker, M. Biofuels and Biomass-To-Liquid Fuels in the Biorefinery: Catalytic Conversion of Lignocellulosic Biomass Using Porous Materials. Angew. Chem. Int. Ed. 2008, 47, 9200–9211. [Google Scholar] [CrossRef]

- Zahed, M.A.; Movahed, E.; Khodayari, A.; Zanganeh, S.; Badamaki, M. Biotechnology for Carbon Capture and Fixation: Critical Review and Future Directions. J. Environ. Manag. 2021, 293, 112830. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Lee, S.-E.; Lee, D.-W. Current Status and Future Prospects of Biological Routes to Bio-Based Products Using Raw Materials, Wastes, and Residues as Renewable Resources. Crit. Rev. Environ. Sci. Technol. 2022, 52, 2453–2509. [Google Scholar] [CrossRef]

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast). 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001 (accessed on 25 September 2024).

- The Paris Agreement|UNFCCC. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 25 September 2024).

- National Energy and Climate Plan for the Years 2021–2030—Ministerstwo Klimatu i Środowiska—Portal Gov.Pl. Available online: https://www.gov.pl/web/klimat/national-energy-and-climate-plan-for-the-years-2021-2030 (accessed on 25 September 2024).

- Energy Policy of Poland Until 2040—Portal Gov.Pl. Available online: https://www.gov.pl/web/klimat/polityka-energetyczna-polski (accessed on 25 September 2024).

- Malacara-Becerra, A.; Melchor-Martínez, E.M.; Sosa-Hernández, J.E.; Riquelme-Jiménez, L.M.; Mansouri, S.S.; Iqbal, H.M.N.; Parra-Saldívar, R. Bioconversion of Corn Crop Residues: Lactic Acid Production through Simultaneous Saccharification and Fermentation. Sustainability 2022, 14, 11799. [Google Scholar] [CrossRef]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of Promising Technologies for Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Ashokkumar, V.; Venkatkarthick, R.; Jayashree, S.; Chuetor, S.; Dharmaraj, S.; Kumar, G.; Chen, W.-H.; Ngamcharussrivichai, C. Recent Advances in Lignocellulosic Biomass for Biofuels and Value-Added Bioproducts—A Critical Review. Bioresour. Technol. 2022, 344, 126195. [Google Scholar] [CrossRef] [PubMed]

- Bielik, P.; Belinska, S.; Bajusová, Z.; Adamičková, I.; Bullová, T.; Belinska, Y.; Husárová, P. Economic Impact of Using Biomass for Biogas Production in the Context of Sustainable Development. WSEAS Trans. Bus. Econ. 2024, 21, 1684–1697. [Google Scholar] [CrossRef]

- Bórawski, P.; Bełdycka-Bórawska, A.; Kapsdorferová, Z.; Rokicki, T.; Parzonko, A.; Holden, L. Perspectives of Electricity Production from Biogas in the European Union. Energies 2024, 17, 1169. [Google Scholar] [CrossRef]

- Czekała, W.; Pulka, J.; Jasiński, T.; Szewczyk, P.; Bojarski, W.; Jasiński, J. Waste as Substrates for Agricultural Biogas Plants: A Case Study from Poland. J. Water Land Dev. 2023, 56, 45–50. [Google Scholar] [CrossRef]

- Kumar, A.; Ramamoorthy, D.; Kumar, N.; Verma, R.; Kumar, A.; Verma, D.K.; Jayabalan, I.; Marwein, B.M.; Jaiswal, K.K. Investigation on the Potential of Eco-Friendly Bio-Char for Amendment in Serpentine Soils and Immobilization of Heavy Metals Contaminants: A Review. Biomass Convers. Biorefinery 2023, 13, 16585–16605. [Google Scholar] [CrossRef]

- Ekka, P.; Patra, S.; Upreti, M.; Kumar, G.; Kumar, A.; Saikia, P. Land Degradation and Its Impacts on Biodiversity and Ecosystem Services. In Land and Environmental Management Through Forestry; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2023; pp. 77–101. ISBN 978-1-119-91052-7. [Google Scholar]

- Gonçalves, J.; Freitas, J.; Fernandes, I.; Silva, P. Microalgae as Biofertilizers: A Sustainable Way to Improve Soil Fertility and Plant Growth. Sustainability 2023, 15, 12413. [Google Scholar] [CrossRef]

- Wyszkowska, J.; Kucharski, J.; Kucharski, M.; Borowik, A. Applicability of Biochemical Indices to Quality Assessment of Soil Polluted with Heavy Metals. J. Elem. 2014, 18, 733–756. [Google Scholar] [CrossRef]

- Wyszkowska, J.; Boros-Lajszner, E.; Kucharski, J. The Impact of Soil Contamination with Lead on the Biomass of Maize Intended for Energy Purposes, and the Biochemical and Physicochemical Properties of the Soil. Energies 2024, 17, 1156. [Google Scholar] [CrossRef]

- Baćmaga, M.; Wyszkowska, J.; Borowik, A.; Kucharski, J. Effect of Sulcotrione and Terbuthylazine on Biological Characteristics of Soil. Appl. Soil Ecol. 2024, 195, 105232. [Google Scholar] [CrossRef]

- Gertsen, M.M.; Arlyapov, V.A.; Perelomov, L.V.; Kharkova, A.S.; Golysheva, A.N.; Atroshchenko, Y.M.; Cardinale, A.M.; Reverberi, A.P. Environmental Implications of Energy Sources: A Review on Technologies for Cleaning Oil-Contaminated Ecosystems. Energies 2024, 17, 3561. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Chebbi, A.; Formicola, F.; Prasad, S.; Gomez, F.H.; Franzetti, A.; Vaccari, M. Remediation of Soil Polluted with Petroleum Hydrocarbons and Its Reuse for Agriculture: Recent Progress, Challenges, and Perspectives. Chemosphere 2022, 293, 133572. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, R.T.; Zdarta, J. Fabrication of Engineered Biochar for Remediation of Toxic Contaminants in Soil Matrices and Soil Valorization. Chemosphere 2024, 358, 142101. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Tariq, S.M.; Yang, H. Engineering Clay Minerals to Manage the Functions of Soils. Clay Miner. 2022, 57, 51–69. [Google Scholar] [CrossRef]

- Garbowski, T.; Bar-Michalczyk, D.; Charazińska, S.; Grabowska-Polanowska, B.; Kowalczyk, A.; Lochyński, P. An Overview of Natural Soil Amendments in Agriculture. Soil Tillage Res. 2023, 225, 105462. [Google Scholar] [CrossRef]

- Mota, J.; Merlo, E.; Martínez-Hernández, F.; Mendoza-Fernández, A.J.; Pérez-García, F.J.; Salmerón-Sánchez, E. Plants on Rich-Magnesium Dolomite Barrens: A Global Phenomenon. Biology 2021, 10, 38. [Google Scholar] [CrossRef]

- Bolan, N.; Sarmah, A.K.; Bordoloi, S.; Bolan, S.; Padhye, L.P.; Van Zwieten, L.; Sooriyakumar, P.; Khan, B.A.; Ahmad, M.; Solaiman, Z.M.; et al. Soil Acidification and the Liming Potential of Biochar. Environ. Pollut. 2023, 317, 120632. [Google Scholar] [CrossRef]

- Abdul-Sahib, A.M.; Golbashy, M.; Abbass, J. Effect of Date Palm Wastes, Perlite and Magnesium on Growth and Flowering in Gerbera Plants (Gerbera jamesonii L.). Int. J. Hortic. Sci. Technol. 2023, 10, 375–386. [Google Scholar] [CrossRef]

- Wyszkowska, J.; Borowik, A.; Zaborowska, M.; Kucharski, J. The Potential for Restoring the Activity of Oxidoreductases and Hydrolases in Soil Contaminated with Petroleum Products Using Perlite and Dolomite. Appl. Sci. 2024, 14, 3591. [Google Scholar] [CrossRef]

- Cedeño, J.M.; Magán, J.-J.; Thompson, R.B.; Fernández, M.-D.; Gallardo, M. Comparison of Methods to Determine Nutrient Uptake of Tomato Grown in Free-Draining Perlite Substrate—Key Information for Optimal Fertigation Management. Horticulturae 2024, 10, 232. [Google Scholar] [CrossRef]

- Ramos, C.G.; dos Santos de Medeiros, D.; Gomez, L.; Oliveira, L.F.S.; Schneider, I.A.H.; Kautzmann, R.M. Evaluation of Soil Re-Mineralizer from By-Product of Volcanic Rock Mining: Experimental Proof Using Black Oats and Maize Crops. Nat. Resour. Res. 2020, 29, 1583–1600. [Google Scholar] [CrossRef]

- Luchese, A.V.; Leite, I.J.G.d.C.; Giaretta, A.P.d.S.; Alves, M.L.; Pivetta, L.A.; Missio, R.F. Use of Quarry Waste Basalt Rock Powder as a Soil Remineralizer to Grow Soybean and Maize. Heliyon 2023, 9, e14050. [Google Scholar] [CrossRef]

- Bandura, L.; Woszuk, A.; Kołodyńska, D.; Franus, W. Application of Mineral Sorbents for Removal of Petroleum Substances: A Review. Minerals 2017, 7, 37. [Google Scholar] [CrossRef]

- Vasilyeva, G.; Mikhedova, E.; Zinnatshina, L.; Strijakova, E.; Akhmetov, L.; Sushkova, S.; Ortega-Calvo, J.-J. Use of Natural Sorbents for Accelerated Bioremediation of Grey Forest Soil Contaminated with Crude Oil. Sci. Total Environ. 2022, 850, 157952. [Google Scholar] [CrossRef] [PubMed]

- Aspectos Ecológicos Del Uso de Sorbentes Para Mejorar La Eficiencia de Bioremediación de Suelos Contaminados Por Petróleo|Fuentes, El Reventón Energético. Available online: https://revistas.uis.edu.co/index.php/revistafuentes/article/view/12501 (accessed on 27 September 2024).

- Wyszkowska, J.; Borowik, A.; Zaborowska, M.; Kucharski, J. The Usability of Sorbents in Restoring Enzymatic Activity in Soils Polluted with Petroleum-Derived Products. Materials 2023, 16, 3738. [Google Scholar] [CrossRef]

- Islam, T.; Li, Y.; Cheng, H. Biochars and Engineered Biochars for Water and Soil Remediation: A Review. Sustainability 2021, 13, 9932. [Google Scholar] [CrossRef]

- Mohanta, S.; Pradhan, B.; Behera, I.D. Impact and Remediation of Petroleum Hydrocarbon Pollutants on Agricultural Land: A Review. Geomicrobiol. J. 2024, 41, 345–359. [Google Scholar] [CrossRef]

- IUSS Working Group. World Reference Base for Soil Resources 2014, Update 2015. International Soil Classification System for Naming Soils and Creating Legends for Soil Maps. World Soil Resour. Rep. 2015, 106, 192. [Google Scholar]

- EuroSuper 95—Unleaded Gasoline—ORLEN. Available online: https://www.orlen.pl/pl/dla-biznesu/produkty/paliwa/benzyna/benzyna-bezolowiowa-95 (accessed on 8 July 2024).

- PN-EN ISO 18125:2017-07; Solid Biofuels—Determination of Calorific Value. Polish Standardization Committee: Warsaw, Poland, 2017.

- Kopetz, H.; Jossart, J.; Ragossnig, H.; Metschina, C. European Biomass Statistics 2007; European Biomass Association: Brussels, Belgium, 2007. [Google Scholar]

- PN-EN ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Polish Standardization Committee: Warsaw, Poland, 2015.

- PN-G-04584:2001; Solid Fuels—Determination of Total and Ash Sulfur Content with Automatic Analyzers. Polish Standardization Committee: Warsaw, Poland, 2006.

- PN-EN ISO 16994:2016-10; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. Polish Standard-Ization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18122:2016-01; Solid Biofuels—Determination of Ash Content. Polish Standardization Committee: War-Saw, Poland, 2016.

- Wyszkowska, J.; Borowik, A.; Zaborowska, M.; Kucharski, J. Calorific Value of Zea Mays Biomass Derived from Soil Contaminated with Chromium (VI) Disrupting the Soil’s Biochemical Properties. Energies 2023, 16, 3788. [Google Scholar] [CrossRef]

- Wyszkowska, J.; Borowik, A.; Kucharski, J. The Role of Grass Compost and Zea Mays in Alleviating Toxic Effects of Tetracycline on the Soil Bacteria Community. Int. J. Environ. Res. Public Health 2022, 19, 7357. [Google Scholar] [CrossRef] [PubMed]

- Wyszkowska, J.; Borowik, A.; Zaborowska, M.; Kucharski, J. Mitigation of the Adverse Impact of Copper, Nickel, and Zinc on Soil Microorganisms and Enzymes by Mineral Sorbents. Materials 2022, 15, 5198. [Google Scholar] [CrossRef] [PubMed]

- Citing RStudio. Available online: https://www.posit.co/ (accessed on 8 July 2024).

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2019. Available online: https://www.r-project.org (accessed on 8 July 2024).

- Warnes, G.R.; Bolker, B.; Bonebakker, L.; Gentleman, R.; Huber, W.; Liaw, A.; Lumley, T.; Maechler, M.; Magnusson, A.; Moeller, S.; et al. Gplots: Various R Programming Tools for Plotting Data. R Package Version 2.17.0. 2020. Available online: https://CRAN.R-Project.org/package=gplots (accessed on 8 July 2024).

- Tibco Software Inc. Statistica, version 13 Data Analysis Software System; Tibco Software Inc.: Palo Alto, CA, USA, 2021. Available online: https://www.tibco.com/ (accessed on 8 July 2024).

- Krzywiński, M.; Schein, J.; Birol, İ.; Connors, J.; Gascoyne, R.; Horsman, D.; Jones, S.J.; Marra, M.A. Circos: An Information Aesthetic for Comparative Genomics. Genome Res. 2009, 19, 1639–1645. [Google Scholar] [CrossRef] [PubMed]

- Udume, O.A.; Abu, G.O.; Stanley, H.O.; Vincent-Akpu, I.F.; Momoh, Y.; Eze, M.O. Biostimulation of Petroleum-Contaminated Soil Using Organic and Inorganic Amendments. Plants 2023, 12, 431. [Google Scholar] [CrossRef]

- Mishra, P.; Kiran, N.S.; Romanholo Ferreira, L.F.; Yadav, K.K.; Mulla, S.I. New Insights into the Bioremediation of Petroleum Contaminants: A Systematic Review. Chemosphere 2023, 326, 138391. [Google Scholar] [CrossRef]

- Aziz, Z.S.; Jazza, S.H.; Dageem, H.N.; Banoon, S.R.; Balboul, B.A.; Abdelzaher, M.A. Bacterial Biodegradation of Oil-Contaminated Soil for Pollutant Abatement Contributing to Achieve Sustainable Development Goals: A Comprehensive Review. Results Eng. 2024, 22, 102083. [Google Scholar] [CrossRef]

- Wei, Z.; Wei, Y.; Liu, Y.; Niu, S.; Xu, Y.; Park, J.-H.; Wang, J.J. Biochar-Based Materials as Remediation Strategy in Petroleum Hydrocarbon-Contaminated Soil and Water: Performances, Mechanisms, and Environmental Impact. J. Environ. Sci. 2024, 138, 350–372. [Google Scholar] [CrossRef]

- Abbaspour, A.; Zohrabi, F.; Dorostkar, V.; Faz, A.; Acosta, J.A. Remediation of an Oil-Contaminated Soil by Two Native Plants Treated with Biochar and Mycorrhizae. J. Environ. Manag. 2020, 254, 109755. [Google Scholar] [CrossRef]

- Dahiya, P.; Behl, M.; Kumari, D.; Arya, E.; Rathour, R.K.; Kumar, V.; Bhatia, R.K. Detoxification of Contaminated Soil to Restore Its Health for Sustainable Agriculture. In Advancements in Microbial Biotechnology for Soil Health; Bhatia, R.K., Walia, A., Eds.; Springer Nature: Singapore, 2024; pp. 295–322. ISBN 978-981-9994-82-3. [Google Scholar]

- Vasilyeva, G.K.; Strijakova, E.R.; Ortega-Calvo, J.J. Remediation of Soils Polluted by Oil Industries. In Soil Remediation Science and Technology; Ortega-Calvo, J.J., Coulon, F., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 191–234. ISBN 978-3-031-60192-7. [Google Scholar]

- Wyszkowski, M.; Kordala, N. Trace Element Contents in Petrol-Contaminated Soil Following the Application of Compost and Mineral Materials. Materials 2022, 15, 5233. [Google Scholar] [CrossRef]

- Murtaza, G.; Ahmed, Z.; Eldin, S.M.; Ali, I.; Usman, M.; Iqbal, R.; Rizwan, M.; Abdel-Hameed, U.K.; Haider, A.A.; Tariq, A. Biochar as a Green Sorbent for Remediation of Polluted Soils and Associated Toxicity Risks: A Critical Review. Separations 2023, 10, 197. [Google Scholar] [CrossRef]

- Van Nguyen, T.T.; Phan, A.N.; Nguyen, T.-A.; Nguyen, T.K.; Nguyen, S.T.; Pugazhendhi, A.; Ky Phuong, H.H. Valorization of Agriculture Waste Biomass as Biochar: As First-Rate Biosorbent for Remediation of Contaminated Soil. Chemosphere 2022, 307, 135834. [Google Scholar] [CrossRef] [PubMed]

- Borowik, A.; Wyszkowska, J.; Zaborowska, M.; Kucharski, J. Soil Enzyme Response and Calorific Value of Zea Mays Used for the Phytoremediation of Soils Contaminated with Diesel Oil. Energies 2024, 17, 2552. [Google Scholar] [CrossRef]

- Wu, H.; Hu, J.; Shaaban, M.; Xu, P.; Zhao, J.; Hu, R. The Effect of Dolomite Amendment on Soil Organic Carbon Mineralization Is Determined by the Dolomite Size. Ecol. Process. 2021, 10, 8. [Google Scholar] [CrossRef]

- Huang, J.; Fisher, P.R.; Argo, W.R. Container Substrate-pH Response to Differing Limestone Type and Particle Size. HortScience 2007, 42, 1268–1273. [Google Scholar] [CrossRef]

- Cai, W.K.; Liu, J.H.; Zhou, C.H.; Keeling, J.; Glasmacher, U.A. Structure, Genesis and Resources Efficiency of Dolomite: New Insights and Remaining Enigmas. Chem. Geol. 2021, 573, 120191. [Google Scholar] [CrossRef]

- Qi, S.; Xue, Q.; Niu, Z.; Zhang, Y.; Liu, F.; Chen, H. Investigation of Zn2+ and Cd2+ Adsorption Performance by Different Weathering Basalts. Water. Air. Soil Pollut. 2016, 227, 126. [Google Scholar] [CrossRef]

- Ai, H.; Li, X.; Chen, C.; Xu, L.; Fu, M.-L.; Sun, W.; Yuan, B. Immobilization of β-FeOOH Nanomaterials on the Basalt Fiber as a Novel Porous Composite to Effectively Remove Phosphate from Aqueous Solution. Colloids Surf. Physicochem. Eng. Asp. 2022, 632, 127815. [Google Scholar] [CrossRef]

- Marková, I.; Kubás, J.; Buganová, K.; Ristvej, J. Usage of Sorbents for Diminishing the Negative Impact of Substances Leaking into the Environment in Car Accidents. Front. Public Health 2022, 10, 957090. [Google Scholar] [CrossRef]

- Sabadash, V. Adsorption of Oil Products by Natural Sorbents. In Modern Technologies in Energy and Transport; Boichenko, S., Zaporozhets, A., Yakovlieva, A., Shkilniuk, I., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 137–158. ISBN 978-3-031-44351-0. [Google Scholar]

- Balidakis, A.; Matsi, T.; Karagianni, A.-G.; Ipsilantis, I. Sewage Sludge Treated with Bentonite, Vermiculite or Biochar Can Improve Soil Properties and Enhance Growth of Grasses. Soil Use Manag. 2023, 39, 1403–1421. [Google Scholar] [CrossRef]

- Faleh, S.T.; Fahmi, A.H.; Abood, M.A. The Role of Biochar and Perlite in Improving Some Chemical Properties of Clay Loam Soil and Sandy Loam Soil. IOP Conf. Ser. Earth Environ. Sci. 2023, 1262, 082011. [Google Scholar] [CrossRef]

- Ansari, S.; Bahmaninia, H.; Mohammadi, M.-R.; Ostadhassan, M.; Norouzi-Apourvari, S.; Schaffie, M.; Ranjbar, M.; Hemmati-Sarapardeh, A. On the Evaluation of Asphaltene Adsorption onto Dolomite Surface: The Roles of Flow Condition, Composition of Asphaltene, and Dolomite Size. Alex. Eng. J. 2022, 61, 9411–9425. [Google Scholar] [CrossRef]

- Yuan, X.; Xia, W.; An, J.; Yin, J.; Zhou, X.; Yang, W. Kinetic and Thermodynamic Studies on the Phosphate Adsorption Removal by Dolomite Mineral. J. Chem. 2015, 2015, 853105. [Google Scholar] [CrossRef]

- Tuchowska, M.; Wołowiec, M.; Solińska, A.; Kościelniak, A.; Bajda, T. Organo-Modified Vermiculite: Preparation, Characterization, and Sorption of Arsenic Compounds. Minerals 2019, 9, 483. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Przybył, J.; Czajkowski, Ł.; Majka, J.; Pawłowski, A. Effects of Harvest Maturity on the Chemical and Energetic Properties of Corn Stover Biomass Combustion. Materials 2022, 15, 2831. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Przybył, J.; Ratajczak, I.; Goliński, P.; Janczak, D.; Waśkiewicz, A.; Szentner, K.; Woźniak, M. Chemical Composition of Maize Stover Fraction versus Methane Yield and Energy Value in Fermentation Process. Energy 2020, 198, 117258. [Google Scholar] [CrossRef]

- Mendes, M.P.; Cunha, D.L.; dos Santos, V.M.L.; Vianna, M.T.G.; Marques, M. Ecological Risk Assessment (ERA) Based on Contaminated Groundwater to Predict Potential Impacts to a Wetland Ecosystem. Environ. Sci. Pollut. Res. 2020, 27, 26332–26349. [Google Scholar] [CrossRef]

- Falih, K.T.; Mohd Razali, S.F.; Abdul Maulud, K.N.; Abd Rahman, N.; Abba, S.I.; Yaseen, Z.M. Assessment of Petroleum Contamination in Soil, Water, and Atmosphere: A Comprehensive Review. Int. J. Environ. Sci. Technol. 2024, 21, 8803–8832. [Google Scholar] [CrossRef]

- Saxena, R.C.; Adhikari, D.K.; Goyal, H.B. Biomass-Based Energy Fuel through Biochemical Routes: A Review. Renew. Sustain. Energy Rev. 2009, 13, 167–178. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Shetti, N.P.; Reddy, K.R.; Kwon, E.E.; Nadagouda, M.N.; Aminabhavi, T.M. Biomass Utilization and Production of Biofuels from Carbon Neutral Materials. Environ. Pollut. 2021, 276, 116731. [Google Scholar] [CrossRef]

- Saleem, M. Possibility of Utilizing Agriculture Biomass as a Renewable and Sustainable Future Energy Source. Heliyon 2022, 8, e08905. [Google Scholar] [CrossRef]

- Gao, C.; El-Sawah, A.M.; Ali, D.F.I.; Alhaj Hamoud, Y.; Shaghaleh, H.; Sheteiwy, M.S. The Integration of Bio and Organic Fertilizers Improve Plant Growth, Grain Yield, Quality and Metabolism of Hybrid Maize (Zea mays L.). Agronomy 2020, 10, 319. [Google Scholar] [CrossRef]

- Zahed, M.A.; Salehi, S.; Madadi, R.; Hejabi, F. Biochar as a Sustainable Product for Remediation of Petroleum Contaminated Soil. Curr. Res. Green Sustain. Chem. 2021, 4, 100055. [Google Scholar] [CrossRef]

- Wyszkowski, M.; Kordala, N. Role of Different Material Amendments in Shaping the Content of Heavy Metals in Maize (Zea mays L.) on Soil Polluted with Petrol. Materials 2022, 15, 2623. [Google Scholar] [CrossRef] [PubMed]

- Sabitov, A.; Atamanov, M.; Doszhanov, O.; Saurykova, K.; Tazhu, K.; Kerimkulova, A.; Orazbayev, A.; Doszhanov, Y. Surface Characteristics of Activated Carbon Sorbents Obtained from Biomass for Cleaning Oil-Contaminated Soils. Molecules 2024, 29, 3786. [Google Scholar] [CrossRef] [PubMed]

- Wyszkowski, M.; Wyszkowska, J.; Kordala, N.; Zaborowska, M. Molecular Sieve, Halloysite, Sepiolite and Expanded Clay as a Tool in Reducing the Content of Trace Elements in Helianthus annuus L. on Copper-Contaminated Soil. Materials 2023, 16, 1827. [Google Scholar] [CrossRef]

- Wyszkowska, J.; Borowik, A.; Zaborowska, M.; Kucharski, J. Biochar, Halloysite, and Alginite Improve the Quality of Soil Contaminated with Petroleum Products. Agriculture 2023, 13, 1669. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, Y. Performance of Different Sorbents toward Stabilizing Per- and Polyfluoroalkyl Substances (PFAS) in Soil. Environ. Adv. 2022, 8, 100217. [Google Scholar] [CrossRef]

- Qu, J.; Zhang, X.; Guan, Q.; Kong, L.; Yang, R.; Ma, X. Effects of Biochar Underwent Different Aging Processes on Soil Properties and Cd Passivation. Environ. Sci. Pollut. Res. 2022, 29, 57885–57895. [Google Scholar] [CrossRef]

- Vocciante, M.; Franchi, E.; Fusini, D.; Pedron, F.; Barbafieri, M.; Petruzzelli, G.; Reverberi, A.P. Sustainable Recovery of an Agricultural Area Impacted by an Oil Spill Using Enhanced Phytoremediation. Appl. Sci. 2024, 14, 582. [Google Scholar] [CrossRef]

- Nguyen Ho, Q.; Hidaka, T.; Rahman, M.A.; Yoshida, N. Application of Natural Zeolite Adsorption in Cooperation with Photosynthesis for the Post-Treatment of Microbial Fuel Cells. RSC Adv. 2024, 14, 26484–26493. [Google Scholar] [CrossRef]

- Atero-Calvo, S.; Magro, F.; Masetti, G.; Navarro-León, E.; Rios, J.J.; Blasco, B.; Ruiz, J.M. Comparative Effects of Root and Foliar Leonardite-Suspension Concentrate Application on Plant Growth and Photosynthetic Efficiency of Lettuce Plants (Lactuca sativa L.). J. Plant Growth Regul. 2024. [Google Scholar] [CrossRef]

- Wyszkowski, M.; Kordala, N. Applicability of Compost and Mineral Materials for Reducing the Effect of Diesel Oil on Trace Element Content in Soil. Materials 2023, 16, 3655. [Google Scholar] [CrossRef] [PubMed]

- Kamenchuk, V.; Rumiantsev, B.; Dzhatdoeva, S.; Sadykhov, E.; Kochkarov, A. Analysis of Cross-Influence of Microclimate, Lighting, and Soil Parameters in the Vertical Farm. Agronomy 2023, 13, 2174. [Google Scholar] [CrossRef]

- Głąb, T.; Gondek, K.; Mierzwa–Hersztek, M. Biological Effects of Biochar and Zeolite Used for Remediation of Soil Contaminated with Toxic Heavy Metals. Sci. Rep. 2021, 11, 6998. [Google Scholar] [CrossRef]

- Morales-Máximo, C.N.; López-Sosa, L.B.; Rutiaga-Quiñones, J.G.; Corral-Huacuz, J.C.; Aguilera-Mandujano, A.; Pintor-Ibarra, L.F.; López-Miranda, A.; Delgado-Domínguez, S.N.; Rodríguez-Magallón, M.d.C.; Morales-Máximo, M. Characterization of Agricultural Residues of Zea Mays for Their Application as Solid Biofuel: Case Study in San Francisco Pichátaro, Michoacán, Mexico. Energies 2022, 15, 6870. [Google Scholar] [CrossRef]

- Priya; Deora, P.S.; Verma, Y.; Muhal, R.A.; Goswami, C.; Singh, T. Biofuels: An Alternative to Conventional Fuel and Energy Source. Mater. Today Proc. 2022, 48, 1178–1184. [Google Scholar] [CrossRef]

- Havrland, B.; Ivanova, T.; Lapczynska-Kordon, B.; Kolaříková, M. Comparative Analysis of Bio-Raw Materials and Biofuels. Eng. Rural. Dev. 2013, 541–544. [Google Scholar]

- Gerssen-Gondelach, S.J.; Saygin, D.; Wicke, B.; Patel, M.K.; Faaij, A.P.C. Competing Uses of Biomass: Assessment and Comparison of the Performance of Bio-Based Heat, Power, Fuels and Materials. Renew. Sustain. Energy Rev. 2014, 40, 964–998. [Google Scholar] [CrossRef]

- Zihare, L.; Soloha, R.; Blumberga, D. The Potential Use of Invasive Plant Species as Solid Biofuel by Using Binders. Agron. Res. 2018, 16, 923–935. [Google Scholar] [CrossRef]

- Kalt, G.; Lauk, C.; Mayer, A.; Theurl, M.C.; Kaltenegger, K.; Winiwarter, W.; Erb, K.-H.; Matej, S.; Haberl, H. Greenhouse Gas Implications of Mobilizing Agricultural Biomass for Energy: A Reassessment of Global Potentials in 2050 under Different Food-System Pathways. Environ. Res. Lett. 2020, 15, 034066. [Google Scholar] [CrossRef]

- Rocha-Meneses, L.; Luna-delRisco, M.; González, C.A.; Moncada, S.V.; Moreno, A.; Sierra-Del Rio, J.; Castillo-Meza, L.E. An Overview of the Socio-Economic, Technological, and Environmental Opportunities and Challenges for Renewable Energy Generation from Residual Biomass: A Case Study of Biogas Production in Colombia. Energies 2023, 16, 5901. [Google Scholar] [CrossRef]

- Raza, A.; Zunaira-Tu-Zehra; Khurram, M.; Khan, M.A.P.; Durez, A.; Khan, L.A.; Raza, A.; Zunaira-Tu-Zehra; Khurram, M.; Khan, M.A.P.; et al. Comparison of Evaporation in Conventional Diesel and Bio-Fuel Droplets in Engine Cylinder. In Exergy—New Technologies and Applications; IntechOpen: London, UK, 2023; ISBN 978-1-83768-545-5. [Google Scholar]

- Rocha-Meneses, L.; Ferreira, J.A.; Mushtaq, M.; Karimi, S.; Orupõld, K.; Kikas, T. Genetic Modification of Cereal Plants: A Strategy to Enhance Bioethanol Yields from Agricultural Waste. Ind. Crops Prod. 2020, 150, 112408. [Google Scholar] [CrossRef]

| Objects | Aboveground Parts (Ya) | Roots (Yr) | Ya/Yr | Greenness Index (SPAD) |

|---|---|---|---|---|

| Grams of Dry Matter per Pot | ||||

| Us | 74.145 a | 7.018 a | 10.565 | 44.322 ab |

| V | 70.961 ab | 8.850 a | 8.018 | 43.984 ab |

| D | 72.325 ab | 7.612 a | 9.502 | 44.856 ab |

| P | 65.447 b | 7.429 a | 8.810 | 42.322 b |

| A | 68.428 ab | 6.685 a | 10.237 | 43.878 ab |

| G | 12.679 e | 1.114 b | 11.384 | 45.372 ab |

| V_G | 26.448 cd | 1.749 b | 15.119 | 45.256 ab |

| D_G | 30.099 c | 2.025 b | 14.862 | 45.753 ab |

| P_G | 20.080 d | 1.874 b | 10.713 | 44.278 ab |

| A_G | 32.946 c | 2.258 b | 14.589 | 48.013 a |

| Objects * | Ash | Nitrogen (N) | Carbon (C) | Hydrogen (H) | Sulfur (S) | Oxygen (O) |

|---|---|---|---|---|---|---|

| Us | 4.971 f | 2.044 g | 51.124 ab | 5.730 ab | 0.092 de | 36.039 b |

| V | 4.970 f | 1.940 h | 51.319 a | 5.788 a | 0.082 e | 35.901 b |

| D | 5.710 d | 2.683 e | 50.865 b | 5.538 cd | 0.098 d | 35.105 c |

| P | 5.097 f | 2.347 f | 49.163 c | 5.488 d | 0.101 d | 37.804 a |

| A | 5.328 e | 2.035 g | 49.212 c | 5.739 a | 0.083 e | 37.604 a |

| G | 9.636 b | 4.158 c | 49.244 c | 5.746 a | 0.215 b | 31.000 g |

| V_G | 10.594 a | 3.962 d | 47.998 d | 5.584 bcd | 0.206 bc | 31.657 f |

| D_G | 9.150 c | 4.615 a | 47.434 e | 5.459 d | 0.195 c | 33.146 e |

| P_G | 9.130 c | 4.316 b | 47.162 ef | 5.503 d | 0.247 a | 33.642 d |

| A_G | 9.547 b | 4.294 b | 47.030 f | 5.676 abc | 0.212 b | 33.240 de |

| Objects * | Heat of Combustion (Q) | Heating Value (Hv) | Energy yield of Plant Biomass (Yep), MJ pot−1 |

|---|---|---|---|

| MJ kg−1 Air-Dry Matter Plants | |||

| Us | 18.710 f | 15.115 f | 1.121 b |

| V | 18.769 e | 15.163 e | 1.076 c |

| D | 19.250 a | 15.563 a | 1.126 a |

| P | 19.268 a | 15.578 a | 1.020 e |

| A | 19.080 b | 15.422 b | 1.055 d |

| G | 18.982 c | 15.340 c | 0.194 j |

| V_G | 18.820 d | 15.206 d | 0.402 h |

| D_G | 19.093 b | 15.432 b | 0.465 g |

| P_G | 18.979 c | 15.337 c | 0.308 i |

| A_G | 19.015 c | 15.368 c | 0.506 f |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borowik, A.; Wyszkowska, J.; Zaborowska, M.; Kucharski, J. Energy Quality of Corn Biomass from Gasoline-Contaminated Soils Remediated with Sorbents. Energies 2024, 17, 5322. https://doi.org/10.3390/en17215322

Borowik A, Wyszkowska J, Zaborowska M, Kucharski J. Energy Quality of Corn Biomass from Gasoline-Contaminated Soils Remediated with Sorbents. Energies. 2024; 17(21):5322. https://doi.org/10.3390/en17215322

Chicago/Turabian StyleBorowik, Agata, Jadwiga Wyszkowska, Magdalena Zaborowska, and Jan Kucharski. 2024. "Energy Quality of Corn Biomass from Gasoline-Contaminated Soils Remediated with Sorbents" Energies 17, no. 21: 5322. https://doi.org/10.3390/en17215322

APA StyleBorowik, A., Wyszkowska, J., Zaborowska, M., & Kucharski, J. (2024). Energy Quality of Corn Biomass from Gasoline-Contaminated Soils Remediated with Sorbents. Energies, 17(21), 5322. https://doi.org/10.3390/en17215322