Analysis of Varying Temperature Regimes in a Conductive Strip during Induction Heating under a Quasi-Steady Electromagnetic Field

Abstract

1. Introduction

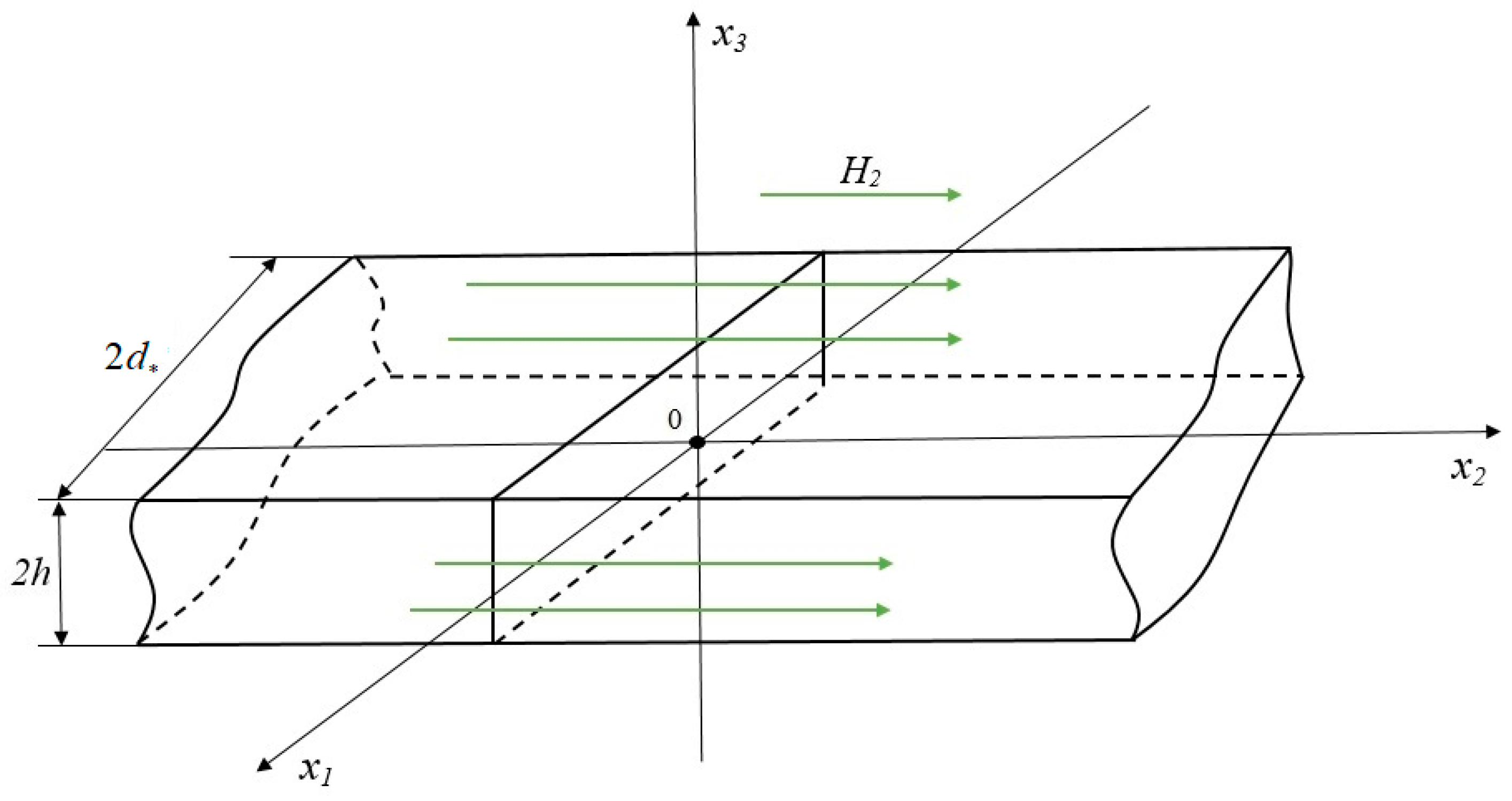

2. Two-Dimensional Physical and Mathematical Model

2.1. Problem Formulation

2.2. Determination of the Electromagnetic Field

2.3. Temperature Field Determination

3. Methods of Building Solutions for Boundary Value Problems

3.1. Building a Solution for the Problem of Electrodynamics

3.2. Building a Solution for the Heat Conduction Problem

4. Building a Solution for the Problem of Conductive Strip Induction Heating under Quasi-Steady EMF

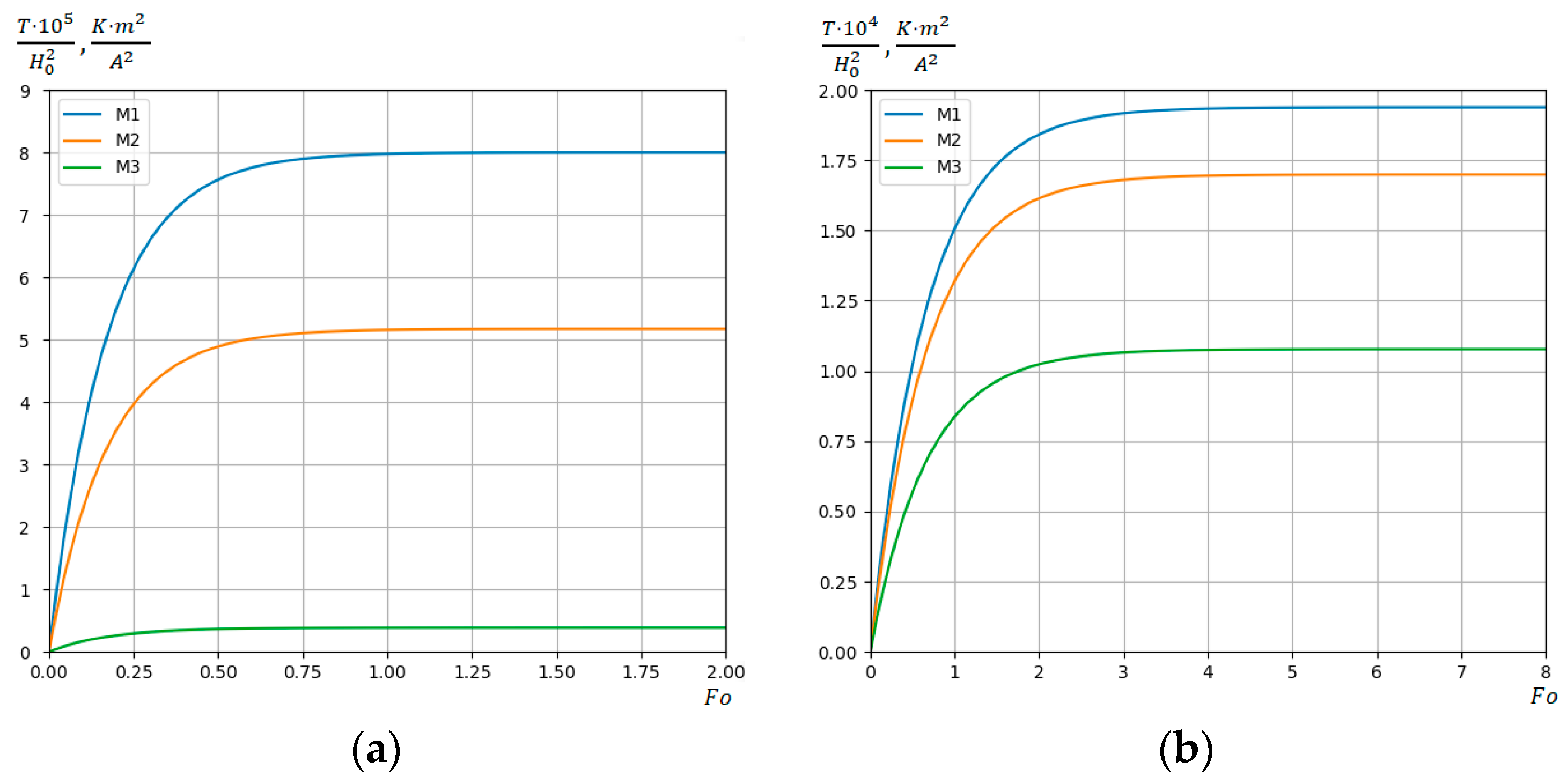

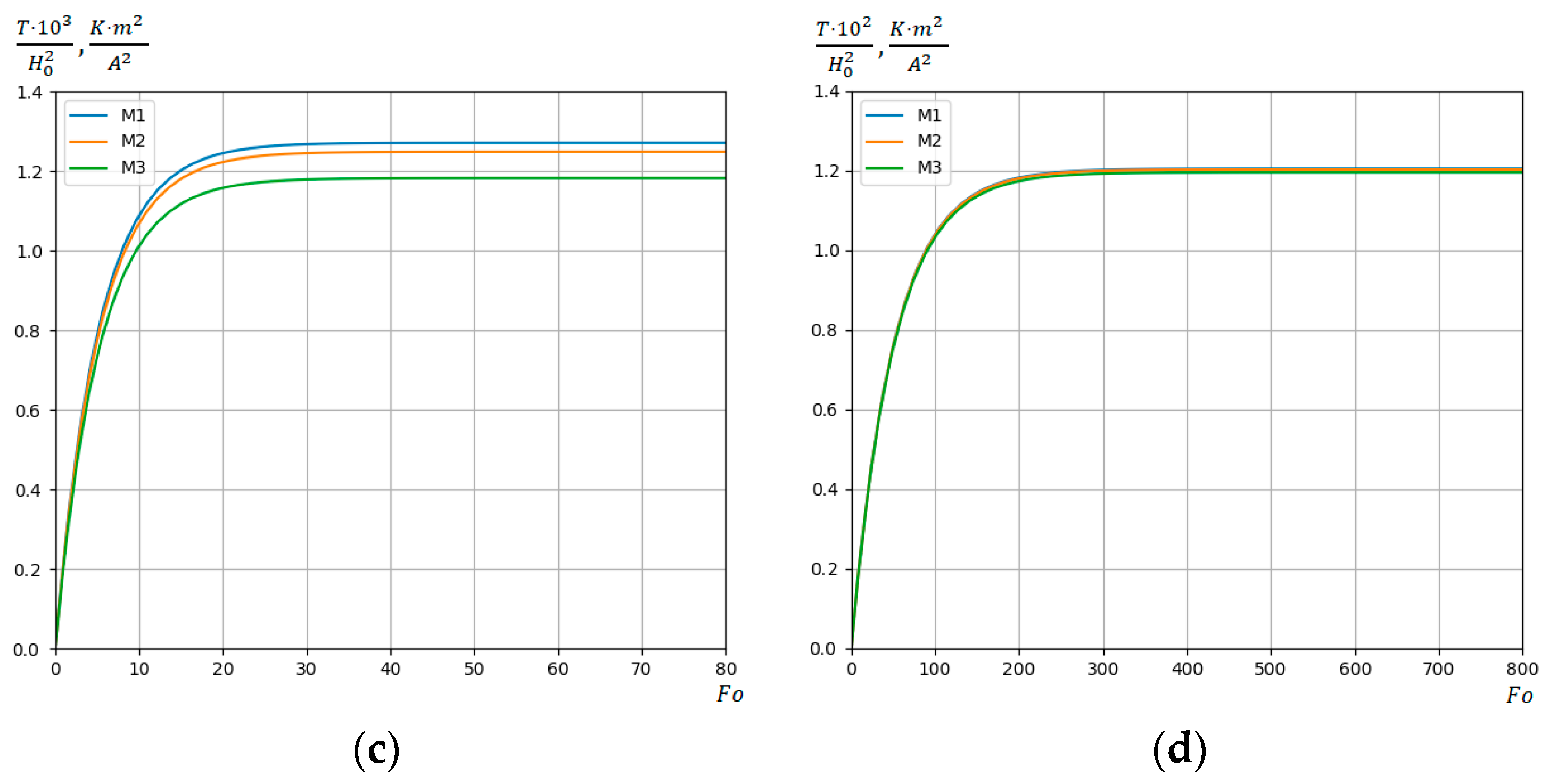

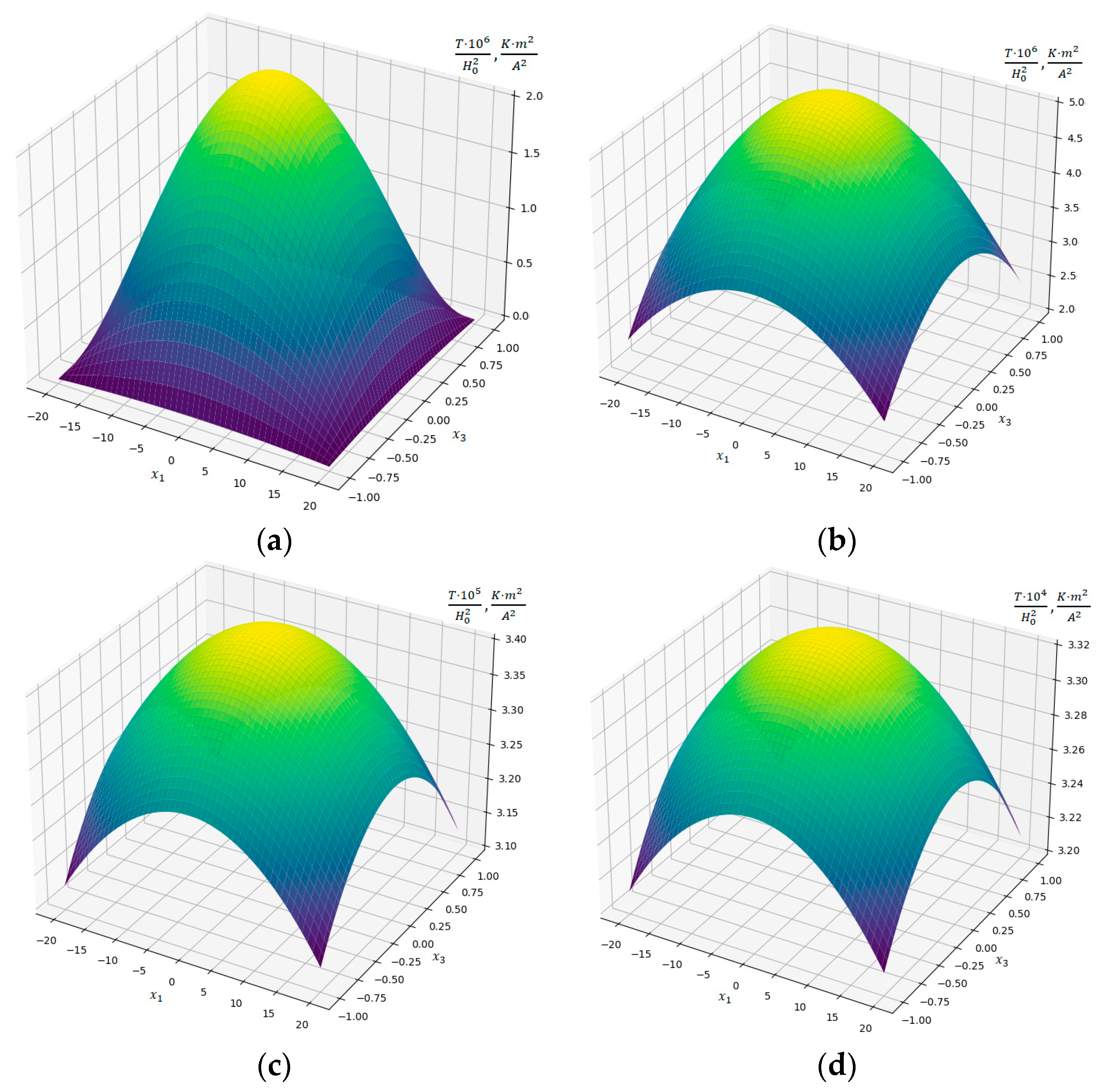

5. Numerical Analysis for the Problem of Induction Heating of a Steel Conductive Strip

- (1)

- is near-surface heating;

- (2)

- is in-depth heating of the strip.

- (1)

- After comparing Figure 2 and Figure 4, it is established that the maximum values of temperature depend on parameter . In particular, during in-depth induction heating at , maximum temperature values are approximately 40 times lower than corresponding temperature values during near-surface induction heating at ;

- (2)

- While near-surface strip heating at and , temperature of the steel strip acquires a value that is close to melting point of the selected stainless steel of which the strip is made. And, at , the steel melting point is reached at ;

- (3)

- In the case of in-depth heating of the strip, the melting point of the selected stainless steel is reached at the value of magnetic field strength for and at for ;

- (4)

- To achieve higher maximum values of strip heating temperature, it is advisable to use near-surface heating.

6. Conclusions

- (1)

- Critical values of and parameters enabling the steel heating temperature to achieve the melting point of the stainless steel under consideration at times are obtained;

- (2)

- At a decreasing Biot number , the temperature maximum value increases in both cases of near-surface and in-depth heating;

- (3)

- Maximum temperature values for all considered values of the Biot number increase at a decreasing induction heating parameter . This regularity is due to the fact that, with a decrease in the parameter , the frequency of the carrier electromagnetic oscillations increases, and therefore the amount of Joule heat that the EMF introduces into the band increases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chaban, A.; Lukasik, Z.; Lis, M.; Szafraniec, A. Mathematical Modeling of Transient Processes in Magnetic Suspension of Maglev Trains. Energies 2020, 13, 6642. [Google Scholar] [CrossRef]

- Holman, J.P. Heat Transfer; McGraw Hill: New York, NY, USA, 2009. [Google Scholar]

- Hetnarski, R. Encyclopedia of Thermal Stresses; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Lupi, S. Fundamentals of Electroheat, Electrical Technologies for Process Heating; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Rudnev, V.; Loveless, D.; Cook, R.L. Handbook of Induction Heating, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Musii, R.; Pukach, P.; Kohut, I.; Vovk, M.; Šlahor, Ľ. Determination and Analysis of Joule heat and Temperature in an Electrically Conductive Plate Element Subject to Short-Term Induction Heating by a Non-Stationary Electromagnetic Field. Energies 2022, 15, 5250. [Google Scholar] [CrossRef]

- Musii, R.; Pukach, P.; Melnyk, N.; Vovk, M.; Šlahor, L. Modeling of the Temperature Regimes in a Layered Bimetallic Plate under Short-Term Induction Heating. Energies 2023, 16, 4980. [Google Scholar] [CrossRef]

- Hachkevych, O.; Musii, R. Mathematical modeling in thermomechanics of electroconductive bodies under the action of the pulsed electromagnetic fields with modulation of amplitude. Math. Model. Comput. 2019, 6, 30–36. [Google Scholar] [CrossRef]

- Milošević-Mitić, V.; Maneski, T.; Andjelić, N.; Milović, L.; Petrović, A.; Gaceša, B. Dynamic temperature field in the ferromagnetic plate induced by moving high frequency inductor. Therm. Sci. 2014, 18, S49–S58. [Google Scholar] [CrossRef]

- Hetnarski, R.; Eslami, M. Heat conduction problems. Solid Mech. Its Appl. 2019, 158, 133–224. [Google Scholar] [CrossRef]

- Zhyltsov, A.V.; Bereziuk, A.O.; Vishtak, T.V. Three-dimensional mathematical model of three-phase heat generator of induction type based on the method of secondary sources. Tech. Electrodyn. 2022, 5, 8–13. (In Ukrainian) [Google Scholar] [CrossRef]

- Jankowski, T.A.; Pawley, N.H.; Gonzales, L.M.; Ross, C.A.; Jurney, J.D. Approximate analytical solution for induction heating of solid cylinders. Appl. Math. Model. 2016, 40, 2770–2782. [Google Scholar] [CrossRef]

- Milošević Mitić, V.; Kozak, D.; Maneski, T.; Andelić, N.; Gaćeša, B.; Stojkov, M. Dynamic nonlinear temperature field in a ferromagnetic plate induced by high frequency electromagnetic wave. Strojarstvo 2010, 52, 115–124. [Google Scholar]

- Vasetsky, Y.; Zaporozhets, A. Approximate Mathematical Models for Analysis of Alternating Electromagnetic Field of Sources Near Conducting Body. Lect. Notes Electr. Eng. 2024, 1070, 33–67. [Google Scholar] [CrossRef]

- Vasetsky, Y.; Zaporozhets, A. Penetration of Non-uniform Sinusoidal Electromagnetic Field into Conducting Half-Space. Lect. Notes Electr. Eng. 2024, 1070, 69–92. [Google Scholar] [CrossRef]

- Spateri, E.; Ruiz, F.; Gruosso, G. Modelling and Simulation of Quasi-Resonant Inverter for Induction Heating under Variable Load. Electronics 2023, 12, 753. [Google Scholar] [CrossRef]

- Gaspare, A.; Sag, M.; Pecha, P. Numerical Modeling of Ferrite Material Impact on the Effectiveness of Induction Heating Process. Commun. Sci. Lett. Univ. Zilina 2015, 17, 12–17. [Google Scholar] [CrossRef]

- Drobenko, B.; Vankevych, P.; Ryzhov, Y.; Yakovlev, M. Rational approaches to high temperature induction heating. Int. J. Eng. Sci. 2017, 117, 34–50. [Google Scholar] [CrossRef]

- Favennec, Y.; Labbé, V.; Bay, F. Induction heating processes optimization a general optimal control approach. J. Comput. Phys. 2003, 187, 68–94. [Google Scholar] [CrossRef]

- Djambazov, G.; Bojarevics, V.; Pericleous, K.; Croft, N. Finite volume solutions for electromagnetic induction processing. Appl. Math. Model. 2015, 39, 4733–4745. [Google Scholar] [CrossRef]

- Iagǎr, A.; Abrudean, C.; Diniş, C.; Pǎnoiu, C. Research upon optimization of the volume induction heating process. Metal. Int. 2008, 13, 27–31. [Google Scholar]

- Areitioaurtena, M.; Segurajauregi, U.; Akujärvi, V.; Fisk, M.; Urresti, I.; Ukar, E. A semi-analytical coupled simulation approach for induction heating. Adv. Model. Simul. Eng. Sci. 2021, 8, 14. [Google Scholar] [CrossRef]

- Barglik, J.; Smalcerz, A. 2.6 Surface Induction Hardening. Ref. Modul. Mater. Sci. Mater. Eng. 2017, 2, 154–170. [Google Scholar] [CrossRef]

- Nikulin, I.L.; Perminov, A.V. Mathematical modelling of frequency and force impacts on averaged metal flows in alternating magnetic field. Int. J. Heat Mass Transf. 2019, 128, 1026–1032. [Google Scholar] [CrossRef]

- Barglik, J.; Smagór, A.; Smalcerz, A.; Desisa, D. Induction heating of gear wheels in consecutive contour hardening process. Energies 2021, 14, 3885. [Google Scholar] [CrossRef]

- Barglik, J. Identification of temperature and hardness distribution during dual frequency induction hardening of gear wheels. Arch. Electr. Eng. 2018, 67, 913–923. [Google Scholar] [CrossRef]

- Lee, K.S.; Kim, S.W.; Eom, D.H. Temperature distribution and bending behaviour of thick metal plate by high frequency induction heating. Mater. Res. Innov. 2011, 15 (Suppl. S1), S283–S287. [Google Scholar] [CrossRef]

- Iskierka, S.; Iskierka, I. Induction hardening of flat elements in a flow-through method. Prz. Elektrotechniczny 2019, 95, 132–135. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musii, R.; Lis, M.; Pukach, P.; Chaban, A.; Szafraniec, A.; Vovk, M.; Melnyk, N. Analysis of Varying Temperature Regimes in a Conductive Strip during Induction Heating under a Quasi-Steady Electromagnetic Field. Energies 2024, 17, 366. https://doi.org/10.3390/en17020366

Musii R, Lis M, Pukach P, Chaban A, Szafraniec A, Vovk M, Melnyk N. Analysis of Varying Temperature Regimes in a Conductive Strip during Induction Heating under a Quasi-Steady Electromagnetic Field. Energies. 2024; 17(2):366. https://doi.org/10.3390/en17020366

Chicago/Turabian StyleMusii, Roman, Marek Lis, Petro Pukach, Andriy Chaban, Andrzej Szafraniec, Myroslava Vovk, and Nataliia Melnyk. 2024. "Analysis of Varying Temperature Regimes in a Conductive Strip during Induction Heating under a Quasi-Steady Electromagnetic Field" Energies 17, no. 2: 366. https://doi.org/10.3390/en17020366

APA StyleMusii, R., Lis, M., Pukach, P., Chaban, A., Szafraniec, A., Vovk, M., & Melnyk, N. (2024). Analysis of Varying Temperature Regimes in a Conductive Strip during Induction Heating under a Quasi-Steady Electromagnetic Field. Energies, 17(2), 366. https://doi.org/10.3390/en17020366