Experimental Study on Temperatures of Water Walls in a 1000 MW Ultra-Supercritical Boiler under the Condition of Flexible Peak Regulation

Abstract

1. Introduction

2. The Specifications of a 1000 MW Ultra-Supercritical Boiler

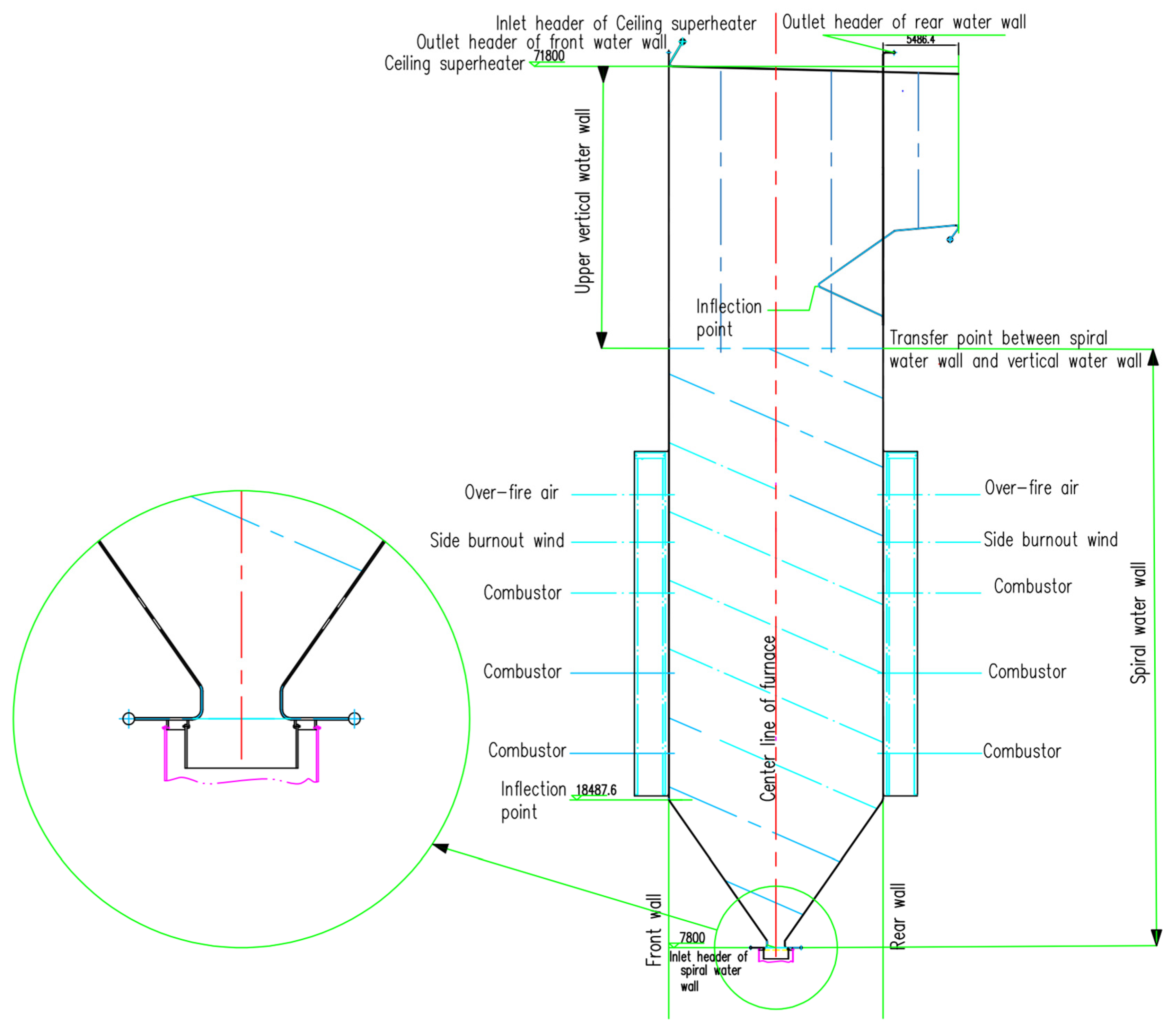

2.1. Furnace

2.2. The Arrangement of Water Wall

3. Experimental Parameters and Working Conditions

4. Experimental Results and Discussion

4.1. The Temperature Distribution of the Spiral Water Wall

4.2. The Temperature Distribution of Vertical Water Wall

4.3. The Comparisons of the Temperatures of the Front, Rear, and Side Water Wall

5. Conclusions and Advice

5.1. Conclusions

- The temperature distribution of the spiral water wall is more uniform than that of the vertical water wall. The temperature valley value of the rear spiral water wall appears at the middle measuring point. On the whole, the temperature of the water wall is more evenly distributed under the condition of a 643.9 MW load. The temperature distribution of the side spiral water wall is more uniform under different loads. The lower the load, the greater the wall temperature fluctuation.

- The temperature of the front vertical water wall has a greater number of peaks under low-load operation. When the load is low, the difference of wall temperature is large, and the water wall is not evenly heated.

- The study found that when the load is 643.9 MW, the change in wall temperature along the horizontal direction of the water wall is different from that under other loads. No reasonable explanation has been found yet. We hope someone can communicate with us.

- We found the change rule of the temperature curve of the side vertical water wall as this equation: y = A + Bx + Cx2. The higher the load, the better the equation for the temperature distributions of the side vertical water wall.

5.2. Advice

- The flue gas flow and furnace temperature deviation should be controlled by adjusting the air–powder ratio in the combustor.

- The temperature of the separator remains in the operation range, and the overheating was prevented by adjusting the coal–water ratio in the running state.

- The operation and combination mode of the coal mill should be standardized. If the carbon content of fly ash can meet the requirement of the running, the lower layer coal mill should be run as much as possible to control the enthalpy increase of the upper furnace.

- The flow section ratio between the front wall and the rear wall of the vertical water wall should be improved to avoid the flow difference between the front wall and the rear wall.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Viswanathan, R.; Sarver, J.; Tanzosh, J.M. Boiler materials for ultra-supercritical coal power plants-steamside oxidation. J. Mater. Eng. Perform. 2006, 15, 255–274. [Google Scholar] [CrossRef]

- Gao, C.; Wu, X.; Li, Z.; Fu, J.; Guo, J.; Qu, S.; Li, B. Statistical analysis and improvement measures of unplanned outage of thermal power units in Jilin power grid. Jilin Electr. Power 2017, 45, 1–4. [Google Scholar] [CrossRef]

- Ranjeeth, R.; Aditya, D.; Gautam, A.; Singh, S.P.; Bhattacharya, S. Failure investigation of a water-wall tube of fossil-fuel fired boiler. Eng. Fail. Anal. 2024, 155, 107727. [Google Scholar] [CrossRef]

- Li, L.; Zhou, Q.; Wen, D.; Li, N.; Yao, Y.; Ao, Y. The working status and deformation risk of membrane walls affected by the arrangement of burners in the arch-fired boiler. Appl. Therm. Eng. 2020, 181, 115995. [Google Scholar] [CrossRef]

- Wei, L.; Zhou, Q.; Liu, Z.; Li, N.; Li, L.; Luo, Q. Experimental study on the distribution of temperature and deformation in the water walls of an opposed firing boiler under variable load conditions. J. Energy Eng.—ASCE 2021, 147, 04021040. [Google Scholar] [CrossRef]

- Xue, W.; Lu, Y.; Wang, Z.; Cao, S.; Sui, M.; Yang, Y.; Li, J.; Xie, Y. Reconstructing near-water-wall temperature in coal-fired boilers using improved transfer learning and hidden layer configuration optimization. Energy 2024, 294, 130860. [Google Scholar] [CrossRef]

- Lv, C.; Wang, G.; Chen, H. Estimation of time-dependent thermal boundary conditions and online reconstruction of transient temperature field for boiler membrane water wall. Int. J. Heat Mass Transf. 2020, 147, 118955. [Google Scholar] [CrossRef]

- Wang, T.; Chen, X.; Zhong, W. Air distribution and coal blending optimization to reduce slagging on coal-fired boiler water wall based on POD reduced order modeling for CFD. Fuel 2024, 357, 129856. [Google Scholar] [CrossRef]

- Wei, L.; Zhou, Q.; Li, N. Experimental study and simulation analysis of heat and deformation in the water walls of an opposed firing boiler under flexible operating conditions. Appl. Therm. Eng. 2022, 213, 118726. [Google Scholar] [CrossRef]

- Zima, W. Analysis of temperature drops on the wall thickness of a supercritical boiler water-wall tube. Therm. Sci. 2019, 23, 1091–1100. [Google Scholar] [CrossRef]

- Dong, J.; Fan, H.; Wu, X.; Zhou, T.; Zhang, J.; Zhang, Z. Study on the effect of flame offset on water wall tube temperature in 600 °C and 700 °C ultra-supercritical boiler. Combust. Sci. Technol. 2019, 191, 472–490. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, Z.; Cheng, D.; Wang, Y.; Deng, X. High temperature corrosion of water wall materials T23 and T24 in simulated furnace atmospheres. Chin. J. Chem. Eng. 2012, 20, 814–822. [Google Scholar] [CrossRef]

- Xiong, X.; Liu, X.; Tan, H.; Deng, S. Investigation on high temperature corrosion of water-cooled wall tubes at a 300 MW boiler. J. Energy Inst. 2020, 93, 377–386. [Google Scholar] [CrossRef]

- Cao, L.; Peng, R.; Deng, Z. Optimization study on high-temperature corrosion prevention of the water wall of a 1000 MW dual circle tangential boiler during operation. Energy Rep. 2021, 7, 915–925. [Google Scholar] [CrossRef]

- Sun, X.; Ning, Y.; Yang, J.; Zhao, Y.; Yang, Z.X.; Zhou, X. Study on high temperature corrosion mechanism of water wall tubes of 350 MW supercritical unit. Eng. Fail. Anal. 2021, 121, 105131. [Google Scholar] [CrossRef]

- Li, X.; Zeng, L.; Zhang, N.; Zhang, X.; Song, M.; Chen, Z.; Li, Z. Effects of the gas/particle flow and combustion characteristics on water-wall temperature and energy conversion in a supercritical down-fired boiler at different secondary-air distributions. Energy 2022, 238, 121983. [Google Scholar] [CrossRef]

- Li, X.; Zeng, L.; Zhang, N.; Chen, Z.; Li, Z.; Qin, Y. Effects of the air-staging degree on performances of a supercritical down-fired boiler at low loads: Air/particle flow, combustion, water wall temperature, energy conversion and NO emissions. Fuel 2022, 308, 121896. [Google Scholar] [CrossRef]

- Fu, J.; Wei, L.; Li, N.; Zhou, Q.; Liu, T. Experimental study on temperature, heat flux, strain and stress distribution of boiler water walls. Appl. Therm. Eng. 2017, 113, 419–425. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, Q.; Niu, K.; Jia, J.; Zhang, Z.; Xu, A.; Ma, Y.; Zhan, Y.; Liu, C.; Dong, H. Water wall tube cracking in an ultra-supercritical boiler caused by deep peaking. Trans. Indian Inst. Met. 2022, 75, 183–191. [Google Scholar] [CrossRef]

- Srikanth, S.; Gopalakrishna, K.; Das, S.K.; Ravikumar, B. Phosphate induced stress corrosion cracking in a waterwall tube from a coal fired boiler. Eng. Fail. Anal. 2003, 10, 491–501. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Z.; Zhang, Z.; Song, D.; Su, D.; Leng, J. Reason analysis and process on vertical rising rifled tube transverse crack of ultra-supercritical boiler. Northeast. Electr. Power Technol. 2013, 34, 24–30. [Google Scholar]

- Pan, J.; Yang, D.; Yu, H.; Bi, Q.; Hua, H.; Gao, F.; Yang, Z. Mathematical modeling and thermal-hydraulic analysis of vertical water wall in an ultra supercritical boiler. Appl. Therm. Eng. 2009, 29, 2500–2507. [Google Scholar] [CrossRef]

- Pan, J.; Yang, D.; Chen, G.; Zhou, X.; Bi, Q. Thermal-hydraulic analysis of a 600 MW supercritical CFB boiler with low mass flux. Appl. Therm. Eng. 2012, 32, 41–48. [Google Scholar] [CrossRef]

- Pan, J.; Wu, G.; Yang, D. Thermal-hydraulic calculation and analysis on water wall system of 600 MW supercritical CFB boiler. Appl. Therm. Eng. 2015, 82, 225–236. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, W.; Xu, W. A study of the hydrodynamic characteristics of a vertical water wall in a 2953t/h ultra-supercritical pressure boiler. Int. J. Heat Mass Transf. 2015, 86, 404–414. [Google Scholar] [CrossRef]

- Lyu, J. Investigation on Heat Flux and Hydrodynamics of Water Wall of a Supercritical Pressure Circulating Fluidized Bed Boiler. Ph.D. Thesis, Tsinghua University, Beijing, China, 2005. [Google Scholar]

- Chen, Y.; Lu, X.; Zhang, W.; Wang, Q.; Chen, S.; Fan, X.; Li, J. An experimental study on the hydrodynamic performance of the water-wall system of a 600 MW supercritical CFB boiler. Appl. Therm. Eng. 2018, 141, 280–287. [Google Scholar] [CrossRef]

- Dong, J.; Zhou, T.; Wu, X.; Zhang, J.; Fan, H.; Zhang, Z. Coupled heat transfer simulation of the spiral water wall in a double reheat ultra-supercritical boiler. J. Therm. Sci. 2018, 27, 592–601. [Google Scholar] [CrossRef]

- Nurbanasari, M.; Abdurrachim. Investigation of leakage on water wall tube in a 660 MW supercritical boiler. J. Fail. Anal. Prev. 2014, 14, 657–661. [Google Scholar] [CrossRef]

- Fan, Q. Research on the water wall temperature excursion in the supercritical and ultra-supercritical boilers. Electr. Power 2006, 39, 59–63. [Google Scholar]

- Che, D. The Boiler; Xi’an Jiaotong University Press: Xi’an, China, 2018. [Google Scholar]

- Huang, S.; Lv, X.; Wei, W.; Zhuang, J. Countermeasures against water wall temperature deviation of ultra-supercritical boiler. Power Energy 2015, 36, 566–569. [Google Scholar]

| Items | Unit | BMCR | THA | BRL |

|---|---|---|---|---|

| Superheated steam flow rate | t/h | 3110 | 2724.04 | 2901.64 |

| Outlet pressure of superheated steam | Mpa(a) | 26.25 | 25.98 | 26.11 |

| Outlet temperature of superheated steam | °C | 605 | 605 | 605 |

| Reheat steam flow | t/h | 2469.16 | 2186.03 | 2299.53 |

| Inlet steam pressure of reheater | Mpa(a) | 5.51 | 4.89 | 5.13 |

| Outlet steam pressure of reheater | Mpa(a) | 5.26 | 4.69 | 4.91 |

| Inlet steam temperature of reheater | °C | 359 | 345 | 351 |

| Outlet steam temperature of reheater | °C | 603 | 603 | 603 |

| Inlet water temperature of economizer | °C | 302 | 293 | 297 |

| Symbol | Unit | Design Bituminous Coal | Symbol | Unit | Design Bituminous Coal |

|---|---|---|---|---|---|

| Car | % | 50.64 | Fe2O3 | % | 3.57 |

| Har | % | 3.43 | CaO | % | 1.06 |

| Oar | % | 5.84 | MgO | % | 0.50 |

| Nar | % | 0.83 | SO3 | % | 0.84 |

| Sar | % | 0.26 | Na2O | % | 0.41 |

| Mar | % | 7.50 | K2O | % | 0.76 |

| Mad | % | 1.60 | TiO2 | % | 1.32 |

| Aar | % | 31.5 | MnO2 | % | 0.011 |

| Vdaf | % | 36.43 | Others | % | 0.299 |

| HGI | 81.00 | DT | °C | >1500 | |

| Qnet,ar | MJ/kg | 19.66 | ST | °C | >1500 |

| SiO2 | % | 64.08 | FT | °C | >1500 |

| Al2O3 | % | 27.15 |

| Load (MW) | Main Steam Pressure (Mpa) | Main Steam Temperature (°C) | Oxygen Content (%) | Water–Fuel Ratio | Air Flow (t/h) |

|---|---|---|---|---|---|

| 217.7 | 9.40 | 563.4 | 6.82 | 6.8 | 1606 |

| 267.9 | 11.45 | 570.0 | 8.10 | 5.2 | 1630 |

| 348.7 | 12.05 | 599.1 | 6.16 | 4.8 | 1821 |

| 448.1 | 12.85 | 601.0 | 4.13 | 4.8 | 2173 |

| 508.4 | 12.42 | 582.4 | 5.79 | 5.5 | 2367 |

| 605.0 | 14.80 | 600.0 | 4.32 | 5.1 | 2569 |

| 643.9 | 23.17 | 598.5 | 3.51 | 4.4 | 2304 |

| 758.8 | 18.58 | 599.4 | 3.22 | 4.6 | 2958 |

| 804.6 | 19.09 | 588.4 | 2.91 | 4.9 | 3018 |

| 898.7 | 22.15 | 598.6 | 2.98 | 5.1 | 3252 |

| 990.1 | 25.03 | 598.1 | 1.94 | 6.0 | 3410 |

| Monitoring Point Name | Monitoring Point | Monitoring Point Elevation |

|---|---|---|

| Outlet wall temperature of rear wall spiral water wall 1-11 | From left of boiler, fit on 26th, 76th, 126th, 176th, 226th, 276th, 326th, 376th, 426th, 476th, and 526th pipes. | 51,300 mm |

| Outlet temperature of side wall spiral water wall 1-10 | From front of boiler, fit on 26th, 76th, 126th, 176th, and 226th pipes (symmetrical arrangement, five monitoring points on left wall and five points on right wall). | |

| Outlet wall temperature of front wall spiral water wall 1-11 | From left of boiler, fit on 26th, 76th, 126th, 176th, 226th, 276th, 326th, 376th, 426th, 476th, and 526th pipes. | |

| Outlet wall temperature of the front wall upper water wall 1-20 | From left of boiler, fit on 27th, 52nd, 77th, 101st, 125th, 149th, 173rd, 197th, 221st, 244th, 267th, 290th, 314th, 338th, 362nd, 386th, 410th, 434th, 458th, and 508th pipes. | 72,300 mm |

| Outlet temperature of side wall upper water wall 1-24 | From front of boiler, fit on 12nd, 23rd, 47th, 71st, 96th, 121st, 147th, 173rd, 197th, 221st, 224th, and 267th pipes. | |

| Outlet wall temperature of slag tube 1-6 | From left of boiler, fit on 8th, 16th, 25th, 34th, 42nd, and 51st pipes. |

| Load (MW) | The Fitting Equation y = A + Bx + Cx2 | |||||||

|---|---|---|---|---|---|---|---|---|

| Left Wall | Right Wall | |||||||

| The Coefficient | R-Square | The Coefficient | R-Square | |||||

| A | B | C | A | B | C | |||

| 217.7 | 297.90455 | 10.90774 | −0.96009 | 0.77022 | 301.16364 | 1.92108 | −0.18801 | 0.44605 |

| 267.9 | 338.39091 | −3.57720 | 0.48052 | 0.31690 | 330.92273 | 5.45055 | −0.52987 | 0.22169 |

| 348.7 | 313.28182 | 22.92143 | −1.98347 | 0.71121 | 339.68636 | 3.32982 | −0.3541 | 0.28670 |

| 448.1 | 339.45000 | 9.08307 | −0.93581 | 0.62520 | 333.77955 | 3.36426 | −0.22595 | 0.09376 |

| 508.4 | 339.27273 | 5.88327 | −0.62303 | 0.59538 | 336.15682 | 2.52600 | −0.20617 | 0.21513 |

| 605.0 | 352.78409 | 6.27635 | −0.71456 | 0.65771 | 348.45000 | 3.58891 | −0.33067 | 0.46070 |

| 643.9 | 386.57045 | 1.46756 | 0.14798 | 0.20792 | 395.01515 | 4.03741 | −0.39592 | 0.84395 |

| 758.8 | 363.80682 | 9.61266 | −0.94118 | 0.67925 | 369.35000 | 2.57822 | −0.29800 | 0.56748 |

| 804.6 | 364.67727 | 8.27727 | −0.80455 | 0.68683 | 368.71591 | 3.85992 | −0.37995 | 0.65562 |

| 898.7 | 382.99318 | 8.45227 | −0.82815 | 0.71737 | 384.77955 | 4.33279 | −0.44063 | 0.70976 |

| 990.1 | 398.42727 | 8.16464 | −0.80949 | 0.77223 | 393.63409 | 7.56396 | −0.69338 | 0.78337 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, L.; Pu, J.; Li, X.; Lv, C.; Wu, X.; Li, L.; Lu, X. Experimental Study on Temperatures of Water Walls in a 1000 MW Ultra-Supercritical Boiler under the Condition of Flexible Peak Regulation. Energies 2024, 17, 4375. https://doi.org/10.3390/en17174375

Yan L, Pu J, Li X, Lv C, Wu X, Li L, Lu X. Experimental Study on Temperatures of Water Walls in a 1000 MW Ultra-Supercritical Boiler under the Condition of Flexible Peak Regulation. Energies. 2024; 17(17):4375. https://doi.org/10.3390/en17174375

Chicago/Turabian StyleYan, Liyun, Jiang Pu, Xueling Li, Cai Lv, Xuehong Wu, Liansheng Li, and Xiaofeng Lu. 2024. "Experimental Study on Temperatures of Water Walls in a 1000 MW Ultra-Supercritical Boiler under the Condition of Flexible Peak Regulation" Energies 17, no. 17: 4375. https://doi.org/10.3390/en17174375

APA StyleYan, L., Pu, J., Li, X., Lv, C., Wu, X., Li, L., & Lu, X. (2024). Experimental Study on Temperatures of Water Walls in a 1000 MW Ultra-Supercritical Boiler under the Condition of Flexible Peak Regulation. Energies, 17(17), 4375. https://doi.org/10.3390/en17174375