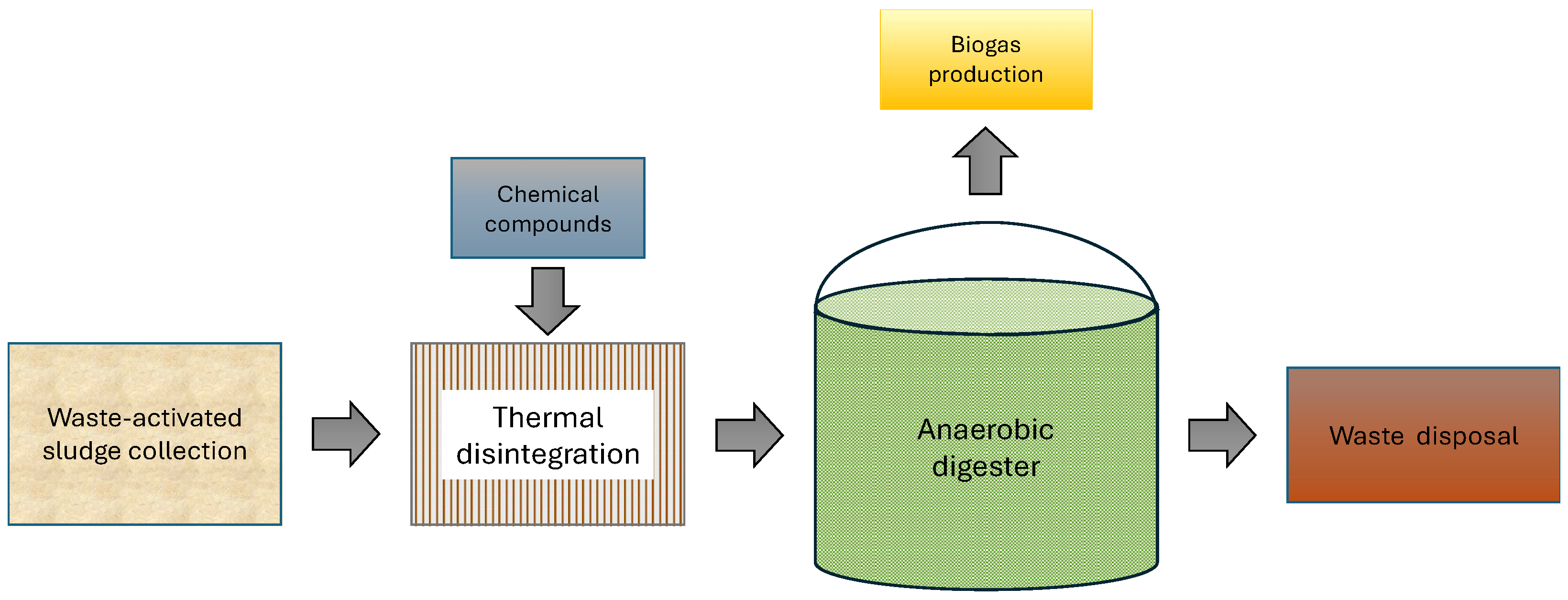

Thermal Disintegration of Waste-Activated Sludge

Abstract

1. Introduction

2. Data Sources and Methodology

3. Mechanisms of Thermal Disintegration of WAS

4. Optimization Parameters for Thermal Disintegration of WAS

5. Combination of Thermal Treatments with Chemical Treatments

5.1. Hydrogen Peroxide

5.2. Calcium Peroxide

5.3. Sodium Percarbonate

5.4. Persulfates

5.5. Alkaline and Acidic Conditions

5.6. Potassium Ferrate

5.7. Sodium Dodecylbenzene Sulfonate

6. Effects on Sludge Properties

6.1. Improvement of Sludge Dewaterability

6.2. Effect on the Composition of Supernatant

6.3. Pathogen Reduction

6.4. Odor Removal

6.5. The Effect of Thermal Treatment on Resource Recovery

7. Full-Scale Implementation and Technological Readiness

8. Economic and Environmental Implications

9. Future Directions and Research Needs

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balkrishna, A.; Singh, S.K.; Pathak, R.; Arya, V. Sludge Management: Current Scenario, Available Solutions and Way Forward. Authorea 2022. preprints. [Google Scholar] [CrossRef]

- Liu, X.; Wang, D.; Chen, Z.; Wei, W.; Mannina, G.; Ni, B.J. Advances in Pretreatment Strategies to Enhance the Biodegradability of Waste Activated Sludge for the Conversion of Refractory Substances. Bioresour. Technol. 2022, 362, 127804. [Google Scholar] [CrossRef] [PubMed]

- Nazari, L.; Yuan, Z.; Santoro, D.; Sarathy, S.; Ho, D.; Batstone, D.; Xu, C.C.; Ray, M.B. Low-Temperature Thermal Pre-Treatment of Municipal Wastewater Sludge: Process Optimization and Effects on Solubilization and Anaerobic Degradation. Water Res. 2017, 113, 111–123. [Google Scholar] [CrossRef]

- Wang, M.; Chen, H.; Liu, S.; Xiao, L. Removal of Pathogen and Antibiotic Resistance Genes from Waste Activated Sludge by Different Pre-Treatment Approaches. Sci. Total Environ. 2021, 763, 143014. [Google Scholar] [CrossRef] [PubMed]

- Trzcinski, A.P. Advanced Biological, Physical, and Chemical Treatment of Waste Activated Sludge. In Advanced Biological, Physical, and Chemical Treatment of Waste Activated Sludge; Taylor & Francis Group: Abingdon, UK, 2018. [Google Scholar] [CrossRef]

- Lambert, N.; Van Aken, P.; Smets, I.; Appels, L.; Dewil, R. Performance Assessment of Ultrasonic Sludge Disintegration in Activated Sludge Wastewater Treatment Plants under Nutrient-Deficient Conditions. Chem. Eng. J. 2022, 431, 133979. [Google Scholar] [CrossRef]

- Xiao, H.; Liang, J.; Zhang, Y.; Chang, J.; Zhang, R.; Zhang, P. Conversion of Materials and Energy in Anaerobic Digestion of Sewage Sludge with High-Pressure Homogenization Pretreatment. Processes 2023, 11, 2467. [Google Scholar] [CrossRef]

- Kumar Biswal, B.; Huang, H.; Dai, J.; Chen, G.H.; Wu, D. Impact of Low-Thermal Pretreatment on Physicochemical Properties of Saline Waste Activated Sludge, Hydrolysis of Organics and Methane Yield in Anaerobic Digestion. Bioresour. Technol. 2020, 297, 122423. [Google Scholar] [CrossRef]

- Zhong, M.; Yang, D.; Liu, R.; Ding, Y.; Dai, X. Effects of Hydrothermal Treatment on Organic Compositions, Structural Properties, Dewatering and Biogas Production of Raw and Digested Sludge. Sci. Total Environ. 2022, 848, 157618. [Google Scholar] [CrossRef]

- de Sousa, T.A.T.; do Monte, F.P.; do Nascimento Silva, J.V.; Lopes, W.S.; Leite, V.D.; van Lier, J.B.; de Sousa, J.T. Alkaline and Acid Solubilisation of Waste Activated Sludge. Water Sci. Technol. 2021, 83, 2980–2996. [Google Scholar] [CrossRef]

- Zhang, C.; Tan, X.; Yang, X.; Wu, F.; Liu, X. Acid Treatment Enhances Phosphorus Release and Recovery from Waste Activated Sludge: Performances and Related Mechanisms. Sci. Total Environ. 2021, 763, 142947. [Google Scholar] [CrossRef]

- Li, J.; Yang, X.; Hu, A.; Li, Y.; Li, Y.; Fu, L.; Yu, C.P. The Performance and Mechanism of Sludge Reduction by the Bioaugmentation Approach. Life 2022, 12, 1649. [Google Scholar] [CrossRef]

- Liu, X.; Li, A.; Ma, L.; Jing, Z.; Yang, J.; Tang, Y.; Hu, B. A Comparison on Phosphorus Release and Struvite Recovery from Waste Activated Sludge by Different Treatment Methods. Int. Biodeterior. Biodegrad. 2020, 148, 104878. [Google Scholar] [CrossRef]

- Hou, H.; Li, Z.; Liu, B.; Liang, S.; Xiao, K.; Zhu, Q.; Hu, S.; Yang, J.; Hu, J. Biogas and Phosphorus Recovery from Waste Activated Sludge with Protocatechuic Acid Enhanced Fenton Pretreatment, Anaerobic Digestion and Microbial Electrolysis Cell. Sci. Total Environ. 2020, 704, 135274. [Google Scholar] [CrossRef] [PubMed]

- Pradel, M.; Lippi, M.; Daumer, M.L.; Aissani, L. Environmental Performances of Production and Land Application of Sludge-Based Phosphate Fertilizers—A Life Cycle Assessment Case Study. Environ. Sci. Pollut. Res. 2020, 27, 2054–2070. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Jiang, S.; Yuan, H.; Zhou, Q.; Gu, G. Hydrolysis and Acidification of Waste Activated Sludge at Different PHs. Water Res. 2007, 41, 683–689. [Google Scholar] [CrossRef]

- Xiao, K.; Chen, Y.; Jiang, X.; Tyagi, V.K.; Zhou, Y. Characterization of Key Organic Compounds Affecting Sludge Dewaterability during Ultrasonication and Acidification Treatments. Water Res. 2016, 105, 470–478. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Li, Y.; Zhao, Y.; Wang, B.; Song, Y.; Chai, X.; Niu, D.; Cao, X. Novel Insights into Enhanced Dewaterability of Waste Activated Sludge by Fe(II)-Activated Persulfate Oxidation. Bioresour. Technol. 2012, 119, 7–14. [Google Scholar] [CrossRef]

- Neyens, E.; Baeyens, J.; Dewil, R.; De Heyder, B. Advanced Sludge Treatment Affects Extracellular Polymeric Substances to Improve Activated Sludge Dewatering. J. Hazard. Mater. 2004, 106, 83–92. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, H.H.P. Influences of Extracellular Polymeric Substances (EPS) on Flocculation, Settling, and Dewatering of Activated Sludge. Crit. Rev. Environ. Sci. Technol. 2003, 33, 237–273. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and Potential of the Anaerobic Digestion of Waste-Activated Sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Myszograj, S.; Płuciennik-Koropczuk, E. Thermal Disintegration of Sewage Sludge as a Method of Improving the Biogas Potential. Energies 2023, 16, 559. [Google Scholar] [CrossRef]

- Peng, S.; Hu, A.; Ai, J.; Zhang, W.; Wang, D. Changes in Molecular Structure of Extracellular Polymeric Substances (EPS) with Temperature in Relation to Sludge Macro-Physical Properties. Water Res. 2021, 201, 117316. [Google Scholar] [CrossRef] [PubMed]

- Appels, L.; Degrève, J.; Van der Bruggen, B.; Van Impe, J.; Dewil, R. Influence of Low Temperature Thermal Pre-Treatment on Sludge Solubilisation, Heavy Metal Release and Anaerobic Digestion. Bioresour. Technol. 2010, 101, 5743–5748. [Google Scholar] [CrossRef]

- Chen, R.; Sheng, Q.; Chen, S.; Dai, X.; Dong, B. The Three-Stage Effect of Hydrothermal Treatment on Sludge Physical-Chemical Properties: Evolution of Polymeric Substances and Their Interaction with Physicochemical Properties. Water Res. 2022, 211, 118043. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.F.; Qian, C.; Jiang, J.K.; Ye, X.D.; Yu, H.Q. Response of Extracellular Polymeric Substances to Thermal Treatment in Sludge Dewatering Process. Environ. Pollut. 2017, 231, 1388–1392. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Yu, X.; Yu, P.; Guo, X.; Zhang, B.; Xiao, B. New Insights into the Effect of Thermal Treatment on Sludge Dewaterability. Sci. Total Environ. 2019, 656, 1082–1090. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, Q.; Du, Z.; Zhang, W.; Wang, D.; Peng, Y. Mechanistic Insights into the Effects of Biopolymer Conversion on Macroscopic Physical Properties of Waste Activated Sludge during Hydrothermal Treatment: Importance of the Maillard Reaction. Sci. Total Environ. 2021, 769, 144798. [Google Scholar] [CrossRef]

- Yan, W.; Xu, H.; Lu, D.; Zhou, Y. Effects of Sludge Thermal Hydrolysis Pretreatment on Anaerobic Digestion and Downstream Processes: Mechanism, Challenges and Solutions. Bioresour. Technol. 2022, 344, 126248. [Google Scholar] [CrossRef]

- Yang, M.; Ding, L.; Wang, P.; Wu, Y.; Areeprasert, C.; Wang, M.; Chen, X.; Wang, F.; Yu, G. Formation of Melanoidins and Development of Characterization Techniques during Thermal Pretreatment of Organic Solid Waste: A Critical Review. Fuel 2023, 334, 126790. [Google Scholar] [CrossRef]

- Val del Río, A.; Morales, N.; Isanta, E.; Mosquera-Corral, A.; Campos, J.L.; Steyer, J.P.; Carrère, H. Thermal Pre-Treatment of Aerobic Granular Sludge: Impact on Anaerobic Biodegradability. Water Res. 2011, 45, 6011–6020. [Google Scholar] [CrossRef]

- Liew, C.S.; Raksasat, R.; Rawindran, H.; Kiatkittipong, W.; Lim, J.W.; Leong, W.H.; Lam, M.K.; Mohamad, M.; Cheng, Y.W.; Chong, C.C. Hydrolysis Kinetics for Solubilizing Waste Activated Sludge at Low Temperature Thermal Treatment Derived from Multivariate Non-Linear Model. Chemosphere 2022, 292, 133478. [Google Scholar] [CrossRef]

- Xiao, K.; Chen, Y.; Jiang, X.; Seow, W.Y.; He, C.; Yin, Y.; Zhou, Y. Comparison of Different Treatment Methods for Protein Solubilisation from Waste Activated Sludge. Water Res. 2017, 122, 492–502. [Google Scholar] [CrossRef] [PubMed]

- Carrère, H.; Bougrier, C.; Castets, D.; Delgenès, J.P. Impact of Initial Biodegradability on Sludge Anaerobic Digestion Enhancement by Thermal Pretreatment. J. Environ. Sci. Health Part A 2008, 43, 1551–1555. [Google Scholar] [CrossRef] [PubMed]

- Mirsoleimani Azizi, S.M.; Haffiez, N.; Mostafa, A.; Hussain, A.; Abdallah, M.; Al-Mamun, A.; Bhatnagar, A.; Dhar, B.R. Low- and High-Temperature Thermal Hydrolysis Pretreatment for Anaerobic Digestion of Sludge: Process Evaluation and Fate of Emerging Pollutants. Renew. Sustain. Energy Rev. 2024, 200, 114453. [Google Scholar] [CrossRef]

- Neyens, E.; Baeyens, J.; Creemers, C. Alkaline Thermal Sludge Hydrolysis. J. Hazard. Mater. 2003, 97, 295–314. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Panico, A.; Esposito, G.; Pirozzi, F.; Lens, P.N.L. Pretreatment Methods to Enhance Anaerobic Digestion of Organic Solid Waste. Appl. Energy 2014, 123, 143–156. [Google Scholar] [CrossRef]

- Zou, J.; Li, Y. Anaerobic Fermentation Combined with Low-Temperature Thermal Pretreatment for Phosphorus-Accumulating Granular Sludge: Release of Carbon Source and Phosphorus as Well as Hydrogen Production Potential. Bioresour. Technol. 2016, 218, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Imbierowicz, M.; Chacuk, A. Kinetic Model of Excess Activated Sludge Thermohydrolysis. Water Res. 2012, 46, 5747–5755. [Google Scholar] [CrossRef]

- Lu, D.; Sun, F.; Zhou, Y. Insights into Anaerobic Transformation of Key Dissolved Organic Matters Produced by Thermal Hydrolysis Sludge Pretreatment. Bioresour. Technol. 2018, 266, 60–67. [Google Scholar] [CrossRef]

- Gao, J.; Li, L.; Yuan, S.; Chen, S.; Dong, B. The Neglected Effects of Polysaccharide Transformation on Sludge Humification during Anaerobic Digestion with Thermal Hydrolysis Pretreatment. Water Res. 2022, 226, 119249. [Google Scholar] [CrossRef]

- Ahmed, B.; Kumar Tyagi, V.; Kazmi, A.A.; Khursheed, A. New Insights into Thermal-Chemical Pretreatment of Organic Fraction of Municipal Solid Waste: Solubilization Effects, Recalcitrant Formation, Biogas Yield and Energy Efficiency. Fuel 2022, 319, 123725. [Google Scholar] [CrossRef]

- Hyder, U.S.; AlSayed, A.; Elbeshbishy, E.; McPhee, J.; Misir, R. Synergistic Addition of Polymer, Ferric Chloride, and Hydrogen Peroxide to Enhance the Post-Treatment Efficiency of Thermophilic Digestate. Waste Biomass Valorization 2024, 15, 4087–4101. [Google Scholar] [CrossRef]

- More, A.; Elder, T.; Jiang, Z. A Review of Lignin Hydrogen Peroxide Oxidation Chemistry with Emphasis on Aromatic Aldehydes and Acids. Holzforschung 2021, 75, 806–823. [Google Scholar] [CrossRef]

- Zhou, P.; Li, D.; Zhang, C.; Ping, Q.; Wang, L.; Li, Y. Comparison of Different Sewage Sludge Pretreatment Technologies for Improving Sludge Solubilization and Anaerobic Digestion Efficiency: A Comprehensive Review. Sci. Total Environ. 2024, 921, 171175. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, S. Reactive Species in Advanced Oxidation Processes: Formation, Identification and Reaction Mechanism. Chem. Eng. J. 2020, 401, 126158. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Wang, J. Fenton/Fenton-like Processes with in-Situ Production of Hydrogen Peroxide/Hydroxyl Radical for Degradation of Emerging Contaminants: Advances and Prospects. J. Hazard. Mater. 2021, 404, 124191. [Google Scholar] [CrossRef]

- Fanaei, F.; Moussavi, G.; Shekoohiyan, S. Enhanced Treatment of the Oil-Contaminated Soil Using Biosurfactant-Assisted Washing Operation Combined with H2O2-Stimulated Biotreatment of the Effluent. J. Environ. Manag. 2020, 271, 110941. [Google Scholar] [CrossRef]

- Gonzalez, A.; van Lier, J.B.; de Kreuk, M.K. Effects of Mild Thermal Pre-Treatment Combined with H2O2 Addition on Waste Activated Sludge Digestibility. Waste Manag. 2022, 141, 163–172. [Google Scholar] [CrossRef]

- Xu, Q.; Huang, Q.S.; Wei, W.; Sun, J.; Dai, X.; Ni, B.J. Improving the Treatment of Waste Activated Sludge Using Calcium Peroxide. Water Res. 2020, 187, 116440. [Google Scholar] [CrossRef]

- Wei, W.; Shi, X.; Wu, L.; Liu, X.; Ni, B.J. Calcium Peroxide Pre-Treatment Improved the Anaerobic Digestion of Primary Sludge and Its Co-Digestion with Waste Activated Sludge. Sci. Total Environ. 2022, 828, 154404. [Google Scholar] [CrossRef]

- Yin, Z.; Wang, J.; Wang, M.; Liu, J.; Chen, Z.; Yang, B.; Zhu, L.; Yuan, R.; Zhou, B.; Chen, H. Application and Improvement Methods of Sludge Alkaline Fermentation Liquid as a Carbon Source for Biological Nutrient Removal: A Review. Sci. Total Environ. 2023, 873, 162341. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Wan, Y.; Wang, Y.; Zhu, Y.; Tao, S.; Xu, Q.; Xiao, K.; Liang, S.; Liu, B.; Hou, H.; et al. Enhancing Waste Activated Sludge Dewaterability by Reducing Interaction Energy of Sludge Flocs. Environ. Res. 2021, 196, 110328. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhang, W.; Wang, D.; Ma, T.; Bai, R.; Yu, D. Enhancement of Waste Activated Sludge Dewaterability Using Calcium Peroxide Pre-Oxidation and Chemical Re-Flocculation. Water Res. 2016, 103, 170–181. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Song, J.; Fang, W.; Cao, H. Enhanced Nitrogen Removal upon the Addition of Volatile Fatty Acids from Activated Sludge by Combining Calcium Peroxide and Low-Thermal Pretreatments. J. Environ. Sci. 2021, 108, 145–151. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Zhang, A.; Wang, L. Enhancing the Quantity and Quality of Short-Chain Fatty Acids Production from Waste Activated Sludge Using CaO2 as an Additive. Water Res. 2015, 83, 84–93. [Google Scholar] [CrossRef]

- Liu, X.; Ren, W.; Zhai, Y.; Xie, Y.; Liang, F.; Xu, Z. Enhanced Recovery of Alginate-like Extracellular Polymers (ALE) from Waste-Activated Sludge Using Sodium Percarbonate: Performance and Characteristics. Sustainability 2023, 15, 14573. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Activation of Persulfate (PS) and Peroxymonosulfate (PMS) and Application for the Degradation of Emerging Contaminants. Chem. Eng. J. 2018, 334, 1502–1517. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, A.; Fan, Y.; Duan, Y.; Liu, Z.; He, Z.; Liu, W.; Yue, X. Using Heat-Activated Persulfate to Accelerate Short-Chain Fatty Acids Production from Waste Activated Sludge Fermentation Triggered by Sulfate-Reducing Microbial Consortium. Sci. Total Environ. 2023, 861, 160795. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, T.; Tian, J.; Zhang, H.; Li, F.; Pei, J. Enhanced Dewaterability of Waste Activated Sludge by UV Assisted ZVI-PDS Oxidation. J. Environ. Sci. 2022, 113, 152–164. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Y. A Comprehensive Review on Persulfate Activation Treatment of Wastewater. Sci. Total Environ. 2022, 831, 154906. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, F.; Kong, L.; Peng, X. Sulfate Radical-Based Removal of Chloride Ion from Strongly Acidic Wastewater: Kinetics and Mechanism. J. Hazard. Mater. 2021, 410, 124540. [Google Scholar] [CrossRef]

- Huang, W.; Xiao, S.; Zhong, H.; Yan, M.; Yang, X. Activation of Persulfates by Carbonaceous Materials: A Review. Chem. Eng. J. 2021, 418, 129297. [Google Scholar] [CrossRef]

- Liao, Z.; Hu, Y.; Chen, Y.; Cheng, J. Enhancing Phosphorus Recovery and Dewaterability of Waste Activated Sludge for Combined Effect of Thermally Activated Peroxydisulfate and Struvite Precipitation. Sustainability 2021, 13, 9700. [Google Scholar] [CrossRef]

- Sari Erkan, H.; Onkal Engin, G. A Comparative Study of Waste Activated Sludge Disintegration by Electrochemical Pretreatment Process Combined with Hydroxyl and Sulfate Radical Based Oxidants. J. Environ. Chem. Eng. 2020, 8, 103918. [Google Scholar] [CrossRef]

- Wang, W.; Chen, M.; Wang, D.; Yan, M.; Liu, Z. Different Activation Methods in Sulfate Radical-Based Oxidation for Organic Pollutants Degradation: Catalytic Mechanism and Toxicity Assessment of Degradation Intermediates. Sci. Total Environ. 2021, 772, 145522. [Google Scholar] [CrossRef]

- Lee, K.M.; Kim, M.S.; Lee, C. Oxidative Treatment of Waste Activated Sludge by Different Activated Persulfate Systems for Enhancing Sludge Dewaterability. Sustain. Environ. Res. 2016, 26, 177–183. [Google Scholar] [CrossRef]

- Xiao, J.; He, D.; Ye, Y.; Yang, B.; Duan, A.; Wang, D. Recent Progress in Persulfate to Improve Waste Activated Sludge Treatment: Principles, Challenges and Perspectives. Chem. Eng. J. 2023, 469, 143956. [Google Scholar] [CrossRef]

- Wu, Y.; Song, K. Effect of Thermal Activated Peroxydisulfate Pretreatment on Short-Chain Fatty Acids Production from Waste Activated Sludge Anaerobic Fermentation. Bioresour. Technol. 2019, 292, 121977. [Google Scholar] [CrossRef]

- Yang, J.; Liu, X.; Wang, D.; Xu, Q.; Yang, Q.; Zeng, G.; Li, X.; Liu, Y.; Gong, J.; Ye, J.; et al. Mechanisms of Peroxymonosulfate Pretreatment Enhancing Production of Short-Chain Fatty Acids from Waste Activated Sludge. Water Res. 2019, 148, 239–249. [Google Scholar] [CrossRef]

- Kokina, K.; Mezule, L.; Gruskevica, K.; Neilands, R.; Golovko, K.; Juhna, T. Impact of Rapid PH Changes on Activated Sludge Process. Appl. Sci. 2022, 12, 5754. [Google Scholar] [CrossRef]

- Toutian, V.; Barjenbruch, M.; Loderer, C.; Remy, C. Impact of Process Parameters of Thermal Alkaline Pretreatment on Biogas Yield and Dewaterability of Waste Activated Sludge. Water Res. 2021, 202, 117465. [Google Scholar] [CrossRef] [PubMed]

- Ruffino, B.; Campo, G.; Cerutti, A.; Zanetti, M.; Lorenzi, E.; Scibilia, G.; Genon, G. Preliminary Technical and Economic Analysis of Alkali and Low Temperature Thermo-Alkali Pretreatments for the Anaerobic Digestion of Waste Activated Sludge. Waste Biomass Valorization 2016, 7, 667–675. [Google Scholar] [CrossRef]

- Huang, L.; Jin, Y.; Zhou, D.; Liu, L.; Huang, S.; Zhao, Y.; Chen, Y.; Huang, L.; Jin, Y.; Zhou, D.; et al. A Review of the Role of Extracellular Polymeric Substances (EPS) in Wastewater Treatment Systems. Int. J. Environ. Res. Public Health 2022, 19, 12191. [Google Scholar] [CrossRef]

- Bou-Sarkis, A.; Pagliaccia, B.; Ric, A.; Derlon, N.; Paul, E.; Bessiere, Y.; Girbal-Neuhauser, E. Effects of Alkaline Solvents and Heating Temperatures on the Solubilization and Degradation of Gel-Forming Extracellular Polymeric Substances (EPS) Extracted from Aerobic Granular Sludge. Biochem. Eng. J. 2022, 185, 108500. [Google Scholar] [CrossRef]

- He, Z.W.; Jin, H.Y.; Ren, Y.X.; Yang, W.J.; Tang, C.C.; Yang, C.X.; Zhou, A.J.; Liu, W.Z.; Wang, A.J. Stepwise Alkaline Treatment Coupled with Ammonia Stripping to Enhance Short-Chain Fatty Acids Production from Waste Activated Sludge. Bioresour. Technol. 2021, 341, 125824. [Google Scholar] [CrossRef] [PubMed]

- Czerwińska, K.; Wierońska-Wiśniewska, F.; Bytnar, K.; Mikusińska, J.; Śliz, M.; Wilk, M. The Effect of an Acidic Environment during the Hydrothermal Carbonization of Sewage Sludge on Solid and Liquid Products: The Fate of Heavy Metals, Phosphorus and Other Compounds. J. Environ. Manag. 2024, 365, 121637. [Google Scholar] [CrossRef]

- Song, G.; Zhao, S.; Wang, J.; Zhao, K.; Zhao, J.; Liang, H.; Liu, R.; Li, Y.Y.; Hu, C.; Qu, J. Enzyme-Enhanced Acidogenic Fermentation of Waste Activated Sludge: Insights from Sludge Structure, Interfaces, and Functional Microflora. Water Res. 2024, 249, 120889. [Google Scholar] [CrossRef]

- Tan, Z.; Liu, Y.; Liu, H.; Yang, C.; Niu, Q.; Cheng, J.J. Effects of 5-Hydroxymethylfurfural on Removal Performance and Microbial Community Structure of Aerobic Activated Sludge Treating Digested Swine Wastewater. J. Environ. Chem. Eng. 2021, 9, 106104. [Google Scholar] [CrossRef]

- Anwar, A.; Liu, X.; Zhang, L. Biogenic Corrosion of Cementitious Composite in Wastewater Sewerage System—A Review. Process Saf. Environ. Prot. 2022, 165, 545–585. [Google Scholar] [CrossRef]

- Hu, J.; Li, Z.; Zhang, A.; Mao, S.; Jenkinson, I.R.; Tao, W. Using a Strong Chemical Oxidant, Potassium Ferrate (K2FeO4), in Waste Activated Sludge Treatment: A Review. Environ. Res 2020, 188, 109764. [Google Scholar] [CrossRef]

- Li, L.; He, J.; Wang, M.; Xin, X.; Xu, J.; Zhang, J. Efficient Volatile Fatty Acids Production from Waste Activated Sludge after Ferrate Pretreatment with Alkaline Environment and the Responding Microbial Community Shift. ACS Sustain. Chem. Eng. 2018, 6, 16819–16827. [Google Scholar] [CrossRef]

- Diak, J.; Örmeci, B. Ferrrate(VI) and Freeze-Thaw Treatment for Oxidation of Hormones and Inactivation of Fecal Coliforms in Sludge. Water Sci. Technol. 2017, 75, 1625–1632. [Google Scholar] [CrossRef] [PubMed]

- Guo, B.; Zeng, J.; Hao, Y.; Hu, J.; Li, Z. Enhanced Methane Production from Waste Activated Sludge by Potassium Ferrate Combined with Thermal Hydrolysis Pretreatment. Environ. Sci. Pollut. Res. 2024, 31, 45862–45874. [Google Scholar] [CrossRef]

- Ma, Y.; Hao, D.; Yao, S.; Zhang, D.; Li, X.; Feng, L. Effects of Potassium Ferrate and Low-Temperature Thermal Hydrolysis Co-Pretreatment on the Hydrolysis and Anaerobic Digestion Process of Waste Activated Sludge. J. Ocean Univ. China 2023, 22, 1583–1591. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Tian, L.; Zheng, K.; Zhu, T.; Chen, X.; Zhao, Y.; Liu, Y. Heat-Assisted Potassium Ferrate Pretreatment Enhancing Short-Chain Fatty Acids Production from Waste Activated Sludge: Performance and Mechanisms. J. Clean. Prod. 2022, 380, 134989. [Google Scholar] [CrossRef]

- Wan, J.; Fang, W.; Zhang, T.; Wen, G. Enhancement of Fermentative Volatile Fatty Acids Production from Waste Activated Sludge by Combining Sodium Dodecylbenzene Sulfonate and Low-Thermal Pretreatment. Bioresour. Technol. 2020, 308, 123291. [Google Scholar] [CrossRef]

- Wu, M.; Fu, Q.; Huang, J.; Xu, Q.; Wang, D.; Liu, X.; Yang, J.; Wu, Y.; He, D.; Ni, B.J.; et al. Effect of Sodium Dodecylbenzene Sulfonate on Hydrogen Production from Dark Fermentation of Waste Activated Sludge. Sci. Total Environ. 2021, 799, 149383. [Google Scholar] [CrossRef]

- Shi, X.; Zhu, L.; Li, B.; Liang, J.; Li, X. yan Surfactant-Assisted Thermal Hydrolysis off Waste Activated Sludge for Improved Dewaterability, Organic Release, and Volatile Fatty Acid Production. Waste Manag. 2021, 124, 339–347. [Google Scholar] [CrossRef]

- Wu, B.; Ni, B.-J.; Horvat, K.; Song, L.; Chai, X.; Dai, X.; Mahajan, D. Occurrence State and Molecular Structure Analysis of Extracellular Proteins with Implications on the Dewaterability of Waste-Activated Sludge. Environ. Sci. Technol. 2017, 51, 9235–9243. [Google Scholar] [CrossRef]

- Oosterhuis, M.; Ringoot, D.; Hendriks, A.; Roeleveld, P. Thermal Hydrolysis of Waste Activated Sludge at Hengelo Wastewater Treatment Plant, The Netherlands. Water Sci. Technol. 2014, 70, 1–7. [Google Scholar] [CrossRef]

- Xiao, K.; Abbt-Braun, G.; Horn, H. Changes in the Characteristics of Dissolved Organic Matter during Sludge Treatment: A Critical Review. Water Res. 2020, 187, 116441. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhai, Y.; Xu, Z.; Zhu, Y.; Zhou, Y.; Wang, Z.; Liu, L.; Liang, F.; Ren, W.; Xie, Y.; et al. One-Pot Production of 5-Methylfurfural (5-MF) and Enhanced Dewaterability of Waste Activated Sludge by Hydrothermal Treatment with Natural Deep Eutectic Solvents (NADES): Experimental and Theoretical Studies. Chem. Eng. J. 2023, 464, 142575. [Google Scholar] [CrossRef]

- Liu, X.; Zhai, Y.; Xu, Z.; Liang, F.; Ren, W.; Xie, Y.; Ma, J.; Qin, L.; He, H. Natural Deep Eutectic Solvents Pretreatments for Sludge Dewaterability Improvement and Subsequent Volatile Fatty Acids Production: Insights of Sludge Disintegration and Metagenomic Characterization. Chem. Eng. J. 2024, 493, 152498. [Google Scholar] [CrossRef]

- Elbing, G.; Dünnebeil, A. Thermal Disintegration with Subsequent Digestion Lab-Scale Investigation. Korresp. Abwasser 1999, 46, 538–547. [Google Scholar]

- Graja, S.; Chauzy, J.; Fernandes, P.; Patria, L.; Cretenot, D. Reduction of Sludge Production from WWTP Using Thermal Pretreatment and Enhanced Anaerobic Methanisation. Water Sci. Technol. 2005, 52, 267–273. [Google Scholar] [CrossRef]

- Xue, T.; Huang, X. Releasing Characteristics of Phosphorus and Other Substances during Thermal Treatment of Excess Sludge. J. Environ. Sci. 2007, 19, 1153–1158. [Google Scholar] [CrossRef]

- Bernat, K.; Kulikowska, D.; Zielińska, M.; Cydzik-Kwiatkowska, A.; Wojnowska-Baryła, I. Nitrogen Removal from Wastewater with a Low COD/N Ratio at a Low Oxygen Concentration. Bioresour. Technol. 2011, 102, 4913–4916. [Google Scholar] [CrossRef]

- Wu, X.; Nawaz, S.; Li, Y.; Zhang, H. Environmental Health Hazards of Untreated Livestock Wastewater: Potential Risks and Future Perspectives. Environ. Sci. Pollut. Res. 2024, 31, 24745–24767. [Google Scholar] [CrossRef]

- Mazzei, H.G.; Specchia, S. Latest Insights on Technologies for the Treatment of Solid Medical Waste: A Review. J. Environ. Chem. Eng. 2023, 11, 109309. [Google Scholar] [CrossRef]

- Płonka, I.; Pieczykolan, B. Thermal Methods, Ultraviolet Radiation, and Ultrasonic Waves for the Treatment of Waterborne Pathogens. In Waterborne Pathogens: Detection and Treatment; Elsevier: Amsterdam, The Netherlands, 2020; pp. 143–167. [Google Scholar] [CrossRef]

- Azim, N.; Diaz, A.; Li, W.; Calle, L.M.; Irwin, T.; Callahan, M.R. Literature Review of Disinfection Techniques for Water Treatment. In Proceedings of the International Conference on Environmental Systems (ICES) 2020, Virtual, 12–16 July 2020. [Google Scholar]

- Lau, M.; Monis, P.; Ryan, G.; Salveson, A.; Fontaine, N.; Blackbeard, J.; Gray, S.; Sanciolo, P. Selection of Surrogate Pathogens and Process Indicator Organisms for Pasteurisation of Municipal Wastewater—A Survey of Literature Data on Heat Inactivation of Pathogens. Process Saf. Environ. Prot. 2020, 133, 301–314. [Google Scholar] [CrossRef]

- Kakar, F.L.; Tadesse, F.; Elbeshbishy, E. Comprehensive Review of Hydrothermal Pretreatment Parameters Affecting Fermentation and Anaerobic Digestion of Municipal Sludge. Processes 2022, 10, 2518. [Google Scholar] [CrossRef]

- Shrestha, B.; Hernandez, R.; Fortela, D.L.B.; Sharp, W.; Chistoserdov, A.; Gang, D.; Revellame, E.; Holmes, W.; Zappi, M.E. A Review of Pretreatment Methods to Enhance Solids Reduction during Anaerobic Digestion of Municipal Wastewater Sludges and the Resulting Digester Performance: Implications to Future Urban Biorefineries. Appl. Sci. 2020, 10, 9141. [Google Scholar] [CrossRef]

- Amoah, I.D.; Kumari, S.; Bux, F. A Probabilistic Assessment of Microbial Infection Risks Due to Occupational Exposure to Wastewater in a Conventional Activated Sludge Wastewater Treatment Plant. Sci. Total Environ. 2022, 843, 156849. [Google Scholar] [CrossRef]

- Malcheva, B.Z.; Petrov, P.G.; Stefanova, V.V. Microbiological Control in Decontamination of Sludge from Wastewater Treatment Plant. Processes 2022, 10, 406. [Google Scholar] [CrossRef]

- Sammarro Silva, K.J.; de Souza Leite, L.; Daniel, L.A.; Sabogal-Paz, L.P. Hydrogen Peroxide-Assisted Pasteurization: An Alternative for Household Water Disinfection. J. Clean. Prod. 2022, 357, 131958. [Google Scholar] [CrossRef]

- Luo, H.; Novak, J.T.; Nguyen, C. Wastewater Carbon Diversion and Recovery via Primary Sludge Production, Thermal Hydrolysis, and Anaerobic Digestion 2023. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Falls Church, VA, USA, 6 September 2023. [Google Scholar]

- Ma, L.; Zhao, R.; Li, J.; Yang, Q.; Liu, Y. Release Characteristics and Risk Assessment of Volatile Sulfur Compounds in a Municipal Wastewater Treatment Plant with Odor Collection Device. J. Environ. Manag. 2024, 354, 120321. [Google Scholar] [CrossRef]

- Yadav, G.D.; Sontakke, J.B.; Yadav, G.D.; Sontakke, J.B. Methods for Separation, Recycling and Reuse of Biodegradation Products. In Biodegradation—Engineering and Technology; IntechOpen: Rijeka, Croatia, 2013. [Google Scholar] [CrossRef]

- Cui, G.; Bhat, S.A.; Li, W.; Ishiguro, Y.; Wei, Y.; Li, F. H2S, MeSH, and NH3 Emissions from Activated Sludge: An Insight towards Sludge Characteristics and Microbial Mechanisms. Int. Biodeterior. Biodegrad. 2022, 166, 105331. [Google Scholar] [CrossRef]

- Revah, S.; Morgan-Sagastume, J.M. Methods of Odor and VOC Control. In Biotechnology for Odor and Air Pollution Control; Springer: Berlin/Heidelberg, Germany, 2005; pp. 29–63. [Google Scholar] [CrossRef]

- Zhu, X.; Yang, X.; Gao, W.; Jiao, R.; Zhao, S.; Yu, J.; Wang, D. Effect of Low-Temperature Thermal Drying on Malodorous Volatile Organic Compounds (MVOCs) Emission of Wastewater Sludge: The Relationship with Microbial Communities. Environ. Pollut. 2022, 306, 119423. [Google Scholar] [CrossRef] [PubMed]

- Waclawek, S.; Grübel, K.; Silvestri, D.; Padil, V.V.T.; Waclawek, M.; Cerník, M.; Varma, R.S. Disintegration of Wastewater Activated Sludge (WAS) for Improved Biogas Production. Energies 2018, 12, 21. [Google Scholar] [CrossRef]

- Neczaj, E.; Grosser, A. Biogas Production by Thermal Hydrolysis and Thermophilic Anaerobic Digestion of Waste-Activated Sludge. In Industrial and Municipal Sludge: Emerging Concerns and Scope for Resource Recovery; Elsevier: Amsterdam, The Netherlands, 2019; pp. 741–781. [Google Scholar] [CrossRef]

- Zhao, P.; Liu, Y.; Dou, C.; Wan, P. Study on Dissolution Characteristics of Excess Sludge by Low-Temperature Thermal Hydrolysis and Acid Production by Fermentation. ACS Omega 2020, 5, 26101–26109. [Google Scholar] [CrossRef]

- Chung, C.; Kim, J.; Sovacool, B.K.; Griffiths, S.; Bazilian, M.; Yang, M. Decarbonizing the Chemical Industry: A Systematic Review of Sociotechnical Systems, Technological Innovations, and Policy Options. Energy Res. Soc. Sci. 2023, 96, 102955. [Google Scholar] [CrossRef]

- Sahu, A.K.; Mitra, I.; Kleiven, H.; Holte, H.R.; Svensson, K. Cambi Thermal Hydrolysis Process (CambiTHP) for Sewage Sludge Treatment. In Clean Energy and Resource Recovery: Wastewater Treatment Plants as Biorefineries, Volume 2; Elsevier: Amsterdam, The Netherlands, 2022; pp. 405–422. [Google Scholar] [CrossRef]

- Balasundaram, G.; Gahlot, P.; Kazmi, A.A.; Tyagi, V.K. Overview of Thermal Based Pre-Treatment Methods for Enhancing Methane Production of Sewage Sludge. In Management of Wastewater and Sludge: New Approaches; Taylor & Francis Group: Abingdon, UK, 2023; pp. 257–270. [Google Scholar] [CrossRef]

- Chauzy, J.; Cretenot, D.; Bausseron, A.; Deleris, S. Anaerobic Digestion Enhanced by Thermal Hydrolysis: First Reference BIOTHELYS® at Saumur, France. Water Pract. Technol. 2008, 3, wpt2008004. [Google Scholar] [CrossRef]

- Di Capua, F.; Spasiano, D.; Giordano, A.; Adani, F.; Fratino, U.; Pirozzi, F.; Esposito, G. High-Solid Anaerobic Digestion of Sewage Sludge: Challenges and Opportunities. Appl. Energy 2020, 278, 115608. [Google Scholar] [CrossRef]

- Djafer, M.; Crampon, C.; Dimassimo, R. Continuous “Digestion-THP-Digestion” (DLD) at Lille (France) WWTP: Results after One Year Operation. Proc. Water Environ. Fed. 2016, 2016, 887–892. [Google Scholar] [CrossRef]

- Ferrentino, R.; Langone, M.; Fiori, L.; Andreottola, G. Full-Scale Sewage Sludge Reduction Technologies: A Review with a Focus on Energy Consumption. Water 2023, 15, 615. [Google Scholar] [CrossRef]

- Long, A.; Weber, N.; Krampe, J.; Peer, S.; Rechberger, H.; Zessner, M.; Zoboli, O. Multi-Criteria Analysis of Strategies towards Sustainable Recycling of Phosphorus from Sewage Sludge in Austria. J. Environ. Manag. 2024, 362, 121339. [Google Scholar] [CrossRef]

- Mekonnen, T.; Mussone, P.; Bressler, D. Valorization of Rendering Industry Wastes and Co-Products for Industrial Chemicals, Materials and Energy: Review. Crit. Rev. Biotechnol. 2016, 36, 120–131. [Google Scholar] [CrossRef]

- Hu, M.; Ye, Z.; Zhang, H.; Chen, B.; Pan, Z.; Wang, J. Thermochemical Conversion of Sewage Sludge for Energy and Resource Recovery: Technical Challenges and Prospects. Environ. Pollut. Bioavailab. 2021, 33, 145–163. [Google Scholar] [CrossRef]

- Abu-Orf, M.; Goss, T. Comparing Thermal Hydrolysis Processes (CAMBITM and EXELYSTM) For Solids Pretreatmet Prior To Anaerobic Digestion. Proc. Water Environ. Fed. 2012, 2012, 1024–1036. [Google Scholar] [CrossRef]

- Lishan, X.; Tao, L.; Yin, W.; Zhilong, Y.; Jiangfu, L. Comparative Life Cycle Assessment of Sludge Management: A Case Study of Xiamen, China. J. Clean. Prod. 2018, 192, 354–363. [Google Scholar] [CrossRef]

- Liew, C.S.; Kiatkittipong, W.; Lim, J.W.; Lam, M.K.; Ho, Y.C.; Ho, C.D.; Ntwampe, S.K.O.; Mohamad, M.; Usman, A. Stabilization of Heavy Metals Loaded Sewage Sludge: Reviewing Conventional to State-of-the-Art Thermal Treatments in Achieving Energy Sustainability. Chemosphere 2021, 277, 130310. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, R.; Ren, J. Developing a Life Cycle Composite Footprint Index for Sustainability Prioritization of Sludge-to-Energy Alternatives. J. Clean. Prod. 2021, 281, 124885. [Google Scholar] [CrossRef]

- Snowden-Swan, L.J.; Zhu, Y.; Bearden, M.D.; Seiple, T.E.; Jones, S.B.; Schmidt, A.J.; Billing, J.M.; Hallen, R.T.; Hart, T.R.; Liu, J.; et al. Conceptual Biorefinery Design and Research Targeted for 2022: Hydrothermal Liquefacation Processing of Wet Waste to Fuels; Report; Pacific Northwest National Laboratory: Richland, WA, USA, 2017. [Google Scholar] [CrossRef]

- Nelson, L.; Park, S.; Hubbe, M.A. Thermal Depolymerization of Biomass with Emphasis on Gasifier Design and Best Method for Catalytic Hot Gas Conditioning. Bioresources 2018, 13, 4630–4727. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, Y.; Yao, J.; Wu, Y.; Tran, Q.C.; Vu, Q.V. Insight into Conditioning Landfill Sludge with Ferric Chloride and a Fenton Reagent: Effects on the Consolidation Properties and Advanced Dewatering. Chemosphere 2020, 252, 126528. [Google Scholar] [CrossRef]

- Chang, S.; Filer, J. Thermal Hydrolysis to Enhance Anaerobic Digestion Performance of Wastewater Sludge. Curr. Pollut. Rep. 2020, 6, 452–467. [Google Scholar] [CrossRef]

- Mong, G.R.; Chong, W.W.F.; Nor, S.A.M.; Ng, J.H.; Chong, C.T.; Idris, R.; Too, J.; Chiong, M.C.; Abas, M.A. Pyrolysis of Waste Activated Sludge from Food Manufacturing Industry: Thermal Degradation, Kinetics and Thermodynamics Analysis. Energy 2021, 235, 121264. [Google Scholar] [CrossRef]

- Singh, K.; Tripathi, S.; Chandra, R. Maillard Reaction Product and Its Complexation with Environmental Pollutants: A Comprehensive Review of Their Synthesis and Impact. Bioresour. Technol. Rep. 2021, 15, 100779. [Google Scholar] [CrossRef]

- Abelleira, J.; Pérez-Elvira, S.I.; Portela, J.R.; Sánchez-Oneto, J.; Nebot, E. Advanced Thermal Hydrolysis: Optimization of a Novel Thermochemical Process to Aid Sewage Sludge Treatment. Environ. Sci. Technol. 2012, 46, 6158–6166. [Google Scholar] [CrossRef]

- Gahlot, P.; Balasundaram, G.; Tyagi, V.K.; Atabani, A.E.; Suthar, S.; Kazmi, A.A.; Štěpanec, L.; Juchelková, D.; Kumar, A. Principles and Potential of Thermal Hydrolysis of Sewage Sludge to Enhance Anaerobic Digestion. Environ. Res. 2022, 214, 113856. [Google Scholar] [CrossRef]

- Tews, I.J.; Garcia-Perez, M. Advanced Oxidative Techniques for the Treatment of Aqueous Liquid Effluents from Biomass Thermochemical Conversion Processes: A Review. Energy Fuels 2022, 36, 60–79. [Google Scholar] [CrossRef]

- Jin, M.; Liu, H.; Deng, H.; Xiao, H.; Liu, S.; Yao, H. Dissociation and Removal of Alkali and Alkaline Earth Metals from Sewage Sludge Flocs during Separate and Assisted Thermal Hydrolysis. Water Res. 2023, 229, 119409. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, S.; Zhang, Q.; Wang, N.; Yang, Q.; Hao, J. Development and Standardization of Spectrophotometric Assay for Quantification of Thermal Hydrolysis-Origin Melanoidins and Its Implication in Antioxidant Activity Evaluation. J. Hazard. Mater. 2024, 476, 135021. [Google Scholar] [CrossRef]

| Technology | Temperature (°C) | Pressure (bar) | Energy Consumption | Performance Outcomes |

|---|---|---|---|---|

| CambiTHP™ | 150–165 | 8–9 | High | High biogas yield, improved dewaterability |

| BioThelys™ | 165 | 9 | High | Enhanced biodegradability, increased methane production |

| Exelys™ | 160 | 6–9 | Moderate | Maximized sludge dissolution, efficient biogas production |

| Turbotec™ | 140–160 | NA | Moderate | Improved dewaterability, increased biogas yield |

| Lysotherm™ | 140–160 | 6–8 | Moderate | Enhanced solubilization, higher biogas yields |

| Biorefinex© | 150–170 | NA | Moderate | Resource recovery, production of biogas and fertilizers |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bułkowska, K.; Zielińska, M. Thermal Disintegration of Waste-Activated Sludge. Energies 2024, 17, 4447. https://doi.org/10.3390/en17174447

Bułkowska K, Zielińska M. Thermal Disintegration of Waste-Activated Sludge. Energies. 2024; 17(17):4447. https://doi.org/10.3390/en17174447

Chicago/Turabian StyleBułkowska, Katarzyna, and Magdalena Zielińska. 2024. "Thermal Disintegration of Waste-Activated Sludge" Energies 17, no. 17: 4447. https://doi.org/10.3390/en17174447

APA StyleBułkowska, K., & Zielińska, M. (2024). Thermal Disintegration of Waste-Activated Sludge. Energies, 17(17), 4447. https://doi.org/10.3390/en17174447