A Review on Application of Pin-Fins in Enhancing Heat Transfer

Abstract

1. Introduction

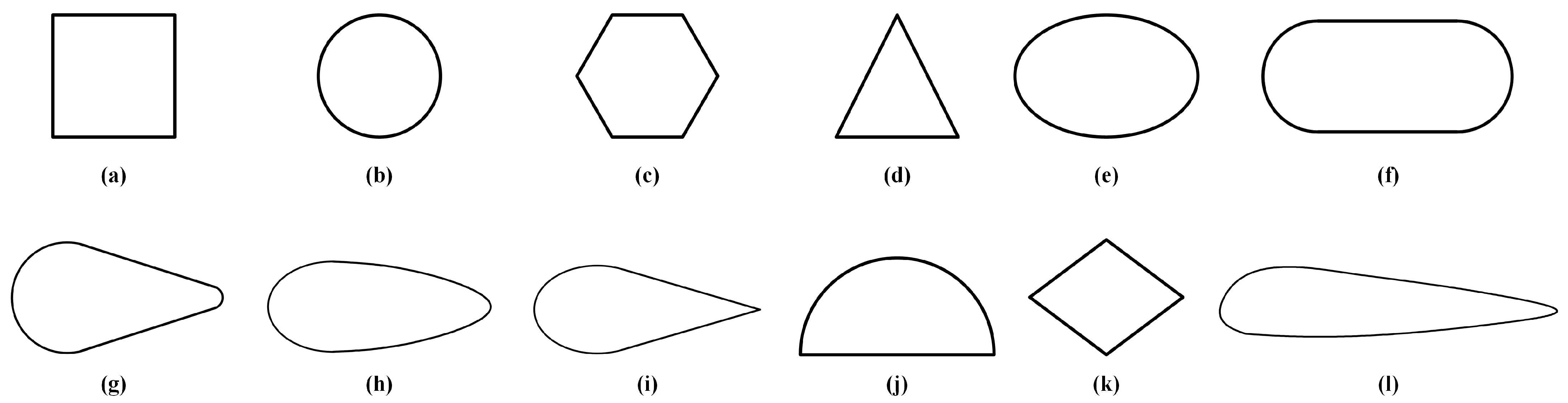

2. Research on the Shape of Pin-Fins

2.1. Regular Pin-Fins

2.2. Improved Circular Pin-Fin and Irregular Pin-Fin

2.3. Geometric Parameters and Arrangement of Pin-Fin

2.4. Research on the Combination of Pin-Fin with Other Cooling Methods

3. Optimization Technology of the Pin-Fin

3.1. Structural Optimization

3.2. Layout Optimization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ligrani, P.M.; Oliveira, M.M.; Blaskovich, T. Comparison of Heat Transfer Augmentation Techniques. AIAA J. 2003, 41, 337–362. [Google Scholar] [CrossRef]

- Siw, S.C.; Chyu, M.K.; Shih, T.I.P.; Alvin, M.A. Effects of Pin Detached Space on Heat Transfer and Pin-Fin Arrays. J. Heat Transf. 2012, 134, 081902. [Google Scholar] [CrossRef]

- Ligrani, P. Heat Transfer Augmentation Technologies for Internal Cooling of Turbine Components of Gas Turbine Engines. Int. J. Rotating Mach. 2013, 2013, 275653. [Google Scholar] [CrossRef]

- Chen, Z.; Su, X.; Yuan, X. Cooling Performance of the Endwall Vertical Hole Considering the Interaction between Cooling Jet and Leading-Edge Horseshoe Vortex. J. Therm. Sci. 2022, 31, 1696–1708. [Google Scholar] [CrossRef]

- Wang, J.M.; Bi, W.T.; Wei, Q.D. Effects of an upstream inclined rod on the circular cylinder–flat plate junction flow. Exp. Fluids 2009, 46, 1093–1104. [Google Scholar] [CrossRef]

- Ambreen, T.; Saleem, A.; Park, C.W. Pin-fin shape-dependent heat transfer and fluid flow characteristics of water- and nanofluid-cooled micropin-fin heat sinks: Square, circular and triangular fin cross-sections. Appl. Therm. Eng. 2019, 158, 113781. [Google Scholar] [CrossRef]

- Ambreen, T.; Kim, M.-H. Effect of fin shape on the thermal performance of nanofluid-cooled micro pin-fin heat sinks. Int. J. Heat Mass Transf. 2018, 126, 245–256. [Google Scholar] [CrossRef]

- Jin, W.; Jia, N.; Wu, J.; Lei, J.; Liu, L. Numerical study on flow and heat transfer characteristics of pin-fins with different shapes. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Jin, W.; Wu, J.; Jia, N.; Lei, J.; Ji, W.; Xie, G. Effect of shape and distribution of pin-fins on the flow and heat transfer characteristics in the rectangular cooling channel. Int. J. Therm. Sci. 2021, 161, 106758. [Google Scholar] [CrossRef]

- Xu, J.; Yao, J.; Su, P.; Lei, J.; Wu, J.; Gao, T. Heat Transfer and Pressure Loss Characteristics of Pin-Fins With Different Shapes in a Wide Channel. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017; p. V05AT16A006. [Google Scholar]

- Siw, S.C.; Chyu, M.K.; Alvin, M.A. Heat transfer enhancement of internal cooling passage with triangular and semi-circular shaped pin-fin arrays. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Ilyushin, Y.V.; Pervukhin, D.A.; Afanasieva, O.V.; Afanasyev, M.P.; Kolesnichenko, S.V. The Methods of the Synthesis of the Nonlinear Regulators for the Distributed One-Dimension Control Objects. Mod. Appl. Sci. 2014, 9, 42–61. [Google Scholar] [CrossRef][Green Version]

- Wang, F.; Zhang, J.; Wang, S. Investigation on flow and heat transfer characteristics in rectangular channel with drop-shaped pin fins. Propuls. Power Res. 2012, 1, 64–70. [Google Scholar] [CrossRef]

- Liu, Z.G.; Guan, N.; Zhang, C.W.; Jiang, G.L. The Flow Resistance and Heat Transfer Characteristics of Micro Pin-Fins with Different Cross-Sectional Shapes. Nanoscale Microscale Thermophys. Eng. 2015, 19, 221–243. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, Z.; Zhang, C.; Guan, N.; Zhao, H. Pressure drop and friction factor of a rectangular channel with staggered mini pin fins of different shapes. Exp. Therm Fluid Sci. 2016, 71, 57–69. [Google Scholar] [CrossRef]

- Corbett, T.M.; Thole, K.A.; Bollapragada, S. Impacts of Pin Fin Shape and Spacing on Heat Transfer and Pressure Losses. J. Turbomach. 2023, 145, 051014. [Google Scholar] [CrossRef]

- Soleymani, Z.; Rahimi, M.; Gorzin, M.; Pahamli, Y. Performance analysis of hotspot using geometrical and operational parameters of a microchannel pin-fin hybrid heat sink. Int. J. Heat Mass Transf. 2020, 159, 120141. [Google Scholar] [CrossRef]

- Ho, J.Y.; Wong, K.K.; Leong, K.C.; Wong, T.N. Convective heat transfer performance of airfoil heat sinks fabricated by selective laser melting. Int. J. Therm. Sci. 2017, 114, 213–228. [Google Scholar] [CrossRef]

- Moon, M.-A.; Kim, K.-Y. Analysis and optimization of fan-shaped pin–fin in a rectangular cooling channel. Int. J. Heat Mass Transf. 2014, 72, 148–162. [Google Scholar] [CrossRef]

- Babaharra, O.; Choukairy, K.; Faraji, H.; Hamdaoui, S. Improved heating floor thermal performance by adding PCM microcapsules enhanced by single and hybrid nanoparticles. Heat Transf. 2023, 52, 3817–3838. [Google Scholar] [CrossRef]

- Hariti, Y.; Hader, A.; Faraji, H.; Boughaleb, Y. Scaling Law of Permeability and Porosity for Fluid Transport Phenomena in Porous PCM Media. J. Appl. Comput. Mech. 2021, 7, 84–92. [Google Scholar]

- Luo, L.; Yan, H.; Du, W.; Su, W.; Wang, S.; Huang, D. Numerical study of a novel curved pin fin for heat transfer enhancement within aeroengine turbine blade. Aerosp. Sci. Technol. 2022, 123, 107436. [Google Scholar] [CrossRef]

- Zeng, L.; Deng, D.; Zhong, N.; Zheng, G. Thermal and flow performance in microchannel heat sink with open-ring pin fins. Int. J. Mech. Sci. 2021, 200, 106445. [Google Scholar] [CrossRef]

- Zhu, F.; Jing, Q.; Xie, Y.; Zhang, D. Numerical investigation on flow and heat transfer characteristics of U-shaped channels with side-wall column ribs. Int. Commun. Heat Mass Transf. 2022, 137, 106221. [Google Scholar] [CrossRef]

- Zhao, Z.; Luo, L.; Qiu, D.; Zhou, X.; Wang, Z.; Sundén, B. Experimental evaluation of longitudinal and transverse vortex generators on the endwall of a serpentine passage. Int. J. Therm. Sci. 2022, 176, 107521. [Google Scholar] [CrossRef]

- Liang, C.; Rao, Y. Numerical study of turbulent flow and heat transfer in channels with detached pin fin arrays under stationary and rotating conditions. Int. J. Therm. Sci. 2021, 160, 106659. [Google Scholar] [CrossRef]

- Hosseinirad, E.; Khoshvaght-Aliabadi, M.; Hormozi, F. Effects of splitter shape on thermal-hydraulic characteristics of plate-pin-fin heat sink (PPFHS). Int. J. Heat Mass Transf. 2019, 143, 118586. [Google Scholar] [CrossRef]

- Yu, X.; Woodcock, C.; Plawsky, J.; Peles, Y. An investigation of convective heat transfer in microchannel with Piranha Pin Fin. Int. J. Heat Mass Transf. 2016, 103, 1125–1132. [Google Scholar] [CrossRef]

- Ferster, K.K.; Kirsch, K.L.; Thole, K.A. Effects of Geometry and Spacing in Additively Manufactured Microchannel Pin Fin Arrays. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference & Exposition, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Ferster, K.K.; Kirsch, K.L.; Thole, K.A. Effects of Geometry, Spacing, and Number of Pin Fins in Additively Manufactured Microchannel Pin Fin Arrays. J. Turbomach. 2018, 140, 011007. [Google Scholar] [CrossRef]

- Haque, M.R.; Hridi, T.J.; Haque, M.M. CFD studies on thermal performance augmentation of heat sink using perforated twisted, and grooved pin fins. Int. J. Therm. Sci. 2022, 182, 107832. [Google Scholar] [CrossRef]

- El-Said, E.M.S.; Abdelaziz, G.B.; Sharshir, S.W.; Elsheikh, A.H.; Elsaid, A.M. Experimental investigation of the twist angle effects on thermo-hydraulic performance of a square and hexagonal pin fin array in forced convection. Int. Commun. Heat Mass Transf. 2021, 126, 105374. [Google Scholar] [CrossRef]

- Pandit, J.; Thompson, M.; Ekkad, S.V.; Huxtable, S.T. Effect of pin fin to channel height ratio and pin fin geometry on heat transfer performance for flow in rectangular channels. Int. J. Heat Mass Transf. 2014, 77, 359–368. [Google Scholar] [CrossRef]

- Chi, X.; Shih, T.I.-P.; Bryden, K.M.; Siw, S.; Chyu, M.K.; Ames, R.; Denni, R.A. Effects of pin fin height on flow and heat transfer in a rectangular duct. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011. [Google Scholar]

- Hua, J.; Li, G.; Zhao, X.; Li, Q.; Hu, J. Study on the flow resistance performance of fluid cross various shapes of micro-scale pin fin. Appl. Therm. Eng. 2016, 107, 768–775. [Google Scholar] [CrossRef]

- Chyu, M.K.; Siw, S.C.; Moon, H.K. Effects of Height-to-Diameter Ratio of Pin Element on Heat Transfer from Staggered Pin-Fin Arrays. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

- Bhandari, P.; Prajapati, Y.K. Thermal performance of open microchannel heat sink with variable pin fin height. Int. J. Therm. Sci. 2021, 159, 106609. [Google Scholar] [CrossRef]

- Li, P.; Fan, X.; Chen, Z. Numerical study on the heat transfer of micro elliptic pin fins in a rectangular minichannel. Numer. Heat Transf. Part A Appl. 2016, 70, 1242–1252. [Google Scholar] [CrossRef]

- Chen, Z.; Feng, Z.; Zhang, Q.; Zhang, J.; Guo, F. Effects of regular triangular prisms on thermal and hydraulic characteristics in a minichannel heat sink. Int. J. Heat Mass Transf. 2022, 188, 122583. [Google Scholar] [CrossRef]

- Jaseliūnaitė, J.; Šeporaitis, M. Performance optimisation of microchannel pin-fins using 2D CFD. Appl. Therm. Eng. 2022, 206, 118040. [Google Scholar] [CrossRef]

- Ireland, P.T.; Jones, T.V. Detailed measurements of heat transfer on and around a pedestal in fully developed passage flow. In Proceedings of the International Heat Transfer Conference, San Francisco, CA, USA, 17–22 August 1986; Volume 3, pp. 975–980. [Google Scholar]

- Won, S.Y.; Mahmood, G.I.; Ligrani, P.M. Spatially-resolved heat transfer and flow structure in a rectangular channel with pin fins. Int. J. Heat Mass Transf. 2004, 47, 1731–1743. [Google Scholar] [CrossRef]

- Kirsch, K.L.; Ostanek, J.K.; Thole, K.A. Comparison of Pin Surface Heat Transfer in Arrays of Oblong and Cylindrical Pin Fins. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, Heat Transfer, San Antonio, TX, USA, 3–7 June 2013; Volume 3A, p. V03AT12A034. [Google Scholar]

- Xu, F.; Pan, Z.; Wu, H. Experimental investigation on the flow transition in different pin-fin arranged microchannels. Microfluid. Nanofluid. 2017, 22, 11. [Google Scholar] [CrossRef]

- Bianchini, C.; Facchini, B.; Simonetti, F.; Tarchi, L.; Zecchi, S. Numerical and Experimental Investigation of Turning Flow Effects on Innovative Pin Fin Arrangements for Trailing Edge Cooling Configurations. J. Turbomach. 2012, 134, 021005. [Google Scholar] [CrossRef]

- Abuşka, M.; Çorumlu, V. A comparative experimental thermal performance analysis of conical pin fin heat sink with staggered and modified staggered layout under forced convection. Therm. Sci. Eng. Prog. 2023, 37, 101560. [Google Scholar] [CrossRef]

- Guo, Z.; Xu, Q.; Zhao, S.; Zhai, S.; Zhao, T.; Ni, M. A new battery thermal management system employing the mini-channel cold plate with pin fins. Sustain. Energy Technol. Assess. 2022, 51, 101993. [Google Scholar] [CrossRef]

- Kewalramani, G.V.; Hedau, G.; Saha, S.K.; Agrawal, A. Study of laminar single phase frictional factor and Nusselt number in In-line micro pin-fin heat sink for electronic cooling applications. Int. J. Heat Mass Transf. 2019, 138, 796–808. [Google Scholar] [CrossRef]

- Bahiraei, M.; Mazaheri, N.; Daneshyar, M.R. Employing elliptical pin-fins and nanofluid within a heat sink for cooling of electronic chips regarding energy efficiency perspective. Appl. Therm. Eng. 2021, 183, 116159. [Google Scholar] [CrossRef]

- Ostaneka, J.K.; Thole, K.A. Effects of Non-Uniform Streamwise Spacing in Low Aspect Ratio Pin Fin Arrays. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference & Exposition, San Antonio, TX, USA, 3–7 June 2013; p. V03AT12A050. [Google Scholar]

- Polat, M.E.; Cadirci, S. Artificial neural network model and multi-objective optimization of microchannel heat sinks with diamond-shaped pin fins. Int. J. Heat Mass Transf. 2022, 194, 123015. [Google Scholar] [CrossRef]

- Mahmood, G.I.; Ligrani, P.M. Heat transfer in a dimpled channel combined influences of aspect ratio, temperature ratio, Reynolds number, and flow structure. Int. J. Heat Mass Transf. 2002, 45, 2011–2020. [Google Scholar] [CrossRef]

- Li, P.; Luo, Y.; Zhang, D.; Xie, Y. Flow and heat transfer characteristics and optimization study on the water-cooled microchannel heat sinks with dimple and pin-fin. Int. J. Heat Mass Transf. 2018, 119, 152–162. [Google Scholar] [CrossRef]

- Xie, Y.; Shi, D.; Shen, Z. Experimental and numerical investigation of heat transfer and friction performance for turbine blade tip cap with combined pin-fin-dimple/protrusion structure. Int. J. Heat Mass Transf. 2017, 104, 1120–1134. [Google Scholar] [CrossRef]

- Karami, M.; Tashakor, S.; Afsari, A.; Hashemi-Tilehnoee, M. Effect of the baffle on the performance of a micro pin fin heat sink. Therm. Sci. Eng. Prog. 2019, 14, 100417. [Google Scholar] [CrossRef]

- Syaiful; Nabilah, H.; Suryo Utomo, M.S.K.T.; Suprihanto, A.; Soetanto, M.F. Numerical simulation of heat transfer enhancement from tubes surface to airflow using concave delta winglet vortex generators. Results Eng. 2022, 16, 100710. [Google Scholar] [CrossRef]

- Effendi, Y.; Syaiful; Djaeni, M.; Winoto, S.H. The analysis of heat transfer and pressure loss for the air flow through heated cylinders with concave delta winglet vortex generators in rectangular channel: An experimental study. IOP Conf. Ser. Mater. Sci. Eng. 2019, 673, 012111. [Google Scholar] [CrossRef]

- Huang, C.-H.; Chen, M.-H. An estimation of the optimum shape and perforation diameters for pin fin arrays. Int. J. Heat Mass Transf. 2019, 131, 72–84. [Google Scholar] [CrossRef]

- Gupta, D.; Saha, P.; Roy, S. Numerical Investigation on Heat Transfer Enhancement with Perforated Square Micro-Pin Fin Heat. In Proceeding of the 2019 IEEE 21st Electronics Packaging Technology Conference (EPTC 2019), Singapore, 4–6 December 2019. [Google Scholar]

- Gupta, D.; Saha, P.; Roy, S. Computational analysis of perforation effect on the thermo-hydraulic performance of micro pin-fin heat sink. Int. J. Therm. Sci. 2021, 163, 106857. [Google Scholar] [CrossRef]

- Al-Damook, A.; Summers, J.L.; Kapur, N.; Thompson, H. Effect of different perforations shapes on the thermal-hydraulic performance of perforated pinned heat sinks. J. Multidiscip. Eng. Sci. Technol. 2016, 3, 4466–4474. [Google Scholar]

- Ahmadian-Elmi, M.; Mashayekhi, A.; Nourazar, S.S.; Vafai, K. A comprehensive study on parametric optimization of the pin-fin heat sink to improve its thermal and hydraulic characteristics. Int. J. Heat Mass Transf. 2021, 180, 121797. [Google Scholar] [CrossRef]

- Li, P.; Kim, K.-Y. Multiobjective Optimization of Staggered Elliptical Pin-Fin Arrays. Numer. Heat Transf. Part A Appl. 2008, 53, 418–431. [Google Scholar] [CrossRef]

- Ghosh, S.; Mondal, S.; Kapat, J.S.; Ray, A. Shape optimization of pin fin arrays using Gaussian process surrogate models under design constraints. In Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, Virtual, Online, 21–25 September 2020. [Google Scholar]

- Horiuchi, K.; Nishihara, A.; Sugimura, K. Multi-Objective Optimization of Pin-Fin Heatsinks. In Proceedings of the ASME 2009 International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009. [Google Scholar]

- Radmard, V.; Hadad, Y.; Rangarajan, S.; Hoang, C.H.; Fallahtafti, N.; Arvin, C.L.; Sikka, K.; Schiffres, S.N.; Sammakia, B.G. Multi-objective optimization of a chip-attached micro pin fin liquid cooling system. Appl. Therm. Eng. 2021, 195, 117187. [Google Scholar] [CrossRef]

- Sahel, D.; Bellahcene, L.; Yousfi, A.; Subasi, A. Numerical investigation and optimization of a heat sink having hemispherical pin fins. Int. Commun. Heat Mass Transf. 2021, 122, 105133. [Google Scholar] [CrossRef]

- Duan, Z.; Xie, G.; Yu, B.; Jin, P. Multi-objective topology optimization and thermal performance of liquid-cooled microchannel heat sinks with pin fins. Case Stud. Therm. Eng. 2023, 49, 103178. [Google Scholar] [CrossRef]

- Nguyen, N.P.; Maghsoudi, E.; Roberts, S.N.; Kwon, B. Shape optimization of pin fin array in a cooling channel using genetic algorithm and machine learning. Int. J. Heat Mass Transf. 2023, 202, 123769. [Google Scholar] [CrossRef]

- Yang, J.; Li, L.; Yang, L.; Li, J. Uniform design for the parameters optimization of pin-fins channel heat sink. Appl. Therm. Eng. 2017, 120, 289–297. [Google Scholar] [CrossRef]

- Li, P.; Guo, D.; Huang, X. Heat transfer enhancement in microchannel heat sinks with dual split-cylinder and its intelligent algorithm based fast optimization. Appl. Therm. Eng. 2020, 171, 115060. [Google Scholar] [CrossRef]

- Ismayilov, F.; Akturk, A.; Peles, Y. Systematic micro heat sink optimization based on hydrofoil shape pin fins. Case Stud. Therm. Eng. 2021, 26, 101028. [Google Scholar] [CrossRef]

- Berber, A.; Gürdal, M. Estimation of forced heat convection in a rectangular channel with curved-winglet vortex generator: A machine learning approach. Therm. Sci. Eng. Prog. 2023, 37, 101563. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology optimization approaches. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Borrvall, T.; Petersson, J. Topology optimization of fluids in Stokes flow. Int. J. Numer. Methods Fluids 2003, 41, 77–107. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y.; Yang, L.; Li, H. Enhanced thermal performance of a pin-fin cooling channel for gas turbine blade by density-based topology optimization. Int. J. Therm. Sci. 2022, 181, 107783. [Google Scholar] [CrossRef]

- Haertel, J.H.K.; Engelbrecht, K.; Lazarov, B.S.; Sigmund, O. Topology optimization of a pseudo 3D thermofluid heat sink model. Int. J. Heat Mass Transf. 2018, 121, 1073–1088. [Google Scholar] [CrossRef]

- Hu, J.; Chen, C.; Wang, X.; Xin, G.; Wang, M. Improvement of flow and heat transfer performance of microchannels with different ribs using topology optimization. Appl. Therm. Eng. 2024, 244, 122672. [Google Scholar] [CrossRef]

- Alexandersen, J.; Sigmund, O.; Aage, N. Large scale three-dimensional topology optimisation of heat sinks cooled by natural convection. Int. J. Heat Mass Transf. 2016, 100, 876–891. [Google Scholar] [CrossRef]

- Xie, L.; Zhang, Y.; Ge, M.; Zhao, Y. Topology optimization of heat sink based on variable density method. Energy Rep. 2022, 8, 718–726. [Google Scholar] [CrossRef]

- Huang, P.; Yang, S.; Pan, M. Pseudo 3D topology optimization of microchannel heat sink with an auxiliary objective. Int. J. Heat Mass Transf. 2022, 187, 122526. [Google Scholar] [CrossRef]

- Gilmore, N.; Timchenko, V.; Menictas, C. Manifold microchannel heat sink topology optimisation. Int. J. Heat Mass Transf. 2021, 170, 121025. [Google Scholar] [CrossRef]

- Meng, J.-H.; Liu, Y.; Zhu, X.-H.; Yang, Z.-J.; Zhang, K.; Lu, G. Performance enhancement for exhaust thermoelectric power generation system by using porous pin fins based on a fully automatic optimization method. Energy Convers. Manag. 2022, 273, 116404. [Google Scholar] [CrossRef]

- Polat, M.E.; Ulger, F.; Cadirci, S. Multi-objective optimization and performance assessment of microchannel heat sinks with micro pin-fins. Int. J. Therm. Sci. 2022, 174, 107432. [Google Scholar] [CrossRef]

- Lee, Y.J.; Kim, S.J. Thermal optimization of the pin-fin heat sink with variable fin density cooled by natural convection. Appl. Therm. Eng. 2021, 190, 116692. [Google Scholar] [CrossRef]

- Moon, M.-A.; Kim, K.-Y. Optimization of Rotating Cooling Channel with Pin Fins Downstream of Turning Region. J. Thermophys. Heat Transf. 2012, 26, 85–97. [Google Scholar] [CrossRef]

- Fallahtafti, N.; Rangarajan, S.; Hadad, Y.; Arvin, C.; Sikka, K.; Hoang, C.H.; Mohsenian, G.; Radmard, V.; Schiffres, S.; Sammakia, B. Shape optimization of hotspot targeted micro pin fins for heterogeneous integration applications. Int. J. Heat Mass Transf. 2022, 192, 122897. [Google Scholar] [CrossRef]

- Zhao, R.; Wen, D.; Lai, Z.; Li, W.; Ye, M.; Zhuge, W.; Zhang, Y. Performance analysis and optimization of a novel cooling plate with non-uniform pin-fins for lithium battery thermal management. Appl. Therm. Eng. 2021, 194, 117022. [Google Scholar] [CrossRef]

| Authors | Pin-Fin Structures | Performance Specifications | References |

|---|---|---|---|

| Luo et al. [22] | Curved | increased by 6.1%. | Conventional circular pin-fin |

| Zeng et al. [23] | Open-ring | increased by 77~260%. | Conventional smooth channels |

| Zhu et al. [24] | Inclined | increased by 37.9%. | Conventional circular pin-fin |

| Moon et al. [19] | Fan-shaped | increased by 22.8%. | Conventional circular pin-fin |

| Zhao et al. [25] | Conical | increased by 35%. | Conventional circular pin-fin |

| Liang et al. [26] | Detached | increased by 29.1%. | Conventional circular pin-fin |

| Yu et al. [28] | Piranha-shaped | increased by 86%. | Conventional smooth channels |

| Haque et al. [31] | Twisted | increased by 27%. | Conventional circular pin-fin |

| Authors | Combination Objects | Performance Specifications | References |

|---|---|---|---|

| Xie et al. [53,54] | Dimple | The average increased by 31.2~72.1%. | Conventional smooth channels |

| Xie et al. [53,54] | Protrusion | The average increased by 87.4~127.3%. | Conventional smooth channels |

| Karami et al. [55] | Baffle | The heat-transfer rate increased by 47.37%, the increased by 77%. | Conventional circular pin-fin |

| Syaiful et al. [56,57] | Winglet | increased by 69.69%. | Conventional circular pin-fin |

| Huang et al. [58] | Perforation | The average increased by 35.8%. | Conventional circular pin-fin |

| Gupta et al. [59,60] | Perforation | The average increased by 53.5~187.3%, decreased by 20.7~39.1%. | Conventional square pin-fin |

| Authors | Initial Structures | Optimization Objects | Optimization Algorithm | Optimal Results | References |

|---|---|---|---|---|---|

| Moon and Kim [19] | Fan-shaped | and minimize the friction loss | Radial basis neural network method | increased by 22.82%, and friction loss increased by 22.82%. | Conventional circular pin-fin |

| Li and Kim [63] | Elliptical | NSGA-II | increased by 38.7%. | Initial elliptical pin-fin | |

| Ghosh et al. [64] | Circular | Bayesian | increased by 33.2%. | Initial circular pin-fin | |

| Horiuchi et al. [65] | Circular | MOGA | decreased by 35.3%. | Initial circular pin-fin | |

| Radmark et al. [66] | Rectangular | ANN combined with NSGA-II | . | Initial rectangular pin-fin | |

| Sahel et al. [67] | Semi-spherical | and minimize the volume and mass | / | increased by 122.94%, and volume decreased by 76%. | Initial semi-spherical pin-fin |

| Duan et al. [68] | Circular | GCMMA | increased by 26.76%. | Initial circular pin-fin | |

| Nguyen et al. [69] | Circular | GA | increased by 20%. | Initial circular pin-fin | |

| Yang et al. [70] | Circular | Regression model | decreased by more than 1.24%. | Initial circular pin-fin | |

| Li et al. [71] | dual split-cylinder | Generalized pattern search (GPS) | increased by 210%. | Initial dual split-cylinder pin-fin | |

| Ismayilov et al. [72] | Wing-shaped | MOGA | increased by 7.3%. | Initial wing-shaped pin-fin | |

| Berber et al. [73] | Curved winglet | ANN | increased by 146.4%~211.5%. | NACA type winglet without curves |

| Authors | Optimization Objects | Optimization Algorithm | Mathematical Solution | Optimal Results | References |

|---|---|---|---|---|---|

| Yeranee et al. [77] | Minimize pressure loss | Variable density method | / | The heat transfer increased by 31.6%, 28.5%, and 34.9%. | Circular, diamond, and triangular pin-fins |

| Haertel et al. [78] | Variable density method | GCMMA | decreased by 13.6%. | Conventional channels | |

| Hu et al. [79] | as a constraint | Variable density method | MMA | decreased by 17%. | Circular pin-fins |

| Alexander et al. [80] | Variable density method | MMA | / | / | |

| Xie et al. [81] | Variable density method | GCMMA | decreased by 42.9% | Conventional channels | |

| Huang et al. [82] | Variable density method | SNOPT | decreased 9.3 °C. | Conventional channels | |

| Gilmore et al. [83] | Variable density method | SNOPT | decreased by 17%. | Conventional channels |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, T.; Zhang, X.; Chang, Z.; Xu, R.; Ma, J.; Xu, L.; Xi, L. A Review on Application of Pin-Fins in Enhancing Heat Transfer. Energies 2024, 17, 4305. https://doi.org/10.3390/en17174305

Yang T, Zhang X, Chang Z, Xu R, Ma J, Xu L, Xi L. A Review on Application of Pin-Fins in Enhancing Heat Transfer. Energies. 2024; 17(17):4305. https://doi.org/10.3390/en17174305

Chicago/Turabian StyleYang, Tao, Xiaoming Zhang, Zhenyuan Chang, Ran Xu, Jiaojiao Ma, Liang Xu, and Lei Xi. 2024. "A Review on Application of Pin-Fins in Enhancing Heat Transfer" Energies 17, no. 17: 4305. https://doi.org/10.3390/en17174305

APA StyleYang, T., Zhang, X., Chang, Z., Xu, R., Ma, J., Xu, L., & Xi, L. (2024). A Review on Application of Pin-Fins in Enhancing Heat Transfer. Energies, 17(17), 4305. https://doi.org/10.3390/en17174305