Three-Dimensional Spatial Microscopic Characteristics and Developmental Influencing Factors of Tight Gas Layers in Hangjinqi Prospect Area, Ordos Basin, China

Abstract

1. Introduction

2. Regional Geological Profile

3. X-CT Test Methods and Procedures

3.1. X-CT Scanning Test Principle

3.2. Sample Selection and Testing Procedure

3.3. Reservoir Spatial Identification and Pore Throat Ball and Stick Modeling

3.3.1. Reservoir Space Identification and Image Acquisition

3.3.2. Modeling of Pore–Throat Ball and Stick

3.4. Quartz Grain Segmentation and Pore Throat Parameter Analysis

3.4.1. Segmentation of Quartz Particles

3.4.2. Analysis of Pore Throat Parameters

4. Results

4.1. Basic Characteristics of Tight Gas Layer

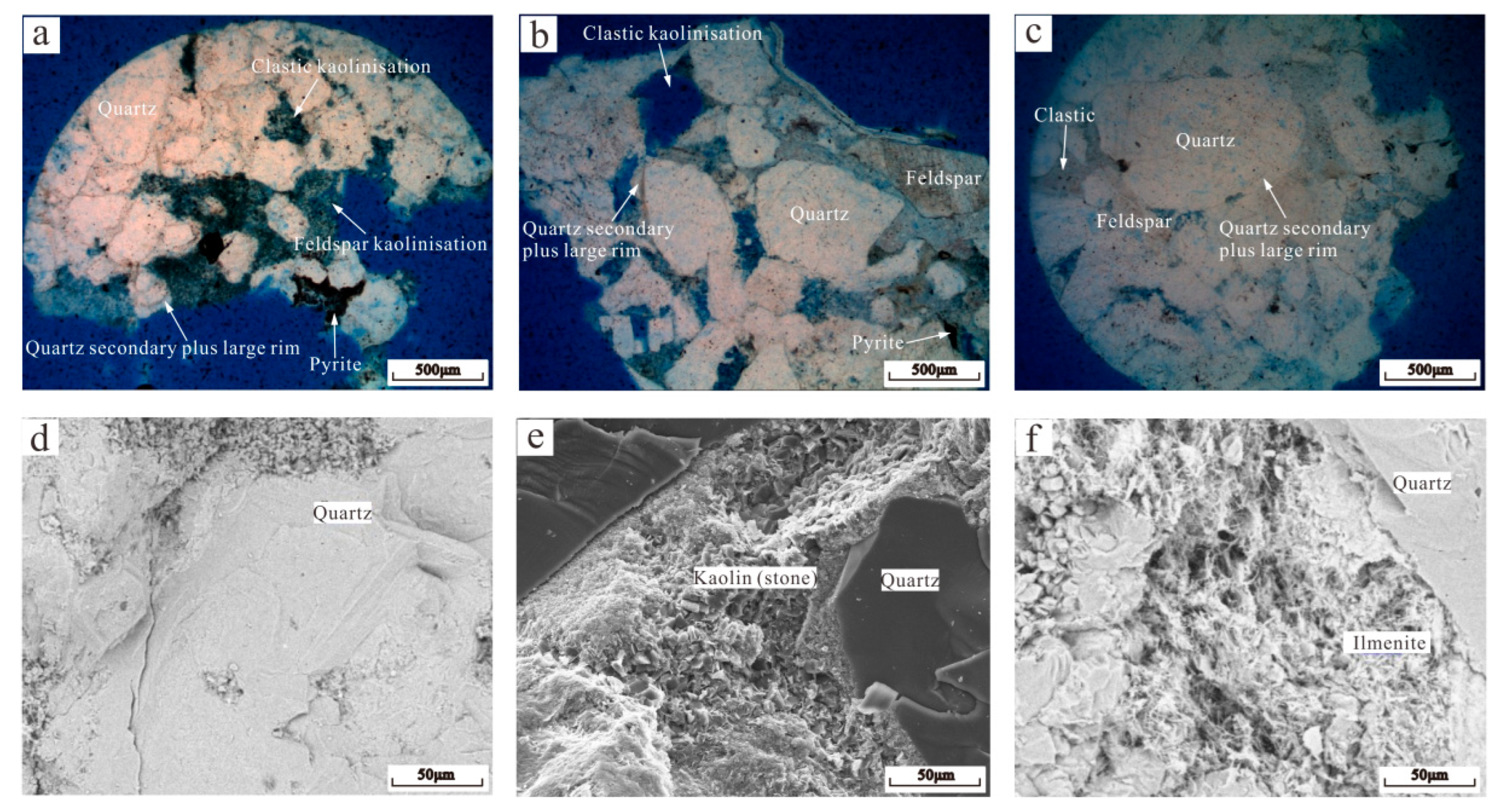

4.1.1. Petrological Features

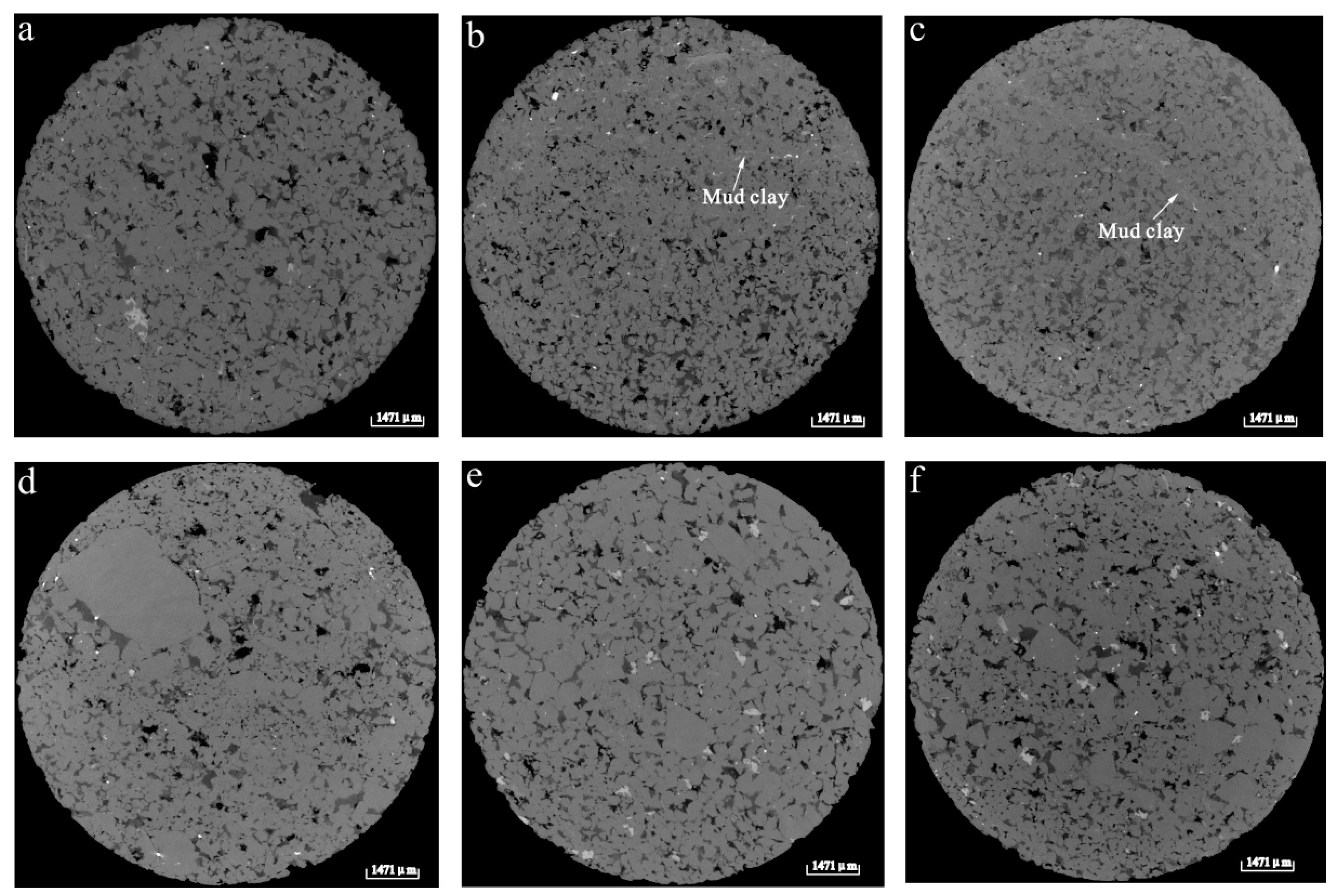

4.1.2. Quartz Particle Size Features

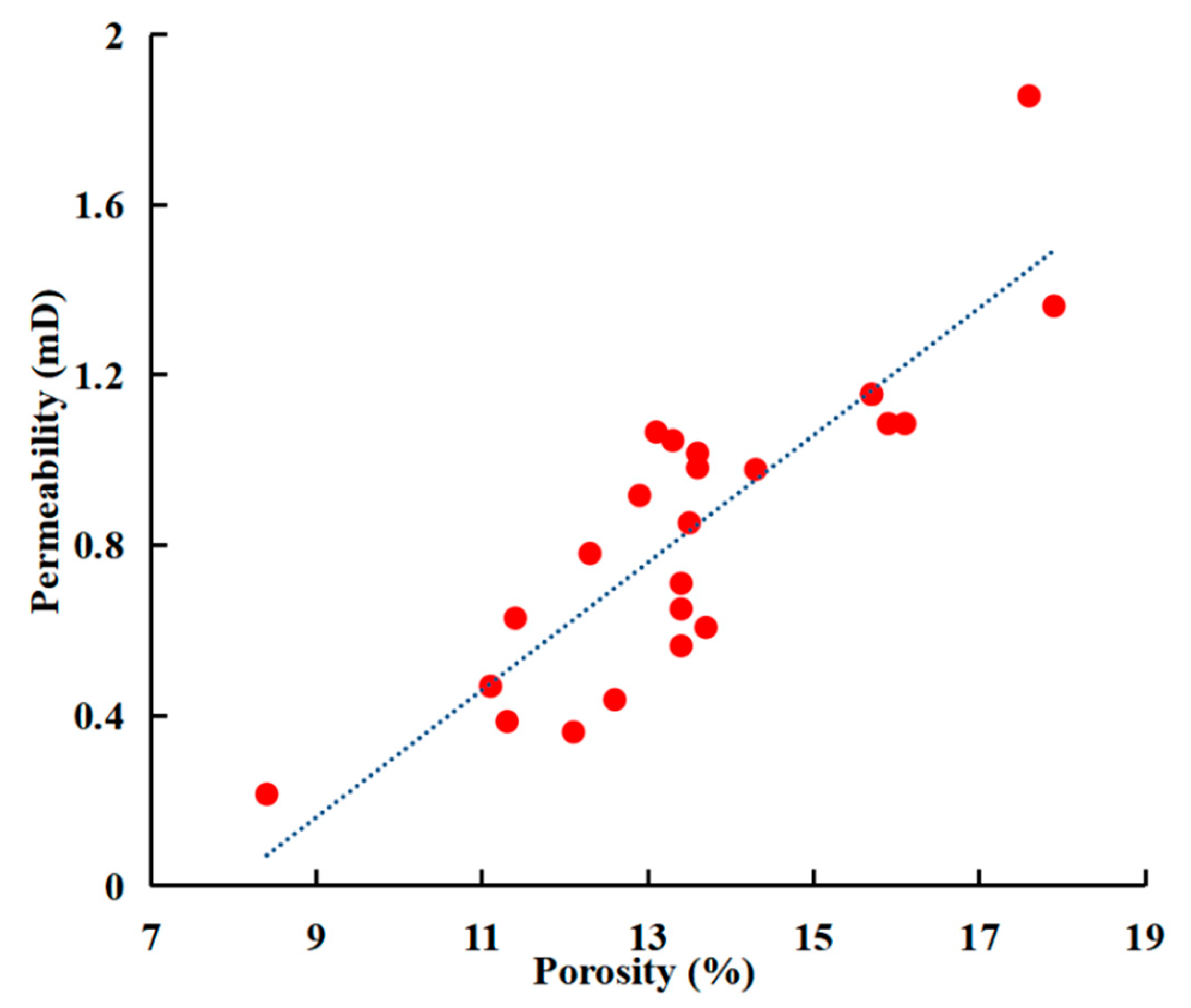

4.1.3. Reservoir Physical Features

4.2. Microscopic Characterization of Tight Gas Layers

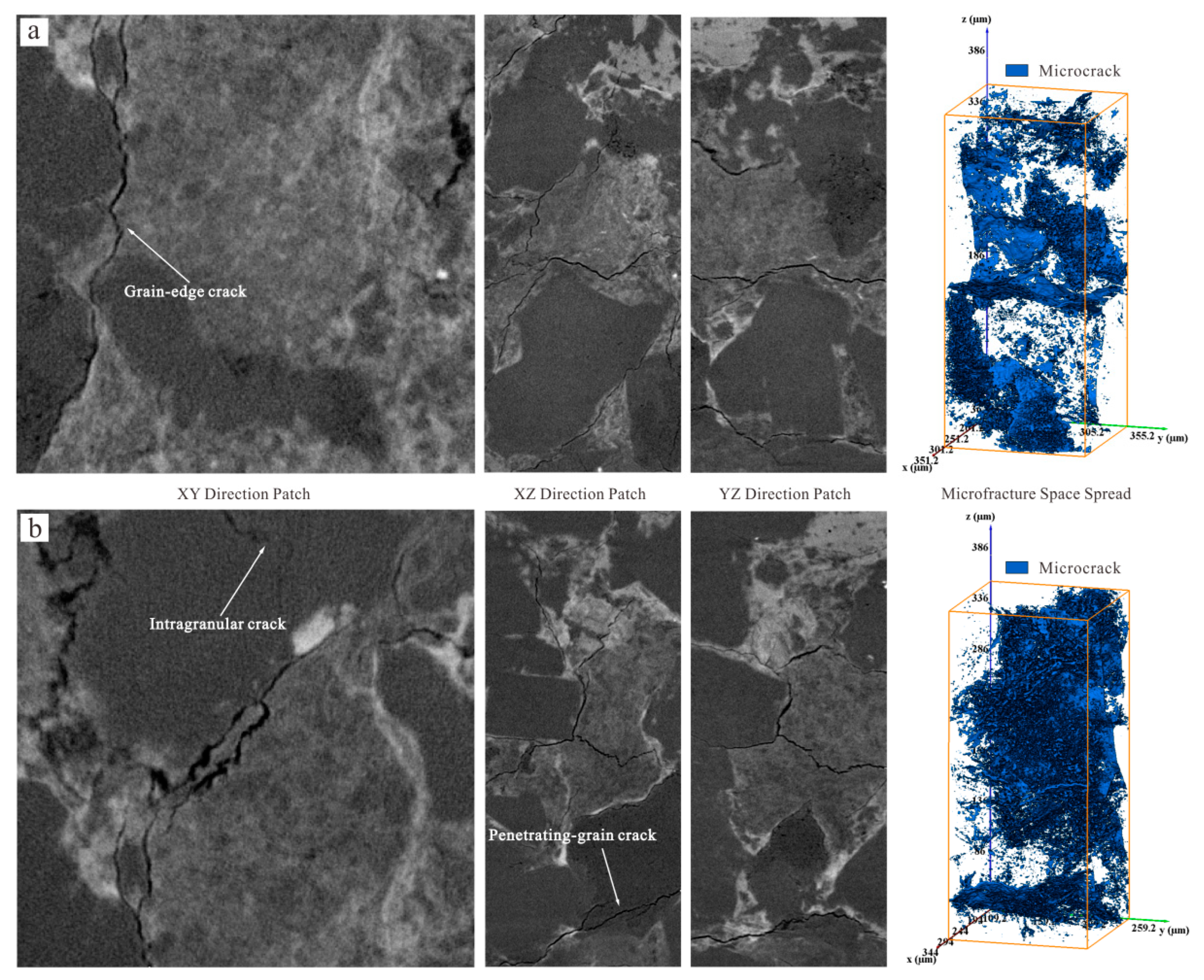

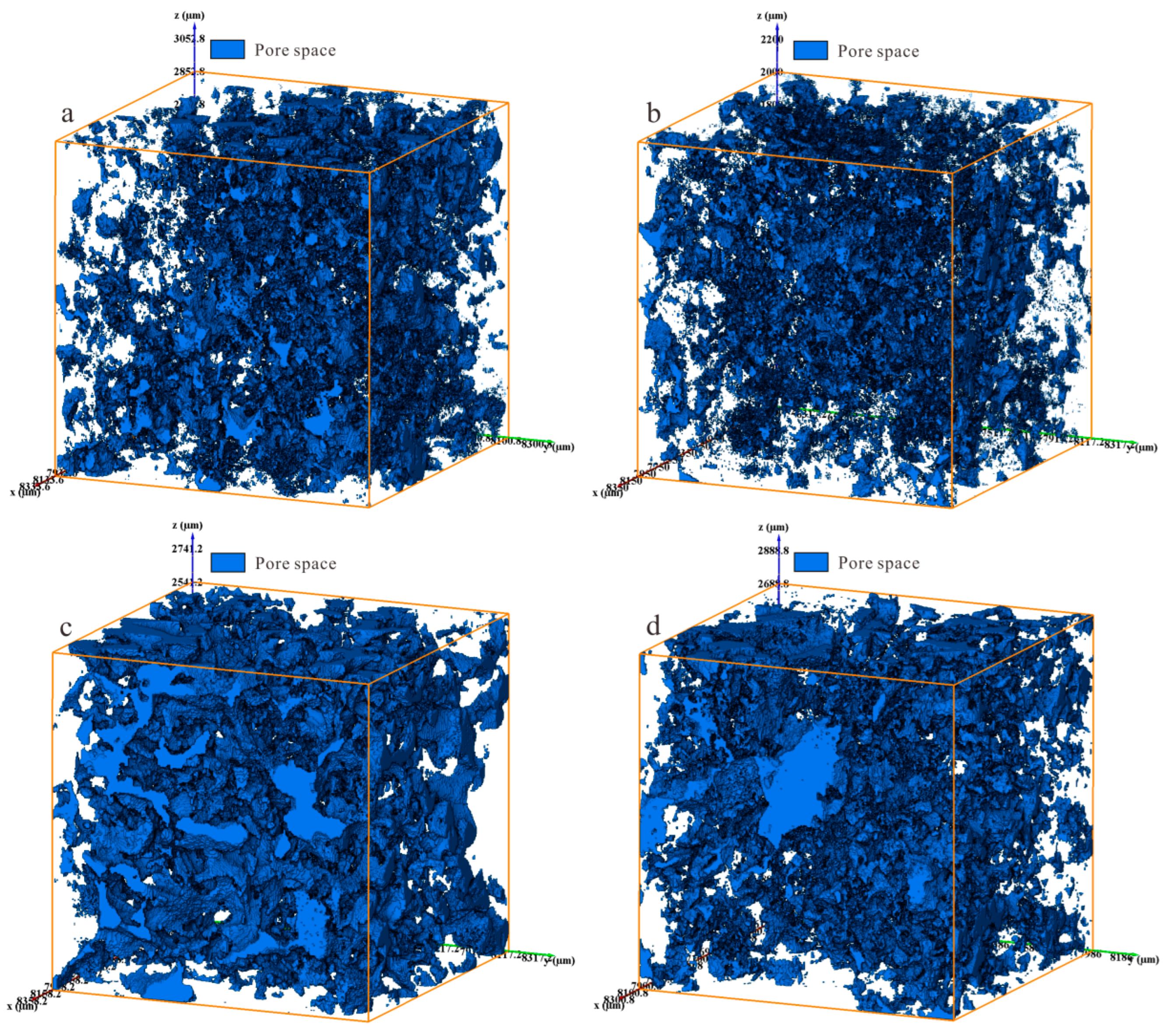

4.2.1. Microscopic Characterization of Reservoir Space

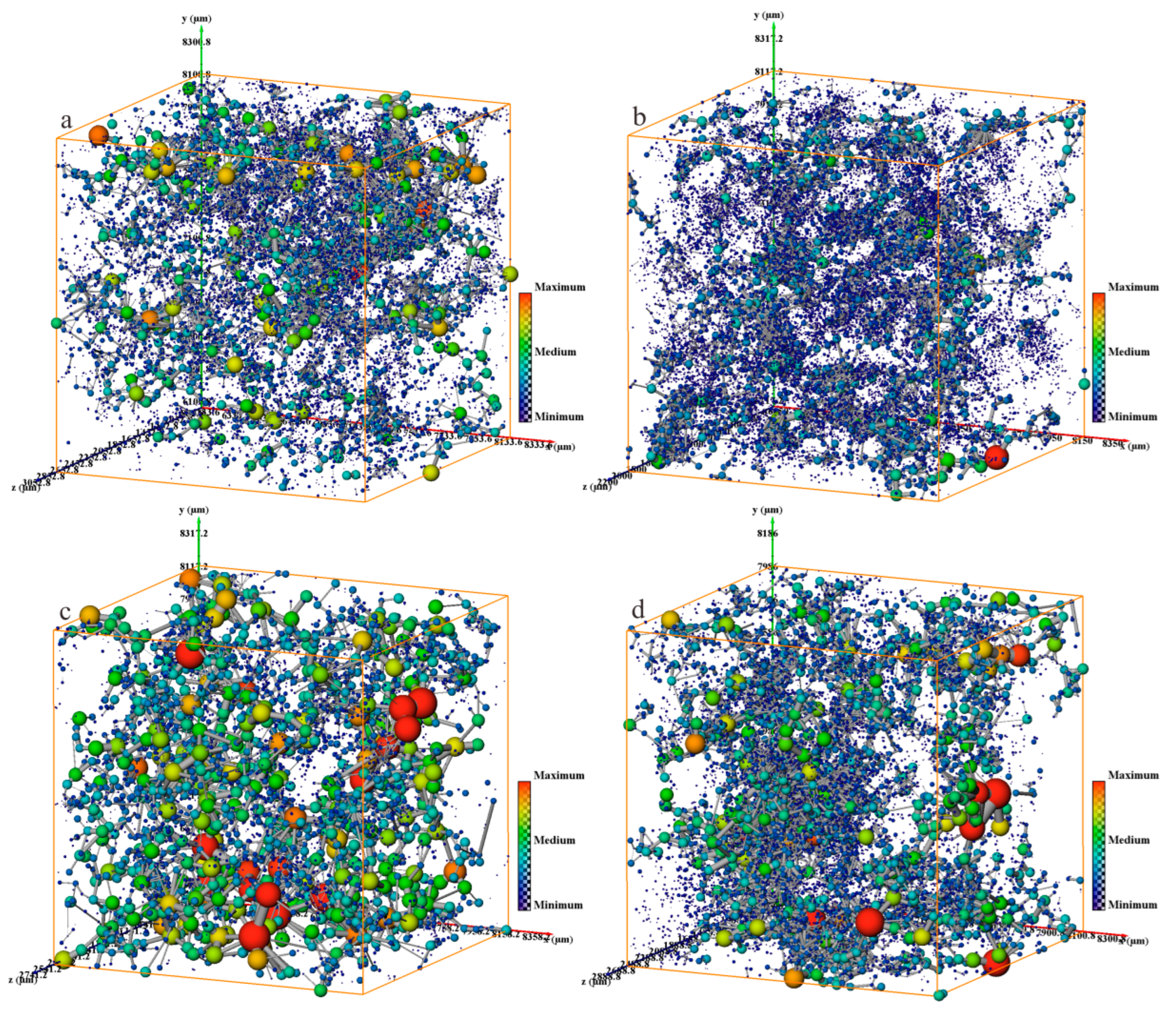

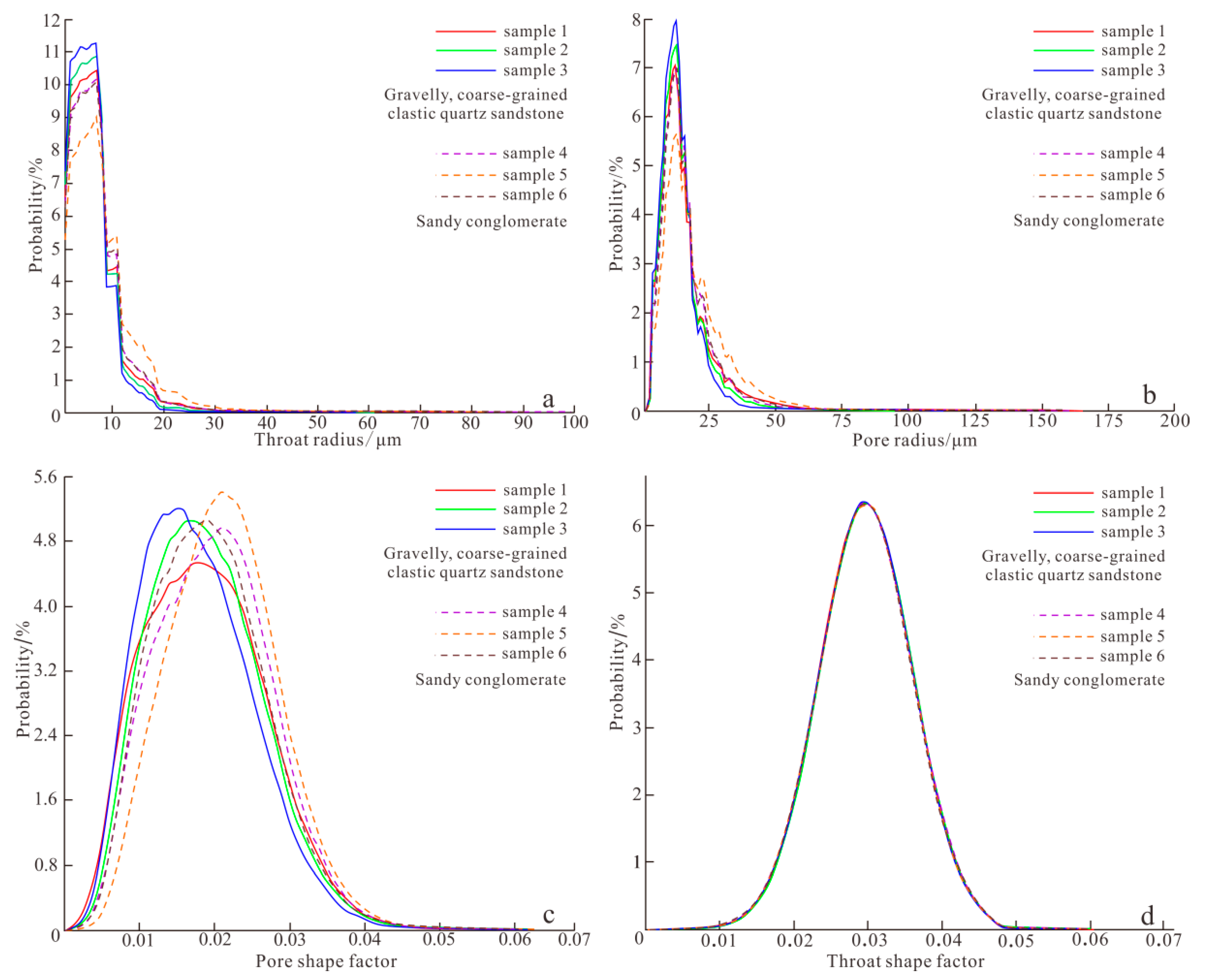

4.2.2. Characterization of Pore–Throat Microstructure

5. Discussion

5.1. Influence of Petrological Characteristics on the Microscopic Characterization of Reservoir Space

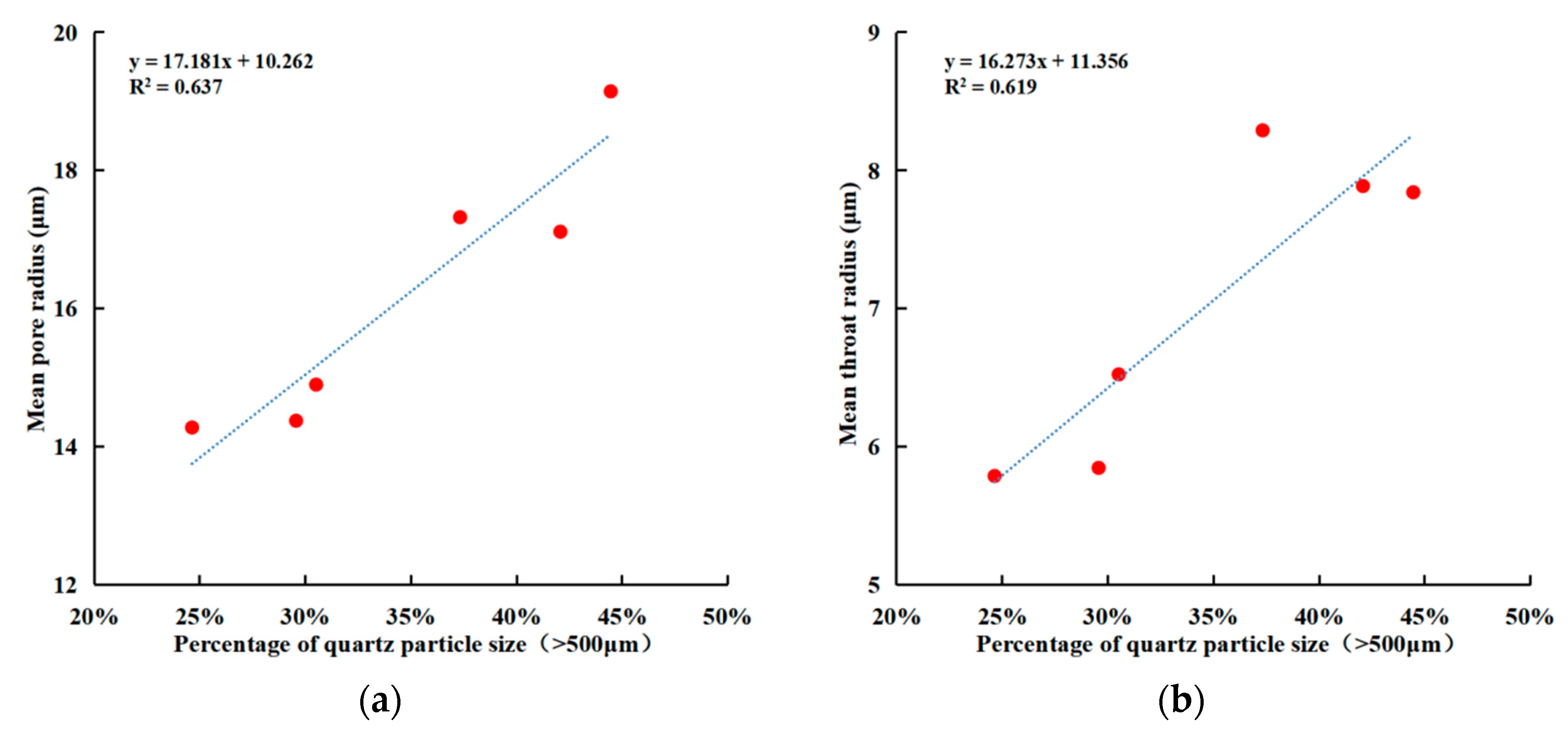

5.2. Relationship between Particle Size and Microscopic Characteristics of Reservoir Space

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arogundade, O.; Sohrabi, M. A review of recent developments and challenges in shale gas recovery. In Proceedings of the SPE Saudi Arabia Section Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 8–11 April 2012; pp. 621–651. [Google Scholar]

- McGlade, C.; Speirs, J.; Sorrell, S. Unconventional gas—A review of regional and global resource estimates. Energy 2013, 55, 571–584. [Google Scholar] [CrossRef]

- Masters, J.A. Deep Basin gas trap, western Canada. AAPG (Am. Assoc. Pet. Geol.) Bull. 1979, 63, 152–181. [Google Scholar]

- Meckel, L. Course Notes on Tight Gas Exploration. In Proceedings of the EAGE Second Middle East Tight Gas Reservoirs Workshop, Manama, Bahrain, 12–15 December 2010; pp. 12–15. [Google Scholar]

- Holditch, S.A. Tight gas sands. Pet. Technol. 2006, 58, 86–93. [Google Scholar] [CrossRef]

- Hayton, S.; Heine, C.; Gratto, B.E. Tight Gas Exploration in Saudi Arabia. 2010. Available online: https://onepetro.org/spedgas/proceedings-abstract/10DGAS/All-10DGAS/SPE-131065-MS/106141 (accessed on 1 December 2023).

- Liu, C.Y.; Wang, J.Q.; Zhang, D.D.; Zhao, H.G.; Zhao, J.F. Genesis of rich hydrocarbon resources and their occurrence and accumulation characteristics in the Ordos Basin. Oil Gas Geol. 2021, 42, 1011–1029. [Google Scholar]

- Li, G.X.; Zhu, R.K. Progress, challenges and key issues of unconventional oil and gas development of CNPC. China Pet. Explor. 2020, 25, 1–13. [Google Scholar]

- Zhang, Y.Y.; Zhang, W. Well loggi Hangjinqiexploration ng assessment of tight sandstone gas reservoirs from the He-1 member of the Permian Lower Shihezi Formation in the area, Ordos Basin. Sediment. Geol. Tethyan Geol. 2016, 36, 53–59. [Google Scholar]

- Zhang, X.L.; Wang, D.G.; Chen, S.H. Characteristics of the mesozoic reservoir bed in Ordos basin south Xun Yi-YiJun area. J. Earth Sci. Environ. 2000, 4, 17–21. [Google Scholar]

- Xie, R.C.; Zhou, W.; Li, L.; Su, Y.; Wang, X. Characteristics of upper Paleozoic sandstone reservoir in Hangjinqi area of Prdos basin. Xinjiang Geol. 2010, 28, 86–90. [Google Scholar]

- Hao, T. Heterogeneous reservoirs of Shihezi 1 Member, Jin 30 well block, Dongsheng gasfield. Nat. Gas Technol. Econ. 2021, 15, 7–13+21. [Google Scholar]

- Xun, X.Q. Reservoir characteristics and influential factors of physical property: An example fromShihezi 1 Member, East Xinzhao block, Dongsheng gasfield, Ordos Basin. Nat. Gas Technol. Econ. 2022, 16, 10–16. [Google Scholar]

- Ortiz-Orduz, A.; Ríos-Reyes, C.A.; Vargas-Escudero, M.A.; García-González, M. Impact of diagenesis on the reservoir rock quality of the cachiri group tight sandstones in cesar sub basin (colombia): A case of study from anh-cr-montecarlo 1x well. J. Nat. Gas Sci. Eng. 2021, 95, 104138. [Google Scholar] [CrossRef]

- Wang, X.C.; Luo, J.L.; Li, W.H.; Hu, Q. Diagenetic evolution and facies of the Shan23 reservoir in Su 77 and Zhao 51 blocks, Ordos basin. Geol. Explor. 2018, 54, 193–202. [Google Scholar]

- Xi, K.L.; Cao, Y.C.; Jahren, J.; Zhu, R.K.; Bjorlykke, K.; Haile, B.G.; Zheng, L.J.; Helge, H. Diagenesis and reservoir quality of the Lower Cretaceous Quantou Formation tight sandstones in the southern Songliao Basin, China. Sediment. Geol. 2015, 330, 90–107. [Google Scholar] [CrossRef]

- Loucks, R.G.; Ruppel, S.C. Mississippian Barnett Shale: Lithofacies and depositional setting of a deep-water shale-gas succession in the Fort Worth Basin, Texas. AAPG Bull. 2007, 91, 579–601. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Mbia, E.N.; Fabricius, I.L.; Krogsbøll, A.; Frykman, P.; Dalhoff, F. Permeability, compressibility and porosity of Jurassic shale from the Norwegian-Danish Basin. J. Pet. Geosci. 2014, 20, 257–281. [Google Scholar] [CrossRef]

- Medina, C.R.; Mastalerz, M.; Rupp, J.A. Characterization of porosity and pore-size distribution using multiple analytical tools: Implications for carbonate reservoir characterization in geologic storage of CO2. Environ. Geosci. 2017, 24, 51–72. [Google Scholar] [CrossRef]

- Dmitriy, A.M.; Shadfar, D.; Ali, K.; Masoud, R.; Yousef, K.; Ma, T.S. Multiscale and diverse spatial heterogeneity analysis of void structures in reef carbonate reservoirs. Geoenergy Sci. Eng. 2024, 233, 212569. [Google Scholar]

- Ali, A.A.; Namam, M.S.; Dmirriy, A.M. Paleoenvironmental Evaluation Using an Integrated Microfacies Evidence and Triangle Model Diagram: A Case Study from Khurmala Formation, Northeastern Iraq. J. Mar. Sci. Eng. 2023, 11, 2162. [Google Scholar]

- Dunsmuir, J.H.; Ferguson, S.R.; D’Amico, K.L.; Stokes, J.P. X-ray microtomography: A new tool for the characterization of porous media. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 6–9 October 1991. [Google Scholar]

- Coenen, J.; Tchouparova, E.; Jing, X. Measurement parameters and resolution aspects of micro X-ray tomography for advanced core analysis. In Proceedings of the International Symposium of the Society of Core Analysts, Abu Dhabi, UAE, 5–9 October 2004. [Google Scholar]

- Attood, D. Microscopy: Nanotomography Comes of age. Nature 2006, 442, 642–643. [Google Scholar] [CrossRef]

- Sakdinawat, A.; Attwood, D. Nanoscale X-ray Imaging. Nat. Photonics 2010, 267, 840–848. [Google Scholar]

- Bai, B.; Zhu, R.K.; Wu, S.T.; Yang, W.J.; Jeff, G.; Allen, G.; Zhang, X.X.; Ling, S. Multi-scale method of Nano(Micro)-CT study on microscopic pore structure of tight sandstone of Yanchang Formation, Ordos Basin. Pet. Explor. Dev. 2013, 40, 329–333. [Google Scholar] [CrossRef]

- Zhang, F.F. Characterization and evaluation of pore-throat structures in ultra-low permeability and tight sandstones and their impacts on petropysical properties: A case study of the lower Cretace-ous in northern Songliao Basin. J. Northeast Pet. Univ. 2018, 42, 54–62+8-9. [Google Scholar]

- Jiang, F.J.; Jia, C.Z.; Pang, X.Q.; Zhang, C.L. Upper Paleozoic total petroleum system and geological model of natural gas enrichment in Ordos Basin, NW China. Pet. Explor. Dev. 2003, 50, 250–261. [Google Scholar] [CrossRef]

- Li, J. Sedimentary Facies Analysis and Its Influence on Reservoirs in Hangjinqi area Lower Shihezi Formation. Master’s Thesis, Chengdu University of Technology, Chengdu, China, 2013. [Google Scholar]

- Xue, H.; Zhang, J.C.; Wang, Y.; Xu, B.; Guo, H.Q. Relationship Between Tectonic Evolution and Hydr-ocarbon in Hangjinqi Block of North Ordos Basin. Geotecton. Metallog. 2009, 33, 206–214. [Google Scholar]

- Li, Y.L.; Zhang, Y.F.; Cong, L.; Xie, Z.; Yan, J.M. Application of X-CT Scanning Technique in the Characterization of Micro Pore Structure of Tight Sandstone Reservoir: An Example from Fuyu Oil Layer in Daan Oilfield. J. Jilin Univ. 2016, 46, 379–387. [Google Scholar]

- Dennis, D. Robust determination of porespace morphology in sedimentary rocks. Pet. Technol. 2004, 56, 69–70. [Google Scholar]

- Dai, Z.; Luo, D.L.; Xie, M.Y. A new method for particle size analysis of cutti-ngs images based on improved watershed algorithm. China Offshore Oil Gas 2019, 31, 103–107. [Google Scholar]

- Liu, F.; Zhou, W.; Li, X.H.; Xie, R.C.; Li, L.; Liu, F.; Zhou, W.; Li, X.H.; Xie, R.C.; Li, L. Analysis of Characteritics of the Clay minerals In the Up-per Palaeozoic Sandstone Reservoir of Hangjinqi Area in North Ordos Basin. Mineral. Petrol. 2006, 26, 92–97. [Google Scholar]

- He, Y.B.; Wang, W.G. Sedimentary Rocks and Sedimentary Phases; Petroleum Industry Press: Beijing, China, 2007; pp. 61–63. [Google Scholar]

- Qiu, L.W.; Mu, X.J.; Li, H.; Zhang, J.; Ge, J.; Xu, S.; Zhou, S.B. Characteristics of detritus development in the Permian lower Shihezi Formation in Hangjinqi area and its influence on reservoir physical properties. Oil Gas Geol. 2019, 40, 24–33. [Google Scholar]

- Wu, Y.Q.; Tahmasebi, P.; Lin, C.Y.; Zahid, M.A.; Dong, C.M.; Golab, A.N.; Ren, L.H. A comprehensive study on geometric, topological and fractal characterizations of pore systems in low-permeability reservoirs based on SEM, MICP, NMR, and X-ray CT experiments. Mar. Pet. Geol. 2019, 103, 12–28. [Google Scholar] [CrossRef]

- Li, X.B. Characterization of Pore Structure and Simulation of Elasticity and Permeability Based on 3D Digital Cores. Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2021. [Google Scholar]

- Chen, C.B.; Fu, L.; Chen, X.J.; Zhang, T.; Xie, Y.H.; Wang, H.B.; Zhu, Y.S. Quantitative Evaluation Method for Micro Heter-ogeneity of Tight Sandstone: A case study of Chang-6 reservoir of Yanchang Formationin Huaqing area, Ordos Basin. Acta Sedimentol. Sin. 2021, 39, 1086–1099. [Google Scholar]

| Serial Number | Lithology | Particle Size/μm | |||

|---|---|---|---|---|---|

| Minimum | Maximum | Mean | Median | ||

| 1 | Gravelly, coarse-grained clastic quartz sandstone | 47.06 | 2090.71 | 426.63 | 408.59 |

| 2 | 47.22 | 1541.39 | 510.91 | 479.69 | |

| 3 | 44.98 | 1543.47 | 434.57 | 419.88 | |

| 4 | Sandy conglomerate | 46.09 | 3157.04 | 494.64 | 474.92 |

| 5 | 48.15 | 2006.57 | 472.73 | 451.23 | |

| 6 | 46.09 | 1644.26 | 488.97 | 463.52 | |

| Serial Number | Lithology | Pore Radius/μm | Throat Radius/μm | Coordination Number | |||

|---|---|---|---|---|---|---|---|

| Maximum | Mean | Maximum | Mean | Maximum | Mean | ||

| 1 | Gravelly, coarse-grained clastic quartz sandstone | 164.654 | 15.274 | 67.298 | 6.788 | 55 | 3 |

| 2 | 95.304 | 14.895 | 60.648 | 6.223 | 45 | 2 | |

| 3 | 113.064 | 13.672 | 57.287 | 5.847 | 46 | 3 | |

| 4 | Sandy conglomerate | 161.819 | 17.141 | 99.354 | 7.841 | 97 | 4 |

| 5 | 140.178 | 19.319 | 83.339 | 8.289 | 61 | 4 | |

| 6 | 158.943 | 17.109 | 90.600 | 7.886 | 76 | 4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, N.; Hu, W.; Gao, L.; Liu, G. Three-Dimensional Spatial Microscopic Characteristics and Developmental Influencing Factors of Tight Gas Layers in Hangjinqi Prospect Area, Ordos Basin, China. Energies 2024, 17, 399. https://doi.org/10.3390/en17020399

Gu N, Hu W, Gao L, Liu G. Three-Dimensional Spatial Microscopic Characteristics and Developmental Influencing Factors of Tight Gas Layers in Hangjinqi Prospect Area, Ordos Basin, China. Energies. 2024; 17(2):399. https://doi.org/10.3390/en17020399

Chicago/Turabian StyleGu, Nanling, Wangshui Hu, Lingyu Gao, and Guowen Liu. 2024. "Three-Dimensional Spatial Microscopic Characteristics and Developmental Influencing Factors of Tight Gas Layers in Hangjinqi Prospect Area, Ordos Basin, China" Energies 17, no. 2: 399. https://doi.org/10.3390/en17020399

APA StyleGu, N., Hu, W., Gao, L., & Liu, G. (2024). Three-Dimensional Spatial Microscopic Characteristics and Developmental Influencing Factors of Tight Gas Layers in Hangjinqi Prospect Area, Ordos Basin, China. Energies, 17(2), 399. https://doi.org/10.3390/en17020399