High-Temperature Heat Pumps for Electrification and Cost-Effective Decarbonization in the Tissue Paper Industry

Abstract

1. Introduction

1.1. Energy Demand in the European Pulp and Paper Industry

1.2. Process Heat Decarbonization through Electrification

1.3. High-Temperature Heat Pumps: Technologies, Costs, and Refrigerants

1.4. Research and Evaluations on HTHP Implementation in Industries

1.5. Scope of the Paper

2. Materials and Methods

2.1. Cases

- The first represents the current state-of-the-art plants with a high degree of thermal recovery.

- The second is characterized by the replacement of the natural gas boiler with an electric one.

- The third introduces the high-temperature heat pump to enhance waste heat recovery.

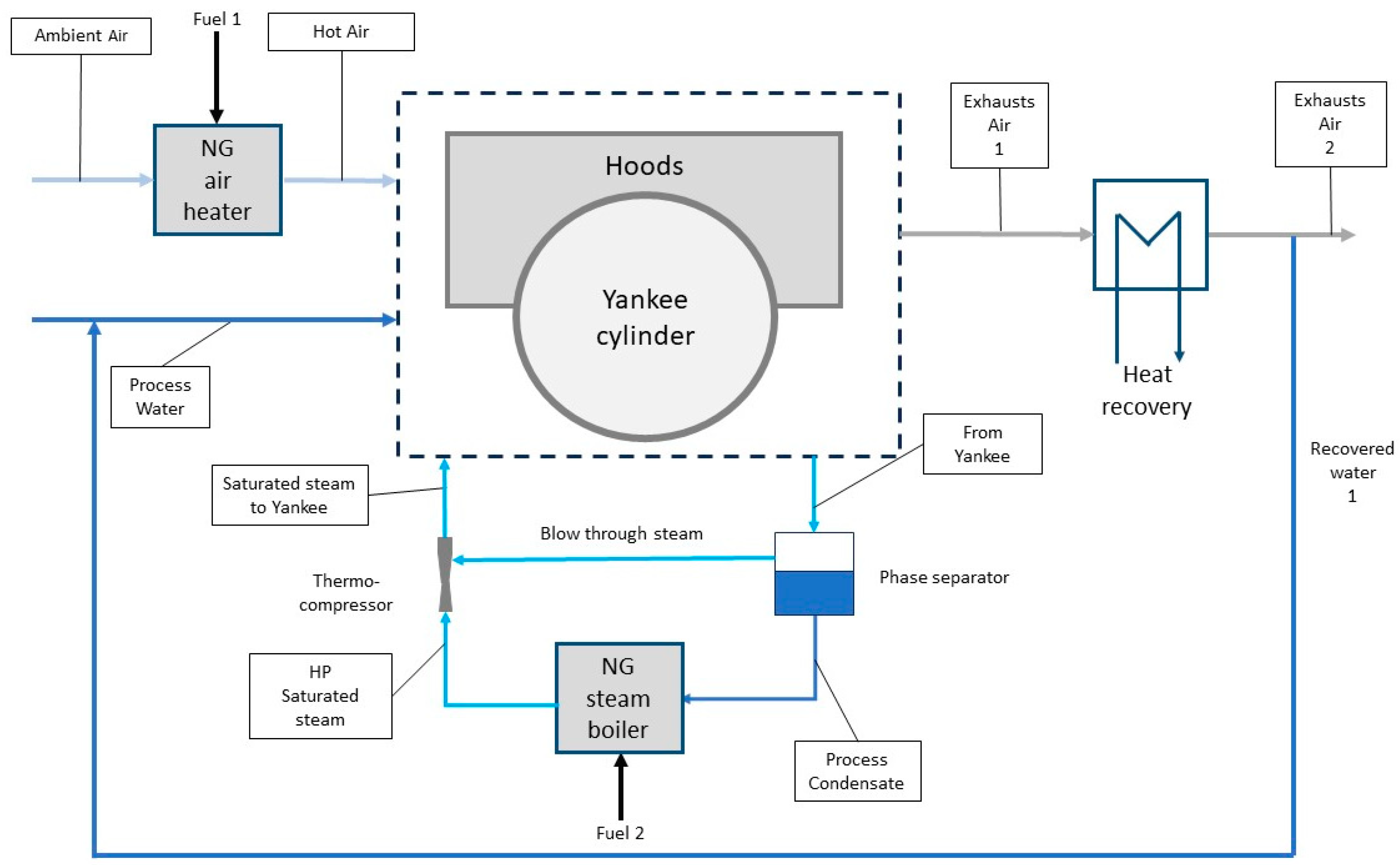

2.1.1. Layout 1: Natural Gas Boiler

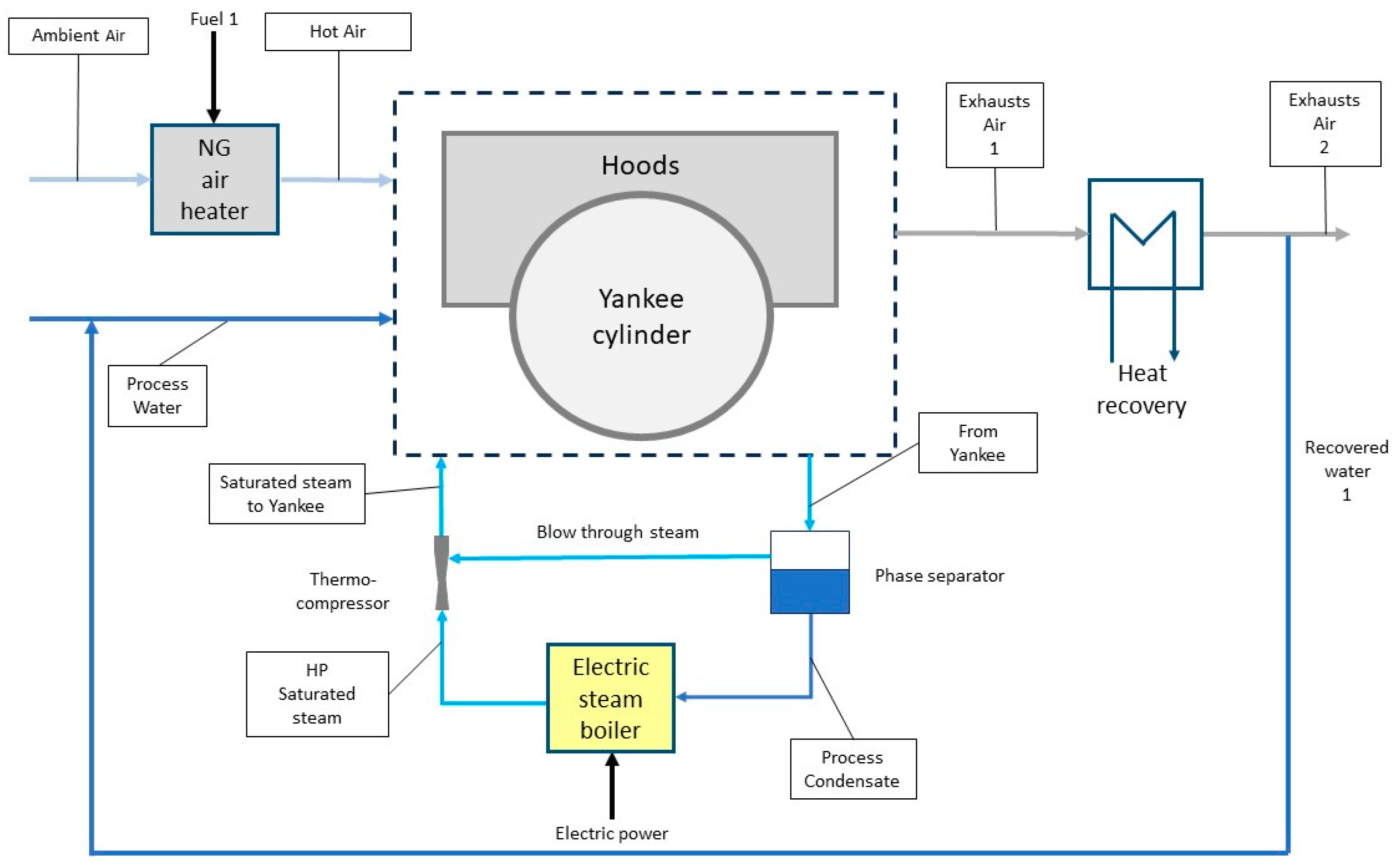

2.1.2. Layout 2: Electric Boiler

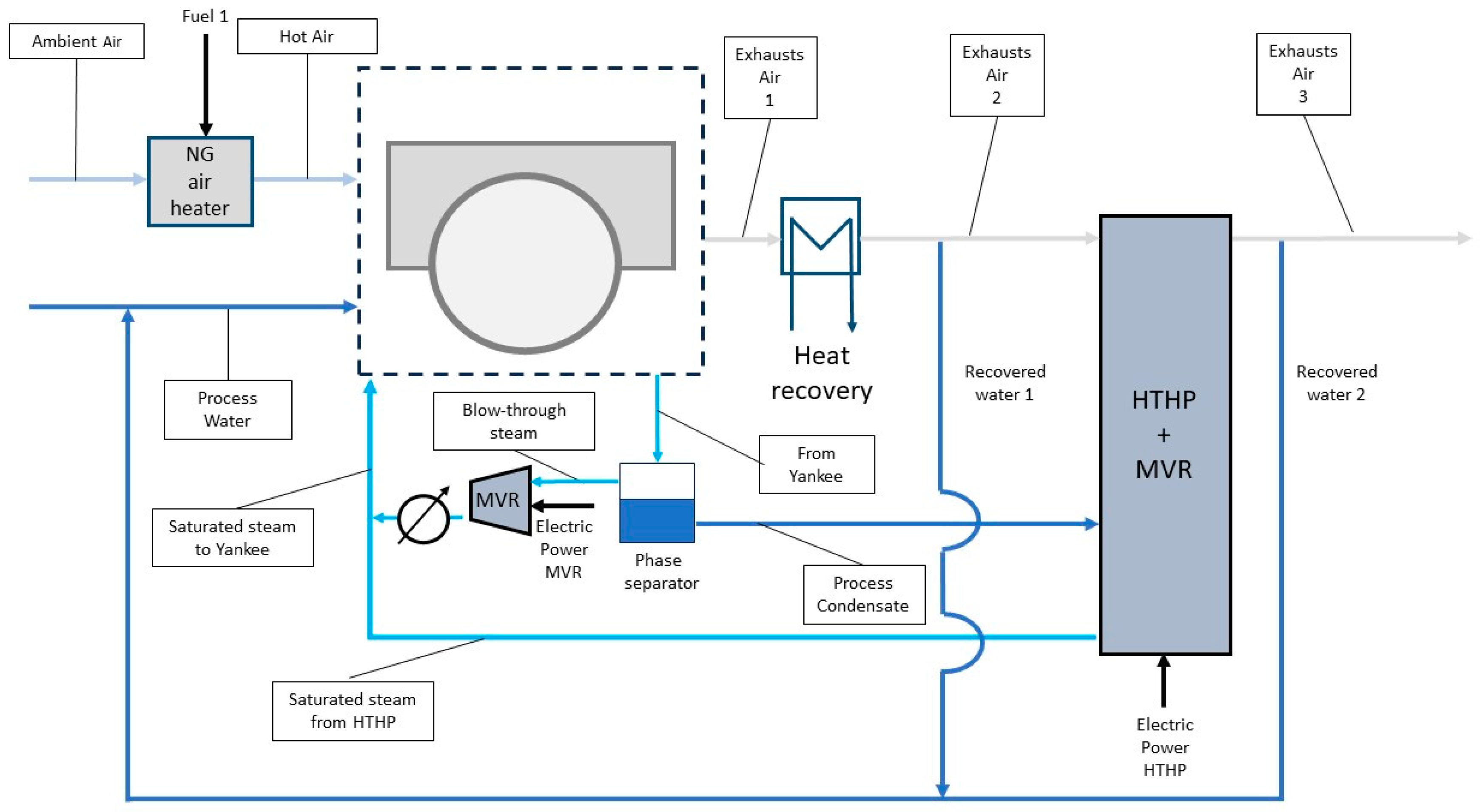

2.1.3. Layout 3: HTHP

2.2. Heat Pump Definition

2.2.1. Waste Heat Source

2.2.2. High-Temperature Heat Pump Layout

2.2.3. Refrigerants

- The critical temperature of the refrigerant should be higher than or near the supply temperature to allow the optimization algorithm to explore a reasonable range of feasible solutions. Consequently, several fluids, such as ammonia, were excluded from consideration.

- The evaporation pressure of the refrigerant at the temperature achievable in the evaporator, using waste heat, should be above atmospheric pressure. The expected evaporation temperature is around 45 °C, so it has assumed that refrigerants must have an evaporation pressure higher than 1.01325 bar (1 atm) at 40 °C. Therefore, despite their proven performance [22,23], water, acetone, and benzene were not considered. Additionally, R365MFC, identified in [23] as the best-performing fluid among those studied, was excluded due to its evaporation pressure being slightly below 1 atm at 40 °C.

2.2.4. Optimization Process and Analysis of Environmental Sustainability

- COP, as defined in Equation (1).

- Volumetric heating capacity (VHC), defined as the ratio between the produced heat flow rate and the refrigerant volumetric flow rate at the compressor inlet. This value is interesting from a technological viewpoint, as the higher it is, the smaller the system dimensions will be.

- Compression ratios (β) of the bottom and top cycle, which can be helpful to argue the number of stages required by the actual compressors.

- Water recovery, defined as the additional water condensed—and recovered—compared to the base case. While water recovery is not the focus of this article, paper companies are called upon to make an effort to manage water resources efficiently and with minimal waste. This issue is intrinsically linked to the broader problem of global warming because one of the potential consequences of climate change is water scarcity [41].

2.2.5. Economic Analysis

3. Results and Discussion

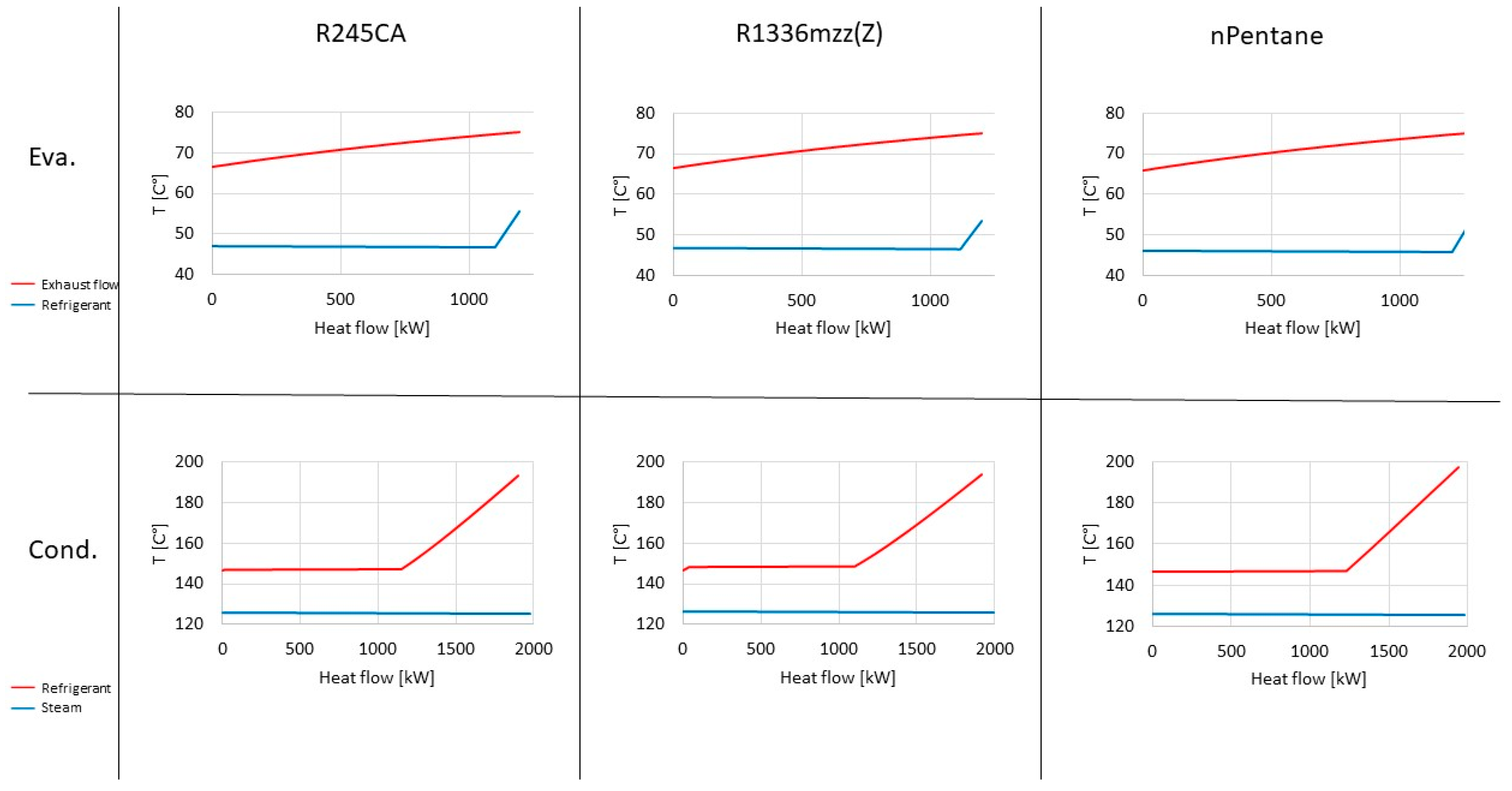

3.1. Heat Pump Performances

3.1.1. Water Recovery

3.1.2. Optimization Results

- Maintain the minimum pinch point of 20 °C, imposed as a constraint in the optimization,

- Extract a significant amount of heat flow rate from the flue gas to reduce the demand for electricity,

- Keep the refrigerant pressure high to reduce the compression ratio, thus improving the COP and maintaining evaporating pressure above atmospheric conditions.

- Maintaining the maximum temperature of discharge from the bottom compressor below 200 °C. This also involves the superheating that the fluid receives at the IHX.

- Limiting the compression ratio to increase COP.

- Maintaining a pinch point of 20 °C at the condenser.

- Maintaining the maximum temperature of discharge from the top compressor below 300 °C.

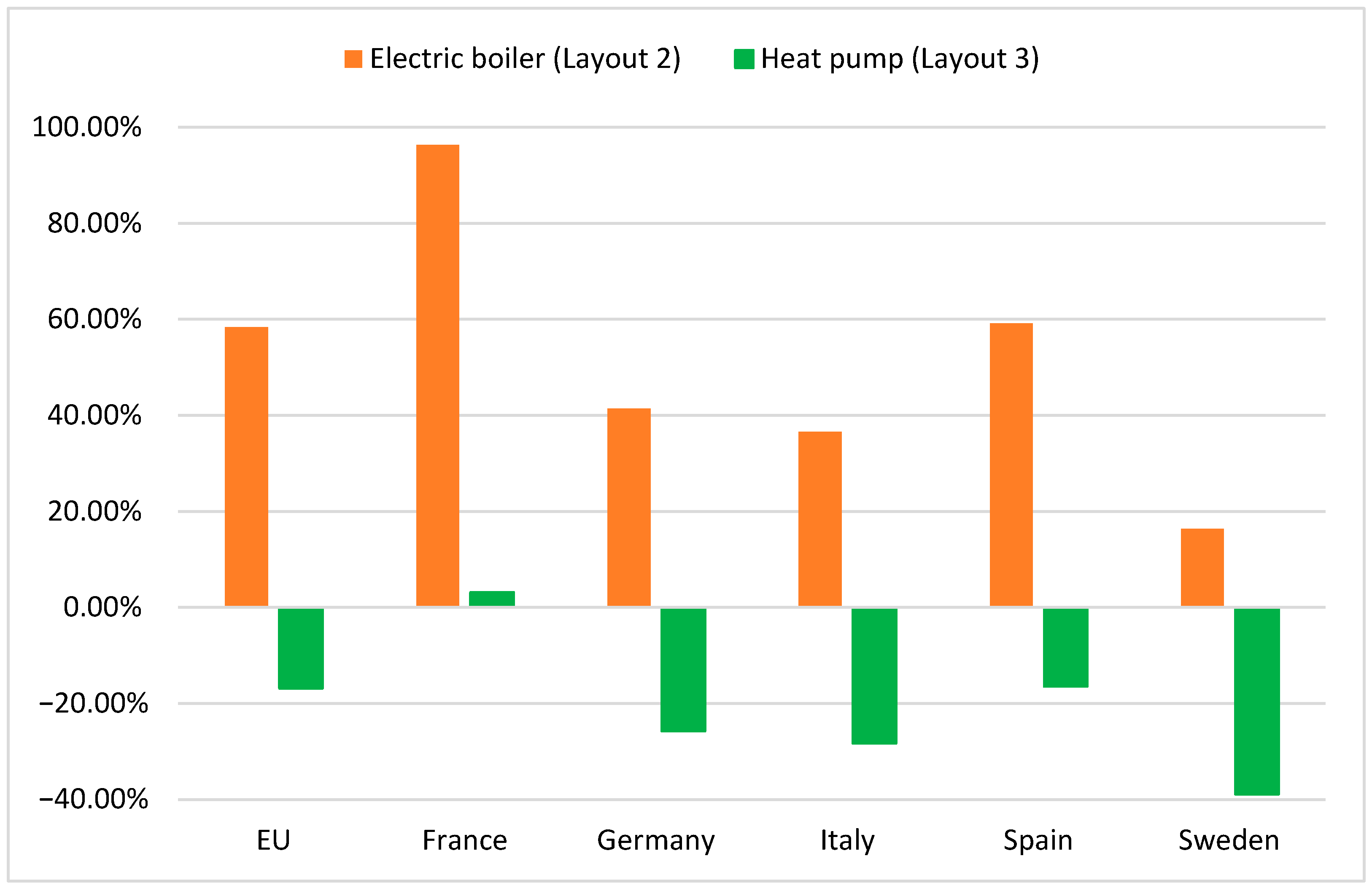

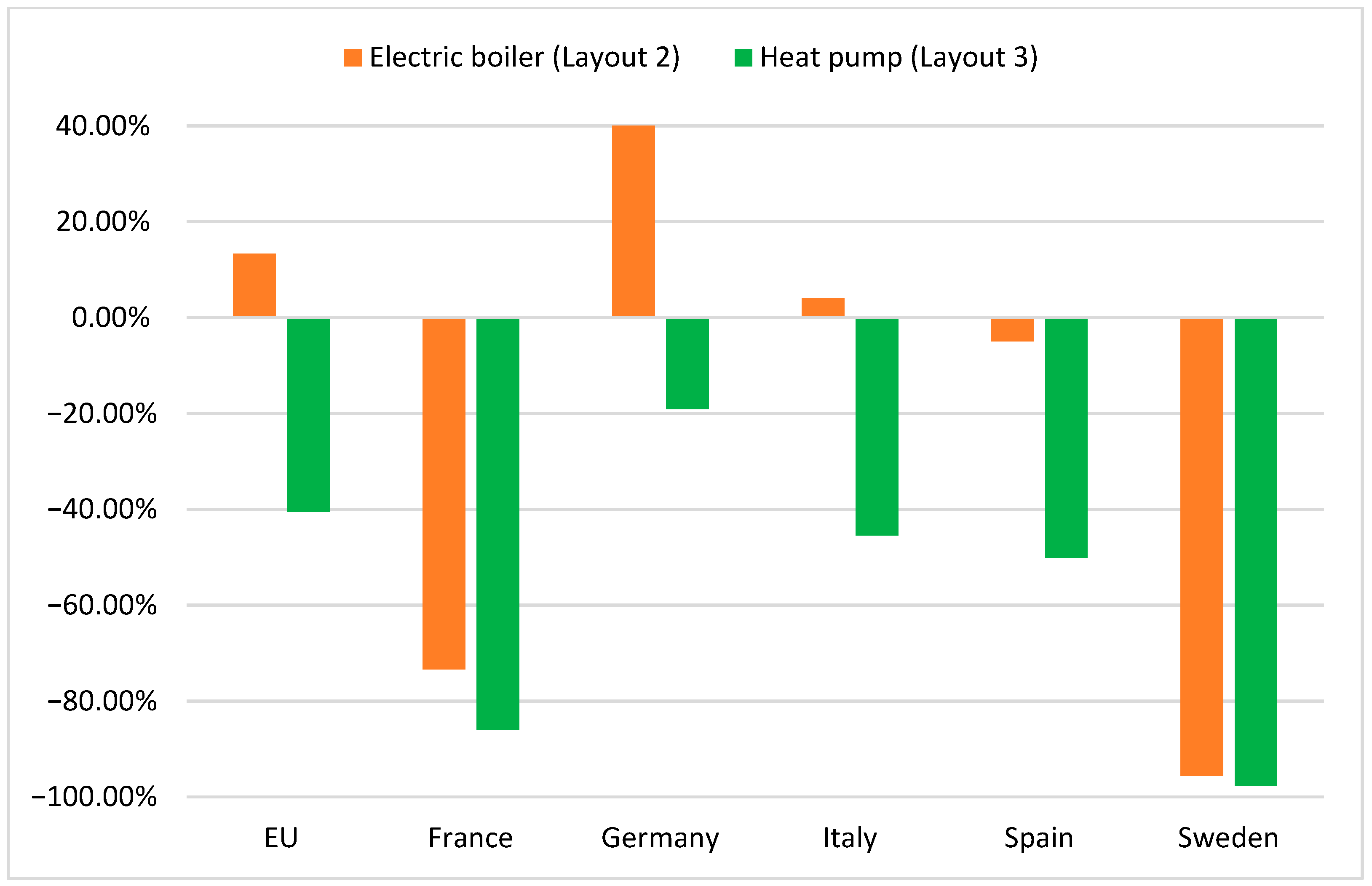

3.2. Analysis of Environmental Sustainability

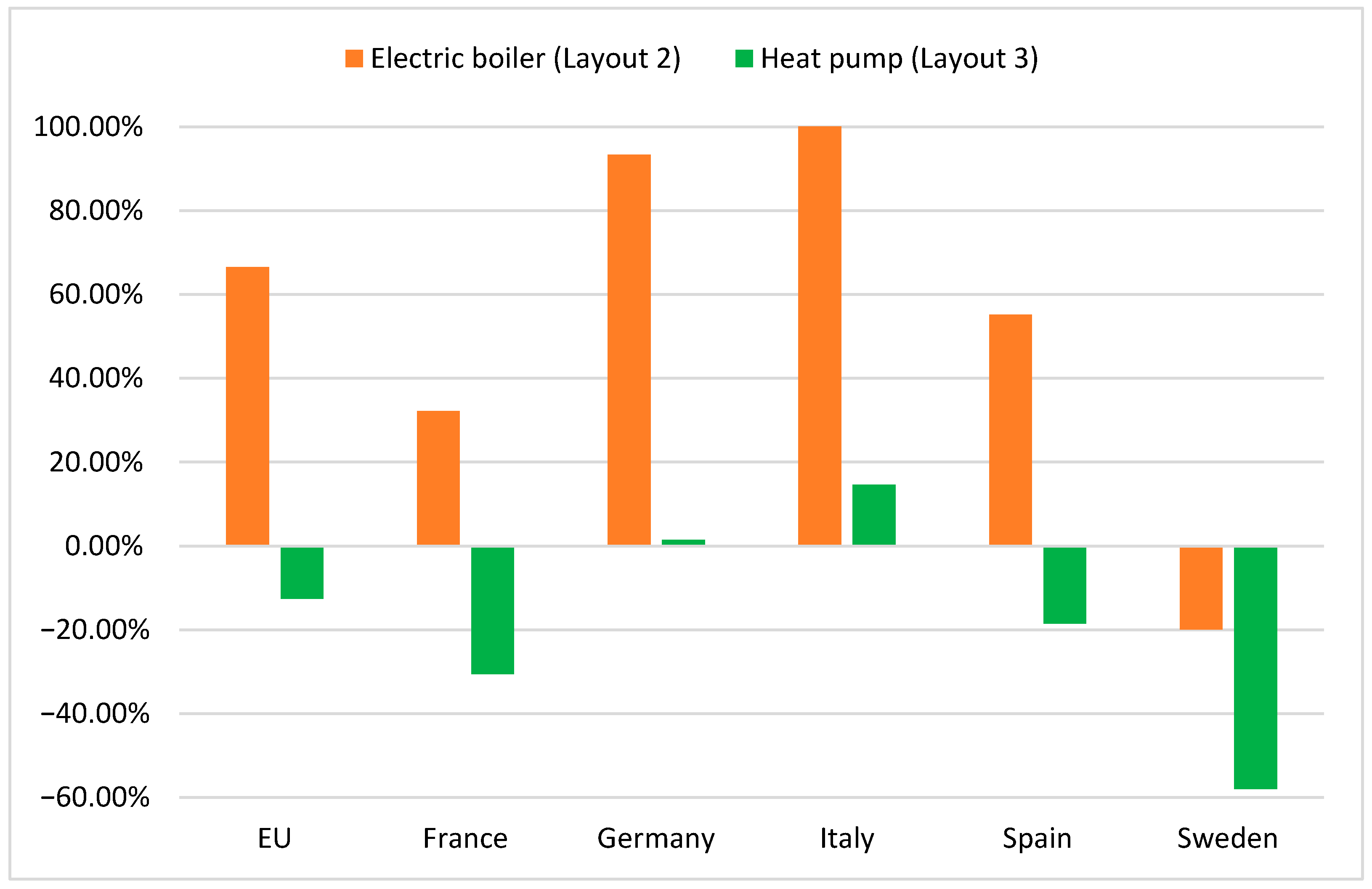

3.3. Economic Analysis Results

Comparing HTHP and Other Decarbonization Strategies

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency, Industry, 11 July 2023. Available online: https://www.iea.org/energy-system/industry (accessed on 12 April 2024).

- International Energy Agency, Pulp and Paper, Settembre 2022. Available online: https://www.iea.org/reports/pulp-and-paper (accessed on 14 April 2023).

- CEPI. Key Statistics; Confederation of European Paper Industries: Brussels, Belgium, 2022. [Google Scholar]

- Lipianen, S.; Kuparinen, K.; Vakkilainen, E.S.E.E. Pulp and paper industry in energy transition: Towards energy-efficient and low carbon operation in Finland and Sweden. Sustain. Prod. Consum. 2022, 29, 421–431. [Google Scholar] [CrossRef]

- Mordor Intelligence, Tissue Paper Market Growth, Trends, COVID-19 Impact, and Forecasts (2023–2028). 2023. Available online: https://www.researchandmarkets.com/reports/5026151/tissue-paper-market-growth-trends-covid-19 (accessed on 16 April 2023).

- Joint Research Center. Best Available Techniques (BAT) Reference Document for the Production of Pulp, Paper and Board; Joint Research Center: Seville, Spain, 2015. [Google Scholar]

- Nilsson, L.; Andreasson, R.; Bengt, A.; Christer, G.; Malutta, R.; Ottoson, A.; Zotterman, F.P.E.C. Fossil Free Tissue Drying Feasibility Study; Energiforsk: Stockholm, Sweden, 2016. [Google Scholar]

- Cooper, S.J.; Allen, S.R.; Gailani, A.; Norman, J.B.; Owen, A.; Taylor, J.B.E.P. Meeting the costs of the decarbonizing industry—The potential effects on prices and competitveness (a case study of the UK). Energy Policy 2024, 184, 113904. [Google Scholar] [CrossRef]

- Gerres, T.; Avila, J.P.C.; Llamas, P.L.; San Román, T.G. A review of cross-sector decarbonization potentials in the European energy intensive industry. J. Clean. Prod. 2019, 2019, 585–601. [Google Scholar] [CrossRef]

- Fleiter, T.; Fehrenbach, D.; Worrell, E.; Eichhammer, W. Energy efficiency in the German pulp and paper industry—A model-based assessment of saving potentials. Energy 2012, 40, 84–99. [Google Scholar] [CrossRef]

- Voith, Press Concepts. Available online: https://voith.com/corp-en/papermaking/press-concepts.html (accessed on 13 May 2024).

- Madeddu, S.; Ueckerdt, F.; Pehl, M.; Peterseim, J.; Lord, M.; Kumar, K.A.; Lurder, C.K.E.G.; Krüger, C.; Luderer, G. The CO2 reduction potential for the European industry via direct electrification of heat supply (power-to-heat). Environ. Res. Lett. 2020, 15, 12. [Google Scholar] [CrossRef]

- Rehfeldt, M.; Worrell, E.; Eichhammer, W.; Fleiter, T. A review of the emission reduction potential of fuel switch towards biomass and electricity in European basic materials industry until 2030. Renew. Sustain. Energy Rev. 2020, 120, 109672. [Google Scholar] [CrossRef]

- Kosmadakis, G. Estimating the potential of industrial (high-temperature) heat pumps for exploiting waste heat in EU industries. Appl. Therm. Eng. 2019, 156, 287–298. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Bertsch, J.S.E.S. High temperature heat pumps: Market overview, state of the art, research status, refrigerants, and application potentials. Energy 2018, 152, 985–1010. [Google Scholar] [CrossRef]

- Klute, S.; Budt, M.; van Beek, M.; Doetsch, C. Steam generating heat pumps—Overview, classification, economics, and basic modeling principles. Energy Convers. Manag. 2024, 299, 117882. [Google Scholar] [CrossRef]

- Smook, G.A. Handbook for Pulp & Paper Technologists; Angus Wilde Publication Inc.: Bellingham, WA, USA, 2012. [Google Scholar]

- International Energy Agency, Annex 58 High Temperature Heat Pumps. 2023. Available online: https://heatpumpingtechnologies.org/annex58/ (accessed on 29 July 2024).

- Confindustria. Proposta di Restrizione REACH sui PFAS; Confindustria: Rome, Italy, 2023. [Google Scholar]

- Greenwood, A. PFAS Restriction in US States Threaten HFO Use in Polyurethanes, 26 September 2023. Available online: https://www.icis.com/explore/resources/news/2023/09/26/10928553/pfas-restrictions-in-us-states-threaten-hfo-use-in-polyurethanes/ (accessed on 11 April 2023).

- Mateu-Royo, C.; Arpagaus, C.; Mota-Babiloni, A.; Navarro-Esbrí, J.; Bertsch, S.S. Advanced high temperature heat pump configurations using low GWP refrigerants for industrial waste heat recovery: A comprehensive study. Energy Convers. Manag. 2021, 229, 113752. [Google Scholar] [CrossRef]

- Frate, G.F.; Ferrari, L.; Desideri, U. Analysis of suitability ranges of high temperature heat pump working fluids. Appl. Therm. Eng. 2019, 150, 628–640. [Google Scholar] [CrossRef]

- Zini, A.; Socci, L.; Vaccaro, G.; Rocchetti, A.; Talluri, L. Working Fluid Selection for High-Temperature Heat Pumps: A Comprehensive Evaluation. Energies 2024, 17, 1556. [Google Scholar] [CrossRef]

- Jiang, J.; Hu, B.; Wang, R.; Deng, N.; Cao, F.; Wang, C.-C. A review and perspective on industry high-temperature heat pumps. Renew. Sustain. Energy Rev. 2022, 161, 112106. [Google Scholar] [CrossRef]

- Faraldo, F.; Byrne, P. A Review of Energy-Efficient Technologies and Decarbonating Solutions for Process Heat in the Food Industry. Energies 2024, 17, 3051. [Google Scholar] [CrossRef]

- European Union, EU Emissions Trading System (EU ETS). Available online: https://climate.ec.europa.eu/eu-action/eu-emissions-trading-system-eu-ets_en (accessed on 13 August 2024).

- Cox, J.; Belding, S.; Lowder, T. Application of a novel heat pump model for estimating economic viability and barriers of heat pumps in dairy applications in the United States. Appl. Energy 2022, 310, 118499. [Google Scholar] [CrossRef]

- Dumont, M.; Wang, R.; Wenzke, D.; Blok, K.; Heijungs, R. The techno-economic integrability of high-temperature heat pumps for decarbonizing process heat in the food and beverages industry. Resour. Conserv. Recycl. 2023, 188, 106605. [Google Scholar] [CrossRef]

- Vieren, E.; Demeester, T.; Beyne, W.; Magni, C.; Abedini, H.; Arpagaus, C.; Bertsch, S.; Arteconi, A.; De Paepe, M.; Lecompte, S. The Potential of Vapor Compression Heat Pumps Supplying Process Heat between 100 and 200 °C in the Chemical Industry. Energies 2023, 16, 6473. [Google Scholar] [CrossRef]

- Obrist, M.D.; Kannan, R.; McKenna, R.; Schmidt, T.J.; Kober, T. High-temperature heat pumps in climate pathways for selected industry sectors in Switzerland. Energy Policy 2023, 173, 113383. [Google Scholar] [CrossRef]

- Obrist, M.D.; Kannan, R.; Schmidt, T.J.; Kober, T. Long-term energy efficiency and decarbonization trajectories for the Swiss pulp and paper industry. Sustain. Energy Technol. Assess. 2022, 52, 101937. [Google Scholar] [CrossRef]

- Wilk, V.; Knottner, S.; Barz, G.D.-S.E.T. Superheated steam drying for paper production: Process efficiency assessment. In Proceedings of the ECOS 2023—The 36th International Conference on Efficiency, Cost, Optimization, Simulation and Envinromental Impact of Energy Systems, Las Palmas De Gran Canaria, Spain, 25–30 June 2023. [Google Scholar]

- Babcock Wanson. Industrial Electric Boilers. Available online: https://www.babcock-wanson.com/product-category/industrial-electric-boilers/ (accessed on 13 May 2024).

- John, M.; Campbell & Co. How to Estimate Compressor Efficiency? Available online: https://www.jmcampbell.com/tip-of-the-month/2015/07/how-to-estimate-compressor-efficiency/ (accessed on 17 August 2024).

- AspenTech. Aspen HYSYS Technical Documentation; AspenTech: Bedford, MA, USA, 2021. [Google Scholar]

- Mehrpooya, M.; Kalhorzadeh, M.; Chahartaghi, M. Investigation of novel integrated air separation processes, cold energy recovery of liquefied natural gas and carbon dioxide power cycle. J. Clean. Prod. 2016, 113, 411–425. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology, REFPROP. Available online: https://www.nist.gov/srd/refprop (accessed on 14 August 2024).

- Vannoni, A.; Sorce, A.; Traverso, A.; Massardo, A.F. Techno-economic optimization of high-temperature heat pumps for waste heat recovery. Energy Convers. Manag. 2023, 290, 117194. [Google Scholar] [CrossRef]

- Fernández-Moreno, A.; Mota-Babiloni, A.; Giménez-Prades, P.; Navarro-Esbrí, J. Optimal refrigerant mixture in single-stage high-temperature heat pumps based on a multiparameter evaluation. Sustain. Energy Technol. Assess. 2022, 52, 101989. [Google Scholar] [CrossRef]

- MAN Energy Solution, RH Horizontal split centrifugal compressors. Available online: https://www.man-es.com/oil-gas/products/compressors/centrifugal (accessed on 29 July 2024).

- United Nations. Water at the Center of the Climate Crisis. Available online: https://www.un.org/en/climatechange/science/climate-issues/water (accessed on 11 April 2024).

- Bilardo, M.; Fabrizio, S.G.E.E. The role of Primary Energy Factors (PEF) for electricity in the evaluation and comparison of building energy performance: An investigation on European nZEBs according to EN 17423:2020. Sustain. Cities Soc. 2022, 87, 104189. [Google Scholar] [CrossRef]

- European Environment Agency. Greenhouse gas emission intensity of electricity generation in Europe. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emission-intensity-of-1?activeAccordion=546a7c35-9188-4d23-94ee-005d97c26f2b (accessed on 22 April 2024).

- Frate, G.F.; Ferrari, L.; Sdringola, P.; Sciacovelli, U.D.E.A. Thermally integrated pumped thermal energy storage for multi-energy districts: Integrated modelling, assessment and comparison with batteries. J. Energy Storage 2023, 61, 106734. [Google Scholar] [CrossRef]

- European Investment Bank. EIB Project Carbon Footprint Methodologies 2023; European Investment Bank: Luxembourg, 2023. [Google Scholar]

- Eurostat. Database. Available online: https://ec.europa.eu/eurostat/web/main/data/database (accessed on 15 April 2024).

- Statista. Average Carbon Price Expectations Worldwide from 2022 to 2030, by Trading System. 10 Luglio 2023. Available online: https://www.statista.com/statistics/1334906/average-carbon-price-projections-worldwide-by-region/ (accessed on 23 November 2023).

- Ruzi, P. The End of Free EU ETS Rights: The Carbon Bill Reshaping European Industry, Radobank . 21 September 2023. Available online: https://www.rabobank.com/knowledge/d011384876-the-end-of-free-eu-ets-rights-the-carbon-bill-reshaping-european-industry (accessed on 22 April 2024).

- Nilsson, L.; Andreasson, R.; Axelsson, B.; Gustavsson, C.; Malutta, R.; Ottosson, A.; Zotterman, F.P.E.C. Fossil Free Tissue Drying; Energiforsk: Stockholm, Sweden, 2016. [Google Scholar]

- Atlas Copco, Mechanical Vapor Recompression key to steam energy upgrade within a polyolefin plant. Available online: https://www.atlascopco.com/content/dam/atlas-copco/compressor-technique/gas-and-process/documents/TMI_MVR_key_to_steam_energy_upgrade_within_a_polyolefin_plant.pdf (accessed on 5 June 2024).

- Saini, P.; Ghasemi, M.; Arpagaus, C.; Bless, F.; Bertsch, S.; Zhang, X. Techno-economic comparative analysis of solar thermal collectors and high-temperature heat pumps for industrial steam generation. Energy Convers. Manag. 2023, 277, 116623. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2023; IEA: Paris, France, 2023. [Google Scholar]

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow, W.R., III; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- Liponi, A.; Pasini, G.; Baccioli, A.; Ferrari, L. Hydrogen from renewables: Is it always green? The Italian scenario. Energy Convers. Manag. 2023, 276, 116525. [Google Scholar] [CrossRef]

| Flow | Specifications |

|---|---|

| Hot air | ṁ = 11 t/h |

| Process water | ṁ = 5.5 t/h |

| Exhaust air 1 | ṁ = 16.5 t/h |

| T = 310 °C | |

| Exhaust air 2 | ṁ = 15 t/h |

| T = 75 °C | |

| Recovered water 1 | ṁ = 1.5 t/h |

| Process condensate * | ṁ = 4 t/h |

| p = 8 bar | |

| HP saturated steam | p = 17 bar |

| Blow-through steam | ṁ = 5 t/h |

| p = 8 bar | |

| Saturated steam to Yankee * | ṁ = 9 t/h |

| p = 9 bar | |

| Fuel 1 | Pth = 3300 kWth |

| Fuel 2 | Pth = 2700 kWth |

| Electric power | Pel = 2400 kWe |

| Saturated steam from HTHP | ṁ = 4 t/h |

| p = 9 bar | |

| Saturated steam to Yankee | ṁ = 9 t/h |

| p = 9 bar | |

| Electric power MVR | Pel = 40 kWe |

| Flow (dry air) | 3.0 kg/s |

| Humidity | 0.37 kgH2O/kgDA |

| Total flow | 15,000 kg/h |

| Temperature | 75 °C |

| Screw compressor (bottom cycle) | Adiabatic efficiency: 80% |

| Electro-mechanic efficiency: 90% | |

| Centrifugal compressor (top cycle) | Adiabatic efficiency: 85% |

| Electro-mechanic efficiency: 95% |

| Name | Class | Critical Point | GWP 100 | Flammability | psat,40°C |

|---|---|---|---|---|---|

| R245ca | HFC | 174.4 °C 39.9 bar | 726 | 1 | 1.73 bar |

| R1336mzz(Z) | HFCO | 171.3 °C 29.0 bar | 2 | 0 | 1.28 bar |

| n-Pentane | HC | 196.6 °C 33.7 bar | 5 | 4 | 1.16 bar |

| Min. pinch point at evaporator/boiler heat exchanger | 20 °C |

| Internal heat exchanger pinch point | 10 °C |

| Max. temperature in the bottom cycle | 200 °C |

| Max. temperature in the top cycle | 300 °C |

| Min. pressure in the bottom cycle | 1.01325 bar |

| Heat flow rate demand | 2300 kWth |

| Country (2019) | Primary Energy Factor [42] (kWhP/kWhel) | GHG Emission Factor [43] (kgCO2/kWh) |

|---|---|---|

| EU | 1.96 | 0.255 |

| France | 2.43 | 0.06 |

| Germany | 1.75 | 0.347 |

| Italy | 1.69 | 0.234 |

| Spain | 1.97 | 0.214 |

| Sweden | 1.44 | 0.01 |

| Primary energy factor per NG | 1.1 [44] |

| GHG emission factor per NG | 0.2 kgCO2/kWh [45] |

| Country (2019) | NG Price (EUR/MWh) | Electric Energy Price (EUR/MWh) |

|---|---|---|

| EU | 26 | 86 |

| France | 26 | 68 |

| Germany | 26 | 100 |

| Italy | 26 | 113 |

| Spain | 28 | 83 |

| Sweden | 39 | 53 |

| Name | COP (−) | VHC (kJ/m3) | β Bottom (−) | β Top (−) | Water Recovery (t/h) |

|---|---|---|---|---|---|

| R245ca | 1.89 | 1650 | 11.4 | 3.8 | 1.7 |

| R1336mzz(Z) | 1.90 | 1240 | 12.3 | 3.7 | 1.7 |

| n-Pentane | 2.01 | 1150 | 10.8 | 3.8 | 1.8 |

| Country | Specific CAPEX (EUR/kW) |

|---|---|

| EU | 280 |

| France | 670 |

| Spain | 420 |

| Sweden | 1600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciambellotti, A.; Frate, G.F.; Baccioli, A.; Desideri, U. High-Temperature Heat Pumps for Electrification and Cost-Effective Decarbonization in the Tissue Paper Industry. Energies 2024, 17, 4335. https://doi.org/10.3390/en17174335

Ciambellotti A, Frate GF, Baccioli A, Desideri U. High-Temperature Heat Pumps for Electrification and Cost-Effective Decarbonization in the Tissue Paper Industry. Energies. 2024; 17(17):4335. https://doi.org/10.3390/en17174335

Chicago/Turabian StyleCiambellotti, Alessio, Guido Francesco Frate, Andrea Baccioli, and Umberto Desideri. 2024. "High-Temperature Heat Pumps for Electrification and Cost-Effective Decarbonization in the Tissue Paper Industry" Energies 17, no. 17: 4335. https://doi.org/10.3390/en17174335

APA StyleCiambellotti, A., Frate, G. F., Baccioli, A., & Desideri, U. (2024). High-Temperature Heat Pumps for Electrification and Cost-Effective Decarbonization in the Tissue Paper Industry. Energies, 17(17), 4335. https://doi.org/10.3390/en17174335