A Reduced-Order Model of a Nuclear Power Plant with Thermal Power Dispatch

Abstract

1. Introduction

2. Modeling and Integration

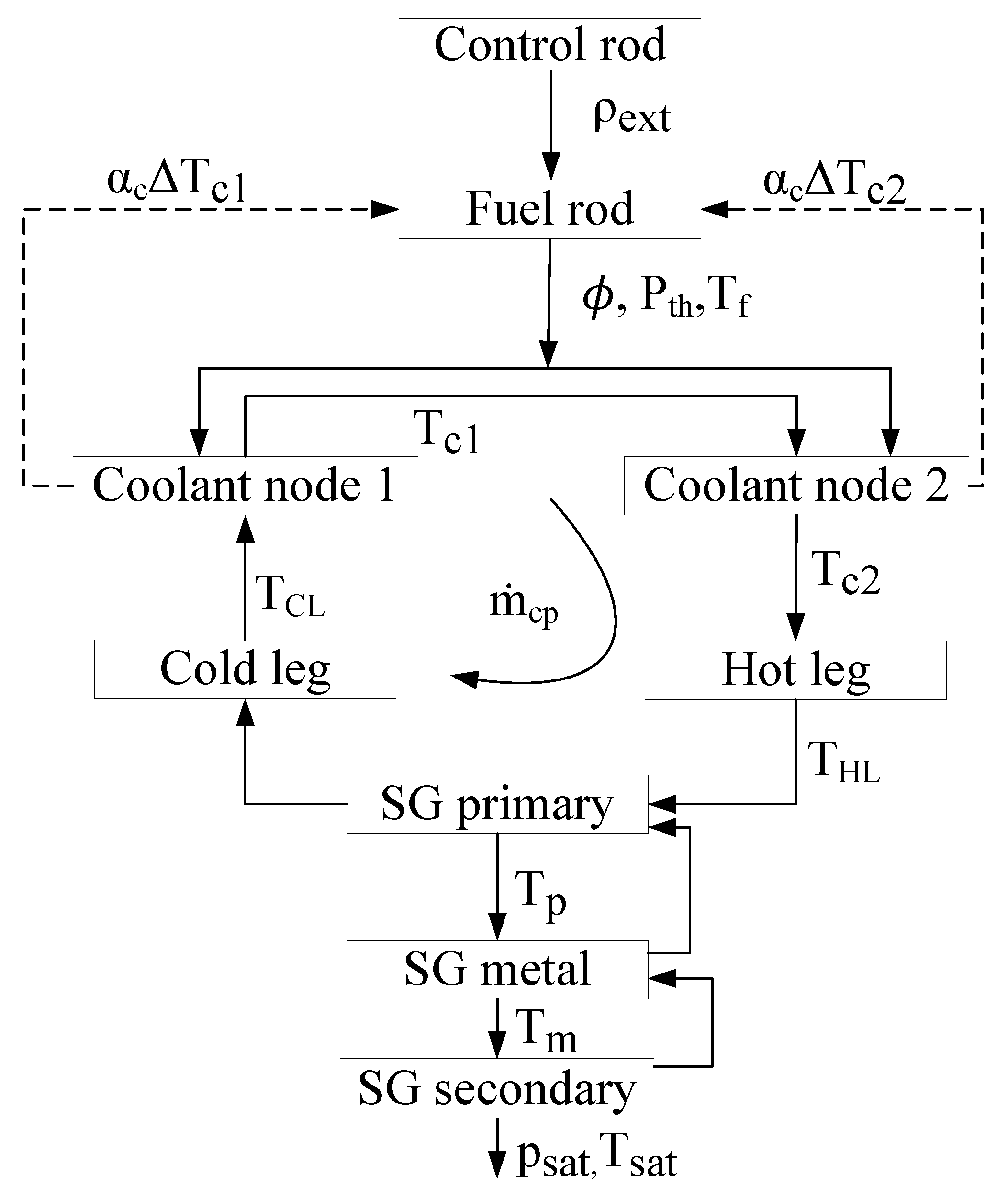

2.1. Primary Coolant System

2.2. Steam Generator

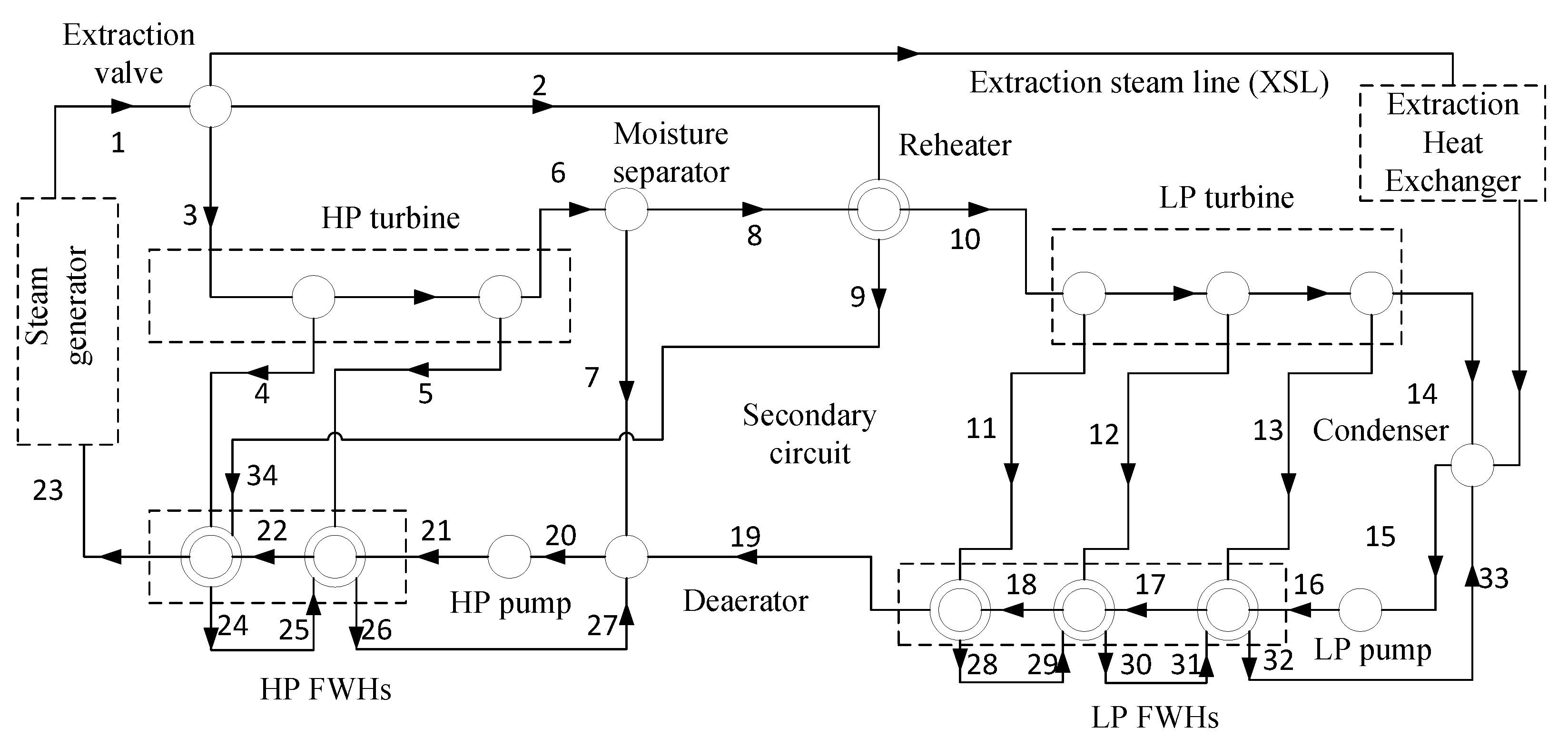

2.3. Secondary Coolant System

2.3.1. Thermodynamic State Calculation

- At steady state, steam exiting the steam generator is saturated. The same assumption was made earlier with the steam generator model, i.e., and . Considering a standard operating condition, steam pressure is known for a given reactor power level.where provides the saturated steam pressure at a given reactor thermal power.

- Changing the TPD extraction level will result in fluctuation of steam pressure at the SG outlet. To maintain the main steam at the given pressure setpoint, the feedwater control system regulates the feedwater supply to the steam generator. Therefore, the feedwater flow rate is an unknown variable that should be calculated at the given TPD extraction level.

- Pressure drop of steam across the valves is negligible. The pressure drops across the moisture separator, reheater, FWHs, feedwater lines, and deaerator are negligible.

- The heat addition in the SG, reheater, and FWHs and the heat rejection in the condenser are adiabatic processes. The pressure values at the inlets and outlets of these equipment are equal.

- Assuming the valve positions for turbine extraction and reheater lines are changed together for different TPD extraction levels, the relative flow resistances of the turbine and feedwater lines also remain the same. Thus, the ratios of flows through different lines and the ratios of pressure drops do not change. The pressure of the steam extracted from a turbine is proportional to the turbine inlet pressure.

- The LP and HP pumps are controlled to maintain their pressure output in a constant ratio with .

2.3.2. Absolute Mass Flow

2.3.3. Turbine Power Output

2.3.4. Thermal Power Dispatch

2.4. Coupled Industrial Process

2.5. Model Initialization

2.6. Model Integration and Simulation

3. Results

3.1. Secondary System Validation

3.2. Thermal Power Dispatch System Validation

3.3. Integrated Model Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Average neutron flux, per unit (pu) | |

| Delayed neutron fraction (0.007) | |

| Prompt neutron lifetime (2 × 10−5 s) | |

| C | Delayed neutron precursor concentration (pu) |

| Decay constant (0.1 s−1) | |

| Net core reactivity and external reactivity due to the control rod | |

| Fuel and moderator temperature coefficients of reactivity (−2.16 × 10−5, −1.8 × 10−4/°C) | |

| Average temperature of SG metal lump and secondary coolant lump in SG region (°C) | |

| Reactor rated power and instantaneous thermal power (Wt) | |

| Fraction of thermal power in the fuel (0.97) | |

| Mass of primary coolant in the core and SG region (kg) | |

| Mass of fuel lump and SG metal lump (kg) | |

| Mass of primary coolant in hot and cold leg plenums (kg) | |

| Mass of saturated liquid and saturated vapor in SG region (kg) | |

| Heat transfer coefficients for fuel to primary coolant, primary coolant to SG metal lump, and SG metal lump to secondary coolant, °C) | |

| Effective heat transfer area for primary coolant to SG metal lump and SG metal lump to secondary coolant (m2) | |

| Effective heat transfer area of fuel to primary coolant (m2) | |

| Average temperature of primary coolant in SG region, hot leg and cold leg (°C) | |

| Average temperature of fuel, primary coolant node 1 and primary coolant node 2 (°C) | |

| Mass flow rates of primary and secondary coolant (kg/s) | |

| , | Mass flow rates of primary coolant due to natural circulation for and respectively (kg/s) |

| Primary coolant flow rate due to foced circulation (kg/s) | |

| Specific heat capacity of fuel lump, primary coolant lump in core region, and primary coolant lump in SG ( °C) | |

| Specific heat capacity of SG metal lump, saturated liquid in secondary of SG, and saturated vapor in secondary of SG ( °C) | |

| Specific heat capacity of feedwater to the secondary of SG, °C) | |

| Internal energy of saturated liquid and vapor in SG secondary (J/kg) | |

| Difference of internal energy of saturated liquid and vapor in SG secondary (J/kg) | |

| Difference of specific volume of saturated liquid and vapor in SG secondary (J/kg) | |

| Specific volume of saturated liquid and vapor in SG secondary (m3/kg) | |

| Saturated vapor pressure at the secondary of SG (steam header) (Pa) | |

| Turbine efficiency | |

| Feedwater inlet temperature (°C) | |

| Temperature deviation of fuel rod from initial steady state (°C) | |

| Temperature deviations at coolant nodes 1 and 2 from initial steady state (°C) | |

| Pressure of fluid at secondary coolant node i (MPa) | |

| Temperature of fluid secondary coolant node i (°C) | |

| Enthalpy of fluid at secondary coolant node i (J/kg) | |

| Steam fraction of fluid at secondary coolant node i | |

| Entropy of fluid at secondary coolant node i (J/kg °C) | |

| Mass flow rate of fluid at secondary coolant node i (kg/s) | |

| Ratio of pressure at node i to steam header pressure | |

| Ratio of mass flow rate at node i to main steam flow rate | |

| , | Mechanical work produced by high-pressure and low-pressure turbines (W) |

| , | Mechanical work consumed by high-pressure and low-pressure pumps (W) |

| Total mechanical power output (W) | |

| Total heat supplied through thermal power dispatch (J) | |

| Residence times of hot and cold leg coolant lumps (s) |

Appendix A. Thermodynamic State Calculations of Secondary Coolant Circuit

Appendix A.1. Main Steam

Appendix A.2. HP Turbine

Appendix A.3. Moisture Separator and Reheater

Appendix A.4. LP Turbines

Appendix A.5. Condenser

Appendix A.6. LP Pump

Appendix A.7. LP FHWs

Appendix A.8. Deaerator

Appendix A.9. HP Pump

Appendix A.10. HP FWHs

Appendix B. Additional Thermal Power Dispatch Figures

| Secondary steam flow | |

| Steam flow to turbine | |

| Steam to thermal delivery loop | |

| Saturation temperature of secondary in the SG | |

| Feedwater temperature to SG | |

| Total power (MWe) | |

| HPT power calculated from flow and enthalpy drop (MWe) | |

| LPT power calculated form flow and enthalpy drop (MWe) | |

| Heat used by industrial process through thermal delivery loop (MWt) |

References

- Francis, M. Renewables Became the Second-Most Prevalent U.S. Electricity Source in 2020. Available online: https://www.eia.gov/todayinenergy/detail.php?id=48896 (accessed on 14 July 2024).

- U.S. Energy Information Administration (EIA). Electrical Generation from Wind; U.S. Energy Information Administration (EIA): Washington, DC, USA, 2021.

- Tyra, B.; Cassar, C.; Harrison, E.; Wong, P.; Yildiz, O. Electrical Power Monthly. February 2021. Available online: https://www.eia.gov/electricity/monthly (accessed on 14 July 2024).

- U.S. Nuclear Regulatory Commission (NRC). List of Power Reactor Units. Available online: https://www.nrc.gov/reactors/operating/list-power-reactor-units.html (accessed on 14 July 2024).

- Scott, M.; Comstock, O. Despite Closures, U.S. Nuclear Electricity Generation in 2018 Surpassed Its Previous Peak. 2019. Available online: https://www.eia.gov/todayinenergy/detail.php?id=38792 (accessed on 14 July 2024).

- Bilicic, G.; Scroggins, S. 2023 Levelized Cost of Energy+; Lazard: Hamilton, Bermuda, 2023. [Google Scholar]

- Light Water Reactor Sustainability Program. Reports. Available online: https://lwrs.inl.gov/SitePages/Reports.aspx (accessed on 14 July 2024).

- World Nuclear News. US Companies Announce Plans for Nuclear-Powered Bitcoin Mine. 2021. Available online: https://www.world-nuclear-news.org/Articles/US-companies-announce-plans-for-nuclear-powered-bi (accessed on 14 July 2024).

- Ulrich, T.; Boring, R.; Lew, R. Extrapolating Nuclear Process Control Microworld Simulation Performance Data from Novices to Experts—A Preliminary Analysis. In Advances in Human Error, Reliability, Resilience, and Performance; Boring, R.L., Ed.; Springer: Cham, Switzerland, 2019; pp. 283–291. [Google Scholar]

- John, J.S. Arizona Public Service Lays out Its Options for Reaching Zero-Carbon Energy by 2050. Green Tech Media. 30 June 2020. Available online: https://www.greentechmedia.com/articles/read/arizona-utility-aps-charts-path-to-zero-carbon-energy-by-2050 (accessed on 14 July 2024).

- Advanced Clean Energy Storage (ACES) Delta. Delivering Hydrogen, Driving Clean Energy for the Western U.S. Available online: https://aces-delta.com/about-us/ (accessed on 14 July 2024).

- World Nuclear Association. Reactor Database. Available online: https://world-nuclear.org/nuclear-reactor-database (accessed on 14 July 2024).

- Statista Research Department. Operable Nuclear Power Reactors Worldwide 2024, by Country; Statista Research Department: Hamburg, Germany, 2024. [Google Scholar]

- Statista Research Department. Number of Operable Nuclear Reactors Worldwide as of July 2024, by Reactor Type; Statista Research Department: Hamburg, Germany, 2024. [Google Scholar]

- Nuclear Energy Agency. High-Temperature Gas-Cooled Reactors and Industrial Heat Applications; Technical Report NEA No. 7629; Organisation for Economic Co-Operation and Development: Paris, France, 2022. [Google Scholar]

- González Rodríguez, D.; Brayner de Oliveira Lira, C.A.; García Hernández, C.R.; Roberto de Andrade Lima, F. Hydrogen production methods efficiency coupled to an advanced high-temperature accelerator driven system. Int. J. Hydrogen Energy 2019, 44, 1392–1408. [Google Scholar] [CrossRef]

- Poudel, B.; Joshi, K.; Gokaraju, R. A Dynamic Model of Small Modular Reactor Based Nuclear Plant for Power System Studies. IEEE Trans. Energy Convers. 2020, 35, 977–985. [Google Scholar] [CrossRef]

- Ibrahim, S.M.A.; Ibrahim, M.M.A.; Attia, S.I. The Impact of Climate Changes on the Thermal Performance of a Proposed Pressurized Water Reactor: Nuclear-Power Plant. Int. J. Nucl. Energy 2014, 2014, 793908. [Google Scholar] [CrossRef]

- Westover, T.; Hancock, S.; Shigrekar, A. Monitoring and Control Systems Technical Guidance for LWR Thermal Energy Delivery; Technical Report NL/EXT-20-57577; Idaho National Laboratory: Idaho Falls, ID, USA, 2020.

- Hancock, S.; Westover, T.; Luo, Y. Evaluation of Different Levels of Electric and Thermal Power Dispatch Using a Full-Scope PWR Simulator; Technical Report INL/EXT-21-63226; Idaho National Laboratory: Idaho Falls, ID, USA, 2020.

- Westover, T.; Brown, J.; Fidlow, H.; Gaudin, H.; Miller, J.; Miller, K.; Neimark, G.; Richards, N.; Kut, P.; Paugh, C.; et al. Light Water Reactor Sustainability (LWRS) Program Report: Preconceptual Designs of 50% and 70% Thermal Power Extraction Systems; Technical Report INL/RPT-24-77206, Rev. 0; Idaho National Laboratory: Idaho Falls, ID, USA, 2024.

- Westover, T.; Boardman, R.; Abughofah, H.; Amen, G.; Fidlow, H.; Garza, I.; Klemp, C.; Kut, P.; Rennels, C.; Ross, M.; et al. Light Water Reactor Sustainability Program Report: Preconceptual Designs of Coupled Power Delivery between a 4-Loop PWR and 100–500 MWe HTSE Plants; Technical Report INL/RPT-23-71939; Idaho National Laboratory: Idaho Falls, ID, USA, 2023.

- Kerlin, T.W.; Katz, E.M.; Thakkar, J.G.; Strange, J.E. Theoretical and Experimental Dynamic Analysis of the H. B. Robinson Nuclear Plant. Nucl. Technol. 1976, 30, 299–316. [Google Scholar] [CrossRef]

- Castagna, C.; Aufiero, M.; Lorenzi, S.; Lomonaco, G.; Cammi, A. Development of a Reduced Order Model for Fuel Burnup Analysis. Energies 2020, 13, 890. [Google Scholar] [CrossRef]

- Chersola, D.; Lomonaco, G.; Marotta, R. The VHTR and GFR and their use in innovative symbiotic fuel cycles. Prog. Nucl. Energy 2015, 83, 443–459. [Google Scholar] [CrossRef]

- Kępisty, G.; Oettingen, M.; Stanisz, P.; Cetnar, J. Statistical error propagation in HTR burnup model. Ann. Nucl. Energy 2017, 105, 355–360. [Google Scholar] [CrossRef]

- Ali, M.R.A. Lumped Parameter, State Variable Dynamic Models for Utube Recirculation Type Nuclear Steam Generators. Ph.D. Thesis, University of Tennessee, Knoxville, TN, USA, 1976. Available online: https://trace.tennessee.edu/utk_graddiss/2548/ (accessed on 14 July 2024).

- Haar, L.; Gallagher, J.; Kell, G. NBS/NRC Steam Tables: Thermodynamic and Transport Properties and Computer Programs for Vapor and Liquid States of Water in SI Units; Hemisphere Publishing Corporation: New York, NY, USA, 1984; p. 320. [Google Scholar]

- Prosser, J.H.; James, B.D.; Murphy, B.M.; Wendt, D.S.; Casteel, M.J.; Westover, T.L.; Knighton, L.T. Cost analysis of hydrogen production by high-temperature solid oxide electrolysis. Int. J. Hydrogen Energy 2024, 49, 207–227. [Google Scholar] [CrossRef]

- Ozcan, H.; Dincer, I. Thermodynamic modeling of a nuclear energy based integrated system for hydrogen production and liquefaction. Comput. Chem. Eng. 2016, 90, 234–246. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Development and assessment of a novel integrated nuclear plant for electricity and hydrogen production. Energy Convers. Manag. 2017, 134, 221–234. [Google Scholar] [CrossRef]

| Parameter | RO-SMR | RO-PWR |

|---|---|---|

| (160 MWt) | (2900 MWt) | |

| Mass of fuel lump (kg) | 11,252 | 82,000 |

| Heat transfer area of fuel to coolant (m2) | 583 | 4415 |

| Primary coolant volume (m3) | 1.879 | 160 |

| Circulation (kg/s) | Passive up to 586.86 | Active at 14,267 |

| Volume of cold loop (m3) | 26.8 | 50.76 |

| Volume of hot loop (m3) | 9.7 | 14 |

| Volume of primary coolant in the SG (m3) | 3.564 | 30.5 |

| Heat transfer area of primary to SG metal lump (m2) | 1123 | 25,272 † |

| Heat transfer area of SG metal lump to secondary (m2) | 1214 | 42,615 † |

| Secondary steam pressure (MPa) | 2.71 | 6.89 |

| Volume of SG (m3) | 13.391 | 70.08 |

| Parameter | GPWR (2900 MWt) | RO-PWR (2900 MWt) |

|---|---|---|

| Secondary pressure (MPa) | 6.89 | 6.89 |

| Primary coolant flow (kg/s) | 14,267 | 14,267 |

| Cold loop temperature (°C) | 292.3 | 285.88 |

| Hot loop temperature (°C) | 326.8 | 322.29 |

| Node | Name | T | p | h | s | x | |

|---|---|---|---|---|---|---|---|

| °C | MPa | kJ/kg | kJ/kg·°C | kg/s | |||

| 1 | gv | 289 | 7.38 | 2767 | 5.79 | 1.00 | 1652 |

| 2 | ms_reheater | 289 | 7.38 | 2767 | 5.79 | 1.00 | 176 |

| 3 | hpt | 289 | 7.38 | 2767 | 5.79 | 1.00 | 1476 |

| 4 | hpt_stg1 | 253 | 4.17 | 2685 | 5.83 | 0.93 | 157 |

| 5 | hpt_stg2 | 216 | 2.16 | 2594 | 5.89 | 0.89 | 103 |

| 6 | hpt_stg3 | 180 | 0.99 | 2492 | 5.96 | 0.86 | 1216 |

| 7 | deaerator | 180 | 0.99 | 761 | 2.14 | 0.00 | 172 |

| 8 | reheater | 180 | 0.99 | 2777 | 6.59 | 1.00 | 1044 |

| 9 | reheater_hpfwh1 | 289 | 7.38 | 1287 | 3.16 | 0.00 | 176 |

| 10 | lpt | 288 | 0.99 | 3026 | 7.08 | 1.00 | 1044 |

| 11 | lpt_stg1 | 201 | 0.39 | 2864 | 7.19 | 1.00 | 72 |

| 12 | lpt_stg2 | 113 | 0.13 | 2700 | 7.32 | 1.00 | 66 |

| 13 | lpt_stg3 | 70 | 0.03 | 2526 | 7.47 | 0.96 | 54 |

| 14 | lpt_stg4 | 33 | 0.01 | 2336 | 7.65 | 0.91 | 851 |

| 15 | cond_mix | 33 | 0.01 | 139 | 0.48 | 0.00 | 1044 |

| 16 | cpump | 33 | 0.99 | 140 | 0.48 | 0.00 | 1044 |

| 17 | lpfwh3 | 66 | 0.99 | 277 | 0.90 | 0.00 | 1044 |

| 18 | lpfwh2 | 103 | 0.99 | 431 | 1.34 | 0.00 | 1044 |

| 19 | lpfwh1 | 139 | 0.99 | 587 | 1.73 | 0.00 | 1044 |

| 20 | fwpump_suction | 164 | 0.99 | 695 | 1.99 | 0.00 | 1652 |

| 21 | fwpump | 165 | 7.38 | 702 | 1.99 | 0.00 | 1652 |

| 22 | hpfwh2 | 197 | 7.38 | 841 | 2.29 | 0.00 | 1652 |

| 23 | hpfwh1 | 234 | 7.38 | 1012 | 2.64 | 0.00 | 1652 |

| 24 | hpfwh1_stm_out | 253 | 4.17 | 1099 | 2.82 | 0.00 | 333 |

| 25 | hpfwh2_stm2 | 216 | 2.16 | 1099 | 2.84 | 0.09 | 333 |

| 26 | hpfwh2_stm_out | 216 | 2.16 | 926 | 2.48 | 0.00 | 436 |

| 27 | deaerator_hpfwh_stm | 180 | 0.99 | 926 | 2.50 | 0.08 | 436 |

| 28 | lpfwh1_stm_out | 143 | 0.39 | 602 | 1.77 | 0.00 | 72 |

| 29 | lpfwh2_stm2 | 106 | 0.13 | 602 | 1.79 | 0.07 | 72 |

| 30 | lpfwh2_stm_out | 106 | 0.13 | 446 | 1.38 | 0.00 | 138 |

| 31 | lpfwh3_stm2 | 70 | 0.03 | 446 | 1.40 | 0.07 | 138 |

| 32 | lpfwh3_stm_out | 70 | 0.03 | 292 | 0.95 | 0.00 | 193 |

| 33 | cond_fw | 33 | 0.01 | 292 | 0.98 | 0.06 | 193 |

| 34 | hpfwh1_stm2 | 253 | 4.17 | 1287 | 3.18 | 0.11 | 176 |

| Node | T | p | h | s | x | |

|---|---|---|---|---|---|---|

| 6 | 0.0% | 0.0% | 0.5% | 0.5% | 0.8% | −10.3% |

| 12 | 6.3% | 0.0% | 0.4% | 0.4% | 0.0% | 3.5% |

| 20 | −8.5% | 0.0% | −8.8% | −7.0% | 0.0% | 39.5% |

| 21 | −8.8% | 0.0% | −9.0% | −7.3% | 0.0% | 2.7% |

| 22 | −7.2% | 0.0% | −7.5% | −5.9% | 0.0% | 2.7% |

| 23 | −5.8% | 0.0% | −6.3% | −4.8% | 0.0% | 2.7% |

| 24 | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 117.5% |

| 25 | 0.0% | 0.0% | 0.0% | 0.0% | 0.2% | 117.5% |

| 26 | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 72.0% |

| 27 | 0.0% | 0.0% | 0.0% | 0.0% | 0.1% | 226.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lew, R.; Poudel, B.; Wallace, J.; Westover, T.L. A Reduced-Order Model of a Nuclear Power Plant with Thermal Power Dispatch. Energies 2024, 17, 4298. https://doi.org/10.3390/en17174298

Lew R, Poudel B, Wallace J, Westover TL. A Reduced-Order Model of a Nuclear Power Plant with Thermal Power Dispatch. Energies. 2024; 17(17):4298. https://doi.org/10.3390/en17174298

Chicago/Turabian StyleLew, Roger, Bikash Poudel, Jaron Wallace, and Tyler L. Westover. 2024. "A Reduced-Order Model of a Nuclear Power Plant with Thermal Power Dispatch" Energies 17, no. 17: 4298. https://doi.org/10.3390/en17174298

APA StyleLew, R., Poudel, B., Wallace, J., & Westover, T. L. (2024). A Reduced-Order Model of a Nuclear Power Plant with Thermal Power Dispatch. Energies, 17(17), 4298. https://doi.org/10.3390/en17174298