Abstract

Transformers are among the most important components in the energy grid due to their missions and high costs. The challenging operating conditions deteriorate their components and shorten the life of the transformers. The health index approach is a critical and effective method for monitoring transformers in the operating environment, early diagnosis of possible malfunctions, and evaluation of their general condition. DGA, OQA, and PIF parameters, which represent the condition of the insulation materials, which mainly determine the life of transformers, constitute the basic inputs of the health index approach. In this study, a new method was proposed to determine the DGAF score based on the dissolved gases in mineral oil. With this method, in addition to the delta and rate values of the gases, the past DGA results of the transformer were also considered in determining the DGAF. In this way, faults experienced during operation are included in the health index calculation. The proposed method was tested using 36 DGA results obtained over a period of approximately 10 years from a transformer operating in the grid. The obtained results are presented in comparison with the traditional DGAF scoring method.

1. Introduction

Transformers are among the most important and valuable assets in power transmission and distribution networks [1]. The failure of transformers due to any fault causes long-term power outages that result in significant financial losses.

Under normal operating conditions, transformers can remain in operation for decades. On the other hand, the lifespan of transformers decreases due to both instantaneous faults and challenging operation conditions over long periods. To remain in operation for a long time despite harmful internal and external effects, transformers must be properly monitored, controlled, maintained, and managed [2]. In this way, it is possible to detect transformer faults at an early stage and immediately take the necessary precautions to minimize long-term energy outages and loss costs through repair and renewal [3].

Monitoring the status of transformers and their components, early diagnosis of faults, and determination of the general status are the main topics of many research studies. Thus, the health index (HI) methodology is used as a powerful tool to assess the condition of transformers [4]. HI calculation algorithms use online and offline test and measurement results applied to transformers and their components and convert the combination of these results into a quantitative index that provides an overall health index of the transformer.

The most useful information source for determining the health index value of transformers is the dissolved gas analysis (DGA) applied to the insulating oil [5]. Low- and high-degree thermal stresses encountered by transformers under operating conditions lead to the degradation of the insulating oil and cellulose-based insulation material and, as a result, to the formation of gas. The most valuable feature of the DGA approach is that it can discover incipient faults at the initial stage based on the detected dissolved gas concentrations, follow the fault development speed, verify the existence of the fault, provide information about the fault type, and offer the operator the opportunity to create a repair program [6].

Various diagnostic techniques, such as the Key Gas Method, Doernenberg Ratio, Rogers Ratio, Three Gas Ratio, Duval Triangle, Duval Pentagon, and Mansour Pentagon, which use gas quantities determined by DGA, have been reported in the literature [7]. With the help of these methods, the type of event occurring in the transformer can be predicted based on the detected gas concentrations and the ratio of these gases to each other [8]. The disadvantage of these diagnostic techniques is that transformer faults cannot be detected in cases that are outside the ratio values specified for each type of event in the applied method, thereby providing poor diagnostic accuracy. As a result of evaluating the DGA results using these methods, the faults in the transformer could be predicted in each analysis. However, since the DGA factor and HI value are calculated independently for each DGA result, it is not possible to reflect the effects of all the events experienced on the health index value. Additionally, gas delta values were not included in the evaluation in this process.

In this study, a new approach is proposed to calculate the DGA factor (DGAF), which is one of the main parameters for determining the health index of transformers. With this approach, the gas delta and rate values, which are not effective in the traditional method, are also taken into consideration. With this new approach, the validity and reliability of all the DGA results obtained throughout the operating period are also questioned, all valid and reliable results are considered, and a generalized DGAF value is determined. Thus, instead of DGAF, which is based on a single DGA result and can often be misleading, a more realistic DGAF value can be calculated by considering the effects of all the events that the transformer encounters during the examination period. The proposed approach was evaluated using the results obtained from 36 DGA tests applied to a transformer operating under operating conditions for approximately 10 years.

2. Health Indexing Using By-Fault Gases

The health index approach is an effective asset management tool that meets the needs of grid operators and industry to diagnose the health status of transformers [9]. With this approach, field and laboratory test results applied to the transformer and its components and observation-based parameters obtained from the working environment are evaluated together and converted into a quantitative value [10]. In this way, valuable information can be obtained to evaluate the damage to transformers over a long period of time under operating conditions, to identify and prioritize equipment in critical condition, and to propose a maintenance plan.

There are several health index studies in which different numbers of parameters obtained from transformers through testing and observation are evaluated as inputs. In this context, an evaluation method and software were developed in [11] to obtain a systematic and reliable method for determining the health status of transformers. The developed software calculates and continuously updates the health status of the transformer based on the tests applied to the transformer, examinations, operating history, known problems, age, and similar information. Then, [12] introduced a method that uses 20 different parameters, including tap changer and bushing conditions, transformer loading history, age, and physical observation data, in addition to DGA and oil test results. In [13], the number of parameters was increased to 24 by adding the winding ratio, leakage reactance, winding resistance, and core-ground measurement values, and the current method was improved. Studies have been conducted to evaluate the use of 27 different parameters as input in [14], 21 in [15], 19 in [16], and 17 in [17].

Although the precision of the determined HI value increases with the number of input parameters in health index calculations, it is not always possible to obtain all the expected parameters for transformers in a power grid. Many researchers and experts have aimed to create a simplified health assessment approach using the parameters deemed most important. The authors of [18] calculated the health index value with six parameters, those of [19,20] with four parameters, and those of [21,22,23,24,25] with only three parameters.

In all these studies and industry practices, DGA, oil quality, and furan compounds are commonly used as determinative parameters for determining the health status of transformers [26]. These tests provide basic parameters for the conditions of liquid and solid insulation materials that are critical for the lifespan of transformers [27]. These parameters are included in health index formulations as the DGA factor (DGAF), oil quality factor (OQF), and paper insulation factor (PIF) [22,28].

The mineral oils used in transformers are mixtures of hydrocarbon molecules. Thermal, mechanical, electrical, and environmental stresses occurring in the operating conditions of transformers cause decomposition of these molecules by breaking of carbon–hydrogen and carbon–carbon bonds. The resulting hydrogen atoms and hydrocarbon fragments recombine, depending on the conditions, to form by-fault gases. Partial discharges, low- and high-energy discharges, and thermal conditions cause the formation of different numbers of hydrocarbon gases in the oil, depending on the temperature. As a result of stray gassing and low-energy electrical discharge events such as partial discharges, hydrogen (H2) gas formation dominates. Such events cause the intensive formation of H2 and methane (CH4) gases around 150 °C. When the temperature reaches 250 °C, ethane (C2H6) concentrations increase, and when it reaches 350 °C, ethylene (C2H4) concentrations increase, and trace amounts of acetylene (C2H2) are formed. When the temperature exceeds 700 °C, a rapid increase is observed in the concentration of C2H2. C2H2 is the key gas at temperatures above 1000 °C, where high-energy discharge events occur. Additionally, oxygen (O2) and nitrogen (N2), which are classified as non-fault gases, are also released.

The DGA factor was calculated using the dissolved gas concentrations obtained by the DGA test applied to the sample taken from the insulating oil in accordance with [29]. However, DGA results alone are not sufficient to make a decision about the health status of the transformer due to the facts that (1) some pre-faults may not cause gas formation and, (2) normal operating conditions may cause gas formation.

Degradation of kraft paper and other cellulosic components used for insulation in transformers also causes contamination of the insulating oil. The presence of temperature, acidity, and moisture accelerates this process. In this process, which involves pyrolysis, hydrolysis, and oxidation, H2, CH4, CO, and CO2 are produced as well as water [30,31,32,33,34]. Pyrolysis also releases furan (2-FAL) and solid particles from the paper material, contaminating the oil [35].

In HI studies, breakdown voltage (BDV), water content, dissipation factor, interfacial tension (IFT), acidity, and color are commonly used parameters to define oil quality. These parameters were measured by physical and chemical tests. Using these parameters, the OQF was calculated and included in the HI algorithms [36].

To determine of the PIF, which represents the condition of the cellulosic components of the transformer, the 2-FAL (2-furfuraldehyde) value, measured according to [37], is used.

The presence of all these gases and furan contents significantly affects the performance of the insulation materials in the transformer structure and therefore the health of the transformer, thereby reducing its lifespan.

The DGAF and OQF values were calculated using Equations (1) and (2), respectively.

In these equations, i denotes the input parameters used to determine the DGAF and OQF values, S is the score determined for each parameter, and W is the corresponding weighting factor used for each parameter. In this method, called Weighted Score Sum (WSS), the calculation is performed using the score determined for each parameter and a weight factor expressing the importance of each parameter [38].

With the help of the determined DGAF, OQF, and PIF values, the general health index value of the transformer can be calculated as in Equation (3).

Here, i denotes each of the DGAF, OQF, and PIF parameters, and S and W are the values determined for each parameter and the weighting factor for that parameter, respectively. The weighting factors for these parameters were commonly set to 10, 8, and 6, respectively [12,39].

In previous studies in the literature, the parameters of the transformer and the on-load tap changer (LTC) were calculated independently. In this case, the general health index is calculated as in Equation (4).

Here, A and B are the weighting factors used for the transformer and LTC and are considered as 60% and 40%, respectively, according to the CIGRE survey [40]. n and m are the total number of inputs used in calculating the DGAF, OQF, and PIF values of the transformer and the DGAF and OQF values of the LTC, respectively.

Although calculated health index values are also expressed in the ranges of 0–1 [14,17], 1–4 [41,42], 1–5 [21], 0–10 [43], 1–10 [44] in different studies in the literature, the most common representation is between 0 and 100 [4,12,13,15,19,25,45,46,47]. According to this ranging, if the HI value is determined to be in the range of 70–100 points, it can be concluded that the transformer is in good condition and can remain in operating conditions by applying normal maintenance processes. If the health index value is calculated within the range of 30–70 points, it is recommended to monitor the transformer by applying diagnostic tests and conducting renewal plans. In cases below 30 points, the transformer should be renewed or replaced immediately [13].

3. Conventional DGA Scoring Method

The formation of combustible and non-combustible gases is a routine process during the operation of transformers in power grids. However, abnormal increases in the concentrations of these gases are indicators of malfunctions experienced by or likely to occur in transformers, and require detailed investigation. Therefore, the DGAF is one of the parameters that has the highest weighting factor for the calculation of the health index [26]. The recommended alarm levels of hydrocarbon gases from different sources including IEEE, IEC, Dorenburg, and the Bureau of Reclamation (BoR), are given in Table 1 [12].

Table 1.

The recommended alarm levels of hydrocarbon gases.

In many studies in the literature, the classification given in [46] was accepted when evaluating the condition of a transformer based on gas concentrations. Here, the risks caused by gas formation are classified into four conditional categories, depending on both the measured concentration of each gas and the total amount of dissolved combustible gas (TDCG). The measured concentrations of six gases, except CO2, were used to calculate the TDCG volume. The classification and concentration limits determined for each category are given in Table 2.

Table 2.

Conditional classification of gas concentrations [46].

To achieve effective transformer management, the recommended actions for monitoring and condition assessment, based on the TDCG volume are specified in [46].

According to this,

- -

- A TDCG below the limit of Cond-1 indicates that the transformer is operating satisfactorily. If any of the combustible gases exceeds its own limit then additional investigation should be conducted.

- -

- A TDCG within the Cond-2 range is greater than the normal combustible gas level. If any of the combustible gases exceeds the specified level, additional investigation should be prompted, and the daily gas rate should be evaluated by increasing the sampling frequency.

- -

- A TDCG within the Cond-3 range indicates high decomposition. If any of the combustible gases exceeds the specified level, additional investigation should be prompted, and the daily gas rate should be evaluated by increasing the sampling frequency.

- -

- TDCG values exceeding this value indicate excessive decomposition. In this condition, it is recommended that increasing surveillance, evaluating the daily gas increasing rate, and actions including removing the unit from service are performed, considering continued operation could result in the failure of the transformer.

To evaluate the individual gas concentrations obtained by DGA in transformers, a six-level scoring is recommended in [25,28,47].

The recommended minimum alarm levels given by IEC and IEEE in Table 1 are considered as the limit values for the category, which are scored as 1 in Table 3.

Table 3.

Scoring rules of hydrocarbon gases.

The conventional health index calculation is based on this scoring, and Equation (1) is used to determine the DGA factor of the transformer. In this equation, the score for each gas is considered on a scale of one to six, which corresponds to the scoring given in Table 3. The weighting factors for the individual gases were set as 1 for CO and CO2, 2 for H2, 3 for CH4, C2H4, and C2H6, and 5 for C2H2 [13].

The conditional classification explained above is becoming an effective indicator when deciding on a transformer, including the scheduling and content of maintenance studies, and even considering whether the transformer is withdrawn from operation. On the other hand, the DGAF value calculated according to the scoring given in Table 3 does not directly express the health of the transformer but is another indicator because it reflects the condition of the mineral oil. At this point, the differences between the classifications in Table 2 and Table 3 and the lower and upper concentration limits of these classes may cause differences in transformer evaluation and the determination of necessary actions.

Comparing Table 2 and Table 3, the limit values of Cond-1, which show the normal status in Table 2, and the category scored as 1 in Table 3, are the same, except for the CH4 and C2H2 gases. However, gas concentrations below the Cond-1 limit specified as 120 ppm for CH4 in Table 2 could be scored as 1 or 2, as shown in Table 3. Similarly, for C2H2, concentrations below the limit value given as 3 ppm in Table 3 can be evaluated as Cond-1 or Cond-2 according to Table 2.

Differences in categories and corresponding limit values between these tables are observed for all gases, depending on their concentrations. These differences affect the final evaluation of the transformer. To eliminate these differences, it is anticipated that it would be beneficial to apply a new method based on conditional classification rather than the scoring shown in Table 3.

4. Proposed DGA Scoring Method

In the conventional health index approach, the condition of the transformer at the oil sampling time is calculated depending on the gas concentrations obtained from DGA and the other inputs explained in previous sections. The DGAF and HI values are separately calculated for each DGA result. In this approach, gas delta or rate values are not considered in the calculations.

Based on the gas concentrations determined by DGA and the ratios of these gases to each other, the type of fault that causes gas formation in transformers can be predicted using well-explained diagnostic methods in the literature. However, using these methods, which evaluate a single oil sample analysis result, issues such as the time of fault occurrence, whether more than one number of faults have occurred, and whether the fault is still active, cannot be clearly determined. For this reason, using gas concentrations determined from a single analysis often does not yield realistic HI results. The evaluation of the general condition of the transformer oil is essentially based on the TDGC value. Gas increase rates are only considered in the process of determining the action to be taken regarding the transformer.

To eliminate these drawbacks, the DGA results of all samples taken from the examined transformer within a certain time should be taken into consideration. In addition to the detected gas quantities, the delta and rate values should be evaluated in the interpretation process of the transformer.

The proposed DGA scoring method in this study was based on [48]. Compared to [46],

- -

- The previously used four conditions (four-level criterion) based on gas concentrations were reduced to three DGA status;

- -

- Acceptable limits of gases were defined individually by considering the O2/N2 rates and transformer age;

- -

- TCG and TDCG interpretations were removed;

- -

- Delta and rate tables were introduced;

- -

- A new interpretation procedure is proposed within this document.

The method used to determine the status can be summarized as follows.

- -

- If the measured gas concentrations are below the 90th percentile limit value specified in the standard, and all calculated delta and rate values are below the limits specified for them, this situation is labeled as Status-1.

- -

- If one of these conditions is not met, the gas concentration and rate values are decisive. It is checked whether any gas concentration exceeds the 95th percentile limit value in the standard and whether the rate value exceeds the limit value determined for it. If one of these two parameters is greater than the limit value, this situation is labeled as Status-3, otherwise it is labeled as Status-2.

According to the situational classification created based on all these regulations and the diagnostic algorithm, the following can be concluded:

- -

- Status-1 indicates the presence of low gas levels and no indication of gassing. In this status, it is recommended to continue the routine DGA and other oil tests of the transformer and continue its normal operation,

- -

- Status-2 indicates intermediate gas levels and/or possible gassing. In this status, investigation of possible causes of gas generation is recommended. In addition, an increase in the oil sampling frequency is recommended.

- -

- Status-3 indicates high gas levels and/or probable active gassing. In this status, it is also recommended to investigate the possible causes of active gassing using DGA interpretation techniques and apply additional tests. In addition, online dissolved gas monitoring and consulting with a manufacturer or transformer expert are recommended.

In this study, the conventional DGAF calculation method was modified based on this three-level situational classification.

The proposed method calculates the DGAF value by considering all reliable and consistent results of the DGAs. Possible gassing and probable active gassing, as highlighted in [48], were also included in the evaluation process.

In addition, the accuracy of the evaluation was increased by eliminating inconsistent results obtained due to reasons such as incorrectly taking the oil sample and contamination from the evaluation process.

Accordingly, in the first step, the validity of the DGA results was tested by examining the gas concentrations. For this purpose, the current concentration of each gas was compared with previous values, and the presence of any unusual changes. When a gas concentration is predicted to be unusual, a confirmation test is performed. If the change cannot be confirmed, then the test result is predicted to be unsafe and excluded from the evaluation.

The gas delta value for each gas is calculated as the difference between two consecutive DGAs, as expressed in Equation (5).

Here, v is the measured gas concentration in µL/L, i is the gas type, and j is the sample number analyzed during the evaluation period.

The rate is the constant gas generation over a certain period, which is computed by the linear best fit from three to six consecutive DGAs covering a period of 4–24 months, in µL/L/year.

Then, based on the gas concentrations, the delta and rate values were calculated using all reliable and consistent DGA measurement results, and the initial condition score (ICS) was obtained for each gas as 1, 2, or 3.

The generalized condition score (GCS), which expresses the cumulative condition of each gas during the evaluation period, is calculated as in Equation (6).

In this equation, i is gas type, j is the sample number analyzed during the evaluation period, ICS is the initial condition score calculated for each sample, and t is the sampling time (day).

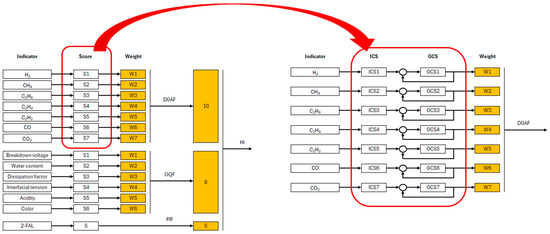

The principal diagram of this proposed approach is shown in Figure 1. The DGAF, which is used to calculate the general HI value of the transformer, is calculated as in Equation (1), using the GCS obtained for each gas and the weight coefficient of this gas.

Figure 1.

Principal diagram of the proposed approach for the calculation of the DGAF.

5. Comparison of Conventional and Proposed DGAF Scoring Methods

In this study, to evaluate the proposed DGAF calculation method, the results of 36 DGA tests applied to a 16-year-old power transformer with a power of 250 MVA and a voltage level of 380 kV/158 kV, which is still operating in a power grid, over the last 3616 days were used.

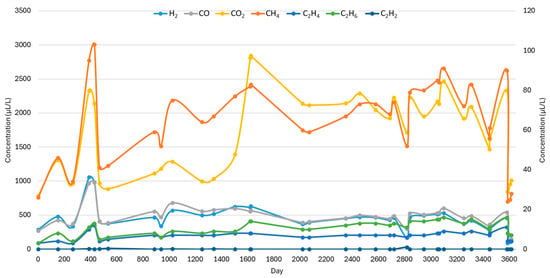

Oil samples taken from the transformer by the operator for a period of approximately 10 years were analyzed in a laboratory environment. Oil samples were collected in accordance with the methods specified in the version of the IEC 60475 standard [29] that was valid at the time of collection. Gas concentrations obtained from these DGAs for H2, CH4, C2H6, C2H4, C2H2, CO, and CO2 gases over time are given in Figure 2.

Figure 2.

Gas concentrations vs. sampling day, obtained from DGAs.

Here, the left-hand axis shows the gas concentrations obtained for H2, CO, and CO2 gases, and the right-hand axis shows the gas concentrations obtained for CH4, C2H6, C2H4, and C2H2 gases, in µL/L. In addition to these gases, the amounts of O2 and N2 gases were determined by DGA and were considered in the DGAF scoring method proposed in this study.

Gas concentrations were evaluated using the Duval Triangle and Duval Pentagon, which are well-known diagnostic methods. The obtained results indicate that T1 + S (T1: thermal fault < 300 °C, S: stray gassing of oil, <200 °C) according to the Duval Triangle 1 and Duval Triangle 4, and S (S: stray gassing of mineral) according to the Duval Pentagon indicate an oil event occurred in the transformer.

Comparing the conventional DGAF scoring method with the proposed one in this study, a condition assessment was firstly performed according to [46], based on the DGA results.

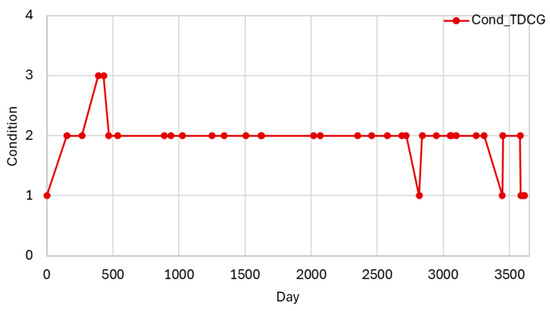

Depending on the minimum and maximum limits listed in Table 2, the conditional classification of the TDCG concentration vs. sampling day is shown in Figure 3.

Figure 3.

Conditional classification of TDCG vs. sampling day.

Accordingly, the total amount of combustible gas in almost all of the 36 DGA measurements was within the limit values determined under Cond-2 (721–1920 ppm). During the 3616-day period, the TDCG amount was in the range classified as Cond-3 twice for short periods and Cond-1 four times. Cond-2 requires the transformer to be observed and the daily gas increase to be determined and evaluated by increasing the gas sampling frequency.

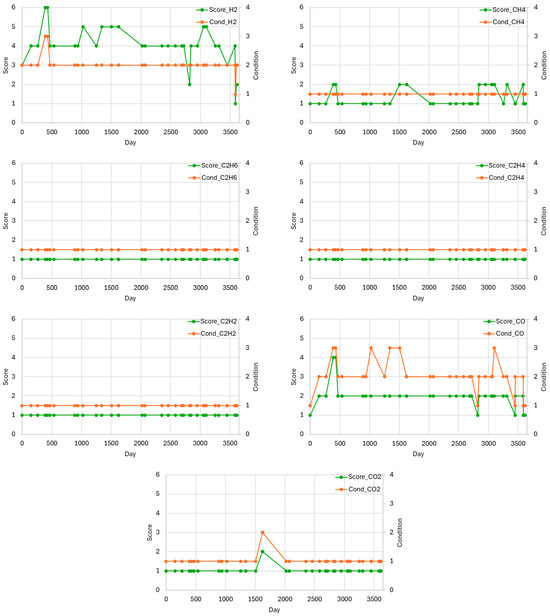

Depending on the minimum and maximum limit values given in Table 2 and Table 3, the conditional categories determined for each gas and the changes in the condition scores are given in Figure 4.

Figure 4.

Score and condition values for each gas vs. sampling day for the conventional scoring approach.

It was observed that the conditional categories of H2, CO2, and CO gases changed depending on the DGA results over time. For H2, the gas concentrations on days 389 and 430 were classified as Cond-3, and the gas concentration on day 3587 was classified as Cond-1. For CO, the gas concentrations were mostly classified as Cond-2, but six times were determined as Cond-3 and four times as Cond-1. Similarly, the concentration of CO2 gas was classified once as Cond-2 on the 1624th day and as Cond-1 throughout the remaining period.

It was observed that CH4, C2H6, C2H4, and C2H2 gases were classified as Cond-1 the entire examination period.

Although the changes in gas concentrations affect the conditional category of that gas to a limited extent, they are observed to change the instantaneous scores used in the calculation of the DGAF value to a greater extent. For example, according to the DGA result of the examined transformer on the 389th day, H2 gas, which was determined as 1056 ppm, was in the sixth category, representing the worst case according to Table 3, but was classified only as Cond-3 in the four-scale representation given in Table 2. The differences between the limit values of categories given in Table 2 and Table 3 are the main reason for this situation.

Similar differences, although to a more limited extent, were also observed in the evaluations of CH4 and CO gases. In some measurements during the review period, it was observed that the concentration of CH4 gas scored as two points was not sufficient to change the conditional category determined as Cond-1 for this gas.

Small changes in the concentration of CO gas measured according to four separate DGA results between the 1026th and the 1505th days did not change the score of this gas but moved the conditional category value from Cond-2 to Cond-3. It was determined that the measured values for other gas types remained constant at a level that did not cause any differences between the categories listed in Table 2 and Table 3.

According to the proposed approach in this study, the method described in [48] can be considered as a reference for determining the DGAF value. In this context, the reliability and consistency of the measurements were first questioned by examining the changes in the concentration of each gas in the 36 available DGA results. For abnormal changes, the consecutive DGA test was considered confirmation test. As a result, the DGA test performed on the 2818th day was not found to be reliable and consistent because it could not be confirmed with the consecutive test and was excluded from the evaluation.

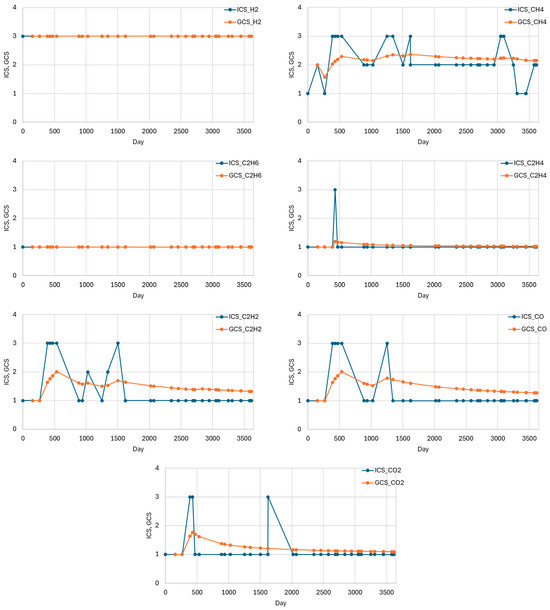

Considering the O2/N2 ratio and the age of the transformer, the limit values for each gas were determined according to [48], and the delta and rate values were also calculated. Depending on these values, the conditional categories determined for the gases and the GCSs vs. time calculated using Equation (6) are given in Figure 5.

Figure 5.

ICS and GCS values of each gas vs. sampling day for the proposed scoring approach.

When the H2 results were examined, the gas concentrations were above the limit values determined depending on the O2/N2 ratio and the age of the transformer throughout the entire measurement period. In addition, the delta and rate values calculated for consecutive measurements were above the limit values determined for them during a great part of the measurement period. Therefore, both the GCS and ICS for H2 gas were determined as three throughout the measurement period.

On the other hand, since both the measured gas concentrations and the calculated delta and rate values for C2H6 were below the limits determined for this gas, the ICS value and GCS were calculated as one throughout the measurement period.

For other gases, the gas concentrations and/or delta and rate values obtained during the measurement period changed, and this change also affected the ICS of the relevant gas. These changes in the ICS of each gas directly affected the GCS of that gas. An increase in the ICS of gas puts the GCS in an increasing trend. Based on subsequent DGA results, if the ICS value is determined to maintain its high value, an increasing trend in GCS continues. This increase will cause the HI value of the transformer, which is calculated based on this value, to gradually decrease.

According to the following DGA results, a decrease in the ICS of a gas causes the GCS to decrease. If new faults that will cause gas formation in the transformer and therefore increase the ICS does not occur, the GCS’s decreasing trend continues.

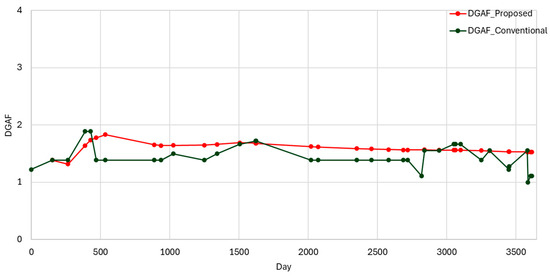

The changes over time in the DGAF values calculated according to the conventional and proposed scoring methods are presented in Figure 6.

Figure 6.

Calculated DGAF scores using the conventional and proposed scoring approaches.

DGAF scores calculated using the conventional method vary between 1000 and 1889. These scores, which are calculated independently for each DGA test, do not include the effects of delta and rate values, making it difficult to obtain a clear and precise evaluation of the health status of transformer oil. In addition, the presence of non-consistent results increased the error rate. The HI assessment to be performed after each DGA using these scores leads to misleading conclusions about the general health status of transformers because it does not include the effects of previous events.

On the other hand, the DGAF score calculated using the proposed method in this study ranged from 1.318 to 1.834. Here, in addition to the measured gas concentrations, delta and rate values were also included in the evaluation process. In addition, test results that were not valid or reliable were excluded from the evaluation. The calculated GCS for each gas is a score determined for the entire inspection period of the transformer up to that point. In this way, the effects of short-term events that cause an increase in gas and are not repeated afterwards on the HI value are limited. However, although it has already been eliminated, the effects of past events on the DGAF value are still being evaluated.

For example, in four DGA tests conducted between the 389th and 536th days, increases in the amounts of CH4, C2H4, C2H2, CO, and CO2 gases caused the GCS calculated for these gases to increase. This condition caused the DGAF score to increase rapidly in this range, depending on the weight of the gases. As of day 1505, there was no increase in the ICSs of C2H6, C2H4, and C2H2, especially those with high weight values. This condition causes the DGAF score to decrease.

However, unlike the conditional DGAF calculation method, the proposed method calculates the DGAF score using the effects of the events encountered during the entire investigation period, thus making it possible to determine a more realistic HI value.

In addition, all the DGA measurements taken during the 10-year investigation period indicate that the partial discharge phenomenon in the transformer is continuous. Despite this, it can be seen that the DGAF calculated by the conventional method exhibits a fluctuating course and occasionally falls below one point. The proposed method reduces the possibility of unrealistic evaluations by preventing sudden or rapid decreases in the DGAF change.

6. Results and Discussion

Transformers are critical and expensive assets in a power grid. The health index approach is a reliable management tool to protect these assets and avoid economic, environmental, and human negative effects caused by malfunctions. It is possible to ensure reliable and sustainable operation of transformers through condition assessment based on the health index.

The DGA results for the insulating oil are used to detect the types of failures in transformers and provide the most valuable data for the transformer health index methodology.

In this study, a new approach is proposed to evaluate the DGA parameter within the health index methodology. With this approach, in addition to the gas concentrations obtained by DGA, delta and rate values are also taken into account when calculating the DGA factor. In addition, the accuracy of the calculated health index was increased by excluding unreliable DGA results.

In the proposed approach, instead of performing an independent evaluation for each DGA result, all DGA results obtained during the examination period of the transformer are included in the evaluation process, and a separate generalized condition score is calculated for each gas. Thus, all events that cause gas formation during the operation period affect the generalized condition score and are included in the HI calculation.

In addition, faults that occur in the transformer for a short time and cause gas formation but are not repeated have a high impact on the DGAF and HI values of the transformer, and misleading evaluations about the condition of the transformer are prevented.

To compare the proposed method with the traditional method, gas concentrations obtained by 36 separate DGAs applied to a transformer over a period of approximately 10 years were used. Although the evaluation of the DGAF values obtained by the traditional method varies considerably during the examination period, depending on the instantaneous DGA results, the proposed method provides a much more stable result.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Ward, S.A.; El-Faraskoury, A.; Badawi, M.; Ibrahim, S.A.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M.F. Towards Precise Interpretation of Oil Transformers via Novel Combined Techniques Based on DGA and Partial Discharge Sensors. Sensors 2021, 21, 2223. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Vandermaar, A.J.; Srivastava, K.D. Review of Condition Assessment of Power Transformers in Service. IEEE Electr. Insul. Mag. 2002, 18, 12–25. [Google Scholar] [CrossRef]

- Vite, V.; Fotis, G.; Chobanov, V.; Pavlatos, C.; Mladenov, V. Predictive Maintenance for Distribution System Operators in Increasing Transformers’ Reliability. Electronics 2023, 12, 1356. [Google Scholar] [CrossRef]

- Hjartarson, T.; Otal, S. Predicting Future Asset Condition Based on Current Health Index and Maintenance Level. In Proceedings of the IEEE 11th International Conference on Transmission and Distribution Construction, Operation and Live-Line Maintenance (ESMO), Albuquerque, NM, USA, 15–19 October 2006. [Google Scholar]

- De Faria, H.; Costa, J.G.S.; Olivas, J.L.M. A review of monitoring methods for predictive maintenance of electric power transformers based on dissolved gas analysis. Renew. Sustain. Energy Rev. 2015, 46, 201–209. [Google Scholar] [CrossRef]

- Bustamante, S.; Manana, M.; Arroyo, A.; Castro, P.; Laso, A.; Martinez, R. Dissolved Gas Analysis Equipment for Online Monitoring of Transformer Oil: A Review. Sensors 2019, 19, 4057. [Google Scholar] [CrossRef] [PubMed]

- Bustamante, S.; Manana, M.; Arroyo, A.; Laso, A.; Martinez, R. Evolution of graphical methods for the identification of insulation faults in oil-immersed power transformers: A review. Renew. Sustain. Energy Rev. 2024, 199, 114473. [Google Scholar] [CrossRef]

- IEC 60599:2022; Mineral Oil-Filled Electrical Equipment In Service—Guidance on the Interpretation of Dissolved and Free Gases Analysis. International Electrotechnical Commission: Geneva, Switzerland, 2022.

- Islam, M.M.; Lee, G.; Hettiwatte, S.N. Application of a general regression neural network for health index calculation of power transformers. Int. J. Electr. Power Energy Syst. 2017, 93, 308–315. [Google Scholar] [CrossRef]

- Aman, T.A.; Mokhtar, A.S.; AizamTalib, M. Assessment the overall health condition of transformer using health index and critical index approach: TNB grid case study. In Proceedings of the IEEE International Conference on Power and Energy (PECon), Penang, Malaysia, 7–8 December 2020. [Google Scholar]

- Dominelli, N.; Lau, M.; Olan, D.; Newell, J. Equipment Health Rating of Power Transformers. In Proceedings of the IEEE International Symposium on Electrical Insulation, Indianapolis, IN, USA, 19–22 September 2004. [Google Scholar]

- Naderian, A.; Cress, S.; Piercy, R.; Wang, F.; Service, J. An approach to determine the health index of power transformers. In Proceedings of the Conference Record of the 2008 IEEE International Symposium on Electrical Insulation, Vancouver, BC, Canada, 8–11 June 2008. [Google Scholar]

- Jahromi, A.N.; Piercy, R.; Cress, S.; Service, J.R.R.; Fan, W. An Approach to Power Transformer Asset Management Using Health Index. IEEE Electr. Insul. Mag. 2009, 25, 20–34. [Google Scholar] [CrossRef]

- Gorgan, B.; Notingher, P.V.; Badicu, L.V.; Tanasescu, G. Calculation of Power Transformers Health Indexes. Ann. Univ. Craiova Electr. Eng. Ser. 2010, 34, 13–18. [Google Scholar]

- Haema, J.; Phadungthin, R. Development of Condition Evaluation for Power Transformer Maintenance. In Proceedings of the 4th International Conference on Power Engineering, Energy and Electrical Drives, Istanbul, Turkey, 13–17 May 2013. [Google Scholar]

- Martins, M.A. Condition and risk assessment of power transformers: A general approach to calculate a Health Index. Cienc. Tecnol. Dos Mater. 2014, 26, 9–16. [Google Scholar] [CrossRef]

- Tanasescu, G.; Notingher, P.V.; Dragomir, O.; Gorgan, B.; Voinescu, L. Health index calculation of electrical equipments using DiagConsole software. In Proceedings of the 8th International Symposium on Advanced Topics in Electrical Engineering, Bucharest, Romania, 23–25 May 2013. [Google Scholar]

- Malik, H.; Azeem, A.; Jarial, R.K. Application research based on modern technology for transformer health index estimation. In Proceedings of the International Multi-Conference on Systems, Signals and Devices, Chemnizt, Germany, 22–23 March 2012. [Google Scholar]

- Nelson, A.A.; Jaiswal, G.C.; Ballal, M.S.; Tatakne, D.R. Remote Condition Monitoring System for Distribution Transformer. In Proceedings of the 18th National Power System Conference, Guwahati, India, 18–20 December 2014. [Google Scholar]

- En-Wen, L.; Bin, S. Transformer Health Status Evaluation Model Based on Multi-feature Factors. In Proceedings of the International Conference on Power System Technology, Chengdu, China, 20–22 October 2014. [Google Scholar]

- Ashkezari, A.D.; Ma, H.; Saha, T.K.; Ekanayake, C. Application of Fuzzy Support Vector Machine for Determining the Health Index of the Insulation System of In-service Power Transformers. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 965–973. [Google Scholar] [CrossRef]

- Ghonheim, S.S.M.; Taha, I.B.M. Comparative Study of Full and Reduced Feature Scenarios for Health Index Computation of Power Transformers. IEEE Access 2020, 8, 181326. [Google Scholar] [CrossRef]

- Tamma, W.R.; Prasojo, R.A.; Suwarno, S. Assessment of High Voltage Power Transformer Aging Condition Based on Health Index Value Considering Its Apparent and Actual Age. In Proceedings of the International Conference on Information Technology and Electrical Engineering, Yogyakarta, Indonesia, 6–8 October 2020. [Google Scholar]

- Alqudsi, A.; El-Hag, A. Assessing the power transformer insulation health condition using a feature-reduced predictor mode. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 853–862. [Google Scholar] [CrossRef]

- Satriyadi Hernanda, I.G.N.; Mulyana, A.C.; Asfani, D.A.; Negara, I.M.Y. Application of Health Index Method for Transformer Condition Assessment. In Proceedings of the IEEE Region 10 Conference, Bangkok, Thailand, 22–25 October 2014. [Google Scholar]

- Azmi, A.; Jasni, J.; Azis, N.; Kadir, M.Z.A. Evolution of transformer health index in the form of mathematical equation. Renew. Sustain. Energy Rev. 2017, 76, 687–700. [Google Scholar] [CrossRef]

- Jin, L.; Kim, D.; Abu-Siada, A. State-of-the-art review on asset management methodologies for oil-immersed power transformers. Electr. Power Syst. Res. 2023, 218, 109194. [Google Scholar] [CrossRef]

- Ortiz, F.; Fernandez, I.; Ortiz, A.; Renedo, C.J.; Delgado, F.; Fernandez, C. Health Indexes for Power Transformers: A Case Study. IEEE Electr. Insul. Mag. 2016, 32, 7–17. [Google Scholar] [CrossRef]

- IEC 60475:2022; Method of Sampling Insulating Liquids. IEC: Geneva, Switzerland, 2022.

- Zhang, E.; Liu, J.; Zhang, C.; Zheng, P.; Nakanishi, Y.; Wu, T. State-of-Art Review on Chemical Indicators for Monitoring the Aging Status of Oil-Immersed Transformer Paper Insulation. Energies 2023, 16, 1396. [Google Scholar] [CrossRef]

- Zhou, L.; Hu, T. Multifactorial condition assessment for power transformers. IET Gener. Transm. Distrib. 2020, 14, 1607–1615. [Google Scholar] [CrossRef]

- Abu Bakar, N.; Abu-Siada, A. Fuzzy logic approach for transformer remnant life prediction and asset management decision. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3199–3208. [Google Scholar] [CrossRef]

- Padmanaban, S.; Khalili, M.; Nasab, M.A.; Zand, M.; Shamim, A.G.; Khan, B. Determination of Power Transformers Health Index Using Parameters Affecting the Transformer’s Life. IETE J. Res. 2023, 69, 8467–8488. [Google Scholar] [CrossRef]

- Ayalew, Z.; Kobayashi, K.; Matsumoto, S.; Kato, M. Dissolved Gas Analysis (DGA) of Arc Discharge Fault in Transformer Insulation Oils (Ester and Mineral Oils). In Proceedings of the IEEE Electrical Insulation Conference, San Antonio, TX, USA, 17–19 June 2018. [Google Scholar]

- Arshad, M.; Islam, S.; Khaliq, A. Fuzzy logic approach in power transformers management and decision-making. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2343–2354. [Google Scholar] [CrossRef]

- IEEE C57.106-2006; IEEE Guide for Acceptance and Maintenance of Insulating Oil in Equipment. IEEE: Piscataway, NY, USA, 2006.

- IEC 61198; Mineral Insulating Oils—Methods for the Determination of 2-Furfural and Related Compounds. IEC: Geneva, Switzerland, 1993.

- Li, S.; Li, X.; Cui, Y.; Li, H. Review of Transformer Health Index from the Perspective of Survivability and Condition Assessment. Electronics 2023, 12, 2407. [Google Scholar] [CrossRef]

- Haema, J.; Phadungthin, R. Condition Assessment of the Health Index for Power Transformer. In Proceedings of the Power Engineering and Automation Conference, Wuhan, China, 18–20 September 2012. [Google Scholar]

- CIGRE. Transformer Reliability Survey; CIGRE WG A2.37; Technical Brochures; CIGRE: Paris, France, 2015; Volume 642, pp. 5–12. [Google Scholar]

- Ashkezari, A.D.; Ma, H.; Ekanayake, C.; Saha, T.K. Multivariate Analysis for Correlations among Different Transformer Oil Parameters to Determine Transformer Health Index. In Proceedings of the IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012. [Google Scholar]

- Ashkezari, A.D.; Ma, H.; Saha, T.K.; Cui, Y. Investigation of Feature Selection Techniques for Improving Efficiency of Power Transformer Condition Assessment. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 836–844. [Google Scholar] [CrossRef]

- Malik, H.; Tarkeshwar; Jarial, R.K. Make Use of DGA to Carry Out the Transformer Oil-Immersed Paper Deterioration Condition Estimation with Fuzzy-Logic. In Proceedings of the International Conference on Communication Technology and System Design, Coimbatore, India, 7–9 December 2011. [Google Scholar]

- Waugh, N.T.; Muir, D.D. Improving the Life Cycle Management of Power Transformers Transforming Data to Life. In Proceedings of the IEEE SoutheastCon, Fort Lauderdale, FL, USA, 9–12 April 2015. [Google Scholar]

- Anders, G.; Otal, S.; Hjartarson, T. Deriving asset probabilities of failure: Effect of condition and maintenance levels. In Proceedings of the Power Engineering Society General Meeting, Montreal, QC, Canada, 18–22 June 2006. [Google Scholar]

- IEEE C57.104-2008; IEEE Guide for the Interpretation of Gases Generated in Oil-Immersed Transformers. IEEE: Piscataway, NY, USA, 2009.

- Aizpura, J.I.; Stewart, B.G.; McArthur, S.D.J.; Garro, U.; Muxika, E.; Mendicute, M.; Catterson, V.M.; Gilbert, I.P.; del Rio, L. Prognostic & Health Management Methods & Tools for Transformer Condition Monitoring in Smart Grids. In Proceedings of the Advanced Research Workshop on Transformers, Cordoba, Spain, 7–9 October 2019. [Google Scholar]

- IEEE C57.104-2019; IEEE Guide for the Interpretation of Gases Generated in Mineral Oil-Immersed Transformers. IEEE: Piscataway, NY, USA, 2019.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).