Heat Pipe-Based Cooling Enhancement for Photovoltaic Modules: Experimental and Numerical Investigation

Abstract

:1. Introduction

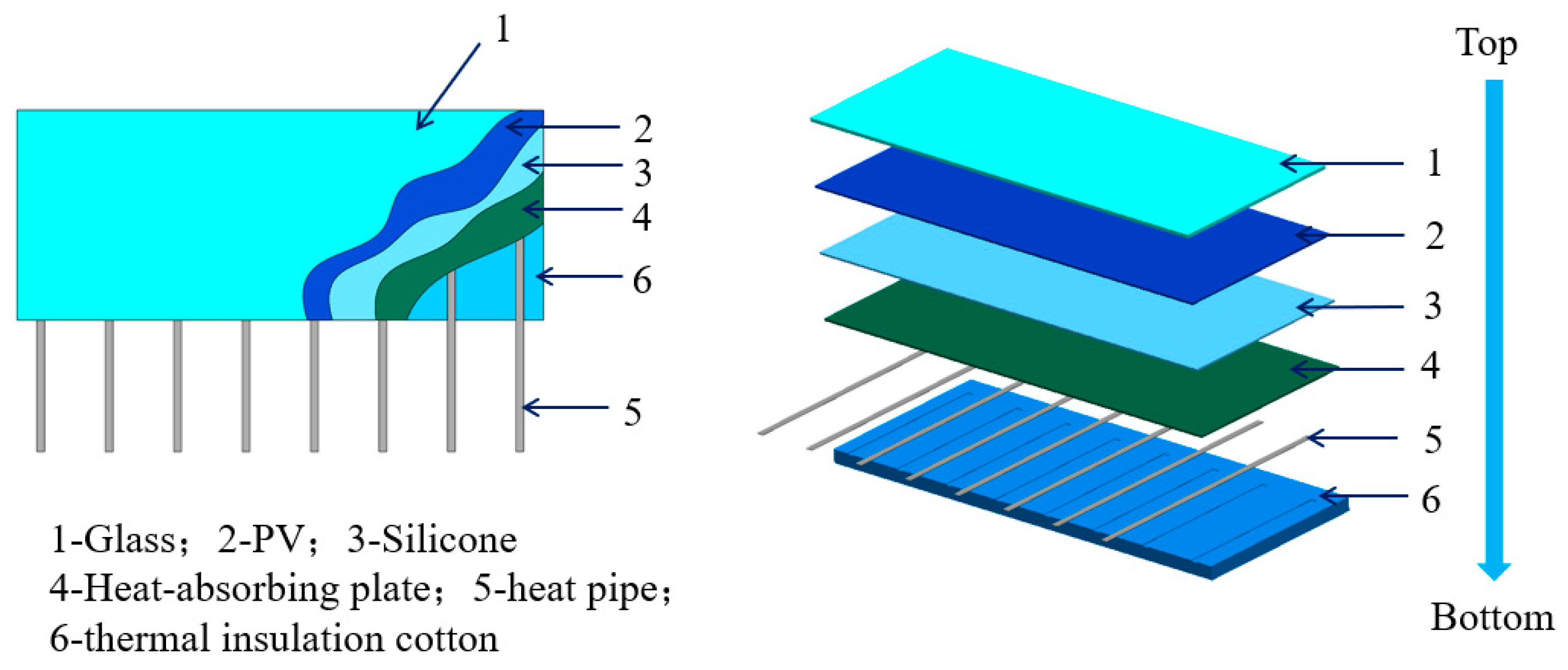

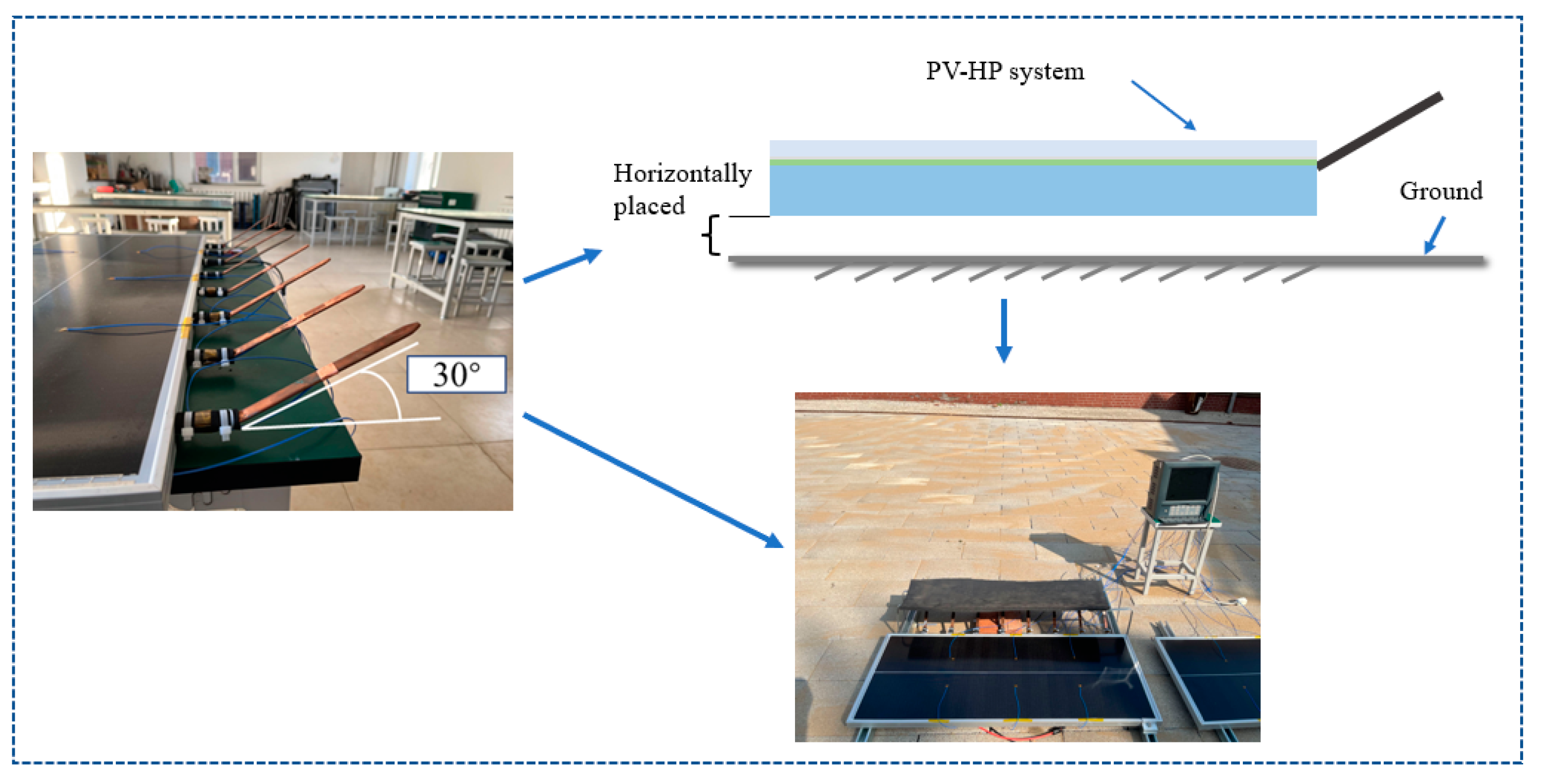

2. Experimental Setup

2.1. Experimental Setup

2.2. Experimental Results

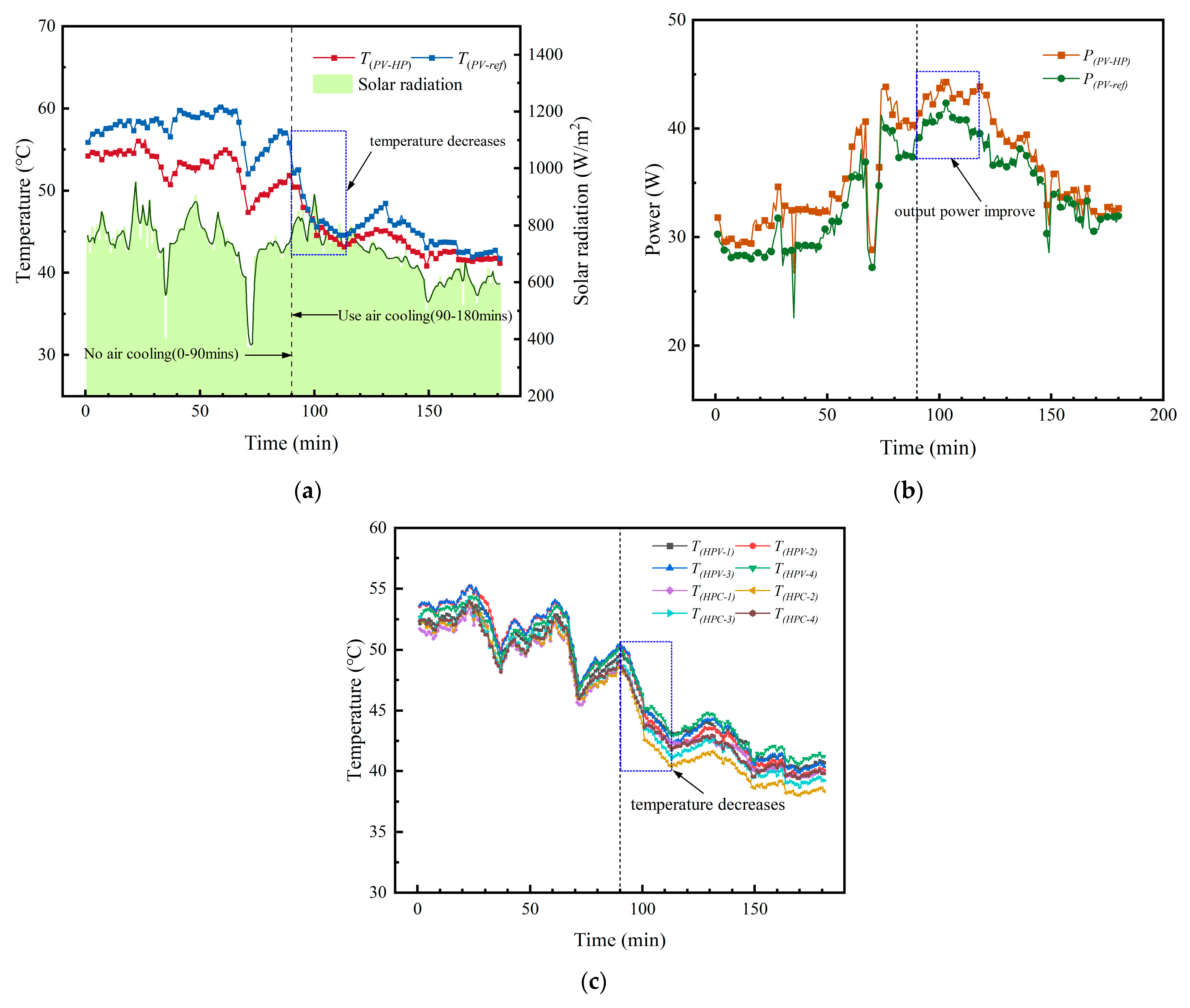

2.2.1. Performance Comparison of Experiment Results

2.2.2. Impact of Air Cooling on the Performance of the PV-HP System

2.2.3. Impact of Angle of HPC on the Performance of the PV-HP System

2.3. Analysis of Experimental Errors

3. Numerical Modeling

3.1. Mathematical Model

- Solar light incidence is perpendicular to the surface of the photovoltaic panel.

- Photovoltaic assembly considers only the glass cover and the cell layer, which are closely integrated, neglecting any contact thermal resistance.

- The aluminum frame is not considered, only the effective generating area is taken into account.

- Thermal insulation cotton provides effective insulation, and there are no additional heat losses in the system.

- Temperature distribution in the evaporation section of the heat pipe is uniform, disregarding any longitudinal heat conduction.

3.2. System Performance

3.3. Solution Methods

3.4. Validation of the Numerical Model

4. Results and Discussion

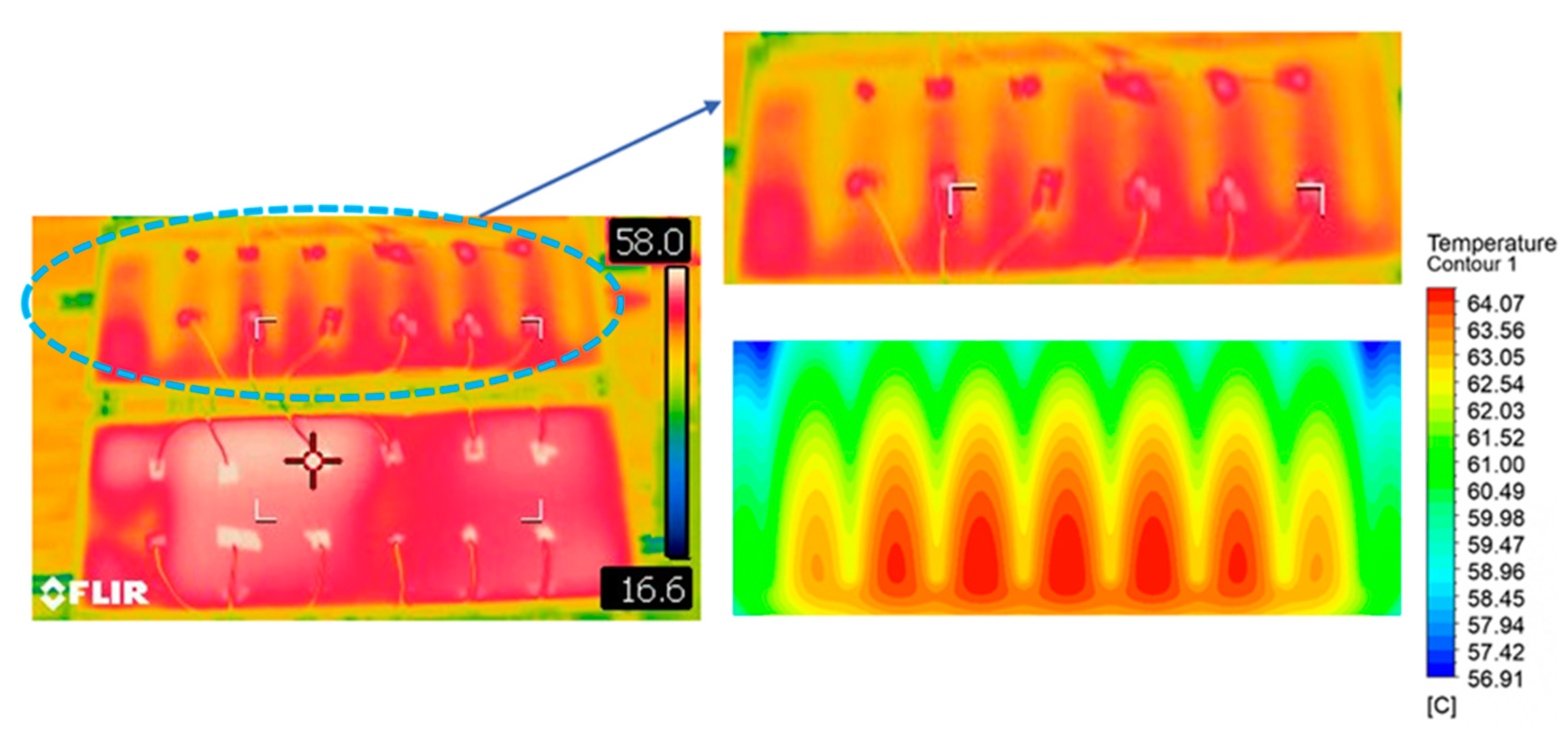

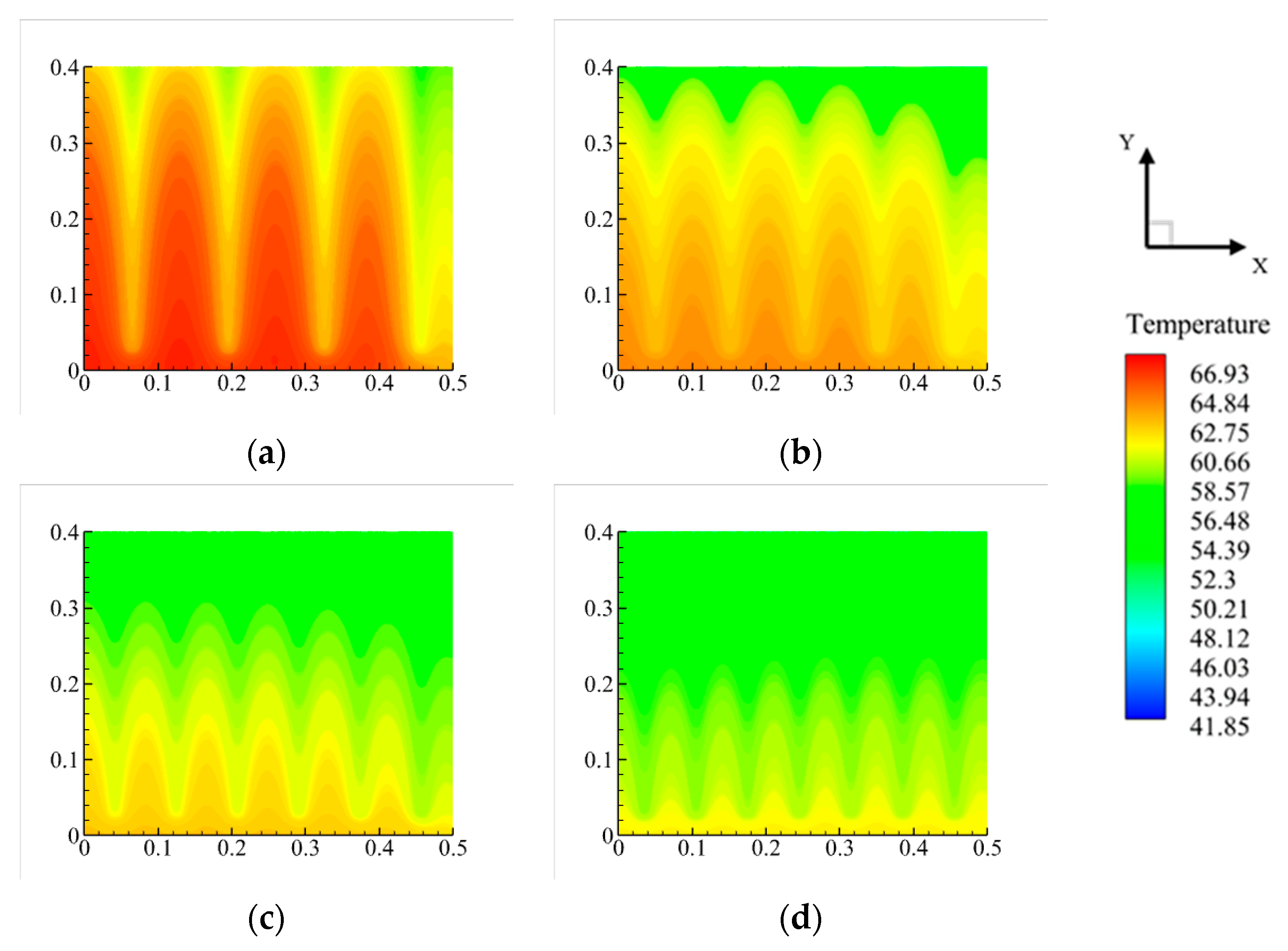

4.1. The Effect of Number of HP

4.2. Effect of Angle of Condensation

4.3. Comparative Analysis

5. Conclusions

- (1)

- The experimental findings’ performance comparison indicates that the temperature of photovoltaic cells mainly fluctuates with solar radiation intensity. The use of heat pipes effectively reduces the temperature of photovoltaic cells, with a temperature difference of 5.47 °C between the PV-HP system and the reference photovoltaic cells, representing a temperature decrease of 10.36%. The PV-HP system increases its average output power by 9.13% when compared to the reference photovoltaic cells. The findings emphasize the PV-HP system’s significant effectiveness in temperature control and efficiency improvement.

- (2)

- The performance of PV-HP with reference PV cells after adding air cooling is analyzed comparatively. When the fan was turned on for 13 min, the temperature of the PV-HP was reduced from 51.28 °C to 43.16 °C, and its power was increased by 10.15%. Furthermore, the fan’s activation reduced the average temperature difference between PV-HP and PV-ref from 4.75 °C to 1.42 °C. The air-cooling contributes positively when An(HPC) is zero.

- (3)

- The effect of the heat pipe condensing section angle of 30° on the performance of PV-HP was analyzed. The experimental results reveal that when the An(HPC) is 30°, the average surface temperature difference between the PV-HP and the PV-ref rises from 2.8 °C before the fan turns on to 3.91 °C after the fan turns on. This means that adjusting the inclination angle can help the heat be transferred more effectively.

- (4)

- The N(HP) has decreased from 8 to 4, resulting in an average temperature reduction of PV cells from 64.45 °C to 58.54 °C, while the PV efficiency has increased from 12.34% to 12.74%. Meanwhile, the An(HPC) increased from 0° to 30°, reducing the average temperature of PV cells from 65.47 °C to 61.34 °C and increasing PV efficiency from 12.27% to 12.55%. When the number of heat pipes is 14 and the inclination angle of the condensation section of the heat pipe is 30 °C, the PV-HP system achieves its maximum photovoltaic power output. However, increasing the number of heat pipes increases the cost.

- (5)

- The heat pipe can combine with other working fluids to collect and utilize the heat from PV cells. This paper did not collect heat through the condensation section of the heat pipe; future research could explore this aspect to enhance energy utilization efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | ||

| A | area | (m2) |

| c | specific heat capacity | (J/(kg·°C)) |

| E | electrical energy production | (W) |

| G | solar irradiance | (W/m2) |

| h | convective heat transfer coefficient | (W/(m2·°C) |

| I | current | (A) |

| P | electrical power output | (W) |

| R | thermal resistance | (°C/W) |

| T | temperature | (°C) |

| U | voltage (V) | (V) |

| v | wind speed | (m/s) |

| α | absorptivity | |

| ρ | density | (kg/m3) |

| η | PV electrical efficiency | (%) |

| ε | emissivity | |

| σ | thickness | (m) |

| β | the ratio of the evaporator area of the heat pipe to the area of the photovoltaic backplane | |

| λ | thermal conductivity | (W/(m·°C) |

| Abbreviation | ||

| PV | Photovoltaic | |

| PV-HP | Photovoltaic-Heat pipe | |

| PV-ref | Reference photovoltaic | |

| PV/T | Photovoltaic/Thermal | |

| PHP | Pump heat pipe | |

| BSPT | Beam-splitting photothermal system | |

| HP | Heat pipe | |

| HPC | Condensation section of heat pipe | |

| HPV | Evaporation section of heat pipe | |

| N(HP) | Number of heat pipes | |

| An(HPC) | Tilt angle of the condensation of heat pipe | |

References

- Shayan, M.E.; Najafi, G.; Ghobadian, B.; Gorjian, S.; Mamat, R.; Ghazali, M.F. Multi-microgrid optimization and energy management under boost voltage converter with Markov prediction chain and dynamic decision algorithm. Renew. Energy 2022, 201, 179–189. [Google Scholar] [CrossRef]

- Wang, Z.; Song, Z.; Yan, Y.; Liu, S.; Yang, D. Perovskite—A Perfect Top Cell for Tandem Devices to Break the S–Q Limit. Adv. Sci. 2019, 6, 1801704. [Google Scholar] [CrossRef]

- Fernández, Á.; Rosell-Mirmi, J.; Regany, D.; Vilarrubí, M.; Barrau, J.; Ibañez, M.; Rosell-Urrutia, J. Impact of DC-DC Converters on the Energy Performance of a Dense Concentrator PV Array under Nonuniform Irradiance and Temperature Profiles. Energies 2024, 17, 1235. [Google Scholar] [CrossRef]

- Raina, G.; Sinha, S.; Saini, G.; Sharma, S.; Malik, P.; Thakur, N.S. Assessment of photovoltaic power generation using fin augmented passive cooling technique for different climates. Sustain. Energy Technol. Assess. 2022, 52, 102095. [Google Scholar] [CrossRef]

- Ghadikolaei, S.S.C. Solar photovoltaic cells performance improvement by cooling technology: An overall review. Int. J. Hydrog. Energy 2021, 46, 10939–10972. [Google Scholar] [CrossRef]

- Piasecka, M.; Piasecki, A.; Dadas, N. An Experimental Investigation and Numerical Simulation of Photovoltaic Cells with Enhanced Surfaces Using the Simcenter STAR-CCM+ Software. Energies 2023, 16, 8047. [Google Scholar] [CrossRef]

- Rabie, R.; Emam, M.; Elwardany, A.; Ookawara, S.; Ahmed, M. Performance evaluation of concentrator photovoltaic systems integrated with combined passive cooling techniques. Sol. Energy 2021, 228, 447–463. [Google Scholar] [CrossRef]

- Maghrabie, H.M.; Mohamed, A.S.A.; Ahmed, M.S. Experimental Investigation of a Combined Photovoltaic Thermal System via Air Cooling for Summer Weather of Egypt. J. Therm. Sci. Eng. Appl. 2020, 12, 041022. [Google Scholar] [CrossRef]

- Özcan, Z.; Gülgün, M.; Şen, E.; Çam, N.Y.; Bilir, L. Cooling channel effect on photovoltaic panel energy generation. Sol. Energy 2021, 230, 943–953. [Google Scholar] [CrossRef]

- Nižetić, S.; Čoko, D.; Yadav, A.; Grubišić-Čabo, F. Water spray cooling technique applied on a photovoltaic panel: The performance response. Energy Convers. Manag. 2016, 108, 287–296. [Google Scholar] [CrossRef]

- Ebaid, M.S.Y.; Ghrair, A.M.; Al-Busoul, M. Experimental investigation of cooling photovoltaic (PV) panels using (TiO2) nanofluid in water -polyethylene glycol mixture and (Al2O3) nanofluid in water- cetyltrimethylammonium bromide mixture. Energy Convers. Manag. 2018, 155, 324–343. [Google Scholar] [CrossRef]

- Kandeal, A.W.; Thakur, A.K.; Elkadeem, M.R.; Elmorshedy, M.F.; Ullah, Z.; Sathyamurthy, R.; Sharshir, S.W. Photovoltaics performance improvement using different cooling methodologies: A state-of-art review. J. Clean. Prod. 2020, 273, 122772. [Google Scholar] [CrossRef]

- Ma, T.; Li, Z.; Zhao, J. Photovoltaic panel integrated with phase change materials (PV-PCM): Technology overview and materials selection. Renew. Sustain. Energy Rev. 2019, 116, 109406. [Google Scholar] [CrossRef]

- Al-Mabsali, S.A.; Chaudhry, H.N.; Gul, M.S. Numerical Investigation on Heat Pipe Spanwise Spacing to Determine Optimum Configuration for Passive Cooling of Photovoltaic Panels. Energies 2019, 12, 4635. [Google Scholar] [CrossRef]

- Gao, Y.; Wu, D.; Dai, Z.; Wang, C.; Chen, B.; Zhang, X. A comprehensive review of the current status, developments, and outlooks of heat pipe photovoltaic and photovoltaic/thermal systems. Renew. Energy 2023, 207, 539–574. [Google Scholar] [CrossRef]

- Ahmed, S.; Li, Z.; Javed, M.S.; Ma, T. A review on the integration of radiative cooling and solar energy harvesting. Mater. Today Energy 2021, 21, 100776. [Google Scholar] [CrossRef]

- Hu, T.; Kwan, T.H.; Yang, H.; Wu, L.; Liu, W.; Wang, Q.; Pei, G. Photothermal conversion potential of full-band solar spectrum based on beam splitting technology in concentrated solar thermal utilization. Energy 2023, 268, 126763. [Google Scholar] [CrossRef]

- Jiang, T.; Zou, T.; Wang, G.; Lin, J.; Duan, Y.; Peng, H.; Chen, H. Design and thermodynamic analysis of an innovative parabolic trough photovoltaic/thermal system with film-based beam splitter. Case Stud. Therm. Eng. 2023, 47, 103093. [Google Scholar] [CrossRef]

- Ma, B.-C.; Lin, H.; Zhu, Y.; Zeng, Z.; Geng, J.; Jing, D. A new Concentrated Photovoltaic Thermal-Hydrogen system with photocatalyst suspension as optical liquid filter. Renew. Energy 2022, 194, 1221–1232. [Google Scholar] [CrossRef]

- Alizadeh, H.; Nazari, M.A.; Ghasempour, R.; Shafii, M.B.; Akbarzadeh, A. Numerical analysis of photovoltaic solar panel cooling by a flat plate closed-loop pulsating heat pipe. Sol. Energy 2020, 206, 455–463. [Google Scholar] [CrossRef]

- Al-Amri, F.; Maatallah, T.S.; Al-Amri, O.F.; Ali, S.; Ali, S.; Ateeq, I.S.; Zachariah, R.; Kayed, T.S. Innovative technique for achieving uniform temperatures across solar panels using heat pipes and liquid immersion cooling in the harsh climate in the Kingdom of Saudi Arabia. Alex. Eng. J. 2022, 61, 1413–1424. [Google Scholar] [CrossRef]

- Du, Y. Advanced thermal management of a solar cell by a nano-coated heat pipe plate: A thermal assessment. Energy Convers. Manag. 2017, 134, 70–76. [Google Scholar] [CrossRef]

- Moradgholi, M.; Nowee, S.M.; Abrishamchi, I. Application of heat pipe in an experimental investigation on a novel photovoltaic/thermal (PV/T) system. Sol. Energy 2014, 107, 82–88. [Google Scholar] [CrossRef]

- Koundinya, S.; Vigneshkumar, N.; Krishnan, A.S. Experimental Study and Comparison with the Computational Study on Cooling of PV Solar Panel Using Finned Heat Pipe Technology. Mater. Today Proc. 2017, 4, 2693–2700. [Google Scholar] [CrossRef]

- Shayan, M.E.; Najafi, G.; Lorenzini, G. Phase change material mixed with chloride salt graphite foam infiltration for latent heat storage applications at higher temperatures and pressures. Int. J. Energy Environ. Eng. 2022, 13, 739–749. [Google Scholar] [CrossRef]

- Zhou, X.; Cao, X.; Leng, Z.; Zhou, X.; Liu, S. Study on the temperature control performance of photovoltaic module by a novel phase change material/heat pipe coupled thermal management system. J. Energy Storage 2023, 64, 107200. [Google Scholar] [CrossRef]

- Soliman, A.M.A.; Hassan, H. An experimental work on the performance of solar cell cooled by flat heat pipe. J. Therm. Anal. Calorim. 2021, 146, 1883–1892. [Google Scholar] [CrossRef]

- Ji, Y.; Zhou, J.; Zhao, K.; Zhang, N.; Lu, L.; Yuan, Y. A novel dual condensers heat pipe photovoltaic/thermal (PV/T) system under different climate conditions: Electrical and thermal assessment. Energy 2023, 278, 128023. [Google Scholar] [CrossRef]

- Fu, Z.; Xue, M.; Shao, Z.; Zhu, Q. Performance evaluation of a novel vacuum-tube PV/T system with inserted PV module and heat pipe. Renew. Energy 2024, 223, 120027. [Google Scholar] [CrossRef]

- Shayan, M.E.; Ghasemzadeh, F.; Rouhani, S.H. Energy storage concentrates on solar air heaters with artificial S-shaped irregularity on the absorber plate. J. Energy Storage 2023, 74, 109289. [Google Scholar] [CrossRef]

- Soliman, A.S.; Radwan, A.; Fouda, M.S.; Sultan, A.A.; Abdelrehim, O. Energy assessment of a sliding window integrated with PV cell and multiple PCMs. J. Energy Storage 2024, 86, 111341. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, J.; Wang, M.; Gao, Q. Experimental study on heat transfer and storage of a heating system coupled with solar flat heat pipe and phase change material unit. J. Energy Storage 2023, 73, 108971. [Google Scholar] [CrossRef]

- Ji, J.; He, H.; Chow, T.; Pei, G.; He, W.; Liu, K. Distributed dynamic modeling and experimental study of PV evaporator in a PV/T solar-assisted heat pump. Int. J. Heat Mass Transf. 2009, 52, 1365–1373. [Google Scholar] [CrossRef]

- Shan, F.; Tang, F.; Cao, L.; Fang, G. Comparative simulation analyses on dynamic performances of photovoltaic–thermal solar collectors with different configurations. Energy Convers. Manag. 2014, 87, 778–786. [Google Scholar] [CrossRef]

- Zhang, Q.; Cao, G.; Zhang, X. Study of wet cooling flat heat pipe for battery thermal management application. Appl. Therm. Eng. 2023, 219, 119407. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Y.; Yu, W.; Wang, T.; Zhu, T. Performance of an air-cooled photovoltaic/thermal system using micro heat pipe array. Appl. Therm. Eng. 2022, 217, 119184. [Google Scholar] [CrossRef]

- Gad, R.; Mahmoud, H.; Ookawara, S.; Hassan, H. Evaluation of thermal management of photovoltaic solar cell via hybrid cooling system of phase change material inclusion hybrid nanoparticles coupled with flat heat pipe. J. Energy Storage 2023, 57, 106185. [Google Scholar] [CrossRef]

| Component | Parameter | Value |

|---|---|---|

| PV module | Maximum power | 100 W |

| Voltage at maximum power | 17.10 V | |

| Current at maximum power | 5.85 A | |

| Size | 1080 mm × 450 mm | |

| Effective PV cell area | 0.398 m2 | |

| Heat pipe | Size | 600 mm × 15 mm × 1.5 mm |

| Condensation | 150 mm | |

| Evaporation | 400 mm | |

| Insulation | 50 mm | |

| Max heat transfer power | 60 W | |

| Average heat transfer thermal resistance | 0.07 °C/W | |

| Heat-absorbing plate | Thickness | 0.5 mm |

| Silicone | Average thickness | 0.4 mm |

| Thermal insulation cotton | Thickness | 30 mm |

| Thermal conductivity | 0.074 W/(m·°C) |

| Apparatus | Type | Measured Data | Measurement Range | Measurement Error |

|---|---|---|---|---|

| Thermocouple | ZW-K | Temperature | 0–200 °C | ±0.2 °C |

| I-V recorder | SZCW-DW-81 | Current | 0.999–9.999 A | ≤±1 mA |

| Voltage | 9.999–600 V | ≤±1 V | ||

| Radiation detector | SANPO-ST8916 | Solar radiation | 0.1–1999.9 W/m2 | ±5 W/m2 |

| Anemometer | SMART-VT110 | Wind speed | 0.15–30 m/s | ±3% |

| Data collector | MEACON-MIK-R8000D | - | - | - |

| Average Difference between T(PV-HP) and T(PV-ref) | Before Using Air Cooling | After Using Air Cooling |

|---|---|---|

| At 0° of HPCs | 4.75 °C | 1.42 °C |

| At 30° of HPCs | 2.80 °C | 3.91 °C |

| Component | Thickness (mm) | Conductivity (W/(m·°C)) | Density (kg/m3) | Specific Heat (J/(kg·°C)) |

|---|---|---|---|---|

| Glass | 3.2 | 1.15 | 2200 | 830 |

| PV | 0.5 | 168.00 | 2330 | 757 |

| Silicone | 0.4 | 2.40 | 2000 | 700 |

| Plate absorber | 0.5 | 202.40 | 2719 | 871 |

| Thermal insulation cotton | 30 | 0.074 | 2300 | 381 |

| Heat pipe | 1.5 | 9000 | 8960 | 386 |

| Parameters | Value | Unit | |

|---|---|---|---|

| Absorptivity | 0.04 | —— | |

| Glass | Emissivity | 0.85 | —— |

| Transmissivity | 0.91 | —— | |

| PV | Absorptivity | 0.9 | —— |

| Solar radiation intensity | 800 | W/m2 | |

| Ambient temperature | 26.85 | °C | |

| Wind speed | 2 | m/s | |

| Sky temperature | 7.68 | °C | |

| No. | Number of Grids | Average PV Surface Temperature (°C) | |Ni+1 − Ni| |

|---|---|---|---|

| 1 | 1,422,483 | 64.344 | - |

| 2 | 2,260,992 | 64.439 | 0.085 °C |

| 3 | 3,189,463 | 64.447 | 0.008 °C |

| 4 | 5,321,532 | 64.449 | 0.002 °C |

| 5 | 10,572,064 | 64.446 | 0.003 °C |

| Time | Average Solar Radiation (W/m2) | Average Ambient Temperature (°C) | Average Temperature (Exp) (°C) | Average Temperature (Sim) (°C) | Average Errors (%) |

|---|---|---|---|---|---|

| 10:55–11:05 | 869.46 | 30.14 | 57.32 | 62.2 | 8.56% |

| 11:25–11:35 | 687.52 | 30.11 | 45.65 | 48.77 | 6.19% |

| 11:55–12:05 | 420.15 | 30.65 | 44.15 | 46.27 | 4.87% |

| 12:25–12:35 | 852.17 | 31.46 | 53.41 | 57.76 | 8.35% |

| 12:55–13:05 | 735.55 | 31.73 | 50.68 | 52.56 | 6.57% |

| 13:25–13:35 | 668.37 | 30.97 | 50.26 | 53.72 | 6.85% |

| 13:55–14:05 | 334.08 | 30.14 | 43.02 | 44.14 | 4.70% |

| 14:25–14:35 | 404.99 | 30.08 | 43.89 | 46.16 | 5.37% |

| 14:55–15:05 | 447.37 | 29.64 | 45.32 | 47.53 | 4.46% |

| 15:25–15:35 | 398.74 | 29.12 | 44.74 | 46.98 | 5.23% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Jin, Y.; Alam, F. Heat Pipe-Based Cooling Enhancement for Photovoltaic Modules: Experimental and Numerical Investigation. Energies 2024, 17, 4272. https://doi.org/10.3390/en17174272

Ma S, Jin Y, Alam F. Heat Pipe-Based Cooling Enhancement for Photovoltaic Modules: Experimental and Numerical Investigation. Energies. 2024; 17(17):4272. https://doi.org/10.3390/en17174272

Chicago/Turabian StyleMa, Shuailing, Yingai Jin, and Firoz Alam. 2024. "Heat Pipe-Based Cooling Enhancement for Photovoltaic Modules: Experimental and Numerical Investigation" Energies 17, no. 17: 4272. https://doi.org/10.3390/en17174272

APA StyleMa, S., Jin, Y., & Alam, F. (2024). Heat Pipe-Based Cooling Enhancement for Photovoltaic Modules: Experimental and Numerical Investigation. Energies, 17(17), 4272. https://doi.org/10.3390/en17174272