A Review of the Energy-Saving Potential of Phase Change Material-Based Cascaded Refrigeration Systems in Chinese Food Cold Chain Industry

Abstract

1. Introduction

2. Cascade Refrigeration Systems

2.1. The Structure of Cascade Refrigeration System

2.2. The Work-Fluid of Cascade Refrigeration System

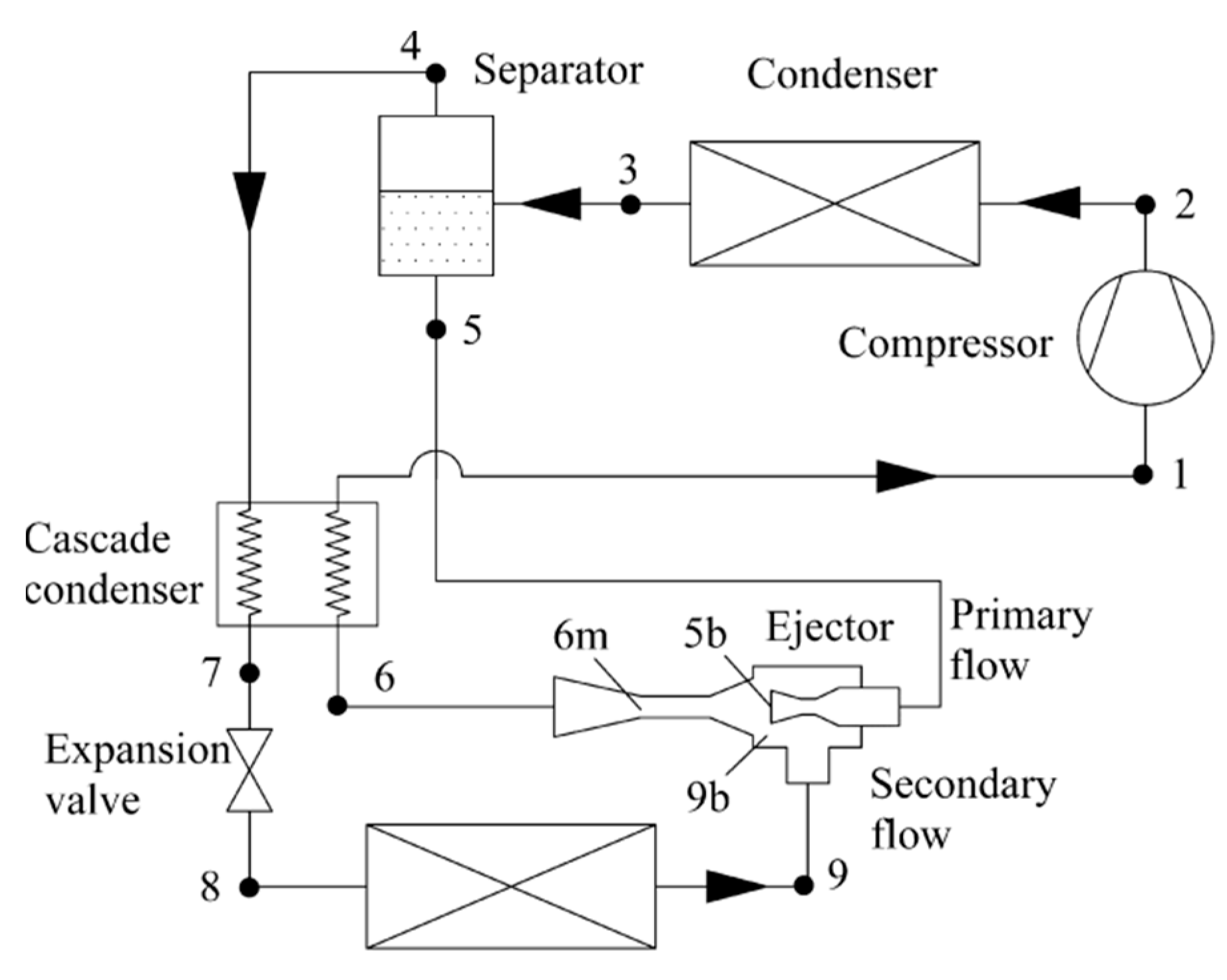

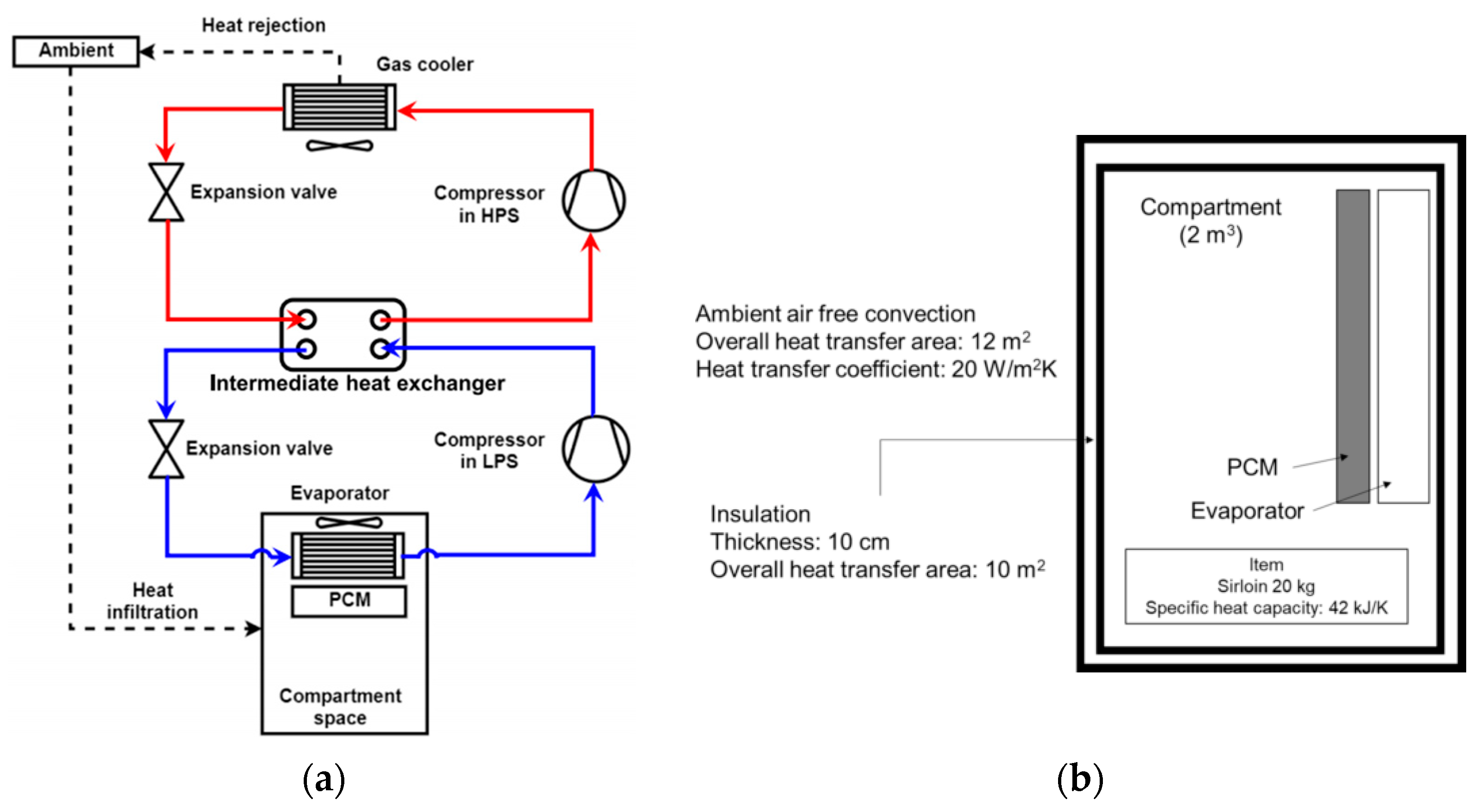

2.3. CARS

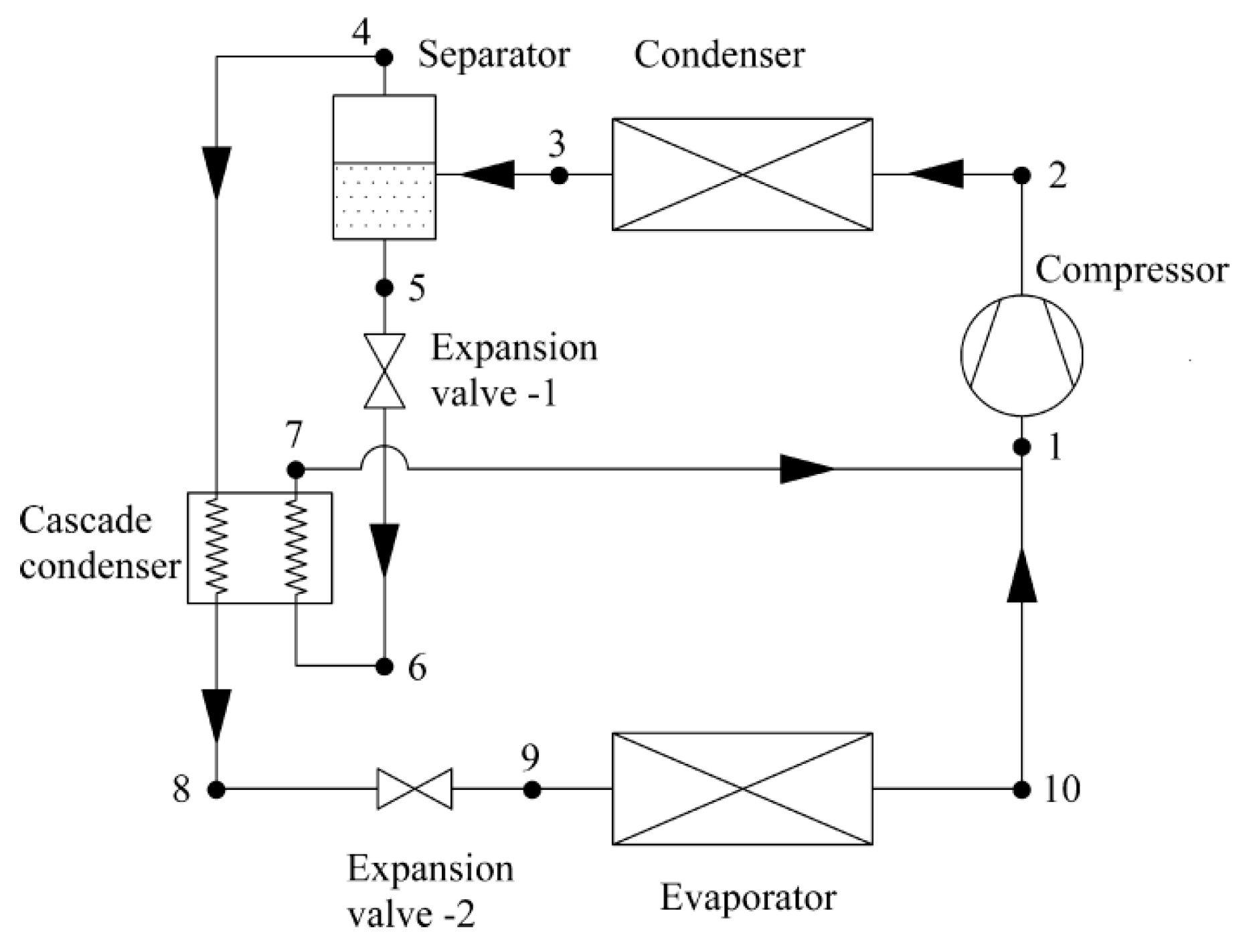

2.4. CCRS

2.5. ACRS

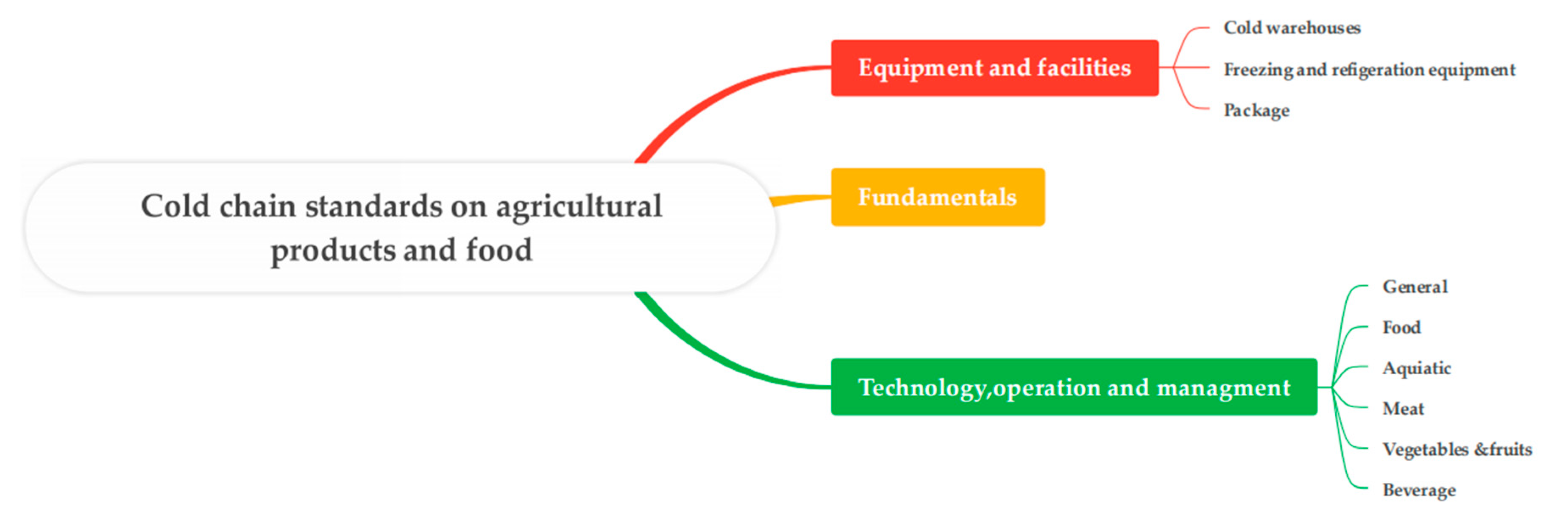

3. Cascaded Refrigeration Systems Applications in the Cold Chain

3.1. Precooling

3.2. Subcooling

4. Phase Change Material

4.1. Characteristics of Phase Change Material

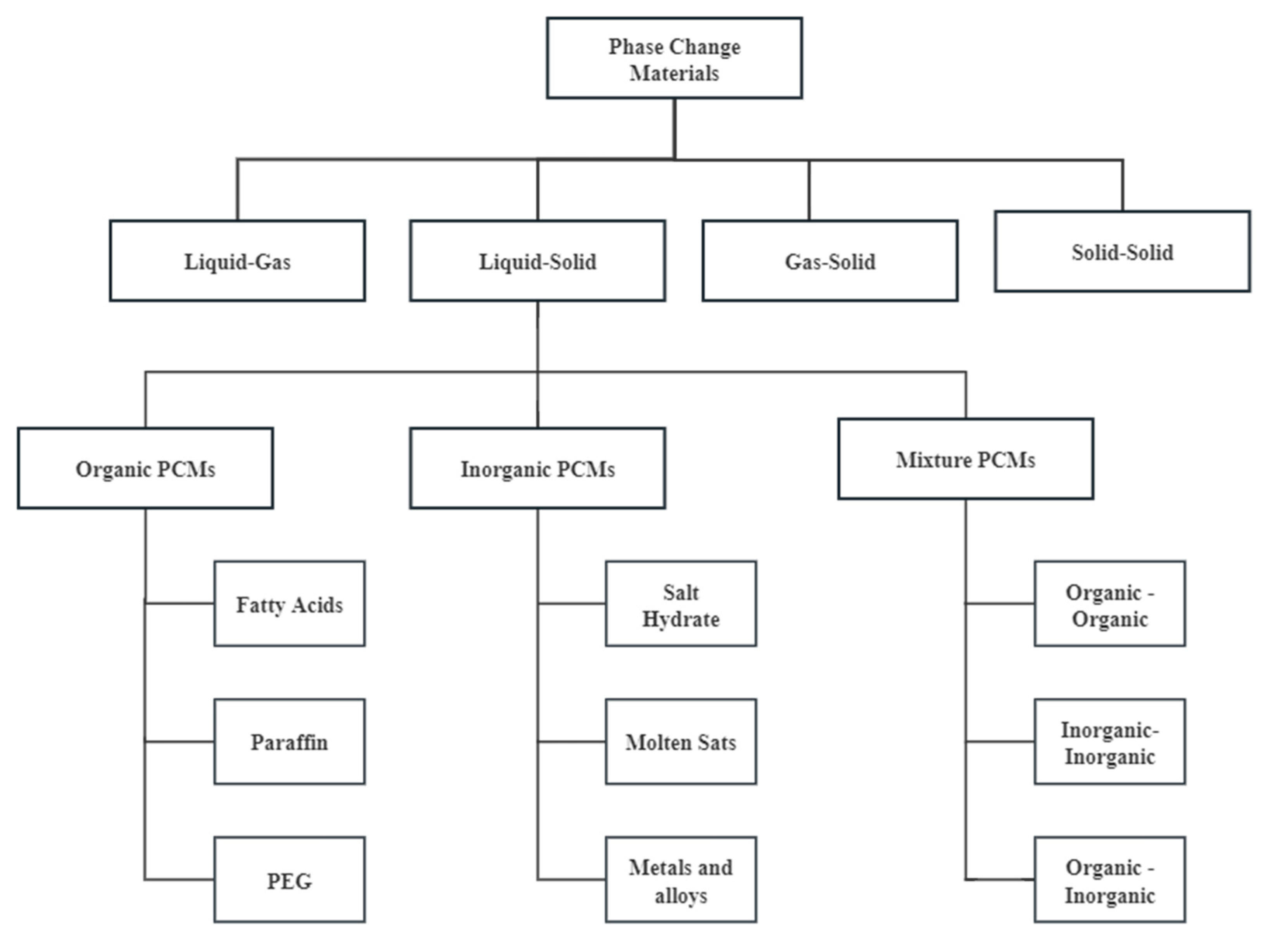

4.1.1. Classification of Phase Change Materials

4.1.2. Selection of Phase Change Materials

4.1.3. Cold Thermal Energy Storage

4.2. PCM Applications on a Refrigeration System

4.3. Use of Phase Change Materials in Cold Chain

4.3.1. PCM in Refrigerated Transportation

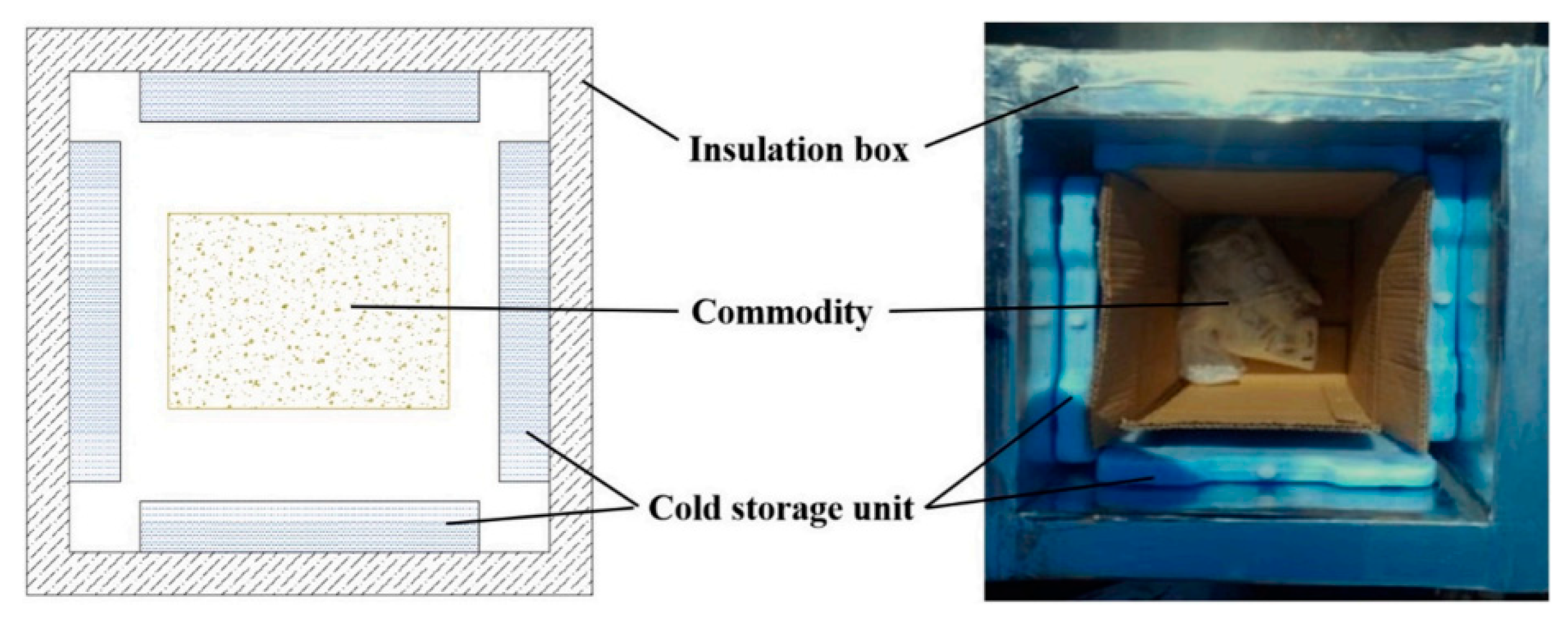

4.3.2. PCM in Cold Storage Boxes

4.3.3. PCM in Domestic Refrigerators and Freezers

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khosravi, A.; Koury, R.N.N.; Machado, L. Thermo-economic analysis and sizing of the components of an ejector expansion refrigeration system. Int. J. Refrig. 2018, 86, 463–479. [Google Scholar] [CrossRef]

- Gani, A. Fossil fuel energy and environmental performance in an extended STIRPAT model. J. Clean. Prod. 2021, 297, 126526. [Google Scholar] [CrossRef]

- Ringel, M. Energy service markets: Status quo and development. In Energy Services Fundamentals and Financing; Academic Press: Cambridge, MA, USA, 2021; pp. 251–275. [Google Scholar]

- Dinga, C.D.; Wen, Z. China’s green deal: Can China’s cement industry achieve carbon neutral emissions by 2060? Renew. Sustain. Energy Rev. 2022, 155, 111931. [Google Scholar] [CrossRef]

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Qiu, B.; Jiang, Y.; Lin, H.; Peng, X.; Wu, Y.; Cui, L. Annual Report on China Building Energy Efficiency; China Architecture and Building Press: Beijing, China, 2007. [Google Scholar]

- Dean, B.; Dulac, J.; Petrichenko, K.; Graham, P. Global Status Report 2016, Towards Zero-Emission Efficient and Resilient Buildings. 2016. Available online: https://www.unep.org/resources/report/global-status-report-2016-towards-zero-emission-efficient-and-resilient-buildings (accessed on 28 July 2024).

- Seck, G.S.; Hache, E.; Barnet, C. Potential bottleneck in the energy transition: The case of cobalt in an accelerating electro-mobility world. Resour. Policy 2022, 75, 102516. [Google Scholar] [CrossRef]

- Pawar, U.; Bhole, K.S.; Oza, A.; Panchal, H.; Shah, M.A.; Jaber, M.M. A case study on the design and development of solar food cooking system with a PCM as a heat storage unit. Int. J. Low-Carbon Technol. 2023, 18, 184–190. [Google Scholar] [CrossRef]

- Affognon, H.; Mutungi, C.; Sanginga, P.; Borgemeister, C. Unpacking postharvest losses in sub-Saharan Africa: A meta-analysis. World Dev. 2015, 66, 49–68. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China 2015–2019 Statistical Yearbook of China. In Chinese. Available online: http://data.stats.gov.cn/easyquery.htm?cn=C01 (accessed on 19 July 2024).

- James, S.J.; James, C. The food cold-chain and climate change. Food Res. Int. 2010, 43, 1944–1956. [Google Scholar] [CrossRef]

- Gao, E.; Cui, Q.; Jing, H.; Zhang, Z.; Zhang, X. A review of application status and replacement progress of refrigerants in the Chinese cold chain industry. Int. J. Refrig. 2021, 128, 104–117. [Google Scholar] [CrossRef]

- Han, J.W.; Zuo, M.; Zhu, W.Y.; Zuo, J.H.; Lü, E.L.; Yang, X.T. A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends. Trends Food Sci. Technol. 2021, 109, 536–551. [Google Scholar] [CrossRef]

- Dong, Y.; Miller, S.A. Assessing the lifecycle greenhouse gas (GHG) emissions of perishable food products delivered by the cold chain in China. J. Clean. Prod. 2021, 303, 126982. [Google Scholar] [CrossRef]

- China Federation of Logistics & Purchasing. Cold Chain Logistics Standard Directory Book; China Federation of Logistics & Purchasing: Beijing, China, 2016; (2016 Edition, in Chinese); Available online: http://www.chinawuliu.com.cn/lhhkx/201607/21/313796.shtml (accessed on 10 August 2024).

- Zilio, C. Moving toward sustainability in refrigeration applications for refrigerated warehouses. HVACR Res. 2014, 20, 1–2. [Google Scholar] [CrossRef]

- McCreanor, V.; Graves, N. An economic analysis of the benefits of sterilizing medical instruments in low-temperature systems instead of steam. Am. J. Infect. Control 2017, 45, 756–760. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Paul, V.; Ezekiel, R.; Pandey, R. Cold storage in India: Present scenario and future directions. Process Food Ind. 2016, 19, 25–28. [Google Scholar]

- Bai, B.; Zhao, K.; Li, X. Application research of nano-storage materials in cold chain logistics of e-commerce fresh agricultural products. Results Phys. 2019, 13, 102049. [Google Scholar] [CrossRef]

- Walsh, B.P.; Murray, S.N.; O’Sullivan DT, J. Free-cooling thermal energy storage using phase change materials in an evaporative cooling system. Appl. Therm. Eng. 2013, 59, 618–626. [Google Scholar] [CrossRef]

- Asgari, S.; Noorpoor, A.R.; Boyaghchi, F.A. Parametric assessment and multi-objective optimization of an internal auto-cascade refrigeration cycle based on advanced exergy and exergoeconomic concepts. Energy 2017, 125, 576–590. [Google Scholar] [CrossRef]

- Torrella, E.; Larumbe, J.A.; Cabello, R.; Llopis, R.; Sanchez, D. A general methodology for energy comparison of intermediate configurations in two-stage vapour compression refrigeration systems. Energy 2011, 36, 4119–4124. [Google Scholar] [CrossRef]

- Shi, Y.; Nie, X.L.; Zhang, B.; Zhou, D. Design and experimental investigation on a 150K auto-cascade refrigeration system. In Proceedings of the 2011 International Conference on Materials for Renewable Energy & Environment, Shanghai, China, 20–22 May 2011; IEEE: Washington, DC, USA, 2011; Volume 2, pp. 1240–1244. [Google Scholar]

- Li, Y.; Liu, G.; Chen, Q.; Yan, G. Progress of auto-cascade refrigeration systems performance improvement: Composition separation, shift and regulation. Renew. Sustain. Energy Rev. 2023, 187, 113664. [Google Scholar] [CrossRef]

- Ko, J.; Thu, K.; Miyazaki, T. Investigation of a cascaded CO2 refrigeration system using phase change materials for energy-saving potentials. Appl. Therm. Eng. 2021, 182, 116104. [Google Scholar] [CrossRef]

- Kasi, P.; Cheralathan, M. Review of cascade refrigeration systems for vaccine storage. J. Phys. Conf. Ser. IOP Publ. 2021, 2054, 012041. [Google Scholar] [CrossRef]

- Dokandari, D.A.; Hagh, A.S.; Mahmoudi SM, S. Thermodynamic investigation and optimization of novel ejector-expansion CO2/NH3 cascade refrigeration cycles (novel CO2/NH3 cycle). Int. J. Refrig. 2014, 46, 26–36. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, J. Performance analysis of an advanced ejector-expansion autocascade refrigeration cycle. Energy 2018, 165, 859–867. [Google Scholar] [CrossRef]

- Megdouli, K.; Ejemni, N.; Nahdi, E.; Mhimid, A.; Kairouani, L. Thermodynamic analysis of a novel ejector expansion transcritical CO2/N2O cascade refrigeration (NEETCR) system for cooling applications at low temperatures. Energy 2017, 128, 586–600. [Google Scholar] [CrossRef]

- Wang, F.; Maidment, G.; Missenden, J.; Robert, T. The novel use of phase change materials in refrigeration plant. Part 2, Dynamic simulation model for the combined system. Appl. Therm. Eng. 2007, 27, 2902–2910. [Google Scholar] [CrossRef]

- Cheng, W.L.; Mei, B.J.; Liu, Y.N.; Huang, Y.H.; Yuan, X.D. A novel household refrigerator with shape-stabilized PCM (Phase Change Material) heat storage condensers: An experimental investigation. Energy 2011, 36, 5797–5804. [Google Scholar] [CrossRef]

- Yu, J.; Tian, G.; Xu, Z. Exergy analysis of Joule–Thomson cryogenic refrigeration cycle with an ejector. Energy 2009, 34, 1864–1869. [Google Scholar] [CrossRef]

- Bai, T.; Yan, G.; Yu, J. Thermodynamics analysis of a modified dual-evaporator CO2 transcritical refrigeration cycle with two-stage ejector. Energy 2015, 84, 325–335. [Google Scholar] [CrossRef]

- Veerakumar, C.; Sreekumar, A. Phase change material based cold thermal energy storage: Materials, techniques and applications–A review. Int. J. Refrig. 2016, 67, 271–289. [Google Scholar] [CrossRef]

- Cerri, G.; Palmieri, A.; Monticelli, E.; Pezzoli, D. Identification of domestic refrigerator models including cool storage. In Proceedings of the International Congress of refrigeration, Washington, DC, USA, 17–22 August 2003. [Google Scholar]

- Zhao, H.; Liu, S.; Tian, C.; Yan, G.; Wang, D. An overview of current status of cold chain in China. Int. J. Refrig. 2018, 88, 483–495. [Google Scholar] [CrossRef]

- Jain, V.; Sachdeva, G.; Kachhwaha, S.S. Energy, exergy, economic and environmental (4E) analyses based comparative performance study and optimization of vapor compression-absorption integrated refrigeration system. Energy 2015, 91, 816–832. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Q.; Xie, Z.; Liu, S.; Su, D.; Cui, Q. Energy and exergy analysis of low GWP refrigerants in cascade refrigeration system. Energy 2019, 170, 1170–1180. [Google Scholar] [CrossRef]

- Harby, K. Hydrocarbons and their mixtures as alternatives to environmental unfriendly halogenated refrigerants: An updated overview. Renew. Sustain. Energy Rev. 2017, 73, 1247–1264. [Google Scholar] [CrossRef]

- Llopis, R.; Sánchez, D.; Sanz-Kock, C.; Cabello, R.; Torrella, E. Energy and environmental comparison of two-stage solutions for commercial refrigeration at low temperature: Fluids and systems. Appl. Energy 2015, 138, 133–142. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Makhnatch, P.; Khodabandeh, R. Recent investigations in HFCs substitution with lower GWP synthetic alternatives: Focus on energetic performance and environmental impact. Int. J. Refrig. 2017, 82, 288–301. [Google Scholar] [CrossRef]

- ASHRAE Standard 34-2010; REFPROP, NIST Standard Reference Database 23, v.9. National Institute of Standards: Gaithersburg, MD, USA, 2010.

- Cui, P.; Yu, M.; Liu, Z.; Zhu, Z.; Yang, S. Energy, exergy, and economic (3E) analyses and multi-objective optimization of a cascade absorption refrigeration system for low-grade waste heat recovery. Energy Convers. Manag. 2019, 184, 249–261. [Google Scholar] [CrossRef]

- Izquierdo, M.; Venegas, M.; Rodríguez, P.; Lecuona, A. Crystallization as a limit to develop solar air-cooled LiBr–H2O absorption systems using low-grade heat. Sol. Energy Mater. Sol. Cells 2004, 81, 205–216. [Google Scholar] [CrossRef]

- Bian, Y.F.; He, G. CAID Research progress of absorption refrigeration working pairs. J. Refrig. 2015, 36, 17–26. [Google Scholar]

- Yanyang, W.; Fengmin, S.; Chengshu, W.; Yifan, W.; Benli, P. Effect of phase change microcapsules on heat and mass transfer during adiabatic spray absorption. J. Dalian Marit. Univ. 2023, 49, 110–116. [Google Scholar]

- Lange, B.; Priesemann, C.; Geiss, M.; Lambrecht, A. Promoting Food Security and Safety via Cold Chains: Technology Options, Cooling Needs and Energy Requirements; Deutsche Gesellschaft fur Internationale Zusammenabeit (GIZ) GmbH: Eschborn, Germany, 2016. [Google Scholar]

- Fernandez-Seara, J.; Sieres, J.; Vazquez, M. Compression–absorption cascade refrigeration system. Appl. Therm. Eng. 2006, 26, 502–512. [Google Scholar] [CrossRef]

- Yılmaz, F.; Selbaş, R.; Özgür, A.E.; Balta, M.T. Performance Analyses of CO2-N2O Cascade System for Cooling. Energy Transp. Glob. Warm. 2016, 499–512. Available online: https://link.springer.com/chapter/10.1007/978-3-319-30127-3_37 (accessed on 10 August 2024).

- Sobieraj, M.; Rosiński, M. High phase-separation efficiency auto-cascade system working with a blend of carbon dioxide for low-temperature isothermal refrigeration. Appl. Therm. Eng. 2019, 161, 114149. [Google Scholar] [CrossRef]

- Bingming, W.; Huagen, W.; Jianfeng, L.; Ziwen, X. Experimental investigation on the performance of NH3/CO2 cascade refrigeration system with twin-screw compressor. Int. J. Refrig. 2009, 32, 1358–1365. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Qin, H.; Sheng, Z.; Wang, Q. An experimental investigation on a modified cascade refrigeration system with an ejector. Int. J. Refrig. 2018, 96, 63–69. [Google Scholar] [CrossRef]

- Pan, M.; Zhao, H.; Liang, D.; Zhu, Y.; Liang, Y.; Bao, G. A review of the cascade refrigeration system. Energies 2020, 13, 2254. [Google Scholar] [CrossRef]

- Keshtkar, M.M. Effect of subcooling and superheating on performance of a cascade refrigeration system with considering thermo-economic analysis and multi-objective optimization. J. Adv. Comput. Sci. Technol. 2016, 5, 42–47. [Google Scholar] [CrossRef]

- Sholahudin, S.; Giannetti, N. Optimization of a cascade refrigeration system using refrigerant C3H8 in high temperature circuits (HTC) and a mixture of C2H6/CO2 in low temperature circuits (LTC). Appl. Therm. Eng. 2016, 104, 96–103. [Google Scholar]

- Yan, G.; Hu, H.; Yu, J. Performance evaluation on an internal auto-cascade refrigeration cycle with mixture refrigerant R290/R600a. Appl. Therm. Eng. 2015, 75, 994–1000. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, H.; Li, Y. Application of an ejector in autocascade refrigeration cycle for the performance improvement. Int. J. Refrig. 2008, 31, 279–286. [Google Scholar] [CrossRef]

- Missimer, D.J. Refrigerant conversion of auto-refrigerating cascade (ARC) systems. Int. J. Refrig. 1997, 20, 201–207. [Google Scholar] [CrossRef]

- Bai, T.; Yan, G.; Yu, J. Experimental investigation on the concentration distribution behaviors of mixture in an ejector enhanced auto-cascade refrigeration system. Int. J. Refrig. 2019, 99, 145–152. [Google Scholar] [CrossRef]

- Wang, Q.; Li, D.H.; Wang, J.P.; Sun, T.F.; Han, X.H.; Chen, G.M. Numerical investigations on the performance of a single-stage auto-cascade refrigerator operating with two vapor–liquid separators and environmentally benign binary refrigerants. Appl. Energy 2013, 112, 949–955. [Google Scholar] [CrossRef]

- Du, K.; Zhang, S.; Xu, W.; Niu, X. A study on the cycle characteristics of an auto-cascade refrigeration system. Exp. Therm. Fluid Sci. 2009, 33, 240–245. [Google Scholar] [CrossRef]

- Yan, G.; Chen, J.; Yu, J. Energy and exergy analysis of a new ejector enhanced auto-cascade refrigeration cycle. Energy Convers. Manag. 2015, 105, 509–517. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, L.; Liang, K. Thermodynamic performance of an auto-cascade ejector refrigeration cycle with mixed refrigerant R32+ R236fa. Appl. Therm. Eng. 2015, 84, 268–275. [Google Scholar] [CrossRef]

- Elansari, A.M.; Yahia, E.M.; Siddiqui, W. Storage systems. In Postharvest Technology of Perishable Horticultural Commodities; Woodhead Publishing: Cambridge, UK, 2019; pp. 401–437. [Google Scholar]

- Sun, D.W.; Zheng, L. Vacuum cooling technology for the agri-food industry: Past, present and future. J. Food Eng. 2006, 77, 203–214. [Google Scholar] [CrossRef]

- Brosnan, T.; Sun, D.W. Precooling techniques and applications for horticultural products—A review. Int. J. Refrig. 2001, 24, 154–170. [Google Scholar] [CrossRef]

- Yenare, R.R.; Sonawane, C.R.; Sur, A.; Singh, B.; Panchal, H.; Kumar, A.; Sadasivuni, K.K.; Siddiqui, M.I.H.; Bhalerao, Y. A comprehensive review of portable cold storage: Technologies, applications, and future trends. Alex. Eng. J. 2024, 94, 23–33. [Google Scholar] [CrossRef]

- Sobolciak, P.; Karkri, M.; Al-Maadeed, M.A.; Krupa, I. Thermal characterization of phase change materials based on linear low-density polyethylene, paraffin wax and expanded graphite. Renew. Energy 2016, 88, 372–382. [Google Scholar] [CrossRef]

- Dincer, I. Heat Transfer in Food Cooling Applications; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Yan, G.; Liu, Y.; Qian, S.; Yu, J. Theoretical study on a vapor compression refrigeration system with cold storage for freezer applications. Appl. Therm. Eng. 2019, 160, 114091. [Google Scholar] [CrossRef]

- Nandanwar, Y.N.; Walke, P.V.; Kalbande, V.P.; Mohan, M. Performance improvement of vapour compression refrigeration system using phase change material and thermoelectric generator. Int. J. Thermofluids 2023, 18, 100352. [Google Scholar] [CrossRef]

- Riahi, A.; Shafii, M.B. Parametric study of a vapor compression refrigeration system integrated with a PCM storage tank for increasing condenser sub-cooled temperature. Case Stud. Therm. Eng. 2023, 47, 103100. [Google Scholar] [CrossRef]

- Natarajan, B.; Kathiresan, A.C.; Subramanium, S.K. Development and performance evaluation of a hybrid portable solar cold storage system for the preservation of vegetables and fruits in remote areas. J. Energy Storage 2023, 72, 108292. [Google Scholar] [CrossRef]

- Qin, Q.; Cao, W.; Zhaxi, D.W.; Chen, X.; Andreeva, D.V.; Chen, K.; Yang, S.; Tian, H.; Shaker, M.; Jin, Z.; et al. Application of 1-decanol loaded in silica aerogel and expanded graphite composite phase change materials in cold chain transport portable boxes. J. Mater. Eng. Perform. 2024, 33, 5029–5040. [Google Scholar] [CrossRef]

- Oró, E.; De Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar] [CrossRef]

- Qi, T.; Ji, J.; Zhang, X.; Liu, L.; Xu, X.; Ma, K.; Gao, Y. Research progress of cold chain transport technology for storage fruits and vegetables. J. Energy Storage 2022, 56, 105958. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, X.; Ji, J.; Yan, H. Review of research progress on corrosion and anti-corrosion of phase change materials in thermal energy storage systems. J. Energy Storage 2023, 63, 107005. [Google Scholar] [CrossRef]

- Solid-Liquid Thermal Energy Storage: Modeling and Applications; CRC Press: Boca Raton, FL, USA, 2022.

- Ilangovan, A.; Hamdane, S.; Silva, P.D.; Gaspar, P.D.; Pires, L. Promising and potential applications of phase change materials in the cold chain: A systematic review. Energies 2022, 15, 7683. [Google Scholar] [CrossRef]

- Sonawane, C.R.; Panchal, H.N.; Hoseinzadeh, S.; Ghasemi, M.H.; Alrubaie, A.J.; Sohani, A. Bibliometric analysis of solar desalination systems powered by solar energy and CFD modelled. Energies 2022, 15, 5279. [Google Scholar] [CrossRef]

- Zhao, T.; Munis, A.; Zheng, M.; Hu, J.; Teng, H.P.; Wei, L.P. 2-(2-Pentadecyl-4, 5-dihydro-1H-imidazol-1-yl) ethanol as a sustainable inhibitor for copper corrosion in molten hydrated phase change materials. J. Mol. Liq. 2020, 316, 113927. [Google Scholar] [CrossRef]

- Shchukina, E.M.; Graham, M.; Zheng, Z.; Shchukin, D.G. Nanoencapsulation of phase change materials for advanced thermal energy storage systems. Chem. Soc. Rev. 2018, 47, 4156–4175. [Google Scholar] [CrossRef] [PubMed]

- Yahia, E.M.; Fonseca, J.M.; Kitinoja, L. Postharvest losses and waste. In Postharvest Technology of Perishable Horticultural Commodities; Elsevier: Amsterdam, The Netherlands, 2019; pp. 43–69. [Google Scholar]

- Khan MI, H. Conventional refrigeration systems using phase change material: A review. Int. J. Air-Cond. Refrig. 2016, 24, 1630007. [Google Scholar] [CrossRef]

- Visek, M.; Joppolo, C.M.; Molinaroli, L.; Olivani, A. Advanced sequential dual evaporator domestic refrigerator/freezer: System energy optimization. Int. J. Refrig. 2014, 43, 71–79. [Google Scholar] [CrossRef]

- Azzouz, K.; Leducq, D.; Gobin, D. Enhancing the performance of household refrigerators with latent heat storage: An experimental investigation. Int. J. Refrig. 2009, 32, 1634–1644. [Google Scholar] [CrossRef]

- Bista, S.; Hosseini, S.E.; Owens, E.; Phillips, G. Performance improvement and energy consumption reduction in refrigeration systems using phase change material (PCM). Appl. Therm. Eng. 2018, 142, 723–735. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, Q.; Chi, Y.; Zhang, L. Performance study on air-cooled household refrigerator with cold storage phase change materials. Int. J. Refrig. 2017, 79, 130–142. [Google Scholar] [CrossRef]

- Wang, F.; Maidment, G.; Missenden, J.; Tozer, R. The novel use of phase change materials in refrigeration plant. Part 1, Experimental investigation. Appl. Therm. Eng. 2007, 27, 2893–2901. [Google Scholar] [CrossRef]

- Kang, Z.; Tan, R.; Qiu, K.; Yao, Q.; Liu, S. Numerical simulation of a medium-sized refrigerated truck box with low-temperature phase change cold storage material. J. Energy Storage 2024, 98, 113175. [Google Scholar] [CrossRef]

- Burgess, S.; Wang, X.; Rahbari, A.; Hangi, M. Optimisation of a portable phase-change material (PCM) storage system for emerging cold-chain delivery applications. J. Energy Storage 2022, 52, 104855. [Google Scholar] [CrossRef]

- Ismail KA, R.; Henríquez, J.R. Solidification of PCM inside a spherical capsule. Energy Convers. Manag. 2000, 41, 173–187. [Google Scholar] [CrossRef]

- Liu, M.; Saman, W.; Bruno, F. Development of a novel refrigeration system for refrigerated trucks incorporating phase change material. Appl. Energy 2012, 92, 336–342. [Google Scholar] [CrossRef]

- Sha, Y.; Hua, W.; Cao, H.; Zhang, X. Properties and encapsulation forms of phase change material and various types of cold storage box for cold chain logistics: A review. J. Energy Storage 2022, 55, 105426. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, X.; Jotham, M.; Li, Y.; Chen, Y.; Chen, Q.; Liu, S. Experimental study on cold retention characteristics of cold storage incubator using Na2SO4· 10H2O as PCMs. Trans. Chin. Soc. Agric. Eng. 2017, 33, 308–314. [Google Scholar]

- Kozak, Y.; Farid, M.; Ziskind, G. Experimental and comprehensive theoretical study of cold storage packages containing PCM. Appl. Therm. Eng. 2017, 115, 899–912. [Google Scholar] [CrossRef]

- Paquette, J.-C.; Mercier, S.; Marcos, B.; Morasse, S. Modeling the thermal performance of a multilayer box for the transportation of perishable food. Food Bioprod. Process. 2017, 105, 77–85. [Google Scholar] [CrossRef]

- Devrani, S.; Tiwari, R.; Khan, N.; Sankar, K.; Patil, S.; Sridhar, K. Enhancing the insulation capability of a vaccine carrier box: An engineering approach. J. Energy Storage 2021, 36, 102182. [Google Scholar] [CrossRef]

- Ray, A.K.; Singh, S.; Rakshit, D. Comparative study of cooling performance for portable cold storage box using phase change medium. Therm. Sci. Eng. Prog. 2022, 27, 101146. [Google Scholar] [CrossRef]

- Abhilash, A.; Menon, A.M.; Anirudh, K. Comparison of a conventional domestic refrigerator with a PCM encapsulated refrigerator. Int. J. Eng. Res. Technol. 2015, 4, 582–587. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Afroz, H.M.M.; Rahman, M.M. Enhancement of higher evaporating temperature of household refrigerator using phase change material. In Proceedings of the International Conference on Mechanical, Industrial and Materials Engineering 2013, Rajshahi, Bangladesh, 1–2 September 2013; pp. 1–3. [Google Scholar]

- Lu, W.; Liu, G.; Xing, X.; Wang, H. Investigation on ternary salt-water solutions as phase change materials for cold storage. Energy Procedia 2019, 158, 5020–5025. [Google Scholar] [CrossRef]

- Azzouz, K.; Leducq, D.; Gobin, D. Performance enhancement of a household refrigerator by addition of latent heat storage. Int. J. Refrig. 2008, 31, 892–901. [Google Scholar] [CrossRef]

- Gin, B.; Farid, M.M.; Bansal, P.K. Effect of door opening and defrost cycle on a freezer with phase change panels. Energy Convers. Manag. 2010, 51, 2698–2706. [Google Scholar] [CrossRef]

- Sonnenrein, G.; Baumhögger, E.; Elsner, A.; Fieback, K.; Morbach, A.; Paul, A.; Vrabec, J. Copolymer-bound phase change materials for household refrigerating appliances: Experimental investigation of power consumption, temperature distribution and demand side management potential. Int. J. Refrig. 2015, 60, 166–173. [Google Scholar] [CrossRef]

- Zhang, X.R. Super cold chain—A high quality, energy-efficient, and environment-friendly method. Int. J. Energy Res. 2017, 41, 1225–1228. [Google Scholar] [CrossRef]

- Taher MA, B.; Ahachad, M.; Mahdaoui, M.; Zeraouli, Y.; Kousksou, T. A survey of computational and experimental studies on refrigerated trucks. J. Energy Storage 2022, 47, 103575. [Google Scholar] [CrossRef]

- Leungtongkum, T.; Flick, D.; Hoang, H.M.; Steven, D.; Delahaye, A.; Laguerre, O. Insulated box and refrigerated equipment with PCM for food preservation: State of the art. J. Food Eng. 2022, 317, 110874. [Google Scholar] [CrossRef]

- Zhang, H.; Wan, X.; Chen, Y.; Guo, B. Research progress in phase change cold-storage materials in cold chain logistics. China Plast. 2021, 35, 106–115. [Google Scholar]

- Liu, C. Research progress on PCCSM used in cold chain logistics. New Chem. Mater. 2021, 49, 16–19. [Google Scholar]

- You, H.; Xie, J. Research progress of low temperature phase change storage materials and their applications in cold chain. Food Ferment. Ind. 2021, 47, 287–293. [Google Scholar]

- Sun, J.; Xie, J. Research progress of phase change cold storage materials and their application in cold storage. Food Mach. 2021, 37, 227–232. [Google Scholar]

- Selvnes, H.; Allouche, Y.; Manescu, R.I.; Hafner, A. Review on cold thermal energy storage applied to refrigeration systems using phase change materials. Therm. Sci. Eng. Prog. 2021, 22, 100807. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Xu, X. Application and research progress of cold storage technology in cold chain transportation and distribution. J. Therm. Anal. Calorim. 2020, 139, 1419–1434. [Google Scholar] [CrossRef]

- Wang, H.; Han, B.; Li, M.; Zeng, X.; Wang, S. Numerical Simulation on Cooling Process of Phase Change Cool Storage Device for Rail Vehicle Air Conditioning System. IOP Conf. Ser. Mater. Sci. Eng. 2020, 746, 012035. [Google Scholar] [CrossRef]

- Xu, Q.; Xie, J. Research progress on energy saving optimization of cold storage plate refrigerator. Food Mach. 2020, 36, 232–236. [Google Scholar]

| Year | Fruits | Vegetables | Meat Aquatic | Products | Poultry and Eggs | Milk |

|---|---|---|---|---|---|---|

| 2015 | 24,524.6 | 66,425.1 | 8749.5 | 6211.0 | 3046.1 | 3297.6 |

| 2016 | 24,405.2 | 67,434.2 | 8628.3 | 6379.5 | 3160.5 | 3176.8 |

| 2017 | 25,241.9 | 69,192.7 | 8654.4 | 6445.3 | 3096.3 | 3148.6 |

| 2018 | 25,688.4 | 70,346.7 | 8624.6 | 6457.7 | 3128.3 | 3173.9 |

| 2019 | 27,400.8 | 72,102.6 | 7758.8 | 6480.4 | 3309.0 | 3295.5 |

| Refrigerant | Formula Weight/(kg/k mol) | Normal Boiling Point/C | Critical Temperature/C | Critical Pressure/MPa | ODP | GWP | Security Classification | |

|---|---|---|---|---|---|---|---|---|

| HTC | R32 | 52.02 | −51.7 | 78.2 | 5.8 | 0 | 550 | A2 |

| R1234yf | 114.04 | −29.45 | 94.7 | 3.38 | 0 | 4 | A2 | |

| R1234ze | 114.04 | 9.745 | 109.37 | 3.64 | 0 | 4 | A1 | |

| R161 | 48.06 | −37.1 | 102.2 | 4.7 | 0 | 12 | A2 | |

| R1270 | 42.08 | −47.7 | 92.4 | 4.67 | 0 | −20 | A3 | |

| R290 | 44.1 | −42.2 | 96.7 | 4.25 | 0 | −20 | A3 | |

| R717 | 17.03 | −33.3 | 132.3 | 11.34 | 0 | <1 | B2 | |

| LTC | R23 | 70.01 | −82.1 | 25.9 | 4.84 | 0 | 12,000 | A1 |

| R170 | 30.07 | −88.9 | 32.2 | 4.87 | 0 | −20 | A3 | |

| R41 | 34.0 | −78.1 | 44.1 | 5.9 | 0 | 97 | A2 | |

| Refrigerant | R717 | R744 | R290 | R152a | R1234ze(E) | R404A | R134a |

|---|---|---|---|---|---|---|---|

| Molecular weight (g mol−1) | 17.03 | 44.01 | 44.10 | 114.04 | 108.4 | 97.60 | 102.03 |

| Critical temperature (°C) | −33.3 | −56.6 | −42.1 | −24 | −19.0 | −26.1 | −46.2 |

| hfg at −30 °C (KJ Kg−1) | 132.3 | 31.0 | 96.7 | 113.3 | 109.4 | 101.1 | 72.0 |

| hfg at 40 °C (KJ Kg−1) | 1099.3 | _ | 307.1 | 260.0 | 154.6 | 163.0 | 120.3 |

| ʋv at −30 °C (m3 Kg−1) | 0.9640 | 0.0269 | 0.2586 | 0.3824 | 0.2817 | 0.2259 | 0.0948 |

| GWP100years | <1 | 1 | ~20 | 133 | 6 | 1370 | 3700 |

| Safety group (ASHRAE standard 34-2010) [43] | B2 (B2L) | A1 | A3 | A2 | A2 | A1 | A1 |

| Food Products | Lowest Safe Temperature (°C) |

|---|---|

| Cranberry and asparagus | 3 |

| Orange, durian, cowpeas, cactus pear, and guava | 5 |

| Pepper, pomegranate, okra, pineapple, and olive | 7 |

| Papaya, lime, cucumber, passion fruit, eggplant, watermelon, tomato (ripe), grapefruit, plantains, and mango (ripe), | 10 |

| Category | Property |

|---|---|

| Thermal | Suitable phase transition temperature and latent heat with good heat transfer characteristics. |

| Physical | High density, small volume change, with favorable phase equilibrium |

| Kinetic | Sufficient crystallization rate; no supercooling. |

| Chemical | Long-lasting stability; no toxicity; nonflammable |

| Component | Advantages | Disadvantages |

|---|---|---|

| Evaporator | Enhancement of system performance | Higher condensation temperature |

| Supports in case of power outages | Longer compression operating time during a single cycle | |

| Decrease in refrigerator noise | ||

| Shorter compressor overall “On-time” ratio | ||

| Reduction in electricity consumption in peak hours | ||

| A decrease in overall costs of the refrigeration system | ||

| Condenser | Higher COP | More refrigerant displacement losses |

| Shorter compressor global “On/Off” ratio | Heat accumulation | |

| Lower condensation temperature and pressure | ||

| Higher subcooling degree | ||

| Faster, stable condition of the refrigerator |

| Author | Key Content | Year | Ref. |

|---|---|---|---|

| Raju R. et al. | The use of phase change materials (PCMs) in conjunction with portable cold storage units | 2024 | [69] |

| Qi et al. | The application and research of phase change cold storage technology in cold chain transportation. | 2023 | [77] |

| Ben Taher et al. | Computational and experimental studies on refrigerated trucks | 2022 | [108] |

| Leungtongkum et al. | Insulated box and refrigerated equipment with PCM for food preservation | 2021 | [109] |

| Zhang et al. | Phase change cold storage materials in cold chain logistics | 2021 | [110] |

| Liu et al. | PCCSM used in cold chain logistics | 2021 | [111] |

| You et al. | Low-temperature phase change materials and their applications in cold chain | 2021 | [112] |

| Sun et al. | Phase change cold materials used in cold storage | 2021 | [113] |

| Selvnes et al. | Cold thermal energy storage applied to refrigeration systems | 2020 | [114] |

| Zhao et al. | Cold storage technology in cold chain transportation and distribution | 2020 | [115] |

| Ning et al. | Phase change cool storage technology in food cold storage transport | 2020 | [116] |

| Xu et al. | Energy-saving optimization of cold storage plate refrigerators | 2020 | [117] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, X.; He, Y.; He, L.; Zhao, C.; Wang, L.; You, W.; Zhu, J. A Review of the Energy-Saving Potential of Phase Change Material-Based Cascaded Refrigeration Systems in Chinese Food Cold Chain Industry. Energies 2024, 17, 4762. https://doi.org/10.3390/en17194762

Meng X, He Y, He L, Zhao C, Wang L, You W, Zhu J. A Review of the Energy-Saving Potential of Phase Change Material-Based Cascaded Refrigeration Systems in Chinese Food Cold Chain Industry. Energies. 2024; 17(19):4762. https://doi.org/10.3390/en17194762

Chicago/Turabian StyleMeng, Xinyu, Yijian He, Lijuan He, Chenlei Zhao, Lifang Wang, Wenxi You, and Jingbo Zhu. 2024. "A Review of the Energy-Saving Potential of Phase Change Material-Based Cascaded Refrigeration Systems in Chinese Food Cold Chain Industry" Energies 17, no. 19: 4762. https://doi.org/10.3390/en17194762

APA StyleMeng, X., He, Y., He, L., Zhao, C., Wang, L., You, W., & Zhu, J. (2024). A Review of the Energy-Saving Potential of Phase Change Material-Based Cascaded Refrigeration Systems in Chinese Food Cold Chain Industry. Energies, 17(19), 4762. https://doi.org/10.3390/en17194762