Wax Deposition of Diesel Oil and Consequent Contamination of Gasoline in Sequential Transportation of Product Oil Pipeline

Abstract

1. Introduction

2. Experimental

2.1. Materials

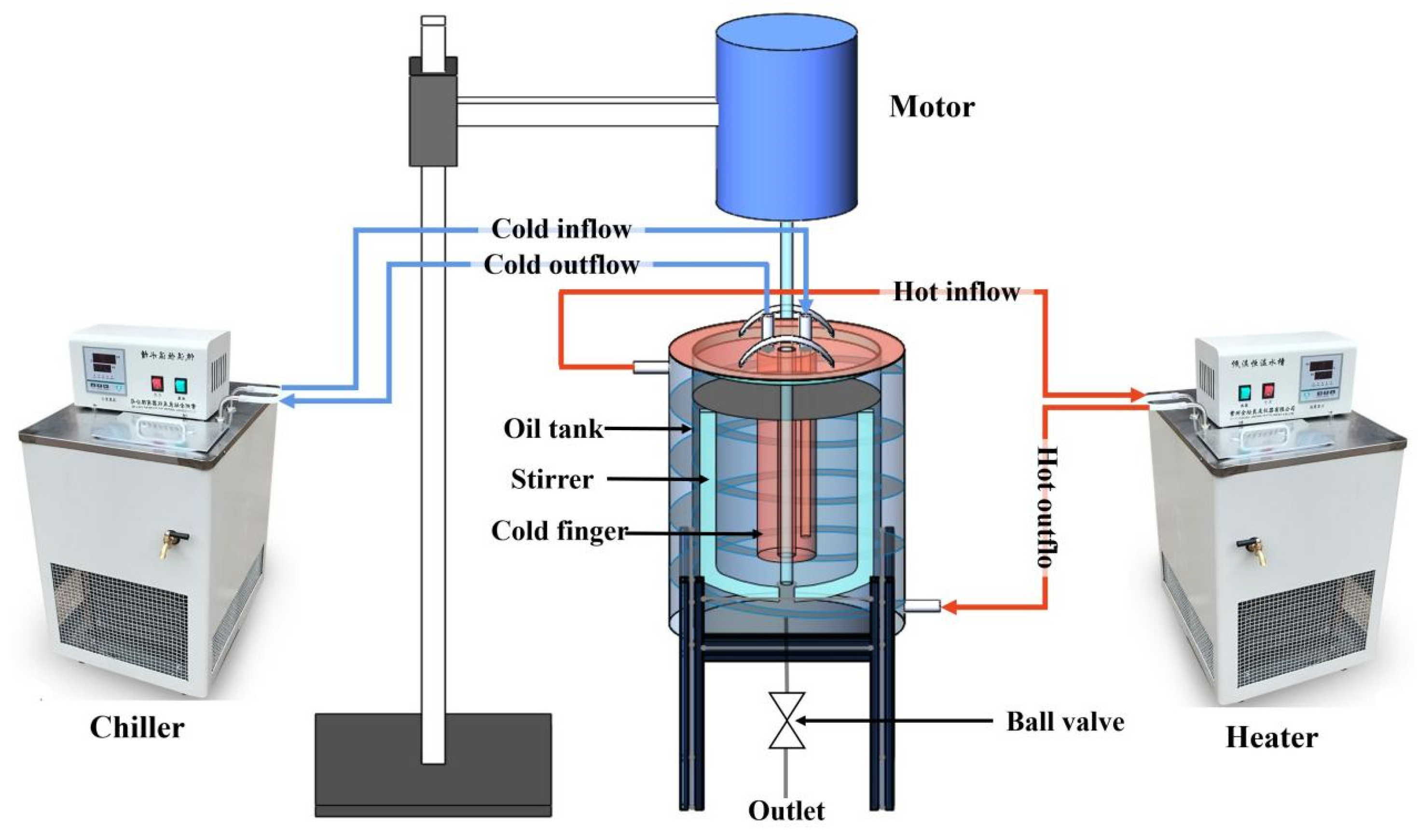

2.2. Cold Finger Apparatus

2.3. Test Procedure

3. Results and Discussion

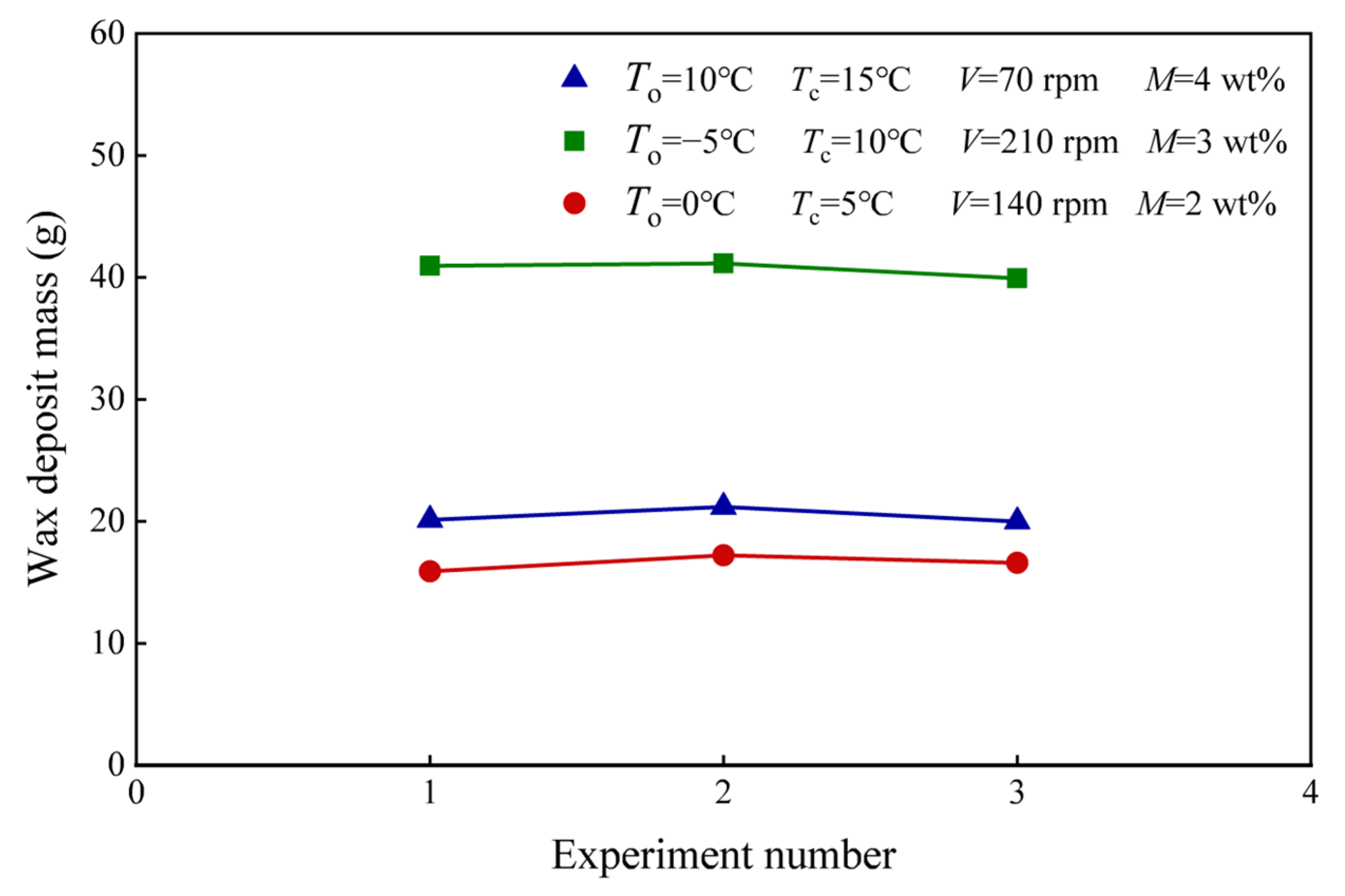

3.1. Repetitive Experiments

3.2. Wax-Deposition Mechanism of Diesel Oil

3.3. Dissolution of Diesel Wax Deposit in Gasoline

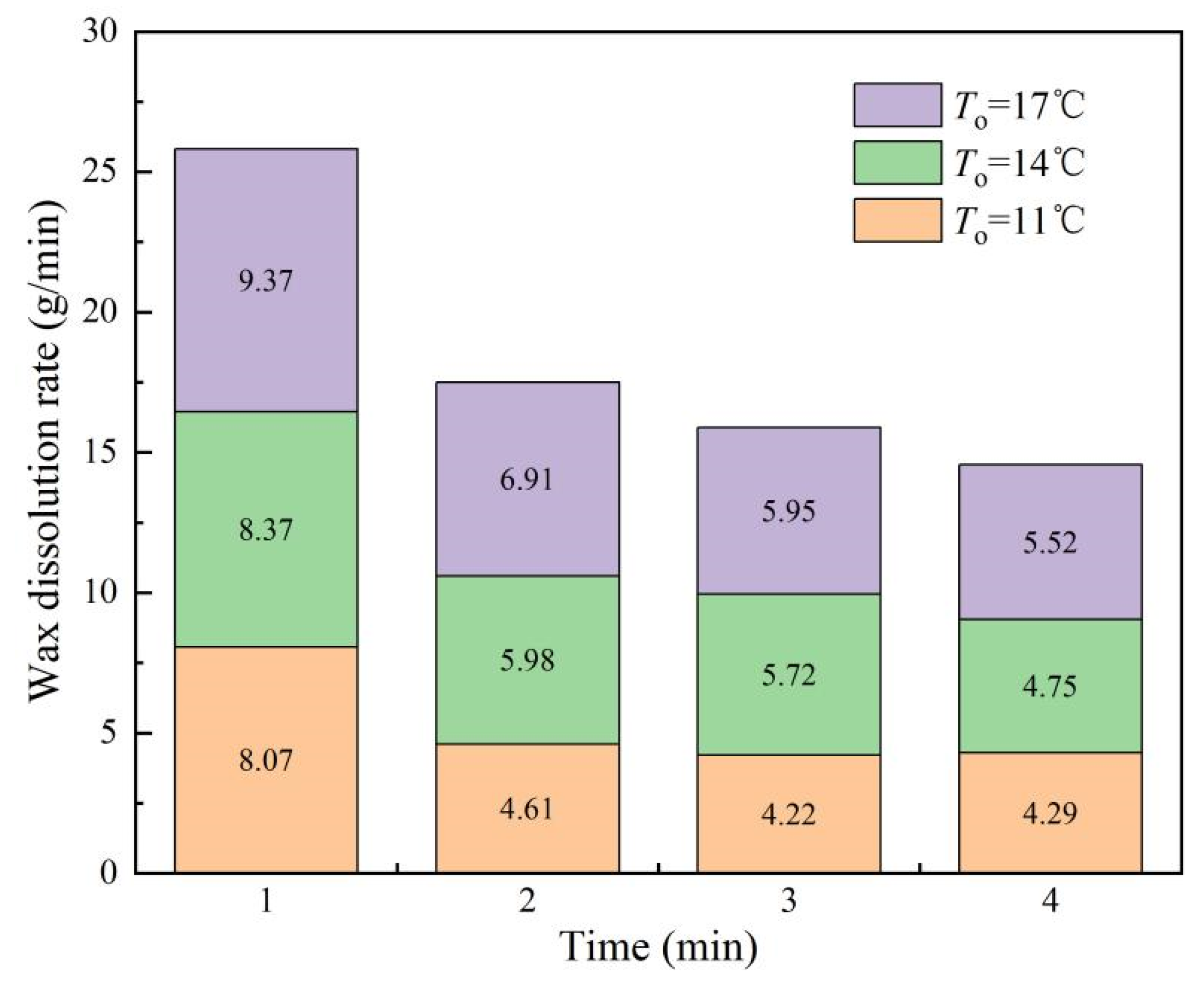

3.3.1. Impact of Gasoline Temperature

3.3.2. Impact of Cold Finger Temperature

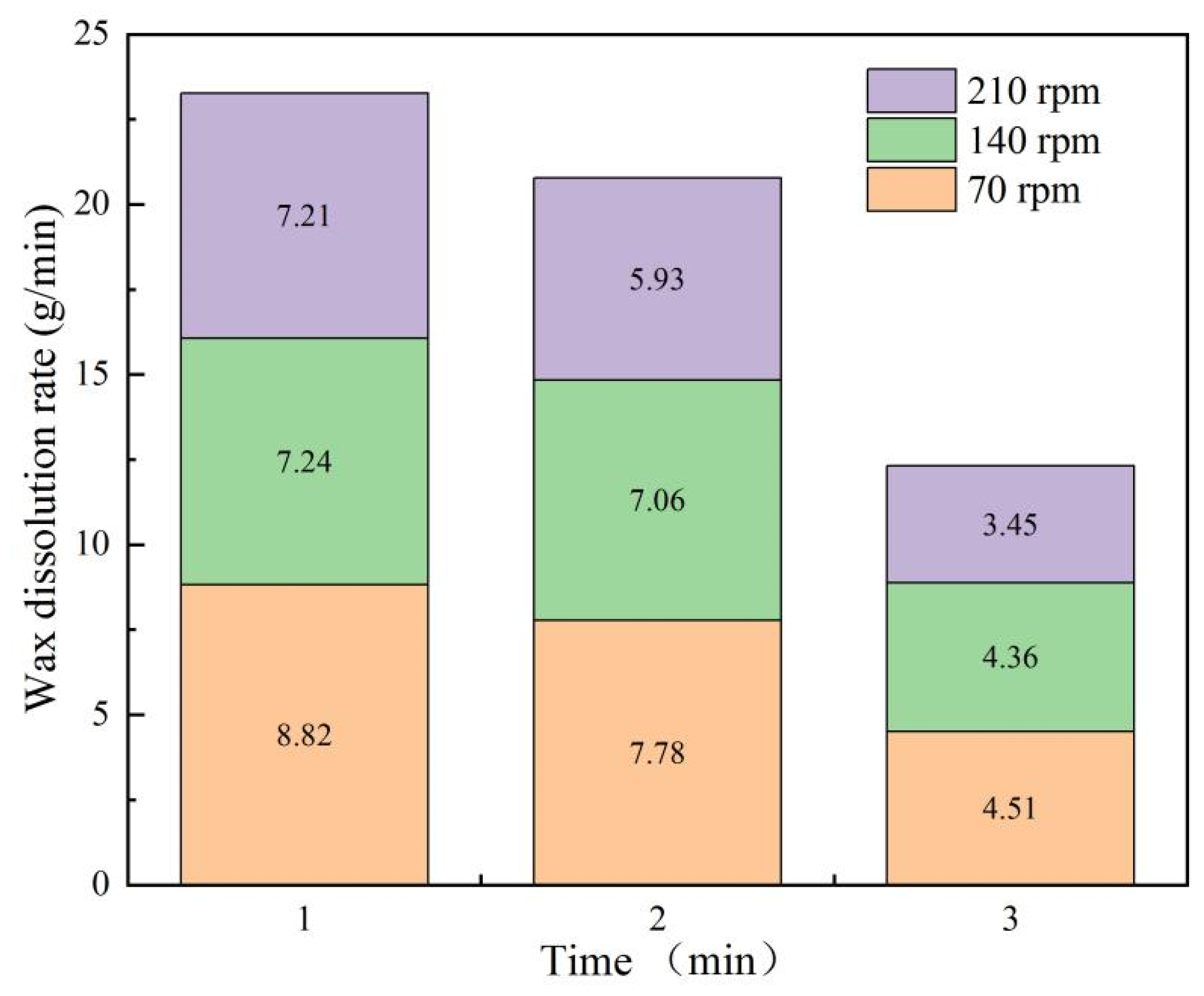

3.3.3. Impact of Shear Stress

3.3.4. Deterioration of Gasoline Quality by Diesel Wax Deposit

3.3.5. Distillation Range

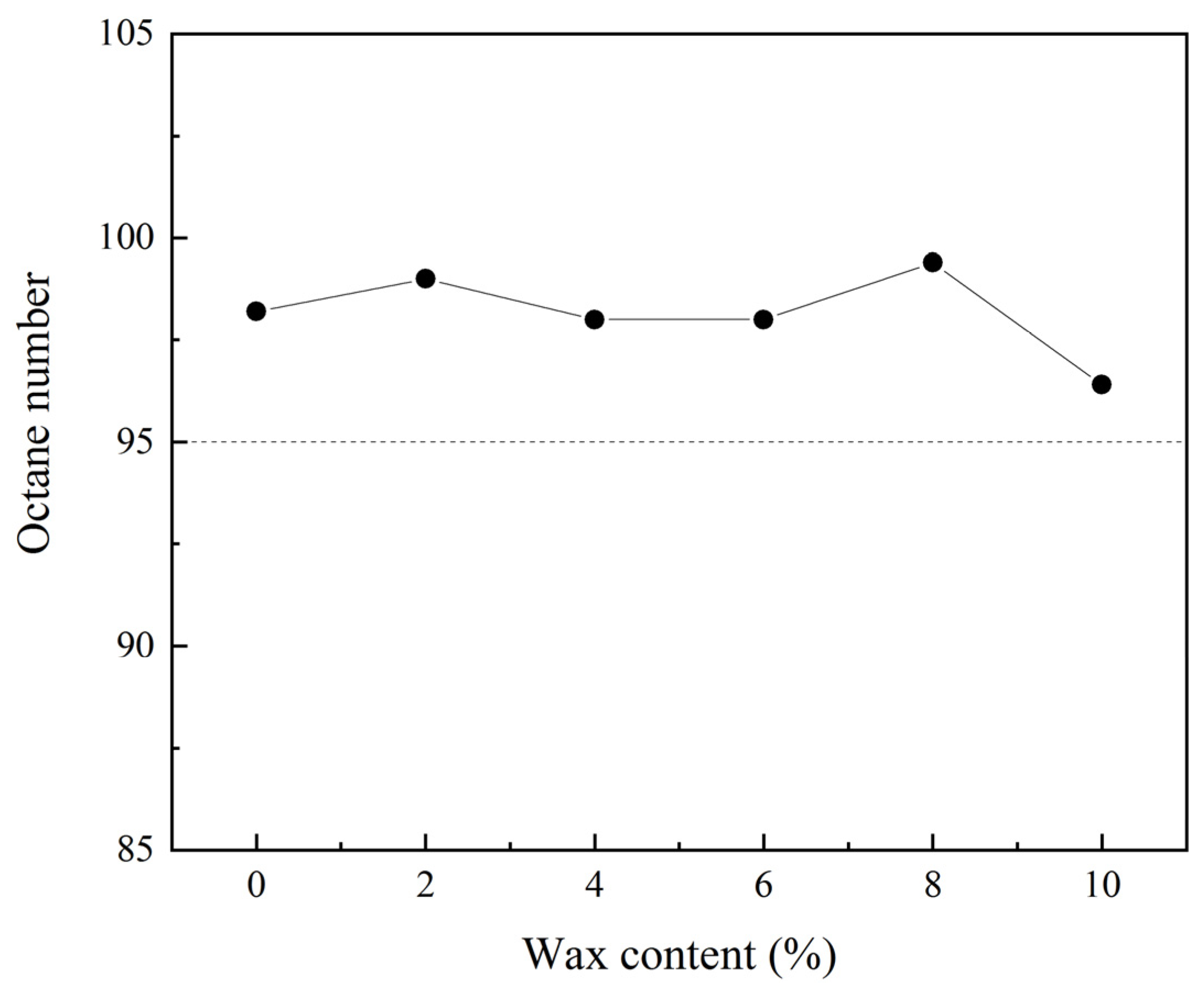

3.3.6. Octane Number

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiao, Y.; Qiu, R.; Liang, Y.; Liao, Q.; Tu, R.; Wei, X.; Zhang, H. Integration optimization of production and transportation of refined oil: A case study from China. Chem. Eng. Res. Des. 2022, 188, 39–49. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, B.; Liu, Y.; Liang, Y. Study on asymmetry concentration of mixed oil in products pipeline. Energies 2020, 13, 6398. [Google Scholar] [CrossRef]

- Wang, W.; Huang, Q.; Zheng, H.; Li, S.; Long, Z.; Wang, Q. Investigation of wax deposition and effective diffusion coefficient in water-in-oil emulsion system. J. Therm. Anal. Calorim. 2018, 134, 1031–1043. [Google Scholar] [CrossRef]

- Fan, K.; Li, S.; Li, R. Development of wax molecular diffusivity correlation suitable for crude oil in wax deposition: Experiments with a cold-finger apparatus. J. Petrol. Sci. Eng. 2021, 205, 108851. [Google Scholar] [CrossRef]

- Lyu, Y.; Huang, Q.; Liu, L.; Zhang, D.; Xue, H.; Zhang, F.; Zhang, H.; Li, R.; Wang, Q. Experimental and molecular dynamics simulation investigations of adhesion in heavy oil/water/pipeline wall systems during cold transportation. Energy 2022, 250, 123811. [Google Scholar] [CrossRef]

- Bern, P.A.; Withers, V.R.; Cairns, R.J. Wax deposition in crude oil pipelines. In Proceedings of the European Offshore Technology Conference and Exhibition, London, UK, 21–24 October 1980. [Google Scholar]

- Akbarzadeh, K.; Zougari, M. Introduction to a novel approach for modeling wax deposition in fluid flows. 1. Taylor−Couette system. Ind. Eng. Chem. Res. 2008, 47, 953–963. [Google Scholar] [CrossRef]

- Fasano, A.; Fusi, L.; Correra, S. Mathematical models for waxy crude oils. Meccanica 2004, 39, 441–482. [Google Scholar] [CrossRef]

- Huang, Q.; Li, L.; Fan, C.B.; Liu, Z. Effect of shear dispersion upon wax deposition of waxy crude. Oil Gas Storage Transp. 2002, 21, 30–33+35. (In Chinese) [Google Scholar]

- Ehsani, S.; Haj-Shafiei, S.; Mehrotra, A.K. Deposition from waxy mixtures in a flow-loop apparatus under turbulent conditions: Investigating the effect of suspended wax crystals in cold flow regime. Can. J. Chem. Eng. 2019, 97, 2740–2751. [Google Scholar] [CrossRef]

- Veiga, H.; Fleming, F.; Azevedo, L. Wax deposit thermal conductivity measurements under flowing conditions. Energy Fuels 2017, 31, 11532–11547. [Google Scholar] [CrossRef]

- Burger, E.D.; Perkins, T.K.; Striegler, J.H. Studies of wax deposition in the trans Alaska pipeline. Petrol. Sci. Technol. 1981, 33, 1075–1086. [Google Scholar] [CrossRef]

- Hsu, J.J.C.; Brubaker, J.P. Wax deposition scale-up modeling for waxy crude production lines. In Proceedings of the Offshore Technology Conference, Texas, HO, USA, 1–4 May 1995. [Google Scholar]

- Singh, P.; Venkatesan, R.; Fogler, H.S. Formation and aging of incipient thin film wax-oil gels. AIChE J. 2000, 46, 1059–1074. [Google Scholar] [CrossRef]

- Singh, P.; Youyen, A.; Fogler, F.S. Existence of a critical carbon number in the aging of a wax-oil gel. AIChE J. 2001, 47, 2111–2124. [Google Scholar] [CrossRef]

- Huang, Z.; Lee, H.S.; Senra, M. A fundamental model of wax deposition in subsea oil pipelines. AIChE J. 2011, 57, 2955–2964. [Google Scholar] [CrossRef]

- Yan, L.; Shen, L. Experiment of wax deposition and dissolution of number-5 diesel fuel transported by aerial bare pipeline in winter. Pipeline Technol. Equip. 2010, 2, 9–11. (In Chinese) [Google Scholar]

- Coutinho, J.A.P.; Dauphin, C.; Daridon, J.L. Measurements and modelling of wax formation in diesel fuels. Fuel 2000, 79, 607–616. [Google Scholar] [CrossRef][Green Version]

- Coutinho, J.A.P. A thermodynamic model for predicting wax formation in jet and diesel fuels. Energy Fuels 2000, 14, 625–631. [Google Scholar] [CrossRef]

- Pauly, J.; Daridon, J.L.; Sansot, J.M.; Coutinho, J.A.P. The pressure effect on the wax formation in diesel fuel. Fuel 2003, 82, 595–601. [Google Scholar] [CrossRef]

- Yang, J.; Liu, W. Numerical investigation on a novel shell-and-tube heat exchanger with plate baffles and experimental validation. Energy Convers. Manag. 2015, 101, 689–696. [Google Scholar] [CrossRef]

- Yin, P.; Xie, L.; Zhang, H.; Li, W.; Wang, W. Modelling wax deposition of diesel in sequential transportation of product oil pipeline using optimized. Can. J. Chem. Eng. 2024, 102, 1764–1776. [Google Scholar] [CrossRef]

- Ribeiro, F.S.; Mendes, P.R.S.; Braga, S.L. Obstruction of pipelines due to paraffin deposition during the flow of crude oils. Int. J. Heat Mass Transf. 1997, 40, 4319–4328. [Google Scholar] [CrossRef]

- Lee, D.G.; Lim, J.S.; Kim, Y.J.; Woo, N.S.; Han, S.M.; Ha, J. Monitoring and detection of paraffin wax deposition process based on ultrasonic analysis. J. Nanosci. Nanotechnol. 2020, 20, 168–176. [Google Scholar] [CrossRef] [PubMed]

- Zheng, S.; Zhang, F.; Huang, Z.; Fogler, H.S. Effects of operating conditions on wax deposit carbon number distribution: Theory and experiment. Energy Fuels 2013, 27, 7379–7388. [Google Scholar] [CrossRef]

- GB 17930-2016; Gasoline for Motor Vehicles. Standards Press of China: Beijing, China, 2016.

| Oil Temperature To (°C) | Cold Finger Temperature Tc (°C) | Temperature Difference (°C) | Agitating Speed V (rpm) | Wax Content M (wt%) |

|---|---|---|---|---|

| 5 | 0 | 5 | 140 | 2 |

| 15 | 10 | 5 | 70 | 4 |

| 10 | −5 | 15 | 210 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Xie, L.; Du, S.; Zhang, H.; Mo, J.; Wei, S.; Yin, P.; Fan, K. Wax Deposition of Diesel Oil and Consequent Contamination of Gasoline in Sequential Transportation of Product Oil Pipeline. Energies 2024, 17, 4398. https://doi.org/10.3390/en17174398

Li W, Xie L, Du S, Zhang H, Mo J, Wei S, Yin P, Fan K. Wax Deposition of Diesel Oil and Consequent Contamination of Gasoline in Sequential Transportation of Product Oil Pipeline. Energies. 2024; 17(17):4398. https://doi.org/10.3390/en17174398

Chicago/Turabian StyleLi, Weidong, Lin Xie, Shengping Du, Hanqing Zhang, Jiazong Mo, Shulong Wei, Pengbo Yin, and Kaifeng Fan. 2024. "Wax Deposition of Diesel Oil and Consequent Contamination of Gasoline in Sequential Transportation of Product Oil Pipeline" Energies 17, no. 17: 4398. https://doi.org/10.3390/en17174398

APA StyleLi, W., Xie, L., Du, S., Zhang, H., Mo, J., Wei, S., Yin, P., & Fan, K. (2024). Wax Deposition of Diesel Oil and Consequent Contamination of Gasoline in Sequential Transportation of Product Oil Pipeline. Energies, 17(17), 4398. https://doi.org/10.3390/en17174398